Page 1

Manual

EN

VMD461with coupling device CD440

LINETRAXX®

Multifunctional voltage relay for DC, 1AC, 3(N)AC systems

Underfrequency 81<U*, overfrequency 81>O*, overvoltage 59*,

undervoltage 27*, phase sequence 47*, unbalance 47*, vector shift 78*,

ROCOF df/dt 81R*

* ANSI codes

Software version, measurement technology: D570 V1.2x

Software version, display: D256 V2.3x

VMD461_D00314_01_M_XXEN/10.2018

Page 2

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Gruenberg • Germany

Londorfer Strasse 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-Mail: info@bender.de • www.bender.de

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission of the publisher.

Subject to change!

Photos: Bender archives

Page 3

Table of Contents

1. Important information .................................................................................... 7

1.1 How to use this manual ................................................................................. 7

1.2 Technical support: service and support ................................................... 8

1.2.1 First level support ............................................................................................. 8

1.2.2 Repair service ..................................................................................................... 8

1.2.3 Field service ........................................................................................................ 9

1.3 Training courses ............................................................................................. 10

1.4 Delivery conditions ....................................................................................... 10

1.5 Inspection, transport and storage ........................................................... 10

1.6 Warranty and liability ................................................................................... 11

1.7 Disposal ............................................................................................................ 12

2. Safety instructions ......................................................................................... 13

2.1 General safety instructions ........................................................................ 13

2.2 Work activities on electrical installations ............................................. 13

2.3 Intended use ................................................................................................... 14

3. Function ........................................................................................................... 15

3.1 Device features .............................................................................................. 15

3.2 Glossary ............................................................................................................. 16

3.3 Functional description ................................................................................ 17

4. Installation and connection ......................................................................... 19

4.1 Fuses .................................................................................................................. 19

4.2 Installation instructions .............................................................................. 20

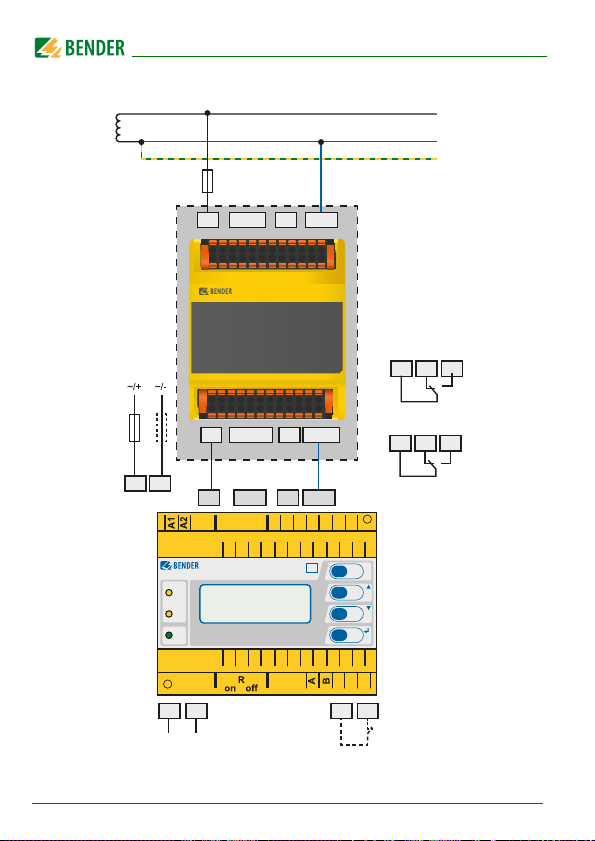

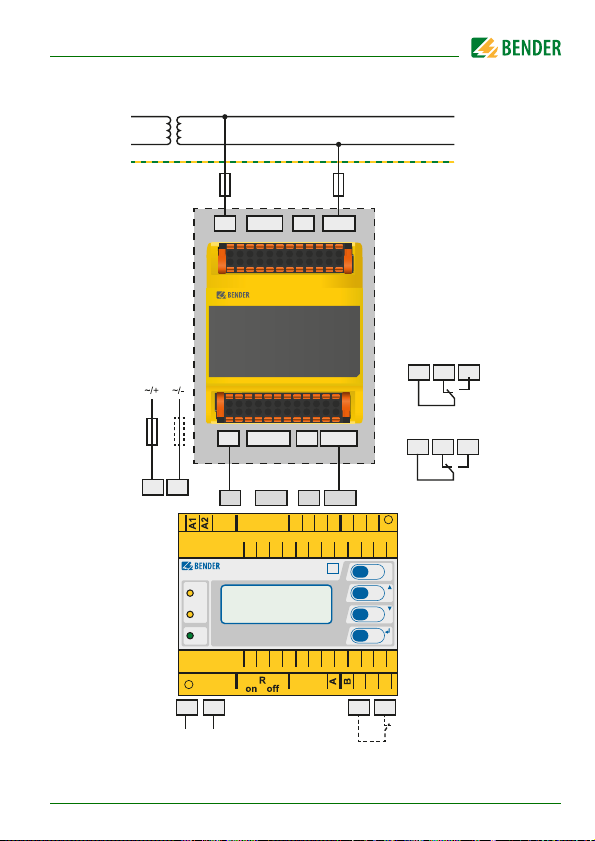

4.3 Schematic diagram ....................................................................................... 20

4.4 System structure ............................................................................................ 21

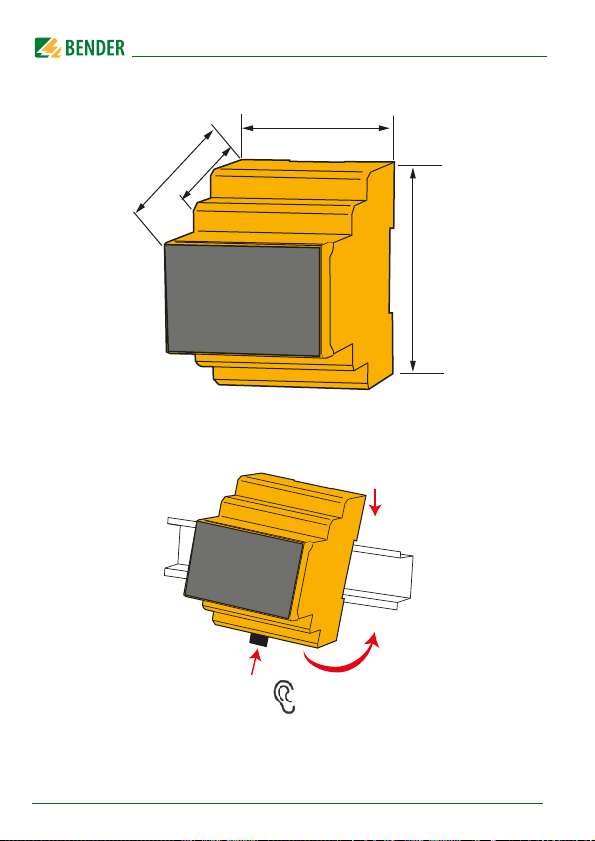

4.5 Dimension diagram VMD461 .................................................................... 21

4.6 Dimension diagram CD440 ....................................................................... 22

VMD461_D00314_01_M_XXEN/10.2018

3

Page 4

Table of Contents

4.7 Mounting on DIN rail .................................................................................... 22

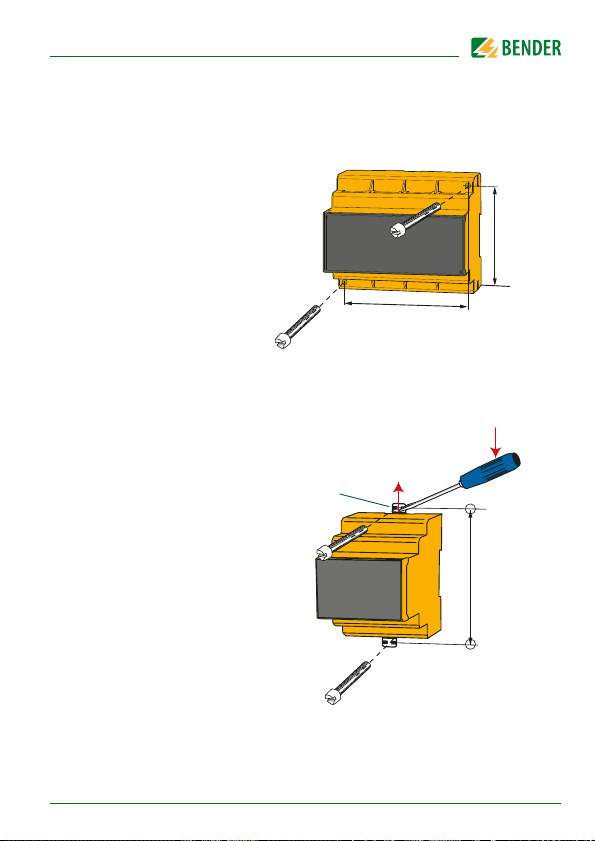

4.8 Screw mounting ............................................................................................ 23

4.8.1 VMD461 ............................................................................................................ 23

4.8.2 CD440 ................................................................................................................ 23

4.9 Wiring diagram .............................................................................................. 24

4.9.1 DC: VMD461 with CD440 ............................................................................ 25

4.9.2 AC: VMD461 with CD440 (earthed system) ......................................... 26

4.9.3 AC: VMD461 with CD440 (unearthed system) .................................... 27

4.9.4 3(N)AC: VMD461 with CD440 (earthed system) ................................ 28

