Page 1

Manual

EN

COMTRAXX® CP700

Condition Monitor

for the connection of Bender BMS devices

and universal measuring devices

to TCP/IP networks

Software version: V1.8

CP700_D00005_02_M_XXEN/06.2014

Page 2

Bender GmbH & Co. KG

P.O.Box 1161 • 35301 Grünberg • Germany

Londorfer Straße 65 • 35305 Grünberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-mail: info@bender.de • www.bender.de

Photos: Bender archives and bendersystembau archives.

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Page 3

Table of Contents

1. Making effective use of this document ............................................................... 9

1.1 How to use this manual ......................................................................................................... 9

1.2 Quick start ................................................................................................................................... 9

2. Safety instructions ............................................................................................... 11

2.1 Work activities on electrical installations ..................................................................... 11

2.2 Intended use ........................................................................................................................... 11

2.3 Address setting and termination .................................................................................... 12

2.4 Delivery conditions, guarantee, warranty and liability ........................................... 12

3. Product description ............................................................................................. 13

3.1 Scope of supply ..................................................................................................................... 13

3.2 Device features ...................................................................................................................... 13

3.3 Possible applications ........................................................................................................... 13

3.4 Description of function ....................................................................................................... 14

3.4.1 Interfaces .................................................................................................................................. 14

3.4.2 Process image ........................................................................................................................ 14

3.4.3 CP700-compatible devices ................................................................................................ 14

3.4.4 Functions available via touch screen ............................................................................. 15

3.4.5 Functions available via the web user interface .......................................................... 15

3.5 Software products used ...................................................................................................... 16

4. Installation, connection and commissioning .................................................. 17

4.1 Preliminary considerations ................................................................................................ 17

4.2 Installing the device ............................................................................................................. 17

4.2.1 Essential information on mounting ............................................................................... 17

4.2.2 Type of installation ............................................................................................................... 18

4.2.3 Practice ..................................................................................................................................... 18

4.3 Connection of the device ................................................................................................... 20

4.3.1 Overview of the bus device interfaces .......................................................................... 20

4.3.2 DC 24 V power supply ........................................................................................................ 21

4.3.3 Earthing .................................................................................................................................... 21

4.3.4 BMS bus, Modbus/RTU ........................................................................................................22

4.4 Commissioning ...................................................................................................................... 23

CP700_D00005_02_M_XXEN/06.2014

3

Page 4

Table of Contents

5. Display and operating elements ....................................................................... 25

5.1 Operating elements at the rear of the device ............................................................. 25

5.1.1 Status LEDs ............................................................................................................................... 26

5.1.2 Battery ....................................................................................................................................... 26

5.1.3 CompactFlash card ............................................................................................................... 26

5.2 Touchscreen ............................................................................................................................ 27

5.3 Operation via touch screen ................................................................................................ 28

5.3.1 Main menu ............................................................................................................................... 28

5.3.2 "Settings" menu ..................................................................................................................... 29

5.3.2.1 "Interface" menu ............................................................................................................. 29

5.3.2.2 "Language" menu ........................................................................................................... 31

5.3.3 "Alarms" menu ........................................................................................................................ 32

5.3.4 "Bus overview" menu ........................................................................................................... 32

5.3.5 Displaying the device info for CP700 ............................................................................. 33

5.3.6 Using the functions for Bender PEM… universal measuring devices ............... 33

6. Web user interface of the CP700 ....................................................................... 35

6.1 Menu structure of the web user interface .................................................................... 35

6.2 Browser configuration ......................................................................................................... 37

6.3 Initial operation of the web user interface: .................................................................. 37

6.4 Start page and operating language ................................................................................ 38

6.4.1 Opening the start page ....................................................................................................... 38

6.4.2 Changing the language ....................................................................................................... 38

6.5 Menu bar ................................................................................................................................... 39

6.6 Bus overview and device information ........................................................................... 40

6.6.1 Creating a password protection for CP700 .................................................................. 40

6.6.2 Buttons for the list of bus devices ................................................................................... 42

6.6.3 CP700 on the internal BMS bus ........................................................................................ 43

6.6.4 Querying device information ............................................................................................ 43

6.6.5 Displaying the help text ...................................................................................................... 44

6.6.6 Loading the menu of a bus device .................................................................................. 45

6.6.7 Displaying the settings of a bus device ......................................................................... 45

6.6.8 Creation and further processing of a bus device Back-up/Report ....................... 46

6.6.8.1 Creating a backup ........................................................................................................... 46

6.6.8.2 Show the backup ............................................................................................................ 47

6.6.8.3 Creating a new backup with a comparison of the device parameters ........ 47

6.6.8.4 Using a backup for parameter setting .................................................................... 48

6.6.9 History memory ...................................................................................................................... 50

6.6.9.1 Displaying the history memory ................................................................................. 50

6.6.9.2 Evaluating the history memory ................................................................................. 51

4

CP700_D00005_02_M_XXEN/06.2014

Page 5

Table of Contents

6.6.9.3 Exporting the history memory .................................................................................. 52

6.6.9.4 Delete the history memory ......................................................................................... 52

6.6.9.5 Displaying the history memory of BMS devices ................................................. 52

6.6.10 Data logger .............................................................................................................................. 53

6.6.10.1 Data logger setting ........................................................................................................ 53

6.6.10.2 Displaying the data logger ......................................................................................... 53

6.6.10.3 Evaluating the data logger ......................................................................................... 54

6.6.10.4 Apply the filter to the graphical representation ................................................. 58

6.6.10.5 Exporting the data logger ........................................................................................... 58

6.6.10.6 Deleting the data logger ............................................................................................. 59

6.6.10.7 Displaying the data logger of BMS devices .......................................................... 59

6.7 Parameter setting for bus devices .................................................................................. 60

6.7.1 Operating elements for parameter setting ................................................................. 60

6.7.2 Setting the parameters for RCMS460-L ......................................................................... 61

6.7.3 Parameter setting of the CP700 using the "Settings" menu ................................. 62

6.8 Entering individual texts ....................................................................................................65

6.8.1 Enter individual texts for an RCMS460-L ...................................................................... 65

6.8.2 Displaying, filtering, exporting and importing individual texts ........................... 67

6.8.2.1 Displaying individual texts ......................................................................................... 67

6.8.2.2 Filtering entries ............................................................................................................... 67

6.8.2.3 Exporting individual texts ........................................................................................... 68

6.8.3 Editing and importing individual texts ......................................................................... 69

6.9 E-mail notification in the event of an alarm ................................................................ 71

6.9.1 Create templates: To whom and when is an e-mail to be sent ............................ 71

6.9.2 Select devices and channels that are to trigger an e-mail notification ............. 74

6.9.3 Displaying an e-mail overview ......................................................................................... 75

6.10 Using the device failure monitoring function ............................................................ 76

6.10.1 Activating/deactivating device failure monitoring function

6.10.2 Displaying overview device failure monitoring

6.11 Alarms ....................................................................................................................................... 80

6.12 Tools ........................................................................................................................................... 81

6.12.1 BMS recording ........................................................................................................................ 82

6.12.2 BMS analyser ........................................................................................................................... 83

6.12.3 BMS Log files ........................................................................................................................... 86

6.12.4 Network parameters ............................................................................................................ 86

6.12.5 Socket state ............................................................................................................................. 87

6.12.6 Software update .................................................................................................................... 88

6.12.7 Software options and licensing ....................................................................................... 90

6.12.7.1 Identifying activated software options .................................................................. 90

in the bus overview .............................................................................................................. 77

and adding devices ..............................................................................................................78

CP700_D00005_02_M_XXEN/06.2014

5

Page 6

Table of Contents

6.12.7.2 Acquiring licences for additional software options and loading the licence

file ......................................................................................................................................... 91

6.12.7.3 Activate acquired software options ......................................................................... 92

6.12.8 Modbus register ..................................................................................................................... 93

6.12.8.1 Modbus representation of device information .................................................... 93

6.12.8.2 Modbus representation of a BMS channel ............................................................ 94

6.12.9 Modbus control commands for BMS devices .............................................................. 95

6.12.10Individual texts, device failure monitoring, e-mail configuration ....................... 96

6.13 Visualisation ............................................................................................................................. 97

6.13.1 Create visualisation ............................................................................................................... 97

6.13.1.1 Creating a new view page ........................................................................................... 99

6.13.1.2 Adding a link to view pages ..................................................................................... 101

6.13.1.3 Adding new elements ................................................................................................ 102

6.13.1.4 Adding a new text line ............................................................................................... 104

6.13.1.5 Adding a new data logger ........................................................................................ 105

6.13.2 Save, export, import and exit configuration ............................................................. 106

6.13.2.1 Save and exit configuration ..................................................................................... 106

6.13.2.2 Export configuration ................................................................................................... 106

6.13.2.3 Import configuration .................................................................................................. 106

6.13.3 Using the visualisation function .................................................................................... 107

6.13.4 Open the operating manual as PDF file ..................................................................... 109

6.13.5 System visualisation .......................................................................................................... 110

6.13.5.1 Start system visualisation ......................................................................................... 110

6.13.5.2 Check the activation of the application memory ............................................. 110

6.13.5.3 Add new device to system visualisation ............................................................. 111

6.13.5.4 Change or delete the device .................................................................................... 111

6.13.5.5 Export system visualisation ...................................................................................... 112

6.13.5.6 Import system visualisation ..................................................................................... 112

6.13.5.7 Sort system visualisation ........................................................................................... 112

6.13.5.8 Use system visualisation ............................................................................................ 113

6.14 Manage Modbus devices ................................................................................................. 114

