Bender ISOMETER isoRW425 User Manual

Manual

ISOMETER® isoRW425

Insulation monitoring device for unearthed

IT AC-, AC/DC and DC systems

for railway applications up to AC/DC 400 V

Software version: D418 V1.0x

isoRW425_D00052_01_M_XXEN / 03.2014

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Grünberg • Germany

P.O. Box 1161 • 35301 Grünberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: info@bender.de

Web: http://www.bender.de

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Table of Contents

1. Making effective use of this document ....................................................... 5

1.1 How to use this manual ................................................................................. 5

1.2 Information about factory setting ............................................................. 5

2. Safety instructions ........................................................................................... 7

2.1 General safety instructions ........................................................................... 7

2.2 Work activities on electrical installations ................................................ 7

2.3 Intended use ...................................................................................................... 7

3. Function ............................................................................................................. 9

3.1 Device features ................................................................................................. 9

3.2 Description of function .................................................................................. 9

3.2.1 Undervoltage/overvoltage monitoring ................................................ 11

3.2.2 Connection monitoring .............................................................................. 11

3.2.3 Self test, automatic ....................................................................................... 11

3.2.4 Self test, manual ............................................................................................ 11

3.2.5 Malfunction ..................................................................................................... 12

3.2.6 Assigning alarm categories to alarm relays K1/K2 ............................ 12

3.2.7 Time delays t, ton and toff ....................................................................... 12

3.2.8 Password protection (on, OFF) ................................................................. 13

3.2.9 Automatic adaptation of the pulse duration ...................................... 13

3.2.10 Response time ................................................................................................ 13

3.2.11 Factory setting FAC ...................................................................................... 13

3.2.12 External, combined test resp. reset button T/R .................................. 13

3.2.13 Fault memory ................................................................................................. 13

3.2.14 History memory HiS ...................................................................................... 13

4. Installation, connection and commissioning ........................................... 15

4.1 Installation ....................................................................................................... 15

isoRW425_D00052_01_M_XXEN / 03.2014

3

Table of Contents

4.2 Connection ...................................................................................................... 17

4.3 Commissioning .............................................................................................. 20

5. Operation and configuration ...................................................................... 21

5.1 Factory setting ............................................................................................... 21

5.2 Getting to know the user interface ......................................................... 22

5.3 Understand the display elements ........................................................... 23

5.3.1 Querying measured values ........................................................................ 24

5.3.2 Alarm indication when an insulation fault has been detected ..... 26

5.4 Display in menu mode ................................................................................ 27

5.4.1 Querying and setting parameters: Overview ...................................... 27

5.4.2 Navigation within the menu ..................................................................... 28

5.4.3 Selecting menus ............................................................................................ 31

5.4.4 Making settings in the AL menu .............................................................. 33

5.4.5 Making settings in the out menu ............................................................ 35

5.4.6 Making settings in the menu item t ....................................................... 41

5.4.7 Making settings in the SEt menu ............................................................. 43

5.4.8 Querying software number and software version with the INF

menu .................................................................................................................. 47

5.4.9 Querying and clearing the history memory using the HiS menu 47

6. Technical data ................................................................................................ 49

6.1 Tabular presentation .................................................................................... 49

6.2 Standards, approvals and certifications ................................................ 52

6.3 Ordering information ................................................................................... 52

6.4 Error codes ....................................................................................................... 53

INDEX .................................................................................................................... 55

4

isoRW425_D00052_01_M_XXEN / 03.2014

1. Making effective use of this document

1.1 How to use this manual

This manual is intended for electrically skilled persons working in

electrical engineering and electronics!

To make it easier for you to understand and revisit certain sections of text and

instructions in the manual, we have used symbols to identify important instructions and information. The meaning of these symbols is explained below:

Information calling attention to hazards are marked

with this warning symbol.

Information intended to assist the user to make optimum

use of the product are marked with the Info symbol.

1.2 Information about factory setting

If you want to reset the ISOMETER® to its factory setting in a specific case, refer

to page 45; page 21 provides a summary of all factory settings.

isoRW425_D00052_01_M_XXEN / 03.2014

5

Making effective use of this document

6

isoRW425_D00052_01_M_XXEN / 03.2014

2. Safety instructions

2.1 General safety instructions

In addition to these operating instructions, the "Important safety instructions

for Bender products“, which are also included in the scope of supply, are an integral part of the device documentation.

2.2 Work activities on electrical installations

Danger as a result of unprofessional work!

Failure to carry out work on electrical installations properly and correctly can put life and limb at risk! Therefore,

observe the following safety instructions!

Only skilled persons are permitted to carry out the work necessary to

install, commission and run a device or system.

Compliance with the applicable regulations governing work on electri-

cal installations and with the regulations derived and associated with

them, is mandatory. EN50110 is of particular importance in this regard.