4.9.5 3(N)AC: VMD461 with CD440 (unearthed system) ........................... 29

4.9.6 Example: VMD461 with 2 circuit breakers ............................................ 31

4.9.7 Details regarding the digital inputs (D1, D2, RT1) ............................. 33

4.9.8 Details regarding the internal resistance .............................................. 33

4.10 Commissioning .............................................................................................. 34

4.11 Trigger circuit test by the system erector ............................................. 34

5. Operation and configuration ...................................................................... 35

5.1 Getting to know the user interface ......................................................... 35

5.2 Various displays ............................................................................................. 36

5.2.1 Standard display ............................................................................................ 36

5.2.2 Info display ...................................................................................................... 37

5.2.3 Alarm display .................................................................................................. 37

5.2.4 Menu display ................................................................................................... 37

5.2.5 Toggling between the individual displays ........................................... 38

5.3 INFO button ..................................................................................................... 39

5.4 MENU button .................................................................................................. 39

6. Menu ................................................................................................................ 41

6.1 Menu "1. Alarm/meas. values" .................................................................. 42

6.2 Menu "2. History" ........................................................................................... 43

6.3 Menu "3. Settings" ......................................................................................... 44

6.3.1 General: Password protection .................................................................. 44

6.3.2 Procedure ......................................................................................................... 44

4

VMD461_D00314_01_M_XXEN/10.2018

Page 5

Table of Contents

6.3.3 Menu structure "3. Settings" ...................................................................... 45

6.3.4 Explanatory comments on individual menu items ........................... 52

6.4 Menu "4. System" ........................................................................................... 62

6.4.1 Menu structure "4. System" ....................................................................... 62

6.4.2 Explanatory comments on individual menu items ........................... 64

6.5 Menu "5. Info" ................................................................................................. 65

6.6 Operation via web user interface ............................................................ 65

7. Maintenance, troubleshooting, messages ............................................... 67

7.1 Manual self test .............................................................................................. 67

7.2 Messages and malfunctions ...................................................................... 68

7.3 LEDs .................................................................................................................... 69

8. Technical data VMD461 ............................................................................... 71

8.1 Standards, approvals and certifications ................................................ 77

8.2 Ordering details ............................................................................................. 77

INDEX .................................................................................................................... 81

5

VMD461_D00314_01_M_XXEN/10.2018

Page 6

Page 7

1. Important information

DANGER

WARNING

CAUTION

1.1 How to use this manual

This manual is intended for qualified personnel working in

electrical engineering and electronics!

Always keep this manual within easy reach for future reference.

To make it easier for you to understand and revisit certain sections in this manual, we have used symbols to identify important instructions and information.

The meaning of these symbols is explained below:

This signal word indicates that there is a high risk of danger

that will result in electrocution or serious injury if not

avoided.

This signal word indicates a medium risk of danger that

can lead to death or serious injury if not avoided.

This signal word indicates a low-level risk that can result in

minor or moderate injury or damage to property if not

avoided.

This symbol denotes information intended to assist the user

in making optimum use of the product.

This manual has been compiled with great care. It might nevertheless contain

errors and mistakes. Bender cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this manual.

VMD461_D00314_01_M_XXEN/10.2018

7

Page 8

Important information

1.2 Technical support: service and support

For commissioning and troubleshooting Bender offers you:

1.2.1 First level support

Technical support by phone or e-mail for all

Bender products

Questions concerning specific customer applications

Commissioning

Troubleshooting

Telephone: +49 6401 807-760*

Fax: +49 6401 807-259

In Germany only: 0700BenderHelp (Tel. and Fax)

E-mail: support@bender-service.de

1.2.2 Repair service

Repair, calibration, update and replacement service for Bender products

Repairing, calibrating, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices in the event of faulty or incorrectly

delivered Bender devices

Extended guarantee for Bender devices, which includes an in-house

repair service or replacement devices at no extra cost

Telephone: +49 6401 807-780** (technical issues)

Fax: +49 6401 807-789

E-mail: repair@bender-service.de

Please send the devices for repair to the following address:

+49 6401 807-784**, -785** (sales)

Bender GmbH, Repair-Service,

Londorfer Straße 65,

35305 Grünberg

8

VMD461_D00314_01_M_XXEN/10.2018

Page 9

Important information

1.2.3 Field service

On-site service for all Bender products

Commissioning, configuring, maintenance, troubleshooting for Bender

products

Analysis of the electrical installation in the building (power quality test,

EMC test, thermography)

Training courses for customers

Telephone: +49 6401 807-752**, -762 **(technical issues)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Internet: www.bender.de

*Available from 7.00 a.m. to 8.00 p.m. 365 days a year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m.

+49 6401 807-753** (sales)

VMD461_D00314_01_M_XXEN/10.2018

9

Page 10

Important information

1.3 Training courses

Bender is happy to provide training regarding the use of test equipment.

The dates of training courses and workshops can be found on the Internet at

www.bender-de.com -> Know-how -> Seminars.

1.4 Delivery conditions

Bender sale and delivery conditions apply.

For software products the "Softwareklausel zur Überlassung von StandardSoftware als Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen

Lieferbedingungen für Erzeugnisse und Leistungen der Elektroindustrie"

(software clause in respect of the licensing of standard software as part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband

Elektrotechnik- und Elektronikindustrie e. V.) (German Electrical and Electronic Manufacturer's Association) also applies.

Sale and delivery conditions can be obtained from Bender in printed or electronic format.

1.5 Inspection, transport and storage

Inspect the dispatch and equipment packaging for damage, and compare the

contents of the package with the delivery documents. In the event of damage

in transit, please contact Bender immediately.

The devices must only be stored in areas where they are protected from dust,

damp, and spray and dripping water, and in which the specified storage temperatures can be ensured.

10

VMD461_D00314_01_M_XXEN/10.2018

Page 11

Important information

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to

property are excluded if they can be attributed to one or more of the following causes:

Improper use of the device.

Incorrect mounting, commissioning, operation and maintenance of the

device.

Failure to observe the instructions in this operating manual regarding

transport, commissioning, operation and maintenance of the device.

Unauthorised changes to the device made by parties other than the

manufacturer.

Non-observance of technical data.

Repairs carried out incorrectly and the use of replacement parts or

accessories not approved by the manufacturer.

Catastrophes caused by external influences and force majeure.

Mounting and installation with device combinations not recom-

mended by the manufacturer.

This operating manual, especially the safety instructions, must be observed by

all personnel working on the device. Furthermore, the rules and regulations

that apply for accident prevention at the place of use must be observed.

VMD461_D00314_01_M_XXEN/10.2018

11

Page 12

Important information

1.7 Disposal

Abide by the national regulations and laws governing the disposal of this device. Ask your supplier if you are not sure how to dispose of the old equipment.

The directive on waste electrical and electronic equipment (WEEE directive)

and the directive on the restriction of certain hazardous substances in electrical and electronic equipment (RoHS directive) apply in the European Community. In Germany, these policies are implemented through the "Electrical and

Electronic Equipment Act" (ElektroG). According to this, the following applies:

Electrical and electronic equipment are not part of household waste.

Batteries and accumulators are not part of household waste and must

be disposed of in accordance with the regulations.

Old electrical and electronic equipment from users other than private

households which was introduced to the market after 13 August 2005

must be taken back by the manufacturer and disposed of properly.

For more information on the disposal of Bender devices, refer to our website

at www.bender-de.com -> Service & support.

12

VMD461_D00314_01_M_XXEN/10.2018

Page 13

2. Safety instructions

DANGER

2.1 General safety instructions

Part of the device documentation in addition to this manual is the enclosed

"Safety instructions for Bender products".

2.2 Work activities on electrical installations

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

If the device is used outside the Federal Republic of Germany, the applicable

local standards and regulations must be complied with. The European standard EN 50110 can be used as a guide.

VMD461_D00314_01_M_XXEN/10.2018

13

Page 14

Safety instructions

2.3 Intended use

The multifunctional voltage monitoring relay VMD461 monitors frequencies,

undervoltages and overvoltages in DC, AC and 3(N)AC systems. The phase

voltages and/or line-to-line voltages are measured as r.m.s. value and are continuously shown on the device display. The measured value required to trigger the alarm relay is stored. The VMD461 features additional measuring

functions for:

ROCOF df/dt

Vector shift monitoring

Unbalance monitoring

Phase sequence monitoring

The corresponding ANSI codes for all available measuring functions are provided.

Configurable delay times allow considering special installation-specific properties (e.g. device-specific start-up procedures).

The VMD461 requires an external supply voltage.

The optional use of a CD440 coupling device extends the voltage range that

can be monitored to DC/3AC 1200 V or 1AC/3NAC 690 V.

The coupling ensures that on the VMD461 the maximum

permissible input voltage in systems > 230/400 V is not

exceeded.

In order to meet the requirements of applicable standards, the equipment

must be adjusted to local equipment and operating conditions by means of

customised parameter settings. Please heed the limits of the range of application indicated in the technical data. Any other use than that described in this

manual is regarded as improper.