6.14.1 Adding a new Modbus device ....................................................................................... 114

6.14.2 Delete Modbus device ......................................................................................................115

6.14.3 Editing a Modbus device ................................................................................................. 115

6.14.4 Creating, editing or deleting templates ..................................................................... 115

6.14.4.1 Add new template ....................................................................................................... 116

6.14.4.2 Delete template ............................................................................................................ 116

6.14.4.3 Change template .........................................................................................................116

6.15 Manage virtual devices ..................................................................................................... 117

6.15.1 Adding a new virtual device ........................................................................................... 117

6.15.2 Deleting a virtual device .................................................................................................. 118

6

CP700_D00005_02_M_XXEN/06.2014

Page 7

Table of Contents

6.15.3 Changing a virtual device ................................................................................................ 118

6.15.4 Setting the channels of a virtual device ...................................................................... 119

7. Data access using the Modbus/TCP protocol ............................................... 121

7.1 Exception code .................................................................................................................... 121

7.2 Modbus requests ................................................................................................................ 121

7.3 Modbus responses .............................................................................................................122

7.4 Structure of an exception code ..................................................................................... 122

7.5 Modbus address structure for BMS devices .............................................................. 122

8. Process image in the memory of the CP700 ................................................. 123

8.1 Data request ......................................................................................................................... 123

8.1.1 Modbus function code ...................................................................................................... 123

8.1.2 How are memory areas organised? .............................................................................. 123

8.2 Memory scheme of the process image ...................................................................... 124

8.2.1 BMS device address assignment within the Modbus ............................................ 124

8.2.2 Memory scheme of an individual BMS device .......................................................... 124

8.2.3 Device type ............................................................................................................................ 126

8.2.4 Timestamp ............................................................................................................................. 126

8.2.5 C = Common alarm and D = Device lost (device failure) ...................................... 126

8.2.6 Channels 1 to 32 with analogue and/or digital values .......................................... 126

8.2.6.1 Float = Floating point value of the BMS channels ........................................... 127

8.2.6.2 A&T = Alarm type and test type (internal) .......................................................... 127

8.2.6.3 R&U = Range and unit ................................................................................................ 128

8.2.6.4 Channel description .................................................................................................... 129

8.2.6.5 Channel 33 to 64 .......................................................................................................... 130

8.3 Reference data records of the process image .......................................................... 131

8.3.1 Address assignment of the reference data record .................................................. 131

8.3.2 Reference value on channel 1 ........................................................................................ 131

8.3.3 Reference value on channel 2 ........................................................................................ 132

8.3.4 Explanation of how to access floating point values ............................................... 132

8.4 Channel descriptions for the process image ............................................................ 133

8.5 Modbus control commands for BMS devices ........................................................... 138

9. Monitor for Power quality ................................................................................ 141

9.1 Displaying alarms/measured values ............................................................................ 141

9.2 Triggering alarm messages in the case of events ................................................... 142

9.2.1 Making settings for events .............................................................................................. 142

9.2.1.1 Creating template for events ................................................................................... 142

9.2.1.2 Activate template for events .................................................................................... 143

CP700_D00005_02_M_XXEN/06.2014

7

Page 8

Table of Contents

9.2.2 Acknowledging alarm messages for events ............................................................. 143

9.2.3 Acknowledging alarm messages for events ............................................................. 143

9.3 Displaying a PEM…'s voltages/currents .................................................................... 144

9.4 Displaying the phasor diagram of a PEM… .............................................................. 145

9.5 Displaying harmonics by means of PEM… ............................................................... 146

9.6 Waveform recorder of a PEM575 universal measuring device .......................... 148

9.6.1 Using the waveform recorder ........................................................................................ 148

9.6.2 Setting the waveform recorder ..................................................................................... 152

9.6.3 Setting the trigger event for the waveform recorder ............................................ 153

9.6.3.1 Setting the trigger event undervoltage/overvoltage (SAG/SWELL) ......... 153

9.6.3.2 Setting the trigger event transients ...................................................................... 154

9.7 Displaying the power diagram of a PEM… ............................................................... 155

9.7.1 Set the options .................................................................................................................... 156

9.8 Data recorders and high-speed data recorders ....................................................... 157

10. Technical data ................................................................................................... 159

10.1 Data in tabular form ........................................................................................................... 159

10.2 Dimension diagram ...........................................................................................................161

10.3 Control panel cut-out ........................................................................................................ 161

10.4 Standards, approvals, certifications ............................................................................. 162

10.5 Ordering information ........................................................................................................162

10.6 Disposal .................................................................................................................................. 162

11. Troubleshooting .............................................................................................. 163

11.1 Damage in transit ............................................................................................................... 163

11.2 Malfunctions ......................................................................................................................... 163

11.2.1 What should be checked? ............................................................................................... 163

11.2.2 Fault messages with error code .................................................................................... 164

11.2.3 Frequently asked questions ............................................................................................ 164

11.2.4 Where do you get help? ................................................................................................... 164

11.2.5 Battery change ..................................................................................................................... 165

INDEX ......................................................................................................................... 167

8

CP700_D00005_02_M_XXEN/06.2014

Page 9

1. Making effective use of this document

DANGER

WARNING

CAUTION

1.1 How to use this manual

This operating manual will concern qualified experts in electrical engineering and communication technology!

To make it easier for you to understand and revisit certain sections of text and instructions in the

manual, we have used symbols to identify important instructions and information. The meaning of

these symbols is explained below:

The signal word indicates that there is a high risk danger that will result in electrocution or serious injury if not avoided.

This signal word means that there is a medium risk of danger that can lead to

death or serious injury, if not avoided.

This signal word indicates a low level risk that can result in minor or moderate

injury or damage to property if not avoided.

This symbol denotes information intended to assist the user

to make optimum use of the product.

1.2 Quick start

Connection of the CP700

If you are familiar with the installation and connection of electrical devices as well as networking,

particularly with Ethernet, you can start right away with the wiring diagram on "Connection of the

device" on page 20.

Using the web user interface

You can easily access the CP700 using a standard web browser. For details refer to page 35.

Using the Modbus/TCP functions

Information about this complex field can be found as of page 121.

CP700_D00005_02_M_XXEN/06.2014

9

Page 10

Making effective use of this document

10

CP700_D00005_02_M_XXEN/06.2014

Page 11

2. Safety instructions

DANGER

CAUTION

2.1 Work activities on electrical installations

Risk of fatal injury from electric shock

Any work on electrical installations which is not carried out properly can lead to

death and injury!

► Only skilled persons are permitted to carry out the work necessary to

install, commission and run a device or system.

Compliance with applicable regulations governing work on electrical installations, and with the

regulations derived from and associated with them, is mandatory. EN 50110 is of particular

importance in this regard.

If the device is being used in a location outside the Federal Republic of Germany, the applicable

local standards and regulations must be complied with. European standard EN 50110 can be

used as a guide.

2.2 Intended use

The Condition Monitor CP700 connects the following devices to Ethernet TCP/IP networks:

Devices on the Bender internal serial BMS bus

Bender universal measuring devices PEM… to Modbus/RTU or Modbus/TCP.

The CP700 converts alarms, measured values and statuses into Modbus/TCP protocols and HTTP.

That allows connection to Modbus/TCP networks as well as visualisation and evaluation using standard web browsers with Silverlight

TM

plugin.

The CP700 has been designed, developed and produced for normal use in the industrial sector. The

CP700 has not been designed for use bearing high risks and dangers, which can result in death, injury, serious physical harm or any other loss unless exceptionally high safety measures are ensured.

In particular, its application for the monitoring of nuclear reactions in nuclear power stations, monitoring of flight control systems, for air traffic control, control of means of mass transport, medical life

support systems, and weapon system control involve these risks.

CP700_D00005_02_M_XXEN/06.2014

The device is only suitable for use in the industrial sector. The emissions of the device may exceed the permissible limits for residential, business or commercial areas or small companies.

The CP700 is not intended for use on smartphones or

tablet PCs.

11

Page 12

Safety instructions

CAUTION

2.3 Address setting and termination

In order to ensure proper functioning of the Condition Monitor CP700, correct address assignment

and termination of the connected bus systems according to their specification is of utmost importance.

Assigning addresses that are already used by existing devices on the bus systems

concerned may cause serious malfunctions.

► Ensure correct address setting and termination of the CP700.

2.4 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender apply.

Conditions of sale and delivery can be obtained from Bender in printed or electronic format.

The five year guarantee "5forU" does not include parts subject to wear, such as

the touch screen and the battery.

