Bender ATICS-2-63A-DIO, ATICS-4-80A-DIO, ATICS-4-125A-DIO, ATICS-4-160A-DIO, ATICS-2-80A-DIO User Manual

Page 1

Manual

EN

ATICS-2-63A-DIO, ATICS-2-80A-DIO,

ATICS-4-80A-DIO, ATICS-4-125A-DIO,

ATICS-4-160A-DIO

Automatic transfer switching devices

for safety power supplies

Software version:

D333 V1.2x/D334 V1.2x/D335 V1.0x

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 2

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Gruenberg • Germany

Londorfer Straße 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-mail: info@bender.de • www.bender.de

Photos: Bender archives.

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Page 3

Table of Contents

1. Important information ........................................................................................... 7

1.1 How to use this manual ......................................................................................................... 7

1.2 Technical support: service and support ........................................................................... 8

1.2.1 First level support .................................................................................................................... 8

1.2.2 Repair service ............................................................................................................................ 8

1.2.3 Field service ................................................................................................................................ 8

1.3 Training courses ....................................................................................................................... 9

1.4 Delivery conditions ................................................................................................................. 9

1.5 Inspection, transport and storage ..................................................................................... 9

1.6 Warranty and liability ............................................................................................................. 9

1.7 Disposal .................................................................................................................................... 10

2. Safety instructions ............................................................................................... 11

2.1 General safety instructions ................................................................................................ 11

2.2 Work activities on electrical installations ..................................................................... 11

2.3 Intended use ........................................................................................................................... 11

2.4 Device-specific safety instructions ................................................................................. 12

2.5 General safety instructions ................................................................................................ 12

3. System description .............................................................................................. 13

3.1 Properties ................................................................................................................................. 13

3.1.1 Product description .............................................................................................................. 13

3.1.2 Changeover ............................................................................................................................. 13

3.1.3 Messages .................................................................................................................................. 13

3.1.4 Other functions ...................................................................................................................... 13

3.2 Functional safety ................................................................................................................... 14

3.2.1 Product life-cycle management ...................................................................................... 14

3.3 Application example ............................................................................................................ 15

3.4 ATICS® tasks ............................................................................................................................. 16

3.5 The ATICS® functions ........................................................................................................... 16

3.5.1 The automatic transfer switching device ..................................................................... 16

3.5.1.1 Time diagram: Changeover between the preferred and the redundant line

18

3.5.1.2 Time diagram: Staggered switching after complete power failure ............. 19

ATICS-DIO_D00080_02_M_XXEN/08.2017

3

Page 4

Table of Contents

3.5.1.3 Time diagram: Changeover to generator mode .................................................. 20

3.5.2 Monitoring the device functions ..................................................................................... 21

3.5.3 Power supply ........................................................................................................................... 21

3.5.4 Manual mode .......................................................................................................................... 21

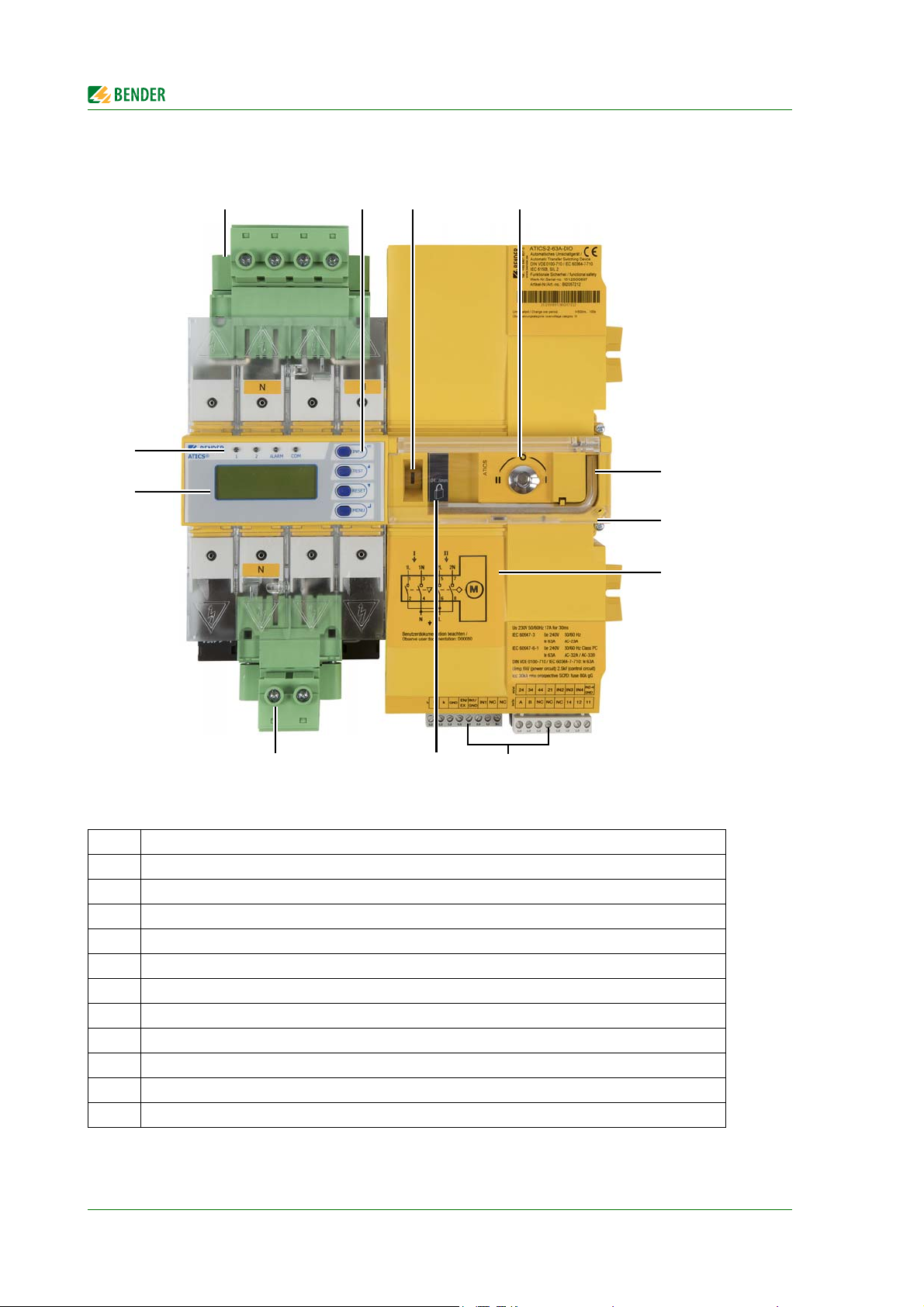

3.6 ATICS-2-DIO front view ....................................................................................................... 22

