Bender LINETRAXX PEM575, LINETRAXX PEM575-251, LINETRAXX PEM575-455, LINETRAXX PEM575-451 Series Manual

Manual

EN

PEM575

B 9310 0575

B 9310 0576

B 9310 0577

B 9310 0578

Universal measuring device

Software version 2.00.xx

PEM575_D00016_00_M_XXEN/04.2015

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Gruenberg • Germany

Postfach 1161 • 35301 Gruenberg • Germany

© Bender GmbH & Co. KG

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: info@bender.de

www.bender.de

All rights reserved.

Reprinting only with permission

of the publisher. Subject to change!

Photos: Bender and bender systembau archives.

Table of Contents

1. Making effective use of this document ............................................... 9

1.1 How to use this manual ......................................................................................... 9

1.2 Technical support: Service and support ........................................................ 10

1.3 Workshops ............................................................................................................... 11

1.4 Delivery conditions, guarantee, warranty and liability ............................ 11

2. Safety ...................................................................................................... 13

2.1 Intended use ........................................................................................................... 13

2.2 Qualified personnel .............................................................................................. 13

2.3 General safety instructions ................................................................................ 14

3. Device description ............................................................................... 15

3.1 Area of application ................................................................................................ 15

3.2 Device features ....................................................................................................... 15

3.3 Versions .....................................................................................................................16

3.4 Application example ............................................................................................ 17

3.5 Description of function ....................................................................................... 17

3.6 Front view and rear view .................................................................................... 18

4. Installation and connection ............................................................... 19

4.1 Project planning ..................................................................................................... 19

4.2 Safety instructions ................................................................................................. 19

4.3 Installing the device ............................................................................................. 19

4.3.1 Dimension diagrams ................................................................................... 19

4.3.2 Front panel mounting ................................................................................ 20

4.4 Connection of the device ................................................................................... 21

4.4.1 Safety information ....................................................................................... 21

4.4.2 Back-up fuses ................................................................................................. 21

4.4.3 Connection of measuring current transformers ............................... 21

PEM575_D00016_00_M_XXEN/04.2015

3

Table of Contents

4.5 Instructions for connection ................................................................................ 21

4.6 Wiring diagram ....................................................................................................... 22

4.7 Connection diagram voltage inputs ............................................................... 23

4.7.1 Three-phase 4-wire system (TN, TT, IT system) .................................. 23

4.7.2 Three-phase 3-wire system ....................................................................... 25

4.7.3 Connection via voltage transformers ................................................... 26

4.8 Digital inputs ........................................................................................................... 26

4.9 Digital outputs ........................................................................................................ 27

4.10 Modbus TCP (connector pin assignment) .................................................... 27

5. Commissioning ...................................................................................... 29

5.1 Check proper connection ................................................................................... 29

5.2 Before switching on .............................................................................................. 29

5.3 Switching on ............................................................................................................ 29

5.4 System .......................................................................................................................30

6. Operation ............................................................................................... 31

6.1 Getting to know the operating elements .................................................... 31

6.2 LCD testing ............................................................................................................... 32

6.3 Getting to know standard display areas ....................................................... 33

6.4 Power and current demands (demand display) ......................................... 36

6.5 LED indication ......................................................................................................... 37

6.6 Standard display .................................................................................................... 37

6.7 Data display ............................................................................................................. 37

6.7.1 "V/I" button ..................................................................................................... 38

6.7.2 "POWER"button ............................................................................................ 40

6.7.3 "HARMONICS" button ................................................................................. 42

6.7.4 "ENERGY" button .......................................................................................... 43

6.8 Setup configuration via the front panel ........................................................ 44

6.8.1 Setup: Function of buttons ....................................................................... 44

6.8.2 Setup: Overview diagram menu ............................................................. 45

6.9 Setup: adjustment possibilities ........................................................................ 46

6.10 Configuration example: ....................................................................................... 52

4

PEM575_D00016_00_M_XXEN/04.2015

Table of Contents

7. Application/inputs and outputs ......................................................... 53

7.1 Digital inputs (DI) ................................................................................................... 53

7.2 Digital outputs (DO) ............................................................................................. 53

7.3 Energy pulsing output ......................................................................................... 54

7.4 Power and energy ................................................................................................. 54

7.4.1 Basic measurements ................................................................................... 54

7.4.2 High-speed measurements ...................................................................... 55

7.4.3 Voltage and current phase angles ......................................................... 55

7.4.4 Energy .............................................................................................................. 55

7.5 Demand DMD ......................................................................................................... 55

7.5.1 Max/Min values per demand period ..................................................... 57

7.6 Setpoints ................................................................................................................... 57

7.7 Logic modules ........................................................................................................ 61

8. Logging ................................................................................................... 63

8.1 Peak demand log ................................................................................................... 63

8.2 Max/Min log ............................................................................................................. 63

8.3 Data recorder (DR) ................................................................................................. 65

8.3.1 Setup parameters ......................................................................................... 65

8.3.2 Selectable measured quantities for data recorders DR .................. 66

8.4 Energy log ................................................................................................................ 78

8.5 Waveform recording (WFR) ................................................................................ 79

8.6 Power Quality log (PQ log) ................................................................................. 81

8.7 Event log (SOE log) ................................................................................................ 81

9. Power Quality ........................................................................................ 83

9.1 Fundamentals ......................................................................................................... 83

9.2 Harmonic distortion .............................................................................................. 83

9.3 Deviation from the pre-set nominal value (

9.4 Undervoltage/overvoltage setpoint (sag/swell setpoint) ...................... 85

9.5 Transient events setpoint ................................................................................... 86

9.6 Time synchronisation ........................................................................................... 86

9.7 E-mail notification ................................................................................................. 87

5

ΔU, Δ

❆) ................................... 85

PEM575_D00016_00_M_XXEN/04.2015

Table of Contents

10. Modbus Register Map ........................................................................ 89

10.1 Basic measurements ............................................................................................. 91

10.2 Energy measurement ........................................................................................... 96

10.3 Pulse counter .......................................................................................................... 98

10.4 Fundamental measurements (Power quality) ............................................. 98

10.5 Harmonic measurements (Power quality) ................................................. 100

10.6 High-speed measurement .............................................................................. 102

10.7 Demand .................................................................................................................. 104

10.7.1 Present demand ........................................................................................ 104

10.7.2 Predicted demand .................................................................................... 106

10.7.3 Maximum values per demand period ............................................... 108

10.7.4 Minimum values per demand period ................................................ 110

10.7.5 Peak demand of this month .................................................................. 112

10.7.6 Peak demand last month ....................................................................... 112

10.7.7 Peak demand data structure ................................................................. 113

10.8 Max/Min log .......................................................................................................... 114

10.8.1 Maximum values of this month .......................................................... 114

10.8.2 Min log of this month .............................................................................. 116

10.8.3 Max log of last month .............................................................................. 118

10.8.4 Min log last month .................................................................................... 120

10.8.5 Max/Min log data structure ................................................................... 121

10.9 Setup parameters ............................................................................................... 122