14

VMD461_D00314_01_M_XXEN/10.2018

Page 15

3. Function

3.1 Device features

When combined with a CD440 coupling device, DC systems up to

1200 V, 1AC systems up to 690 V, 3AC systems up to 1200 V and 3NAC

systems up to 690 V can be monitored

All functions are represented in ANSI codes

Monitoring of DC, 1AC, 3(N)AC systems DIN EN 60255-1:2010-9

Single-fault safety

Unbalance, phase failure and phase sequence monitoring

Monitoring of the connected switches and/or disconnectors (config-

urable: NC/NO/off)

Islanding detection df/dt (ROCOF)

Vector shift function

RS-485 interface (data exchange/parameter setting/software update)

Test function to determine the switch-off time

Test button for the trigger circuit

The last 300 network faults can be recalled with time stamp/real-time

clock

Continuous monitoring of the phase voltage and line-to-line voltage

Special switch-on conditions after an infringement of a response value

Language selection (German, English, French)

Backlit graphic LC display

Password protection for device setting

Remote shutdown via ripple control signal receiver

Sealable enclosure

VMD461_D00314_01_M_XXEN/10.2018

15

Page 16

3.2 Glossary

Ter m s De s cr ip ti o n

t

start-up

t

on

t

off

t

(off ) total

Start-up delay

Once the supply voltage is applied, the start-up delay

t

begins. Measured voltage and frequency val-

start-up

ues changing during this time do not influence the

switching state of the alarm relays K1 and K2. At that

moment, the switching state of the alarm relays K1

and K2 depends on the "Start alarm" parameter

(menu: 3.8.4. Start alarm).

Switch-on delay

All switch-on conditions have to be met for the duration of the switch-on delay t

ing alarm relay operates.

Response delay

Minimum period that a limit value infringement must

exist so that the corresponding alarm relay trips.

When the contact monitoring for switches/discon-

nectors is activated, the time until the switch/disconnector actually switches off (t

measured during a test.

The longer one of the two switch-off times is indicated

at t

(off) total

so that the correspond-

on

(off) total

(menu 1.15, see page 42).

Function

) is additionally

16

VMD461_D00314_01_M_XXEN/10.2018

Page 17

Function

CAUTION

3.3 Functional description

Once the supply voltage is applied, the start-up delay t

ured voltage and frequency values changing during this time do not influence

the switching state of the alarm relays K1 and K2.

The devices feature three separately adjustable limit values for overvoltage/

undervoltage as well as overfrequency/underfrequency which are respectively linked to their own response delay t

.

off

Nominal voltage and overvoltage limit values U>, U>>

and U>>> (ANSI code 59)

By means of the nominal voltage and the overvoltage parameters, limit values above the maximum voltages of the

measuring circuit (compare "Chapter 8. Technical data

VMD461) can be set.

The user must ensure that the overvoltage limit values

do not exceed the maximum voltages.

If the measured quantity exceeds or falls below the set response value and the

related response delay t

ue switches and the corresponding LED lights.

has elapsed, the relay assigned to the response val-

off

Fault memory

When the fault memory is disabled, the device automatically attempts to

switch on:

If the measured quantity falls below or exceeds the release value after the

alarm relays have switched, the set switch-on delay t

When the fault memory is enabled, the fault must be manually reset on the

device.

on

start-up

starts.

begins. Meas-

df/dt

A passive method for islanding detection (three-phase voltage and frequency

monitoring).

VMD461_D00314_01_M_XXEN/10.2018

17

Page 18

Function

Vector shift

Vector shift detection is triggered by a sudden phase displacement (vector

shift).

Unbalance

The unbalance is calculated between the phase voltages (in conformity with

IEEE) and the line-to-line voltages (in conformity with NEMA). The higher of

the two values will be compared to the specified response value.

Phase sequence

When phase sequence monitoring is enabled, an alarm is triggered in 3(N)AC

systems as soon as the phase sequence no longer matches the specified value.

In DC systems, an alarm is triggered when the polarity no longer matches the

specified value (measurement time approx. 50 ms).

Automatic self test

The device runs a continuous self test during which internal malfunctions are

detected and shown on the display as error codes. The electrical installation is

not disconnected from the mains during this test.

History memory

The device utilises a history memory for fail-safe storing of up to 300 data

records (date, time, channel, event code, measured value).

After reaching 301 data records, the existing data records, starting with the

oldest one, will be overwritten. After manually activating the deletion process

(menu: 4.1. History), the history memory will be irreversibly deleted.

18

VMD461_D00314_01_M_XXEN/10.2018

Page 19

4. Installation and connection

DANGER

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Danger of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

4.1 Fuses

Equip the supply voltage of all system ‐components with fuses. IEC 60364-4473 requires protective devices to be used to protect the component in the

event of a short circuit. Bender recommends the use of 6 A fuses.

VMD461_D00314_01_M_XXEN/10.2018

19

Page 20

Installation and connection

DANGER

4.2 Installation instructions

Danger of electric shock!

Make sure that the installation area is disconnected from any

electrical source . Consider the data on the rated voltage

and supply voltage as specified in the technical data!

The maximum length of the connecting cable of device

connections DG1/2, D1, D2, RTG and RT1 is 10 m.

In order to ensure the proper functioning of the VMD461 in

the event of a power failure, an external UPS is to be used.

The devices are suitable for the following types of installation:

Standard distribution panels in accordance with DIN 43871 or DIN rail

mounting in accordance with IEC 60715

Screw mounting using two M4 screws

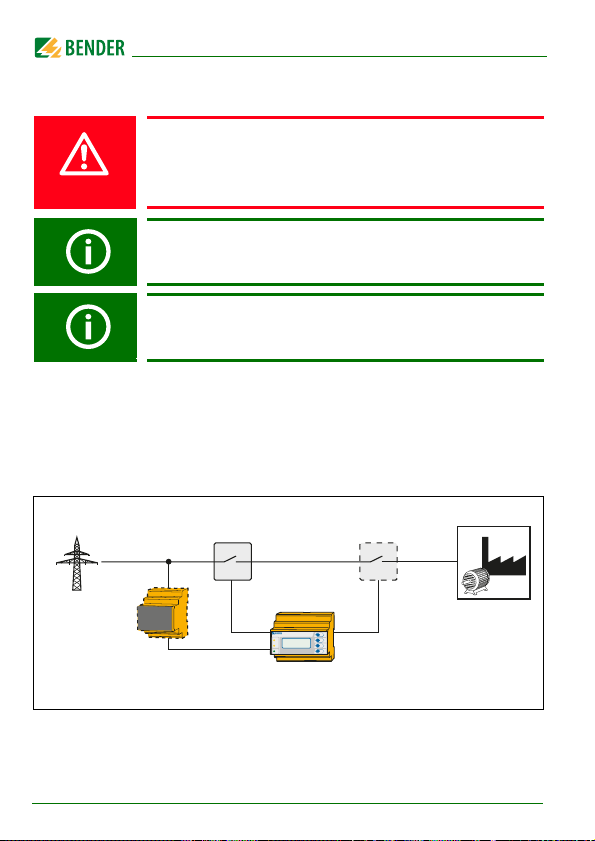

4.3 Schematic diagram

Circuit breaker Circuit breaker

Public grid

20

CD440

(optional)

VMD461

Fig. 4.1: Schematic diagram with circuit breakers

VMD461_D00314_01_M_XXEN/10.2018

Page 21

Installation and connection

4.4 System structure

(optional)

120 Ω

(DIP switch

VMD461)

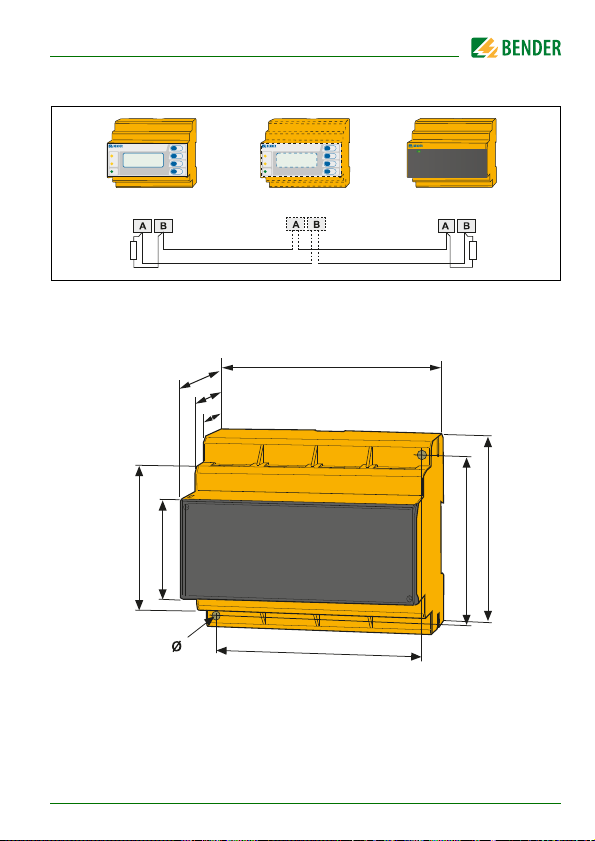

4.5 Dimension diagram VMD461

74

47.5

31.1

45

67.5

4.5

Fig. 4.2: Dimension diagram VMD461 (mm)

108

98

COM465IPVMD461 VMD461

120 Ω

(DIP switch

COM465IP)

93

77

VMD461_D00314_01_M_XXEN/10.2018

21

Page 22

4.6 Dimension diagram CD440

62.5

48.5

Fig. 4.3: Dimension diagram CD440 (mm)

4.7 Mounting on DIN rail

Installation and connection

71.7

93.0

1.

3.

4.

„Klick“

2.

Snap the rear mounting clip of the device into place in such a way that a safe

and tight fit is ensured.

22

VMD461_D00314_01_M_XXEN/10.2018

Page 23

Installation and connection

77 mm

98 mm

M4

M4

4.8 Screw mounting

4.8.1 VMD461

4.8.2 CD440

1. Use a tool to position

the rear mounting

clips so that they

project beyond the

enclosure (a second

mounting clip is

required, see ordering information).

