Bender ATICS UMA710-2-63-ISO, ATICS UMA710-2-63-ISO-BP, ATICS UMA710-2-80-ISO, ATICS UMA710-2-80-ISO-BP User Manual

Page 1

Manual

of ATICS® modules type

UMA710-2-63-ISO

UMA710-2-63-ISO-BP

UMA710-2-80-ISO

UMA710-2-80-ISO-BP

2-pole

automatic changeover and monitoring modules

with insulation monitoring

for medically used rooms

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 1

Page 2

Imprint

Issued by:

Bender GmbH & Co KG

Londorferstr. 65

35305 Grünberg, Germany

Tel: +49 6401-807-0

Fax: +49 6401-807-259

info@bender.de

www.bender-de.com

All rights reserved.

Subject to change without notice.

Reprinting only with permission of the publisher.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 2

Page 3

Table of content

Imprint ............................................................................................................................................................. 2

Table of content ............................................................................................................................................... 3

1. How to use this operating manual effectively ...................................................................................... 5

1.1. How to use this manual ....................................................................................................................... 5

1.2. Explanations of symbols and notes ..................................................................................................... 5

2. Safety instructions ............................................................................................................................... 6

2.1. Intended use ........................................................................................................................................ 6

2.2. Skilled persons .................................................................................................................................... 6

2.3. Device-specific safety instruction ........................................................................................................ 6

2.4. General safety instructions .................................................................................................................. 7

2.5. Delivery conditions, guarantee, warranty and liability ......................................................................... 7

3. System description .............................................................................................................................. 8

3.1. MEDICS® ............................................................................................................................................ 8

3.2. Example applications ........................................................................................................................... 9

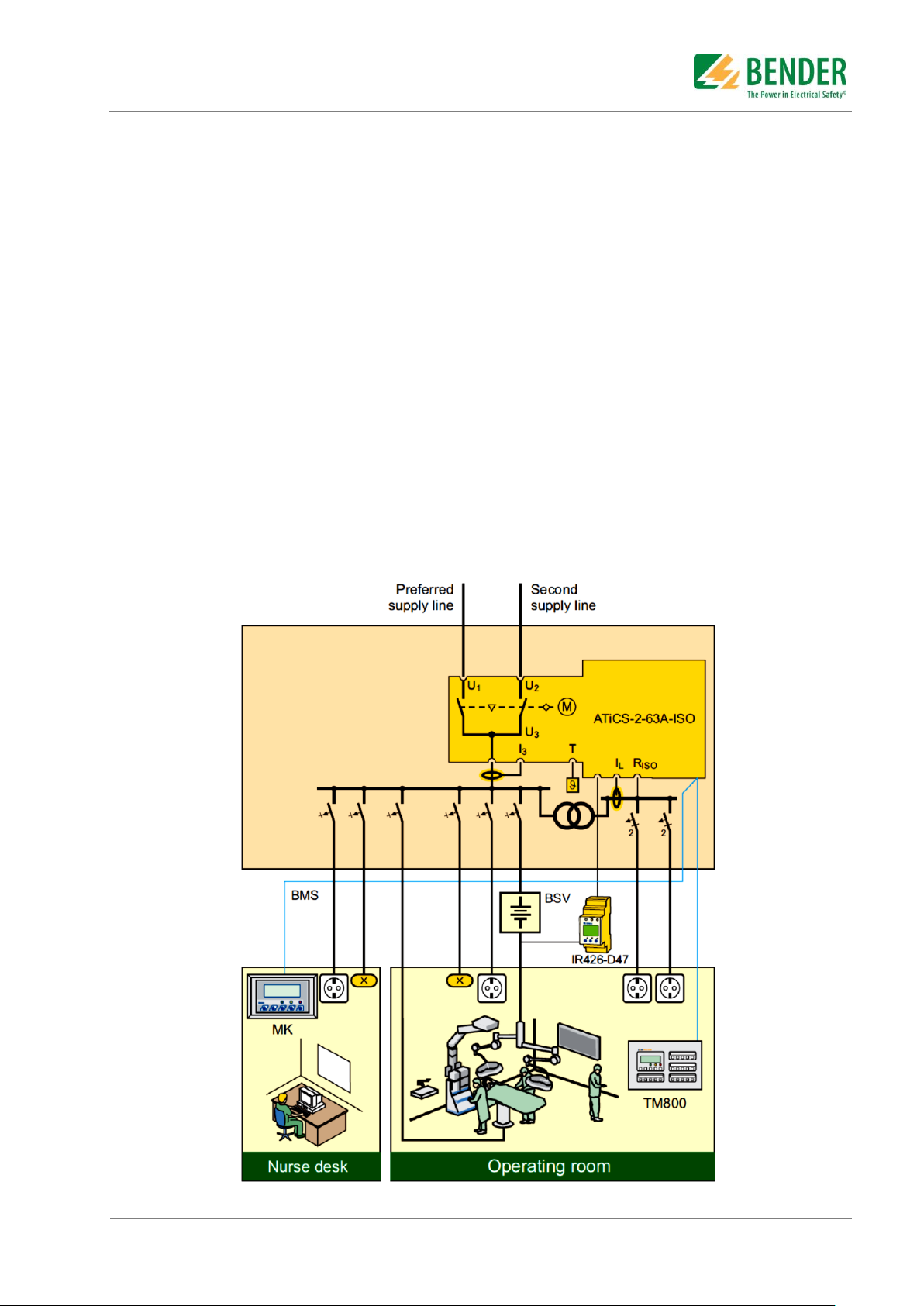

3.2.1. Example application operating theatre ................................................................................................ 9

