Page 1

EN

Manual

ISOMETER®

isoNAV685-D-B

Insulation Monitoring Device for IT AC systems

with galvanically connected rectifiers and inverters

and for IT DC systems

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 2

PLEASE READ THIS MANUAL AND ANY ACCOMPANYING DOCUMENTS CAREFULLY AND KEEP THEM IN A SECURE PLACE FOR FUTURE

REFERENCE.

Bender GmbH & Co. KG

Postfach 1161 • 35301 Gruenberg • Germany

Londorfer Straße 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: info@bender.de

Web: www.bender.de

Customer service

Service-Hotline: 0700-BenderHelp (Telephone and Fax)

Carl-Benz-Straße 8 • 35305 Gruenberg • Germany

Tel.:+49 6401 807-760

Fax:+49 6401 807-629

E-Mail:info@bender-service.com

© Bender GmbH & Co. KG

All rights reserved.

Reproduction only with permission

of the publisher.

Subject to change.

Page 3

Table of contents

1. Important information .................................................................... 6

1.1 How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.1 First level support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 Repair service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.3 Field service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Training courses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Delivery conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Inspection, transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Safety instructions ............................................................................ 8

2.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Work activities on electrical installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Device-specific safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Function ........................................................................................... 10

3.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Self test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Device overview .............................................................................. 12

4.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Connections and panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Display elements and device buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. Connection .......................................................................................16

6.1 Connection requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Connection to a 3(N)AC system/system type 3AC . . . . . . . . . . . . . . . . . . .18

6.3 Connect to a frequency converter to monitor in the off state (Offline)18

6.4 Connection to the X1 interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.5 Connection to the supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.6 Connection to the Ethernet interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.7 Connection to the relay 1 interface (11 12 14) . . . . . . . . . . . . . . . . . . . . . . 20

6.8 Connection to the relay 2 interface (21 22 24) . . . . . . . . . . . . . . . . . . . . . . 21

7. Commissioning ............................................................................... 22

7.1 General initial commissioning process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.2 Recommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8. Display ..............................................................................................23

8.1 Standard display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

8.2 Fault display (active) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Fault display (inactive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8.4 Acknowledge fault memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.5 History memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.6 Initial measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

9. Menu ................................................................................................. 27

9.1 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

9.2 Operating and navigating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.2.1 Easy operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5. Mounting .......................................................................................... 15

5.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Screw mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 DIN rail mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 4

Table of contentsTable of contents

10. Settings .......................................................................................... 29

10.1 Settings in the device menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.0) Alarm settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.1) Insulation alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.1.1) Alarm 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.1.2) Fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.2) Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.3) System type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.4) Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.5) T(Start). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.6) Coupling monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 (1.7) Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.1 (1.7.1) Digital 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.1 (1.7.1.1) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.1 (1.7.1.2) t(on) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.1 (1.7.1.3) t(off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.1 (1.7.1.4) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.1 (1.7.2) Digital 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.7.3) Digital 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.8) Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.8.1) Relay 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.8.1.1) TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.8.1.2) Relay mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.8.1.3) Function 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 (1.8.1.4) Function 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.1.5) Function 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.2) Relay 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.3) Digital 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.3.1) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.3.2) Function 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.3.3) Function 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.3.4) Function 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.4) Digital 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 (1.8.5) Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (1.8.5.1) TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (1.8.5.2) Function 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (1.8.5.3) Function 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (1.8.5.4) Function 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (2.0) Data measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (3.0) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

10.1 (4.0) History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

10.1 (5.0) Device settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

10.1 (5.1) Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (5.2) Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (5.2.1) Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (5.2.2) Format (time). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1 (5.2.3) Summer time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.2.4) Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.2.5) Format (date). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.2.6) NTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.2.7) NTP server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.2.8) UTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.3) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.3.1) Write access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.3.2) Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.3.2.1) DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 (5.3.2.2) IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.2.3) SN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.2.4) Std. GW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.2.5) DNS server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.2.6) Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.3) BCOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.3.1) System name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.3.2) Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.3.3) Device address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.3.4) Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.3.5) TTL for subscription . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.4) Modbus TCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.4.1) Port 502. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.3.5) BMS bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.4) Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.4.1) Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.5) Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.5.1) Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 (5.5.2) Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 (5.6) Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 (5.7) Data backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 (5.8) Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 (6.0) Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 5

Table of contentsTable of contents

11. Device communication ............................................................... 37

11.1 Ethernet interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.2 BCOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.3 Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.4 Web server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12. Diagrams ........................................................................................ 41

12.1 Response time profile offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.2 Relative uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

13. Alarm messages ............................................................................ 42

14. Factory settings ............................................................................ 43

15. Technical data ............................................................................... 44

15.1 Tabular data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

15.2 Standards and certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

15.3 Ordering details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

16. Glossary .......................................................................................... 48

17. Modbus settings ...........................................................................49

17.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

17.2 Data access by means of Modbus/TCP-Protokoll . . . . . . . . . . . . . . . . . . .49

17.2.1 Exception code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

17.2.2 Modbus request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

17.2.3 Modbus response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

17.2.4 Structure of exception code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

17.3 Measuring value information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

17.3.1 High-byte test status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

17.3.2 Low-byte alarm status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

17.3.3 High-byte range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

17.3.4 Low-byte unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

17.4 Modbus register assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Index ........................................................................................................60

5

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 6

1. Important information

DANGER

WARNING

CAUTION

Important information

1.1 How to use this manual

This manual is intended for qualified personnel working in electrical engineering and electronics!

Always keep this manual within easy reach for future reference.

To make it easier for you to understand and revisit certain sections in this manual, we

have used symbols to identify important instructions and information. The meaning of

these symbols is explained below:

This signal word indicates that there is a high risk of danger that will result in electrocution or serious injury if not avoided.

This signal word indicates a medium risk of danger that can lead to

death or serious injury if not avoided.

1.2 Technical support

For commissioning and troubleshooting Bender offers you:

1.2.1 First level support

Technical support by phone or e-mail for all Bender products

• Questions concerning specific customer applications

• Commissioning

• Troubleshooting

Telephone: +49 6401 807-760*

Fax: +49 6401 807-259

In Germany only: 0700BenderHelp (Tel. and Fax)

E-mail: support@bender-service.de

1.2.2 Repair service

Repair, calibration, update and replacement service for Bender products

• Repairing, calibrating, testing and analysing Bender products

• Hardware and software update for Bender devices

• Delivery of replacement devices in the event of faulty or incorrectly delivered Bender devices

• Extended guarantee for Bender devices, which includes an in-house repair service or

replacement devices at no extra cost

This signal word indicates a low level risk that can result in minor or moderate injury or damage to property if not avoided.

This symbol denotes information intended to assist the user in making

optimum use of the product.

6

Telephone: +49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (sales)

Fax: +49 6401 807-789

E-mail: repair@bender-service.de

Please send the devices for repair to the following address:

Bender GmbH, Repair-Service,

Londorfer Strasse 65,

35305 Grünberg

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 7

Important informationImportant information

1.2.3 Field service

On-site service for all Bender products

• Commissioning, parameter setting, maintenance, troubleshooting for Bender products

• Analysis of the electrical installation in the building (power quality test, EMC test,

thermography)

• Training courses for customers

Telephone: +49 6401 807-752**, -762 **(technical issues)

+49 6401 807-753** (sales)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Internet: www.bender-de.com

*Available from 7.00 a.m. to 8.00 p.m. 365 days a year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m.

1.3 Training courses

Bender is happy to provide training regarding the use of test equipment.

The dates of training courses and workshops can be found on the Internet at

www.bender-de.com -> Know-how -> Seminars.

1.4 Delivery conditions

Bender sale and delivery conditions apply.

For software products the "Softwareklausel zur Überlassung von Standard-Software als

Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen Lieferbedingungen für

Erzeugnisse und Leistungen der Elektroindustrie" (software clause in respect of the licensing of standard software as part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI

(Zentralverband Elektrotechnik- und Elektronikindustrie e. V.) (German Electrical and

Electronic Manufacturer's Association) also applies.

Sale and delivery conditions can be obtained from Bender in printed or electronic format.

1.6 Disposal

Abide by the national regulations and laws governing the disposal of this device. Ask

your supplier if you are not sure how to dispose of the old equipment.

The directive on waste electrical and electronic equipment (WEEE directive) and the directive on the restriction of certain hazardous substances in electrical and electronic

equipment (RoHS directive) apply in the European Community. In Germany, these policies are implemented through the "Electrical and Electronic Equipment Act" (ElektroG).

According to this, the following applies:

• Electrical and electronic equipment are not part of household waste.

• Batteries and accumulators are not part of household waste and must be disposed

of in accordance with the regulations.

• Old electrical and electronic equipment from users other than private households

which was introduced to the market after 13 August 2005 must be taken back by the

manufacturer and disposed of properly.

For more information on the disposal of Bender devices, refer to our homepage at

www.bender-de.com -> Service & support.

1.5 Inspection, transport and storage

The devices must only be stored in areas where they are protected from dust, damp, and

spray and dripping water, and in which the specified storage temperatures can be ensured.

7

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 8

2. Safety instructions

DANGER

WARNING

CAUTION

Safety instructions

2.1 General safety instructions

Part of the device documentation in addition to this manual is the enclosed "Safety instructions for Bender products".

2.2 Work activities on electrical installations

Only qualified personnel are permitted to carry out the work necessary

to install, commission and run a device or system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

• An electric shock

• Damage to the electrical installation

• Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-energised. Observe the rules for working on elec-

trical installations.

