Bender LINETRAXX PEM555 Quick Start Manual

Quick start: PEM555

Quick start

LINETRAXX®

PEM555

This short operating instruction does not replace the manual!

You will find the manual on the website

www.bender.de

Make sure that the personnel has read this manual and understood all instructions relating to safety.

V/I

Intended use Scope of delivery

The universal measuring device PEM555 is suitable for

● the analysis of energy and power (Power Analyzer)

● monitoring of the power supply quality (Power Quality)

● data recording for energy management (Energy Manage-

ment).

As a compact device for front panel mounting, it is suitable to replace analogue indicating instruments. The PEM555 is suitable for

3 and 4-wire systems and can be used in TN, TT and IT systems.

The current measurement inputs of the PEM are connected via

external ../1 A or ../5 A measuring current transformers.

Measurement in medium and high-voltage systems are principally carried out using measuring current and voltage transformers.

The accuracy of the active energy metering corresponds to class

0.2 S in compliance with the DIN EN 62053-22 (VDE 0418 Part 3-

22):2003-11.

● 1 PEM555

● Safety instructions

● This short operating instructions

● 1 sealing frame "IP54"

Safety instruction

Danger of electric shock!

Follow the basic safety rules when working with electricity.

Consider the data on the rated voltage and supply voltage as

specified in the technical data!