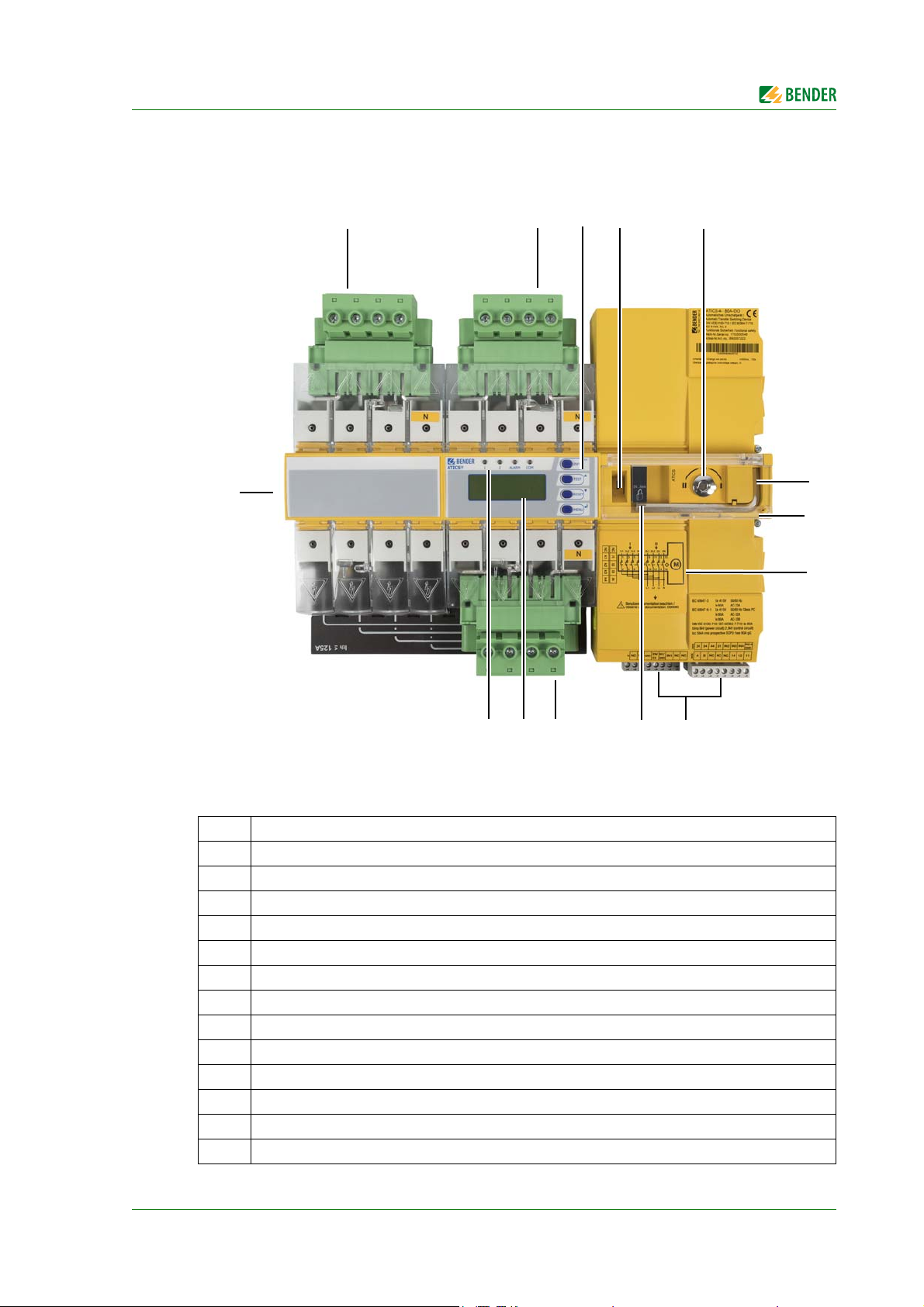

3.7 ATICS-4-DIO front view ....................................................................................................... 23

4. Installation and connection ............................................................................... 25

4.1 Mounting .................................................................................................................................. 25

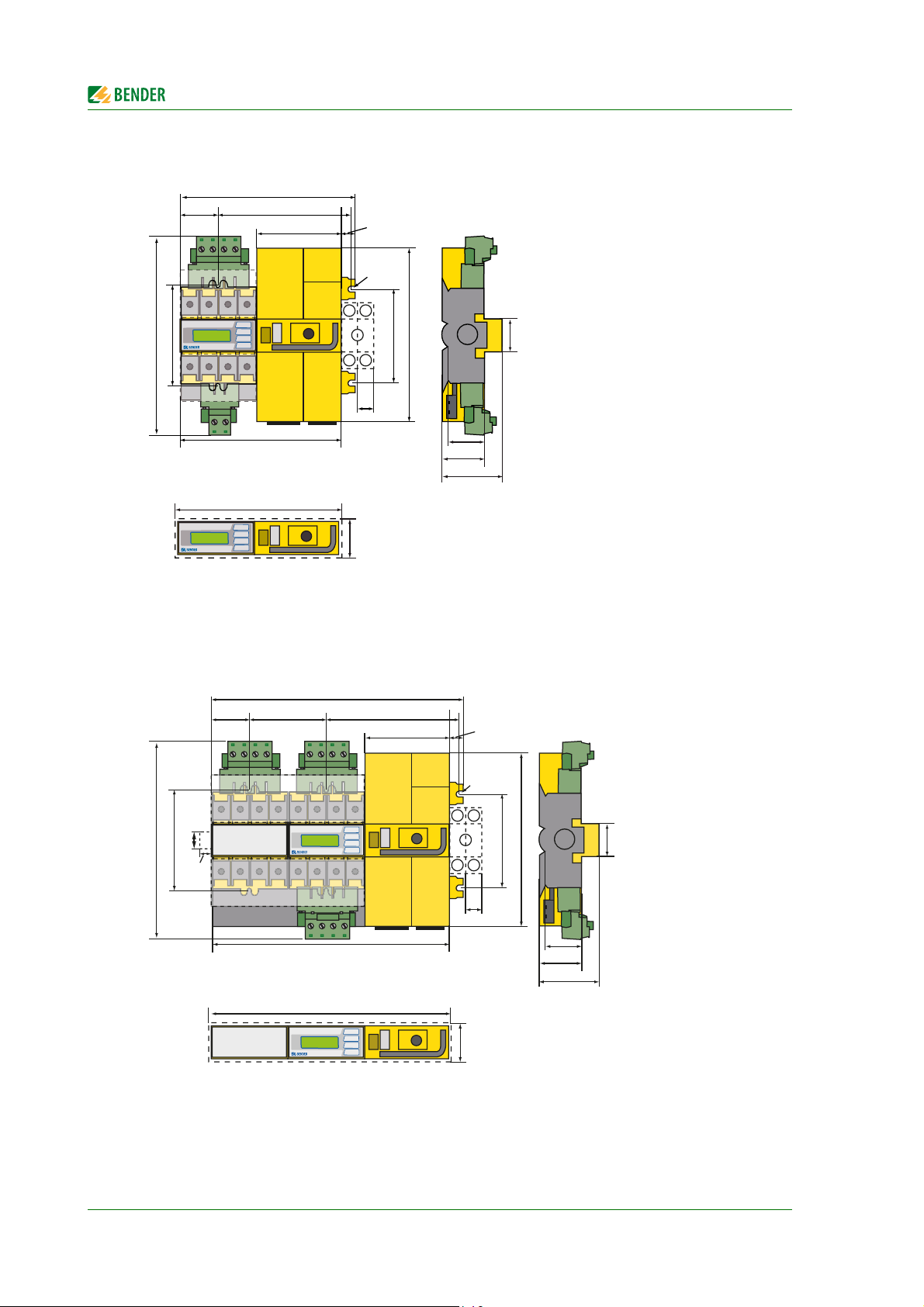

4.1.1 ATICS-2-DIO dimension diagram ..................................................................................... 26

4.1.2 ATICS-4-DIO dimension diagram ..................................................................................... 26

4.1.3 Removing the terminal covers .......................................................................................... 27

4.1.4 Mounting on DIN rail ............................................................................................................ 27

4.1.5 Screw mounting on plate ................................................................................................... 28

4.2 Connection ............................................................................................................................... 29

4.2.1 Short-circuit protection ....................................................................................................... 29

4.2.2 Connecting ATICS® safely ...................................................................................................30

4.2.3 Connection example: ATICS-2-DIO basic configuration .......................................... 33

4.2.4 Connection example: ATICS-4-DIO basic configuration .......................................... 34

4.2.5 Connection example: ATICS-2-DIO with bypass switch .......................................... 35

4.2.6 Connection example: ATICS-2-DIO with bypass switch .......................................... 36

4.2.7 Instructions for connection ................................................................................................37

4.2.7.1 BMS bus .............................................................................................................................. 37

4.2.7.2 MK… alarm indicator and test combination and TM… alarm indicator and

operator panels ............................................................................................................... 37

4.2.7.3 SCADA systems (Supervisory Control and Data Acquisition) ......................... 37

4.2.7.4 Bypass switch (optional) ............................................................................................... 37

4.2.8 Fastening, inserting and securing connections .......................................................... 38

4.3 Other functions ...................................................................................................................... 39

4.3.1 Sealing the transparent cover of the transfer switching device ........................... 39

4.3.2 Manual mode .......................................................................................................................... 39

4.3.3 Locking the transfer switching device with a padlock ............................................. 40

5. Commissioning, settings and testing ............................................................... 41

5.1 Design and installation ........................................................................................................ 41

5.1.1 Configure MK… or TM… .................................................................................................... 42

5.1.2 ATICS-2-DIO: Messages on the BMS bus (channel use) ........................................... 42

5.1.3 ATICS-4-DIO: Messages on the BMS bus (channel use) ........................................... 43

5.1.4 Tests, decommissioning ...................................................................................................... 44

5.2 Setting and testing according to the checklist ........................................................... 45

4

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 5

Table of Contents

5.3 Addressing example ............................................................................................................ 46

6. Operation ............................................................................................................... 47

6.1 Operating and display elements ..................................................................................... 47

6.2 Quick reference guide ......................................................................................................... 48

6.2.1 ATICS-2-DIO: Display under normal operating conditions .................................... 48

6.2.2 ATICS-4-DIO: Display under normal operating conditions .................................... 49

6.2.3 Display during fault condition ......................................................................................... 50

6.2.4 Test function ........................................................................................................................... 51

6.2.4.1 Test menu 1: Autom. changeover ............................................................................ 52

6.2.4.2 Test menu 2: Manual changeover ............................................................................ 53

6.2.4.3 Test menu 3: Last switch .............................................................................................. 54

6.2.4.4 Test menu 4: Generator ............................................................................................... 55

6.2.4.5 Test menu 5: Test communication .......................................................................... 56

6.2.5 Reset function ........................................................................................................................ 57

6.2.5.1 Reset menu 1: Alarm ..................................................................................................... 57

6.2.5.2 Reset menu 2: SwitchBackLock ................................................................................. 58

6.2.5.3 Reset menu 3: Changeover ......................................................................................... 59

7. Menu mode: Operation and setting ................................................................. 61

7.1 Switching on and calling up the main menu .............................................................. 61

7.2 Menu overview diagram .................................................................................................... 62