10.10 Clear/reset register ............................................................................................. 128

10.11 Setpoint setup parameters ............................................................................. 130

10.11.1 Structure of the setpoint register (standard) .................................. 131

10.11.2 Setpoint register structure (high speed) ........................................... 131

10.12 Logic module ....................................................................................................... 134

10.12.1 Logic module registers ............................................................................ 134

10.12.2 Logic module data structure ................................................................. 134

10.13 Data recorder (DR) .............................................................................................. 136

10.13.1 Data recorder register .............................................................................. 136

10.13.2 High-speed data recorder register structure .................................. 138

10.13.3 Standard data recorder register structure ....................................... 140

10.14 Waveform recording (WFR) ............................................................................. 141

6

PEM575_D00016_00_M_XXEN/04.2015

Table of Contents

10.15 Energy log ............................................................................................................. 144

10.16 PQ log ..................................................................................................................... 146

10.17 Event log (SOE log) ............................................................................................. 148

10.17.1 Energy log register .................................................................................... 148

10.17.2 Event log data structure ......................................................................... 149

10.17.3 Event classification (SOE log) ............................................................... 150

10.18 Time setting .......................................................................................................... 159

10.19 DOx output control ........................................................................................... 159

10.20 Universal measuring device information ................................................... 161

11. Technical data .................................................................................. 163

11.1 Standards and certifications ........................................................................... 165

11.2 Ordering information ........................................................................................ 165

INDEX ......................................................................................................... 167

7

PEM575_D00016_00_M_XXEN/04.2015

1. Making effective use of this document

DANGER

WARNING

CAUTION

1.1 How to use this manual

This manual is aimed at qualified personnel in electrical engineering and communica-

tions technology,

encing in the immediate vicinity of the device.

To make it easier for you to understand and revisit certain sections of text and instructions in the manual, we have used symbols to identify important instructions and information. The meaning of these symbols is explained below:

installers and users of the product and must be kept ready for refer-

The signal word indicates that there is a high risk of danger,, that will

result in death or serious injury if not avoided.

This signal word indicates a medium risk of danger that can lead to

death or serious injury if not avoided.

This signal word indicates a low level risk that can result in minor or

moderate injury or damage to property if not avoided.

This symbol denotes information intended to assist the user in making

optimum use of the product.

Although great care has been taken in the drafting of this operating manual, it may nevertheless contain errors and mistakes. Bender cannot accept any liability for injury to

persons or damage to property resulting from errors or mistakes in this manual.

Each of the registered trademarks which appears in this document remains the

property of its owner.

PEM735_D00084_00_M_XXEN/02.2015

9

Making effective use of this document

1.2 Technical support: Service and support

For commissioning and troubleshooting Bender offers you:

First level support

Technical support by phone or e-mail for all Bender products

All questions about customer applications

Commissioning

Troubleshooting

Phone: +49 6401 807-760*

Fax: +49 6401 807-259

only available in Germany: 0700BenderHelp (Tel. and Fax)

E-mail: support@bender-service.com

Repair service

Repair, calibration, update and replacement service for all Bender products

Repair, calibration, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices for faulty or incorrectly delivered Bender devices

Extended warranty for Bender devices with in-house repair service resp. replace-

ment devices at no extra cost

Phone: +49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (commercial matters)

Fax: +49 6401 807-789

E-mail: repair@bender-service.com

Please send the devices for repair to the following address:

Bender GmbH, Repair Service

Londorfer Strasse 65

35305 Gruenberg, Germany

10

PEM735_D00084_00_M_XXEN/02.2015

Making effective use of this document

Field service

On-site service for all Bender products

Commissioning, parameter setting, maintenance, trouble shooting for Bender

products

Analysis of the electrical installation in the building (power quality test, EMC test,

thermography)

Practical training courses for customers

Phone: +49 6401 807-752**, -762 **(technical issues)

+49 6401 807-753** (commercial matters)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.com

Internet: www.bender.de.

*Available from 7.00 a.m. to 8.00 p.m. on 365 days of the year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m.

1.3 Workshops

Bender would be happy to provide training in respect of the use of the universal

measuring device.

Current dates of training courses and workshops can be found on the Internet at

www.bender.de -> Know-how -> Seminars.

1.4 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender apply.

For software products, the "Softwareklausel zur Überlassung von Standard- Software als Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen Lieferbedingungen für Erzeugnisse und Leistungen der Elektroindustrie" (software clause

in respect of the licensing of standard software as part of deliveries, modifications

and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband Elektrotechnik- und Elektronikindustrie e.V., (German Electrical and Electronic Manufacturers' Association) also

applies.

Conditions of sale and delivery can be obtained from Bender in printed or

electronic format.

PEM735_D00084_00_M_XXEN/02.2015

11

Making effective use of this document

12

PEM735_D00084_00_M_XXEN/02.2015

2. Safety

2.1 Intended use

The universal measuring device PEM575 is suitable for

the analysis of energy and power

monitoring of the power supply quality

data recording for energy management.

As a compact device for front panel mounting, it is a replacement for analogue indicating instruments. Das PEM575 is suitable for 2, 3 and 4-wire systems and can be

used in TN, TT and IT systems. The current measurement inputs of the PEM are connected via external ../1 A or ../5 A measuring current transformers. In principle, measurements in medium and high voltage systems are carried out via measurement

transformers and voltage transformers.

Use for the intended purpose also includes:

Device-specific settings according to local equipment and operating conditions.

The observation of all information in the operating manual.

2.2 Qualified personnel

Only electrically skilled persons are authorised to install and commission this device.

Electrically skilled persons are those who have the relevant education, knowledge

and experience, as well as knowledge of the relevant safety standards and who are

able to perceive risks and to avoid hazards which electricity can create when work

activities are carried out on electrical installations. The electrically skilled person is

specially trained for carrying out work activities in his specific working environment

and has a thorough knowledge of the relevant standards and regulations. In Germany, an electrically skilled person must meet the requirements of the accident

prevention regulation BGV A3. In other countries the applicable regulations have

to be observed and followed.

PEM735_D00084_00_M_XXEN/02.2015

13

Safety

DANGER

2.3 General safety instructions

Bender devices are designed and built in accordance with the state of the art and

accepted rules in respect of technical safety. However, the use of such devices may

introduce risks to the life and limb of the user or third parties and/or result in damage to Bender equipment or other property.

Danger of electric shock!

Touching live parts will cause danger of electric shock with fatal

consequences.

All work activities on electrical installations as well as installation

activities, commissioning activities and work activities with the device in

operation may only be carried out by electrically skilled persons!

Only use Bender equipment:

– as intended

– in perfect working order

– in compliance with the accident prevention regulations and guidelines appli-

cable at the location of use

Eliminate all faults immediately which may endanger safety.

Do not make any unauthorised changes and only use replacement parts and opti-

onal accessories purchased from or recommended by the manufacturer of the

equipment. Failure to observe this requirement can result in fire, electric shock

and injury.