In particular, only test equipment of overvoltage category III or higher

may be used for fault detection.

If the device is being used in a location outside the Federal Republic of

Germany, the applicable local standards and regulations must be complied with. European standard EN 50110 can be used as a guide.

2.3 Intended use

The isoRW425 ISOMETER® monitors the insulation resistance of unearthed

AC/C main circuits (IT systems) with mains voltages of AC, AC/DC …V or

DC 0…400 V.

isoRW425_D00052_01_M_XXEN / 03.2014

7

Safety instructions

DC components existing in AC/DC systems do not influence the operating

characteristics. A separate supply voltage allows de-energised systems to be

monitored too. The maximum permissible system leakage capacitance is

300µF.

8

isoRW425_D00052_01_M_XXEN / 03.2014

3. Function

3.1 Device features

Insulation monitoring for unearthed AC and DC systems with galvani-

cally connected rectifiers or inverters

Two separately adjustable response ranges of 1…990 k (Alarm 1,

Alarm 2)

Automatic adaptation to the system leakage capacitance up to 300 F

Measured value display via multi-functional LCD

Measurement of the nominal system voltage (RMS) with undervoltage

and overvoltage detection

Measurement of DC voltages system to earth (L+/PE and L-/PE)

Alarm signalling via LEDs (AL1, AL2), display and alarm relays (K1, K2)

N/C operation or N/O operation selectable

Automatic device self test

BMS interface (Bender measuring device interface) for data exchange

with other Bender components; RS-485 electrically isolated

Start-up delay, response delay and delay on release

Password protection to prevent unauthorised changes being made to

device settings

Fault memory can be activated

Connection monitoring

3.2 Description of function

The isoPV425 runs a device test when the supply voltage is connected. and

the start-up delay has elapsed. Then, the insulation resistance of the system is

determined.

When the values are below the set response values R

sponse delay t

relays "K1/K2" switch and the alarm LEDs "AL1/AL2" light up.

begins. Once the response delay "ton" has elapsed, the alarm

on

an1

bzw. R

an2

, the re-

isoRW425_D00052_01_M_XXEN / 03.2014

9

Function

A fault at conductor L+ or L– or a symmetrical insulation fault is shown on the

display. In case of asymmetrical DC faults, a + or a - sign will be displayed in

addition to the value. Pressing the arrow up and down button allows scrolling

up and down in the display via the division of the insulation resistance up to

the percentage value.

The value range to be displayed ranges from -100 % through 0 % to +100 %:

Displays Meaning

–100 % one-side fault at conductor L-

0 % symmetrical fault

+100 % one-side fault at conductor L-

The resistance values can be determined using the following formulas:

R

Fault at conductor L–

Fault at c on ductor L+

= (200 % * RF)/(100 % – R %)

F (–)

= (200 % * RF)/(100 % + R %)

R

F (+)

This could be an indication of the fault location with regard to conductor L+

or L–, also refer to the display in line 11 of the table on page 25.

It is possible to assign the detected fault resp. the faulty conductor to an alarm

relay via the menu.

If the insulation resistance exceeds the release value (response value plus hysteresis) the release delay t

alarm relays will switch back to their initial state and the alarm LEDs AL1/AL2

begins. When the release delay has elapsed, the

off

will go out. If the fault memory is activated, the alarm relays will not switch

back and the LEDs will not go out until the reset button is pressed or the supply voltage is interrupted.

The device function can be tested using the test button T. Parameters are assigned to the device via the LCD and the control buttons on the front panel;

this function can be password-protected. Parameterisation is also possible via

the BMS bus using the BMS Ethernet gateway, e.g. COM460IP.

10

isoRW425_D00052_01_M_XXEN / 03.2014

Function

3.2.1 Undervoltage/overvoltage monitoring

In the response value menu AL both parameters can be activated resp. deactivated. The maximum undervoltage value is limited by the overvoltage value.

3.2.2 Connection monitoring

After connecting to the supply voltage, the following connections are

checked periodically, every 24 h (can be adjusted) or by pressing the test button T:

– Power supply connection L1(+)/L2(–)

– PE connection E/KE

In case of interruption of a connecting lead, the alarm relay K2 switches, the

LEDs

ON/AL1/AL2 flash and a fault message appears on the LC display:

E.01 = Connection fault PE

E.02 = Connection to the system incorrect

E.07 = Fault system leakage capacitance C

E.xx = Internal device error

Once the fault has been eliminated, the alarm relays will switch back to their

initial state either automatically or by pressing the reset button.

Connection monitoring can be switched off in the menu nEt, if required, see

page 45.

> 300 µF

e

3.2.3 Self test, automatic

The device runs a self test after connection to the system to be monitored and

later every 24 hours (selectable: off, 1 h, 24 h). Internal malfunctions detected

during this test are shown on the display as error codes. The alarm relays are

not switched.