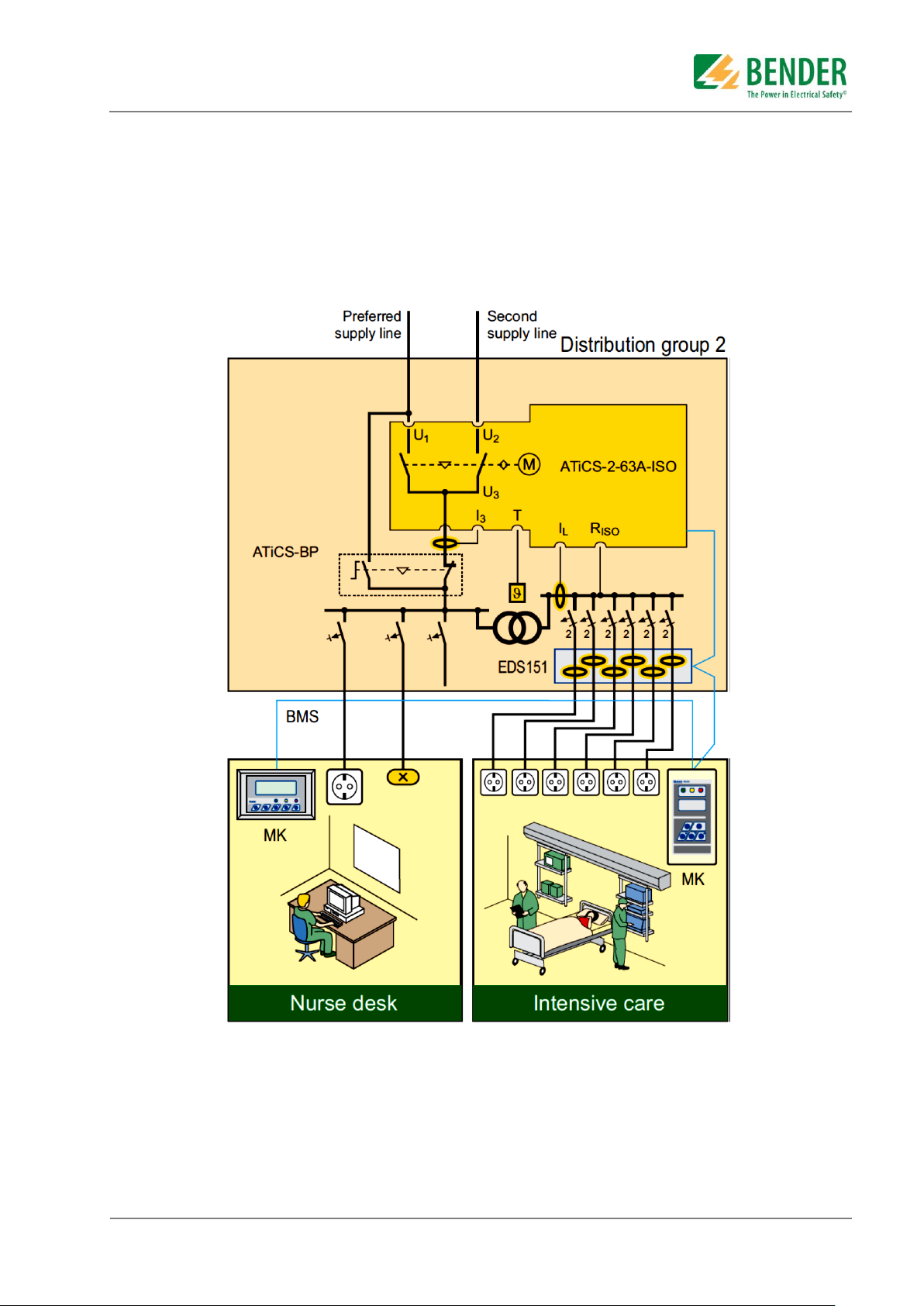

3.2.2. Example intensive care unit ............................................................................................................... 10

3.3. Features of the UMA710… ................................................................................................................ 11

3.4. The automatic changeover module UMA710… ................................................................................ 12

3.4.1. The transfer switching device ............................................................................................................ 12

3.4.2. Insulation monitoring of the IT-System .............................................................................................. 14

3.4.3. Monitoring the device functions ......................................................................................................... 14

3.4.4. Power supply ..................................................................................................................................... 15

3.4.5. Manual mode ..................................................................................................................................... 15

3.4.6. Bypass mode (optional) ..................................................................................................................... 15

4. System components .......................................................................................................................... 16

4.1. Front view of atypical UMA710-2-xx-ISO-BP .................................................................................... 17

4.2. Typical mounting arrangement UMA710-2-xx-ISO-BP ..................................................................... 18

4.3. Automatic changeover and monitoring unit ATICS® ......................................................................... 19

4.4. Typical terminal setup ........................................................................................................................ 20

5. Installation of UMA710-2-xx-ISO-xx-… ............................................................................................. 21

5.1. Safety Advice ..................................................................................................................................... 21

5.1.1. Short circuit protection ....................................................................................................................... 21

5.2. Changeover module .......................................................................................................................... 23

5.2.1. Typical connection ............................................................................................................................. 23

5.2.2. Wiring diagram UMA710-2-xx-ISO, …-BP ........................................................................................ 23

5.3. Notes for connecting the module ....................................................................................................... 24

5.3.1. Transformer ....................................................................................................................................... 24

5.3.2. Temperature sensor .......................................................................................................................... 24

5.3.3. Out-going branch circuit breakers (optional) ..................................................................................... 24

5.3.4. Remote alarm indicator ..................................................................................................................... 25

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 3

Page 4

5.3.5. Building management and SCADA system ....................................................................................... 25

5.3.6. Bypass-switch (optional) .................................................................................................................... 25

6. Commissioning, settings and testing ................................................................................................. 26

6.1. Design and installation notes ............................................................................................................. 26

6.2. Setting and testing according to the checklist ................................................................................... 26

6.3. Avoiding errors ................................................................................................................................... 27

6.4. Example on how to set the addresses .............................................................................................. 28

6.5. Operation of the ATICS® unit ............................................................................................................ 29

6.6. Use of the bypass circuitry (optional) ................................................................................................ 29

7. Troubleshooting ................................................................................................................................. 31

7.1. Fault and alarm messages ATICS® .................................................................................................. 31

7.1.1. Alarm messages: ............................................................................................................................... 31

7.1.2. Messages with Error code or Service code ....................................................................................... 33

7.2. Replacements .................................................................................................................................... 34

7.2.1. Replacing the ATICS® unit ................................................................................................................ 34

7.2.2. Replacing the ATICS® unit when a bypass switch is installed ......................................................... 34

7.3. Fuses F1, F2 ...................................................................................................................................... 35

8. Periodic verification and Service ....................................................................................................... 36

8.1. Periodic verification ........................................................................................................................... 36

8.2. Commissioning and service ............................................................................................................... 37

8.3. Maintenance ...................................................................................................................................... 37

9. Data ................................................................................................................................................... 38

9.1. TÜV-Test report ................................................................................................................................. 38

9.2. Standards .......................................................................................................................................... 39

9.3. Manufacturer's certificate ................................................................................................................... 39

9.4. Technical data ................................................................................................................................... 40

9.4.1. Dimensions and weights .................................................................................................................... 42

9.5. Utilisation data ................................................................................................................................... 42

10. Manufacturers certificate, checklist, documentation .......................................................................... 43

11. Appendix ............................................................................................................................................ 43

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 4

Page 5

1. How to use this operating manual effectively

1.1. How to use this manual

This operating manual describes how to operate the UMA710... changeover and monitoring module. It is

designed for skilled persons working in electrical engineering and electronics; and in particular for those,

installing and operating electrical equipment in the medical sector.

Before using the equipment, please read this operating manual, the supplement entitled "Important safety

instructions for Bender Products" and the instruction leaflets supplied with the individual system

components. This document must be kept in an easily accessible location near to the equipment.

Should you have any further questions, please contact our Technical Sales Department. We are also

happy to provide on-site service. Please contact our Service Department for more information.

In this manual, the two redundant supplies for the power supply will be designated "preferred supply" or

"line 1" and "second supply" or "line 2". Devices with displays use the terms "line 1" and "line 2" in the text

they indicate.

This manual has been compiled with great care. Nevertheless errors and omissions cannot be entirely

excluded. The Bender Group cannot accept any liability for injury to persons or damage to property

resulting from errors or mistakes in this operating manual.

1.2. Explanations of symbols and notes

The following terms and symbols are used to denote hazards and instructions in Bender documentation:

This symbol indicates an immediate risk to life and limb.

Failure to observe the associated instructions and take appropriate precautions will result in

death, severe bodily injury or substantial damage to property.

This symbol indicates a potential risk to life and limb.

Failure to observe these warnings and take appropriate precautions may result in death, severe

bodily injury or substantial damage to property.

This symbol indicates a potentially dangerous situation.

Failure to observe the associated instructions and take appropriate precautions may result in

minor bodily injury or damage to property.

This symbol indicates important information about the correct use of the equipment purchased.

Failure to observe the associated instructions can result in equipment malfunctioning or cause

problems in the environment in which it is being used

This symbol indicates tips for using the equipment and particularly useful information. This type

of information will help you to optimise your use of the equipment.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 5

Page 6

2. Safety instructions

2.1. Intended use

Changeover devices are used everywhere there is dependence on high availability from the power supply.

The ATICS® transfer switching device is intended for the application described in the chapter "System

description". When the preferred supply fails, the ATICS® automatically switches to the second supply.

Areas of application:

Group 1 and 2 medical locations according to DIN VDE 0100-710 and IEC 60364-7-710

Hospital main distribution boards (DIN VDE 0100-710)

Locations open to the public (DIN VDE 0100-718)

Emergency power supplies

Heating, air conditioning, ventilation, cooling

EDP, computer centres

Fire extinguisher and sprinkler systems

Several versions of the ATICS® are available. They differ for example by changing over from the two or

four-pole systems or by the load current (see chapter "ATICS® tasks" on page 15). Please heed the limits

of the area of application indicated in the technical specifications. Use which deviates from or is beyond the

scope of these technical specifications is considered non-compliant.

In order to meet the requirements of applicable standards, customised parameter settings must be made

on the equipment in order to adapt it to local equipment and operating conditions.

Intended use includes following all the instructions in the operating manual and complying with the test

intervals.