7.3 Main menu functions ........................................................................................................... 63

7.3.1 Menu 1: Alarm/meas.values .............................................................................................. 63

7.3.1.1 Alarm/meas. values ATICS-2-DIO ............................................................................. 63

7.3.1.2 Alarm/meas. values ATICS-4-DIO ............................................................................. 64

7.3.2 Menu 2: Changeover ............................................................................................................ 65

7.3.3 Menu 3: History/Logger ...................................................................................................... 66

7.3.3.1 Operating example: History ....................................................................................... 67

7.3.3.2 Operating example: Config.logger .......................................................................... 67

7.3.4 Menu 4: Settings .................................................................................................................... 68

7.3.4.1 Settings menu 1: Changeover ................................................................................... 69

7.3.4.2 Settings menu 2: Voltage ............................................................................................ 71

7.3.4.3 Settings menu 3: Current ............................................................................................ 72

7.3.4.4 Settings menu 4: Relay ................................................................................................. 73

7.3.4.5 Settings menu 5: Digital input ................................................................................... 75

7.3.4.6 Settings menu 6: Data logger .................................................................................... 77

7.3.4.7 Settings menu 7: Language ........................................................................................ 79

7.3.4.8 Settings menu 8: Interface .......................................................................................... 79

7.3.4.9 Settings menu 9: Clock ................................................................................................. 80

ATICS-DIO_D00080_02_M_XXEN/08.2017

5

Page 6

Table of Contents

7.3.4.10 Settings menu 10: Password ....................................................................................... 81

7.3.4.11 Settings menu 11: Service ........................................................................................... 82

7.3.5 Menu 5: Control ...................................................................................................................... 83

7.3.6 Menu 6: Digital Input ............................................................................................................ 83

7.3.7 Menu 7: Info ............................................................................................................................. 83

8. Troubleshooting ................................................................................................... 85

8.1 Fault and alarm messages .................................................................................................. 85

8.1.1 Plain text messages ............................................................................................................... 85

8.1.2 Messages with error code or service code ................................................................... 86

8.2 Frequently asked questions ............................................................................................... 88

9. Periodic verification and service ....................................................................... 91

9.1 Periodic verification .............................................................................................................. 91

9.2 Maintenance ............................................................................................................................ 92

9.3 Cleaning .................................................................................................................................... 92

9.4 Operation with bypass switch .......................................................................................... 92

9.5 Replace ATICS® ....................................................................................................................... 93

9.5.1 Removing the existing ATICS® .......................................................................................... 94

9.5.2 Installing a new ATICS® ........................................................................................................ 97

10. Technical data ..................................................................................................... 99

10.1 Tabular data ............................................................................................................................. 99

10.2 TÜV test report according to VDE0100 Part 710 ..................................................... 103

10.3 TÜV certificate regarding functional safety .............................................................. 104

10.4 Standards and certifications ........................................................................................... 105

10.5 Ordering details ................................................................................................................... 106

10.6 Additional documents ...................................................................................................... 107

INDEX ......................................................................................................................... 109

6

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 7

1. Important information

DANGER

WARNING

CAUTION

1.1 How to use this manual

This manual describes how to operate the ATICS® automatic transfer switching device.

Before using the devices, please read this operating manual, the supplement entitled "Important

safety instructions for Bender products" and the instruction leaflets supplied with the individual system components.

This manual is intended for qualified personnel working in electrical engineering and electronics, and in particular for those designing, installing and operating electrical equipment in the medical and non-medical sector.

In this manual, the two redundant supply lines of the power supply are labelled as follows:

– "Preferred supply" or "Preferred line" and

– "Second supply" or "Redundant line".

Devices with displays use the terms "Line 1" and "Line 2" in the text they indicate.

Always keep this manual within easy reach for future reference.

To make it easier for you to understand and revisit certain sections in this manual, we hav e used symbols to identify important instructions and information. The meaning of these symbols is explained

below:

This signal word indicates that there is a high risk of danger, that will result in

death or serious injury if not avoided.

This signal word indicates a medium risk of danger that can lead to death or serious injury, if not avoided.

This signal word indicates a low-level risk that can result in minor or moderate

injury or damage to property if not avoided.

This symbol denotes information intended to assist the user in making optimum

use of the product.

ATICS-DIO_D00080_02_M_XXEN/08.2017

7

Page 8

Important information

This manual has been compiled with great care. It might nevertheless contain errors and mistakes.

Bender cannot accept any liability for injury to persons or damage to property resulting from errors

or mistakes in this manual.

ATICS® is a registered trademark of Bender GmbH & Co. KG.

1.2 Technical support: service and support

For commissioning and troubleshooting Bender offers you:

1.2.1 First level support

Technical support by phone or e-mail for all

Bender products

Questions concerning specific customer applications

Commissioning

Troubleshooting

Telephone:

Fax:

In Germany only:

E-mail:

+4 19 640 807-76 0*

+4 640129 807- 59

0700BenderHelp (Tel. and Fax)

support@bender-service.de

1.2.2 Repair service

Repair, calibration, update and replacement service for Bender products

Repairing, calibrating, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices in the event of faulty or incorrectly delivered Bender devices

Extended guarantee for Bender devices, which includes an in-house repair service or replace-

ment devices at no extra cost

Telephone:

Fax:

E-mail:

Please send the devices for repair to the following address:

+49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (sales)

+4 640179 807- 89

repair@bender-service.de

Bender GmbH, Repair-Service,

Londorfer Straße 65,

35305 Grünberg

1.2.3 Field service

On-site service for all Bender products

Commissioning, parameter setting, maintenance, troubleshooting for Bender products

Analysis of the electrical installation in the building (power quality test, EMC test,

thermography)

Training courses for customers

8

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 9

Important information

Telephone:

+49 6401 807-752**, -762 **(technical issues)

+49 6401 807-753** (sales)

Fax:

E-mail:

Internet:

+49 6401 807-759

fieldservice@bender-service.de

www.bender.de

*Available from 7.00 a.m. to 8.00 p.m. 365 days a year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m.

1.3 Training courses

Bender is happy to provide training regarding the use of test equipment. The dates of training courses and workshops can be found on the Internet at www.bender-de.com -> Know-how -> Seminars.

1.4 Delivery conditions

Bender sale and delivery conditions apply.

For software products the "Softwareklausel zur Überlassung von Standard-Software als Teil von

Lieferungen, Ergänzung und Änderung der Allgemeinen Lieferbedingungen für Erzeugnisse und

Leistungen der Elektroindustrie" (software clause in respect of the licensing of standard software as

part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband Elektrotechnik- und Elektronikindustrie e. V.) (German Electrical and Electronic Manufacturer's Association) also applies.

Sale and delivery conditions can be obtained from Bender in printed or electronic format.

1.5 Inspection, transport and storage

Inspect the dispatch and equipment packaging for damage, and compare the contents of the package with the delivery documents. In the event of damage in transit, please contact Bender immediately.

The devices must only be stored in areas where they are protected from dust, damp, and spray and

dripping water, and in which the specified storage temperatures can be ensured.

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to property are excluded if

they can be attributed to one or more of the following causes:

Improper use of the device.

Incorrect mounting, commissioning, operation and maintenance of the device.

Failure to observe the instructions in this operating manual regarding transport,

commissioning, operation and maintenance of the device.

Unauthorised changes to the device made by parties other than the manufacturer.

Non-observance of technical data.

Repairs carried out incorrectly and the use of replacement parts or accessories not approved by

the manufacturer.

Catastrophes caused by external influences and force majeure.

Mounting and installation with device combinations not recommended by the manufacturer.

This operating manual, especially the safety instructions, must be observed by all personnel working

on the device. Furthermore, the rules and regulations that apply for accident prevention at the place

of use must be observed.

ATICS-DIO_D00080_02_M_XXEN/08.2017

9

Page 10

Important information

1.7 Disposal

Abide by the national regulations and laws governing the disposal of this device. Ask your supplier

if you are not sure how to dispose of the old equipment.

The directive on waste electrical and electronic equipment (WEEE directive) and the directive on the

restriction of certain hazardous substances in electrical and electronic equipment (RoHS directive)

apply in the European Community. In Germany, these policies are implemented through the "Electrical and Electronic Equipment Act" (ElektroG). According to this, the following applies:

Electrical and electronic equipment are not part of household waste.

Batteries and accumulators are not part of household waste and must be disposed of in accord-

ance with the regulations.

Old electrical and electronic equipment from users other than private households which was

introduced to the market after 13 August 2005 must be taken back by the manufacturer and

disposed of properly.

For more information on the disposal of Bender devices, refer to our website at www.bender-de.com

-> Service & support.

10

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 11

2. Safety instructions

DANGER

2.1 General safety instructions

Part of the device documentation in addition to this manual is the enclosed "Safety instructions for

Bender products".

2.2 Work activities on electrical installations

Only qualified personnel are permitted to carry out the work necessary to install, commission and run a device or system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-energised. Observe the rules for working on electrical installa-

tions.