12

CP700_D00005_02_M_XXEN/06.2014

Page 13

3. Product description

3.1 Scope of supply

You will receive:

The CP700

This operating manual as pdf file in the device memory,

accessible via the web user interface under "Tools" > "Manual"

A short operating instruction

A pluggable screw clamp for the voltage supply

Two RS-485 cables for the connection to the BMS bus and the Modbus/RTU, 2 m

Two terminating resistors each for BMS bus and Modbus/RTU (bus termination set)

Four mounting brackets for panel mounting

3.2 Device features

Condition Monitor for Bender BMS devices and universal measuring devices

7“ TFT WVGA Colour Display

Analogue resistive touch screen

Small mounting depth

Fanless operation

Integrated gateway to Ethernet (TCP/IP), 10/100/1000 Mbit/s

Remote access via LAN, WAN or Internet

Support of devices connected to the internal bus via Modbus/RTU or Modbus/TCP

Access to all devices connected to the BMS bus using the web server

Can be operated on Modbus/RTU

History memory for 1000 entries

12 data loggers, freely configurable with 1000 entries each

3.3 Possible applications

Clearly presented information about the status of devices and systems via 7“ touch screen

Specific system overview according to individual system description

Display und visualisation of device and system statuses via web browser

Selective e-mail notification to various user groups in the event of alarms

Support of professional visualisation programs

Observing and analysing of compatible Bender products (universal measuring devices, RCMS,

Isometer, EDS systems)

Parameter setting for devices, storing, documentation and restoring of parameters in a clear

and practice-oriented manner

Remote diagnosis, remote maintenance

CP700_D00005_02_M_XXEN/06.2014

13

Page 14

Product description

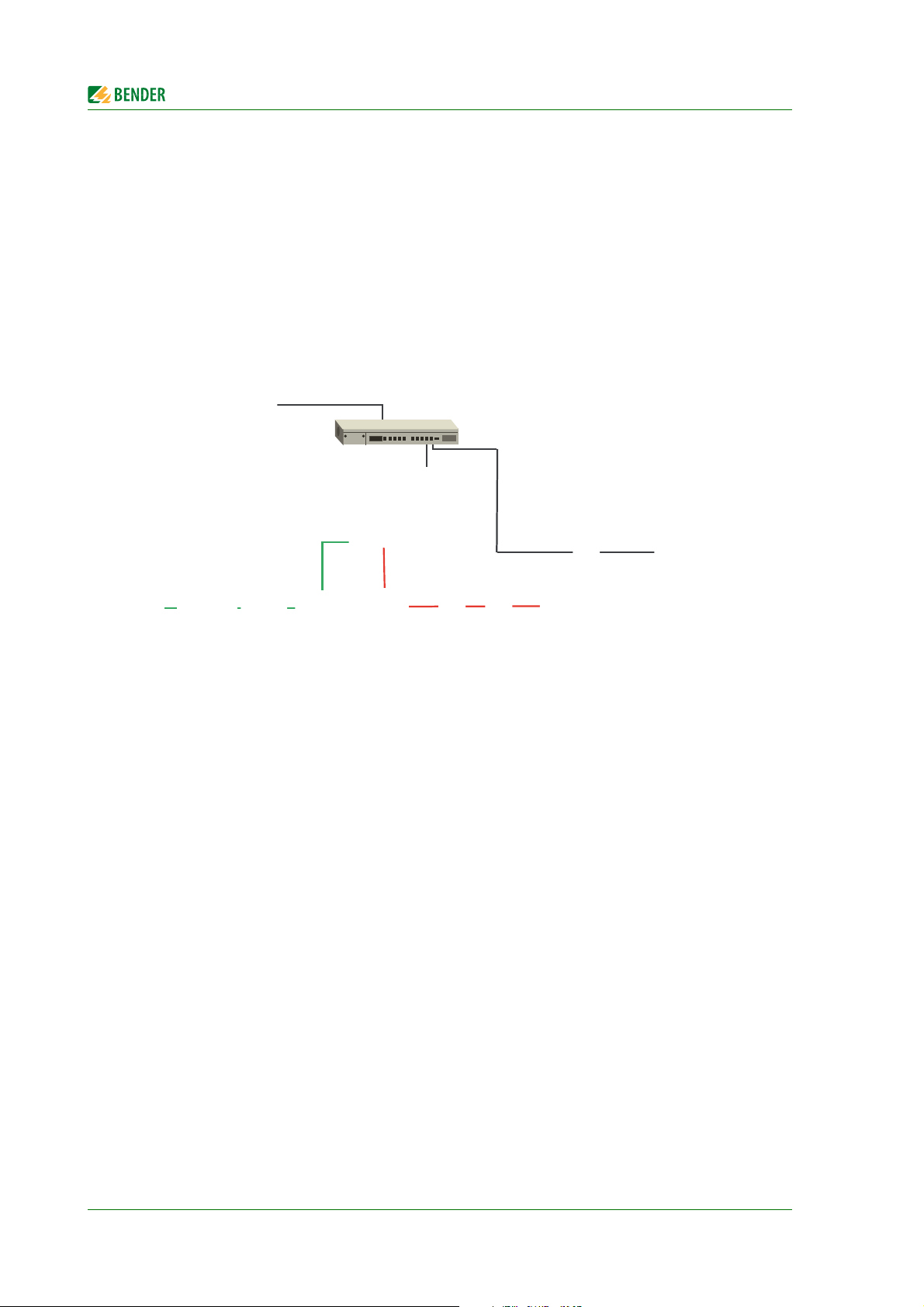

Condition

Monitor

CP700

PEM..5

PEM..3, PEM..5*

Modbus/RTU

Modbus/TCP

BMS-Bus

PC

Ethernet/TCP/IP

3.4 Description of function

3.4.1 Interfaces

The CP700 communicates with the associated devices via three different interfaces:

BMS bus (RS-485) for Bender systems such as EDS46x/49x, RCMS46x/49x and MEDICS. The

CP700 can be operated as master or slave. With the CP700 in master mode, requests can be

answered faster. The CP700 can only be operated on the internal BMS bus.

Modbus/RTU (RS-485) CP700 in master mode for Bender universal measuring devices PEM..3

and also PEM..5 with reduced functionality (*).

Modbus/TCP Ethernet) for Bender universal measuring devices PEM..5

The CP700 can usually be integrated into existing LAN structures, but can also be operated on a single PC via Ethernet/TCP/IP. The CP700 can also be used as master for Bender BMS devices and/or universal measuring devices without being connected to a PC.

3.4.2 Process image

Using the information from communication with the assigned devices, the CP700 creates and saves

a process image. This process image contains all alarms, status information and measured values of

the associated devices.

The CP700 combines the information of three different interfaces and makes it available for:

indication on the integrated touch screen

the operation of a PC via the web user interface

the transmission to external visualisation programs or PLCs via Modbus/TCP.

The CP700 provides a uniform user interface for the devices associated via different interfaces (max.

247 devices). In order to be able to identify each individual device, one individual address is available

for each device on this interface. BMS and Modbus/RTU devices receive the appropriate address for

their interface. A virtual address is assigned to Modbus/TCP devices.

3.4.3 CP700-compatible devices

For an up-to-date list of the Bender BMS devices compatible with CP700 and the universal measuring

devices PEM…. refer to:

http://www.bender-de.com/en/products/system-components/cp700-compatible-devices.html

14

CP700_D00005_02_M_XXEN/06.2014

Page 15

Product description

3.4.4 Functions available via touch screen

Display of current alarm messages including help texts

Bus overview of the assigned devices. Indication of alarm and measured values. Indication of the

interfaces of the devices in use. In case of universal measuring devices, also the indication of the

harmonics in tabular form or as a chart. Waveform recorder and graphical representation of measuring values (bar graph, phasor diagram, power triangle).

Interface settings with password protection

Operating language, selectable

3.4.5 Functions available via the web user interface

The device utilises an integrated web server which can be used to display data in a convenient way

on any PC by means of a web browser and Silverlight

In addition, it provides a Modbus/TCP server which converts data of the associated devices for a

Modbus client. Also, the CP700 contains an FTP server for file access. Functions available via the web

user interface are:

Bus overview of the associated devices (max. 247 devices).

– Indication of alarm and measured values.

– Indication of the interfaces of the devices in use.

– In case of universal measuring devices, also the indication of the harmonics in tabular form

or as a chart. Waveform recorder and graphical representation of measuring values (bar

graph, phasor diagram, power triangle).

– Parameter setting

– Device failure monitoring

– The "Backup/Report" function saves measured values and settings. Saved settings from pre-

vious configurations can be compared with the current settings made on the CP700. The

saved settings can be reloaded into the CP700.

– Assignment of individual texts for devices, measuring points (channels) and alarms.

– E-mail notifications to different user groups according to a time controlled schedule in the

event of alarms and system faults. The sender's e-mail address can be entered.

– Display of virtual devices. A virtual "measuring point" is obtained by evaluating "real" meas-

ured values of devices connected to the CP700 logically or numerically.

Manage Modbus devices

– Adding/deleting devices to/from the bus overview.

– Creating a template with selected measured values

Visualisation

– Fast and simple visualisation without any programming. Measured values or alarms can be

displayed in front of a graphic (system diagram, room plan).

– Displaying an overview page. Click to jump to another view. Return to the overview page.

From an external application (e.g. visualisation software) commands can be sent to BMS devices.

The "Modbus control commands" menu provides Modbus control commands for selected BMS

commands. These commands can be copied to the clipboard of the PC and then included in the

programming for external application.

A graphical representation for the CP700 data logger and compatible Bender devices is avail-

able. The time axis can be varied to view different periods.

TM

plug-in.

CP700_D00005_02_M_XXEN/06.2014

15

Page 16

Product description

System visualisation: Displaying several gateways (COM460IP, CP700) on one website. Display-

ing common alarms of the devices. Clicking on a device being displayed will open its web user

interface.

Displaying the CP700 operating manual

3.5 Software products used

MIT license (http://opensource.org/licenses/mit-license.php)

– jQuery-Scrollbar

–jQuery Timer Plugin

– jQuery NiceScroll Plugin

– jsmn JSON parser (http://zserge.bitbucket.org/jsmn.html)

FJCore and jqPlot under the MIT license (http://www.opensource.org/licenses/mit-license.php)

AES256 implementation:

– Copyright (c) 2007-2009 Ilya O. Levin, ?http://www.literatecode.com

– Other contributors: Hal Finney(modified to AES128)

Silk icons. This work is licensed under a Creative Commons Attribution 2.5 License.