2.2. Skilled persons

Only appropriately qualified personnel may work on Bender devices. Persons who are familiar with the

assembly, commissioning and operation of the equipment and have undergone appropriate training are

considered skilled persons. Such persons must have read this manual and understood all instructions

relating to safety.

2.3. Device-specific safety instruction

Failure to adjust the settings may result in malfunction.

The settings must be changed in order to adapt the ATICS® transfer switching device to the

existing equipment. When doing so, follow the instructions in chapter "5. Commissioning,

settings and testing“.

Functional safety according to IEC 61508 can only be guaranteed when used properly.

Please follow the instructions given in this operating manual and in the check list.

In particular note the information on the pages: 12, 13, 14, 20, 52 and 76 in the technical

operating manual TGH1443 of the ATICS® device.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 6

Page 7

2.4. General safety instructions

Bender devices are designed and built in accordance with the state of the art and accepted rules in respect

of technical safety. However, the use of such devices may introduce risks to the life and limb of the user or

third parties and/or result in damage to Bender devices or other property.

Only use Bender equipment:

– As intended

– In perfect working order

– In compliance with the accident prevention regulations and guidelines applicable at the

location of use

Eliminate all faults immediately which may endanger safety.

The device may not be opened.

Do not make any unauthorised changes and only use replacement parts and optional accessories

purchased from or recommended by the manufacturer of the equipment. Failure to observe this

requirement can result in fire, electric shock and injury.

Information plates must always be clearly legible. Replace damaged or illegible plates immediately.

Make sure that the dimension of the UPS (special safety power supply source), the generator set

and the whole wiring is adequate. Abide by the relevant, applicable national and international

standards. If there is an overload and short-circuit, this is the only way to guarantee the necessary

safety and to ensure that the safety devices respond selectively.

If the device is overloaded by overvoltage or a short-circuit current load, it must be checked and

replaced if necessary.

2.5. Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender GmbH shall apply.

Conditions of sale and delivery can be obtained from Bender GmbH in printed or electronic format.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 7

Page 8

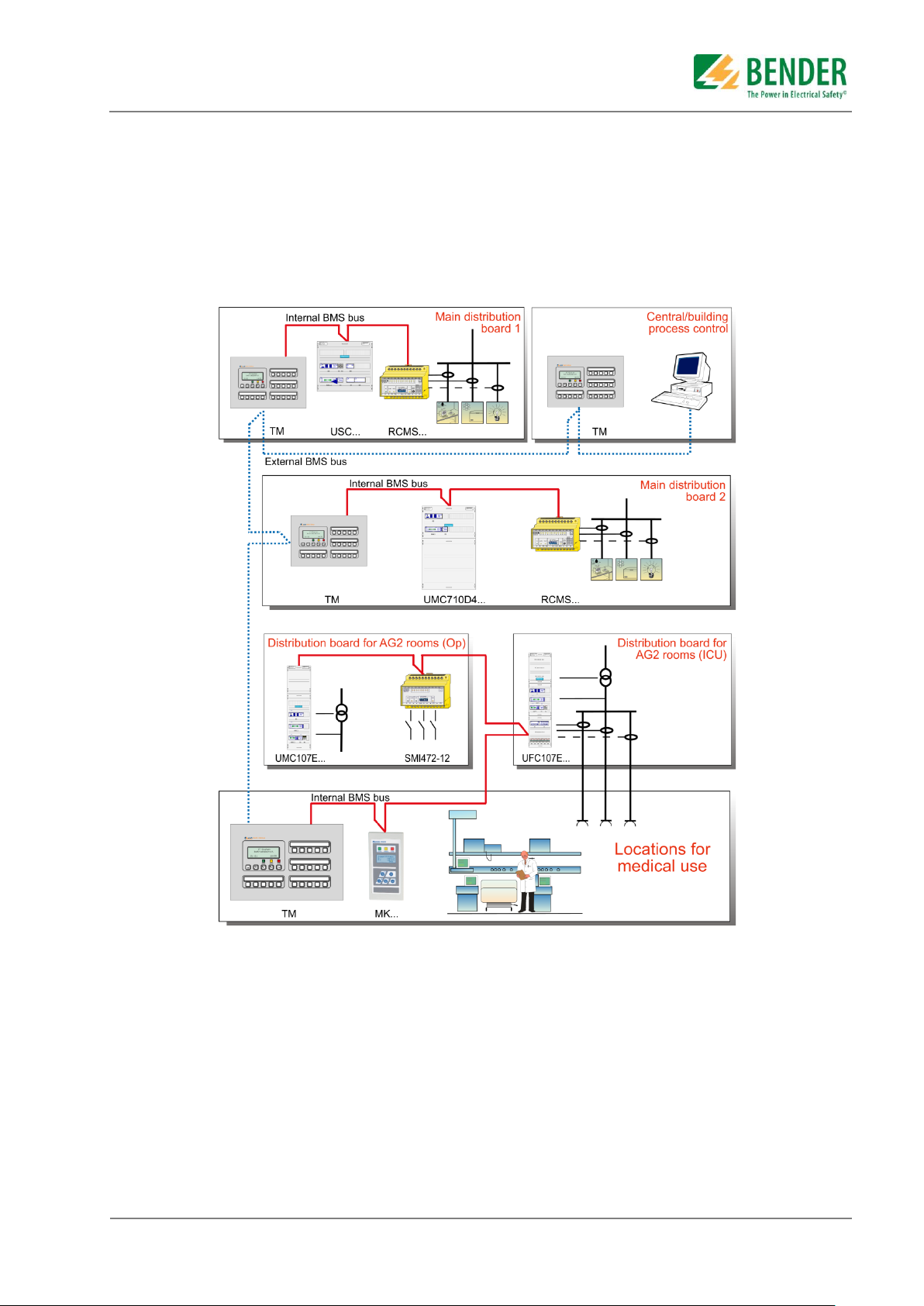

3. System description

3.1. MEDICS®

The UMA710... change over and monitoring module is a part of the MEDICS® system. MEDICS® does not

refer to a single product, but rather an intelligent system for safe power supplies in medical locations.

Example of a section of a hospital with the MEDICS® system

Table to the example

MK... Alarm indicator and test combination

RCMS... Residual current monitoring system for TN-S systems

SMI472 Signal converter for third-party technical equipment (e. g. med. gases, UPS)

TM Alarm and control panel

UMA710-2... Change over and monitoring module ATICS® for IT-Systems

UMC107E.. Change over and monitoring module with contactors for IT-Systems

UMA710-2... Change over and monitoring module ATICS® for IT-Systems with EDS... insulation fault

location system.

UFC107E... Change over and monitoring module for IT systems with EDS... insulation fault location

system

UMC710D... Changeover and monitoring module for main distribution boards

USC710D... Control module for changeover modules (preferably in main distribution boards)

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 8

Page 9

MEDICS® includes::

AC and 3(N) AC changeover and monitoring modules. Examples of modules in the MEDICS®

system include UMC..., USC..., UFC... and EDS.... insulation fault location systems.

Display and operating units such as alarm indicator and operator panels or alarm indicator and test

combinations.

Communication between these components takes place via the BMS bus (two-wire connection).

The connection of third-party technical equipment by means of protocol converters (gateways), via

digital inputs and relay outputs.

The real strength of MEDICS® is to be found in communication between all involved components and the

resulting information provided to the user. Readiness for operation is monitored constantly; and operating

states, irregularities, faults and equipment failures are displayed. From the user's point of view, this means

high operational reliability.

