Page 1

Manual

EN

COMTRAXX® COM462RTU

BMS-Modbus RTU gateway for the connection

of BMS-capable Bender devices

to the Modbus RTU

Software version: D415 V1.2x

COM462RTU_D00010_03_M_XXEN/04.2018

Page 2

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Grünberg • Germany

Londorfer Str. 65 • 35305 Grünberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-mail: info@bender.de • www.bender.de

© Bender GmbH & Co. KG

All rights reserved.

Reprinting and duplicating only with permission of the publisher.

Subject to change!

Photos: Bender archives

Page 3

Table of Contents

1. Important information .................................................................................... 7

1.1 How to use this manual ................................................................................. 7

1.2 Technical support: Service and support .................................................. 8

1.2.1 First level support ............................................................................................. 8

1.2.2 Repair service ..................................................................................................... 8

1.2.3 Field service ........................................................................................................ 9

1.3 Training courses ................................................................................................ 9

1.4 Delivery conditions .......................................................................................... 9

1.5 Inspection, transport and storage ........................................................... 10

1.6 Warranty and liability ................................................................................... 10

1.7 Disposal ............................................................................................................ 11

1.8 Quick-start guide ........................................................................................... 11

2. Safety instructions ......................................................................................... 13

2.1 General safety instructions ........................................................................ 13

2.2 Work activities on electrical installations ............................................. 13

2.3 Intended use ................................................................................................... 14

2.4 Address setting and termination ............................................................. 14

3. Product description ....................................................................................... 15

3.1 Scope of delivery ........................................................................................... 15

3.2 Short description ........................................................................................... 15

3.3 Device features .............................................................................................. 15

3.4 Possible applications ................................................................................... 15

3.5 Details about the Modbus RTU ................................................................ 16

4. Installation, connection and commissioning ........................................... 17

4.1 Preliminary considerations ........................................................................ 17

4.2 COM462RTU on the internal BMS bus ................................................... 18

COM462RTU_D00010_03_M_XXEN/04.2018

3

Page 4

Table of Contents

4.3 Installing the device ..................................................................................... 19

4.4 Connecting the device ................................................................................ 20

4.5 Commissioning .............................................................................................. 22

5. Operation and configuration ...................................................................... 23

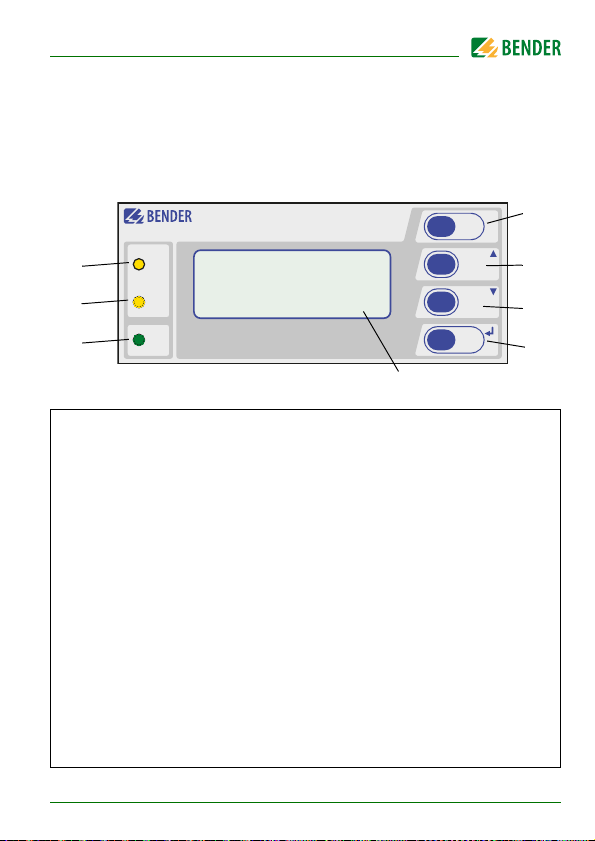

5.1 Display and operating elements .............................................................. 23

5.1.1 Automatic contrast setting for the display .......................................... 24

5.1.2 Display in standard mode .......................................................................... 24

5.1.3 Display in menu mode ................................................................................ 25

5.2 Factory settings .............................................................................................. 25

5.3 Settings on the device ................................................................................. 26

5.3.1 Operating example: Setting BMS address ............................................ 26

5.4 Display INFO list ............................................................................................. 28

6. Data access using Modbus RTU protocol .................................................. 29

6.1 Exception code ............................................................................................... 29

6.2 Modbus requests ........................................................................................... 30

6.3 Modbus responses ........................................................................................ 30

6.4 Structure of the exception code .............................................................. 31

6.5 Modbus address structure for BMS devices ......................................... 31

7. Modbus process image in the memory of the COM462RTU ................. 33

7.1 Querying data ................................................................................................. 33

7.1.1 Modbus function code ................................................................................ 33

7.1.2 How are the memory areas organised? ................................................ 33

7.2 Memory scheme of the process image ................................................. 35

7.2.1 BMS device address assignment on the Modbus .............................. 35

7.2.2 Memory scheme of an individual BMS device .................................... 36

7.2.3 Device type ...................................................................................................... 38

7.2.4 Timestamp ....................................................................................................... 39

7.2.5 Common alarm and device failure .......................................................... 39

7.2.6 Channels 1 to 32 with analogue and/or digital values .................... 40

7.2.6.1 Float = Floating point value of the BMS channels .................... 40

4

COM462RTU_D00010_03_M_XXEN/04.2018

Page 5

Table of Contents

7.2.6.2 AT&T = Alarm type and test type (internal/external) .............. 41

7.2.6.3 R&U = Range and unit ......................................................................... 43

7.2.6.4 Channel description ............................................................................ 45

7.2.6.5 Channel 33 to 64 ................................................................................... 46

7.3 Reference data records of the process image .................................... 47

7.3.1 Address assignment of the reference data record ............................ 47

7.3.2 Reference value on channel 1 ................................................................... 48

7.3.3 Reference value on channel 2 ................................................................... 49

7.3.4 Explanation of how to access floating point values ......................... 49

7.4 Channel descriptions for the process image ....................................... 51

7.5 Modbus control commands ...................................................................... 63

8. Technical data ................................................................................................. 67

8.1 Tabular data .................................................................................................... 67

8.2 Dimension diagram ...................................................................................... 69

8.3 Standards, approvals, certifications ........................................................ 69

8.4 Ordering details ............................................................................................. 70

9. Troubleshooting ............................................................................................ 71

9.1 Malfunctions ................................................................................................... 71

9.1.1 What should be checked? .......................................................................... 71

9.1.2 Where to find help? ...................................................................................... 71

INDEX ..................................................................................................................... 73

COM462RTU_D00010_03_M_XXEN/04.2018

5

Page 6

Table of Contents

6

COM462RTU_D00010_03_M_XXEN/04.2018

Page 7

1. Important information

DANGER

WARNING

CAUTION

1.1 How to use this manual

This manual is intended for qualified personnel working in

electrical engineering and electronics!

Always keep this manual within easy reach for future reference.

To make it easier for you to understand and revisit certain sections in this manual, we have used symbols to identify important instructions and information.

The meaning of these symbols is explained below:

This signal word indicates that there is a high risk of danger,

that will result in death or serious injury if not avoided.

This signal word indicates a medium risk of danger that can

lead to death or serious injury, if not avoided.

This signal word indicates a low-level risk that can result in

minor or moderate injury or damage to property if not

avoided.

This symbol denotes information intended to assist the user

in making optimum use of the product.

COM462RTU_D00010_03_M_XXEN/04.2018

7

Page 8

Important information

This manual has been compiled with great care. It might nevertheless contain

errors and mistakes. Bender cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this manual.