If the device is used outside the Federal Republic of Germany, the applicable local standards and regulations must be complied with. The European standard EN 50110 can be

used as a guide.

2.3 Device-specific safety information

Make sure that the basic settings meet the requirements of the IT system.

Children and unauthorised persons must not have access to or contact

with the ISOMETER®.

Make sure that the operating voltage is correct!

Prior to insulation and voltage tests, the ISOMETER® must be disconnected

from the IT system for the duration of the test. In order to check the correct

connection of the device, a functional test has to be carried out before starting the system.

In the event of an alarm message of the ISOMETER®, the insulation fault

should be eliminated as quickly as possible.

If the ISOMETER® is installed inside a control cabinet, the insulation fault

message must be audible and/or visible to attract attention.

When using ISOMETER®s in IT systems, make sure that only one active

ISOMETER® is connected in each interconnected system. If IT systems are

interconnected via coupling switches, make sure that ISOMETER®s not

currently used are disconnected from the IT system and deactivated. IT

systems coupled via diodes or capacitances may also influence the insulation monitoring process so that a central control of the different

ISOMETER®s is required.

8

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 9

Prevent measurement errors!

When a monitored IT system contains galvanically coupled DC circuits, an

insulation fault can only be detected correctly if the rectifier valves (e.g.

rectifier diode, thyristors, IGBTs, frequency inverters, …) carry a minimum

current of > 10 mA.

Safety instructionsSafety instructions

2.4 Intended use

Only qualified personnel are permitted to carry out the work necessary

to install, commission and run a device or system.

Unspecified frequency range

When connecting to an IT system with frequency components below the

specified frequency range, the response times and response values may

differ from the indicated technical data. However, depending on the application and the selected measurement method, continuous insulation

monitoring is also possible in this frequency range.

There is no influence on the insulation monitoring for IT systems with frequency components above the specified frequency range, e.g. within the

range of typical switching frequencies of frequency inverters (2…20 kHz).

The ISOMETER® isoNAV685-D-B monitors the insulation resistance of loads that are

switched off. These loads, which are temporarily or mostly switched off, are powered by

TN, TT or IT systems.

The internal mains switch has a circuit capacity of AC 0…690 V and DC 0…1000 V.

Due to the separate supply voltage, de-energised systems can also be monitored. The

maximum permissible system leakage capacitance is 150 µF.

Intended use also implies:

• The observation of all information in the operating manual

• Compliance with test intervals

In order to meet the requirements of applicable standards, customised parameter settings must be made on the equipment in order to adapt it to local equipment and operating conditions. Please heed the limits of the area of application indicated in the

technical specifications.

Any other use than that described in this manual is regarded as improper.

9

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 10

3. Function

*

Function

3.1 Features

• ISOMETER® to monitor the insulation resistance in systems that are switched off.

• Automatic adaptation to the existing system leakage capacitance.

• measurement method.

• An adjustable response value in the range 1 k…10 M

(factory setting = 50 k).

• High-resolution graphic LC display for excellent readability and recording of the

device status.

• Ground fault monitoring.

• Automatic device self test.

• History memory with real-time clock (buffer for three days) for storing 1023 alarm

messages with date and time.

• Freely programmable digital inputs and outputs.

• Remote setting of certain parameters via Internet

(Option; COMTRAXX® Gateway).

• Worldwide remote diagnosis via Internet.

• Modbus TCP, web server and BCOM.<

3.2 Product description

The ISOMETER® isoNAV685-D-B is an insulation monitoring device for IT systems in accordance with IEC 61557-8. It is universally applicable in TN, TT or IT systems that are

switched off.

3.3 Functional description

The insulation monitoring device ISOMETER® isoNAV685-D-B monitors the entire insulation resistance of systems that are switched off and triggers an alarm when the insulation

resistance value falls below a preset response value.

The insulation resistance of the L1, L2 and L3 coupling paths is measured sequentially.

This means that faults are not only measured, but they can also be localized or located.

The test time may vary, e.g. it may be longer, depending on the leakage capacitance.

To obtain a measurement the device has to be connected between the IT system (unearthed system) and the protective earth conductor (PE). A measuring current in the A

range is superimposed onto the system which is recorded and evaluated by a micro-controlled measuring circuit. The measuring time is dependent on the selected measurement profiles, the system leakage capacitance, the insulation resistance and possible

system-related disturbances.

The response values and other parameters are set using a commissioning wizard as well

as via different setup menus using the device buttons and a high-resolution graphical LC

display. The selected settings are stored in a permanent fail-safe memory. Different languages can be selected for the setup menus as well as the messages indicated on the display. The device utilises a clock for storing fault messages and events in a history memory

with time and date stamp. The settings can be protected against unauthorised modifications by entering a password. To ensure proper functioning of connection monitoring,

the device requires the setting of the system type 3AC and the

appropriate terminals

L1/+, L2, L3/-.

prescribed wiring of the

10

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 11

FunctionFunction

TEST

√ Measurement

Coupling

Earth connection

Outputs

33 %

√

The insulation monitoring device is able to measure the insulation resistance reliably and

precisely in all common IT systems (unearthed systems). Due to various applications, system types, operating conditions, application of variable-speed drives, high system leakage capacitances etc., the measurement technique must be able to meet varying

requ irements in order to ensure an op timised respons e time an d relati ve uncer tainty. Different measurement profiles which can be selected from a setup menu allow optimum

adaptation of the measurement technique to the specific application.

If the resistance value below a set response value R

vated, the LED ALARM 1 (alarm at L1 or L2) or ALARM 2 (alarm at L3) lights and the LCD

shows the measured value. If the fault memory is activated, the fault message will be

stored. Pressing the RESET button resets the insulation fault message, provided that the

current insulation resistance displayed at the time of resetting is at least 25 % above the

actual response value. As additional Information, the quality of the measuring signal and

the time required to update the measured value are shown on the display.

, the associated alarm relay is acti-

an

3.4 Interfaces

• Communication protocol Modbus TCP

• BCOM for Bender device communication via Ethernet

• Integrated web server for reading out measured values and for parameter setting

3.5 Self test

After switching on the supply voltage, the ISOMETER® automatically and continuously

checks all internal measuring functions, the components of the process control such as

the data and parameter memory, as well as the connections to the IT system and earth.

The self test can also be activated manually by means of the test button to check the functions of the relays (depending on the configuration) or it can be selected via the "Control"

menu (refer to “Control” on page 33).

The progress of the manual self test is shown on the LC display by a bar graph. Depending

on the conditions in the IT system being monitored, the self test is completed after

15…20 seconds. The device then returns to the standard mode (measurement mode)

and the actual measured value will be displayed after the measuring time has expired.

The display shows the message

ured (refer to “Initial measurement” on page 26).

If a fault is detected during the self test, the respective LEDs of the device light (refer to

“Alarm messages” on page 42). In addition, the respective message will be indicated on

the display and a previously programmed output will provide the respective signal.

Initial measurement

until the first valid value is meas-

11

The test has been run and the result was positive.

The test has been run and the result was negative.

The test is not available and is not carried out

(e.g. due to specific device settings).

The test is running.