3.2. Example applications

3.2.1. Example application operating theatre

UMA710 Module, Changeover between the preferred and redundant line while monitoring the

medical IT system with transformer load and temperature monitoring

IR426-D47: Monitoring the operating theatre light IT system (optional)

MK2430 / MK800 / TM800: Alarm for at least two points with independent power supplies for

functional safety

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 9

Page 10

3.2.2. Example intensive care unit

UMA Module, Changeover between the preferred and redundant line while monitoring the

medical IT system with transformer load and temperature monitoring including a bypass switch

EDS151 Insulation fault locator for fast insulation fault location (recommended)

ATICS-BP: Bypass switch for uninterrupted test / maintenance (recommended)

MK2430 / MK800 / TM800: Alarm for at least two points with independent power supplies for

functional safety

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 10

Page 11

3.3. Features of the UMA710…

The ATICS® transfer switching device has the following features:

Continuous monitoring of the internal electronic and the circuitry with automatic alarm

Preventive safety due to an automatic reminder of mandatory testing procedures

Maximum reliability of the switching

o Patented switching system with mechanical and electrical interlocking

o Short circuit proof contacts with the mechanic of a moulded case circuit breaker

o Insensitive to voltage fluctuation and vibration due to stable switch position and permanent

contact pressure

Easy to use and a good overview due to a clear menu structure and user interface

The right information at the right time with clear alarm text and a backlit graphic display as well as

via the BMS bus

Can manually be operated and can be locked for maintenance in position “0”

Automatic logging of events e.g. switching, testing, parameter changes

External functional test or replacement of the ATICS® via an optional bypass switch

The ATICS® switch is pluggable

Electronic and switching elements all in one enclosure respectively on a mounting rack

Chang over and IT-System monitoring in one unit

Optional bypass switch

Communication of components with one another via BMS bus

Communication with remote alarm indicator and test combinations and TM alarm indicator and

operator panels via BMS bus

Can be used in systems in accordance with IEC 60364-7-710:2002-11, sections 556.5.2.2, 556.7

and 556.8 and DIN VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.564.6 with a

changeover period = 15 s or = 0.5 s

Functional Safety according to IEC 61508 for use in special safety environment according to SIL2

Easy field wiring, completely prewired and type tested assembly

The UMA710 module is a configured unit and is only certified and tested in this assembly. Do

not make any changes to the components, their password-protected settings or the wiring

without consulting Bender first. In each case you should make the settings that are required for

adaptation to the application case in question and local conditions.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 11

Page 12

3.4. The automatic changeover module UMA710…

3.4.1. The transfer switching device

If the preferred supply fails, the ATICS® ensures the power supply is changed over safely. The switch

contacts are offset on a rotating shaft. This design prevents simultaneous switching of line 1 and line 2. The

switch has three positions:

1 Line 1 switched on

0 Both lines switched off

2 Line 2 switched on

Either line 1 or line 2 can be set as the preferred line

In the normal condition (fault-free operation) the preferred supply is connected. The ATICS® will

switch to the redundant line if:

– the preferred line fails

– the "TEST" button is pressed

– a digital input is configured to "TEST" and this input is enabled

– the setting "Preferred supply" is reconfigured to the other line

The ATICS® switches from the redundant line back to the preferred line if

– the voltage on the preferred line is restored

- the return transfer delay time T(2->1) has expired and no switching back interlocking function is

enabled

- or immediately after pressing the "RESET" button or when the redundant line fails (even when the

switching-back interlocking function is enabled)

– the setting "Preferred supply" is reconfigured to the other line

– the digital input is configured to "TEST" and this input is reset

– a transfer switching device test is enabled and the test time has expired

With the optional ATICS-ES energy storage device only: The ATICS® changes to switch position

"0" and stays there if the following conditions are simultaneously met:

– Line1 and Line 2 have failed

– Automatic mode is set

– No short-circuit is present downstream of the transfer switching device

– The setting "Load disconnection" is set to "on" and the external ATICS-ES energy storage device

is connected

Malfunction if delay times are not adjusted

The response delay T(on), the return transfer delay time T(2->1), the delay on release T(off)

and the dead time T(0) of the ATICS® are adjustable and must be adjusted to the

requirements of the specific case, the short-circuit-calculation and the requirements of DIN

VDE 0100-710 (VDE 0100 Part 710) Section 710.537.6 automatic changeover devices (see

also chapter "Commissioning, settings and testing").

The factory settings guarantee a changeover period of t = 0.5 seconds and switching back within 10

seconds when voltage is restored on the preferred supply. Therefore, the ATICS® can be used in IT

systems with a requirement for a changeover period t ≤ 0.5 s (IT systems with operating theatre lights,

endoscopic field illumination in operating theatres or other essential sources of light, etc.).

When there is a short circuit downstream of the transfer switching device, the transfer switching device

must not continually change back and forth between the two lines. This can occur when the short-circuit

current is small and the transfer switching device switches faster than the short circuit breaker trips. The

ATICS® monitors the load current downstream of the transfer switching device in order to detect a possible

short circuit. If the preferred line fails and a short-circuit current is detected at the same time, the ATICS®

does not change over immediately but only once the circuit breaker has tripped.

If the ATICS® detects a supply failure or a fault, an alarm appears on the LCD, the "ALARM" LED lights

up, the alarm relay trips (if set) and this alarm is forwarded to other Bender devices (such as an alarm

indicator and test combination) via the BMS bus.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 12

Page 13

Typical time diagrams can be found in the following chapters of the ATICS® switch user manual

TGH1443 issued by Bender GmbH.

TGH1443, chapter 3.5.1.1

Time diagram: Changeover between the preferred and redundant line

Example: Line 1 is set as the preferred line.

TGH1443, chapter 3.5.1.2

Time diagram: Staggered switching after total power failure

The external ATICS-ES energy storage device (optional, see "Ordering information") is required for the

staggered switching. If there is no voltage on either of the power supplies, the ATICS® switches to position

"0". When the power is restored, the ATICS® switches on the supply again with the set delay time T(start).

Example: Line 1 is set as the preferred line.

TGH1443, chapter 3.5.1.3

Time diagram: Changeover to generator mode

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 13

Page 14

3.4.2. Insulation monitoring of the IT-System

Insulation monitoring

The integrated insulation monitoring device measures the insulation resistance on AC IT systems, which

may also contain DC voltage components. Adaptation to the system leakage capacitances occurs

automatically. The measuring time increases as the system leakage capacitances increase.

Load current measurement

The load current on the IT system is measured using an STW2 measuring current transformer.

Temperature monitoring

The temperature in the transformer winding is measured via PTC thermistors.

Evaluation

If any of the measured values does not fall within the limits, an alarm is triggered. A message appears

on the LCD, the "ALARM" LED lights up, the alarm relay trips (if set) and this alarm is forwarded to other

Bender devices (such as an alarm indicator and test combination) via the BMS bus.

Locating current injector

When an insulation fault is detected on an IT system, the integrated locating current injector generates

a defined locating current signal to locate the insulation fault. The locating current is limited to

1 mA. This feature can be switched on or off (see chapter "7.4.4.4 Settings menu 4: IT system").

The locating current flowing between the IT system and earth can cause controller faults in

sensitive parts of the system, such as the PLC or relay. It must therefore be ensured that the

locating current is compatible with the monitoring

3.4.3. Monitoring the device functions

The control circuits are designed in such a way that, even though it is almost certain that a particular fault

will occur, it cannot cause the power supply at the output of the automatic transfer switching device to fail.

The ATICS® also continuously monitors:

The switch position of the switch and coils 1 and 2 of the switch

Power supplies 1 and 2, which supply the electronics from the systems concerned

Internal microcontrollers and memory modules

Important connecting wires, such as:

– Measuring current transformer connection

– Temperature sensor connection

– Power supply and PE connection

For alarm and test combinations, and alarm indicator and operator panels, device failure

monitoring can also be programmed via the BMS bus (necessary for functional safety).

On systems with generator: total power failure possible

If the preferred line fails, the ATICS® starts the generator which is connected to the redundant

line. If the generator does not start, the line downstream of the transfer switching device will be

dead. When the generator is switched off, the ATICS® cannot check the redundant line.

Therefore, regularly test the generator and the changeover function to make sure they are

working properly (see checklist in the Appendix to this manual).

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 14

Page 15

3.4.4. Power supply

The coils of the switching device are each supplied from the line which is not currently switched on. This

ensures that it is possible to switch to the redundant line if the preferred line fails, for example. The power

supply of the electronic system is of redundant supply from the lines 1 and 2. This ensures constant supply

to the electronic system even when one line fails. If both lines fail, the changeover switch remains in the

last switch position. Optionally, the external ATICS-ES energy storage device can be connected to supply

the two coils and the electronic system. It is then possible to change over to switch position "0". If several

ATICS® are installed on one system, they can be switched to the preferred line one-by-one starting from

switch position "0" on voltage recovery. This prevents peak loads occurring which would otherwise occur if

the lines of several transfer switching devices were switched on simultaneously.