Information plates must always be clearly legible. Replace damaged or illegible

plates immediately.

If the device is overloaded by overvoltage or a short-circuit current load, it must

be checked and replaced if necessary.

If the device is being used in a location outside the Federal Republic of Germany,

the applicable local standards and regulations must be complied with.

European standard EN 50110 can be used as a guide.

14

PEM735_D00084_00_M_XXEN/02.2015

3. Device description

3.1 Area of application

For humans, electric current is not immediately visible. Universal measuring devices for monitoring electrical parameters are used wherever energy consumption,

performance measurements or the quality of the supply voltage are to be made visible.

The PEM575 is suitable for monitoring

power generation systems (PV systems, CHPs, hydro power and wind power

plants)

energy-intensive equipment and parts of installation

sensitive equipment

3.2 Device features

The universal measuring device PEM575 for power quality and energy management is characterised by the following features:

Accuracy class in accordance withIEC 62053-22: 0.2 S

Password protection

16 programmable setpoints

LED pulse outputs for active and reactive energy

Modbus RTU communication via RS-485 interface

6 digital inputs

3 digital outputs

Power and current demands for particular time frames

Peak demands with timestamps

Individual, current/voltage harmonics up to the 63

Max and Min values

High-resolution waveform recording (12.8 kHz)

Data recorder

Event log: 512 events, setup changes, setpoint alarming, DI status changes, DO

switching operations

Sag/swell detection

Detection of transient events

Communication:

rd

harmonic

PEM735_D00084_00_M_XXEN/02.2015

15

– Galvanically isolated RS-485 interface (1,200 … 19,200 bit/s)

– Modbus/RTU protocol

– Modbus/TCP (10/100 Mbit/s)

Measured quantities

– Phase voltages U

– Line-to-line voltages U

– Phase currents I

– Neutral current (calculated) I

– Neutral current (measured) I

, UL2, U

L1

, U

L1L2

, I2, I3 in A

1

in A

0

in A

4

L2L3

L3

in V

, U

– Frequency f in Hz

– Phase angle for U and I in °

– Power per phase conductor P in kW, Q in kvar, S in kVA

– Total power P in kW, Q in kvar, S in kVA

– Displacement factor cos (φ)

– Power factor λ

– Active and reactive energy import in kWh, kvarh

– Active and reactive energy export in kWh, kvarh

– Voltage unbalance in %

– Current unbalance in %

– Harmonic distortion

(THD, TOHD, TEHD) for U and I

– K-factor for I

L3L1

Device description

in V

3.3 Versions

PEM575 230/400 V;

Current input 5 A

PEM575-251 230/400 V

Current input 1 A

PEM575-455 400/690 V, 50 Hz

Current input 5 A

PEM575-451 400/690 V, 50 Hz

Current input 1 A

16

PEM735_D00084_00_M_XXEN/02.2015

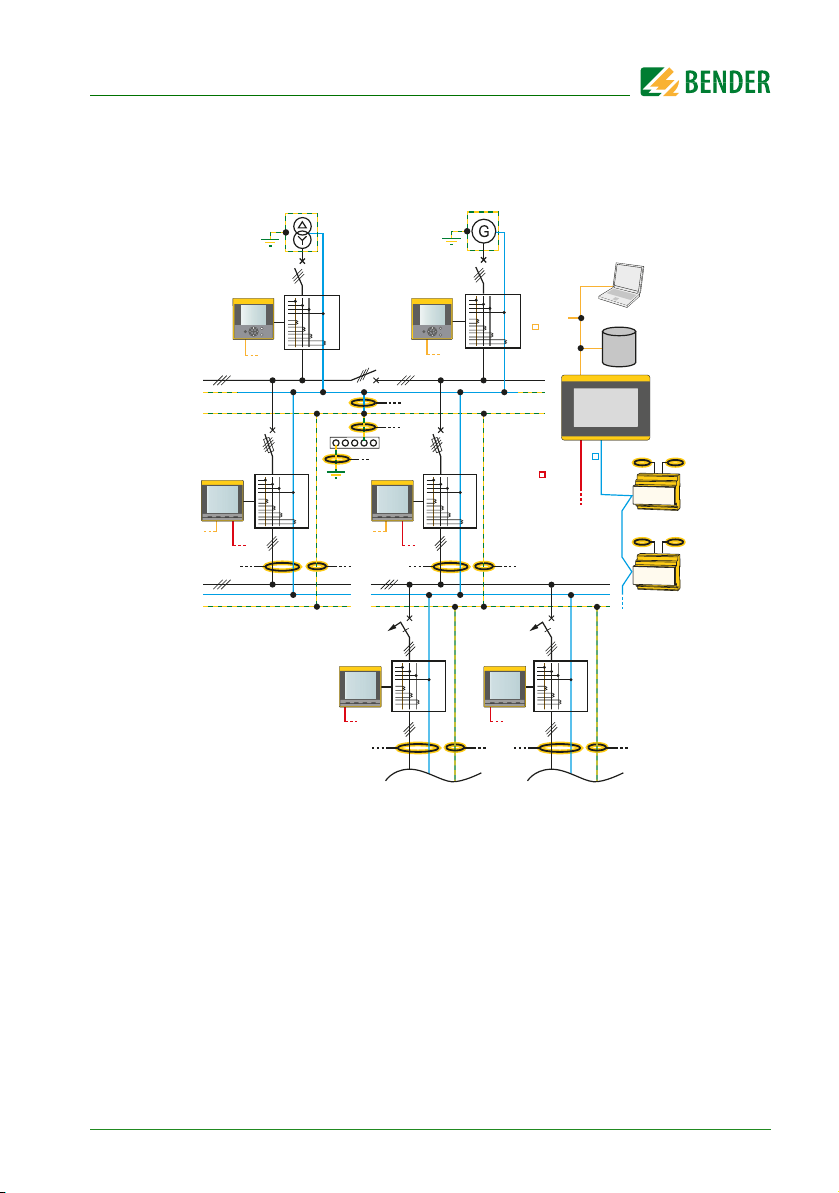

3.4 Application example

PEM7xx

Modbus TCP

L

PEN

PE

PEM5xx PEM5xx

Modbus TCP

Modbus RTU

L

N

PE

U

I

U

I

UV1

PEM3xx

Fig. 3.1: Application example

Modbus TCP

Modbus RTU

Modbus RTU

PAS

PEM7xx

Modbus TCP

3

U

Ethernet

I

NSHV

CP700

Modbus

U

I

PEM3xx

U

I

Modbus RTU

RTU

3

U

I

UV2

BMS

Datenbank

1…12

RCMS

1…12

RCMS

3.5 Description of function

The digital universal measuring device PEM575 is suited for measuring and displaying electrical quantities of a public electricity network. The PEM575 is able to perform current, voltage, energy consumption and performance measurements as

well as displaying individual harmonic components of current and voltage for assessment of the voltage and current quality.

PEM735_D00084_00_M_XXEN/02.2015

17

Device description

The accuracy of the active energy metering corresponds to class 0.2 S in compliance with the DIN EN 62053-22 (VDE 0418 Part 3-22):2003-11.