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 12

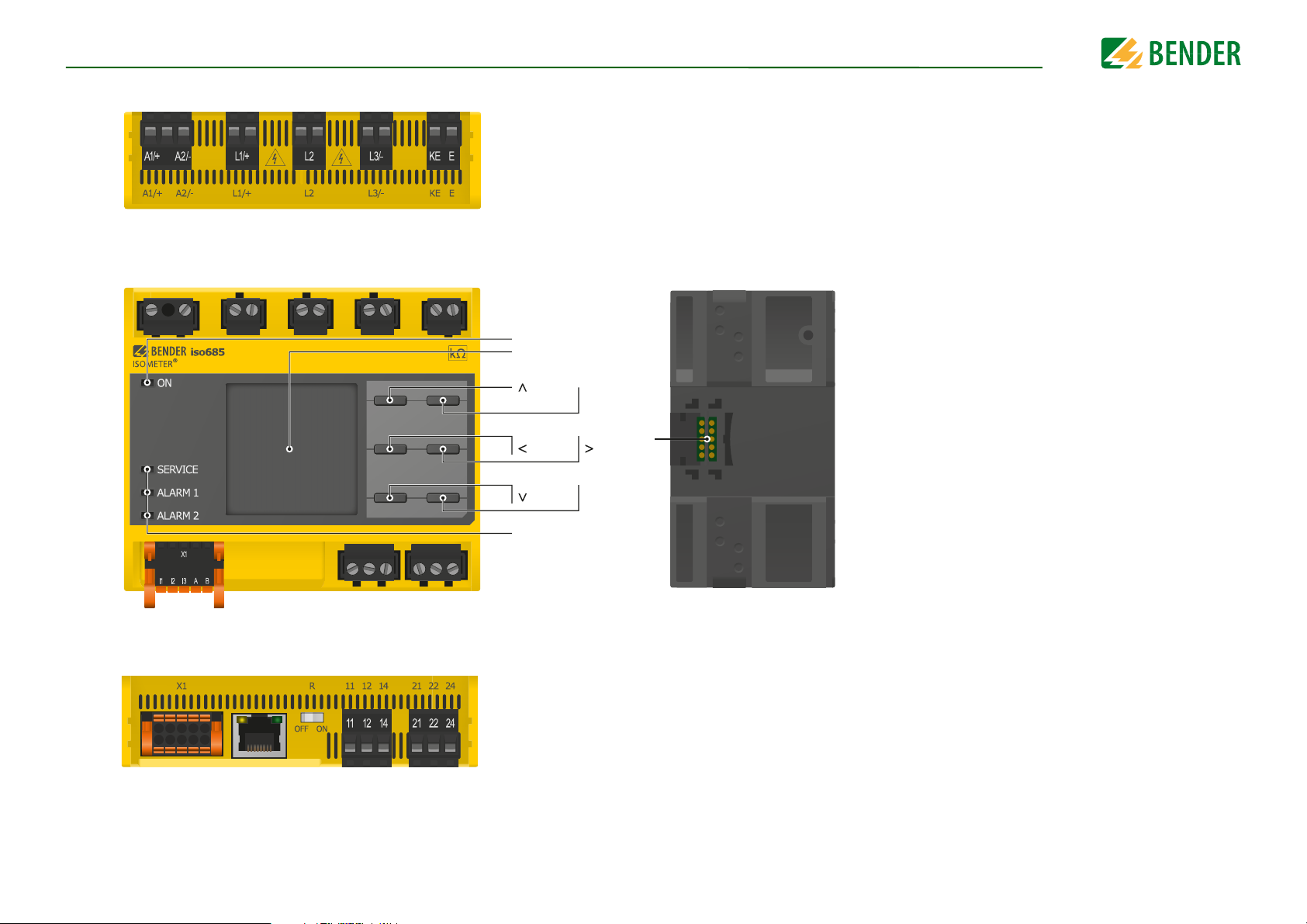

4. Device overview

4.1 Dimensions

108 mm

110 mm

mm 39

12

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 13

Device overview

A1/+, A2/- Connection to the power supply voltage U

s

L1/+ Connection to the IT system to be monitored

L2 Connection to the IT system to be monitored

L3/- Connection to the IT system to be monitored

KE, E Connection to PE

To p

X3 Optional expansion module for Bender devices (e. g. BB-Bus)

ETH

X1 Digital interface

ETH Ethernet interface

R Selectable resistance R

11 12 14 Connector for alarm relay 1

21 22 24 Connector for alarm relay 2

Bottom

4.2 Connections and panel

ON

Display

MENU

ESC

13

RESET

DATA

LEDs: SERVICE,

ALARM 1, ALARM 2

TEST

INFO

OK

X3

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 14

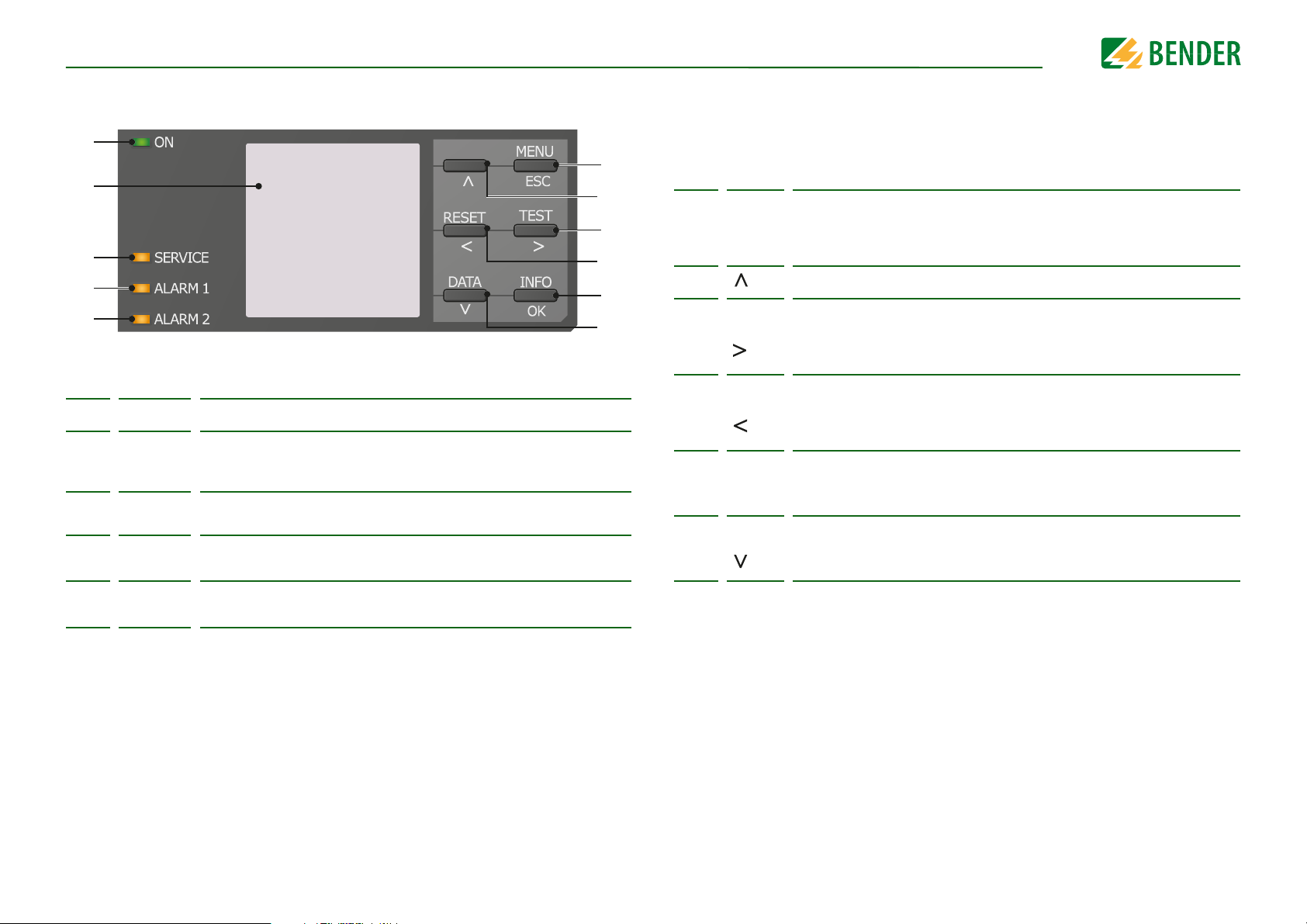

Device overviewDevice overview

1

7

8

9

10

11

2

3

4

5

6

4.3 Display elements and device buttons

Display elements

1 ON The LED "ON" lights when the device is turned on.

The device display shows information regarding the device and the

2

3

4

5

SERVICE

ALARM 1

ALARM 2

measurements.

Other information is available in the chapter “Display” from page 23.

The LED "SERVICE" lights when there is either a device fault or a connection fault, or when the device is in maintenance mode.

The LED "ALARM 1" lights when the insulation resistance of the IT system

falls below the set response value R

The LED "ALARM 2" lights when the insulation resistance of the IT system

falls below the set response value R

an1

an2

.

.

Device buttons

You can adjust the device settings in the respective menu using the menu buttons.

Depending on the menu entry, one of the options displayed below is assigned to the

buttons.

MENU Opens the device menu.

6

7

8

9

10

11

ESC

TEST

RESET

Info

OK

DATA

Cancels the current process or

navigates one step back in the device menu.

Navigates up in a list or increases a value.

Starts the device self test.

Navigates forwards (e.g. to the next setting step) or

selects a parameter.

Resets alarms.

Navigates backwards (e.g. to the previous setting step) or

selects a parameter.

Shows information.

Confirms an action or a selection.

Indicates data and values.

Navigates down in a list or reduces a value.