3.4.5. Manual mode

In manual mode, changeover can be achieved using an Allen key. The changing over to switch position "0"

can be locked with a padlock.

3.4.6. Bypass mode (optional)

By using the optional bypass switch (S1) the changeover and monitoring module can be set into the bypass

mode. In this case the switch will bypass the ATICS® (N1) unit. The ATICS® switch can then be tested or

replaced without power interruption downstream to the changeover and monitoring module.

Only skilled persons may work or operate the changeover and monitoring module. Skilled

means, persons who are familiar with the assembly, commissioning and operation of the

equipment and have undergone appropriate training. Such persons must have read this manual

and understood all instructions relating to safety.

Please refer to the chapter “operation of the bypass mode”.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 15

Page 16

Description

Identification

Function

ATICS-2-xx-ISO

N1

Automatic changeover and monitoring

unit, 63A or 80A nominal current

including IT-system monitoring

CP-D24/0.24

(or AN410 )

T1

Auxiliary power supply for remote alarm

indicator MK-series

BV384213 (STW2)

T4

Measuring current transformer for the

actual load current on transformer

secondary

STW3

T3

Measuring current transformer for the

total load current and to identify a short

circuit condition

ES710…

ES710…

IT-System transformer, 3150VA upto

8000VA,

According to DIN VDE 0100-710

Fuse

F1, F2,

Short circuit protection

MK2430-xx

MK2430-xx

for remote alarm indicator MK-series

Bypass switch

(optional)

S1

To bypass the load contacts of the

ATICS® switch, with auxiliary contacts

E219-2CD48

(optional with bypass switch)

H1

indicator, red + green to indicate the

bypass mode

4. System components

In the appendix of this manual you will find the data sheets, technical manuals and further detailed

information on all system components.

The changeover and monitoring modules are designed to be mounted on DIN rails but can also be

mounted on mounting plates.

Multiple DIN rails are mounted on mounting racks of at least one vertical section of 250mm in width. Other

mounting arrangements with multiple vertical sections are also possible.

Depending on the number of sections the DIN rails may also differ. E.g. a wall mounted enclosure with 6

DIN rails in one vertical section or a switchgear cabinet with 10 or 12 DIN rails per vertical and multiple

sections in a free standing cabinet.

The following mounting racks will show some typical arrangements only.

The optional bypass switch is also being showed in these examples.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 16

Page 17

Legend

1. Cover of the terminal area

2. Cover with all mounted components

3. Label with technical data

4. Type label

5. Aux. supply, T1

6. indicator, H1 (optional), for bypass-circuitry

7. bypass switch S1 (optional)

8. label (optional), for bypass-circuitry with

important operating instructions

9. automatic changeover and monitoring unit

ATICS®, N1

10.

This is only an example of a typical mounting rack

arrangement only. Please refer to the attached

individual, job or project related documentation like

wiring diagram and elevation drawing.

4.1. Front view of atypical UMA710-2-xx-ISO-BP

Example: front view UMA710-2-xx-ISO-BP on a single section mounting rack by ABB/Striebel & John.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 17

Page 18

Legend

1. terminals, in-coming

2. terminals, IT-System transformer

3. fuses, F1, F2 (see also chapter 7.3)

4. terminals, interfacing

5. measuring current transformer T3 (for load

current monitoring)

6. aux. supply T1, DC 24V

7. bypass switch S1 (optional)

8. indicator H1 (optional), for bypass circuitry

9. current transformer T4 (for short circuit

detection)

10. automatic changeover and monitoring unit

ATICS®, N1

This is only an example of a typical mounting rack

arrangement only. Please refer to the attached

individual, job or project related documentation like

wiring diagram and elevation drawing.

4.2. Typical mounting arrangement UMA710-2-xx-ISO-BP

Example: UMA710-2-xx-ISO-BP on a single section mounting rack by ABB/Striebel & John.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 18

Page 19

1. LCD Display, indication of status, and alarm

messages and user menu

2. Status and alarm-LEDs

3. Push buttons/controls

4. green terminal plug, connection of line 1 and 2

5. inspection window for the switch position

6. manual operation of the ATICS® switch

showing also the switch position

7. Allen key wrench for manual operation

8. transparent cover for the changeover switch

(when opened in manual mode) lead-sealable

9. wiring schematic for line 1, 2 and 3

10. three coded connector plugs

11. latch for a patch lock to lock-up in position 0

12. green terminal plug, connection of line 3

4.3. Automatic changeover and monitoring unit ATICS®

For mounting and connection of the changeover and monitoring unit ATICS® read chapter 4 of

the technical user manual TGH1443

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 19

Page 20

Legend

1. In-coming terminals

2. IT-System transformer terminals

3. F1, F2: fuses (see also chapter 7.3)

4. Interfacing terminals

This is only an example of a typical mounting rack arrangement only. Please refer to the

attached individual, job or project related documentation like wiring diagram and elevation

drawing.

4.4. Typical terminal setup

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 20

Page 21

5. Installation of UMA710-2-xx-ISO-xx-…

5.1. Safety Advice

The safe use of this electrical equipment implies that it has been wired-up and commissioned by electrical

skilled personnel.

Only skilled persons may work on this module. Skilled means, persons who are familiar with

the assembly, commissioning and operation of the equipment and have undergone appropriate

training. Such persons must have read this manual and understood all instructions relating to

safety.

• The latest standards and regulations have to be followed.

• The national safety and accident prevention regulations have to be followed.

• The power has to be turned off before working on this electrical equipment.

• Precautions have to be made that the equipment can not be turned back on by accident.

• The connection/wiring is only allowed in compliance to the wiring diagram and its comments.

If the comments and wiring diagrams are not being followed, the wiring been changed or not recommended

accessory is being used, injury, fire, electrical shock and other damage can occur.

The unique and individual wiring diagram and elevation drawings of this module as well as the

data sheets of the installed components, are also part of this operation manual and must be

carefully read as well.

5.1.1. Short circuit protection

Please observe the requirements of IEC 60364-7-710:2002-11 and DIN VDE 0100-710 (VDE 0100 Part

710) when selecting fuses for the supply cables and outgoing circuits of the changeover modules:

Section: 710.512.1.6.2 (VDE), sections 710.5.3.1, 710.512.1.6 (IEC), Transformers for the IT

system: Where transformers, their primary supply conductor and secondary outgoing line are

concerned, overcurrent protective devices are only permitted for short-circuit protection. The

transformer supply cable from the changeover module and the transformer outgoing cable to the

next distribution board section should be laid so that they are short-circuit proof and earth fault

proof. Recommended cable/wire: Halogen-free, flexible single core, double insulated rubber wire

type NSHXAFö 1.8/3kV.

Section: 710.53.2 (VDE), section 710.413.1 (IEC), Protection of the cable system in Group 2

locations: The choice of protective devices must ensure that when the anticipated short-circuit

current occur, the protective device upstream of a fault will selectively trip the protective devices

that are further upstream.

Section 710.537.6.2. (VDE), section 710.413.1.1 (IEC), Connecting several load groups

downstream of a changeover module must not lead to all the load groups failing in the event of a

fault. As a result, the choice of fuses F should ensure both short-circuit protection for the

transformer and selectivity for the overcurrent devices connected downstream in the IT systems

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 21

Page 22

When selecting fuses, please observe both the maximum permissible values laid down by the guidelines

that apply to the location of use and national and international standards, in order to ensure that the

contactor contacts cannot weld. The considerations presented below are based on the standard DIN VDE

0100-710 (VDE 0100 Part 710):2002-11, section 710.537.6.

Selecting the fuse with one consumer only.

The circuitry has only one consumer (IT-System

transformer)

The minimum rating of the fuse has to be given by

the transformer manufacturer

The nominal current of the ATICS® unit must be

higher or at least equal to the nominal current of

the IT-system transformer.