3.2.4 Self test, manual

The device runs a self test when the test button is pressed (> 1.5 s). Internal

malfunctions detected during this test are shown on the display as error

codes. The alarm relays are not checked (factory setting). It is possible to

change this setting to "on" in the "out" menu, also see line 26 on page 39. Consequently, the alarm relays would switch during the manual self test.

isoRW425_D00052_01_M_XXEN / 03.2014

11

Function

While the internal test button T is pressed and held, all display elements available for this device are shown. During the test, the display indicates "tES".

3.2.5 Malfunction

In the event of an internal malfunction, all three LEDs will flash. An error code

will appear on the display, refer to page 53.

3.2.6 Assigning alarm categories to alarm relays K1/K2

The alarm categories device error, insulation fault, undervoltage/overvoltage

or alarm triggered by device test can be assigned to the alarm relays via the

"out" menu.

3.2.7 Time delays t, t

The times t, ton and t

relays.

and t

on

described below, delay alarm signalling via LEDs and

off,

off

Start-up delay t

After connection to the supply voltage US, the alarm indication is delayed by

the preset time t (0…10 s).

Response delay t

When the value drops below or exceeds the response value, the device has a

response time t

response delay t

t

and delays alarm signalling (total delay time tan = tae + ton).

ae

If the insulation fault does not continue to exist during the response delay, no

alarm will be signalled.

Delay on release t

If the alarm no longer exists during the response delay and the fault memory

is deactivated, the alarm LEDs will go out and the alarm relays switch back to

their initial state. After activating the delay on release (0…99 s), the alarm

state is continuously maintained for the selected period. If the alarm occurs

again during the delay on release, the device remains in the alarm state.

12

on1/2

that must have elapsed before an alarm is activated. A set

an

(0…99 s) adds up to the device-related operating time

on1/2

off

isoRW425_D00052_01_M_XXEN / 03.2014

Function

3.2.8 Password protection (on, OFF)

If password protection has been activated (on), settings can only be made

subject to the correct password being entered (0…999).

3.2.9 Automatic adaptation of the pulse duration

After connection to the supply voltage, the device automatically adjusts itself

to the leakage capacitance and the insulation resistance of the system to be

monitored. This consequently determines the shortest pulse duration.

In case of system interferences, the required measuring times will be extended, capacitance measurement is also no longer possible.

3.2.10 Response time

The response time tan depends on the insulation resistance and the leakage

capacitance. If, for example, the maximum permissible leakage capacitance is

C

= 300 µF and an insulation fault of RF = 2.5 k (Ran = 5 k) occurs in a 400-

e

V-DC system, the response time would be t

High leakage capacitances and system interferences lead to longer response

times.

< 40 s.

an

3.2.11 Factory setting FAC

Activating the factory setting will reset all modified settings, with the exception of the BMS address, to the default upon delivery.

3.2.12 External, combined test resp. reset button T/R

Reset = Pressing the external button < 1.5 s

Test = Pressing the external button > 1.5 s

3.2.13 Fault memory

It can be activated or deactivated (menu: out/M). Stored alarms can be reset

by means of the reset button R.

3.2.14 History memory HiS

The history memory provides space for exactly one data record consisting of

all current measured values. On the occurrence of the first fault, all the associ-

isoRW425_D00052_01_M_XXEN / 03.2014

13

Function

ated measured values from the fault memory are imported to the history

memory. This data can be read out using the HiS menu item. In order to be

able to record a new data record for a subsequent fault, the history memory

must first be cleared via the menu using the Clr button. Refer to the menu

item HiS starting on page 47.

14

isoRW425_D00052_01_M_XXEN / 03.2014

4. Installation, connection and commissioning

Risk of electric shock!

Touching uninsulated live conductors can result in death or serious injury. Therefore avoid any physical contact with active conductors and ensure compliance with the regulations for working

on electrical installations.

isoRW425 complies with the EMC limits for Class A devices intended for use in industrial environments. In case of interferences, the operator may be required to take adequate counter

measures.