14

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 15

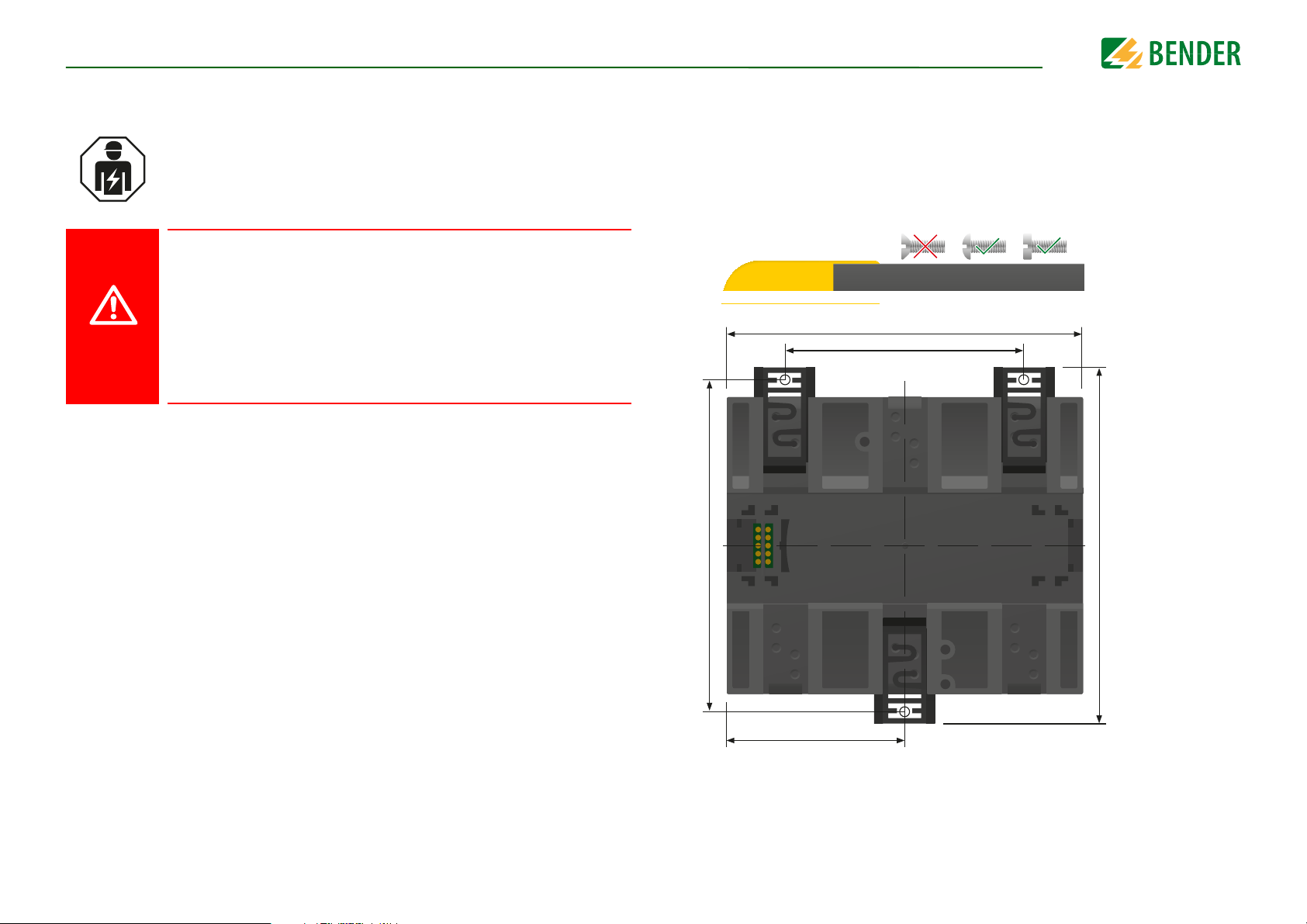

5. Mounting

DANGER

72 mm

108 mm

54 mm

100 mm

107,3 m m

Mounting

5.1 General instructions

Only qualified personnel are permitted to carry out the work necessary

to install, commission and run a device or system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

• An electric shock

• Damage to the electrical installation

• Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-energised. Observe the rules for working on elec-

trical installations.

5.2 Screw mounting

18. Fix the three mounting clips delivered with the device (two of them packed separately) manually or using a tool, as illustrated below.

19. Drill the mounting holes for the M4 thread according to the dimensioned drilling template.

20. Fix the ISOMETER® using three M4 screws.

15

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 16

Connection

DANGER

DANGER

DANGER

WARNING

6. Connection

5.3 DIN rail mounting

1. Fix the three mounting clips delivered with the device (two of them packed separately) manually or using a tool, as illustrated below.

2. Fix the ISOMETER® onto the DIN rail until it snaps into place.

6.1 Connection requirements

Consider the minimum distance to adjacent devices:

lateral 0 mm, top 20 mm, bottom 20 mm.

Only qualified personnel are permitted to carry out the work necessary

to install, commission and run a device or system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

• An electric shock

• Damage to the electrical installation

• Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-energised. Observe the rules for working on elec-

trical installations.

Risk of electric shock!

Nominal voltages up to 1000 V may be present on the terminals L1/+ to

L3/- which can be lethal. Make sure the terminal covers are properly

mounted and clicked in before putting the device into operation.

16

Risk of electric shock!

High voltage is applied at the terminals, which in case of direct contact

can be life-threatening. If the terminals L1/+, L2, L3/- of the device are connected to a live IT system, the terminals E and KE must not be disconnected

from the protective conductor (PE).

Warning of insulation monitoring devices that do not work correctly!

Connect the terminals KE and E individually to the protective earth conductor PE.

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 17

ConnectionConnection

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Provide line protection!

According to DIN VDE 0100-430, a line protection shall be provided for the

supply voltage.

Risk of injury from sharp-edged terminals!

Risk of lacerations.

Touch the enclosure and the terminals with due care.

Ensure disconnection from the IT system!

When insulation or voltage tests are to be carried out, the device must be

isolated from the system for the test period. Otherwise the device may be

damaged.

Risk of property damage due to unprofessional installation!

If more than one insulation monitoring device is connected to a conductively connected system, the system can be damaged. If several devices

are connected, the device does not function and does not signal insulation faults. Make sure that only one insulation monitoring device is connected in each conductively connected system.

Prevent measurement errors!

When an AC system being monitored contains galvanically coupled DC

circuits, take into consideration that: an insulation fault can only be detected correctly when the rectifier valves carry a minimum current of

>10 mA.

For UL applications:

Use 60/70 °C copper lines only!

For UL and CSA applications, the supply voltage must be protected via 5 A

fuses.

17

Risk of property damage due to unprofessional installation!

The connecting lines L1/+, L2, L3/- to the system to be monitored must be

carried out as spur lines. Inadmissible load current can result in damage

to property and personal injury. Do not apply any load current to the terminals.

Check proper connection!

Prior to commissioning of the installation, check that the device has been

properly connected and check the device functions. Perform a functional

test using an earth fault via a suitable resistance.

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 18

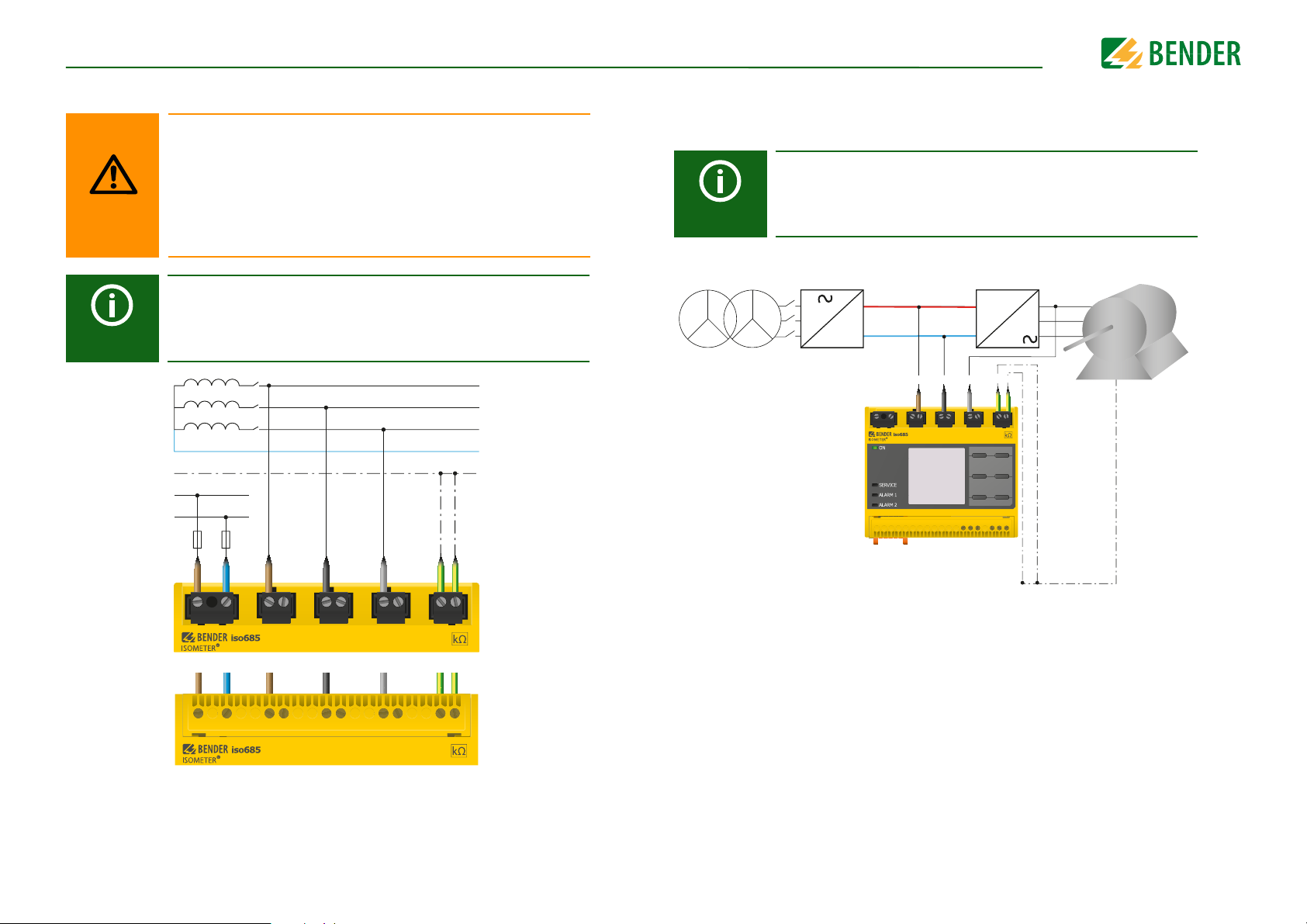

ConnectionConnection

WARNING

L1

L2

L3

N

PE

U

S

6A

U

n

PE

M

DC+

DC-

AC

KE E

IT System

OK

230 kΩ

R(an) 4 0kΩ/10kΩ

OK

230 kΩ

L1/+ L2 L3/-

L1/+ L2 L3/- KE E

3

=

3

=

6.2 Connection to a 3(N)AC system/system type 3AC

Risk of injury, fire and damage to property due to a short circuit!

According to DIN VDE 0100-430, devices used to protect against a

short circuit when terminals L1/+, L2 und L3/- are coupled to the IT

system to be monitored can be omitted if the wiring is carried out

in such a manner as to reduce the risk of a short-circuit to a minimum. Ensure short-circuit proof and earth-fault proof wiring.

The ISOMETER® may only be used for monitoring de-energized systems. The device must be deactivated via the digital input before

the mains voltage is switched on.