The maximum possible fuse F1 and F2 up-stream

is given by the technical data of the ATICS® unit

Selecting the fuse with more than one consumer.

This circuitry branches off in multiple consumers.

This implies that there is a fuse for each consumer

behind the ATICS® unit.

Nevertheless the maximum possible fuse F1 and

F2 up-stream is given by the technical data of the

ATICS® unit.

The fuse F1 and F2 must be selected that there is

a discrimination to the fuses F3, F4 and F5.

Therefore the fuse F3 must be at least two ranges

lower than the ATICS® nominal current.

The total current of the changeover arrangement is

the total expected load current of all connected

consumers.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 22

Page 23

Function

Terminal description

Preferred supply line, line 1 *)

Phase, L

Neutral, N

Earth, PE

Second supply line, line 2 *)

Phase, L

Neutral, N

Earth, PE

IT-System transformer *)

Primary, L

Primary, N

Secondary, L1

Secondary, L2

Shield, PA/S

Temperature monitoring

Remote alarm indicator, control panel

(MK2430-xx, MK800-xx)

Internal BMS-Bus, A, B

Internal BMS-Bus, A , B

The terminals can also be used to terminate the bus

with a 120ohm resistor.

Shield S = PE (The shield shall be earthed on one

side of the cable only.)

Aux. Supply voltage, +24V, 0V

Alarm contact

Volt-free changeover contact, (programmable)

„Bypass ON“ contact

Volt-free N.O. contact, (optional, for bypass only)

Alarm and control panel

(TM, FM, TCP)

Aux. supply voltage AC 230V,

L1 , L2, PE

IT-System branch circuits

Terminal block L1/L2/PE

5.2. Changeover module

5.2.1. Typical connection

Connect the changeover module to the typical terminals:

*) Select the cross section according to the applicable national and international standards.

(e.g. DIN VDE 0100 part 430)

Please refer to the attached individual, job or project related documentation like wiring diagram

and elevation drawing

5.2.2. Wiring diagram UMA710-2-xx-ISO, …-BP

The complete wiring diagram can be found in the appendix of this manual.

Please refer to the attached individual, job or project related documentation like wiring diagram

and elevation drawing

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 23

Page 24

5.3. Notes for connecting the module

On any of the below please refer to the attached individual, job or project related

documentation like wiring diagram and elevation drawing.

5.3.1. Transformer

The power supply of Group 2 location is supplied via an isolating transformer. For protection

against indirect contact, one of the following measures is to be used for the transformer:

Protective insulation according to DIN VDE 0100-410 (VDE 0100 Part 410):2007-06, 413.2 (Use of

a protection class II transformer)

Protection by non-conductive location according to DIN VDE 0100-410 (VDE 0100 Part 410):2007-

06, section 413.3

Protection by a local, earth-free equipotential bonding according to DIN VDE 0100-410 (VDE 0100

Part 410):2007-06, section 413.4

Protection by special installation. For this measure, please note the following:

- The protection class I transformer must be installed isolated and must not be connected to

the PE conductor. In Bender's ES710 range of transformers, the fixing angles are isolated

from the transformer core.

- A warning label is to be affixed to the transformer and its cover as follows:

Warning! Accessible parts of the transformer may be live. You must always verify

that there is no voltage present before touching parts of it.

- The transformer is to be installed behind a cover, which can only be opened using a tool or

a special key. It must only be accessed by skilled persons.

- The shield winding can be connected to the PE conductor. It must be ensured that the

connecting wire is installed so that it is short-circuit proof and earth-fault proof.

5.3.2. Temperature sensor

Bender IT system transformers are equipped with the temperature sensors required according to their

insulation class. These temperature sensors (maximum of 6 sensors connected in series) are connected to

terminals Z1 and Z2.

5.3.3. Out-going branch circuit breakers (optional)

As an option the UMA module can be equipped with 2-pole branch circuit breakers to provide the ITSystem supply. The load circuits can be connected to terminal block. Please refer to the attached

individual, job or project related documentation like wiring diagram and elevation drawing.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 24

Page 25

5.3.4. Remote alarm indicator

Ex works, the following A+B terminals are provided for the connection of BMS bus devices:

Remote alarm indicator, control panels and other Bender-BMS-bus devices can be connected to these

terminals.

1. A BMS device or an existing BMS bus with several devices is connected to terminals: The last

device at the other end of the bus must be terminated with 120ohm. Terminals A and B remain

terminated.

2. An existing BMS bus that has already been terminated on both ends, is disconnected; one open

branch is connected to terminals A+B, while the other one is connected to the other terminals A+B:

The 120 Ω resistor, provided ex works, must be removed and the open bus branches must be

connected to the specified terminals.

Please read the information on cable routing in the "BMS bus" instruction leaflet as well as the

individual, job or project related BMS bus wiring schematic if applicable.

The power supply unit T1 (DC 24V, 420mA) can supply power to a maximum of three MK2430 alarm

indicator and test combinations via the terminals +24V and 0V. In this respect, please refer to the

documentation for the relevant devices. The power supply unit T1 is not suitable for supplying power to

TM... operator panels. Alarm and control panels /e.g. TM, FM, TCP series) can be supplied via the 230V

terminals (where applicable).

5.3.5. Building management and SCADA system

If messages from the UMA changeover and monitoring module are to be transmitted to a SCADA system,

you have the following options:

Protocol converter (Gateways)

OPC-Server

Common alarm via the relay outputs of the ATICS® unit

Conversion between BMS bus and digital inputs and outputs by means of alarm indicator and

operator panels (e.g. TM, FM, TCP) or signal converters (e.g.SMO480-12, SMO482-12, SMI 472-

12).

5.3.6. Bypass-switch (optional)

By using the optional bypass switch (S1) the changeover and monitoring module can be set into the bypass

mode. In this case the switch will bypass the ATICS® (N1) unit. The ATICS® switch can then be tested or

replaced without power interruption downstream to the changeover and monitoring module.

Only skilled persons may work or operate the changeover and monitoring module. Skilled

means, persons who are familiar with the assembly, commissioning and operation of the

equipment and have undergone appropriate training. Such persons must have read this manual

and understood all instructions relating to safety.

Please refer to the chapter “operation of the bypass mode” of this manual.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 25

Page 26

6. Commissioning, settings and testing

6.1. Design and installation notes

Note for the design:

During installation and connection, abide by the relevant standards and regulations and follow the

operating manuals for the device.

Provide for MK… alarm indicator and test combinations or TM… alarm indicator and operator

panels at least two places. These show messages from the ATICS® transfer switching device and

monitor one another for failure.

Example of locations for the MK… or TM… in a hospital:

o Medical locations

o Continuously manned area (e.g. nurse service area)

o Technical area

Provide a fail-safe power supply for the MK… or TM… or TCP

The TM… and MK… for the medical and technical area must be supplied with power from different

lines and sources. Example:

The MK… or TM… in the medical field is supplied from line 3 of the transfer switching device.

The MK… in the technical area is supplied from a fail-safe battery-backed line..

Notes on parameter settings:

MK… resp. TM…or TCP must display at least the following faults detected by the ATICS®:

Failure line 1, failure line 2

Device error, device failure ATICS®

Failure of the other MK… or TM… or TCP

Insulation fault, overload, over temperature of the IT-System

EDS channels with circuit and/or room name (where applicable)

Device error with complete text or error code

An overview of the ATICS® messages on the BMS bus (channel use) can be found in the technical user

manual TGH1443.

6.2. Setting and testing according to the checklist

The settings made at the factory take into account a total changeover period t ≤ 0.5 s and switching back to

the preferred supply within 10 seconds on voltage recovery.

Typical time diagrams can be found in the following chapters of the ATICS® switch user manual TGH1443

issued by Bender GmbH.