[ http://creativecommons.org/licenses/by/2.5/ ]

GPLv2 license (http://www.gnu.org/licenses/old-licenses/gpl-2.0.html):

mongoose web server (https://code.google.com/p/mongoose/)

GPL 3 (http://code.google.com/p/rootaufs/)

(C) 2008 Kishore Nallan for DesignShack

(http://www.kishorelive.com) kishore.nc@… (jquery Keyboard (modified))

16

CP700_D00005_02_M_XXEN/06.2014

Page 17

4. Installation, connection and commissioning

If you are familiar with the configuration of computer networks, you can carry

out the connection of the CP700 yourself. Otherwise please contact your EDP

administrator!

4.1 Preliminary considerations

1. Have all the questions as regards the installation been answered by the technician responsible

for the installation?

2. Do you know the BMS address to be set?

Can CP700 be operated as the master (BMS address 1)? If apart from the CP700, an alarm indicator and test combination MK800 is connected to the internal bus, the CP700 must not have

address 1 (Master).

You will find more detailed information on the BMS topic, in particular about the wiring of bus

devices, in the separate document "BMS bus". You can download the document from the

download area of the website www.bender.de.

3. Does the computer network comprise a DHCP server?

Otherwise, the network data such as the IP address and netmask allocated by the person

responsible for the electrical installation have to be set manually.

4. Ask for the IP address of the NTP server, which is required for automatic time setting.

5. Are suitable PC hardware and software available for commissioning?

Minimum system requirements: 1.6-GHz prozessor/512 MB RAM/Windows XP/Vista/7/web

browser with Microsoft Silverlight

System requirements (recommended): Dual-Core processor/1024 MB RAM/

Windows XP/Vista/7/web browser with Microsoft Silverlight

For initial connection, the basic configuration of the CP700 is to be undertaken outside the installation, depending on the specific situation.

TM

(version 5.0 or higher).

TM

(version 5.0 and higher)

4.2 Installing the device

4.2.1 Essential information on mounting

Mounting is to be carried out with suitable equipment and tools according to the documenta-

tion.

The device must only be installed by appropriately qualified personnel in de-energised state.

Disconnect the switchboard cabinet from the power supply and protect the system against

accidental switch-on.

The general safety conditions as well as the prevailing national accident prevention regulations

are adhered to. Electrical installation is to be carried out according to all applicable local laws

(e.g. wire cross section, protection, PE connection).

The climatic conditions must be complied with. The device is only permitted to be used in

enclosed rooms. The device must not be exposed to direct sunlight.

CP700_D00005_02_M_XXEN/06.2014

17

Page 18

Installation, connection and commissioning

The device must be installed on a flat surface. While tightening the screws, irregularities may

damage the display.

The ventilation holes must not be covered.

When installing the device, the permissible mounting positions are to be observed.

Take into consideration that the wall or the sheet metal of the switchboard cabinet can hold

four times the total weight of the device.

When connecting the cables it is essential to note the bending radius.

The device should be positioned in such a way that it is visible for the user and that reflexions

on the screen are avoided as far as possible.

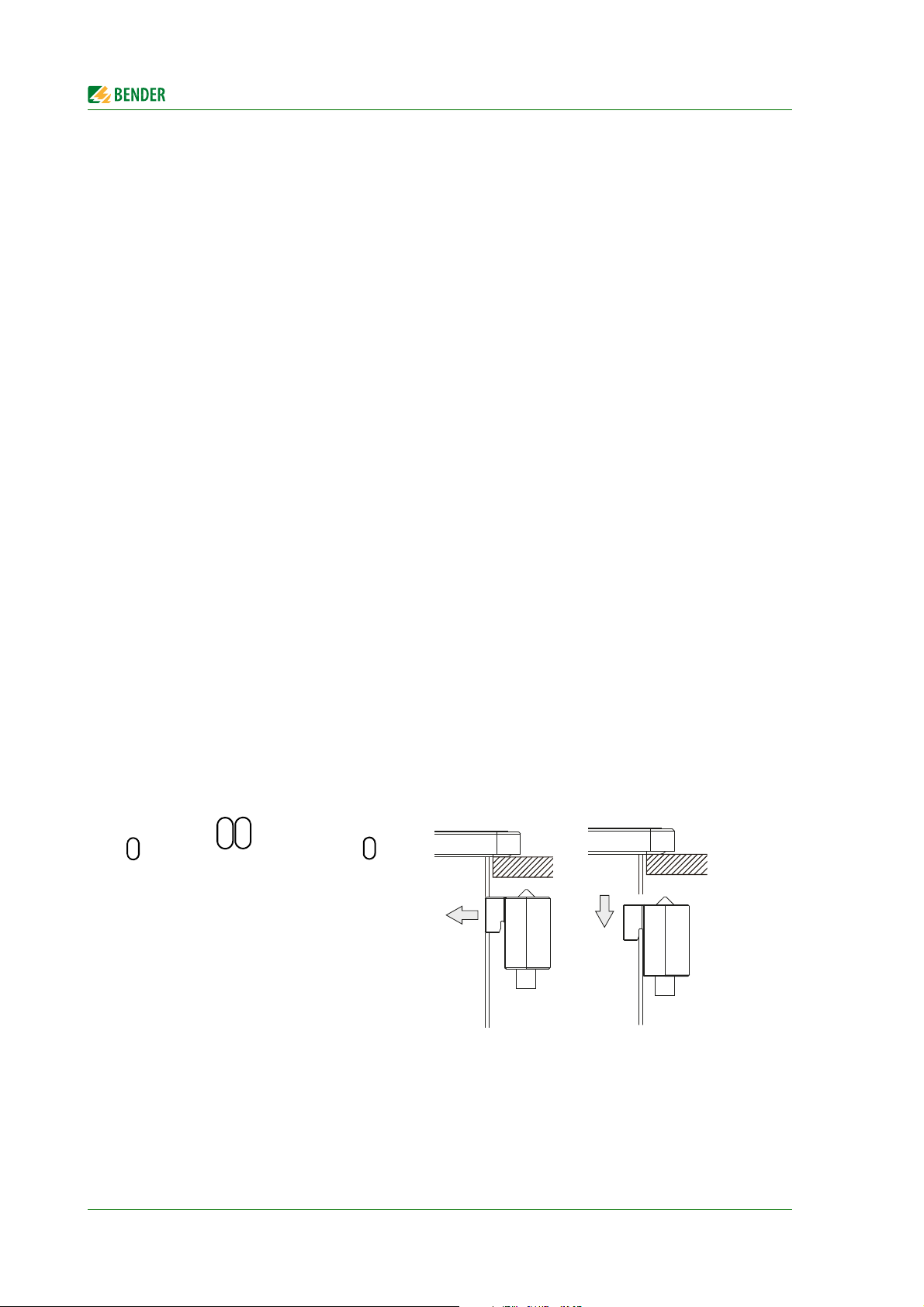

4.2.2 Type of installation

The CP700 is preferably installed into consoles and control panel doors using the mounting brackets

supplied with the device. Strength of the material to be clamped: minimum 2 mm, maximum 6 mm.

4.2.3 Practice

1. Insert the device frontally into the prepared, plane and smooth installation cut-out. The dimensions for the installation cut-outs can be found on page 161.

2. Attach the mounting brackets to the CP700. For this purpose, insert all mounting brackets into

the slots (marked with orange circles) at the CP700 and slide them down.