6.3 Connect to a frequency converter to monitor in the off state (Offline)

The ISOMETER® may only be used for monitoring de-energized systems. The device must be deactivated via the digital input before

the mains voltage is switched on.

18

Position the terminal cover and click it into place

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 19

ConnectionConnection

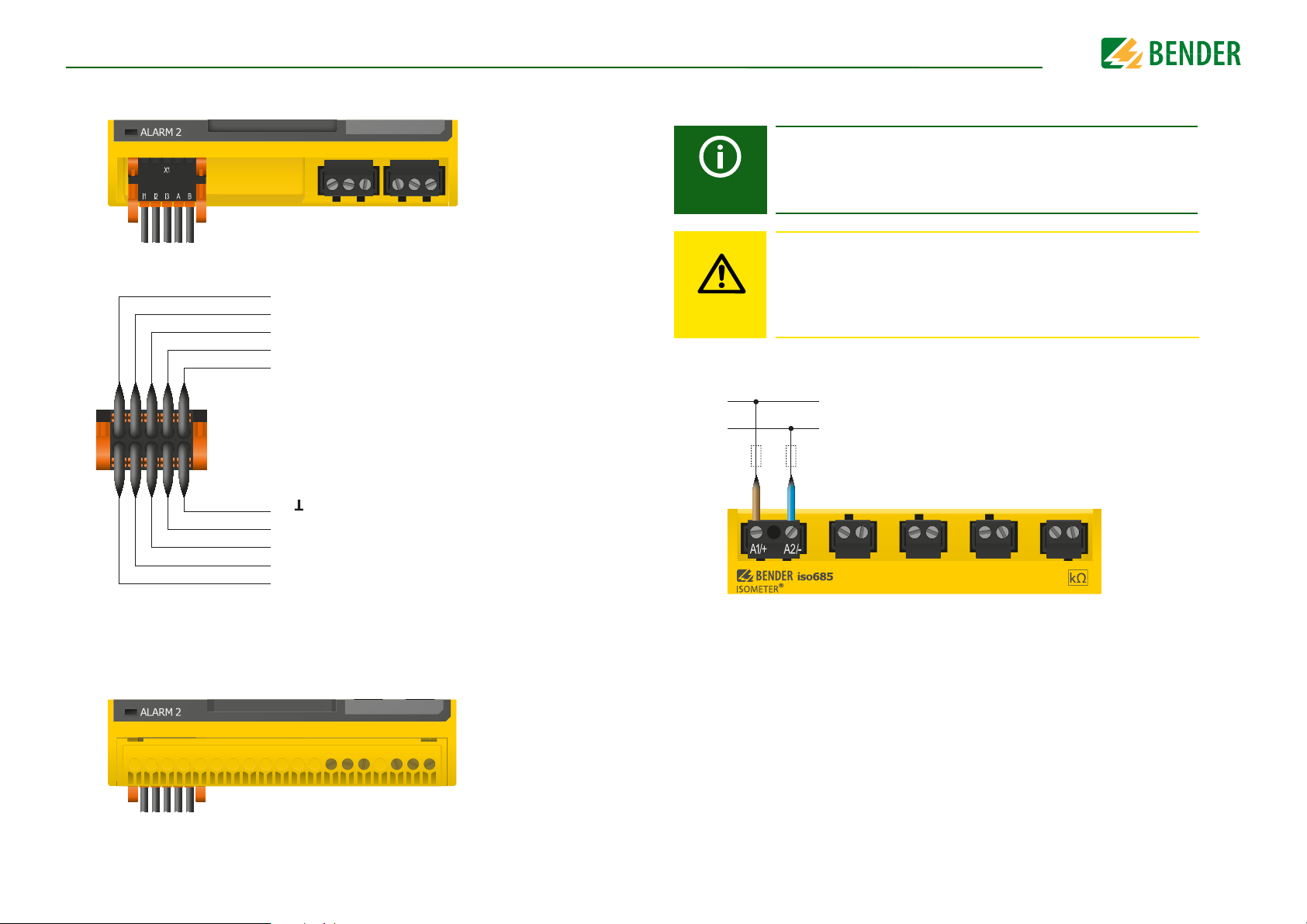

I1

I2

I3

A

B

M+

Q2

Q1

+

Electrical overload protection.

Auto shut-off in the event of

a short circuit and transients

(resettable)

Input 1

Input 2

Input 3

RS-485 A

RS-485 B

Ground

unused

Output 2

Output 1

+24 V

CAUTION

U

S

6.4 Connection to the X1 interface

6.5 Connection to the supply voltage

External Power supply for powering the ISOMETER® via terminal X1

must fulfil immunity and emission standards of the required application. For wiring longer than 1 m the use of a shielded cable is

prescribed.

Danger of damage to property due to faulty connections!

The device can be damaged if the unit is simultaneously connected

to the supply voltage via the X1 interface, and A1/+ and A2/- terminals. Do not connect the device simultaneously via X1, and A1/+

and A2/- to different supply voltages.

Position the terminal cover and click it into place

19

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 20

ConnectionConnection

11

12

14

Relay 1

Common contact

Normally open (n.o)

Normally closed (n.c)

6.6 Connection to the Ethernet interface

Position the terminal cover and click it into place

6.7 Connection to the relay 1 interface (11 12 14)

Position the terminal cover and click it into place

20

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 21

6.8 Connection to the relay 2 interface (21 22 24)

21

22

24

Relay 2

Common contact

Normally closed (n.c)

Normally open (n.o)

Position the terminal cover and click it into place

ConnectionConnection

21

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 22

7. Commissioning

Commissioning the ISOMETER®

Adjust basic settings if

necessary

Install the device according to the

wiring diagram

and documentation

Connect the supply voltage

Connect the system voltage

The ISOMETER® performs a self

test

Function test with a suitable

resistance between system and

earth. Resistance value: 50% of

the response value Alarm 2

Remove the resistance

The ISOMETER® is properly

connected and

functions reliably

Run the commissioning

wizard

For further information regarding device settings, refer to chapter “Settings”

from page 29.

Commissioning

7.1 General initial commissioning process

1. Check that the ISOMETER® is properly connected to the system to be monitored.

2. Connect the supply voltage to the ISOMETER®. The ISOMETER® then performs a 4step self test during which the alarm relays are not checked. After completion of the

test, the measured insulation resistance is shown on the display. If the value exceeds

the response values indicated in the lowest line of the display, the message "OK" will

additionally be displayed.

For customer-specific configured devices, the commissioning wizard

might be deactivated and cannot be run. In this case, the device is preset.

However, the commissioning wizard can be started as described at

3. Check the ISOMETER® in the system being monitored, e.g. using a suitable resistance to earth.

7.2 Recommissioning

If the device has already been put into operation before, the self-test will be started shortly after the supply voltage has been connected.

The device settings can also be carried out via the commissioning-wizard, which can be

manually started via the menu path:1

Menu/Device settings/Commissioning

This menu can be used to modify settings made previously.

“Display” on page 23.

Observe device status!

The device is in an alarm state until initial commissioning has been

completed.

Commissioning flow chart

Observe the device status!

The device changes from the alarm state to normal state after

22

completing initial commissioning and initial measurement by adhering to the response values set.