If the device is used outside the Federal Republic of Germany, the applicable local standards and regulations must be complied with. The European standard EN 50110 can be used as a guide.

2.3 Intended use

Changeover devices are used everywhere there is dependence on high availability from the power

supply. The ATICS® transfer switching device is intended for the application described in the chapter

"System description". When the preferred supply fails, ATICS® automatically switches to the second

supply.

Areas of application:

Group 1 and 2 medical locations according to DIN VDE 0100-710 and

IEC 60364-7-710

Hospital main distribution boards (DIN VDE 0100-710)

Locations open to the public (DIN VDE 0100-718)

Emergency power supplies

Heating, air conditioning, ventilation, cooling

EDP, computer centres

Fire extinguisher and sprinkler systems

Several versions of ATICS® are available. They differ for example by changing over from two- or fourpole systems or by the load current (see chapter "ATICS® tasks" on page 16). Please heed the limits of

the range of application indicated in the technical data.

ATICS-DIO_D00080_02_M_XXEN/08.2017

11

Page 12

Safety instructions

WARNING

WARNING

In order to meet the requirements of applicable standards, customised parameter settings must be

made on the equipment in order to adapt it to local equipment and operating conditions.

Intended use includes following all the instructions in the operating manual and complying with the

test intervals.

Any use other than that described in this manual is regarded as improper.

2.4 Device-specific safety instructions

Failure to adjust settings may result in malfunction

The settings must be changed in order to adapt the ATICS® transfer switching device to the existing equipment. When doing so, follow the instructions in

chapter "5. Commissioning, settings and testing", page 41 et seq.

Functional safety according to IEC 61508 can only be guaranteed when

used properly

Please follow the instructions given in this operating manual and in the check

list.

In particular note the information on the pages: 14, 15, 16, 21, 59 and 88.

2.5 General safety instructions

Bender devices are designed and built in accordance with the state of the art and accepted rules in

respect of technical safety. However, the use of such devices may introduce risks to the life and limb

of the user or third parties and/or result in damage to Bender devices or other property.

Use Bender devices only:

–as intended

– in perfect working order

– in compliance with the accident prevention regulations and guidelines applicable at the

location of use

Eliminate all faults immediately which may endanger safety.

The device may not be opened.

Do not make any unauthorised changes and only use replacement parts and optional accesso-

ries purchased from or recommended by the manufacturer of the devices. Failure to observe

this requirement can result in fire, electric shock and injury.

Reference signs must always be clearly legible. Replace damaged or illegible signs immediately.

Make sure that the dimensions of the BSV (battery-supported safety power supply), the genera-

tor set and the whole wiring is adequate. Abide by the relevant, applicable national and international standards. In the event of an overload and short circuit, this is the only way to

guarantee the necessary safety and to ensure that the safety devices respond selectively.

If the device is overloaded by overvoltage or a short-circuit current load, it must be checked

and replaced if necessary.

The overvoltage protective device required by the standards VDE 0100-443 and VDE 0100-534

must be installed in the electrical installation or system.

12

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 13

3. System description

3.1 Properties

3.1.1 Product description

The ATICS® transfer switching devices provide all functions for changeover between two independent power supplies. The integration of both the electronic system and the switching elements in one

flat, compact device reduces space requirements in the switchgear cabinet, minimises the amount

of wiring, and reduces the fault probability. For maximum reliability, ATICS® was designed in strict

accordance with the guidelines for functional safety.

Connectors at all connecting wires in combination with bypass switches enable ATICS® to be tested

during ongoing operation. In case of need for service, it is possible to repair or replace the device

without interrupting the power supply. ATICS® considerably enhances the safety level in industry

and other sensitive environments like hospitals.

3.1.2 Changeover

Automatic changeover to the second (redundant) line on loss of the preferred supply or when

the values are outside the permissible voltage range

Voltage monitoring line 1/2 (input) and line 3 (output)

Automatic return to the preferred line on voltage recovery

Monitoring for short circuits at the output or at the distribution board downstream of the trans-

fer switching device avoids damaging switching operations

Manual operation, optionally locked with a padlock

3.1.3 Messages

Status indication of operating, warning and alarm messages via integrated graphic display

and external indication at MK2430/MK800/TM800 alarm indicator and operator panels

Automatic reminder for prescribed tests and service intervals

History memory for events, messages, tests and parameter changes

Exchange of information with alarm indicator and operator panels via BMS bus

3.1.4 Other functions

Automatic monitoring of all programme and data storage as well as essential internal compo-

nents and connecting wires for proper functioning

4 programmable relay outputs (alarm relays)

4 programmable digital inputs

ATICS-DIO_D00080_02_M_XXEN/08.2017

13

Page 14

System description

Production Commissioning RecyclingDecommissioningMaintenance

Bender plant operator Bender

3.2 Functional safety

Functional safety according to IEC 61508 guarantees safety from risks arising from malfunction when

used properly. ATICS® is suitable for use in safety-related systems according to SIL2. SIL stands for

"Safety Integrity Level".

3.2.1 Product life-cycle management

Safety must be guaranteed over the entire life cycle, from the time it is designed, developed, manufactured, commissioned, maintained to the time it is taken out of service.

Responsibility during the life cycle:

For detailed information refer to

chapter "5. Commissioning, settings and testing" on page 41

chapter "9. Periodic verification and service" on page 91

14

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 15

System description

I

II

I

II

U

1

U

2

U

3

I

computing centre

Anlage

betriebsbereit

MK800

NORMAL WARNING ALARM

ESC

TEST MENU

RCMS

ATI C S

M

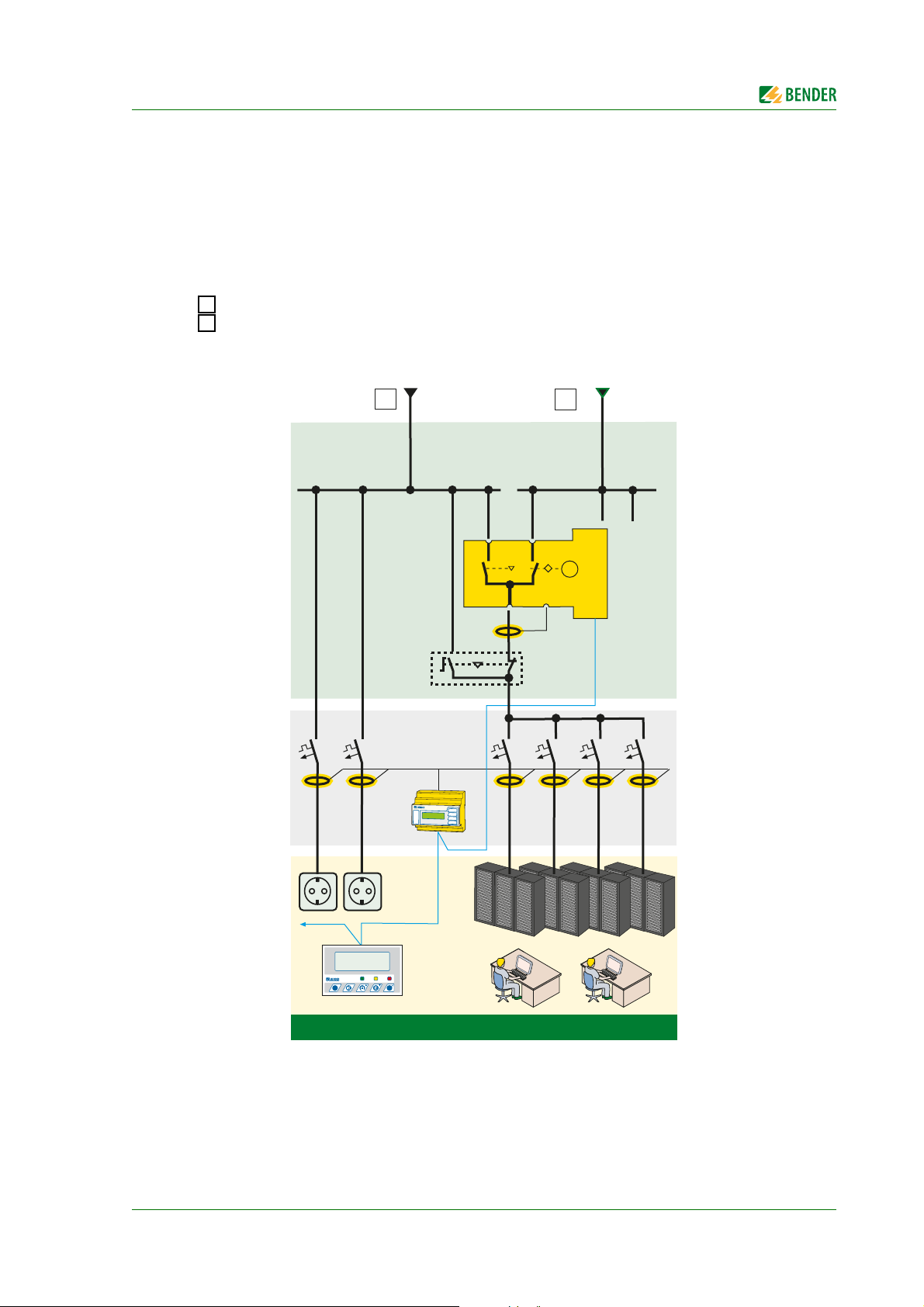

3.3 Application example

ATICS-2-63A-DIO: Changeover between the preferred and the redundant line

MK2430/MK800/TM800: Alarm at at least two points with independent power supplies for func-

tional safety

RCMS: RCMS460 or RCMS490 residual current monitors for localising residual and operating

currents in TT and TN-S systems

Preferred supply line

Redundant supply line (e.g. generator)