2. Then fix the device

using two M4 screws.

B98060008

M4

3.

2.

„Klick“

1.

100 mm

VMD461_D00314_01_M_XXEN/10.2018

M4

4.

23

Page 24

Installation and connection

CAUTION

4.9 Wiring diagram

Depending on the application, connect the device according to the following

wiring diagrams.

The VMD461 can be operated without a CD440 in

appropriate power supply systems (230/400 V).

Risk of unwanted device failure!

Do not supply device from the monitored system. Pay

attention to maximum supply voltage.

24

VMD461_D00314_01_M_XXEN/10.2018

Page 25

Installation and connection

4.9.1 DC: VMD461 with CD440

6 A

L1

L2/DC+

L1 L3 N/DC-L2/DC+

CD440

L3 N/DC-

*

CD440 optional

L+

L-

PE

U

S

L1'

6 A

6 A

A1

A2

LINETRAXX®

ALARM

L2'/DC+' L3'

L1

L2/DC+

VMD461

2

1

ON

A B

Fig. 4.4: DC voltage connection

VMD461_D00314_01_M_XXEN/10.2018

L1' L3' N'/DC-'L2'/DC+'

N'/DC-'

L3

N/DC-

1112142122

D2

D1

DG1/2

V

L1

24

L3

L2/DC+

ESC

INFO

TEST

RESET

MENU

N/DC-

RT1

RTGRT1

RTG

21 241222

K2

11

K1

14

25

Page 26

Installation and connection

4.9.2 AC: VMD461 with CD440 (earthed system)

6 A

L1

L2/DC+

L3 N/DC-

*

N/DC-

D2

V

CD440 optional

24

L3

L1

L2/DC+

ESC

INFO

TEST

RESET

MENU

N/DC-

RTG

RT1

21 241222

11

L1 L3 N/DC-L2/DC+

S

LINETRAXX®

ALARM

ON

L1' L3' N'/DC-'L2'/DC+'

L1' L2'/DC+' L3'

L1

VMD461

2

1

6 A

U

6 A

A1 A2

A B RTGRT1

CD440

L2/DC+

N'/DC-'

L3

1112142122

D1

DG1/2

L1

N

PE

K2

14

K1

26

Fig. 4.5: AC connection (earthed)

VMD461_D00314_01_M_XXEN/10.2018

Page 27

Installation and connection

4.9.3 AC: VMD461 with CD440 (unearthed system)

U

n

L1

L2

PE

6 A

U

S

6 A

A1 A2

LINETRAXX®

2

ALARM

1

ON

6 A

L1

L2/DC+

L1 L3 N/DC-L2/DC+

CD440

L1' L3' N'/DC-'L2'/DC+'

L1' L2'/DC+' L3'

L1

L2/DC+L3N/DC-

VMD461

6 A

L3 N/DC-

N'/DC-'

1112142122

D2

D1

DG1/2

V

A B RTGRT1

Fig. 4.6: AC connection (unearthed system)

*

CD440 optional

24

L3

L1

L2/DC+

ESC

INFO

TEST

RESET

MENU

N/DC-

RTG

RT1

21 241222

11

K1

K2

14

VMD461_D00314_01_M_XXEN/10.2018

27

Page 28

Installation and connection

4.9.4 3(N)AC: VMD461 with CD440 (earthed system)

L1

L2

L3

N

PE

6 A

L2/DC+

L3 N/DC-

L1 L3 N/DC-L2/DC+

CD440

L1' L3' N'/DC-'L2'/DC+'

L1' L2'/DC+' L3'

L1

L2/DC+L3N/DC-

VMD461

N'/DC-'

1112142122

D2

D1

DG1/2

V

*

CD440 optional

24

L3

L2/DC+

L1

ESC

INFO

TEST

RESET

MENU

N/DC-

RTG

RT1

RTGRT1

21 241222

11

K1

K2

14

6 A

U

S

6 A

A1 A2

LINETRAXX®

2

ALARM

1

ON

A B

6 A 6 A

L1

Fig. 4.7: Wiring diagram VMD461 with CD440 (earthed system)

28

VMD461_D00314_01_M_XXEN/10.2018

Page 29

Installation and connection

4.9.5 3(N)AC: VMD461 with CD440 (unearthed system)

L1

L2

L3

N

PE

6 A

L2/DC+

L1 L3 N/DC-L2/DC+

CD440

6 A

L3 N/DC-

*

CD440 optional

6 A 6 A

L1

S

LINETRAXX®

ALARM

L1' L3' N'/DC-'L2'/DC+'

L1' L2'/DC+' L3'

L1

VMD461

2

1

ON

N'/DC-'

L2/DC+L3N/DC-

1112142122

D2

D1

DG1/2

V

L1

24

L3

L2/DC+

ESC

INFO

TEST

RESET

MENU

N/DC-

RT1

RTG

6 A

U

6 A

A1 A2

A B RTGRT1

Fig. 4.8: Wiring diagram VMD461 with CD440 (unear thed system)

VMD461_D00314_01_M_XXEN/10.2018

21 241222

11

K1

K2

14

29

Page 30

Installation and connection

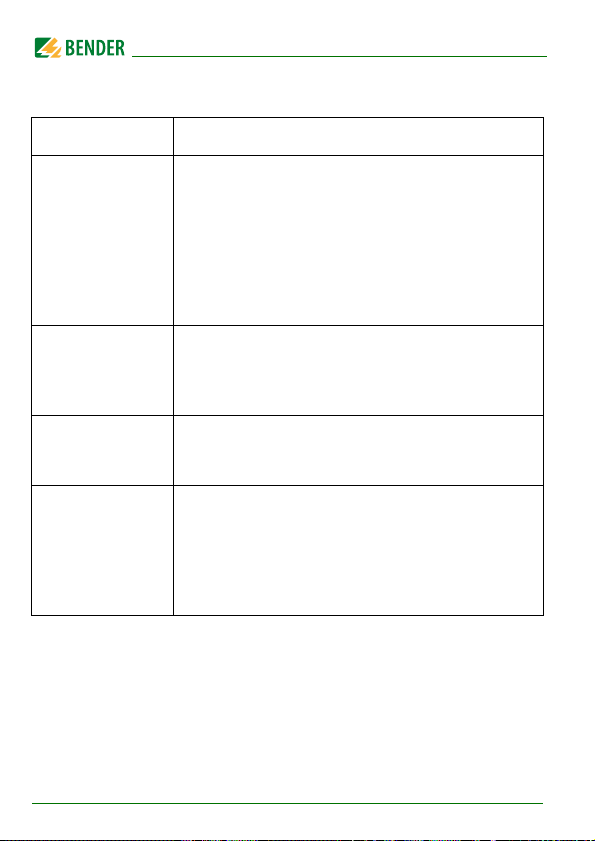

Legend wiring diagrams fig. 4.3…4.8

Element Function

A1, A2

L1, L2/DC+, L3,

N/DC-

Supply voltage U

Power supply connection

11, 12, 14 Connection to alarm relay K1

21, 22, 24 Connection to alarm relay K2

DG1/2,

D1, D2

Contact monitoring

DG1/2: GND

D1: Feedback signal contact to alarm relay K1

D2: Feedback signal contact to alarm relay K2

(feedback signal contacts optionally NC/NO/off)*

RTG, RT1

RTG: GND

RT1: Remote-trip input (optionally NC/NO/off)*

A, B Connection to communication interface BMS bus

R

on/off

Activate or deactivate the terminating resistor of the BMS

bus (120

* Explanation: NC (closed in non-operating state)

NO (open in non-operating state)

off (switched off)

(see ordering details)

s

Ω )

30

VMD461_D00314_01_M_XXEN/10.2018

Page 31

Installation and connection

4.9.6 Example: VMD461 with 2 circuit breakers

Q1 Q2

L1

L2

L3

N

6 A 6 A

6 A

L1

L2/DC+

L3 N/DC-

L1 L3 N/DC-L2/DC+

CD440

*

CD440

optional

L1' L3' N'/DC-'L2'/DC+'

U

S

6 A

6 A

A1 A2

LINETRAXX®

ALARM

ON

2

1

L1' L2'/DC+' L3'

L1

VMD461

N'/DC-'

L2/DC+L3N/DC-

1112142122

D2D1DG1/2

V

L1

24

L2/DC+

INFO

TEST

RESET

MENU

RT1

A B RTGRT1

Fig. 4.9: Wiring diagram VMD461 with 2 circuit breakers

VMD461_D00314_01_M_XXEN/10.2018

L3

ESC

N/DC-

RTG

DG1/2

D1

11 21 2412 2214

K1 K2

D2

31

Page 32

Installation and connection

Legend wiring diagram fig. 4.9

Element Function

A1, A2

L1, L2/DC+, L3,

N/DC-

11, 12, 14 Connection to alarm relay K1

21, 22, 24 Connection to alarm relay K2

Q1, Q2 Circuit breakers

DG1/2,

D1, D2

RTG, RT1

A, B Connection to communication interface BMS bus

R

on/off

* Explanation: *NC (in non-operating state closed)

Supply voltage U

Power supply connection

Contact monitoring circuit breakers Q1/Q2

DG1/2: GND

D1: Feedback signal contact to alarm relay K1

D2: Feedback signal contact to alarm relay K2

(feedback signal contacts optionally NC/NO/off)*

RTG: GND

RT1: Remote-trip input (optionally NC/NO/off)*

Activate or deactivate the terminating resistor of the BMS

bus (120

NO (in non-operating state open)

off (switched off)

(see ordering details)

s

Ω )

Single-fault safety

The device is designed to be single-fault safe. Coupling and relays as well as

their controls for shutdown are designed redundantly.