18

CP700_D00005_02_M_XXEN/06.2014

Page 19

Installation, connection and commissioning

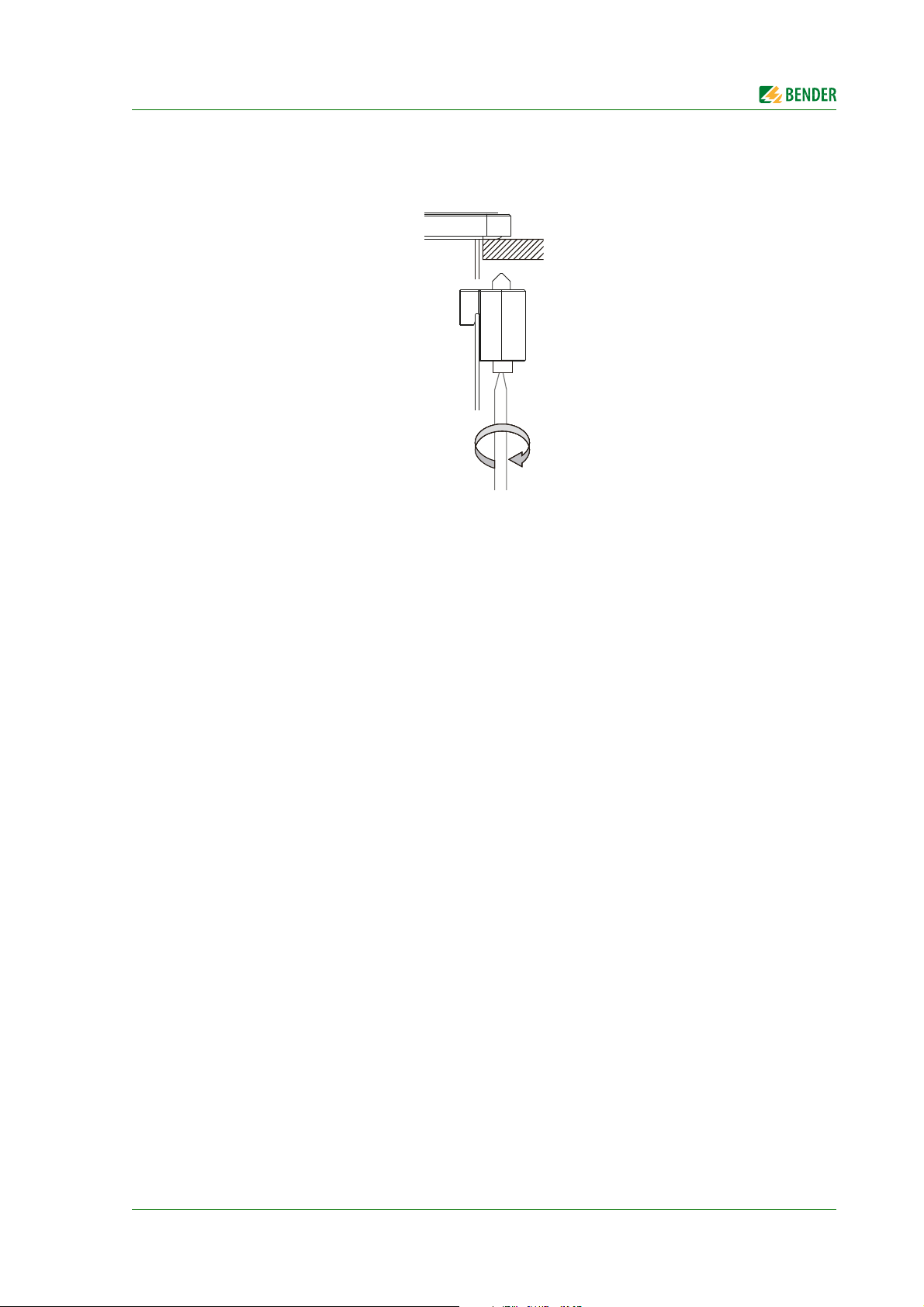

3. Fix the mounting brackets to the wall resp. to the sheet metal of the switchboard cabinet by

tightening the screws using a large flat-tip screwdriver. A tightening torque of approx. 0.5 Nm

is recommended.

CP700_D00005_02_M_XXEN/06.2014

19

Page 20

4.3 Connection of the device

15

910

234

678

4.3.1 Overview of the bus device interfaces

Installation, connection and commissioning

Key

Modbus/RTU interface. (cable included in the scope of delivery)

1

Switch for terminating resistor/bus bias voltage for Modbus/RTU interface.

2

BMS bus (Bender measuring device interface, cable included in the scope of delivery)

3

Switch for BMS bus termination/bus bias voltage.

4

USB interface, is not used

5

Connection to the supply voltage,

6

"see chapter "DC 24 V power supply" on page 21

Functional earth, see chapter "Earthing" on page 21

7

USB interfaces, are not used

8

Ethernet 10/100/1000, RJ45 socket for connection to a personal computer or to the local

9

network (hub, switch, router)

RS-232 interface, is not used

10

Details on the items 2 and 4:

"Terminating resistor/bus bias voltage" switch for Modbus/RTU interface:

Communication

mode

MASTER left activated on

Switch position

Terminating resistor/

bus bias voltage

LED

"Terminating resistor/bus bias voltage" switch for BMS interface.

Communication

mode

MASTER left activated on

Slave right deactivated off

Switch position

Terminating resistor/

bus bias voltage

20

LED

CP700_D00005_02_M_XXEN/06.2014

Page 21

Installation, connection and commissioning

1 2 3

CAUTION

4.3.2 DC 24 V power supply

The 3-pole plug required for the connection of the power supply is included in the scope of delivery.

The pin assignment is shown in the following table or is printed on the enclosure. The supply voltage

is internally protected by a permanently soldered fuse (10 A, fast-acting), so that in case of overload

(replacement of the fuse required) or wrong connection of the supply voltage the device will not be

damaged. If the fuse is damaged due to a fault, the device has to be returned to Bender for repair.

Pin Description

1 +

2 Functional earth

3-

Recommended power supply units:

Material

number/Type

0PS1025.2 B&R DC 24 V power supply unit, 2.5 A,

0PS1020.0 B&R DC 24 V power supply unit, 2 A,

1SVR427044R0200/

CP-D 24/2.5

EAN:

4016779661188

Manu-

facturer

DIN rail mounting/wall mounting

ABB Power supply unit

In: AC 100…240 V Out: DC 24 V/2.5 A,

Description

input AC 100…240 V,

WxHxD: 72 x 90 x 61 mm

input AC 100…240 V,

DIN rail mounting

WxHxD: 45 x 99 x 107 mm

DIN rail mounting

WxHxD: 71 x 91 x 57.5 mm

4.3.3 Earthing

Connect the functional earth (Pin 2) to the earth connection (e.g. switchboard

cabinet) using a cable as short as possible. Use the largest possible conductor

cross section that is permitted for the supply plug.

In addition, the earthing connection on the rear of the device has to be connected as follows.

CP700_D00005_02_M_XXEN/06.2014

21

Page 22

Installation, connection and commissioning

1

CP700

BMS

device

2

BMS

device

1

BMS

device

3

A2

A1

B2B1

15

69

BMS

BABA BA

CP700

RTU

device

2

RTU

device

1

RTU

device

3

A2

A1

B2B1

15

69

Modbus/RTU

D- D+D- D+ D- D+

BMS bus

Modbus/RTU

An earthing connection (1) is located at the rear of the CP700 for connection to a central earthing

point in the switchboard cabinet or the system where the device is to be installed. The largest possible wire cross section (minimum 2.5 mm²) should be used.

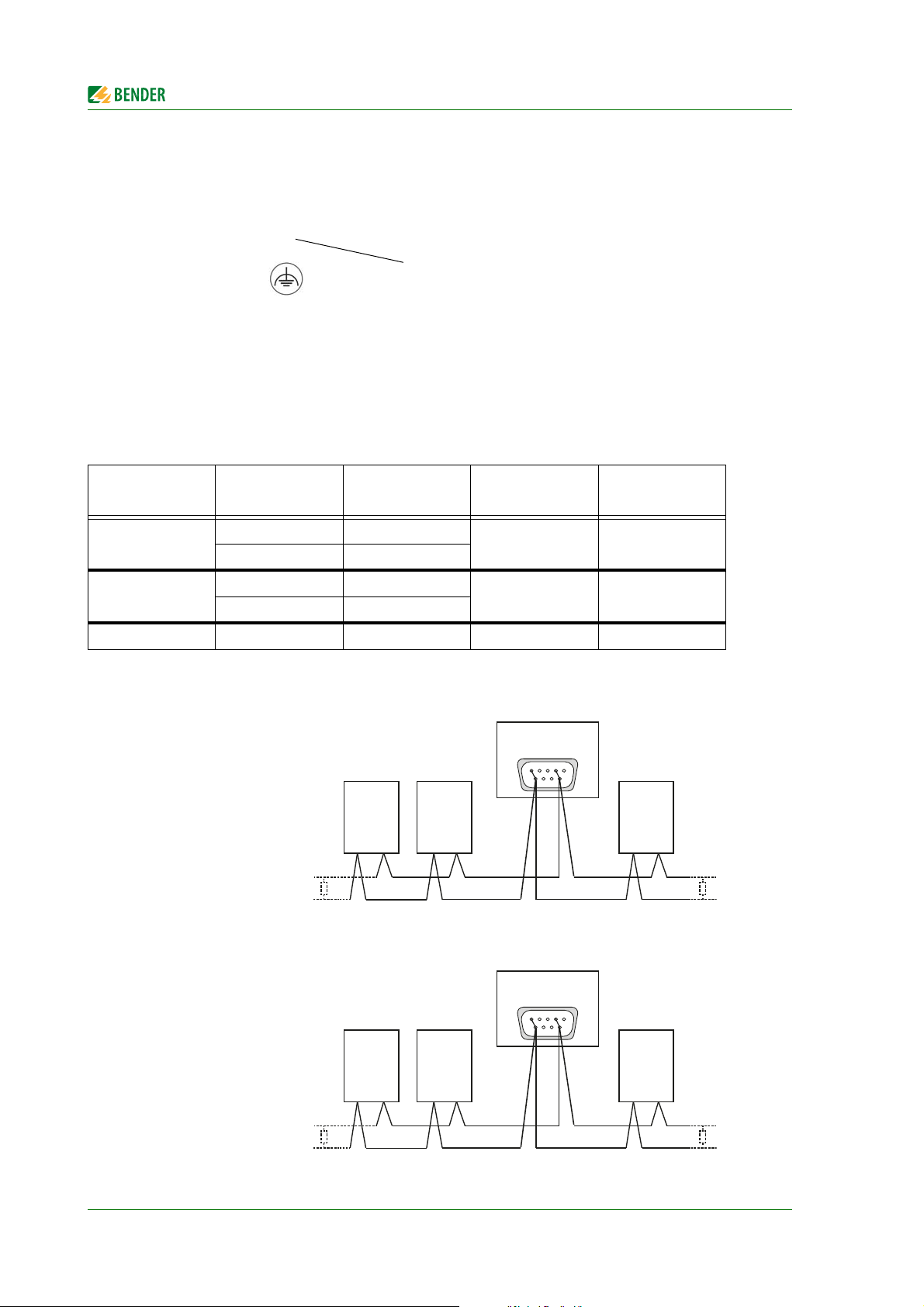

4.3.4 BMS bus, Modbus/RTU

Two connecting cables (RS-485 cable) are included in the scope of delivery. The double cable ends

facilitate the connection of the device if it is arranged in the middle of the bus. Both cables have the

same pin assignment.