ATICS-DIO_D00080_02_M_XXEN/08.2017

15

Page 16

System description

3.4 ATICS® tasks

The ATICS® transfer switching device has the following capabilities:

Two-pole or four-pole changeover of the power supply

Voltage monitoring for the preferred supply (Line 1)

Voltage monitoring for the second supply (Line 2)

Voltage monitoring at the transfer switching device output (line 3)

Monitoring of the changeover switch for correct switch position

Internal functional testing, including checking the switching times

Communication to remote MK... alarm indicator and test combinations, and to TM… alarm indi-

cator and operator panels via BMS bus

Option for adjusting the time delay for the changeover process according to DIN VDE 0100-710

(VDE 0100 Part 710)

Possible field of application in systems according to DIN VDE 0100-710 (VDE 0100 Part 710) with

a changeover period ≤ 15 s or even ≤ 0.5 s

3.5 The ATICS® functions

3.5.1 The automatic transfer switching device

If the preferred supply fails, ATICS® ensures that the power supply is changed over safely.

The switch contacts are offset on a rotating shaft. This design prevents simultaneous switching of

line 1 and line 2. The switch has three positions:

1 Line 1 switched on

0 Both lines switched off

2 Line 2 switched on

Either line 1 or line 2 can be set as the preferred line (setting described in "Settings menu 1: Changeover" on page 69 or "Settings menu 5: Digital input" on page 75).

1. In normal operating condition (fault-free operation) the preferred supply is connected. ATICS®

will switch to the redundant line if:

– the preferred line fails

– the "TEST" button is pressed

– a digital input is configured to "TEST" and this input is enabled

– the setting "Preferred Line" is reconfigured to the other line

16

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 17

System description

WARNING

2. ATICS® will switch from the redundant line back to the preferred line if

– the voltage on the preferred line is restored

- the return transfer delay time t(2->1) has expired and no switching back interlocking

function is enabled

- immediately after pressing the "RESET" button or when the redundant line fails

(even when the switching back interlocking function is enabled)

– the setting "Preferred Line" is reconfigured to the other line

– the digital input is configured to "TEST" and this input is reset

– a test of the transfer switching device is active and the test period has elapsed

Failure to adjust delay times may result in malfunctions

The response delay t(on), the return transfer delay time t(2->1), the delay on release t(off) and the dead time t(0) of ATICS® are adjustable and must be adjusted

to the requirements of the specific case, the short-circuit calculation and the requirements of DIN VDE 0100-710 (VDE 0100 Part 710) for automatic changeover

devices (see chapter "Commissioning, settings and testing").

The factory settings guarantee a changeover period of t ≤ 0.5 seconds and switching back within 10

seconds when voltage is restored on the preferred supply. Therefore, ATICS® can be used in IT systems with a requirement for a changeover period t ≤ 0.5 s (IT systems with operating theatre lights,

endoscopic field illumination in operating theatres or other essential sources of light, etc.).

When there is a short circuit downstream of the transfer switching device, the transfer switching device must not continually change back and forth between the two lines. This can occur when the

short-circuit current is small and the transfer switching device switches faster than the short-circuit

breaker trips. ATICS® monitors the load current downstream of the transfer switching device in order

to detect a possible short circuit. If the preferred line fails and a short-circuit current is detected at

the same time, ATICS® does not switch over immediately but only once the circuit breaker has

tripped.

If ATICS® detects a supply failure or a fault, an alarm appears on the LCD, the "ALARM" LED lights up,

the alarm relay trips (if set) and this alarm is forwarded to other Bender devices (such as an alarm indicator and test combination) via the BMS bus.

Phase sequence direction errors are recognised and indicated on the LC display. Even so ATICS®

switches over to the redundant line.

ATICS-DIO_D00080_02_M_XXEN/08.2017

17

Page 18

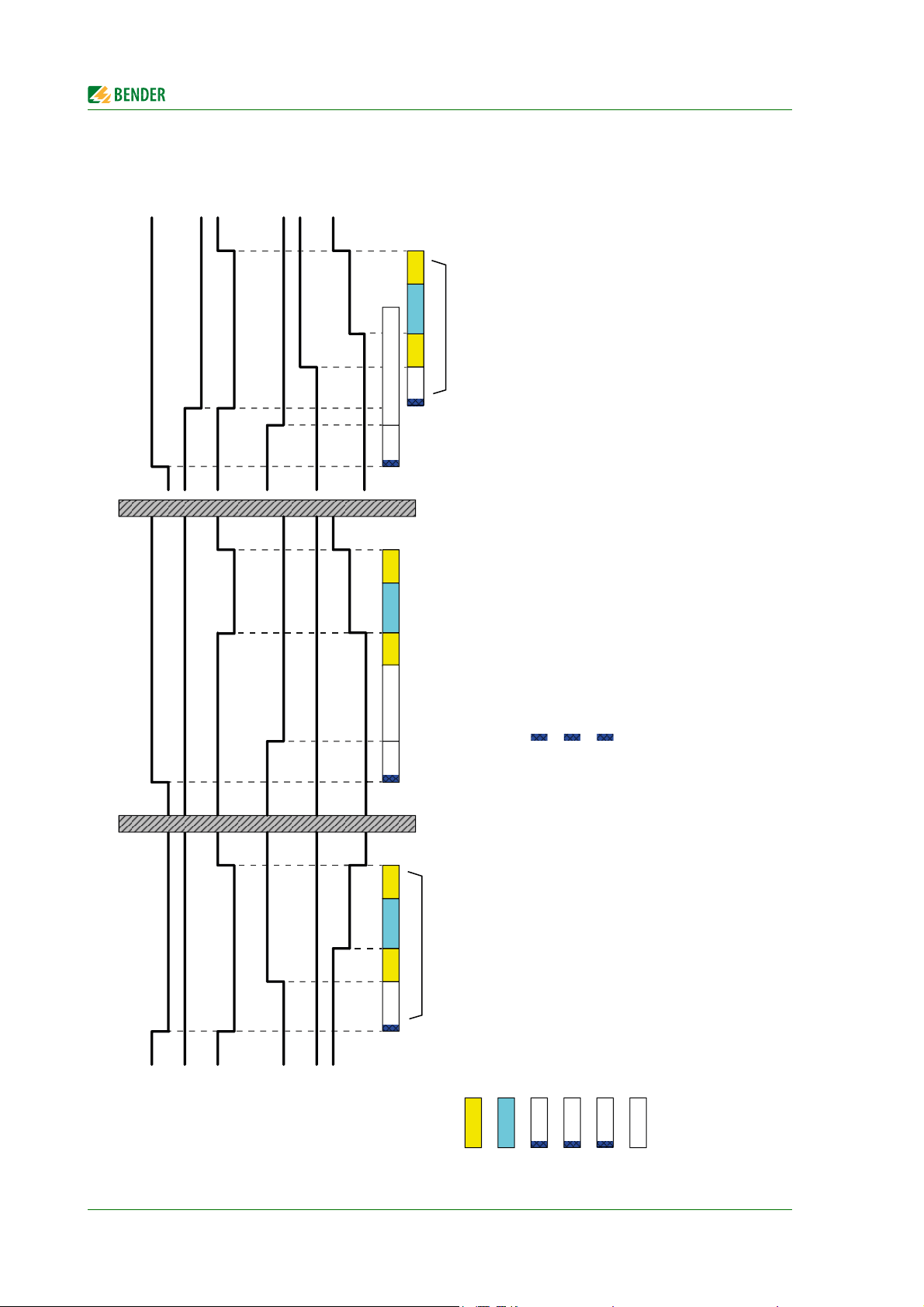

3.5.1.1 Time diagram: Changeover between the preferred and the redundant line

Note: Times are not shown to scale.

Example: Line 1 is set as the preferred line.