The large display of the panel mounting device makes the relevant measured

quantities easily legible and enables fast configuration. In addition, the RS-485 interface allows a central evaluation and processing of data. Switching operations

can be monitored or initiated via the digital inputs and outputs (Example: Switching off uncritical loads if the peak load limit value is exceeded).

The universal measuring device PEM575 provides the following functions:

Provision of energy consumption data for a well-thought-out energy manage-

ment

Allocation of energy costs

Power quality monitoring for cost reduction and increased plant availability

High-resolution waveform recording allow analysis of power quality phenomena

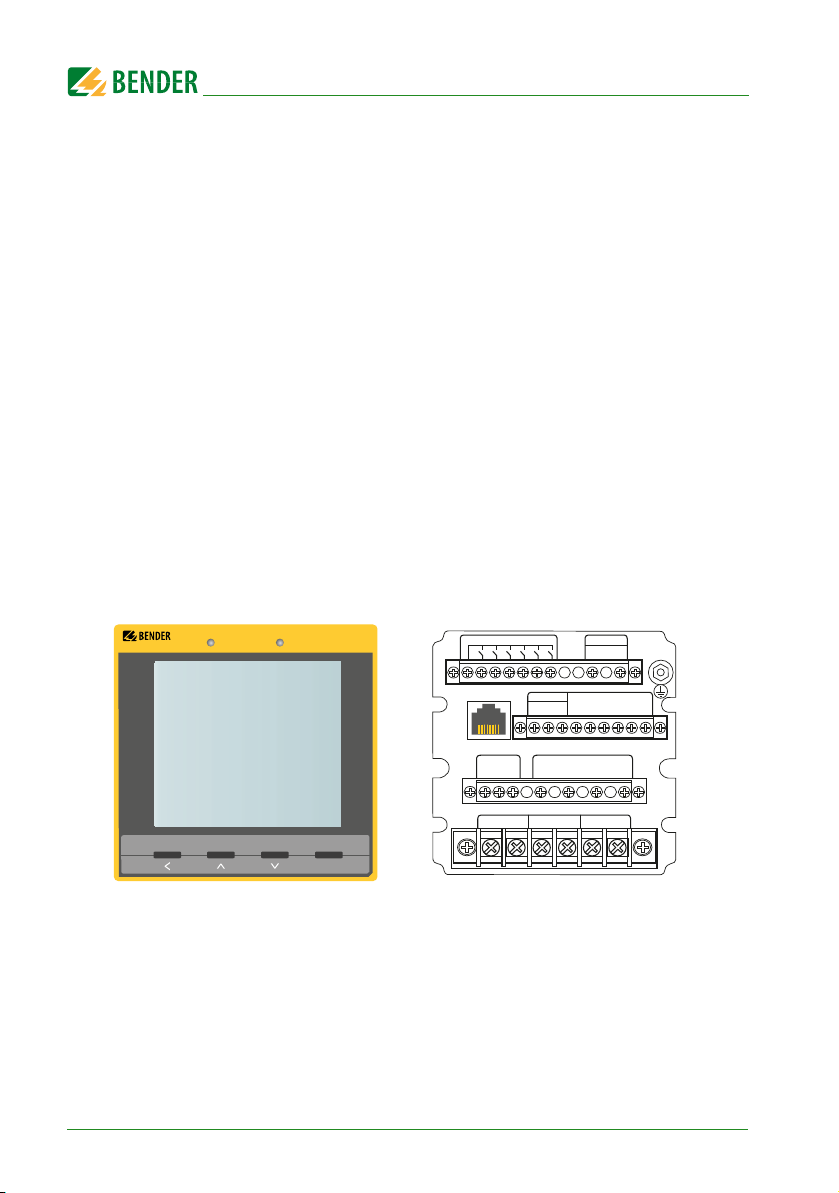

3.6 Front view and rear view

The connecting terminals are located at the rear of the device.

18

LINETRAXX®

PEM575

V/I

kWh

POWER HARMONICS

kvarh

ENERGY

OK

DIC DI1 DI2 DI3 DI4 DI5 DI6

• l41

• l11

Fig. 3.2: Front view (left) and rear view (right) PEM575

PEM735_D00084_00_M_XXEN/02.2015

RS-485ETH

D

D+

l42SH

L1 L2 L3 N

l12

• l21 • l31

A1 A2

DO34 DO33 DO24 DO23 DO14 DO13

-

SH

l22 l32

Power

4. Installation and connection

DANGER

4.1 Project planning

For any questions associated with project planning, please contact Bender:

Internet: www.bender.de

Tel.: +49-6401-807-0

4.2 Safety instructions

Only electrically skilled persons are allowed to connect and commission the device.

Such persons must have read this manual and understood all instructions relating

to safety.

Danger of electric shock!

Follow the basic safety rules when working with electricity.

Consider the data on the rated voltage and supply voltage as specified

in the technical data!