The response delay T(on), the dead time T(0), the delay on release T(off) and the return transfer delay time

T(2->1) of the ATICS® are adjustable and must be adjusted to the requirements of the specific case, the

short-circuit calculation and the requirements of DIN VDE 0100-710 (VDE 0100 Part 710) Section

710.537.6 (automatic changeover devices):

The total off-time (from the point at which the fault occurs until the arc in the overcurrent protective

device is cleared) must be less than the minimum delay for the changeover of the automatic

transfer switching device. Setting: Response delay T(on)

If several transfer switching devices are connected in series in a power supply system, it is

recommended that they be time-graded. Setting: Response delay T(on), return transfer delay time

T(2->1) and delay on release T(off).

As part of the response delay (to be custom-set), you must, at the very least, take into account the

periods of time when the circuit experiences short interruptions, and the response times of the

short-circuit protection equipment upstream or downstream. Regardless of this, a switchover pause

corresponding to the installation location should be taken into account, in order to avoid switching

overvoltages. Setting: Response delay T(on), dead time T(0) and return transfer delay time T(2>1).

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 26

Page 27

The factory settings and system-specific settings of the ATICS® transfer switching device are

documented on the checklist. Please carry out all the work outlined in the list and log each test

step. The checklist can be found in the attached documentation. Keep the checklist with this

manual in the vicinity of the device.

6.3. Avoiding errors

Risk of missing or false messages on the display on MK… , TM… or FTC…

MK… alarm indicator and test combinations, TM… alarm indicator and operator panels or

FTC… protocol converters or BMS Ethernet gateways COM460IP, which, together with an

ATICS®, are connected to a BMS bus must be loaded with the latest operating software (e.g.

MK800/TM800 V 4.0 or higher, MK2430 V3.0 or higher). Older MK…, TM… or FTC… cannot

interpret the alarms of the ATICS®. They must either be updated or replaced.

The TMK-SET configuration software must also be the latest version.

Communication via the BMS bus can only be guaranteed when there is only one terminating

resistor at the beginning and the end of the BMS bus. Additional terminating resistors can lead

to malfunctions and therefore must not be used.

Please also note the information in the "BMS bus" instruction leaflet.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 27

Page 28

Unit

Parameter

Address setting

ATICS® for area A

Bus- Address

3

first MK…

(central monitoring)

Address

1

Test- Address

3, 6

Alarm- Address

2*, 3, 4**, 5, 6

second MK…

for area A

Address

2

Test- Address

3

Alarm- Address

1*, 3, 4**

EDS151 (optional)

Bus- Address

4

ATICS® for area B

Bus- Address

6

first MK…

for area B

Address

5

Test- Address

6

Alarm-Address

6

6.4. Example on how to set the addresses

Please also note the information in the "BMS bus" instruction leaflet.

Two ATICS® units and multiple remote alarm indicators and fault location:

* These alarm addresses are required to monitor each other.

** Each EDS channel shall be programmed individually to identify the branch circuit and the room in which

the load is being supplied.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 28

Page 29

6.5. Operation of the ATICS® unit

A brief commissioning instruction for the skilled personal is enclosed with the documentation.

Please refer to the document TKA1443. For detailed instruction of the changeover and

monitoring unit ATICS® read the technical user manual TGH1443.

6.6. Use of the bypass circuitry (optional)

By using the optional bypass switch (S1) the changeover and monitoring module can be set into the bypass

mode. In this case the switch will bypass the ATICS® (N1) unit. The ATICS® switch can then be tested or

replaced without power interruption downstream to the changeover and monitoring module.

Next to the bypass switch S1 is a green and red indicator H1 as well as the auxiliary power supply T1.

The green indicator is showing that the ATICS® unit is in position “I”. Only if the green indicator is ON the

bypass circuitry can be operated. In a fault free condition line 1 is in use and voltage is applied.

The bypass switch S1 must be operated only if:

- The ATICS® switch N1 is on position “I”

- The green indicator H1 is ON.

- If the red LED is ON or both are OFF there is a risk of short circuiting the supply.

The bypass switch must not be operated if the green indicator is OFF !

A failure to observe this may result in a short circuit when switching S1 to position “I+II” and

may result in the loss of power to the connected loads.

Important instruction:

If a power failure of line 1 occurs while the switch S1 is set to bypass mode in position “II” the

switch must not be operated again! In this case the ATICS® unit must be manually switched to

position “0” using the Allen key wrench.

Before the clear cover of the ATICS® unit is being firmly closed the bypass switch S1 has to be set

to position “I” again. If this instruction is not being followed the ATICS® will automatically

changeover to line 2 as soon as the cover is being firmly closed. Closing the clear cover will

activate the automatic mode of the ATICS® unit.

After each and every switching operation the normal operating condition has to be verified and logged in a

protocol.

Only skilled persons may work or operate the changeover and monitoring module. Skilled

means, persons who are familiar with the assembly, commissioning and operation of the

equipment and have undergone appropriate training. Such persons must have read this manual

and understood all instructions relating to safety.

Turn the bypass switch continuously from position “I” via “I+II” to position “II” to bypass the

ATICS® unit. Turn the bypass switch continuously from position “II” via “I+II” to position “I” to

run the ATICS® unit again in the none-bypass/normal mode.

The time in which the bypass is active in position “II” must be minimized.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 29

Page 30

Before operating the bypass circuitry note the instruction on the blue label on the cover: (optional)

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 30

Page 31

Fault/message

Description

Action

Failure Line xx

(xx stands for: 1, 2,

AV, SV, UPS, BSV),

Under voltage or

overvoltage

Voltage is no longer available on

line 1 or line 2

(Channel 1 = Line 1,

Channel 2 = Line 2)

- Measure voltage on line xx

- Check cause

- Eliminate fault on the system

- Check the setting for voltage

and hysteresis

Failure Line 2

Generator delivers no voltage

within the set time

- Measure voltage on line xx

- Check cause

- Eliminate fault on the system

- Check the setting for voltage

and hysteresis

Insulation fault

IT-System insulation/earth fault

- Look for insulation fault

- Eliminate fault on the system

Overload

Current consumption too high

- Check setting for transformer

load current

- Switch off any loads which are

not urgently needed

Over temperature

Temperature on the IT system

transformer is too high

Switch off any loads which are

not urgently needed

CT connection

Measuring current transformer

STW2 (T4), isolating transformer

load, channel 10

- Check connecting wire of

measuring current transformer

CT short-circuit

Measuring current transformer

STW2 (T4), isolating transformer

load, channel 10

- Check connecting wire of

measuring current transformer

Mains power

connection

Connection to the IT system

interrupted or voltage in the

system being monitored below

150 V

- Check connection of ports

L1/IT, L2/IT to the IT system

- Check voltage in the IT system

Earth connection

Connection to PE interrupted

Check that the E and KE are

connected to the protective earth

conductor by two separate lines

on.

Device error +

Error code

For details about actions to be taken refer to table section "Error

code/service code". The message is on channel 6 of the BMS bus..

Short-circuit

distribution board

Short-circuit detected

- Eliminate short-circuit

Failure distribution board

No voltage on line 3, contact of

the changeover switch defective

Replace the ATICS®

Overcurrent I3

Overcurrent detected by

measuring current transformer

STW3 (T3)

- Eliminate the cause of

overcurrent

- Eliminate any damage

CT connection

Measuring current transformer

STW3 (T3), channel 7

- Check connecting wire of

measuring current transformer

7. Troubleshooting

7.1. Fault and alarm messages ATICS®

If a fault occurs, the message of the ATICS® transfer switching device will enable you to narrow down the

possible causes. Some messages may point to several causes.

The following possible faults are indicated by messages on the ATICS® display:

Plain text fault messages

Fault messages with error code or service code

7.1.1. Alarm messages:

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 31

Page 32

CT short-circuit

Measuring current transformer

STW3 (T3), channel 7

- Check connecting wire of

measuring current transformer

No Master

There is no device with master

function (device with address "1")

or backup master available on

the RS-485 interface

- Check BMS bus connection

cable.