1

t(Imp)

System description

Switching back to Line 1

(if Line 2 has failed)

Switching back to Line 1

(normal operation with delay on relase)

t(2->1)

1

t(off)

t(0)

t(Imp)

2

t(on)

*2

0

2

1

t(Imp)

0

t(0)

t(Imp)

t(2->1)

1

t(off)

: Measuring time: approx. 50 ms

: Measuring time: approx. 50 ms

: Measuring time: approx. 50 ms

: Changeover period t(1->2) indicated during a test

: The return transfer delay time may differ from the changeover period (t(1->2)

*2

*1

Changeover to Line 2

(if Line 1 has failed)

Voltage

Line 1

Voltage

18

Line 2

Voltage

Output

Alarm Failure

ATICS

Line 1

2

t(Imp)

t(0)

*1

t(Imp)

1

t(on)

10

102

Alarm Failure

Line 2

Switch

position

Time

delay

: Response delay ALARM failure voltage Line 1

: Pulse time: 15 … 30 ms

t(0) : Dead time

t(Imp)

: Delay on release ALARM failure voltage Line 1

1

1

t(off)

t(on)

ATICS-DIO_D00080_02_M_XXEN/08.2017

: Response delay ALARM failure voltage Line 2

2

t(on)

t(2->1) : Return transfer delay time

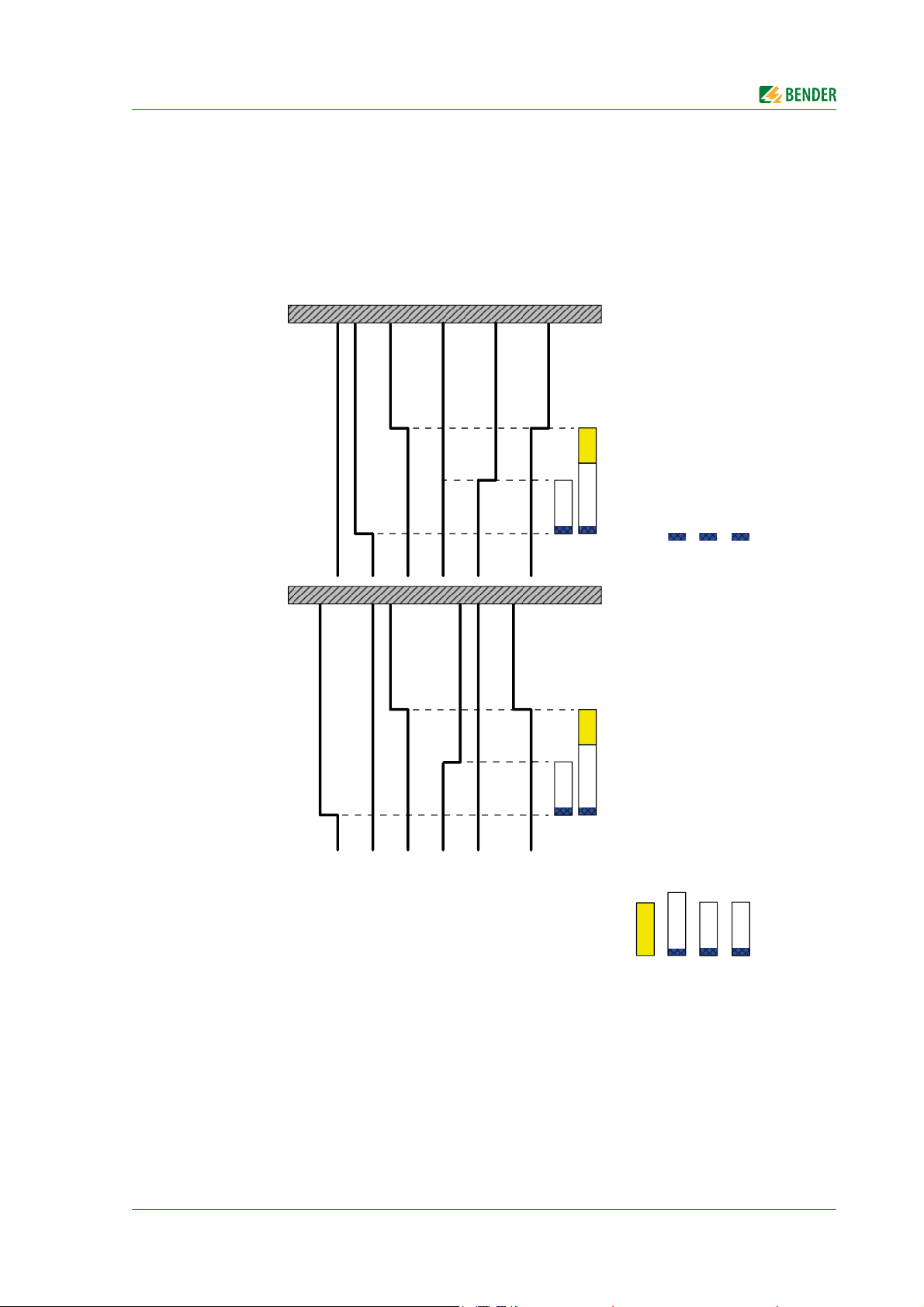

Page 19

System description

102

Option: Staggered

switching after total

power failure

t(Start)

t(Imp)

0

1

Option: Staggered

switching after total

power failure

0

2

Voltage

Line 1

Switch

position

Voltage

Output

ATICS

Voltage

Line 2

Time

delay

Alarm failure

Line 1

Alarm failure

Line 2

t(Start)

: Switch-on delay after total power failure

: Delay on release ALARM failure voltage Line 1

Wenn die Spannung kommt, starten gleichzeitig t(off) und t(Anlauf). Die längere Zeit bestimmt das Verhalten.

t(Imp)

: Pulse time: 15 … 30 ms

: Measuring time: approx. 50 ms

: Measuring time: approx. 50 ms

t(off)

1

t(Start)

t(Imp)

t(off)

2

t(off)

1

: Delay on release ALARM failure voltage Line 2

: Measuring time: approx. 50 ms

t(off)

2

Note: Times are not shown to scale.

3.5.1.2 Time diagram: Staggered switching after complete power failure

After a complete power failure (i.e. no voltage on either of the power supplies) it is often necessary

to switch to the supply at staggered intervals. This prevents all loads being switched on simultaneously. Switch ATICS® to position "0" using an Allen key. When power is restored, ATICS® switches on

the supply again with the set delay time t(start).

Example: Line 1 is set as the preferred line.

ATICS-DIO_D00080_02_M_XXEN/08.2017

19

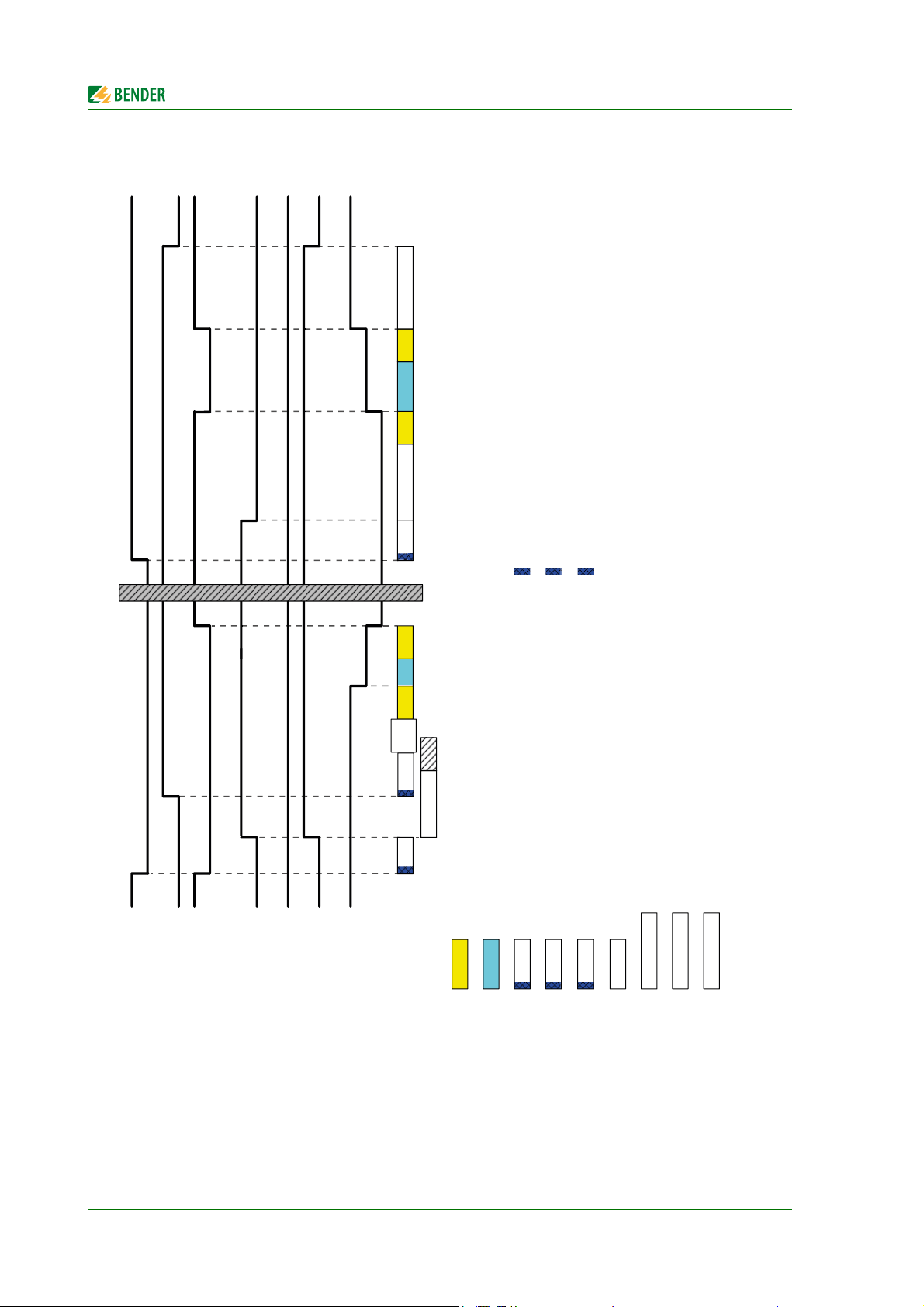

Page 20

3.5.1.3 Time diagram: Changeover to generator mode

Note: Times are not shown to scale.