1.2 Technical support: Service and support

For commissioning and troubleshooting Bender offers you:

1.2.1 First level support

Technical support by phone or e-mail for all Bender products

Questions concerning specific customer applications

Commissioning

Troubleshooting

Telephone: +49 6401 807-760*

Fax: +49 6401 807-259

In Germany only: 0700BenderHelp (Tel. and Fax)

E-mail: support@bender-service.de

1.2.2 Repair service

Repair, calibration, update and replacement service for Bender products

Repairing, calibrating, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices in the event of faulty or incorrectly

delivered Bender devices

Extended guarantee for Bender devices, which includes an in-house

repair service or replacement devices at no extra cost

Telephone: +49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (sales)

Fax: +49 6401 807-789

E-mail: repair@bender-service.de

8

COM462RTU_D00010_03_M_XXEN/04.2018

Page 9

Important information

Please send the devices for repair to the following address:

Bender GmbH, Repair-Service,

Londorfer Straße 65,

35305 Grünberg

1.2.3 Field service

On-site service for all Bender products

Commissioning, parameter setting, maintenance, troubleshooting for

Bender products

Analysis of the electrical installation in the building (power quality test,

EMC test, thermography)

Training courses for customers

Telephone: +49 6401 807-752**, -762 **(technical issues)

+49 6401 807-753** (sales)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Internet: www.bender-de.com

*Available from 7.00 a.m. to 8.00 p.m. 365 days a year (CET/UTC+1)

**Mon-Thurs 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m.

1.3 Training courses

Bender is happy to provide training regarding the use of test equipment.

The dates of training courses and workshops can be found on the Internet at

www.bender-de.com -> Know-how -> Seminars.

1.4 Delivery conditions

Bender sale and delivery conditions apply.

COM462RTU_D00010_03_M_XXEN/04.2018

9

Page 10

Important information

For software products, the "Softwareklausel zur Überlassung von StandardSoftware als Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen

Lieferbedingungen für Erzeugnisse und Leistungen der Elektroindustrie"

(software clause in respect of the licensing of standard software as part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband

Elektrotechnik- und Elektronikindustrie e.V.) (German Electrical and Electronic

Manufacturers' Association) also applies.

Sale and delivery conditions can be obtained from Bender in printed or electronic format.

1.5 Inspection, transport and storage

Inspect the dispatch and equipment packaging for damage and compare the

contents of the package with the delivery documents. In the event of damage

in transit, please contact Bender immediately.

The devices must only be stored in areas where they are protected from dust,

damp, and spray and dripping water, and in which the specified storage temperatures can be ensured.

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to

property are excluded if they can be attributed to one or more of the following causes:

Improper use of the device.

Incorrect mounting, commissioning, operation and maintenance of the

device.

Failure to observe the instructions in this operating manual regarding

transport, commissioning, operation and maintenance of the device.

Unauthorised changes to the device made by parties other than the

manufacturer.

Non-observance of technical data.

Repairs carried out incorrectly and the use of replacement parts or

accessories not approved by the manufacturer.

10

COM462RTU_D00010_03_M_XXEN/04.2018

Page 11

Important information

Catastrophes caused by external influences and force majeure.

Mounting and installation with device combinations not recom-

mended by the manufacturer.

This operating manual, especially the safety instructions, must be observed by

all personnel working on the device. Furthermore, the rules and regulations

that apply for accident prevention at the place of use must be observed.

1.7 Disposal

Abide by the national regulations and laws governing the disposal of this device. Ask your supplier if you are not sure how to dispose of the old equipment.

The directive on waste electrical and electronic equipment (WEEE directive)

and the directive on the restriction of certain hazardous substances in electrical and electronic equipment (RoHS directive) apply in the European Community. In Germany, these policies are implemented through the "Electrical and

Electronic Equipment Act" (ElektroG). According to this, the following applies:

Electrical and electronic equipment are not part of household waste.

Batteries and accumulators are not part of household waste and must

be disposed of in accordance with the regulations.

Old electrical and electronic equipment from users other than private

households which was introduced to the market after 13th August 2005

must be taken back by the manufacturer and disposed of properly.

For more information on the disposal of Bender devices, refer to our

homepage at www.bender-de.com -> Service & support.

1.8 Quick-start guide

Connection of the COM462RTU

If you are familiar with the installation and connection of electrical devices,

particularly with Modbus RTU, you can start right away with the wiring diagram on page 20.

It may also be helpful to refer to the block diagrams representing an application example with an internal BMS bus (BMS=Bender measuring device interface) on page 18.

COM462RTU_D00010_03_M_XXEN/04.2018

11

Page 12

Important information

Using the Modbus RTU functions

Information about this field can be found from page 29 onwards.

12

COM462RTU_D00010_03_M_XXEN/04.2018

Page 13

2. Safety instructions

DANGER

2.1 General safety instructions

Part of the device documentation in addition to this manual is the enclosed "

Safety instructions for Bender products".

2.2 Work activities on electrical installations

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

If the device is used outside the Federal Republic of Germany, the applicable

local standards and regulations must be complied with. The European standard EN 50110 can be used as a guide.

COM462RTU_D00010_03_M_XXEN/04.2018

13

Page 14

Safety instructions

CAUTION

2.3 Intended use

The BMS-Modbus RTU gateway COM462RTU connects the serial Bender BMS

bus to the serial Modbus RTU. The gateway converts alarms, measured values

and statuses from the BMS bus to Modbus RTU. Control commands can be

converted from Modbus RTU to BMS bus.

This allows connection to Modbus networks. The gateway is operated on the

internal BMS bus.

2.4 Address setting and termination

In order to ensure proper functioning of the BMS-Modbus RTU gateway

COM462RTU, correct address assignment and termination of the BMS bus and

the Modbus RTU is of utmost importance.

Assigning addresses that are already used by existing devices

in the BMS or Modbus RTU networks concerned may cause

serious malfunctions.

Ensure correct address setting and termination of the COM462RTU. For details

refer to "Commissioning" on page 22.

Interface on the Modbus RTU side

The COM462RTU is always operated as slave on the Modbus

RTU side. Therefore, the COM462RTU and its Modbus RTU

has to be communicated to the Modbus RTU master.

Interface on the BMS side:

COM462RTU can be operated as master or slave.

14

COM462RTU_D00010_03_M_XXEN/04.2018

Page 15

3. Product description

3.1 Scope of delivery

You will receive:

the COM462RTU

an operating manual

3.2 Short description

The BMS-Modbus RTU gateway COM462RTU contains a Modbus RTU slave

that converts BMS data for a Modbus master.

A setting menu makes it possible to configure the COM462RTU using the setting menu (see "Commissioning" on page 22).

3.3 Device features

Setting of address data for the BMS bus and Modbus RTU and date and

time setting using the internal operating menu.

Time synchronisation for all BMS bus devices

Operation on the internal BMS bus

Modbus RTU data access to the internal BMS bus, max. 150 BMS

devices

Commands can be sent from an external application (e.g. visualisation

software) to BMS devices and measured values read.

3.4 Possible applications

The use of professional visualisation programs by converting BMS data

to Modbus RTU protocols.

Observing and analysing Bender products that support communica-

tion, such as RCMS, EDS and MEDICS® systems.

COM462RTU_D00010_03_M_XXEN/04.2018

15

Page 16

Product description

3.5 Details about the Modbus RTU

The Modbus RTU (Remote Terminal Unit) field bus has been specified by Modicon, a company under the Schneider Automation brand and made available

to the market license-free.

Modbus uses the serial hardware interface RS-485 and communicates via a

two-wire, twisted copper wire. A transmission rate of 19200 baud is s tandard.

Key data:

Master-slave communication

Up to 32 bus devices per network, or up to 247 bus devices (with

repeater)

Baud rate between 1200 and 57600 bit/s

Diagnostics mechanisms

16

COM462RTU_D00010_03_M_XXEN/04.2018

Page 17

4. Installation, connection and commissioning

DANGER

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

If you are familiar with the configuration of Modbus RTU

networks, you can carry out the connection of the

COM462RTU by yourself. Otherwise please contact your

EDP administrator!

4.1 Preliminary considerations

1. Have all the questions as regards the installation been answered by the

technician responsible for the installation?

2. The device is operated on the internal bus. Is the BMS address to be set

known?

If, apart from the COM462RTU, an alarm indicator and test combination

MK800 is connected to the internal bus, the COM462RTU must not

have the address 1 (master).

You will find more detailed information on the BMS topic, in particular

about the wiring of bus devices, in the separate document "BMS bus".

COM462RTU_D00010_03_M_XXEN/04.2018

17

Page 18

Installation, connection and commissioning

COM462RTU

D+ D- D- D-D+ D+

D-D+

Modbus RTU

You can download the document from the download area of the website www.bender-de.com.