In order to ensure single-fault safety in the system to be monitored, two circuit

breakers are connected in series (Q1 and Q2, see Fig. 4.9). They have to be

connected to the digital inputs D1 and D2, each with a positively driven, potential-free contact (DG1/2 is the common ground).

The signalling relays K1 and K2 must be connected as shown in Fig. 4.9 and

have to operate in N/C mode.

32

VMD461_D00314_01_M_XXEN/10.2018

Page 33

Installation and connection

4.9.7 Details regarding the digital inputs (D1, D2, RT1)

low : < 4 V DC

high : > 6 V DC

U

= 30 V DC

max

1

24 V

2

DC

Source

Open

Collector

Q1

I < 5 mA

Relay

Contact

Dx

DGx

V1

GND

Dx: D1, D2, RT1

DGx: DG1/2, RTG

Fig. 4.10: Block diagram (simplified representation)

4.9.8 Details regarding the internal resistance

L1 L2/DC+ L3 N/DC-

2

MΩ

L1‘ L2‘/DC+‘ L3‘ N‘/DC-‘

L1 L2/DC+ L3 N/DC-

480

kΩ

MΩ

480

kΩ

2

2,7

MΩ

660

kΩ

MΩ

480

kΩ

2

12 V

R1

μC

CD440

VMD461

Abb. 4.11: Block diagram internal resistance VMD461 and CD440

VMD461_D00314_01_M_XXEN/10.2018

GND

33

Page 34

Installation and connection

4.10 Commissioning

Danger of electric shock!

Improper connection can lead to injury to persons and

damage to the device!

Prior to commissioning make sure that the device is

properly connected!

Initial commissioning

When commissioning the device for the first time you have to:

Select a language (English, German, French) (menu 4.2).

Set date and time (menu 4.3).

You can only change settings in the menus after the settings listed above have

been carried out.

The contrast of the LC display can be adjusted to any

ambient brightness.

Select the contrast ratio from an infinite loop display.

Simultaneously press and hold down the buttons "INFO" and

"MENU" until the display text is clearly readable. After

reaching a black display, the contrast setting process starts

again with a white display.

4.11 Trigger circuit test by the system erector

During commissioning, the system erector has to check the correct function

of the trigger circuit of the switches and/or disconnectors as illustrated in the

wiring diagram of this operating manual, consisting of alarm relay K1, alarm

relay K2, switch/disconnector 1 and switch/disconnector 2.

Press the test button to activate the switches and/or disconnectors.

Tripping must be visualised by the switch and/or disconnector.

Contact monitoring switches and/or disconnectors (optional)

Observe the information about recurrent tests on page 67.

34

VMD461_D00314_01_M_XXEN/10.2018

Page 35

5. Operation and configuration

1

2

3

4

5

6

7

5.1 Getting to know the user interface

LINETRAXX®

Legend

No. Element Function

1

2

ALARM1

ALARM2

3

VMD461_D00314_01_M_XXEN/10.2018

Power On LED, green;

ON

lights when the voltage supply is available and the device

is in operation;

flashes when the device is being started or when an internal device error has occurred

Alarm LEDs, yellow: installation switched off

Only ALARM 1 lights: alarm relay K1 has tripped

and

Only ALARM 2 lights: alarm relay K2 has tripped

ALARM 1 and ALARM 2 light: response value violation of

voltage or frequency, df/dt, vector shift detection, unbalance, phase sequence, remote trip

ALARM 1 and ALARM2 flash: internal device error or

error in contact monitoring

Backlit LC display

VMD461

V

35

Page 36

Operation and configuration

L1-N 229.9V L1-L2 397.2V

L2-N 229.5V L2-L3 401.9V

L3-N 232.9V L3-L1 400.1V

f 50.00 Hz

4

5

6

RESET

7

MENU

Standard display: Toggle between standard display and

INFO

device information

ESC

Menu display: Exit the parameter setting menu

saving; switch to the next higher menu level

Standard display: Use the TEST button (< 1.5 s) to start a

TEST

manual self test which triggers both alarm relays (trigger

test to check the switches/disconnectors). In addition, the

switch-off times are documented, see "Manual self test"

on page 67.

Menu display: arrow-up button for parameter change

and scrolling

Standard display: (> 1.5 s) Acknowledge fault messages

from contact monitoring

Menu display: arrow-down button for parameter

change/scrolling

Standard display: Toggle between standard, menu and

alarm display

Menu display: button

Jump to setting parameter; save the changed parameters

without

5.2 Various displays

5.2.1 Standard display

In the standard display, the line-to-line voltages, the phase voltages and the

frequency are indicated on the display.

36

Fig. 5.1: Standard display

VMD461_D00314_01_M_XXEN/10.2018

Page 37

Operation and configuration

VMD461

22.05.17 12:34

Address: xx

Software: D570Vxx.xx

ALARM 2/3

Undervoltage

U

(1-N) : 180.3 V

Addr.:1 Chan.:1

Exit

1. Alarm/meas.values

2. History

3. Settings

5.2.2 Info display

Device-specific information is indicated on the info display.

Fig. 5.2: Info display

For detailed information, refer to page 39.

5.2.3 Alarm display

Type and source of alarms are indicated on the alarm display in plain text format.

Fig. 5.3: Al arm displ ay

Explanation: In the example above, the second message of three is being indicated (2/3). The current measured value for U

The address "Addr.:" shows the BMS-bus address of the device sending the

(1-N)

is 180.3 V.

alarm. The alarm is output on measuring channel 1 and can be accessed via

channel number 1 in the "Alarm/meas. values" menu.

5.2.4 Menu display

Alarms, currently measured values, device settings as well as the history memory can be called up via the menu display.

VMD461_D00314_01_M_XXEN/10.2018

Fig. 5. 4: Menu displa y

37

Page 38

Operation and configuration

5.2.5 Toggling between the individual displays

You can toggle between the different displays by using the four device buttons. Depending on the type of display (standard display, alarm display, menu

display, info display), the meaning of the buttons is different. The picture below illustrates which button is to be pressed for accessing the individual display. First, you have to distinguish between an alarm condition and no alarm

condition.

no alarm alarm

Info

display

INFO

Standard

display

ESC MENU

Menu

display

ESC

ESC

INFO

ESC

Info

display

Standard

display

ESC

Alarm

display

MENU

Menu

display

MENU

MENUMENU

Fig. 5.5: Toggling between the displays (alarm condition or no alarm condition)

38

VMD461_D00314_01_M_XXEN/10.2018

Page 39

Operation and configuration

5.3 INFO button

Dev ice i nfor matio n in c lear t ext f orma t (Inf o dis play) ca n be c alled up wi th th e

"INFO" button. For this purpose press the "INFO" button in the standard display once. Scroll through the individual lines using the arrow buttons :

Device type

Current date and time

BMS bus address

Software version, measurement technology

Software date, measurement technology

Software version, display

Software date, display

Manufacturer of the device

Address of the manufacturer

Internet address of the manufacturer

Return to standard display via "ESC" or .

5.4 MENU button

Toggling between the standard, alarm and menu display (see page 38).

The individual entries in the menu display can be accessed using the arrow

buttons :

The menu display provides the following submenus:

Exit

1. Alarm/meas.values

2. History

3. Settings

4. System

5. Info

VMD461_D00314_01_M_XXEN/10.2018

39

Page 40

Operation and configuration

40

VMD461_D00314_01_M_XXEN/10.2018

Page 41

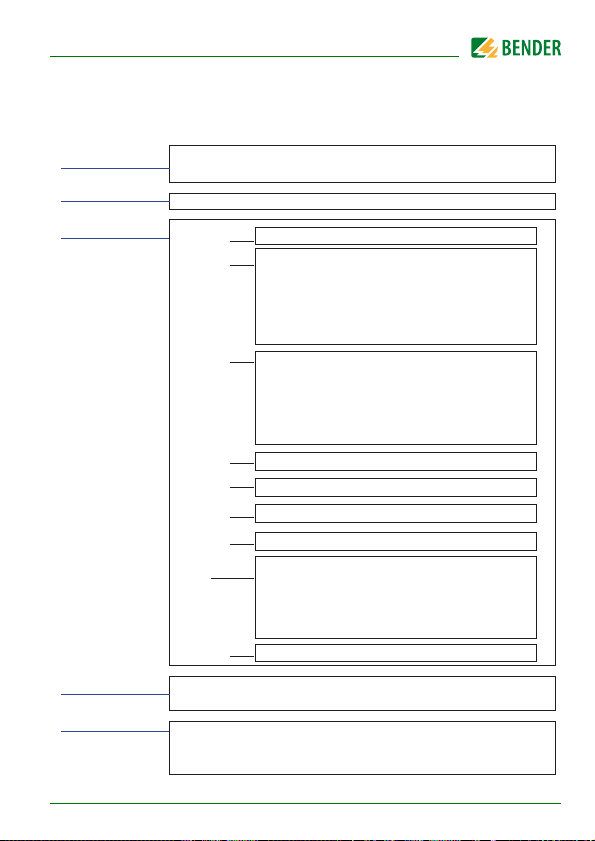

6. Menu

1. Alarm/meas. values

2. History

3. Settings

4. System

5. Info

U

, U

, U

, U

, U

, U

(1-N)

(2-N)

(3-N)

Frequency, df/dt (81R), Vect.sh.(78), Status, t

(1-2)