System description

Switching back to Line 1

(normal operation with delay on release)

1

0

t(GenOff)

t(Imp)

t(0)

t(Imp)

t(2->1)

1

t(off)

: Measuring time: approx. 50 ms

: Measuring time: approx. 50 ms

2

t(Imp)

t(0)

t(Imp)

t(Gen

Start)

1

t(off)

Generator mode

Voltage

Line 1

20

Voltage

Line 2

Voltage

Output

ATICS

Alarm failure

Alarm failure

Line 1

Line 2

t(GenMax)

1

t(on)

10

102

Generator

start relay

Switch

position

Time

delay

: Pulse time: 15 … 30 ms

t(Imp)

: Response delay ALARM failure voltage Line 1

: Delay on release ALARM failure voltage Line 1

: Delay on release ALARM failure voltage Line 2 : Measuring time: approx. 50 ms

1

t(off)

2

t(off)

1

t(0) : Dead time

t(on)

: Generator start-up delay, delayed changeover to generator.

t(GenStart)

t(2->1) : Return transfer delay time

ATICS-DIO_D00080_02_M_XXEN/08.2017

Measurements beyond "Voltage Line 2" ok.

t(GenOff) : Generator disconnecting delay time, delayed switching-off of the generator.

t(GenMax) : Generator start-up time. Monitoring the generator start-up.

Page 21

System description

WARNING

3.5.2 Monitoring the device functions

The control circuits are designed in such a way that, even though it is almost certain that a particular

fault will occur, it cannot cause the power supply at the output of the automatic transfer switching

device to fail.

ATICS® tests the switch position of the switch as well as coils 1 and 2 of the switch once a day at 12:00

p.m.

ATICS® also continuously monitors:

Power supplies 1 and 2, which supply the electronics from the systems concerned

Internal microcontrollers and memory modules

Important connecting wires, such as the measuring current transformer connection

For alarm and test combinations and alarm indicator and operator panels, device failure moni-

toring can also be programmed via the BMS bus (necessary for functional safety).

For systems with generator: total power failure possible

If the preferred line fails, ATICS® will start the generator connected to the redundant line. If the generator does not start, the line downstream of the transfer

switching device will be dead.

When the generator is switched off, ATICS® cannot check the redundant line.

Therefore, regularly test the generator and the transfer switching device to make

sure they are working properly (see checklist in the appendix to this manual).

3.5.3 Power supply

The coils of the switching device are each supplied from the line which is not currently switched on.

This ensures that it is possible to switch to the redundant line if the preferred line fails, for example.

The power supply of the electronic system is of redundant supply from lines 1 and 2. This ensures

constant supply to the electronic system even when one line fails.

If both lines fail, the changeover switch remains in the last switch position. Switch ATICS® to position

"0" using an Allen key. When power is restored, ATICS® switches on the supply again with the set delay time t(start). If several ATICS® are installed in one system, they can be switched to the preferred

line one by one starting from switch position "0" on voltage recovery. This prevents the peak loads

that would occur if the lines of several transfer switching devices were switched on simultaneously.

3.5.4 Manual mode

In manual mode, changeover can be achieved using an Allen key. The switching device can be held

in switch position "0" and locked with a padlock.

ATICS-DIO_D00080_02_M_XXEN/08.2017

21

Page 22

3.6 ATICS-2-DIO front view

14

5

6

8

32

12

11

10 9

7

System description

Legend

1 Green plug connector for line 1 and line 2

2 Control buttons

3 Inspection window for switch position

4 Manual mode of the transfer switching device, indicates the switch position

5 Allen key for manual mode

6 Transparent cover for changeover switch (manual mode), sealable

7 Wiring diagram for lines 1, 2 and 3

8 Three coded connector plugs

9 Locking device for switch position 0

10 Green plug connector for line 3

11 LCD

12 Operating and alarm LEDs

22

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 23

System description

15

6

7

9

43

14

11 10

8

13 12

2

3.7 ATICS-4-DIO front view

Legend

1 Green plug connector for line 1

2 Green plug connector for line 2

3 Control buttons

4 Inspection window for switch position

5 Manual mode of the transfer switching device, indicates the switch position

6 Allen key for manual mode

7 Transparent cover for changeover switch (manual mode), sealable

8 Wiring diagram for lines 1, 2 and 3

9 Three coded connector plugs

10 Locking device for switch position 0

11 Green plug connector for line 3

12 LCD

13 Operating and alarm LEDs

14 Connector plug for measuring current transformer

ATICS-DIO_D00080_02_M_XXEN/08.2017

23

Page 24

System description

24

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 25

4. Installation and connection

DANGER

CAUTION

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of electric shock. Before fitting

the device and prior to working on the device connections, make sure that the

power supply has been disconnected. Observe the rules for working on electrical

installations.

In manual mode, ATICS® can be held in switch position "0" and locked with a

padlock.

Disturbance due to loud switching noise

Install ATICS® in a closed electrical operating area or in a sound-proof distribution board.

4.1 Mounting

Risk of destruction by plastering

Liquid plaster may run into the device and the device may jam.

Do not seal the device with plaster.

ATICS® is suitable for DIN rail mounting or screw mounting on plate. To guarantee the protection

against accidental contact, it is to be installed behind a plastic cover.

ATICS-DIO_D00080_02_M_XXEN/08.2017

25

Page 26

4.1.1 ATICS-2-DIO dimension diagram

*

**

***

***

340

115,3

17610452

14,7

324

263

132

23

15

132

245

M5

18

46

73,5

53

45

326

47

*

**

***

***

****

***

*****

234

52

176

115,3

14,7

M5

Installation and connection

263

132

220

222

18

47

132

245

46

52

73,5

45

* Only when using the bypass switch ATICS-BP-…: additional space required for auxiliary contact

** Adjust the cutout to the terminal cover

*** Dimensions for screw mounting on mounting plate

4.1.2 ATICS-4-DIO dimension diagram

* Only when using the bypass switch ATICS-BP-…: additional space required for auxiliary contact