3. Is the Modbus RTU address to be set known?

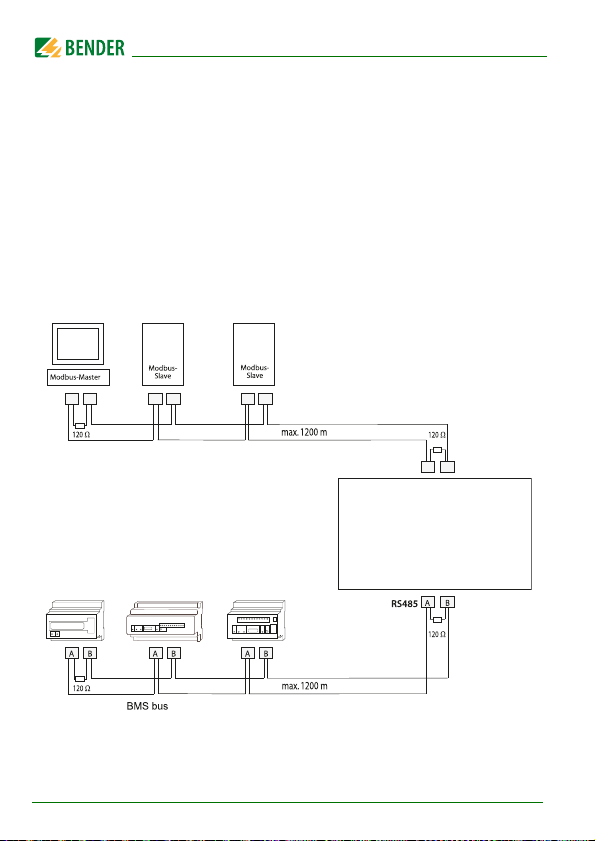

4.2 COM462RTU on the internal BMS bus

Bender systems such as EDS46x/49x, RCMS46x/49x and MEDICS communicate with each other via the Bender measuring device interface BMS.

The BMS-Modbus RTU gateway COM462RTU provides the coupling between

the BMS bus and Modbus RTU networks. The following block diagram illustrates the operation of the gateway in an internal BMS bus.

Fig. 4.1: Block diagram of a coupling between an internal BMS bus

and Modbus RTU

18

COM462RTU_D00010_03_M_XXEN/04.2018

Page 19

Installation, connection and commissioning

WARNING

Internal and external BMS bus

The majority of Bender devices communicate via the interna l

BMS bus.

Individual devices, such as MK800, TM800 or Bender panels

can communicate via both the internal BMS bus (BMS i) and

the external BMS bus (BMS e).

The BMS-Modbus RTU gateway COM462RTU can only

communicate via the internal BMS bus (BMS i).

4.3 Installing the device

Possible methods of mounting:

DIN rail mounting

Screw mounting with 2 x M4 (dimension diagram on page 69)

When installing the device, please take into consideration

that the device is only to be used in locations that are

protected from unauthorised entry! This can be installation

in a switch cabinet, for example.

COM462RTU_D00010_03_M_XXEN/04.2018

19

Page 20

Installation, connection and commissioning

4.4 Connecting the device

For UL applications, the following is to be observed:

– Supply voltage U

– Maximum ambient temperature: 55°C

– For use in pollution degree 2 environments

– Use 60/70 °C copper lines only

– Tightening torque for terminals: 0.5…0.6 Nm

Connect the terminals and sockets on the COM462RTU according to the wiring diagram.

U

S

: see nameplate and ordering details

s

20

6 A

6 A

A1

A2

A1 A2

GND

IN2

IN1

1/2

ALARM

COM

ON MENU

GND

IN4

IN3

3/4

A

BMS-Bus

RS-485

COM462RTU_D00010_03_M_XXEN/04.2018

11

AMB

BMB

B

AMB BMB

Modbus RTU

RS-485

14

ESC

INFO

RMB

(AMB, BMB)

Page 21

Installation, connection and commissioning

Terminal Description

A1, A2

A, B

A

MB, BMB

R

on/off

(A, B)

R

MB

on/off

(A

MB, BMB)

IN1,

GND1/2,

IN2

11, 14

IN3,

GND3/4,

IN4

Connection to the supply voltage, 6 A fuse recommended,

two-pole fuses should be used in IT systems.

For UL and CSA applications, it is mandatory to use 5 A fuses.

Connection to the BMS bus (internal) with shielded cable

(e.g. J-Y(St)Y 2x0.8).

Connection Modbus RTU with shielded cable

(e.g. J-Y(St)2x0.8).

Switch for BMS bus termination. When the device is installed

at the end of the bus, set the terminating switch to "on".

Switch for Modbus RTU termination. When the device is

installed at the end of the bus, set the terminating switch to

"on".

Currently has no function (digital inputs)

Currently has no function (alarm relay K1)

Currently has no function (digital inputs)

COM462RTU_D00010_03_M_XXEN/04.2018

21

Page 22

Installation, connection and commissioning

4.5 Commissioning

1. Apply the supply voltage to the COM462RTU. The green "ON" LED

lights up.

2. Set language and time.

3. Set the BMS bus. The COM462RTU is operated on the internal BMS bus.

4. Set the Modbus RTU.

For details about the settings, refer to the chapter "Settings on the device" on

page 26.

22

COM462RTU_D00010_03_M_XXEN/04.2018

Page 23

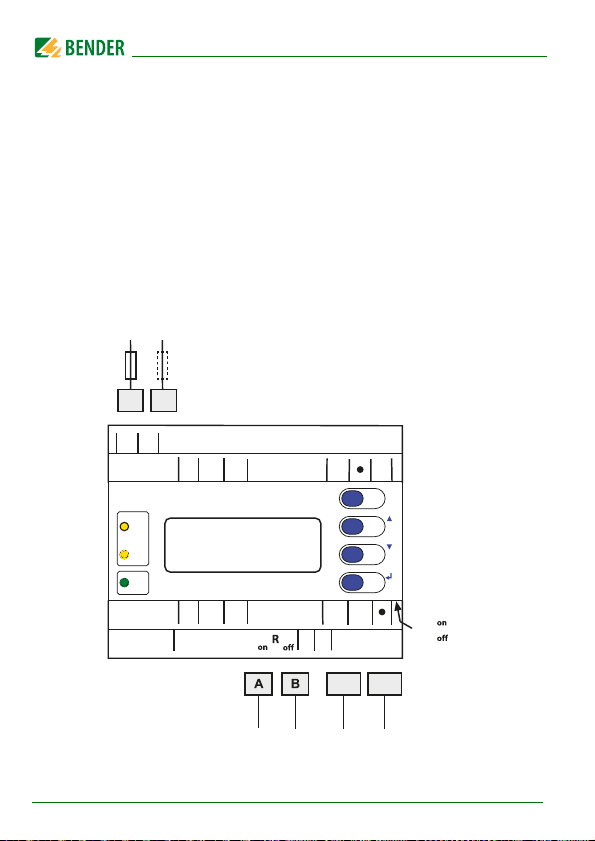

5. Operation and configuration

1

2

3

4

5

6

7

8

5.1 Display and operating elements

COMTRAXX®

Legend

"ON“ LED lights when supply voltage is applied.

1

"COM" LED lights when the gateway is responding to BMS

2

requests.

"ALARM“ LED, lights to signal an internal device error on the

3

COM462RTU.

"INFO" button, to query the COM462RTU for device-specific infor-

4

mation.

"ESC" button to exit the menu function without changing parameters.

5

"" button: to move up in the menu, to increase values

6

"" button: to move down in the menu, to decrease values

"MENU" button for starting and exiting the menu.

7

↵" button to confirm parameter change.

"

LC display for standard and menu mode.

8

COM462

ALARM

COM

ON MENU

COM462RTU_D00010_03_M_XXEN/04.2018

ESC

INFO

23

Page 24

Operation and configuration

5.1.1 Automatic contrast setting for the display

The display contrast control is factory set to an optimum value. In exceptional

cases, it may be necessary to adjust the contrast manually.

Press and hold the buttons "ESC" and "↵" simultaneously. All available con-

trast modes are continuously indicated in an infinite loop: minimum contrast,

maximum contrast, no contrast (lasting some seconds), then the same cycle

starts again. If the button "" is additionally pressed, the contrast modes will

be displayed in the opposite direction.