, Unbalance, Phase sequence,

(2-3)

(3-1)

on1

, t

, t

on2

off total

History

1. General

2. Voltage

(59/27)

3. Frequency(81)

4. df/dt (81R)

5. Vect.sh. (78)

6. Unbalance

(47)

7. Phase

sequence(47)

8. Relays

9. Dig. input

Delete history, Language, Clock, Password, Interface, Alarm addresses,TEST,

RESET, Test communication, External devices, Service, Factory settings

Device type, Current date and time, BMS bus address, Software version

measurement technology, Software date measurement technology,

Software version display, Software date display, Manufacturer of the device,

Address of the manufacturer, Internet address of the manufacturer

Coupling, System type, U

U>>> (59.S3), t

U>> (59.S2), t

U> (59.S1), t

U

(on)max

U< (27.S1), t

U<< (27.S2), t

U<<< (27.S3), t

f>>> (81>.S3), t

f>> (81>.S2), t

f> (81>.S1), t

f

(on)max

f< (81<.S1), t

f<< (81<.S2), t

f<<< (81<.S3), t

, f

, U

(on)min

off

off

off

(on)min

off

off

off

off

off

off

off

off

off

Function, Resp.value, Hysteresis, Meas.window, t

Function, Resp.value, t

Function, Resp.value, Hysteresis, t

Function, Phase sequence

Relay mode, t

Device error, TEST, U>>> (59.S3), U>> (59.S2),

U> (59.S1), U< (27.S1), U<< (27.S2, U<<< (27.S3),

f>>> (81>.S3),f>> (81>.S2), f> (81>.S1), f< (81<.S1),

f<< (81<.S2), f<<< (81<.S3), df/dt (81R), Vect.sh. (78),

Unbalance, Phase sequence, Remote trip

Mode, t

, Fault memory, Start alarm,

on

start-up

(L-N)

start-up

, t

, t

start-up

on

, Remote trip

off, ton

off

VMD461_D00314_01_M_XXEN/10.2018

41

Page 42

6.1 Menu "1. Alarm/meas. values"

Select the individual entries by means of the buttons:

Menu

(1-N)

(2-N)

(3-N)

(1-2)

(2-3)

(3-1)

: VALUE

: VALUE

: VALUE

: VALUE

: VALUE

: VALUE

1. U

2. U

3. U

4. U

5. U

6. U

7. Unbalance: VALUE

8. Phase sequence: VALUE

9. Frequency: VALUE

10. df/dt (81R): VALUE

11. Vect.sh.(78): VALUE

12. Status*

13. t

14. t

15. t

*: VALUE

(on1)

*: VALUE

(on2)

(off) total

*: VALUE

For each of these entries you can check whether an alarm exists or not:

= no alarm

= alarm

The numbering of the measuring channels matches the BMS

bus channels.

*

Status: measuring channel 12: The text depends on the existing mes-

sages.

t

: measuring channel 13/14: Current switch-on delay of alarm relay

(ON…)

K1 and alarm relay K2.

t

: measuring channel 15

(off) total

(only when contact monitoring is connected): Indicates the total time

of the shutdown process of the alarm relays with the switches/disconnectors.

42

VMD461_D00314_01_M_XXEN/10.2018

Page 43

Menu

History no. 297

From: 01.05.17 / 15:57:00

Ack.:

To: 01.05.17 / 16:07:03

History No. 297

Undervoltage

Min. 21 V/max.198 V

Addr.:2 Chan.:1

6.2 Menu "2. History"

The fail-safe history memory stores up to 300 events (alarms, tests) with information about alarms and acknowledgements and the time the event happened. If the history memory is full, the oldest entry will be deleted in the

event of an alarm to create space for the new entry (FIFO principle).

For details about deleting the entire history memory manually, refer to

page 64.

Fig. 6. 1: Histor y (overview)

Legend for Fig. 6.1:

Line 1: Event number

Line 2: Start of the event: Date/time

Line 3: Acknowledgement of the event: Date/time

Line 4: End of the event: Date/time

Navigating through the list:

1. If you are searching for an event that occurred at a specific time, scroll

through the different entries using the arrow buttons.

2. Calling up details: Use the button to call up the current history

memory entry.

VMD461_D00314_01_M_XXEN/10.2018

Fig. 6.2: History (detail)

43

Page 44

Menu

Please enter

password:

0 0 0

Legend for Fig. 6.2:

Line 1: Data record number

Line 2: Alarm status and alarm text (e.g. undervoltage,

underfrequency,…)

= no alarm

= alarm, fault

Line 3: Minimum and maximum measured value after the occur-

rence of an alarm

Line 4: BMS-bus address and measuring channel of the device

sending the signal

6.3 Menu "3. Settings"

6.3.1 General: Password protection

Settings can be password protected (menu 4.4). If the password is enabled, all

settings can be displayed. When an attempt is made to change settings, the

password entry screen appears automatically:

Once a valid password has been entered, access will be granted to settings in

all menus until menu mode is exited. If you cannot remember your password,

contact the Bender Service.

6.3.2 Procedure

The values can be changed in the third level of the menu (column "twice ")

using .

There are two different ways to exit the settings menu:

Save and exit: " "

Exit without saving: "ESC"

44

VMD461_D00314_01_M_XXEN/10.2018

Page 45

Menu

6.3.3 Menu structure "3. Settings"

The following table gives an overview of the menu structure.

Menu:

Settings

once twice

3.1 General Exit

1. Coupling yes

2. System type 3NAC

3. U(L-N) 50…260 V 230 V

4. t

5. Remote trip off

3.2 Voltage

(59/27)

Exit

1. U>>>

2. t

3. U>>

4. t

5. U>

6. t

7. U

no

DC

1AC

3AC

(start-up)

200 ms…60 min

N/C

N/O

(59.S3)

* 50 ms…60 min --

(off )

(59.S2)

* 50 ms…60 min --

(off )

(59.S1)

* 50 ms…60 min 100 ms

(off )

(on)max

off

100…150 %

off

100…150 %

off

100…150 %

off

100…150 %

Factory setting

no

3NAC

200 ms

off

off

off

110 %

105 %

VMD461_D00314_01_M_XXEN/10.2018

45

Page 46

Menu

Menu:

Settings

3.2 Voltage (59/

27)

3.3 Frequency

(81)

once twice

8. U

(on)min

off

1…100 %

9. U<

(27.S1)

10. t

* 50 ms…60 min 100 ms

(off )

11. U<<

(27.S2)

* 50 ms…60 min --

12. t

(off )

13. U<<<

14. t

(27.S3)

* 50 ms…60 min --

(off )

off

1…100 %

off

1…100 %

off

1…100 %

Exit

1. f>>>

(81>.S3)

2. t

* 50 ms…60 min --

(off)

3. f>>

(81>.S2)

* 50 ms…60 min --

4. t

(off)

5. f>

(81>.S1)

6. t

* 50 ms…60 min 100 ms

(off)

7. f

(on)max

8. f

(on)min

off

50…65 Hz

off

50…65 Hz

off

50…65 Hz

off

50…65 Hz

off

45…60 Hz

Factory setting

95 %

90 %

off

off

off

off

51.50 Hz

50.10 Hz

49.90 Hz

46

VMD461_D00314_01_M_XXEN/10.2018

Page 47

Menu

Menu:

Settings

3.3 Frequency

once twice

9. f<

(81)

10. t

11. f<<

12. t

13. f<<<

14. t

3.4 df/dt (81R) Exit

1. Function off

2. Resp. value 0.05…9.95 Hz/s 1.00 Hz/s

3. Hysteresis 1…50 % 20.0 %

4. Meas. window 50 ms…1 s 200 ms

5. t

6. t

3.5 Vect.sh. (78) Exit

1. Function off

2. Resp. value 1…25 ° 8.0 °

(81<.S1)

off

45…60 Hz

* 50 ms…60 min 100 ms

(off)

(81<.S2)

* 50 ms…60 min --

(off)

(81<.S3)

off

45…60 Hz

off

45…60 Hz

* 50 ms…60 min --

(off)

on

* 50 ms…60 min 100 ms

(off )

*off

(on)

50 ms…60 min

all

L3

L2

L1

Factory setting

48.50 Hz

off

off

off

off

off

VMD461_D00314_01_M_XXEN/10.2018

47

Page 48

Menu

Menu:

Settings

once twice

3.5 Vect.sh. (78) 3. t

4. t

3.6 Unbalance

(47)

Exit

1. Function off

2. Resp. value 1…50 % 5.0 %

3. Hysteresis 1…50 % 20.0 %

4. t

3.7 Phase

sequence (47)

Exit

1. Function on

2. Phase sequence right

(start-up)

off

50 ms…60 min

(on)

off

50 ms…60 min

on

* 50 ms…60 min 100 ms

(off)

off

left

Factory setting

2.00 s

off

off

on

right

48

VMD461_D00314_01_M_XXEN/10.2018

Page 49

Menu

Menu:

Settings

once twice

3.8 Relay ** Exit

1. Relay mode N/C

2. t

3. Fault memory on

4. Start alarm on

5. Device error on

6. TEST on

7. U>>>

8. U>>

9. U>

10. U<

(on)

(59.S3)

(59.S2)

(59.S1)

(27.S1)

Factory setting

N/C

N/O

50 ms…60 min 10 s

on

off

Duration

off

off

on

off

on

off

on

on

off

on

on

off

on

on

off

on

on

off

VMD461_D00314_01_M_XXEN/10.2018

49

Page 50

Menu

Menu:

Settings

once twice

3.8 Relay ** 11. U<<

12. U<<<

13. f>>>

14. f>>

15. f>

16. f<

17. f<<

18. f<<<

19. df/dt

20. Vect.sh.

21. Unbalance on

22. Phase

sequence

23. Remote trip on

(27.S2

(27.S3)

(81>.S3)

(81>.S2)

(81>.S1)

(81<.S1)

(81<.S2)

(81<.S3)

(81R)

(78)

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

off

on

off

off

Factory setting

on

on

on

on

on

on

on

on

on

on

on

on

on

50

VMD461_D00314_01_M_XXEN/10.2018

Page 51

Menu

Menu:

Settings

once twice

Factory setting

3.9 Dig. input ** Exit

1. Mode off

off

N/C

N/O

2. t

(start-up)

off

50 ms…60 min

--

Tab. 6.1: Settings menu

Note:

* t

can only be set when the corresponding parameter U…

(off)

or f… is activated.