Plug connector

Bridge 4--9

Bridge 1--6

Not connected shield black shield shield

Loose cable

ends

A1 white

A2 yellow

B1 brown

B2 green

Core colour

Connection to

the BMS bus

AD+

BD-

Connection to

Modbus

Wiring examples

22

CP700_D00005_02_M_XXEN/06.2014

Page 23

Installation, connection and commissioning

4.4 Commissioning

1. Switch the supply voltage on. - The "Settings" > "Interface" menu appears on the touch screen

(for details and factory settings refer to page 29).

Click on "Login" enter the settings.

2. Set the IP address.

If the connected computer network contains a DHCP server, activate the "DHCP" button. An IP

address is automatically assigned and displayed.

If the computer network does not include a DHCP server, the IP address, network mask (SN)

and standard gateway must be specified by the EDP administrator.

An IP address has been permanently assigned to the device. Therefore, deactivate the "DHCP"

button.

3. Set the BMS bus address for the CP700.

4. Set the baud rate and parity for the Modbus/RTU.

5. Set the display timeout. If no entry is made via the touchscreen of the CP700 for a predefined

time (e.g. five minutes), the screen is blanked.

The touch screen will be activated again when

– a new alarm occurs

– the number of alarms changes

– the screen is touched

6. Deactivate the "Show at startup" button. The "Settings" > "Interface" menu will no longer be

displayed during startup.

7. Confirm the changed settings with "OK". Tap on "Log out" when no more settings are to be

changed (not logged in).

CP700_D00005_02_M_XXEN/06.2014

23

Page 24

Installation, connection and commissioning

24

CP700_D00005_02_M_XXEN/06.2014

Page 25

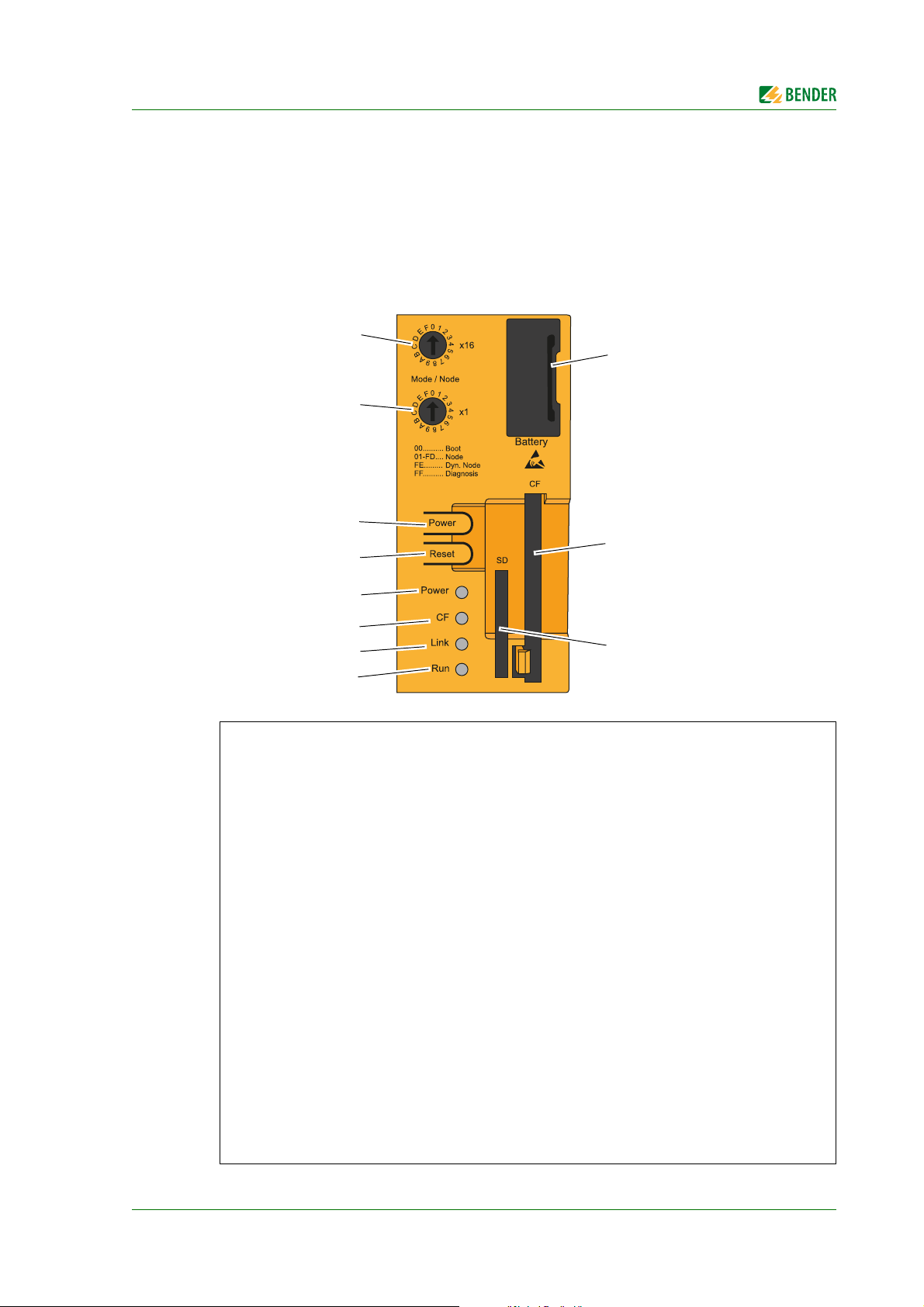

5. Display and operating elements

1

2

7

6

5

4

3

11

10

9

8

5.1 Operating elements at the rear of the device

Key

LED "Run"

1

LED "Link"

2

LED "CF"

3

LED "Power".

4

"Reset" button,

5

operation is not required. CP700 starts as soon as supply voltage is applied.

When the "Reset" button is pressed, a hardware reset will be initiated. The device restarts (cold

start). A system reset may result in data loss!

"Power" button“, operation not required. CP700 starts as soon as supply voltage is applied.

6

The function of the "Power" button is identical to that of a mains switch of current desktop personal computers:

Pressing the button for a short timewill switch the device on resp. will shut the operating system

down and switch the device off.

Pressing the button for a long timewill switch the device off without shutting down the operating system (Risk of data loss!)

"Mode/Node x16" switch, has no function

7

"Mode/Node x1" switch, has no function

8

SD memory card slot, has no function. Must not be used!

9

CompactFlash Slot. Must not be removed.

10

Battery, see chapter "Battery" on page 26

11

CP700_D00005_02_M_XXEN/06.2014

25

Page 26

Display and operating elements

LED Color Status Meaning LED indicator

On Supply voltage OK

The device has booted, the battery status is "BAD".

Green

Blinking

Information:

For more information, see see " Battery" on page 33.

On The system is in standby mode (S5: soft-off mode or S4: hiber-

nate mode - suspend-to-disk)

Red

Blinking The MTCX is running, the battery status is "BAD". The system

is in standby mode (S5: soft-off mode or S4: hibernate mode suspend-to-disk)

Faulty or incomplete BIOS, MTCX or I/O FPGA update, battery

status OK, power supply OK

Faulty or incomplete BIOS, MTCX or I/O FPGA update, battery

status OK, standby mode (S5: soft-off mode or S4: hibernate

mode - suspend-to-disk)

Faulty or incomplete BIOS, MTCX or I/O FPGA update, battery

status BAD, power supply OK

Faulty or incomplete BIOS, MTCX or I/O FPGA update, battery

status BAD, standby mode (S5: soft-off mode or S4: hibernate

mode - suspend-to-disk)

Power

Red / green Blinking

Information:

An update must be performed again.

CF Yellow On Indicates IDE drive access (CF)

On Indicates an active SDL connection on the panel plug.

An active SDL connection has been interrupted by a loss of

power in the display unit.

Link Yellow

Blinking

Information:

Check the power supply / power connector of the

connected display unit.

Green Blinking Automation Runtime booting

Handled by Automation Runtime (ARemb and ARwin).

Green On Application running

Handled by Automation Runtime (ARemb and ARwin).

Run

Red On Application in service mode

Handled by Automation Runtime (ARemb and ARwin).

CAUTION

5.1.1 Status LEDs

For the status LEDs (Power, CF, Link, Run), the following time frame is being used:

Box width: 250 ms

Interval: 500 ms; Hence, 2 boxes correspond to one interval

5.1.2 Battery

The lithium battery (3 V, 950 mAh) buffers the internal real-time clock (RTC) and is located behind the

black cover. The duration of the battery is at least four years (at 50 °C, 8.5 μA current requirements of

the supplied components and a self-discharge of 40 %). The battery is subject to wear and should be

replaced regularly (at least following the specified life span) (see chapter "Battery change" on

page 165).

5.1.3 CompactFlash card

Do not remove the CompactFlash card in order to ensure that all device properties are available!

If a replacement of the CompactFlash card becomes necessary, you have to disconnect the device from the power supply.

26

CP700_D00005_02_M_XXEN/06.2014

Page 27

Display and operating elements

CAUTION

5.2 Touchscreen

Do not apply excessive force to the screen. Do not use a ballpoint pen, a pencil or

other sharp objects to operate the touch screen. This may damage or destroy the

touch screen.

The integrated 7 inch touch screen is used at the same time for indication and operation. This is a

resistive touch screen which responds to pressure.

For operation solely use finger or a touch pen. When sliding your finger over the display (e.g. when

scrolling through the language selection), apply the necessary pressure to the display.