Release the button as soon as the desired level of contrast is reached.

5.1.2 Display in standard mode

Network-related parameters will be indicated.

COM462RTU

1

Address:1

2

Modbus:240

3

22.06.2013 12:34

4

Legend

Device type

1

BMS address of the COM462RTU

2

Modbus address of the COM462RTU

3

Current date and time

4

24

COM462RTU_D00010_03_M_XXEN/04.2018

Page 25

Operation and configuration

5.1.3 Display in menu mode

Use the "MENU" button to switch to the Menu mode.

Exit

1. Settings

2. Info

A blinking cursor supports menu navigation.

You can access the individual menus by means of the "" or "" but-

ton.

Press the "↵" button to confirm the selection of a menu or any setting

you changed.

To leave the respective menu level or discard a setting which is not

confirmed yet, press the "ESC" button.

Menu mode is exited if no button is pressed for longer than

five minutes.

Menu item Function Page

Exit Exit menu mode

1.Settings Make the necessary settings for this device 26

2.Info Display information on device type and

firmware versions. The same information as

indicated in the standard mode when

pressing the "INFO" button.

5.2 Factory settings

All factory settings you will find in the table on page 26.

COM462RTU_D00010_03_M_XXEN/04.2018

28

25

Page 26

Operation and configuration

5.3 Settings on the device

The menu is divided into three levels. All menu items listed in the table can be

called up via the main menu item "1. Settings" in the top menu level. All control buttons are explained on page 23.

5.3.1 Operating example: Setting BMS address

The following example shows the operating principle. All settings are carried

out in the same way.

1. Press the "MENU" button on the COM462RTU

2. Select "1. Settings" > "1. Interface" > "1. Address". The factory-set BMS

address will be displayed and can be changed now.

3. Modify the addresses using the button "" or "".

4. Confirm the modified BMS address with "↵".

Menu

level 2

Menu

level 3

Fac tor y

setting

Description

1. Interface 1. Address 2 Set the BMS address of

COM462RTU: 1…99 (internal BMS

bus)

2. Interval 2 s Set the cycle time 1…3s for the

sequence:

- Querying alarms in the BMS bus

- Querying new bus devices

- Offering the BMS master function

3. Failure

monitoring

5

Number of BMS bus cycles until a

BMS device failure is signalled. The

setting is only effective when the

COM462RTU has the master function on the BMS bus (address 1).

Adjustable cycles: 1…10

26

COM462RTU_D00010_03_M_XXEN/04.2018

Page 27

Operation and configuration

Menu

level 2

2. Modbus 1. Address 2 Set the Modbus RTU address for

3. Language

4. Clock 1. Format d.m.y Date format: m-d-y/d.m.y

5. Password

Menu

level 3

2. Baud rate 19200 Set the baud rate

3. Parity even Set the parity

4. Control off Switch on or switch off the control

1. English Deutsch Selection of the operating language

2. Deutsch

3. Français

2. Date 01.01.2010 Date

3. Time 00:00 Time

4. Summertime

1. Password 000 Enter/change password: 0…999

2. Status

Fac tor y

setting

Description

COM462RTU: 2…247

commands via Modbus

off Select Central European Summer

Time:

off = Function switched off

DST = Automatic switchover, USA,

CDN

CEST = Automatic switchover, Central Europe

on = Set time zone +1 h

off Enable/disable password protection

for parameter setting via the buttons of the COM462RTU

COM462RTU_D00010_03_M_XXEN/04.2018

27

Page 28

Operation and configuration

Menu

level 2

6. Service For authorised Bender Service personnel only.

Menu

level 3

Fac tor y

setting

Description

5.4 Display INFO list

Open the "INFO" menu:

In standard mode: press the "INFO" button or

In menu mode: select function "2. Info"

COM462RTU

Address:1

Device:B95061022

S:0123456789

This menu displays information about the device and the software. Navigate

in the list using the "" resp. the "" button.

1. Name of the device

2. BMS address

3. Order number

4. Serial number

5. Software version

6. Manufacturer's address

Please have this information to hand if you need to contact us for assistance

by telephone.

28

COM462RTU_D00010_03_M_XXEN/04.2018

Page 29

6. Data access using Modbus RTU protocol

Request to the COM462RTU are sent using the function code 0x03 (read several registers). The COM462RTU generates a function-related response and returns it.

6.1 Exception code

If a request cannot be answered for whatever reason, the COM462RTU sends

a so-called exception code with which possible faults can be narrowed down.

Exception

code

0x01

0x02

0x03

0x04

0x05

0x06

0x08

0x0A

0x0B

Description

Impermissible function

Impermissible data access

Impermissible data value

Slave device error

Acknowledgement of receipt (answer will be time-delayed)

Request not accepted (repeat request, if necessary)

Memory: Parity Error

Gateway path not available

Gateway error

COM462RTU_D00010_03_M_XXEN/04.2018

29

Page 30

Data access using Modbus RTU protocol

6.2 Modbus requests

The required words of the process image can be read from the "Holding registers" in the COM462RTU using the function code 0x03. For this purpose, the

start address and the number of the registers to be read out have to be entered.

A complete bus image including all devices and device parameters is stored

in these "Holding registers". This image represents the current statuses and

values of up to 150 BMS devices for each monitored internal BMS bus. The operating manuals of the devices indicate which channel contains which information. Example: In the table below, Words 0 and 1 are to be read out from

the "Holding registers“ 0x100 and 0x101.

Byte Name Example

Byte 0 BMS address of the COM462RTU 0x02

Byte 1 Function code 0x03

Byte 2, 3 Start address 0x01 00

Byte 4, 5 Number of registers 0x00 02

Byte 6, 7 CRC16 0x12 34

6.3 Modbus responses

The responses consist of 2 bytes per register.

Byte Name Example

Byte 0 BMS address of the COM462RTU 0x02

Byte 1 Function code 0x03

Byte 2 Number of data bytes 0x04

Byte 3…6 Information 0xAB CD 01 23

Byte 7, 8 CRC16 0x12 34

30

COM462RTU_D00010_03_M_XXEN/04.2018

Page 31

Data access using Modbus RTU protocol

6.4 Structure of the exception code

Byte Name Example

Byte 0 BMS address of the COM462RTU 0x02

Byte 1 Function code (0x03) + 0x80 0x83

Byte 2 Data 0x04

Byte 3, 4 CRC16 0x12 34

6.5 Modbus address structure for BMS devices

Function Address range

Device type 0x00…0x09 20 bytes 10 words

Timestamp 0x0A…0x0D 8 bytes 4 words

Common alarm 0x0E

No BMS bus connection

Unused 0x0F 2 bytes 1 word

Channel 1…32 0x10…0x8F 32 x 8 bytes 128 words

Alarm and test

Channel 33…64

COM462RTU_D00010_03_M_XXEN/04.2018

(high byte)

0x0E

(low byte)

0x90…0xFC 218 x 8 bytes 109 words

Number of

bytes

1 byte 0.5 words

1 byte 0.5 words

Number of

words

31

Page 32

Data access using Modbus RTU protocol

32

COM462RTU_D00010_03_M_XXEN/04.2018

Page 33

7. Modbus process image in the memory of the COM462RTU

The device holds a process image in memory. This image represents the curren t sta tuses and v alue s of u p to 15 0 BMS devices for each monitored internal

BMS bus.

7.1 Querying data

7.1.1 Modbus function code

The memory in the COM462RTU can be read using the Modbus function 0x03

(read several registers). The volume of the queried data depends on the

number of bytes selected in the Modbus client used. Up to 125 words (0x7D)

can be read with a single query.

An individual addressable byte, such as the set bit for a saved common alarm,

can also be read.

7.1.2 How are the memory areas organised?

Memory utilisation Start address

Reference values

for test purposes

Process image 0x0100 0x95FF 0x9500

Unused 0x96FF 0xFFFF 0x6900

COM462RTU_D00010_03_M_XXEN/04.2018

0x0000 0x00FF 0x0100

End of

memory area

Size of memory

area

33

Page 34

Modbus process image in the memory of the COM462RTU

In some Modbus clients, an offset of 1 must be added to the

register addresses.

Example: process image start address = 0x0101.