kWh

POWER HARMONICS

kvarh

ENERGY

OK

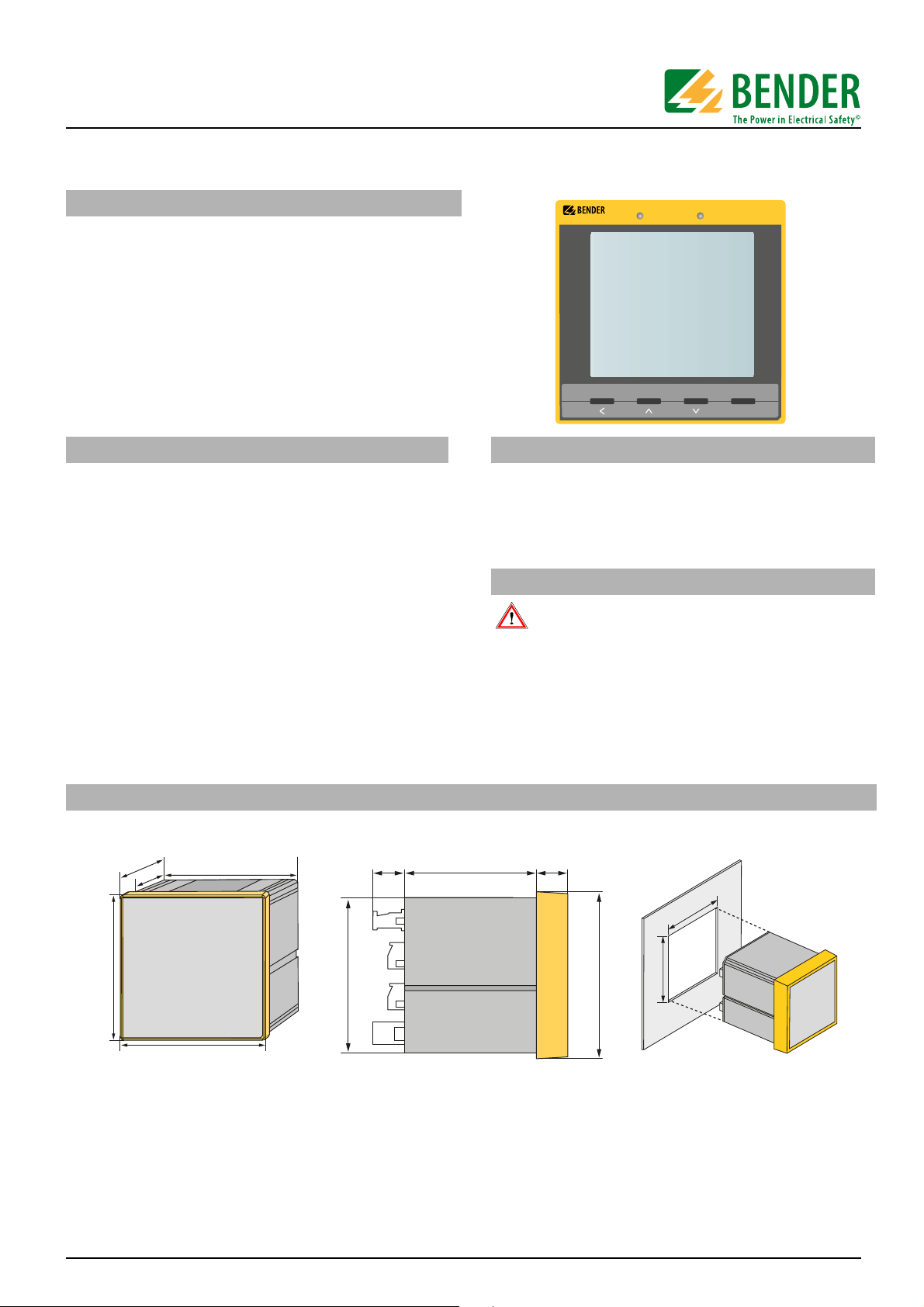

Installing the device

Front-panel mounting (front view, side view, panel cutout)

106

88

96

91

91

96

A front-panel cutout of 92 mm x 92 mm is required for the device.