4.3 Installing the device

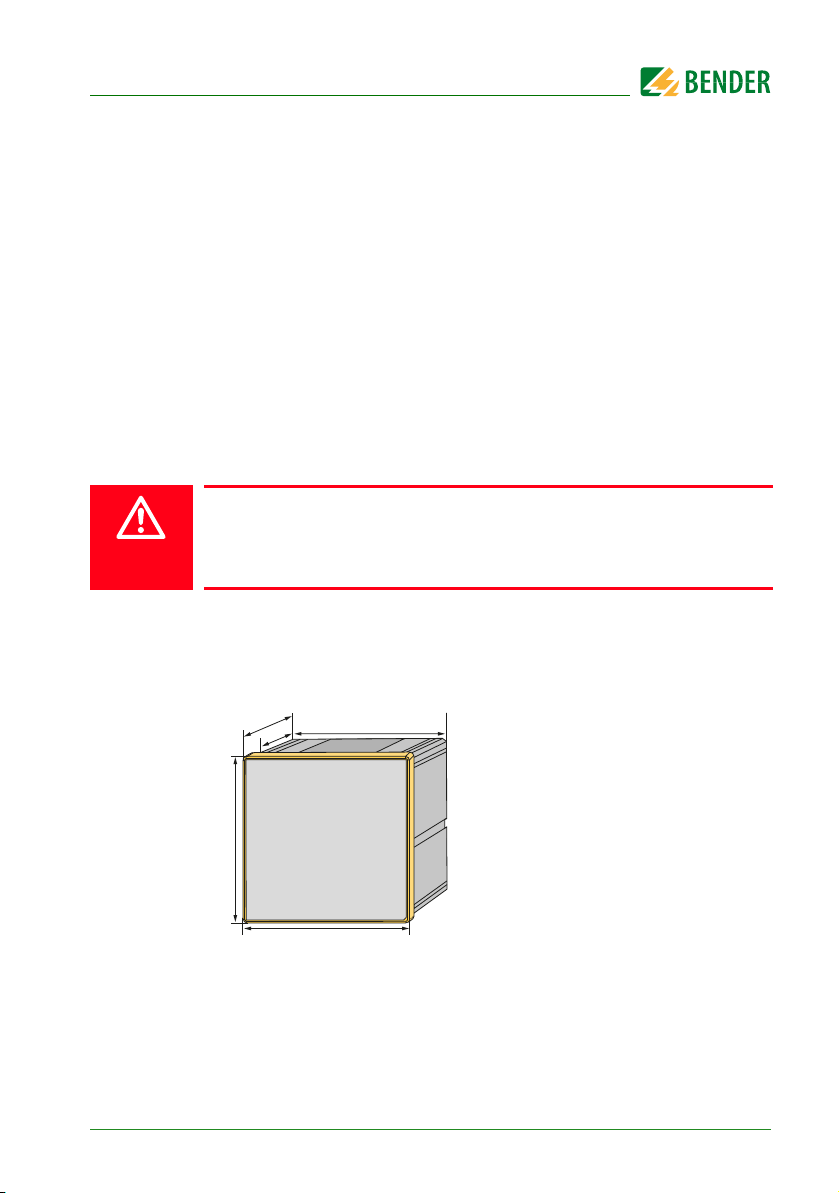

4.3.1 Dimension diagrams

106

88

96

96

Fig. 4.1: Dimension diagram PEM575 (front view)

PEM735_D00084_00_M_XXEN/02.2015

91

19

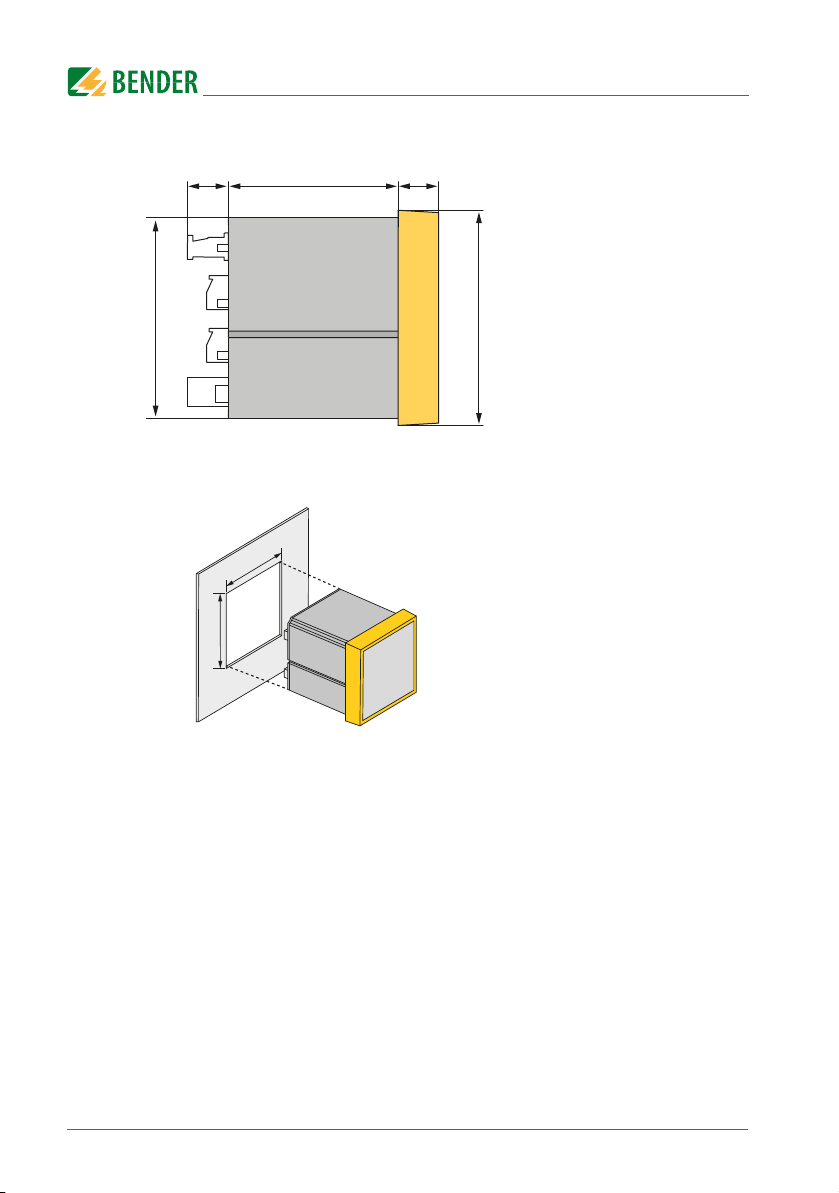

Installation and connection

18 88

91

Fig. 4.2: Dimension diagram PEM575 (side view)

92

92

Fig. 4.3: Dimension diagram PEM575 (panel cutout)

18

96

4.3.2 Front panel mounting

A front panel cutout of 92 mm x 92 mm is necessary for installation.

1. Insert the device through the cutout in the front panel.

2. Insert the two installation clips into the equipment rail from behind.

3. Push the clips towards the front panel and tighten the associated screws by

hand.

4. Check the device to ensure that it is firmly installed in the front panel.

The device is installed.

20

PEM735_D00084_00_M_XXEN/02.2015

Installation and connection

DANGER

4.4 Connection of the device

4.4.1 Safety information

Danger of electric shock!

Follow the basic safety rules when working with electricity.

Consider the data on the rated voltage and supply voltage as specified

in the technical data!

4.4.2 Back-up fuses

Back-up fuse supply voltage: 6 A

Short-circuit protection Protect the measuring inputs according to the require-

ments of the standards. (Recommendation: 2 A). A suitable isolation means must

be provided. For details refer to the operating manuals of the measuring current

transformers currently used.

If the supply voltage Us is supplied by an IT system, both lines are to be

protected.

4.4.3 Connection of measuring current transformers

When connecting the measuring current transformers it is important to consider

the requirements of DIN VDE 0100-557 (VDE 0100-557) –

Low voltage installations - Part 5: Selection and erection of electrical equipment Section 557: Auxiliary circuits.

4.5 Instructions for connection

Connect the PEM575 to the supply voltage (terminals A1 and A2 resp. +/-). Con-

nect terminal " " to the protective conductor.

Power protection by a 6 A fuse, quick response. If being supplied from an IT sys-

tem, both lines have to be protected by a fuse.

Connection to the RS-485 bus is made via the terminals D+, D- and SH. Up to 32

devices can be connected to the bus. The maximum cable length for the bus connection of all devices is 1200 m.