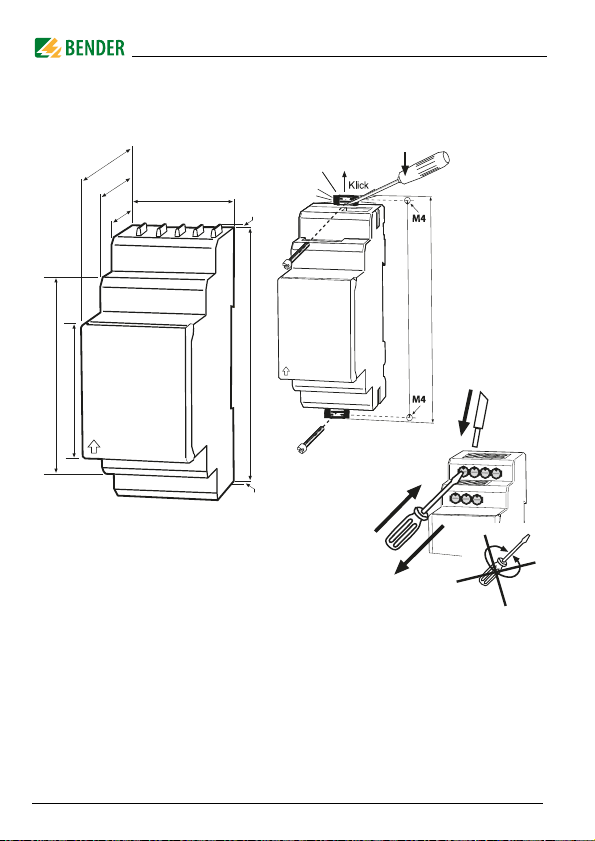

4.1 Installation

Mounting on a DIN rail:

Snap the mounting clip at the rear of the device onto the DIN rail so

that it sits securely or

Screw fixing:

Use a tool to position the rear mounting clips so that they project

beyond the enclosure (a second. mounting clip is required, see order-

ing information). Fix the device with two M4 screws, see the following

sketch.

isoRW425_D00052_01_M_XXEN / 03.2014

15

Installation, connection and commissioning

1

2

3

100 mm

116 mm

Zubehör/

Accessory

Dimension diagram, sketch for screw mounting, push-wire terminal connection:

70,5

47,5

36 mm

31,1

2

67,5

45

The front plate cover can be opened at the lower part marked with an arrow.

90 mm

2

16

isoRW425_D00052_01_M_XXEN / 03.2014

Installation, connection and commissioning

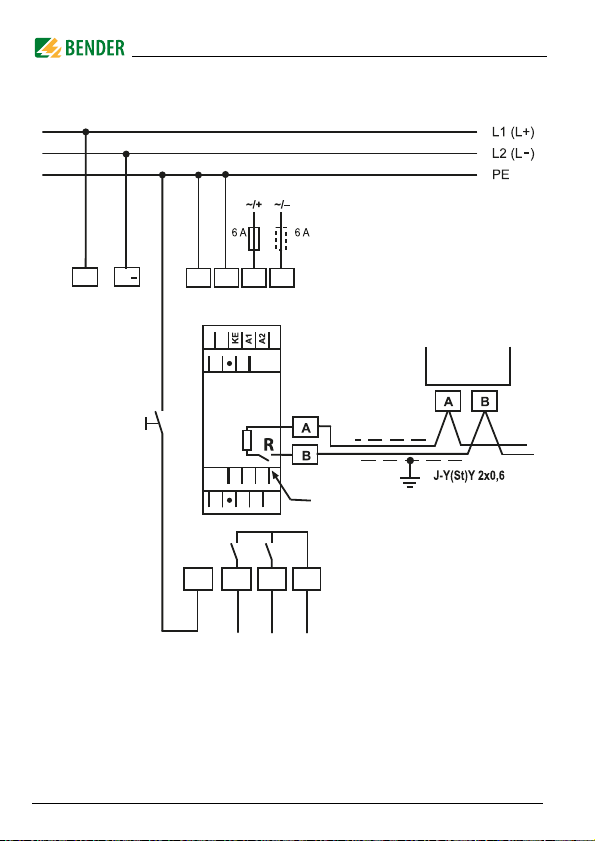

4.2 Connection

Connect the terminals A1 and A2 to the supply voltage according to

IEC 60364-4-43, i.e. the connections are to be protected against short-circuit

by means of a protective device (a 6 A fuse is recommended).

Devices for protection against short-circuit in conformity with IEC 0100-430

for the coupling of terminals L1/L2 to the IT system to be monitored can be

omitted if the wiring is carried out in such a manner as to reduce the risk of a

short-circuit to a minimum.

Only one ISOMETER® may be controlled via a test/reset button. It is not allowed to use a parallel connection of several test or reset inputs for testing

multiple ISOMETER®s.

For UL application:

Only use 60/70 °C copper lines!

For UL and CSA applications, it is mandatory to use 5 A fuses for the protection

of the supply voltage.

isoRW425_D00052_01_M_XXEN / 03.2014

17

Installation, connection and commissioning

Connect the device as illustrated in the wiring diagram:

U

S

L1/+

L2/

KE A1 A2

E

L1/+

E

L2/-

COM460IP

18

Test / Reset

isoRW425

T/R

K1 K2

T/R

RS-485

11

14

24

on

A

B

off

24 11

14

isoRW425_D00052_01_M_XXEN / 03.2014

Loading...

Loading...