1. Insert the device into the installation opening of the front panel.

2. Insert the two installation clips into the equipment rail from behind.

3. Push the installation clips towards the front panel and tighten the screws by hand.

4. Check the device to ensure that it is firmly mounted in the front panel.

18 88

18

92

96

92

PEM555_D00016_00_Q_XXEN/04.2014

1

Quick start: PEM555

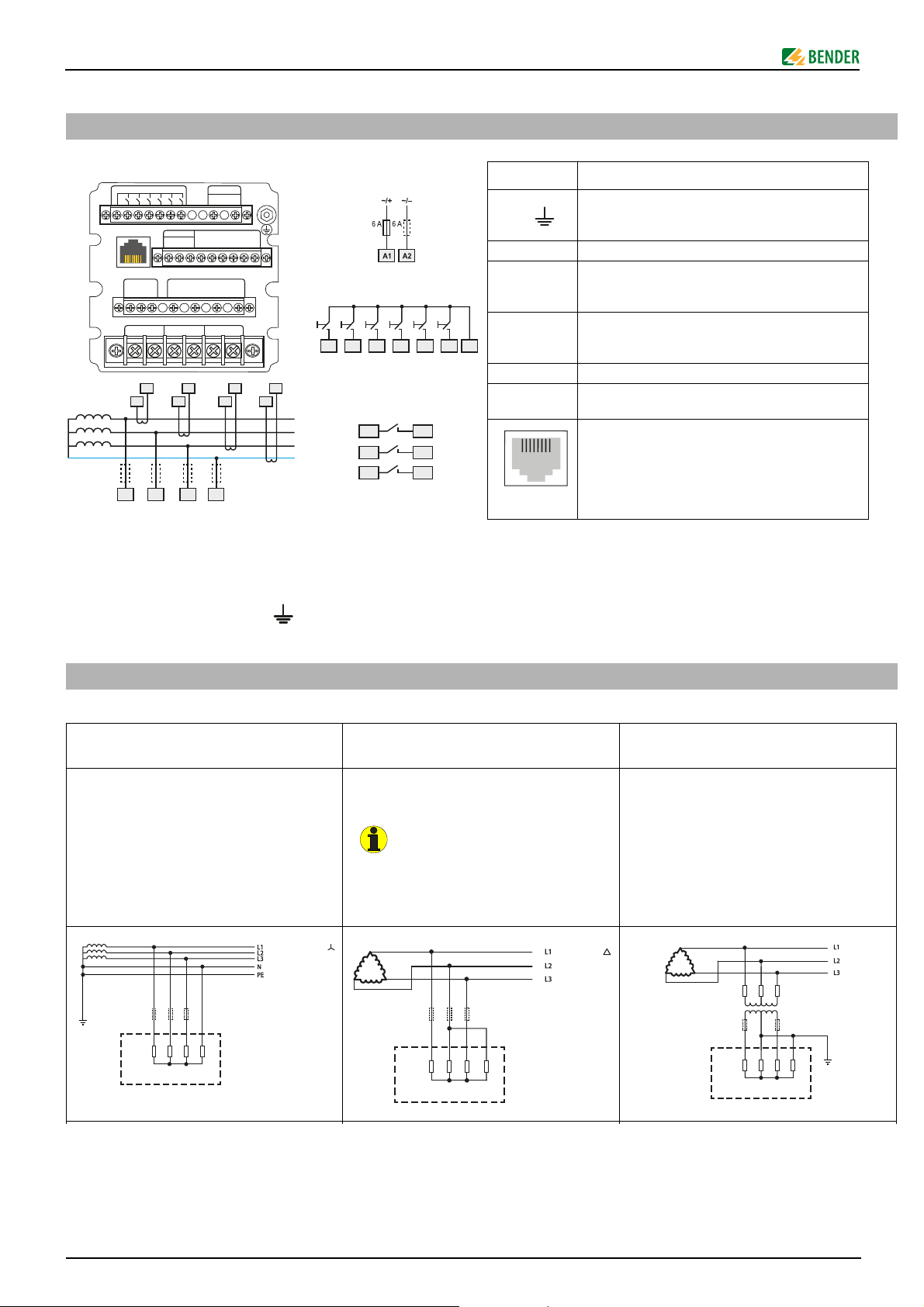

Terminal Description

A1, A2,

Connection to supply voltage, 6 A fuse (when supplied by IT systems, both phase conductors have to

be protected).

DI1…DI6, DIC Digital inputs

DO13, DO14,

DO23, DO24

DO33, DO34

Digital outputs (N/O contacts)

I11, I12,

I21, I22,

I31, I32

Connection to the system to be monitored

D+, D-, SH Connection RS-485 bus

L1, L2, L3, N

Measuring voltage inputs: The measuring leads

should be protected with appropriate fuses.

Modbus TCP: Pin assignment

1 Transmit Data +

2 Transmit Data –

3 Receive Data +

4, 5, 7, 8 not used

6 Receive Data –

Three-phase 4-wire system (TN, TT, IT

systems)

Three-phase 3-wire system Connection via voltage transformers

The PEM can be used in three-phase 4-wire

systems, independent of the type of distribution system (TN, TT, IT system).

The PEM can be used in three-phase 3-wire

systems. The line conductor voltage must not

exceed AC 400 V.

When used in 3-wire systems, the connection type (TYPE) has to be set to delta connection (DELTA).

For this purpose, the measuring inputs L2 and

N are to be bridged.

The coupling via measuring current transformers allows the use of the measuring device in medium and high voltage systems.

The transformation ratio can be adjusted in

the PEM555 (1…2200).

V

Connection of the device

Wiring diagram

DIC DI1 DI2 DI3 DI4 DI5 DI6

RS-485ETH

D+

• l41

l42SH

• l11

l12

• l21 • l31

I12

I11

L1 L2 L3 N

Power

A1 A2

DO34 DO33 DO24 DO23 DO14 DO13

D

-

SH

L1 L2 L3 N

l22 l32

I22

I21

I31

U

S

DI1 DICDI5 DI6DI2 DI3 DI4

I32

I42

I41

L1

L2

L3

N

DO13 DO14

DO23 DO24

DO33 DO34

Connection

1. Connect the device according the wiring diagram. The connections are located on the rear of the device. Connect the

PEM555 to the supply voltage (terminals A1 and A2

resp. +/-). Connect terminal " " to the protective conductor.

Connection diagram voltage inputs

12345678

2. Line protection: 6 A fuse recommended. If being supplied

from an IT system, both lines have to be protected by a fuse.

3. Connection to the RS-485 bus is made via the terminals D+,

D- and SH. Up to 32 devices can be connected to the bus.

The maximum cable length for the bus connection of all

devices is 1200 m.

2

L1L2L3

R

i

PEM

N

AC 400 V / 230 V

PEM

L1L2L3

R

i

N

AC 400 V

L1L2L3

R

i

PEM

PEM555_D00016_00_Q_XXEN/04.2014

N

LV / MV / H

Loading...

Loading...