The assignment of the memory addresses and the associated memory content is described below.

34

COM462RTU_D00010_03_M_XXEN/04.2018

Page 35

Modbus process image in the memory of the COM462RTU

7.2 Memory scheme of the process image

7.2.1 BMS device address assignment on the Modbus

As illustrated in the table, the Modbus start address for the respective process

image is derived from the BMS device address. 256 (0x100) Words or 512 bytes

are reserved for each BMS device. They contain all the information requested

and transmitted from the bus.

Modbus address ranges of the process images in the

memory

Word

BMS

Device

address

10x01 Device 1

2 0x02 Device 2

30x03 Device 3

…… …

32 0x20 Device 32

HiByte LoByte

00 … FF

…… …

150 0x96 Device 150

Tab. 7.1: Modbus start address for each BMS device for which a request is to be

sent.

COM462RTU_D00010_03_M_XXEN/04.2018

35

Page 36

Modbus process image in the memory of the COM462RTU

7.2.2 Memory scheme of an individual BMS device

BMS devices feature various types of analogue and/or digital channels. Please

take into consideration that there are device-specific differences:

BMS devices usually feature 12 channels

MK800/TM800 supports up to 64 digital channels in the master mode

The channels 33 to 64 transmit digital messages only

Use the tables on page 35 and page 38 to determine the start address to request the following device parameters:

Device type

Timestamp

Common alarm

Device error

BMS channel

Example:

In our example, channel 2 of the device with BMS address 3 is queried. How is

the start address determined for querying the channel? In our example, the

relevant cells in the table are marked bold.

1. The first address part 0x03 (HiByte) is applied from table 7.1 for BMS

device address 3.

2. The second address part 0x14 (LoByte) is applied from table 7.2 for

channel 2. Apply number 4 from the same table for the number of

words to be queried: (0x14 to 0x17 = 0x04).

3. The start address 0x0314 is composed by HiByte and LoByte.

36

COM462RTU_D00010_03_M_XXEN/04.2018

Page 37

Modbus process image in the memory of the COM462RTU

Memory image of a BMS device

0123456789ABCDEF

LoByte

--------------------------- Device type -----------------------

0x00

Channel 1 Channel 2 Channel 3 Channel 4

0x10

Channel 5 Channel 6 Channel 7 Channel 8

0x20

Channel 9 Channel 10 Channel 11 Channel 12

0x30

Channel 13 Channel 14 Channel 15 Channel 16

0x40

Channel 17 Channel 18 Channel 19 Channel 20

0x50

Channel 21 Channel 22 Channel 23 Channel 24

0x60

Channel 25 Channel 26 Channel 27 Channel 28

0x70

Channel 29 Channel 30 Channel 31 Channel 32

0x80

--

---- Time stamp ---- C D R.

33343536373839404142434445464748495051525354555657585960616263

0x90

R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R.

0xA0

R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R.

0xB0

R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R.

0xC0

COM462RTU_D00010_03_M_XXEN/04.2018

64

37

Page 38

Modbus process image in the memory of the COM462RTU

R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R.

0xD0

R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R.

0xE0

R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R. R.

0xF0

Tab. 7.2: Modbus address assignment of the channels in a BMS device; Hex

representation: horizontal = units, vertical = sixteens

Abbreviations for memory contents:

C = Common alarm

D = Device lost (device failure)

R. = Reserved

A detailed description of the data formats for the device type, timestamp etc.

is given below.

7.2.3 Device type

Word

0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09

0x00

ASCII text, 10 Words/20 bytes

The device type is set by a BMS bus scan.

38

COM462RTU_D00010_03_M_XXEN/04.2018

Page 39

Modbus process image in the memory of the COM462RTU

7.2.4 Timestamp

Word 0x0A 0x0B 0x0C 0x0D

HiByte LoByte HiByte LoByte HiByte LoByte HiByte LoByte

Yea r

YY

The timestamp is set according to a datagram received from a transmitting

device.

MonthMMDayDDHourhhMinutemmSecondssReserve

d

7.2.5 Common alarm and device failure

C = Common alarm und D = Device lost (device failure)

Word 0x0E

HiByte LoByte

CD

Common alarm, 1 byte:

LSB = 0 or 1

The common alarm bit is set as soon as an alarm status from the respective

BMS device is detected.

The device error bit is set when communication with the respective BMS device is no longer possible.

Device error, 1 byte:

LSB = 0 or 1

COM462RTU_D00010_03_M_XXEN/04.2018

39

Page 40

Modbus process image in the memory of the COM462RTU

7.2.6 Channels 1 to 32 with analogue and/or digital values

Word 0x00 0x01 0x02 0x03

HiByte LoByte HiByte LoByte HiByte LoByte HiByte LoByte

Floating point value (Float) AT&T R&U

Channel

description

Every analogue BMS device channel can contain alarm messages, operating

messages, measured values, test messages and descriptive text. Both analogue and digital information can be transmitted.

AT&T = Alarm type and test type (internal/external)

R&U = Range and unit

For details on the channel description refer to chapter 7.4.

7.2.6.1 Float = Floating point value of the BMS channels

Word

HiByte LoByte HiByte LoByte

Byte

31

30

Bit

S E E E E E E E E MMMMMMMMMMMMMMMMMMMMMMM

0x00 0x01

242322

16

15

8

7

Presentation of the bit order for processing analogue measuring values according to IEEE 754

S = Sign

E = Exponent

M = Mantissa

40

COM462RTU_D00010_03_M_XXEN/04.2018

0

Page 41

Modbus process image in the memory of the COM462RTU

7.2.6.2 AT&T = Alarm type and test type (internal/external)

Bit 76543210 Meaning

Errors

Status

Test internal

Tes t e xte rn al

XXXXX000 No alarm

XXXXX001 Prewarning

00XXX010 Device error

XXXXX011 Reserved

Alarm type

XXXXX100

X X X X X 1 0 1 Alarm (red LED)

XXXXX110 Reserved

XXXXX……… Reserved

XXXXX111 Reserved

00XXXXXX No test

01XXXXXX Internal test

Tes t

10XXXXXX External test

Reserved

Alarm

Reserved

Alarm (yellow LED), e.g.

insulation fault

The alarm type is coded by the bits 0 to 2. The bits 3 and 4 are reserved and

always have the value 0. Bit 5 usually has the value 0 and represents the digital

value of the status (this column is relevant for the SMI472 only).

COM462RTU_D00010_03_M_XXEN/04.2018

41

Page 42

Modbus process image in the memory of the COM462RTU

Bit 6 or 7 is usually set when an internal or external test has been completed.

Other values are reserved. The complete byte is calculated from the sum of

the alarm type and the test type.

42

COM462RTU_D00010_03_M_XXEN/04.2018

Page 43

Modbus process image in the memory of the COM462RTU

7.2.6.3 R&U = Range and unit

Bit 76543210 Meaning

XXX00000 Invalid (init)

XXX00001 No unit

XXX00010 Ω

XXX00011 A

XXX00100 V

XXX00101 %

XXX00110 Hz

XXX00111 Baud

XXX01000 F

XXX01001 H

Unit

XXX01010 °C

XXX01011 °F

XXX01100 Second

XXX01101 Minute

XXX01110 Hour

XXX01111 Day

XXX10000 Month

X X X …………… Reserved

XXX11110 CODE

XXX11111 Reserved

X X X …………… Reserved

XXX11111 Reserved

COM462RTU_D00010_03_M_XXEN/04.2018

43

Page 44

Modbus process image in the memory of the COM462RTU

Bit 76543210 Meaning

00XXXXXX Actual value

01XXXXXX The actual value is lower

10XXXXXX The actual value is higher

11XXXXXX Invalid value

Range of validity

The units of the bits 0 to 4 are coded.

Bits 6 and 7 describe the validity range of a value. Bit 5 is reserved.

The complete byte is calculated from the sum of the unit and the range of validity.

Caution!

If the unit byte refers to CODE, the recorded value or status will result in a text

message. The content of this text message is listed in the table on page 45 or

page 51. The floating point value contains an internal CODE but no valid

measured value.