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 23

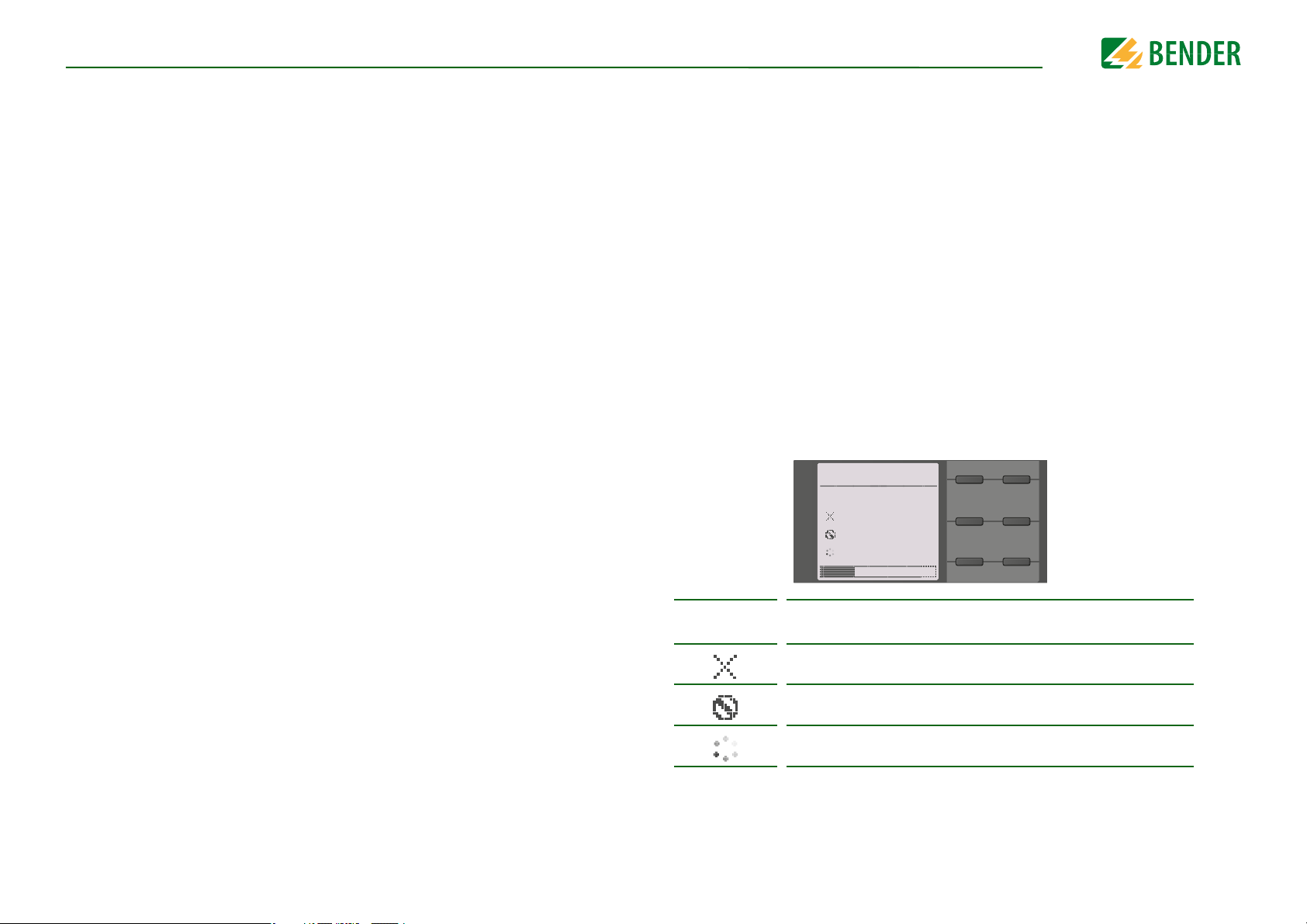

8. Display

IT System

OK

L1 230 kΩ

L2 250 kΩ

L3 130 kΩ

R(an) 50kΩ

OK

L1 230 kΩ

L2 250 kΩ

L3 130 kΩ

Display

8.1 Standard display

In normal operation, the ISOMETER® displays the message OK and below the latest measured insulation resistance of the connected system points L1, L2 and L3.

The signal quality of the measurement suits the selected profile.

The better the signal quality, the faster and more exact the device can

measure.

The signal quality of the measurement does not suit the selected profile. Select a different measurement profile.

Update period between the test pulses

In the bottom line of the display, the set limit value for R(an) is indicated.

In the example shown below Ran=50 k.

8.2 Fault display (active)

An active fault is displayed by . The upper part of the display will become orange and

displays the fault message.

Depending on the type of fault, the LEDs ALARM 1, ALARM 2 or SERVICE are activated.In

the example below, the insulation resistance is still 23

If several fault messages have appeared, you can navigate through the faults using the

and button.

ALARM

Iso. Alarm L1

23 kΩ

23

5/7

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 24

DisplayDisplay

230 kΩ

IT System

3x

1/4

230 kΩ

Insulation fault

28.03.14 17:0 2

28.03.14 17:18

2/4

7 kΩ7 kΩ

8.3 Fault display (inactive)

An inactive fault is displayed by . If several faults have occurred, the number of faults

will also be indicated.

This message means that there has been a fault in the past but the device is no longer in

fault condition.

If several fault messages occur, you can navigate through the faults using the and

button. In addition to the type of fault and the associated alarm value, you can see when

the fault has occurred and how long it has been active.

24

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 25

DisplayDisplay

RESET 3.2

Reset current

messages? All

messages are

saved in the

history memory.

Cancel RESET

Historie 4.1

Isolationsfehler

11kΩ

28.03.14 17:02

28.03.14 17:18

8/8

Next message

Leave view

Fault description

Alarm value

Feault occured

Fault disappeared

Previous message

Number of selected

errors/

Tot al number of

error messages

8.4 Acknowledge fault memory

In order to acknowledge the fault message and return to the ISOMETER®'s standard

display, all faults must be acknowledged by means of the reset button.

This means that fault messages can only be reset when the cause of the fault has been

eliminated.

Press the reset button, then and OK to clear the fault memory.

The ISOMETER® then returns to the standard display.

8.5 History memory

Up to 1023 alarm messages and device errors are stored in the history memory with date

and t ime stam p. When t he histo ry memory is deleted, the minimum insulation resistance

will also be reset under Menu/ Data Measured values - Data insulation - Reset.

R

min

25

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 26

8.6 Initial measurement

IT System

R(an) 40kΩ/10 kΩ

Initial

measurement

Initial

measurement

During the initial measurement, the device records all measured values.

All measured values that may have been recorded before will be discarded if a new initial

measurement is started.

DisplayDisplay

26

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 27

9. Menu

1. Alarm settings 1. Insulation alarm 1. Alarm 1

2. Voltage

3. t(on)

3. Memory

2. Profile

3. System type

4. Coupling

5. Device

6. t(start)

7. Coupling monitoring

8. Inputs 1. Digital 1 1. Mode

2. t(on)

3. t(off)

4. Function

2. Digital 2 1. Mode

2. t(on)

3. t(off)

4. Function

3. Digital 3 1. Mode

2. t(on)

3. t(off)

4. Function

9. Ausgänge 1. Relais 1 1. Test

2. Relay mode

3. Function 1

4. Function 2

5. Function 3

2. Relais 2 1. Test

2. Relay mode

3. Function 1

4. Function 2

5. Function 3

3. Digital 1 1. Test

2. Relay mode

3. Function 1

4. Function 2

5. Function 3

4. Digital 2 1. Test

2. Relay mode

3. Function 1

4. Function 2

5. Function 3

5. Summer 1. Test

2. Function 1

3. Function 2

4. Function 3

2. Data meas. values

3. Control

4. History

5. Device settings 1. Language

2. Cloc

k

1. Time

2. Format

3. Summer time

4. Date

5. Format

6. NTP

7. NTP Server

8. UTC

3. Interface 1. Write access

2. Ethernet 1. DHCP

2. IP

3. SN

4. Std. GW

5. DNS Server

6. Domäne

3. BCOM 1. System name

2. Subsystem

3. Device address

4. Timeout

5. TTL

4. Modbus TCP 1. Port 502

5. BS-Bus 1. Address

4. Displa

y

1. Brightness

5. Passwort 1. Passwort

2. Status

6. Commissioning

7. Data protection

8. Service

6. Info

9.1 Menu structure

Menu

27

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 28

9.2 Operating and navigating

System type 5.6.6

• 3AC

Date 5.2.4

14.01.2014

min. 1

max. 31

Ethernet 6.3.2

-.0123456789abcdef

ghijklmnopqrstuvwx

yz del

Navigate through the device menu using the device buttons. The functions of the device

buttons are described in the chapter “Display elements and device buttons” on page 14.

9.2.1 Easy operation

Navigation in lists

To make a selection in a list, navigate using

the and buttons to the required

menu item. Then click "OK".

Navigation with arrows

You can increase or decrease a value using

the and buttons. You can move to

the left or the right to set different values

using the and buttons. The value positioned between the symbols is the value that is set.

MenuMenu

Text input

Go step by step through the numbers and

letters indicated on the display by using

the button (forwards) and the button

(backwards). Navigate to the right using

the button to enter the next character.

To delete a character that has been entered, use the and buttons to navigate to the character to be deleted and

then select "del" using the and buttons.

Confirm the entered text with "OK".

28

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 29

10. Settings

t

R

an1

Alarm 1

aktiv

Alarm 1

inaktiv

Δ 25 % + 0,5 kΩ

Settings

10.1 Settings in the device menu

The settings of the ISOMETER® are explained in the order of the device menu.

10.1 (1.0)Alarm settings

The limit values for the insulation resistances of alarm 1 and alarm 2 can be specified in

the alarm settings menu and can be adapted to the user profile of the ISOMETER®.

A device password is required for entering the settings. You can adjust the following

functions:

10.1 (1.1) Insulation alarm

10.1 (1.2) Profile

The ISOMETER® profile is set to "Offline".

System

Measuring

voltage

± 5 V

Offline

leakage

capacitanc

e

µF

150

Description

For disconnected loads and

frequency converters.

In the "Insulation alarm" menu, you can set the limits for the ISOMETER® ALARM:

10.1 (1.3) System type

The activation or deactivation of the alarm for R

is illustrated in the following graph:

an

The device is set to a 3AC system.

An alarm will become inactive as soon as +25 % +0.5 k of the set operating value is

exceeded.

•3AC

3AC system

(refer to “Connection to a 3(N)AC system/system type 3AC”

on page 18)

10.1 (1.4) Device

Set the ISOMETER® insulation resistance measurement function to active or inactive:

•Active

•Inactive

The device is active.

The device DOES NOT measure the insulation resistance, the

message Device inactive appears on the display. The

IT system is NOT being monitored!

10.1 (1.1.1) Alarm 1

For Alarm 1, an insulation resistance of between 1 k…10 M can be set.

10.1 (1.1.2) Fault memory

Automatic reset of inactive faults at the outputs relay 1, relay 2, digital output 1, digital

output 2:

10.1 (1.5) T(Start)

The ISOMETER® can be operated with a start-up delay of 0…120 seconds. The start-up is

delayed until the initial measurement takes place.

10.1 (1.6) Coupling monitoring

Coupling monitoring (L1, L2, L3 network connection monitoring) is deactivated.

•on

•off

If a fault becomes inactive, the programmed outputs remain

in fault condition until they are reset manually.

If a fault becomes inactive, the programmed outputs automatically change the state.

•off

Coupling monitoring is deactivated.

29

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 30

10.1 (1.7) Inputs

I2

I3

A

B

M+

Q2

Q1

+

Device

inactive

Reset Test

I1

+I

x

X1 X1

t

0

1

t(on)

Reaction

Impulse on

Reaction

Impulse o

+I

x

X1 X1

The ISOMETER® provides a total of three digital inputs.