** The relay or digital input number is displayed in the first line.

Change selection: Jump to the first line using and change

entry.

VMD461_D00314_01_M_XXEN/10.2018

51

Page 52

Menu

6.3.4 Explanatory comments on individual menu items

General (menu 3.1)

Activation of external coupling device CD440 (menu 3.1.1)

Is the VMD461 operated with a CD440 coupling device?

yes VMD461 with CD440

no VMD461 without CD440

System type (menu 3.1.2)

3NAC The system to be monitored consists of three phases

DC The system to be monitored consists of the two conductors

1AC The system to be monitored consists of one phase

including the neutral conductor. In the "1. Alarm/meas.

values" menu all measured values are available. The

nominal voltage is indicated as phase voltage (U

(L-N)

).

DC+ and DC–.

When set to system type "DC", the system to be monitored

must be connected to the terminals L2/DC+ and N/DC– !

In the "1. Alarm/meas. values" menu, the non-applicable

display indications for phase voltages and line-to-line

voltages, unbalance, phase sequence, frequency and

vector shift can be blanked (indication: --).

including the neutral conductor. In the "Alarm/meas.

values" menu, the non-applicable display indications for

line-to-line voltages, unbalance, and phase sequence can

be blanked (indication: --).

The nominal voltage is indicated as phase voltage (U

(L-N)

).

52

When set to system type "1AC", the system to be monitored

must be connected to the terminals L1 and N!

VMD461_D00314_01_M_XXEN/10.2018

Page 53

Menu

3AC The system to be monitored consists of three phases

without neutral conductor. In the "1. Alarm/meas. value"

menu, non-applicable display indications for phase

voltages can be blanked (indication: --).

The nominal voltage is indicated as line-to-line voltage

(U

).

Remote trip (menu 3.1.5)

(L-L)

This connection can optionally be activated and is intended

for disconnecting the electrical installation from the mains

supply by remote control via an external contact. After

activating the remote control, the switches/disconnectors

are switched after ≤ 50 ms.

Voltage (59/27) (menu 3.2)

The VMD461 can consider three different over- and undervoltage limit values.

A separate response delay t

The limit values for U

(on)max

For the intended use, the following requirement must be

complied with when setting several over- and undervolt-

age limit values:

[U>>>] > [U>>] > [U>] > [U

[U<<] > [U<<<].

can be set for each limit value.

(off)

and U

are also set here.

(on)min

(on)max

] > [U

(on)min

] > [U<] >

Separate switch-on limit values can be defined by means of the U

eters.

(on)…

param-

If the parameters are set to "off", the corresponding switch-off limit values are

also the switch-on limit values (no hysteresis). The measured values may not

exceed these limit values to allow connection of the electrical installation.

VMD461_D00314_01_M_XXEN/10.2018

53

Page 54

Menu

Frequency (81) (menu 3.3)

The VMD461 can consider three different over- and underfrequency limit values. A separate response delay t

The limit values for f

(on)max

For the intended use, the following requirement must be

complied with when setting several over- and undervolt-

age limit values:

[f>>>] > [f>>] > [f>] > [f

[f<<<].

can be set for each limit value.

(off)

and f

are also set here.

(on)min

(on)max

] > [f

] > [f<] > [f<<] >

(on)min

Separate switch-on limit values can be defined by means of the f

(on)…

parameters.

If the parameters are set to "off", the corresponding switch-off limit values are

also the switch-on limit values (no hysteresis). The measuring values may not

exceed these limit values to allow connection of the electrical installation.

df/dt (81R) (menu 3.4)

Islanding detection (df/dt) (ROCOF)

The VMD461 uses a passive method for islanding detection (three-phase voltage and frequency monitoring).

The monitoring of the "Rate of Change of Frequency" (df/dt)

is an islanding detection function.

If a subnetwork is shut down by the energy provider it might still be supplied

by electrical installations contained in the subnetwork. Underfrequency and

overfrequency monitoring might not be sufficient to detect this dangerous,

uncontrollable state, since the generators try to keep the frequency at the

nominal frequency level.

Due to an unbalance between the generated energy and the consumed energy the frequency fluctuates around the nominal frequency. If this happens at

a certain minimum speed, it is a sign of islanding and the VMD461 shuts down

the electrical installation.

54

VMD461_D00314_01_M_XXEN/10.2018

Page 55

Menu

Function (menu 3.4.1) Enable/disable df/dt monitoring.

Resp. value (menu 3.4.2) Specify a limit value at which tripping is to be

executed (in 0.05 Hz/s steps).

Hysteresis (menu 3.4.3) Adjust hysteresis.

Meas. window (menu 3.4.4) Period of time used to calculate the average of

the frequency changes (positive and negative

changes cancel each other out). The bigger the

measuring window selected the less sensitive

will the df/dt function be.

t

(menu 3.4.5) Response delay: Period of time during which the

(off)

limit value

df/dt must be violated until the VMD461 shuts

down the electrical installation.

t

(menu 3.4.6) Switch-on delay, when df/dt has caused a

(on)

shutdown. You can choose between a precise

value and "off". When the "off" setting is

selected, the normal switch-on delay t

menu 3.8.3 will be used.

(on)

from

VMD461_D00314_01_M_XXEN/10.2018

55

Page 56

Menu

Vector shift detection (78) (menu 3.5)

Vector shift detection is triggered by a sudden phase displacement (vector

shift).

A phase displacement may occur when a mechanical generator is used for

public grid infeed and the load is changing suddenly (as can be the case with

islanding).

In addition to the risk of islanding synchronisation to the rest of the system

can be lost during the interruption so that the generator and parts of the drive

may become electrically and mechanically overloaded during reconnection.

Function (menu 3.5.1) Enable/Disable vector shift detection and indicate

Resp. value (Menu 3.5.2) Specify a limit value at which tripping is to be

t

(menu 3.5.3) Time during which vector shift detection is

(start-up)

t

(menu 3.5.4 ) Switch-on delay after the vector shift detection has

(on)

which phases should be monitored (L1 / L2 / L3 / all

/ off). If all phases are selected, the vector shift must

occur on all three phases simultaneously.

Otherwise the device will not trip.

If the device is set to single-phase connection

(3.1.2 System type: 1 AC) and vector shift detection

is ena ble d, L 1 wi ll alw ays be a uto mat ic all y se lec ted

as the phase to be monitored (independent of the

current parameter setting).

executed (in ° )

suppressed. This time begins as soon as the

VMD461 has connected the electrical installation.

t

has to ensure that there is no tripping due

(start-up)

to voltage fluctuations during the switch-on

period.

resulted in a shutdown. You can choose between

a precise value and "off". In case of "off", the normal

switch-on delay from menu 3.8.3 is used.

56

VMD461_D00314_01_M_XXEN/10.2018

Page 57

Menu

Unbalance (47) (menu 3.6)

The unbalance is calculated between the phase voltages and the line-to-line

voltages. The higher of the two values will be compared to the specified response value and can lead to a shutdown of the electrical installation.

Function (menu 3.6.1) Enable/Disable monitoring

Resp. value (menu 3.6.2) Specify a limit value at which tripping is to be

Hysteresis (menu 3.6.3) Set a hysteresis

t

(menu 3.6.4) Response delay: Period of time during which the

(off)

executed (in 0.1 % steps)

unbalance limit value must be violated until the

VMD461 shuts down the electrical installation

Phase sequence (47) (menu 3.7)

AC system:

When phase sequence monitoring is enabled, the alarm relays K1 and/or K2

trip when the detected phase sequence no longer matches the specified value (measurement time approx. 50 ms).

Function (menu 3.7.1) Enable/Disable monitoring phase sequence

Phase sequence(menu 3.7.2)Select specified phase sequence (right, left)

DC system:

When phase sequence monitoring is enabled, the polarity of the system is

tested.

The alarm relays K1 and/or K2 trip when the polarity no longer matches the

specified value (measurement time approx. 50 ms).

Function (menu 3.7.1) Enable/Disable monitoring polarity

Phase sequence (menu 3.7.2)Select polarity

right: L2/DC+= +

N/DC–= –

left: L2/DC+= –

VMD461_D00314_01_M_XXEN/10.2018

N/DC–= +

57

Page 58

Relays (menu 3.8)

Alarm assignments to the alarm relays

Set here which messages should make the alarm relays switch.

The alarm relay to be adjusted is indicated in the first line.

Entering changes:

Use the button to jump to the top line, activate

modification with the button and modify alarm relay.