PEM735_D00084_00_M_XXEN/02.2015

21

Installation and connection

2

3

4

7

5

6

1

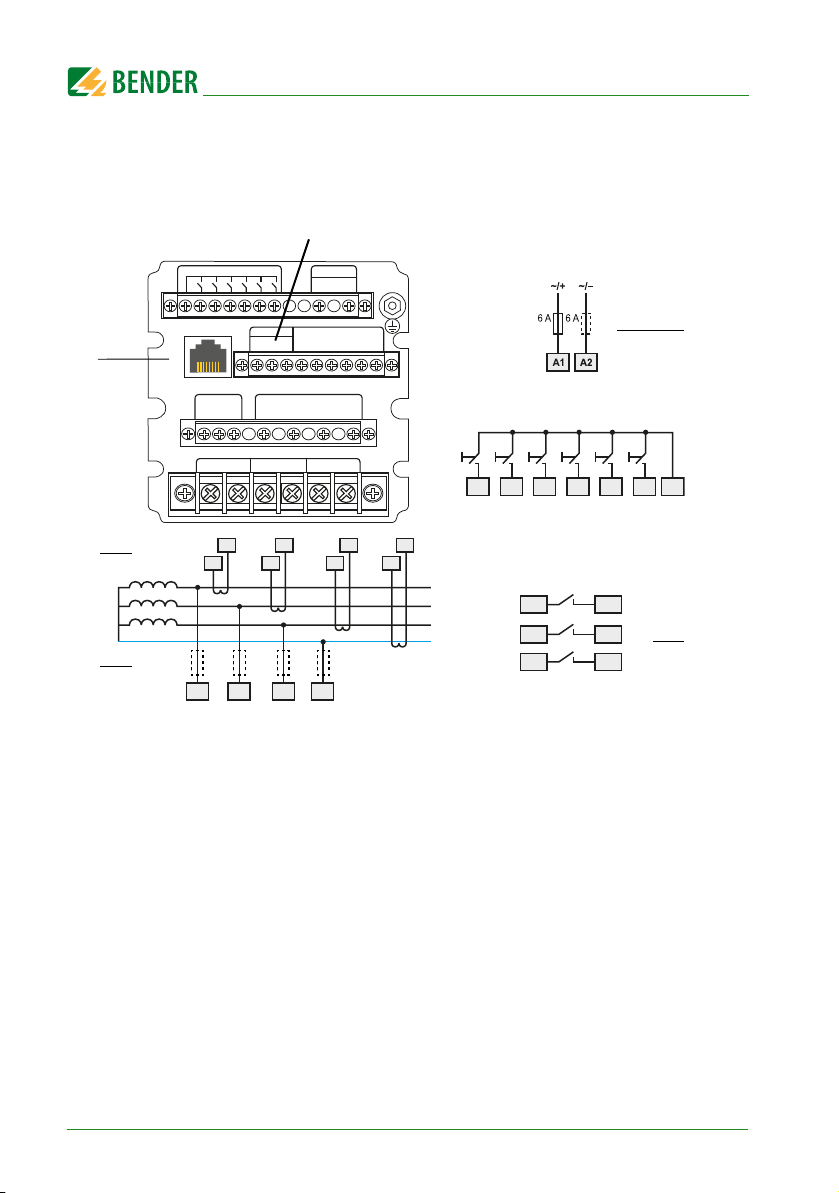

4.6 Wiring diagram

Connect the device according the wiring diagram. The connections are located at

the rear of the device.

DIC DI1 DI2 DI3 DI4 DI5 DI6

RS-485ETH

D+

• l41

l42SH

L1 L2 L3 N

• l11

l12

• l21 • l31

I12

I11

L1 L2 L3 N

DO34 DO33 DO24 DO23 DO14 DO13

D

-

SH

l22 l32

I22

I21

Power

A1 A2

I32

I31

I42

I41

Fig. 4.4: Wiring diagram

DI1 DICDI5 DI6DI2 DI3 DI4

L1

L2

L3

N

U

S

DO13 DO14

DO23 DO24

DO33 DO34

22

PEM735_D00084_00_M_XXEN/02.2015

Installation and connection

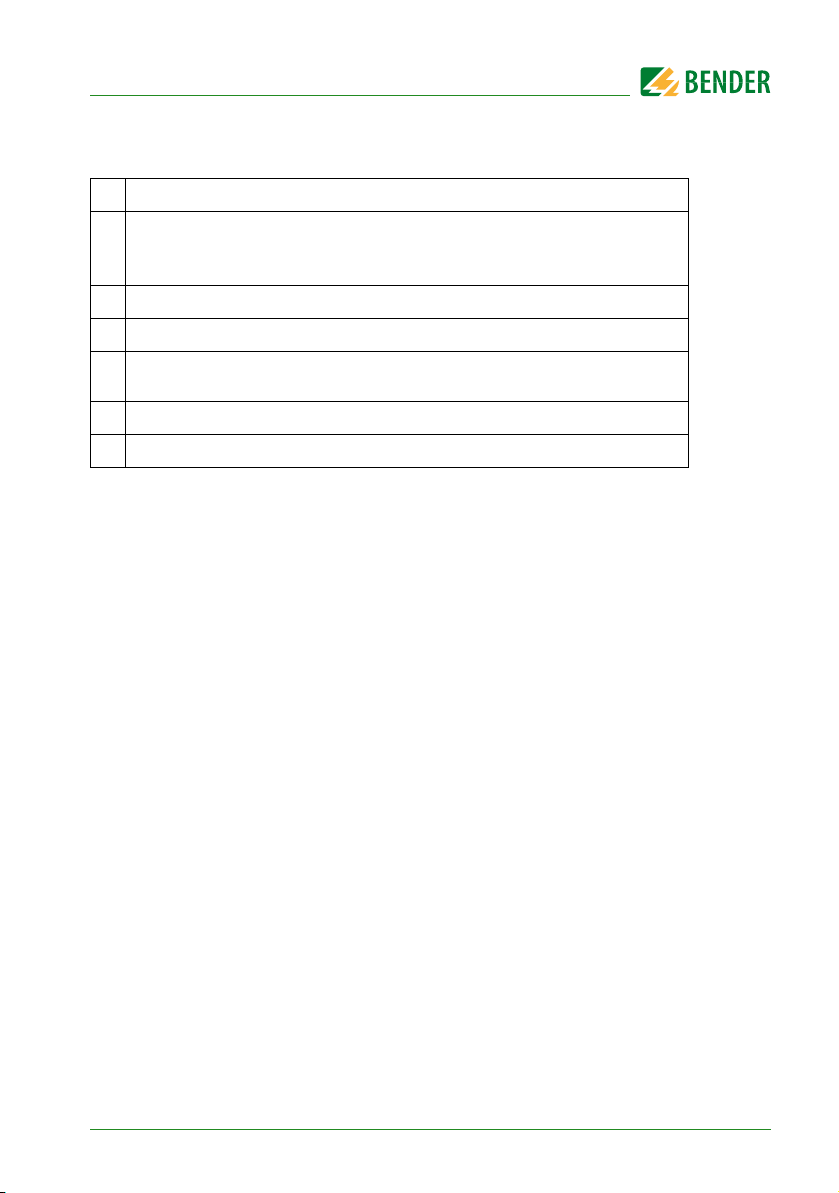

Legend to wiring diagram

Connection RS-485 bus

1

Supply voltage. Power protection by a 6 A fuse, quick response. If

2

being supplied from an IT system, both lines have to be

protected by a fuse.