The exemplary wiring diagram shows how the digital inputs can be wired:

SettingsSettings

•Active low

1

An event is carried out on the falling edge of the digital input (high

to low).

Response time t(on)/t(off) after a switch-off signal.

10.1 (1.7.1) Digital 1

The following parameters can be set for the digital input:

10.1 (1.7.1.1) Mode

The operating mode for the digital input can be set to the following values:

•Active high

< t(on)

An event is carried out on the rising edge of the

digital input (low to high).

Response time t(on)/t(off) after a switch-on signal.

Reaction Reaction

0

< t(on)

t(on)

Impulse onImpulse o

t

10.1 (1.7.1.2) t(on)

The response time t(on) after a switch-on signal can be set between 100 milliseconds and

300 seconds (refer to “10.1 (1.7.1.1) Mode”).

10.1 (1.7.1.3) t(off)

The response time t(off) after a switch-off signal can be set between 100 milliseconds and

300 seconds (refer to “10.1 (1.7.1.1) Mode”).

10.1 (1.7.1.4) Function

The parameters for the function of the digital inputs of the ISOMETER® can be set

differently:

•off

•TEST

•RESET

•Deactivate

device

Digital input without function

Device self test

Reset of fault and alarm messages

The device DOES NOT measure the insulation resistance, the message Device inactive appears on the display.

The IT system is NOT being monitored!

30

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 31

SettingsSettings

≥ 1

Response

Function 1

Function 2

Function 3

10.1 (1.7.2) Digital 2

Refer to “10.1 (1.7.1) Digital 1”.

10.1 (1.7.3) Digital 3

Refer to “10.1 (1.7.1) Digital 1”.

10.1 (1.8) Outputs

The ISOMETER® provides a total of six outputs.

The following parameters can be set for the outputs:

10.1 (1.8.1) Relay 1

The following parameters can be set for each relay:

10.1 (1.8.1.1) TEST

The functional test of the relay can be activated or deactivated. This only applies to the

manual test and not to the cyclic device self test:

•on

•off

The manual test checks the switching function of the relay

The manual test does not check the switching function of the relay

10.1 (1.8.1.2) Relay mode

The relay mode can be adapted to the application:

•N/C

Normally closed- N/C operation contacts11-12-14 / 21-22-24

(in fault-free condition, the alarm relay is energised).

Select the appropriate setting for function 1. The following parameters can be set.

•off

•Ins. Alarm 1

•Ins. Alarm 2

•Connection fault

•Device fault

•Device inactive

The function is not used.

The status of the output changes when the value falls below the set

response value R

The status of the output changes when the value falls below the set

response value R

The status of the output changes when one of the following connection fault occurs:

• No low-resistance connection between the line conductors.

• No low-resistance connection between the terminals E and KE to

earth (PE).

• The load connected to the current output is too low

• The load connected to the current output is too high.

• Load on X1 too high.

The status of the output changes in the event of an internal device

fault.

The status of the output changes when the device has been

deactivated via a digital input or the control menu.

an1.

an2.

•N/O

Normally opened - N/O operation contacts

(in fault-free condition, the alarm relay is de-energised).

11-12-14 /

21-22-24

10.1 (1.8.1.3) Function 1

Up to three functions can be assigned to one output. The functions are linked to an OR

operator:

31

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 32

SettingsSettings

X1

iso685

Qx

+

oder

internal

external

10.1 (1.8.1.4) Function 2

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.1.5) Function 3

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.2) Relay 2

Refer to “10.1 (1.8.1) Relay 1”.

10.1 (1.8.3) Digital 1

The following parameters can be set for each of the digital outputs:

The functional test of the digital output can be activated or deactivated. This only applies

to the manual test and not to the cyclic device self test:

•on

•off

The manual test changes the status of the digital output.

The manual test does not change the status of the digital output.

10.1 (1.8.3.1) Mode

The following settings can be used to set the operating mode for the digital output:

•Active

In the active mode +24 V will be internally applied across the output.

X1

+

Qx

X1

+

Qx

•Passive

iso685

In the passive mode ≤ 32 V are externally connected (see technical

data). The output switches the applied potential to ground.

X1

+

iso685

Qx

iso685

32

Observe the maximum output current!

Maximum output current in case of internal voltage supply

via A1/+ and A2/-: 200 mA in total to X1.

Also refer to the formula for calculating I

der “Digital Outputs (Q1, Q2)” on page 45.

10.1 (1.8.3.2) Function 1

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.3.3) Function 2

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.3.4) Function 3

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.4) Digital 2

in the Technical Data un-

LmaxX1

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 33

SettingsSettings

Refer to “10.1 (1.8.3) Digital 1”.

10.1 (1.8.5) Buzzer

The following parameters can be set for the buzzer:

10.1 (1.8.5.1) TEST

The functional test of the buzzer can be activated or deactivated. This only applies to the

manual test and not to the cyclic device self test:

•on

•off

The manual test activates the buzzer sound.

The manual test does not activate the buzzer sound.

10.1 (1.8.5.2) Function 1

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.5.3) Function 2

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (1.8.5.4) Function 3

Refer to “10.1 (1.8.1.3) Function 1”.

10.1 (2.0) Data measured values

The ISOMETER® stores certain measured values for a specific period of time. You can view

these data at the "Data meas. values" menu point. Navigate through the different views

using the and buttons:

10.1 (4.0) History

In the history menu, the faults detected by the ISOMETER® are displayed. For a detailed

functional description, refer to “History memory” on page 25.

•History

•Delete

Overview of faults that have occurred

Reset the history memory

10.1 (5.0) Device settings

The device settings menu allows you to configure the basic settings for the ISOMETER®.

10.1 (5.1) Language

Choose the language to be displayed by the ISOMETER®. For example, you can set the languages:

•German

•English

10.1 (5.2) Clock

In the clock menu you can set the display format of time and date for the ISOMETER®:

10.1 (5.2.1) Time

Based on the selected time format you can set the current time to display 24-hour or 12hour notation (am/pm).

•Insulation data

Display the insulation resistance of the three coupling paths L1, L2,

L3

10.1 (3.0) Control

In the control menu, you can start a manual test reset, reset alarm messages and start an

initial measurement:

•TEST

•RESET

Manual device test

Reset of fault and alarm messages

33

10.1 (5.2.2) Format (time)

Select the appropriate time format to be displayed:

•12 h

•24 h

12-hour notation am/pm

24-hour notation

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 34

SettingsSettings

10.1 (5.2.3) Summer time

Summer time can be considered in the following settings:

•off

•DST

•CEST

No automatic change between summer time and standard time.

Daylight Saving Time

Automatic change between summer and standard time according to

North American regulation.

North American summer time begins on each second Sunday in

March at 02:00 local time by setting the clock forward by one hour

from 2:00 to 03:00 local time. Summer time always ends the first Sunday in October at 03:00 local time by setting the clock back one hour

from 3:00 to 2:00.

Central European Summer Time

Automatic change between summer time and standard time according to Central European regulation.

Central European summer time begins on each last Sunday in March

at 02:00 CEST by setting the clock forward by one hour from 2:00 to

03:00. Central European summer time always ends on the last Sunday in October at 03:00 CEST by setting the clock back one hour

from 3:00 to 2:00.

When set to DST or CEST, changing between summer time and normal time

is only done on the date of the official time change.

10.1 (5.2.6) NTP

Select if you would like to synchronise the current time via NTP:

•on

•off

Synchronisation via NTP server is activated.

Synchronisation via NTP server is deactivated.

10.1 (5.2.7) NTP server

Set NTP server.

10.1 (5.2.8) UTC

Set the time according to UTC (coordinated world time). For Germany, set +1 for wintertime (MEZ) and +2 for summer time (MESZ).

10.1 (5.3) Interface

Set the parameters for the connection of other devices to the ISOMETER® in the interface

menu:

10.1 (5.3.1) Write access

Set whether the device can be parameterised externally via Modbus or web server. Displaying and reading out data via Modbus and web server is always possible, regardless of

this setting.

•Allow

•Deny

Allow external parameter setting.

Refuse external parameter setting.

10.1 (5.2.4) Date

Based on the selected date format you can set the current date.

10.1 (5.2.5) Format (date)

Select the appropriate date format you want to be displayed:

•dd.mm.yy

•mm-dd-yy

day, month, year

month, day, year

34

10.1 (5.3.2) Ethernet

Set the parameters for communication with other devices via the Ethernet interface. The

Ethernet interface can be used for communication with Modbus, web server and BCOM.

10.1 (5.3.2.1) DHCP

Select whether you want to use automatic address assignment via your DHCP server.

When the automatic IP address assignment is activated, the IP address, subnet mask and

the standard gateway are assigned automatically. When the automatic IP address assignment is deactivated, you have to make these settings manually in the menu.

The IP address can be viewed in the “Info“ menu (see “Info” on page 36).

•on

Activate automatic IP address assignment.

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 35

SettingsSettings

•off

Deactivate automatic IP address assignment.

10.1 (5.3.2.2) IP

Set the appropriate IP address for the ISOMETER®.

10.1 (5.3.2.3) SN

Set the appropriate subnet mask.

10.1 (5.3.2.4) Std. GW

If a standard gateway is used, enter the IP address here.

10.1 (5.3.2.5) DNS server

If a DNS server is used, enter the server's IP address.

Contact your network administrator in case you have questions about the configuration

of the DNS server.

10.1 (5.3.2.6) Domain

Enter the domain.

Contact your network administrator in case you have questions about the configuration

of the domain.