CP700_D00005_02_M_XXEN/06.2014

27

Page 28

Display and operating elements

4

321

98756

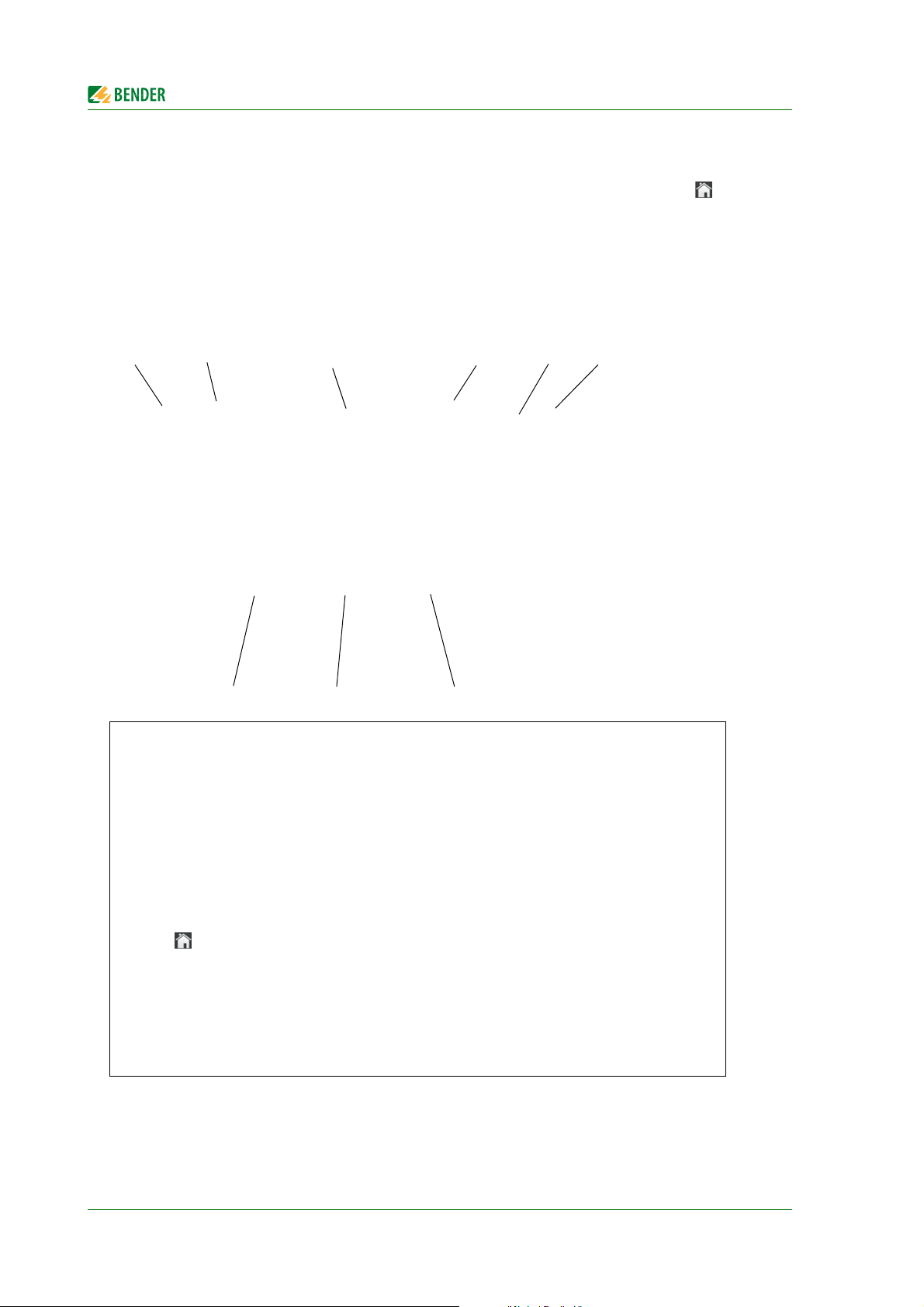

5.3 Operation via touch screen

After the initial power-up, the CP700 enters the "Settings" > "Interface" menu. By tapping the " "

button you will access the main menu. If no entry has been made via the touch screen for several

minutes and the touch screen has switched to standby mode, the CP700 will automatically switch to

the main menu.

5.3.1 Main menu

The CP700 is equipped with a touch screen. That allows intuitive operation using your finger or a

special touch screen stylus.

Key

"Bus overview" button. Shows a list of the bus devices for selection, querying and parameterisa-

1

tion. BMS-bus device, Modbus/RTU devices, Modbus/TCP devices and virtual devices are displayed in the same list.

"Alarms" button. Shows a table of the pending alarms.

2

The background of the button

- is red when an alarm exists

- is white when no alarm exists.

"Settings" button. Allows the setting of the interface and the operation language of the device.

3

"Back" button. One operating step back.

4

5

" " button. Return to the main menu.

Device type or an individually entered text in the web user interface.

6

Date and time display.

7

Display "Logged in". Settings in the "Interface" menu can only be carried out after "Login". This

8

login applies to the operation of the touch screen only.

"Alarms" button. Shows a table of the pending alarms.

9

The same function as "2", but accessible from each submenu.

28

CP700_D00005_02_M_XXEN/06.2014

Page 29

Display and operating elements

5.3.2 "Settings" menu

Select:

Interface Interface parameter setting

Language Selection of the operation language for the CP700

5.3.2.1 "Interface" menu

Display settings

The existing settings will be displayed.

If you have not logged in, you cannot change the settings. Therefore the buttons for the setting values are not active (greyed out).

CP700_D00005_02_M_XXEN/06.2014

29

Page 30

Display and operating elements

Changing settings

The settings can only be changed in the "Logged in" mode. Tap on the "Login" button.

A password can be set in the "Bus overview > "Settings" > "Password" menu via the web user interface. The password consists of a 3-digit number. If a password has been set and activated (status

"on"), the following entry field will appear:

Enter the password. Then tap on "OK". The status "Logged in" is displayed.

If no password has been set, the status "logged in" will be displayed immediately.

Tap on the entry to be changed. An entry field appears. Enter the new value and Tap on "Close".

CP700 will check the settings:

identifies a permissible setting value

identifies an impermissible setting value or a setting value that makes no sense

30

CP700_D00005_02_M_XXEN/06.2014

Page 31

Display and operating elements

Parameter settings and factory settings

Factory setting Description

IP

SN

Standard

gateway

BMS

Modbus/RTU

DHCP

Display

timeout (min)

Show on

startup

192.168.0.254 Set the IP address of CP700

255.255.0.0 Set the subnet mask of CP700

192.168.0.1 Set the IP address of the gateway

2 Set the BMS address of CP700: 1…99 (internal BMS bus)

9600 Bd, even Modbus/RTU: Select baudrate and parity

Activate/deactivate automatic IP address assignment using the

DHCP server

1

If no entry is made via the touchscreen of the CP700 for a predefined time (e.g. five minutes), the screen is blanked.

Activate/deactivate the display of the "Settings" > "Interface"

menu when starting the device.

The CP700 can also be set via the web user interface (see "Parameter setting of

the CP700 using the "Settings" menu" on page 62).

5.3.2.2 "Language" menu

Select the preferred language by tapping on the respective button in the language column. Changes

take effect immediately.

The scroll bar on the right of the touch screen shows that more languages are

listed below. Move the presently displayed content upwards to display other languages.

CP700_D00005_02_M_XXEN/06.2014

31

Page 32

Display and operating elements

5.3.3 "Alarms" menu

Indication of alarm messages. Tap on "i" for a help text about this alarm.

5.3.4 "Bus overview" menu

The bus overview lists all devices connected to the CP700 as well as all virtual devices. Here, it does not

make a difference whether these devices are connected via BMS bus, Modbus/TCP or Modbus/RTU.

Address

,

Device name

Interface

Menu

32

Description

Device address

Indicates for this device: "No alarm" or "Alarm"

Device name. If previously entered in the web user interface, also an individual text will

be displayed.

Interface of the device that is used for communication with CP700, virtual device (VD)

Button to display all available menus of the device.

Example: Display alarm/meas. values and device info of the CP700.

The display is being updated. An update is performed every 3…5 seconds.

CP700_D00005_02_M_XXEN/06.2014

Page 33

Display and operating elements

5.3.5 Displaying the device info for CP700

Select "Bus overview" > "CP700 " > "Device info".

This menu displays information about the device and the software. Please have this information to

hand if you should need to contact us for assistance by telephone.

The scroll bar on the right of the touch screen shows that more information is

given below. Move the presently displayed content upwards to display the rest of

the information.

5.3.6 Using the functions for Bender PEM… universal measuring devices

Select "Bus overview" > "PEM575 " > "Device info". For a description of these functions refer to

chapter "Monitor for Power quality" on page 141.

CP700_D00005_02_M_XXEN/06.2014

33

Page 34

Display and operating elements

34

CP700_D00005_02_M_XXEN/06.2014

Page 35

6. Web user interface of the CP700

6.1 Menu structure of the web user interface

The table below provides an overview of the menus. The menus are easy to use by means of a browser. The listing is arranged according to the menu-bar shown below.

Menu bar Submenu: Description Page

Start

Bus overview

Alarms

Tools

Deutsch Indication and selection of the operating language 38

English

Other languages..