44

COM462RTU_D00010_03_M_XXEN/04.2018

Page 45

Modbus process image in the memory of the COM462RTU

30x0droW

dezi-

mal

BedeutungByte

etyBoLetyBiH

Bit1514131211109876543210

Alarme und Warnungen

0000000000000000 0 Reserviert

0000000000000001 1 Isolationsfehler

0000000000000010 2 Überlast

0000000000000011 3 Übertemperatur

0000000000000100 4 Ausfall Leitung 1

0000000000000101 5 Ausfall Leitung 2

0000000000000110 6 Isolation OP-Lampe

0000000000000111 7 Reserviert

0000000000001000 8 Ausfall Verteiler

0000000000001001 9 Sauerstoff

0000000000001010 10 Vakuum

0000000000001011 11 Narkosegas

0000000000001100 12 Druckluft 5 Bar

………………………………………… … …

7.2.6.4 Channel description

A code with the associated descriptive text is available for each channel. The

table above only shows an extract from the texts. For a complete list of the

available codes or texts refer to page 51.

COM462RTU_D00010_03_M_XXEN/04.2018

45

Page 46

Modbus process image in the memory of the COM462RTU

7.2.6.5 Channel 33 to 64

Bit 76543210 Meaning

Errors

Status

Tes t in ter nal

Tes t ext erna l

XXXXX000 No alarm

XXXXX001 Prewarning

000XX010 Device error

XXXXX011 Reserved

Alarm type

XXXXX100

XXXXX101 Alarm (red LED)

XXXXX110 Reserved

XXXXX……… Reserved

XXXXX111 Reserved

00XXXXXX No test

01XXXXXX Internal test

Te st

10XXXXXX External test

Reserved

Alarm

Reserved

Alarm (yellow LED), e.g. insu-

lation fault

The BMS channels 33 to 64 only provide digital information. The information

is coded as an alarm or message type or test type (internal, external).

The coding is similar to the data format AT&T for the channels 1 to 32, with the

exception of the additional bit 4, which is used for coding device errors, e.g.

connection faults or internal device errors.

46

COM462RTU_D00010_03_M_XXEN/04.2018

Page 47

Modbus process image in the memory of the COM462RTU

7.3 Reference data records of the process image

To make it easier to check the configuration and the Modbus RTU data access

to BMS devices, COM462RTU provides a reference data record at the virtual

BMS address 0.

A real BMS device cannot have BMS address 0!

Address 0 only serves to simulate data access.

Special features of the Modbus communication are the byte offset and the

word and byte order in the memory (Big Endian). At the end of this chapter, a

few examples of correct configuration are given, which might be helpful.

7.3.1 Address assignment of the reference data record

As shown in the following table, the Modbus start address for access to the

reference data record is derived from BMS device address 0.

Modbus addresses for reference data record

Virtual

BMS

Device

address

0

COM462RTU_D00010_03_M_XXEN/04.2018

Word

HiByte

0x00

Tab. 7.3: Start addresses for the reference data record query

00 0E 10 14

Device

type

Common

Alarm

LoByte

Channel 1 Channel 2

47

Page 48

Modbus process image in the memory of the COM462RTU

The start addresses provide the following reference values:

0x0000: TEST (device type)

0x000E: 1 (common alarm, LSB of the HiByte is set)

0x0010: 230 V undervoltage (reference value on channel 1)

0x0014: 12.34 A overcurrent (reference value on channel 2)

7.3.2 Reference value on channel 1

The following reference value is stored in this channel: 230.0 V undervoltage

Word 0x10 0x11 0x12 0x13

HiByte LoByte HiByte LoByte HiByte LoByte HiByte LoByte

0x43 0x66 0x00 0x00 0x00 0x04 0x00 0x4D

Floating point value (Float) AT&T R&U Description

230.0 No/No Volt Undervoltage

Tab. 7.4: Reference data stored in channel 1

48

COM462RTU_D00010_03_M_XXEN/04.2018

Page 49

Modbus process image in the memory of the COM462RTU

7.3.3 Reference value on channel 2

The following reference value is stored in this channel:12.34 A

Word 0x14 0x15 0x16 0x17

HiByte LoByte HiByte LoByte HiByte LoByte HiByte LoByte

0x41 0x45 0x70 0xA4 0x00 0x03 0x00 0x4A

Floating point value (Float) AT&T R&U Description

12,34 No/No Ampere Overcurrent

Tab. 7.5: Reference data stored in channel 2

7.3.4 Explanation of how to access floating point values

The test value 12.34 can be read out via Modbus RTU using Modbus function

0x03 at the address 0x0014. The test value has a size of 2 words.

Proceed as follows:

1. Determine the correct byte offset

Interpreting both words as unsigned integer values should result in the

following values:

Word 1 with address 0x14: unsigned integer value => 16709 (0x4145)

Word 2 with address 0x15: unsigned integer value => 28836 (0x70A4)

2. Determine the correct byte resp. word swap

There are four different combinations of swapping. The only correct

value is 12.34.

All swapping combinations are represented in the following table.

COM462RTU_D00010_03_M_XXEN/04.2018

49

Page 50

Modbus process image in the memory of the COM462RTU

Hex value

sequence

CORRE CT

Word

swapping

Byte

swapping

Word and byte

swapping

Word 1 Word 2 Floating

Byte 1 Byte 2 Byte 3 Byte 4

A

41

C

70

B

45

D

A4

45

A4

41

70

B

D

A

C

70

41

A4

45

C

A

D

B

D

A4

B

45

C

70

A

41

point

value

12.34

4.066E+29

3098.27

-5.21E-17

50

COM462RTU_D00010_03_M_XXEN/04.2018

Page 51

Modbus process image in the memory of the COM462RTU

7.4 Channel descriptions for the process image

Measured value

Valu e

0

1 (0x01) Insulation fault

2 (0x02) Overload

3 (0x03) Overtemperature

4 (0x04) Failure line 1

5 (0x05) Failure line 2

6 (0x06) Insul. OP light Insulation fault operating

7 (0x07)

8 (0x08) Failure distribution

9 (0x09) Failure oxygen

description

alarm message/

operating message

board

Note

theatre light

10 (0x0A) Failure vacuum

11 (0x0B) Anaesthetic gas

12 (0x0C) Compressed air 5

bar

COM462RTU_D00010_03_M_XXEN/04.2018

51

Page 52

Valu e

Modbus process image in the memory of the COM462RTU

Measured value

description

alarm message/

operating message

Note

13 (0x0D) Compressed air 10

14 (0x0E) Failure nitrogen

15 (0x0F) Failure CO2

16 (0x10) Insulation UPS Insulation fault UPS

17 (0x11) Overload UPS

18 (0x12) Converter UPS

19 (0x13) UPS fault

20 (0x14) UPS emergency

21 (0x15) UPS test run

22 (0x16) Failure air condi-

23 (0x17) Batt.op. OP-L Battery-operated operat-

24 (0x18) Batt.op. OP-S Battery-operated Sat OP

25 (0x19) Fail.norm.supply Line normal power supply

bar

operation

tioning

ing theatre light

light

52

COM462RTU_D00010_03_M_XXEN/04.2018

Page 53

Modbus process image in the memory of the COM462RTU

Measured value

Valu e

26 (0x1A) Fail.safet.supply Line safety power supply

description

alarm message/

operating message

Note

27 (0x1B) Failure UPS Line additional safety

power supply

28 (0x1C) Ins.safety supply

29 (0x1D) Fail.N conductor

30 (0x1E) Short dist. panel Short circuit distribution

board

31 (0x1F)

32 (0x20)

33 (0x21)

34 (0x22)

35 (0x23) Standby function (Measuring function

switched off (standby))

36 (0x24)

37 (0x25)

38 (0x26) Batt.op. UPS Battery operation, special

safety power supply

39 (0x27) Phase sequ. left

COM462RTU_D00010_03_M_XXEN/04.2018

53

Page 54

Valu e

Modbus process image in the memory of the COM462RTU

Measured value

description

alarm message/

operating message

Note

40 (0x28) Failure UPS Battery-supported safety

41 (0x29)

66 (0x42)