The following alarms can be assigned to the alarm relays K1 and K2:

Start alarm

Device error

TEST

U>, U>>, U>>> (59.S1…3)

U<, U<<, U<<< (27.S1…3)

f>, f>>, f>>> (81>.S1…3)

f<, f<<, f<<< (81<.S1…3)

df/dt (81R)

Vector shift (78)

Unbalance

Phase sequence

Remote trip

Relay mode (menu 3.8.1)

N/C Normally closed -

Relay is energised during normal operation and will be

deactivated in the event of a fault.

N/O Normally open -

The relay is de-energised in normal operation and will be

activated in the event of a fault.

Menu

58

VMD461_D00314_01_M_XXEN/10.2018

Page 59

Menu

Switch-on delay t

t

can be adjusted separately for each alarm relay.

on

(menu 3.8.2)

on

The alarm relay to be adjusted is indicated in the first line.

Entering changes:

Use the button to jump to the top line, activate

modification with the button and modify settings.

All switch-on conditions of the measuring functions assigned to the alarm relay have to be met for the duration of the switch-on delay t

so that the cor-

on

responding alarm relay operates.

When all switch-on conditions are met, the corresponding switch-on delay t

elapses.

on

It is possible to view the time that is still required for switchon:

menu 1.13 (t

menu 1.14 (t

on1

on2

) or

)

Special case:

If the electrical installation has been shut down due to a vector shift or an islanding detection, a different switch-on delay can be defined for these cases.

Menu: 3.4. df/dt

Menu: 3.5. Vect.sh.

VMD461_D00314_01_M_XXEN/10.2018

59

Page 60

Menu

Fault memory(menu 3.8.3)

The fault memory behaviour can be adjusted separately for each alarm relay.

The element to be adjusted is indicated in the first line.

Entering changes:

Use the button to jump to the top line, activate

modification with the button and modify settings.

The fault memory can be enabled, disabled or set to continuous mode. If the

fault memory is set to "cont." mode, a stored alarm remains in the memory

even if there is a failure of the supply voltage.

Setting options:

on The alarm relays remain in the alarm state until the supply

voltage is interrupted or a reset is carried out.

off The alarm relays return to their initial position as soon as the

limit value is no longer violated.

cont. The alarm relays remain in the alarm state even after the

supply voltage has failed until a reset is carried out.

Start alarm (menu 3.8.4)

on Starting the device with a simulated alarm

off Starting the device without a simulated alarm

When the start alarm is activated, K1 or K2 switches to alarm state after applying the supply voltage. The device remains in alarm state for the delay time

t

. Afterwards, the switch-on delays t

(start-up)

stallation condition. Then, the alarm relays K1 or K2 switch back, provided that

) elapse according to the in-

(on…

no fault has been detected at the measuring input.

Device error (menu 3.8.5)

The alarm assignment "Device errors" includes internal errors as well as external errors in the contact monitoring.

60

VMD461_D00314_01_M_XXEN/10.2018

Page 61

Menu

Dig. input (contact monitoring) (menu 3.9)

Contact monitoring can be enabled separately for the switched-on and

switched-off condition of the installation. The following table shows an overview of the settings:

Mode

(menu 3.9.1)

Contact monitoring when installation is

switched on switched off

off ——

N/C or N/O X

(delay 500 ms,

not configurable)

t

(menu 3.9.2)

(start-up)

off 50 ms…60 min

— X

Dig. input Select digital input that is to be configured.

The digital input to be configured is indicated in the first line.

Entering changes:

Use the button to jump to the top line, activate

modification with the button and modify settings.

Mode (menu 3.9.1) Select operating mode of the digital input.

off Disable contact monitoring

N/C Normally closed

In non-operating state, the auxiliary contact is

closed.

N/O Normally open

In non-operating state, the auxiliary contact is open.

t

(menu 3.9.2) Configure time delay after which the VMD461 (after

(start-up)

switching on the electrical installation) should

check the switching contact monitoring of the

switches/disconnectors connected to alarm relays

K1and/or K2.

VMD461_D00314_01_M_XXEN/10.2018

61

Page 62

Menu

off Disable contact monitoring of connected instal-

lation

50 ms…60 min Time delay contact monitoring

.

A delay of 500 ms is recommended for active contact

monitoring of the connected installation. In case of slow

motor-operated switches/disconnectors it may be necessary

to increase t

(start-up)

.

6.4 Menu "4. System"

The following table gives an overview of the menu structure. The values can

be changed in the third level of the menu (column "twice ") using .

There are two different ways to exit the system menu:

Save and exit: " "

Exit without saving: "ESC"

6.4.1 Menu structure "4. System"

Menu: System

1. History Exit

2. Language Exit

once twice

Delete

1)

Delete

Cancel

English

German

Frenc h

62

VMD461_D00314_01_M_XXEN/10.2018

Page 63

Menu

Menu: System

3. Clock Exit

4. Password Exit

5. Interface Exit

6. Alarm addresses Exit

7. TEST Cancel

8. RESET Cancel

9. Test communication

once twice

Format d. m.y

Date Toggling between date elements

Time Toggling between hour and

Summertime auto

Password * * *

Status off

Address

Address xxx

TEST

RESET

Exit

1. Channel

m-d-y

with

minute with

off

Toggling between positions with

on

1…90

1: Master

2…90: Slave

1…150: off/on

Test is carried out

Reset is carried out

Channel (1…12)

VMD461_D00314_01_M_XXEN/10.2018

63

Page 64

Menu

Menu: System

10. External devices Exit

11. Service Service menu only available for Bender service

12. Factory settings Cancel fac-

once twice

1…150: Address of VMD461 and

List of connected

devices

tory settings

Tab. 6.2: Menu structure "4. System"

external devices

Restore factory settings

6.4.2 Explanatory comments on individual menu items

Clear history memory (menu 4.1)

After starting the deletion process the history memory is

irreversibly deleted.

Password

Manual self test (menu 4.7 )

Factory settings (menu 4.12 )

(menu 4.4 )

Password protection is deactivated (off) by default.

Navigate through the system also when the password

protection is activated. However, the password is required for

change of parameters.

The self test can only be started manually when the

VMD461 is connected and free of alarms. The alarm relays

K1 and K2 switch when the corresponding alarm

assignment (menu: 3.8.6 "Test") is activated.

Activating the factory settings will reset the device to the

default upon delivery.

64

VMD461_D00314_01_M_XXEN/10.2018

Page 65

Menu

6.5 Menu "5. Info"

The following table gives an overview of the information to be called up.

Scroll through the individual lines using the arrow buttons :

Device type

Current date and time

BMS bus address

Software version, measurement technology

Software date, measurement technology

Software version, display

Software date, display

Manufacturer of the device

Address of the manufacturer

Internet address of the manufacturer

6.6 Operation via web user interface

The parameters of the VMD461 can be set via the network when using a protocol converter (CP700, COM465, …).

Consider logical dependencies when setting

parameters:

Since, for example, the setting limits of the parameter

"Nominal voltage" depend on "Coupling" and "System type",

these must be configured and saved before. Only after doing

this, the nominal voltage can be adjusted.

VMD461_D00314_01_M_XXEN/10.2018

65

Page 66

Menu

66

VMD461_D00314_01_M_XXEN/10.2018

Page 67

7. Maintenance, troubleshooting, messages

7.1 Manual self test

The self test can only be started manually when the electrical installation has

been started by the VMD461 and is free of alarms (both alarm LEDs are off).

In case of a manual self test, alarm relays K1 and K2 trip if the

corresponding alarm assignment is activated in menu 3.8.6.

"Test".

Start of the manual self test:

1. Press the test button in the standard display (> 1.5 s) or

2. Select in the menu 4.7 Test.

The alarm relays K1 and K2 switch during the self test and open or close the

contacts 11/12/14 and 21/22/24.

When contact monitoring is activated for switch/disconnector K1 and/or

K2, the time until the switch/disconnector has actually switched off is additionally measured (t

The longer one of the two switch-off times is shown as an alarm in the display

for 10 seconds and can be read in the menu 1.15 (t

shut down.

The manual self test is stored in the history memory.

(off) total

).

) until the device is

(off) total

VMD461_D00314_01_M_XXEN/10.2018

67

Page 68

Maintenance, troubleshooting, messages

7.2 Messages and malfunctions

In case of messages and malfunctions, alarm relays K1 and

K2 trip if the corresponding alarm assignment is activated in

menu 3.8.6. "Device error".

Both alarm LEDs flash: internal device error or fault in contact monitoring

The (error) code or the message is shown in clear text on the display.

Code/

message

1…20, 23Both alarm

Contact

monitor.

K1

Contact

monitor.

K2

Remote

trip

LED Meaning Remedy

LEDs flash

Both alarm

LEDs flash

Both alarm

LEDs light

continuously

68

Internal error Write down the error code

"xx2 and contact Bender

service.

Error: Contact

monitoring K1

(D1)

Error: Contact

monitoring K2

(D2)

Remote shutdown active

After rectifying the fault at

the switch/disconnector/

main switch (e.g. manual

connection of the backup

switch), the fault is automatically cleared. If the same fault

occurs three times within 30

seconds at the digital input,

normal operation must be

started again after fault elimination by pressing the

"RESET" button (in the standard display).

Connect RTG/RT1 or deactivate input in the menu (off)

VMD461_D00314_01_M_XXEN/10.2018

Page 69

Maintenance, troubleshooting, messages

7.3 LEDs

The state of the VMD461 can be determined by means of the LEDs. The following table provides an overview of the possibilities.

LEDs Meaning Action

2

ALARM

1

ON

2

ALARM

1

ON

yellow off

yellow off

green lights

yellow lights

yellow lights