Digital inputs

3

Digital outputs (N/O contacts)

4

Measuring voltage inputs: The measuring leads should be

5

protected with appropriate fuses.

Connection to the system to be monitored

6

Connection Modbus TCP

7

4.7 Connection diagram voltage inputs

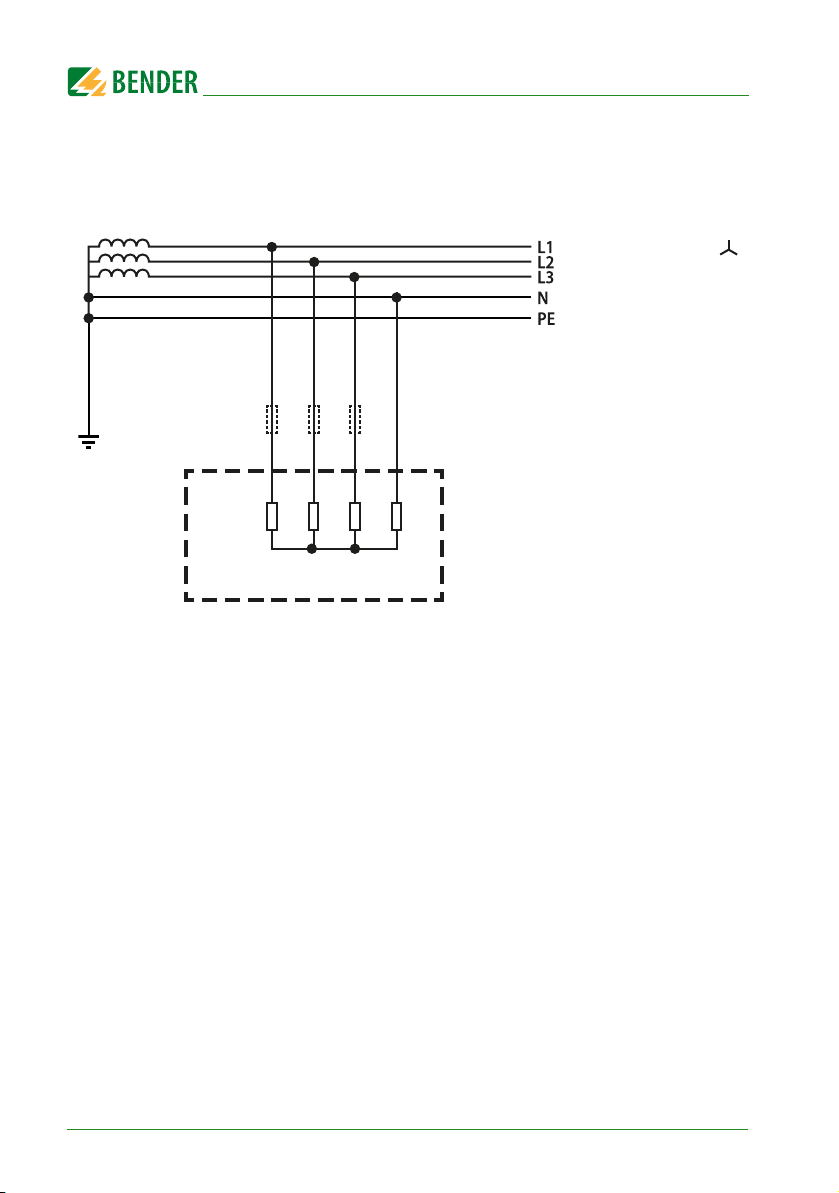

4.7.1 Three-phase 4-wire system (TN, TT, IT system)

The universal measuring device PEM575 can be used in three-phase-4-wire sys-

PEM735_D00084_00_M_XXEN/02.2015

23

Installation and connection

tems, independent of the type of distribution system (TN, TT, IT system).

AC 400 V / 230 V

L1

R

i

L2

L3

N

PEM

Fig. 4.5: Connection diagram three-phase 4-wire system

(e.g. TN-S system)

24

PEM735_D00084_00_M_XXEN/02.2015

Installation and connection

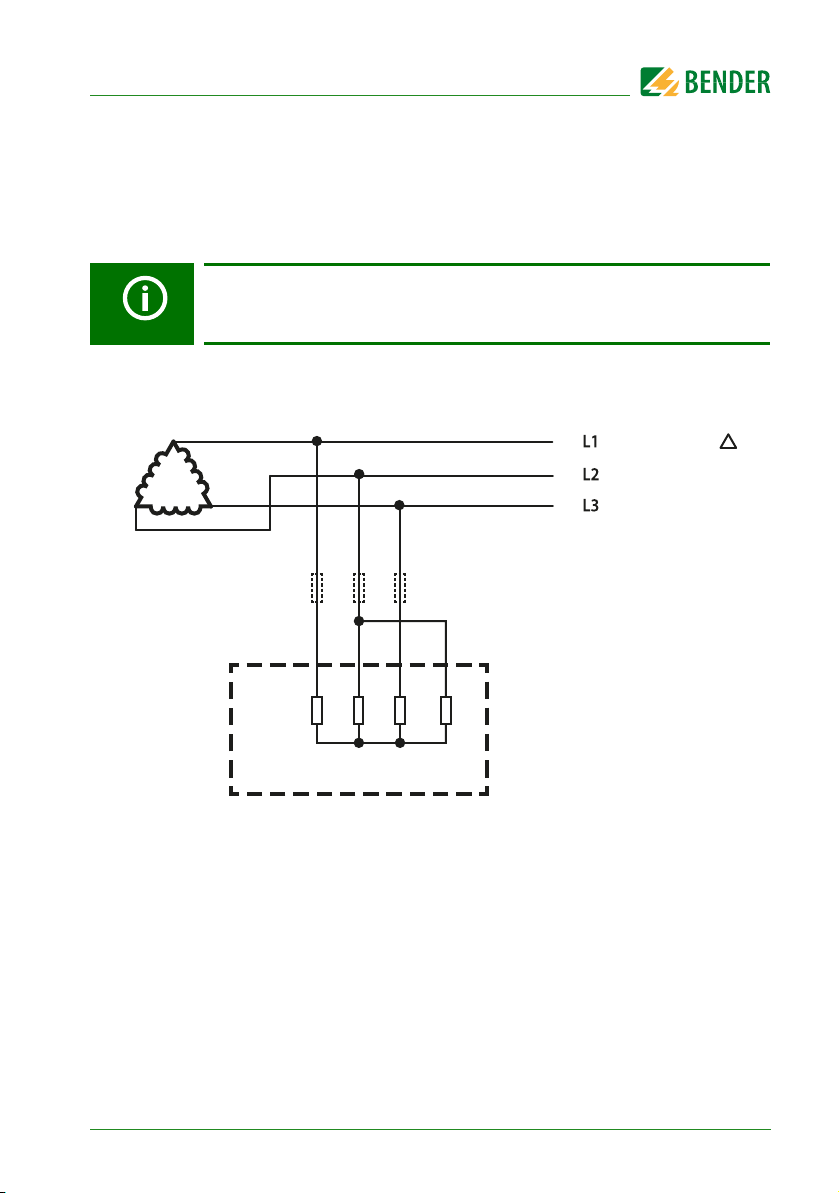

4.7.2 Three-phase 3-wire system

The universal measuring device PEM575 can be used in three-phase-3-wire systems.