67 (0x43) Function test till: Date

68 (0x44) Service till: Date

69 (0x45) Ins.fault locat Insulation fault location

70 (0x46) Peak Fault EDS system

71 (0x47) Insulation fault Insulation resistance in Ω

72 (0x48) Current Measured value in A

73 (0x49) Undercurrent

74 (0x4A) Overcurrent

75 (0x4B) Residual current Measured value in A

76 (0x4C) Voltage Measured value in V

power supply

54

COM462RTU_D00010_03_M_XXEN/04.2018

Page 55

Modbus process image in the memory of the COM462RTU

Measured value

Valu e

77 (0x4D) Undervoltage

78 (0x4E) Overvoltage

79 (0x4F) Frequency Measured value in Hz

80 (0x50)

81 (0x51) Asymmetry

82 (0x52) Capacitance Measured value in F

83 (0x53) temperature Measured value in °C

84 (0x54) Overload Measured value in %

85 (0x55) Digital input State 0 or 1

86 (0x56) Insulation fault Impedance

description

alarm message/

operating message

Note

87 (0x57) Insulation fault Alarm from an insulation

88 (0x58) Load Measured value in %

89 (0x59) Total Hazard Cur-

rent

90 (0x5A) Inductance Measured value in H

COM462RTU_D00010_03_M_XXEN/04.2018

fault locator

THC

55

Page 56

Valu e

Modbus process image in the memory of the COM462RTU

Measured value

description

alarm message/

operating message

Note

97 (0x61) Service code Information about service

101 (0x65) Connection system

102 (0x66) Connection earth

103 (0x67) Short-circuit trans-

former

104 (0x68) No CT connected

105 (0x69) Short temp.sensor Temperature sensor

106 (0x6A) Temp.sensor open. Connection temperature

107 (0x6B) K1 Fault contactor K1

108 (0x6C) K2 Fault contactor K2

109 (0x6D)

56

intervals

CT short circuit

short-circuit

sensor

COM462RTU_D00010_03_M_XXEN/04.2018

Page 57

Modbus process image in the memory of the COM462RTU

Measured value

Valu e

110 (0x6E)

111 (0x6F) No address: Failure BMS device

112 (0x70)

113 (0x71) Failure K1/Q1 Failure contactor K1/Q1

114 (0x72) Failure K2/Q2 Failure contactor K2/Q2

115 (0x73) Device error Fault ISOMETER

116 (0x74) Manual mode K1/2 manual mode

117 (0x75) Open circuit K1on Line to K1 on interrupted

118 (0x76) Open circ. K1off Line to K1 off interrupted

119 (0x77) Open circuit K2 on Line to K2 on interrupted

120 (0x78) Open circ. K2 off Line to K2 off interrupted

121 (0x79) K/Q1on Fault

description

alarm message/

operating message

Note

122 (0x7A) K/Q1off Fault

123 (0x7B) K/Q2on Fault

124 (0x7C) K/Q2off Fault

125 (0x7D) Failure K3

COM462RTU_D00010_03_M_XXEN/04.2018

57

Page 58

Modbus process image in the memory of the COM462RTU

Measured value

Valu e

126 (0x7E) Q1 Fault

127 (0x7F) Q2 Fault

128 (0x80) No master

129 (0x81) Device error

130 (0x82)

131 (0x83) Fault RS-485

132 (0x84)

133 (0x85)

134 (0x86)

135 (0x87)

136 (0x88)

137 (0x89) Short circuit Q1

description

alarm message/

operating message

Note

138 (0x8A) Short circuit Q2

139 (0x8B) CV460 CV460 fault

140 (0x8C) RK4xx Fault RK4xx

58

COM462RTU_D00010_03_M_XXEN/04.2018

Page 59

Modbus process image in the memory of the COM462RTU

Measured value

Valu e

description

alarm message/

operating message

Note

141 (0x8D) Address collision BMS address has been

142 (0x8E) Invalid address

143 (0x8F) Several masters

144 (0x90) No menu access

145 (0x91) Own address

201 (0xC9) Line 1 normal op

202 (0xCA) Line 2 normal op

203 (0xCB) Switch. el. 1 on

204 (0xCC) Switch. el. 2 on

205 (0xCD)

206 (0xCE) Auto mode

207 (0xCF) Manual mode

208 (0xD0)

assigned several times

COM462RTU_D00010_03_M_XXEN/04.2018

59

Page 60

Modbus process image in the memory of the COM462RTU

Measured value

Valu e

209 (0xD1)

210 (0xD2) Line AV on

211 (0xD3) Line SV on

212 (0xD4) Line UPS on

213 (0xD5) Channel disabled

description

alarm message/

operating message

Note

214 (0xD6) switching back

interlocking function

215 (0xD7) Phase sequ. right

216 (0xD8) Switch. el. pos.0

217 (0xD9) Line BSV on

218 (0xDA) On SMO48x: Alarm, relay

60

Switching back interlocking function enabled

COM462RTU_D00010_03_M_XXEN/04.2018

Page 61

Modbus process image in the memory of the COM462RTU

To convert parameter data, data type descriptions are required. Text representation is not necessary in this case.

Value Description of parameters

1023 (0x3FF) Parameter/measured value invalid.

1022 (0x3FE) No measured value/no message

1021 (0x3FD) Measured value/parameter inactive

1020 (0x3FC) Measured value/parameter only temporarily inactive

1019 (0x3FB) Parameter/measured value (value) unit not displayed

1018 (0x3FA) Parameter (code selection menu) unit not displayed

1017 (0x3F9) String max. 18 characters (e.g. device type, - variant, …)

1016 (0x3F8)

1015 (0x3F7) Time

1014 (0x3F6) Date: Day

1013 (0x3F5) Date: Month

1012 (0x3F4) Date: Year

1011 (0x3F3) Register address (unit not displayed)

1010 (0x3F2) Time

The menu item of this parameter is not displayed.

(e.g. during the transfer of a new parameter) Display in

the menu "…".

COM462RTU_D00010_03_M_XXEN/04.2018

61

Page 62

Modbus process image in the memory of the COM462RTU

Value Description of parameters

1009 (0x3F1) Factor multiplication [*]

1008 (0x3F0) Factor division [/]

1007 (0x3EF) Baud rate

62

COM462RTU_D00010_03_M_XXEN/04.2018

Page 63

Modbus process image in the memory of the COM462RTU

7.5 Modbus control commands

Commands can be sent to BMS devices by an external application (e.g. visualisation software).

Control via Modbus can be enabled or disabled in the browser menu "1. Settings" > "2. Modbus" > "4. Control".

Command structure (example)

Example: system setup:

BMS addr. 1 COM460IP

BMS addr. 2 COM462RTU (Modbus addr. 2)

BMS addr. 4 IRDH275

Request:

Byte Name Example

Byte 0 Modbus address of the COM462RTU 02

Byte 1 Function code 10

Byte 2, 3 Start register FC 00

Byte 4, 5 Number of registers 00 04

Byte 6 Number of bytes 08

Byte 7, 8 External address:

must always be "1" for COM462RTU.

Byte 9, 10 The internal BMS address to which the com-

mand applies.

Byte 11, 12 Channel 00 00

Byte 13, 14 Control command 00 01

Byte 15, 16 CRC16 Checksum 84 86

00 01

00 04

COM462RTU_D00010_03_M_XXEN/04.2018

63

Page 64

Modbus process image in the memory of the COM462RTU

Answer:

Byte Name Example

Byte 0 Modbus address of the COM462RTU 02

Byte 1 Function code 10

Byte 2, 3 Start register FC 00

Byte 4, 5 Number of registers 00 04

Byte 6, 7 CRC16 Checksum F1 A9

Register addresses for writing. function code write: 0x10

0xFC00: Ext. address.

0xFC01: Int. address.

0xFC02: Channel

0xFC03: Control command

Writing to register:

Use the COM462RTU's address.

Use function code 0x10 (write several registers).

Start address in the register: 0xFC00

Number of registers: 4

Number of bytes: 8

External address: must always be "1" for COM462RTU.

The internal BMS address to which this control command applies.

Channel number

Control command

CRC16 Checksum

64

COM462RTU_D00010_03_M_XXEN/04.2018

Page 65

Modbus process image in the memory of the COM462RTU

Register addresses for reading. Function code read: 0x03

0xFC00: Ext. address.

0xFC01: Int. address.

0xFC02: Channel

0xFC03: Control command

0xFC04: Status

Reading out register:

To read, use function code 0x03 (read several registers).