- Check whether master has

failed or whether its address has

changed

Service __ (date)

Reminder for next service

- Agree date with Bender Service

Test __ (date)

Reminder for next test

- Plan date for test

- Carry out test

Manual mode

Message "Manual mode"

although manual mode has not

been activated

- Check the connections of the

digital input

Error during the

changeover process

When the test set-ups do not

supply enough current for

switching the coils of the ATICS

- Only use test set-ups that

provide the necessary

peak current.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 32

Page 33

Error Code/

Service code

Description

Action

1.xx, 9.xx

Fault message from the internal memory

monitoring

- Contact Bender-Service

3.11

Max. number of hours exceeded

- Plan device replacement Alarm

can be cancelled "Reset menu 3:

Changeover" see the technical

manual TGH1443.

3.12

Max. number of changeovers exceeded

- Plan device replacement Alarm

can be cancelled "Reset menu 3:

Changeover" see the technical

manual TGH1443.

3.13

Changeover due to overcurrent or short

circuit.

These changeovers reduce the life

of the device. Currents which are

measured

in excess of 150 times the rated current

are evaluated as over currents or

short-circuit currents

- Have personnel assess the

short-circuit load. Contact Bender

Service. Alarm can be cancelled

see the technical manual

TGH1443

3.5

Service has been carried out. This is not

a fault message. Display only on service

logger

- No action required

6.xx, 7.xx, 8.xx

Device error. The internal self-monitoring

of the device has detected a fault which

could impair the safe operation of the

device.

- Replace device immediately

8.51 … 8.66

Fault during changeover process. Occurs

when the voltage on the new line fails

during the changeover. Also occurs when

the test set-ups do not supply sufficient

current for switching the coils of the

ATICS.

- RESET -> execute alarm, - then

test the changeover function.

- If fault persists: replace the

device.

- Only use test set-ups that can

supply the

necessary peak current

7.1.2. Messages with Error code or Service code

In case a failure occurs, proceed as follows:

1. Activate manual mode, if necessary. (refer to the technical manual TGH1443)

2. Make a note of what happened prior to the fault: operator inputs, device error messages,

environmental conditions, etc.

3. Keep the device type, article and device serial number of the ATICS® to hand.

4. Keep the project number, job number and drawing number, according to the type label of the

changeover module or the Bender switchgear cabinet to hand.

5. Speak to Bender Service, describe the type of fault and quote the three-digit error code

Please read the chapter „Frequently asked questions“ of he technical manual TGH1443 by Bender.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 33

Page 34

7.2. Replacements

7.2.1. Replacing the ATICS® unit

Replacing the ATICS® unit might be necessary if:

ATICS® has reached the end of life time or

an event has occurred which jeopardises safety: e.g. overvoltage, switching if there is a short

circuit or component failure.

If a replacement of the ATICS® unit is necessary after consulting our service or commissioning department

the technical manual TGH1443 by Bender must be read first.

Only skilled persons may work or operate the changeover and monitoring module. Skilled

means, persons who are familiar with the assembly, commissioning and operation of the

equipment and have undergone appropriate training. Such persons must have read this manual

and understood all instructions relating to safety.

Danger to life caused by electric shock !

While touching electrically live parts the risk of electrical shock exists.

Make sure that no voltage is being present before working on any electrical connection.

The latest standards and regulations have to be followed.

The national safety and accident prevention regulations have to be followed.

The power has to be turned off before working on this electrical equipment.

Precautions have to be made that the equipment can not be turned back on by accident.

The connection/wiring is only allowed in compliance to the wiring diagram and its comments.

If the comments and wiring diagrams are not being followed, the wiring been changed or not

recommended accessory is being used, injury, fire, electrical shock and other damage can occur.

If the ATICS® is being bypassed by the bypass switch S1, special precautions have to be complied

with in accordance to the national and international standards for working under electrically live

conditions.

7.2.2. Replacing the ATICS® unit when a bypass switch is installed

With the bypass switch S1 the out-going line 3 can be supplied without interruption and the ATICS® unit

can be replaced. The same precautions apply as written in the previous chapter above.

The chapter “Use of the bypass circuitry” must read as well.

The bypass switch must not be operated if the green indicator is OFF !

A failure to observe this may result in a short circuit when switching S1 to position “I+II” and

may result in the loss of power to the connected loads.

Conditions and settings of the ATICS® unit for the use of the bypass switch S1:

The wiring must be done in accordance to the provided wiring diagram:

In the menu of the ATICS® unit under menu „4. settings“ and under menu „6. Dig. input" the

following settings have to be made:

o „1. Function" Bypass

o „2. Voltage“ 0V

o „3. T(on)“ 100ms

o „4. T(off)“ 100ms

Note the bypass label.

The green plugs of the ATICS® unit must be held on the isolated part only. A failure not to do

this will result in danger of electric shock.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 34

Page 35

Technical data of the fuses

Tripping current

4A, slow acting

Breaking capacity

10kA

ELU Type

189140

Dimensions

6,25 x 32mm

7.3. Fuses F1, F2

The changeover and monitoring module UMA is equipped with two fuses (F1, F2) as a short circuit

protection of the ATICS® unit.

If one of the fuse is tripped, there may be a defect in the changeover module. These fuses

should only be replaced after consulting the Bender Service department.

Optional the changeover and monitoring module UMA can be equipped with an additional 2-pole circuit

breaker F3. This breaker protects an 230V auxiliary output for supplying alarm and control panels (e.g. FM, TM-, TCP-series) An overload or short circuit situation will trip this breaker. The 230V auxiliary output is

provided on terminal.

Please refer to the attached individual, job or project related documentation like wiring diagram

and elevation drawing.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 35

Page 36

Test

To be

performed by

Interval

Functional test of IT system monitoring

(insulation, load current, transformer temperature and connection

monitoring) by pressing the TEST button on the remote alarm indicator

or on the alarm and control panel.

Medical

personnel

once every

working day

Functional test of the changeover module*)

Test of the automatic changeover modules. Please observe the

information in chapter "Testing the changeover module"!

Skilled person

every 6 months

Functional test of the IT system monitoring *)

(insulation, load current, transformer temperature and connection

monitoring) on the insulation monitoring device.

Skilled person

every 6 months

Testing the set values and the changeover periods *)

Skilled person

every 12

months

Testing of the changeover module*), the IT system monitoring*), the

connection to the SCADA system *) (Supervisory Control And Data

Acquisition) if applicable and the interaction of the components in the

system.

This test includes the following services:

- Inspection: Marking, display elements, mechanical components,

wiring, parameterisation, connection of third-party equipment,

evaluation of fault memory

- Measurement: Internal/external supply voltages/potentials, bus

voltage, bus protocol, bus scan

- Practice test: Device function, device communication

- Documentation: Test results, recommendations for remedial action

Bender-Service

every 24

months

8. Periodic verification and Service

8.1. Periodic verification

The following periodic verification must be performed on electrical installations in compliance with the local

or national regulations that apply. We recommend for your Bender products:

*) This test must only be performed by an electrically skilled person who has been commissioned

to do so in agreement with the person responsible for the medical location

Before carrying out the tests, please refer to the instructions relating to the functional tests in the attached

checklist.

If no national directives apply, you should perform the tests recommended by IEC 60364-7-710:2002-11,

section 710.62 and DIN VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.62.

Alle Rechte und Änderungen vorbehalten. Subject to change without notice. All rights reserved. © Bender GmbH & Co KG

UMA710-2-xx-ISO-xx, Manual.docx Issued: 11.Jan.2016 36

Page 37

8.2. Commissioning and service

For on-site commissioning of the changeover and monitoring module or switchgear systems by Bender

contact:

Bender GmbH

Londorferstr. 65 • 35305 Grünberg • Germany

Tel: +49 6401 807-0 • Fax: +49 6401 807-259

E-Mail: info@bender.de • www.bender-de.com

For the periodic verification of the changeover and monitoring module or switchgear systems by the Bender

Service department contact:

Service-Hotline:

0700-BenderHelp (Telefon and Fax)

8.3. Maintenance

The changeover and monitoring module does not contain any parts that require maintenance. Despite this,

the intervals specified for periodic verification should be adhered to.

We do recommend to check and tighten all terminal screws (e.g. on the ATICS® unit, bypass switch,…)

when doing the periodic verification by skilled personnel.