The line voltage must not exceed AC 400 V.

When used in 3-wire systems, the connection type (TYPE) has to be set to

DELTA (refer to page 46). For this purpose, the measuring inputs L2 and

N are to be bridged.

AC 400 V

L1

R

i

PEM

Fig. 4.6: Connection diagram three-phase-3-wire system

PEM735_D00084_00_M_XXEN/02.2015

L2

L3

N

25

Installation and connection

V

4.7.3 Connection via voltage transformers

The coupling via voltage transformers allows the use of the measuring device in

medium and high voltage systems.

The transformation ratio can be adjusted in the PEM575 (1…2200).

LV / MV / H

L1

R

i

L2

L3

N

PEM

Fig. 4.7: Connection diagram 3-wire system via voltage transformers

4.8 Digital inputs

The universal measuring device PEM575 provides 6 digital inputs. The inputs are

supplied by a galvanically isolated DC 24 V voltage. An external circuit providing at

least a current of I

> 2.4 mA is required for triggering the inputs.

min

DI1 DICDI5 DI6DI2 DI3 DI4

26

PEM735_D00084_00_M_XXEN/02.2015

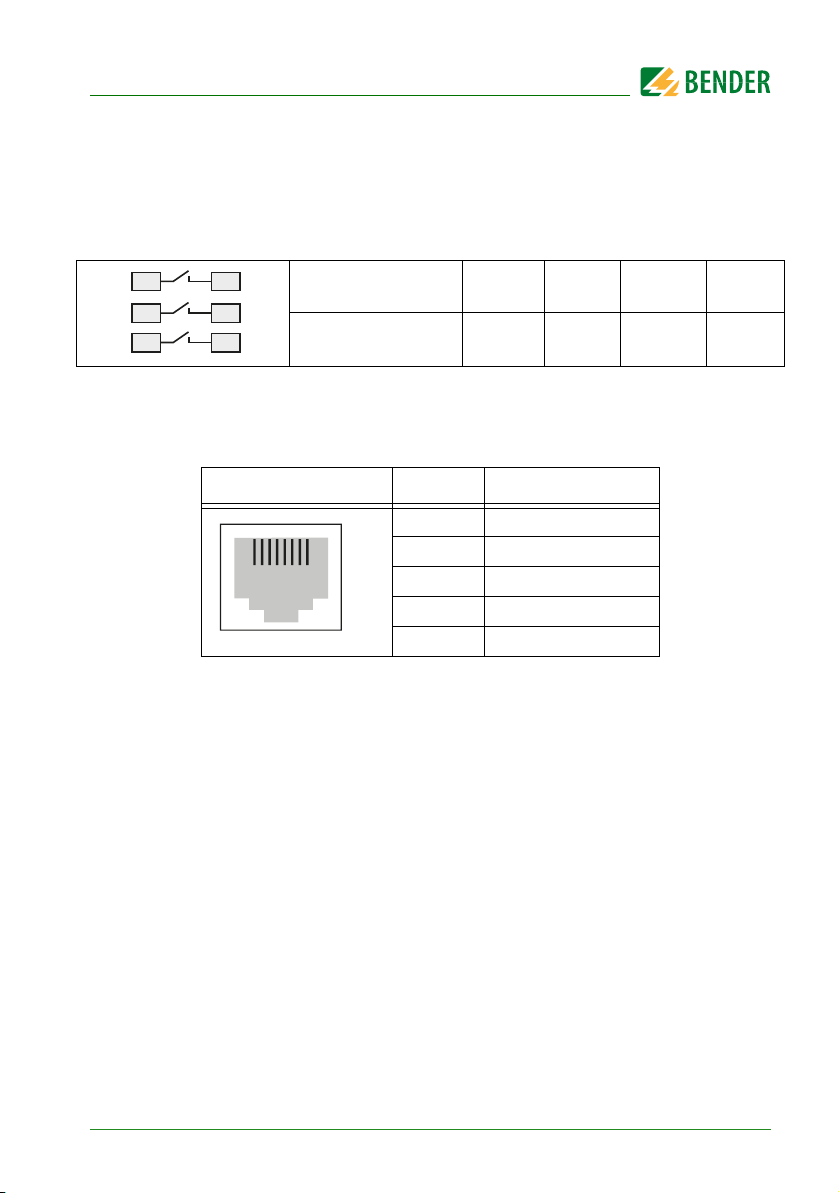

4.9 Digital outputs

The universal measuring device PEM575 features 3 configurable outputs

(N/O contact).

DO13 DO14

DO23 DO24

DO33 DO34

Rated operational

voltage

Rated

operational current

AC 230 V DC 24 V AC 110 V DC 12 V

5 A 5 A 6 A 5 A

4.10 Modbus TCP (connector pin assignment)

RJ45 Pin assignment

1 Transmit Data +

2 Transmit Data –

12345678

3 Receive Data +

4, 5, 7, 8 not used

6 Receive Data –

PEM735_D00084_00_M_XXEN/02.2015

27

Installation and connection

28

PEM735_D00084_00_M_XXEN/02.2015

5. Commissioning

5.1 Check proper connection

Observe the relevant standards and regulations that have to be observed for installation and connection as well as the operating manual of the respective device.

5.2 Before switching on

Before switching on think carefully about these questions:

1. Does the connected supply voltage correspond to the nameplates' information?

2. Are you sure that the nominal insulation voltage of the measuring current

transformer has not been exceeded?

3. Does the measuring current transformer's maximum current correspond to

the nameplate information of the connected device?

5.3 Switching on

After switching on, proceed as follows:

1. Connect the supply voltage.

2. Set the bus address/IP address.

3. Set the CT transformation ratio (for each channel).

4. Change the measuring current transformer's counting direction, if required.

5. Set the nominal voltage (line-to-line voltage U

6. Select wye connection or delta connection.

).

LL

PEM735_D00084_00_M_XXEN/02.2015

29

Commissioning

5.4 System

The universal measuring device PEM575 can be programmed and queried via Modbus RTU. For details refer to „chapter 10. Modbus Register Map“ or the Internet

www.modbus.org.

In addition, it is possible to integrate the device into Bender's own BMS (Bender

measuring device interface) bus protocol via additional communication modules.

In this way, communication with (already existing) Bender devices for device parameterisation and visualisation of measured values and alarms can be achieved.

Help and examples of system integration can be found on the Bender homepage

www.bender.de or you can contact our Bender Service for personal advice (see

„chapter 1.2 Technical support: Service and support“).

30

PEM735_D00084_00_M_XXEN/02.2015

Loading...

Loading...