Possible response in "Status" register:

0 Busy Processing command.

1 Error An error has occurred.

2 Ready Command has been processed suc-

cessfully.

Control commands for the internal BMS bus:

Register

Ext

Register

Int

Register

channel

Register

control

command

Func tion

1 1-150 0 1 Test Isometer

11-1500 2Test changeover

device PRC

1 1-150 0 3 Start automatic test

changeover

1->2. End after time

T(test)

1 1-150 0 4 Start test generator

without changeover

COM462RTU_D00010_03_M_XXEN/04.2018

65

Page 66

Modbus process image in the memory of the COM462RTU

Register

Ext

11-1500 5Switchover to line 1

11-1500 6Switchover to line 2

1 0 0 7 RESET alarm (broad-

1 0 0 8 RESET alarm EDS

1 1-150 0 9 Buzzer off [for alarm

1 1-150 1-12 10 Switch on relay/

1 1-150 1-12 11 Switch off relay/

Register

Int

Register

channel

Register

control

command

Func tion

cast)

(broadcast)

address] (BC)

switch

switch

66

COM462RTU_D00010_03_M_XXEN/04.2018

Page 67

8. Technical data

( )* = factory settings

8.1 Tabular data

Insulation coordination acc. to IEC 60664-1

Rated insulation voltage .................................................................................................................................. AC 250 V

Rated impulse withstand voltage/pollution degree .......................................................................................... 4 kV/3

Supply voltage

Supply voltage U

Frequency range U

Power consumption ....................................................................................................................... See ordering details

LED indicators

ALARM ........................................................................................................................................... internal device error

COM ................................................................................................................................................ data traffic BMS bus

ON ..................................................................................................................................................... operation indicator

Interfaces

BMS bus internal:

Interface/protocol.................................................................................................................. RS-485/BMS bus internal

Operating mode........................................................................................................................... master/slave (slave)*

Baud rate BMS internal.................................................................................................................................... 9.6 kbit/s

Cable length ....................................................................................................................................................≤ 1200 m

Cable (twisted pairs, shielded, shield connected to PE on one side)........................... recommended: J-Y(St)Y 2x0.8

Connection, BMS internal ........................................................................................................................ terminals A, B

Terminating resistor................................................................................................................................120 Ω (0.25 W)

Device address, BMS bus internal .............................................................................................................. 1…99 (2)*

Modbus RTU:

Interface/protocol..........................................................................................................................RS-485/Modbus RTU

Operating mode....................................................................................................................................................... slave

Baud rate Modbus RTU....................................................................................................................... 9.6…57.6 kbit/s

Cable length ....................................................................................................................................................≤ 1200 m

............................................................................................................................ See ordering details

s

......................................................................................................................... See ordering details

s

COM462RTU_D00010_03_M_XXEN/04.2018

67

Page 68

Technical data

Cable (twisted pairs, sh ielded, shield connected to PE on one side) ........................... recommended: J-Y(St)Y 2x0.8

Connection, Modbus RTU ....................................................................................................................terminals D+, D-

Terminating resistor................................................................................................................................120 Ω (0.25 W)

Device address, Modbus RTU ................................................................................................................... 2…247 (2)*

Environment/EMC)

EMC .............................................................................................................................................................. EN 61326-1

Classification of climatic conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3) ....................................................... 3K5 (except condensation and formation of ice)

Transport (IEC 60721-3-2) ...................................................................................................................................... 2K3

Long-term storage (IEC 60721-3-1)........................................................................................................................ 1K4

Operating temperature............................................................................................................................ -10…+55 °C

Classification of mechanical conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3)............................................................................................................................... 3M4

Transport (IEC 60721-3-2) ..................................................................................................................................... 2M2

Long-term storage (IEC 60721-3-1) ...................................................................................................................... 1M3

Connection

Connection type ............................................................................................................................ screw-type terminals

Connection properties:

Rigid/flexible............................................................................................... 0.2…4/0.2…2.5 mm

2

(AWG 24…12)

Multi-conductor connection (2 condu ctors with the same cross section):

Rigid/flexible........................................................................................................................ 0.2…1.5/0.2…1.5 mm

Stripping length ............................................................................................................................................. 8…9 mm

Tightening torque ..................................................................................................................................... 0.5…0.6 Nm

General data

Operating mode ........................................................................................................................... Continuous operation

Mounting............................................................................................................................................... display oriented

Degree of protection, internal components (IEC 60529) ....................................................................................... IP30

Degree of protection, terminals (IEC 60529) ......................................................................................................... IP20

Type of enclosure .....................................................................................................................................................X460

Screw mounting ................................................................................................................................................... 2 x M4

DIN rail mounting acc. to................................................................................................................................. IEC 60715

Flammability class ............................................................................................................................................ UL94V-0

Weight ................................................................................................................................................................≤ 310 g

2

68

COM462RTU_D00010_03_M_XXEN/04.2018

Page 69

Technical data

Option "W" data different from the standard version

Classification of climatic conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3) .................................................... 3K5 (condensation and formation of ice possible)

8.2 Dimension diagram

93

8.3 Standards, approvals, certifications

For information about UL applications refer to page 20.

COM462RTU_D00010_03_M_XXEN/04.2018

69

Page 70

Technical data

Other interface protocols

Connection to SCADA systems (Supervisory Control and Data Acquisition)

and/or PLCs via OPC, BACnet or other protocols on request.

8.4 Ordering details

Typ e

COM462RTU

BMSModbus RTU

Gateway

COM462RTUW

BMSModbus RTU

Gateway

* Absolute values

Supply voltage/

frequency range

U

S

AC/DC 76…276 V */

AC 42…460 Hz/DC

For UL application:

US AC = 76…250 V,

40…150 mA,

42…460 Hz

US DC = 76…250 V,

10…35 mA

AC/DC 76…276 V */

AC 42…460 Hz/DC

Power

consumption

3.5…40 VA,

2.4 W

3.5…40 VA,

2.4 W

UL:

Approval

available

Lloyds

Approval

available

Lloyds

Approval

available

:

:

Art.

No.

B 9506

1022

B 9506

1022W

Option W

Devices with the suffix "W“ feature increased shock and vibration resistance.

The electronics is covered with a special varnish to provide increased protection against mechanical stress and moisture. This particular feature permits

the use in ships, on rolling stock and also in seismic environment.

70

COM462RTU_D00010_03_M_XXEN/04.2018

Page 71

9. Troubleshooting

9.1 Malfunctions

If the COM462RTU causes malfunctions in the connected networks, please refer to this operating manual.

9.1.1 What should be checked?

Check whether…

the device is supplied with the correct supply voltage.

the BMS bus cable is correctly connected and terminated (120 Ω).

the Modbus RTU cable is correctly connected and terminated (120 Ω).

the BMS address is set correctly.

The Modbus RTU address is correctly set and communicated to the

master.

9.1.2 Where to find help?

If, despite thorough study of the technical manual and intensive troubleshooting in your installation, you cannot rectify the fault related to the BMSModbus RTU gateway COM462RTU, please contact our Service department

(refer to page 8).

COM462RTU_D00010_03_M_XXEN/04.2018

71

Page 72

Troubleshooting

72

COM462RTU_D00010_03_M_XXEN/04.2018

Page 73

INDEX

A

Address setting

- BMS address

- Modbus RTU address

Addressing

Application with an internal BMS bus

B

BMS bus 11

BMS device address assignment on the

Modbus

Button

- down

- INFO

- MENU

- UP

Byte offset

Byte or word swapping

C

Clock setting 27

COM462RTU on the internal BMS bus

Commissioning

D

Dimension diagram 69

Display and operating elements

Display in menu mode

Display in standard mode

26

27

14

35

23

23

23

23

49

49

22

23

25

24

18

18

E

Exception code 29

F

Factory settings 25

I

Intended use 14

L

LED

- ALARM

23

- COM

23

M

Main menu 25

Malfunctions

Measured value descriptions for the process

Memory image of a BMS device

Memory scheme of the process image

Menu overview of the functions adjustable

Modbus

71

image, list

51

37

at the device

- Address structure for BMS devices

- control commands

- function code

- Process image

- requests

26

63

33

33

30

35

31

COM462RTU_D00010_03_M_XXEN/04.2018

73

Page 74

- responses 30

O

Ordering details 70

P