10.1 (5.3.3) BCOM

Set the parameters for communication with other devices via BCOM.

For further information, refer to “BCOM” on page 37.

10.1 (5.3.3.1) System name

Set the system name of the network in which the devices are located. In order to guarantee that all devices are able to communicate via BCOM, all devices must have the same

system name.

10.1 (5.3.3.2) Subsystem

Configure the subsystem address of the network in which the devices are located. The devices can communicate with subsystems with the same or different subsystem addresses.

10.1 (5.3.3.3) Device address

Assign a device address. Each device must have a different address to distinguish it from

another in the system and ensure correct communication.

10.1 (5.3.3.4) Timeout

Set the timeout for messages between 100 ms…10 s.

This time specification defines the maximum permissible time for a device to respond.

10.1 (5.3.3.5) TTL for subscription

Set a time between 1 s…1092 min.

This time defines the intervals at which the ISOMETER® sends messages to e.g. a gateway.

Severe alarms (e.g. insulation alarms or substantial value changes) are always sent immediately.

10.1 (5.3.4) Modbus TCP

Settings for communication with other devices via Modbus TCP.

For further information, refer to “Modbus TCP” on page 37.

10.1 (5.3.4.1) Port 502

Choose whether Modbus TCP should be used:

•on

•off

Modbus TCP can be used for communication with other devices.

Modbus TCP cannot be used for communication with other devices.

10.1 (5.3.5) BMS bus

The function of the BMS bus is not available in this device.

10.1 (5.4) Display

Adjust the display brightness for the ISOMETER® in the display menu:

10.1 (5.4.1) Brightness

Adjust the display brightness between 0 % and 100 % in steps of 10.

If no button is pressed on the display for 15 minutes, the brightness of the display is reduced. If now a button is pressed, the normal brightness is restored.

10.1 (5.5) Password

Use the password function to protect the device parameters against unauthorised adjustment. The default password is 0000.

10.1 (5.5.1) Password

Enter an individual four-digit password.

35

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 36

10.1 (5.5.2) Status

Decide if the password query should be used:

SettingsSettings

•on

•off

Password query active

Password query inactive

10.1 (5.6) Commissioning

In the commissioning menu you can open the ISOMETER®'s commissioning wizard again.

10.1 (5.7) Data backup

In the data backup menu device settings can be saved or device settings already saved

can be restored.

•Save

•Restore

The ISOMETER® saves your device settings.

The ISOMETER® restores your initial device settings.

10.1 (5.8) Service

The service menu can only be accessed by Bender Service staff.

10.1 (6.0) Info

The ISOMETER®'s current settings can be viewed in the Info menu. Navigate through the

different views using the and buttons:

•Device

•Software

Device name, serial number, article number

Software version measurement technique,

software version HMI

•Measurement

-technique

•Clock

•Ethernet

•BMS bus

36

Selected profile, selected system type

Time, date, summer time

IP address, DHCP status, MAC address

No function

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 37

11. Device communication

Device communication

11.1 Ethernet interface

The Ethernet interface can be used for communication with Modbus, web server and

BCOM.

11.2 BCOM

BCOM is intended for communication between Bender devices via Ethernet.

All devices that communicate via BCOM must have the same system name. Devices can

be organised in subsystems. Each device requires an individual device address.

For more information regarding BCOM, refer to the BCOM manual (D00256)

at http://www.bender.de/manuals.

When address 0 has been set for communication via BCOM the device can

be accessed via the network (e.g. for parameter setting, etc.) but it cannot

communicate with other devices.

11.3 Modbus TCP

Modbus is an international widely used protocol for data transfer between devices.

All measured values, messages and parameters are stored in virtual register addresses.

Data can be read out with a read command on the register address. With a write command, data can be written into a register address.

The register addresses of the individual measured values und parameters can be found

in the manual "iso685-D Annex A" with the title "ISOMETER® iso685 device family - Modbus settings" at http://www.bender.de/manuals.

A maximum of 5 TCP/IP connections can be used simultaneously.

In order to be able to parameterise the device externally via Modbus, the

menu item "Allow" must have been set in the "Write access" menu (see

“Write access” on page 34).

37

isoNAV685-D-B_D00264_03_M_XXEN/06.2017

Page 38

Device communicationDevice communication

1

2

3

4

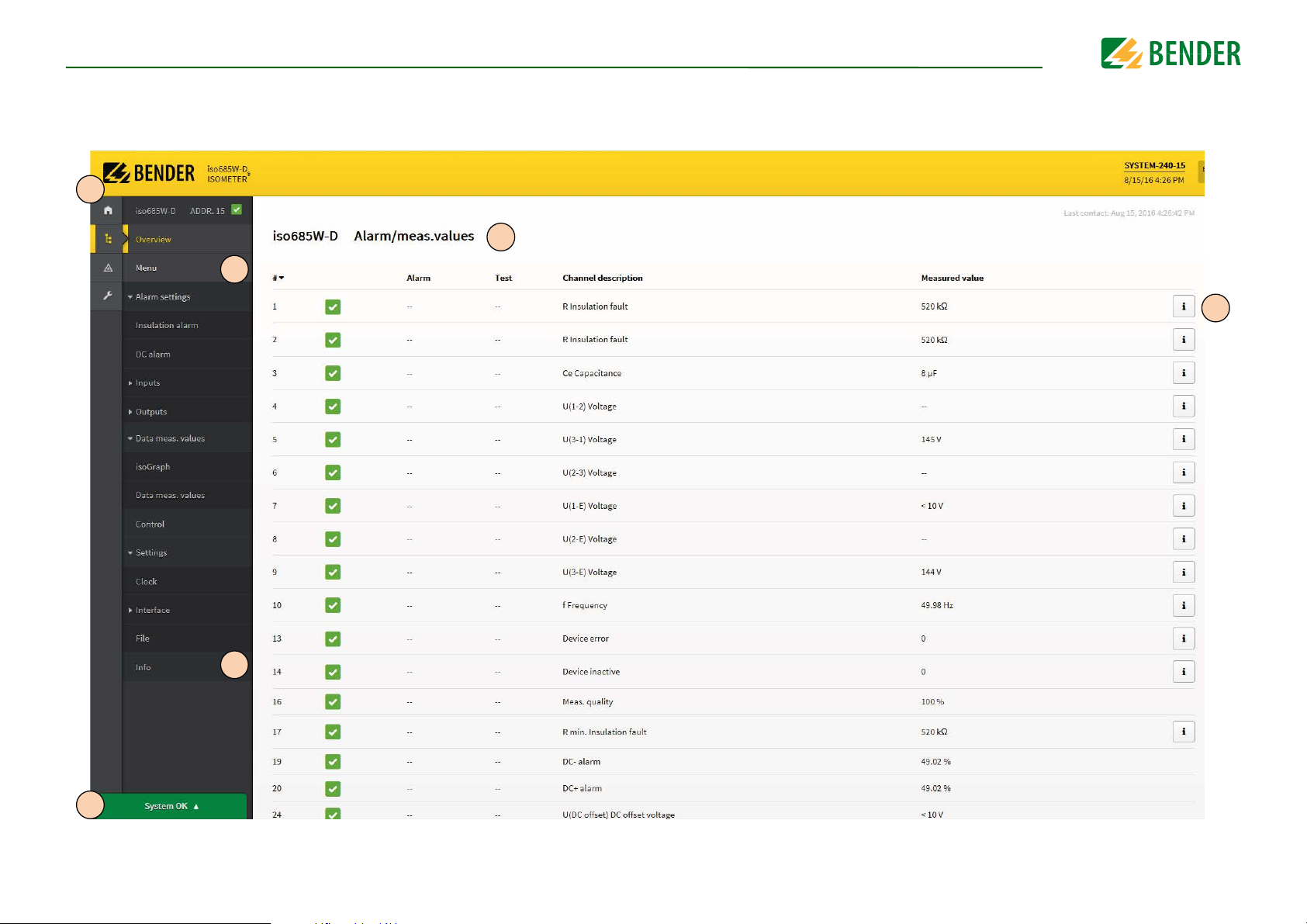

11.4 Web server

The ISOMETER® has an integrated web server which displays ISOMETER® data comfortably on every PC via a web browser. The web server can be used to read out measured values and parameterise the ISOMETER®s. You can access the web server by entering the IP

address of the ISOMETER® into the browser (e.g. http://192.168.0.5). The Info menu provides information about the ISOMETER®‘s IP address (see 10.1 (6.0) “Info” on page 36).

The web server offers the following functions:

• Visualisation

• Indication of device information (e.g. device type, software version, etc.)

• Indication of current device settings.

• Indication of alarm messages.

• Indication of the Modbus information of the individual parameters.

• Indication of the interfaces in use.

• Overview of the current measured values.

• Detailed graphic representation of the insulation resistance (isoGraph).

• Fast and simple visualisation without any programming.

• Parameter setting

• Easy and fast parameter setting of the device.

• Easy assignment and edition options of device and measuring channel texts.

• Maintenance

• Data storage of specific events for fast support by Bender Service.

A maximum of 5 TCP/IP connections can be used simultaneously.

The write access is deactivated by default in the device menu (= Deny). To

be able to set parameters via the web server the write access must first be

activated in the device menu (= Allow) (see “Write access” on page 34).

Use the web server preferably with the following web browsers:

Google Chrome, Mozilla Firefox or Internet Explorer.

Web server device menu (first level)

Legend for web server device menu (first level)

1 START Indication of general device information.

2DEVICE

3 ALARMS Indication of alarm messages.

4

PARAMETER

ADDRESSES