List of bus devices for

- Selection

- Query

- Parameter setting

Alarm window Presentation of all pending alarms and data of

BMS recording Manual recording of the BMS bus activity,

BMS analyser Evaluation of the BMS recording 83

BMS log files Selection and indication of the recorded BMS-log

Network parameters Displaying and changing network parameters* 86

Socket state Indication of the socket status in the browser win-

– Presentation of the bus structure with the exist-

ing interfaces (BMS, Modbus/RTU, Modbus/TCP)

– Colour coding of the bus devices according their

alarm or operating state

– Presentation of additional data of the bus device

selected via the "Device info" button

– Menu presentation of a selected bus device

– Parameter setting of the bus device selected

– Create, export or import a back-up/report includ-

ing all parameters of the respective device

– Enter individual texts for devices and channels

– Configure e-mail notification for alarm condition

– Activate/deactivate monitoring function for

device failure

– History memory and data logger

devices sending an alarm.

saving the record to a storage media outside the

CP700.

files in the browser window*

dow*

42

42

43

45

60

46

65

71, 74

77

50, 53

80

82

86

86

CP700_D00005_02_M_XXEN/06.2014

35

Page 36

Info

Visualisation

Web user interface of the CP700

Software update Update of the system software of CP700* 88

Software options Indication of the range of functions of the corre-

sponding option and the licensing of additional

options.

Modbus register Modbus register presentation of the connected

BMS devices and PEM... Bender universal measuring

devices

Modbus control commands Commands can be sent to BMS devices and Bender

PEM... universal measuring devices from an external

application (e.g. visualisation software). The "Modbus control commands" menu provides Modbus

control commands for selected BMS commands.

These commands can be copied to the clipboard of

the PC and then included in the programming for

external application.

Manage Modbus devices This function is used to make settings for Bender

devices of the PEM… series connected via Modbus/

RTU or Modbus/TCP and to save them in a template.

Individual texts Overview of all individual texts in the web user

interface pre-defined for devices and measuring

points (channels). Individual texts can be:

- exported to CSV format,

- processed externally (e.g. in Excel®)

- and imported.

Device failure monitoring Overview of all devices for which device failure

monitoring has been activated.

E-mail overview Overview of all devices and channels for which an

e-mail notification has been configured in the event

of an alarm.

E-mail configuration Setting e-mail templates: days of the week, time of

day, e-mail addressee and texts.

Visualisation Fast and simple visualisation without any program-

ming.

Manual Function, connection, operation etc.* 109

System visualisation Several gateways (COM460IP, CP700) on one web-

site. Displaying common alarms of the devices.

Manage virtual devices Set/modify/delete virtual devices 117

Software D405 V2.5x

Software D278 V2.5x

This menu displays information about the device

and the software. Please have this information to

hand if you need to contact us for assistance by tel-

ephone.

Carrying out visualisation 107

90

93

95

114

67

78

75

71

97

110

89

* Deactivate the pop-up-blocker function to use these functions, see chapter "6.2 ".

36

CP700_D00005_02_M_XXEN/06.2014

Page 37

Web user interface of the CP700

6.2 Browser configuration

The latest version of the Windows© Internet Explorer is recommended.

In order to fully benefit from all functions of the web user interface Silverlight

on the computer being used and Java Script has to be activated too. In addition, the pop-up blocker

has to be deactivated so that all functions are available to you.

Silverlight

JavaScript Should be activated; required for backup/report, software update etc.

Pop-up blocker Should be deactivated for the IP address of the CP700; otherwise there would be no

ActiveX Not required.

Microsoft Silverlight (version 5.0 or higher) must be installed.

access to the manual , software updates, network settings etc.

6.3 Initial operation of the web user interface:

1. Select the screen resolution as follows:

Width ≥ 1000 pixels, height ≥ 900 pixels, example: 1600 x 1200

2. Start the Internet browser

3. Read the IP address from the "Settings" > "Interface" menu using the touch screen and enter

the address into your Internet browser.

4. Select the user language for the web user interface. Click the language you want to use resp.

click the appropriate flag.

5. Click on "Bus overview" to get a graphical representation of all BMS bus devices. If everything

works properly, a list of all accessible BMS devices should appear after a few seconds. In the

most unfavourable case, it can take up to 7.5 minutes to list all the accessible devices on the

internal BMS bus (CP700 = MASTER).

If, nevertheless, malfunctions occur at the bus devices, please check if you use the current software

version for the respective device (also see "CP700-compatible devices" on page 14).

TM

has to be installed

CP700_D00005_02_M_XXEN/06.2014

37

Page 38

Web user interface of the CP700

6.4 Start page and operating language

6.4.1 Opening the start page

1. Open an Internet browser.

2. Enter the IP address of the CP700 into the address line (Example: http://162.18.22.18/). The

start screen will appear:

6.4.2 Changing the language

If a German Windows operating system is installed on the PC, the web user interface will start up in

German language.

1. Click " ".

2. Click the required language resp. on the typical national flag, to select the operating language

for the graphical user interface.

Fig. 6.1: Language selection

38

CP700_D00005_02_M_XXEN/06.2014

Page 39

Web user interface of the CP700

1342

6.5 Menu bar

The user interface can largely be controlled per mouse click.

Key

Menus and functions. Example: Start = select the menu language.

1

Input field for entering the password to log in. The edit filed won't appear unless a

2

"Login" password has been assigned in the password menu of the CP700 and the password protection has been activated before.

Button "Log in" resp. "Log out".

3

Logging in is the precondition for:

- the parameter setting of the recorded bus devices

- the settings of device failure monitoring, e-mail notification, individual texts and visualisation

Logging in ensures that only one user can change parameters at a given point of time.

For detailed information about parameter setting refer to page 60.

Common alarm indication. In the example illustrated above, two alarms exist. Click this

4

button to display the alarms (the same effect as menu item "Alarms").

CP700_D00005_02_M_XXEN/06.2014

39

Page 40

Web user interface of the CP700

DANGER

6.6 Bus overview and device information

6.6.1 Creating a password protection for CP700

Risk of damage to equipment due to unauthorized access

The password protection for the CP700 protects against unauthorised access to

a limited extent only. Attackers from the Internet may still be able to read data

and to change settings.

It is absolutely necessary

- that the network is separated from the Internet

- common security mechanisms are applied (firewall, VPN access)

The device allows a staggered password protection. The necessary settings are carried out via the

web user interface. Select "Bus overview" > "CP700" > "Load menu" resp. "Reload menu" > "Settings"

> "Password".

Protec-

Password

for

tion

ex

factory

Password

ex factory

Function of the password types

Character pool for passwords

Access to the "Settings" > "Interface" menu of

Device off 000

Server off default

Login off default

FTP off default

the CP700.

Login via the touch screen of the CP700

Password: 000…999

Access to the web server of the CP700 by logging on to the web server;

Password: a...z, 0...9, minus sign, underscore

Access to the parameterisation functions by logging on to the web user interface;

Password: a...z, 0...9, minus sign, underscore

Access to the FTP server of the CP700;

Password: a...z, 0...9, minus sign, underscore

If you log in with the password types "Server" and "FTP", you have to enter the

username "user" first!

Fig. 6.2: The standard user "user" logs on to the web server or FTP server with "default"

or by entering his password.

40

CP700_D00005_02_M_XXEN/06.2014

Page 41

Web user interface of the CP700

Example:

The parameterisation function of the CP700 is to be protected by a new password. According to the

table above, a login password has to be assigned. The password protection must also be activated!

1. Select "Bus overview" > "CP700" > "Load menu" resp. "Reload menu" > "Settings" > "Password"

> "Login".

In the first line, the appropriate edit field appears after which the maximum number of characters currently used is displayed. Double-click the current password and overwrite it with your

new password. After entering the first character, the colour of the edit field changes.

2. Click the button in the status line and select "on" in order to activate the password protection.

3. Press "Save". The result of the changes will appear in the "Parameterisation overview" window.

4. Click the "Log out" button in the menu bar.

As of now, parameter setting of the CP700 can only be carried out after logging in with the

new login password.

5. For logging on again, enter the password

CP700_D00005_02_M_XXEN/06.2014

Click "Login" prior to parameterisation even if password protection is deactivated! Logging in ensures that only one user can change parameters at a given

point of time.

41

Page 42

6.6.2 Buttons for the list of bus devices

CP700 on the internal BMS bus

3421 5

8

9

7

10

6

11

Web user interface of the CP700

Key

Button to open or close the list of bus devices and the device menu. Instead of using the

1

triangular buttons it is also possible to double-click or click the button of the bus device

resp. on the sub menus.

Alarm status of the device

2

Green Operating message

Red Alarm message

Grey Bus device has not responded for several minutes.

The grey symbol will only appear if the device failure monitoring function has

been activated before. As soon as the device failure monitoring function is

deactivated, the device will disappear from the list.

Internal BMS bus address

3

Type of BMS device

4

Click this button to open the device window indicating the measured values and alarms.

For details refer to chapter "6.6.4 Querying device information"

Indication of the CP700 the web server of which was used to set up a connection (font

5

"bold" and dark background)

Interface of the device that is used for communication with CP700:

6

B BMS bus

R Modbus/RTU

T Modbus/TCP

VD Virtual device

Number of alarms of this BMS device

7

Dark background identifies the selected bus device or menu item

8

Buttons for editing individual texts, configuring e-mails and activating device failure

9

monitoring function. You have to log in to activate the buttons. For details refer to

chapter "6.5 Menu bar"

Individual text "PQ Main Building"

10

11

+ Add Modbus devices or virtual devices.

Note: BMS devices are automatically recognised.

Close all opened menus of the bus overview

42

CP700_D00005_02_M_XXEN/06.2014

Page 43

Web user interface of the CP700

6.6.3 CP700 on the internal BMS bus

The device is operated on the internal bus. Only the internal addresses and bus devices are displayed.

6.6.4 Querying device information

1. Click on "Bus overview" in the menu bar to open the menu of the same name.

2. After uploading all devices, select the respective device from the list.

The device window will open displaying the measured values and alarms.