** Adjust the cutout to the terminal cover

*** Dimensions for screw mounting on mounting plate

**** Additional space required for the connector plug of the measuring current transformer

***** 80 A/125 A version. 160 A version without plug connector.

26

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 27

Installation and connection

B

A

B

A

C

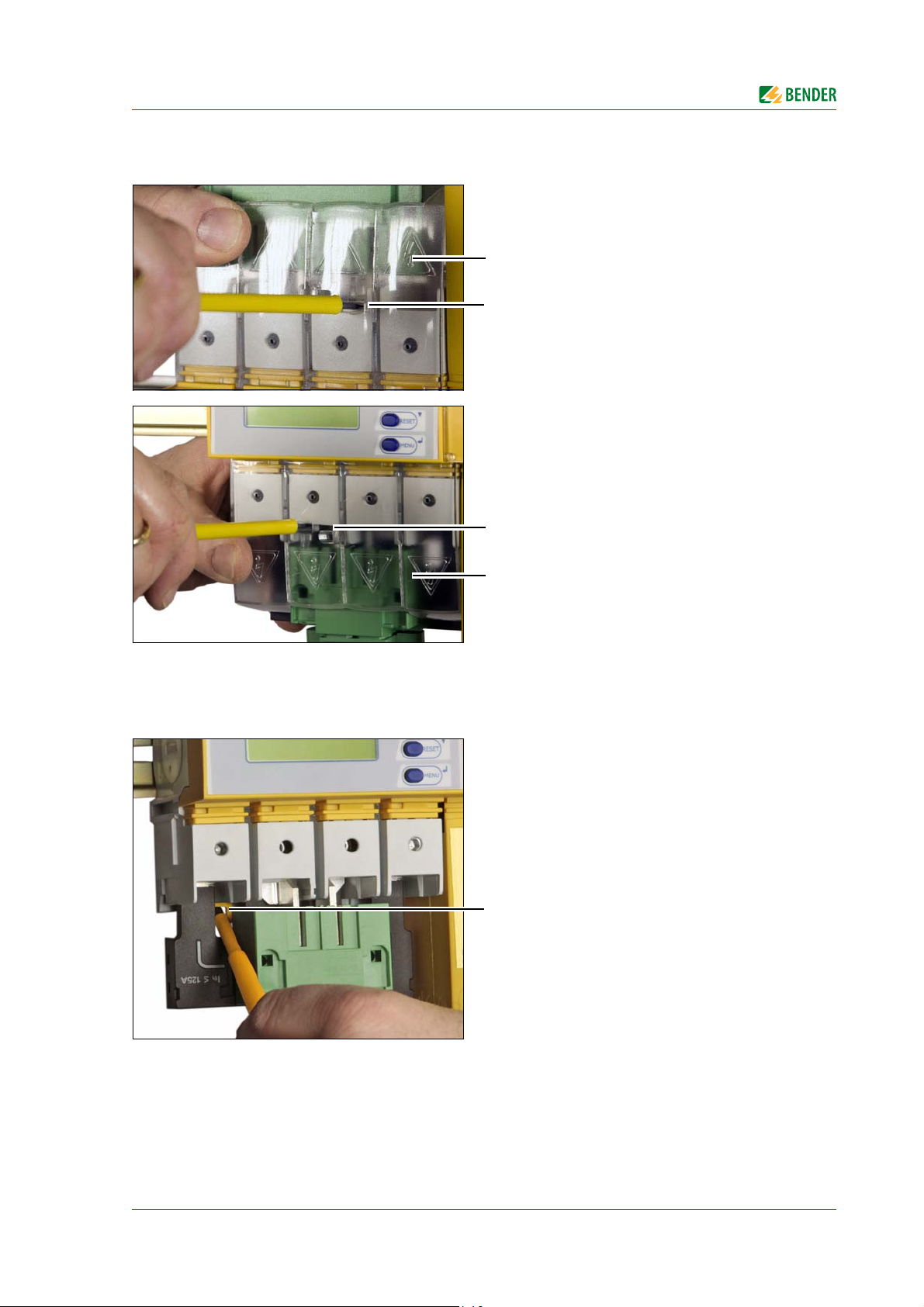

4.1.3 Removing the terminal covers

1. Push back the locking hook (B) in the

middle of the top and bottom terminal

cover (A) using a screwdriver.

2. Remove the terminal cover.

4.1.4 Mounting on DIN rail

Photo shows ATICS-2-DIO.

The description also applies to ATICS-4-DIO.

1. Place ATICS® on the top edge of the rail.

2. ATICS-2-DIO: Use a screwdriver to pull

down the lower yellow slide lock (C) and

snap ATICS® into place with slight pressure.

ATICS-4-DIO: Remove lower green plug

connector. Use a screwdriver to pull

down the two lower yellow slide lock (C)

and snap ATICS® into place with slight

pressure.

Check that the slide locks are properly

snapped into position by pulling slightly

the lower part of the enclosure.

3. Secure all terminals including the unused

terminals with Allen screws.

Tightening torque: 5 Nm.

4. Fasten the terminal covers.

ATICS-DIO_D00080_02_M_XXEN/08.2017

27

Page 28

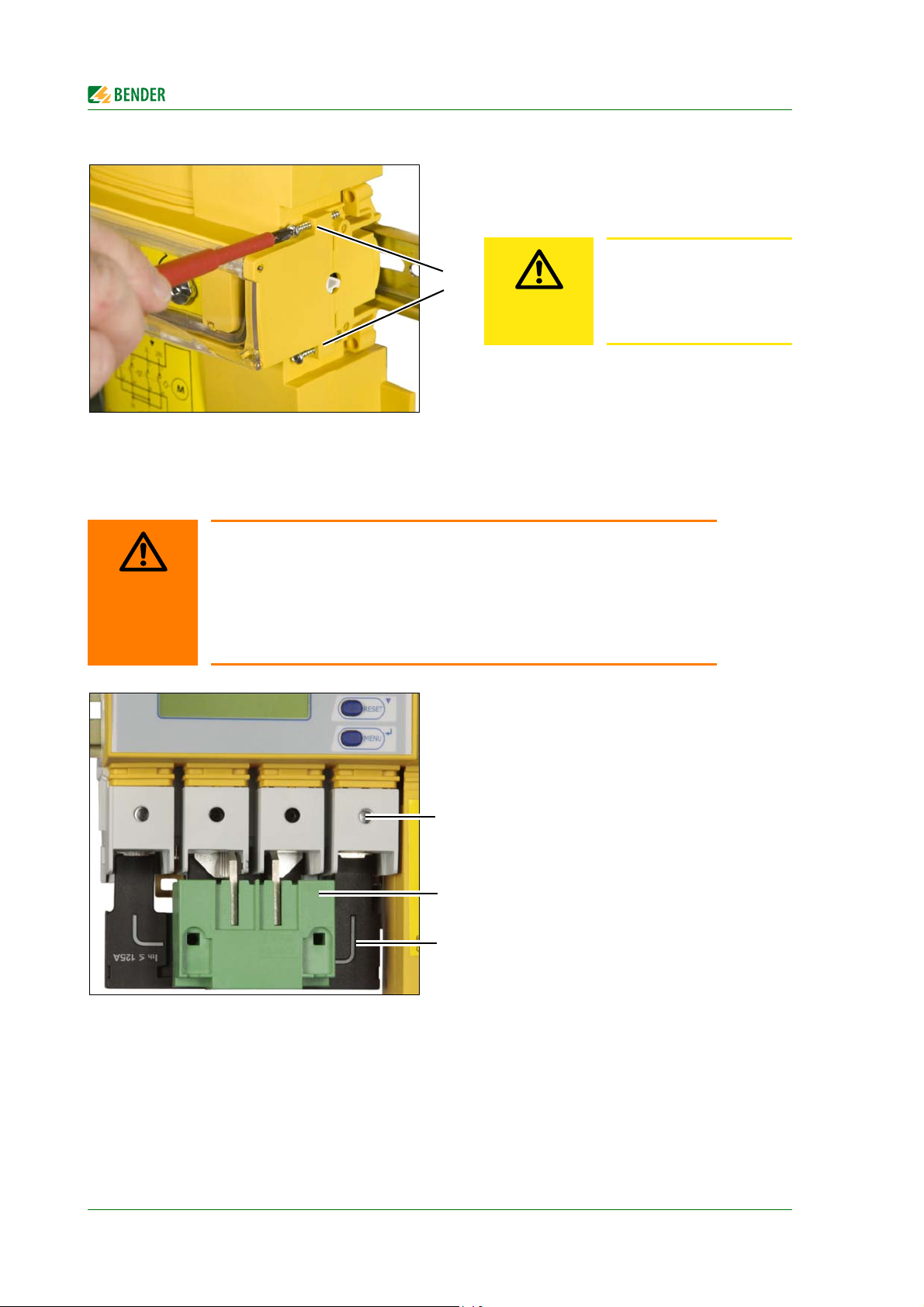

4.1.5 Screw mounting on plate

D

If the screws are not tightened, the vibration occurring during the switching

process may damage

ATICS®.

CAUTION

WARNING

D

E

C

Provide for sufficient clearance to live conductors (voltage clearance) by using

mounting screws with flat screw heads and flat washers.

If mounted on electrically conductive material: the mounting plate has to be

earthed and the area under the terminals has to be covered with insulating material.

It is the responsibility of the mounting staff to select the appropriate mounting

plate and mounting screws and to keep the prescribed torque setting.

Installation and connection

5. Always tighten the mounting screws (D)

(PZ1, 8,8 lb-in, 1 Nm).

The photo shows ATICS-2-DIO.

The description also applies to ATICS-4-DIO.

1. Undo the Allen screws of the terminals

(C).

2. Remove the green plug connectors (D)

top and bottom.

3. Remove the black bridge (E) bottom.

4. Fasten ATICS® to the mounting plate with

M5 mounting screws, torque setting 22

lb-in, 2.5 Nm (see "ATICS-2-DIO dimension diagram").

5. Insert the black bridge (E), bottom.

6. Plug in the green plug connectors (D) top

and bottom.

7. Use Allen screws to tighten all terminals

(C) including the unused terminals.

Tightening torque: 5 Nm.

8. Fasten the terminal covers.

28

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 29

Installation and connection

4.2 Connection

4.2.1 Short-circuit protection

The choice of back-up fuses F should ensure both short-circuit protection for the transformer and selectivity for the overcurrent devices connected downstream in the IT systems.

The connecting wires between the automatic transfer switching devices and the overcurrent protective device downstream are to be laid so that they are short-circuit and earth-fault proof.

When choosing back-up fuses, keep to both the maximum permissible values laid down by the

guidelines which apply to the site of use and national and international standards to make sure that

the contacts do not weld.

For recommendations on the use of the appropriate fuse, refer to the nameplate of ATICS® and to

the ordering details in this manual.

ATICS-DIO_D00080_02_M_XXEN/08.2017

29

Page 30

4.2.2 Connecting ATICS® safely

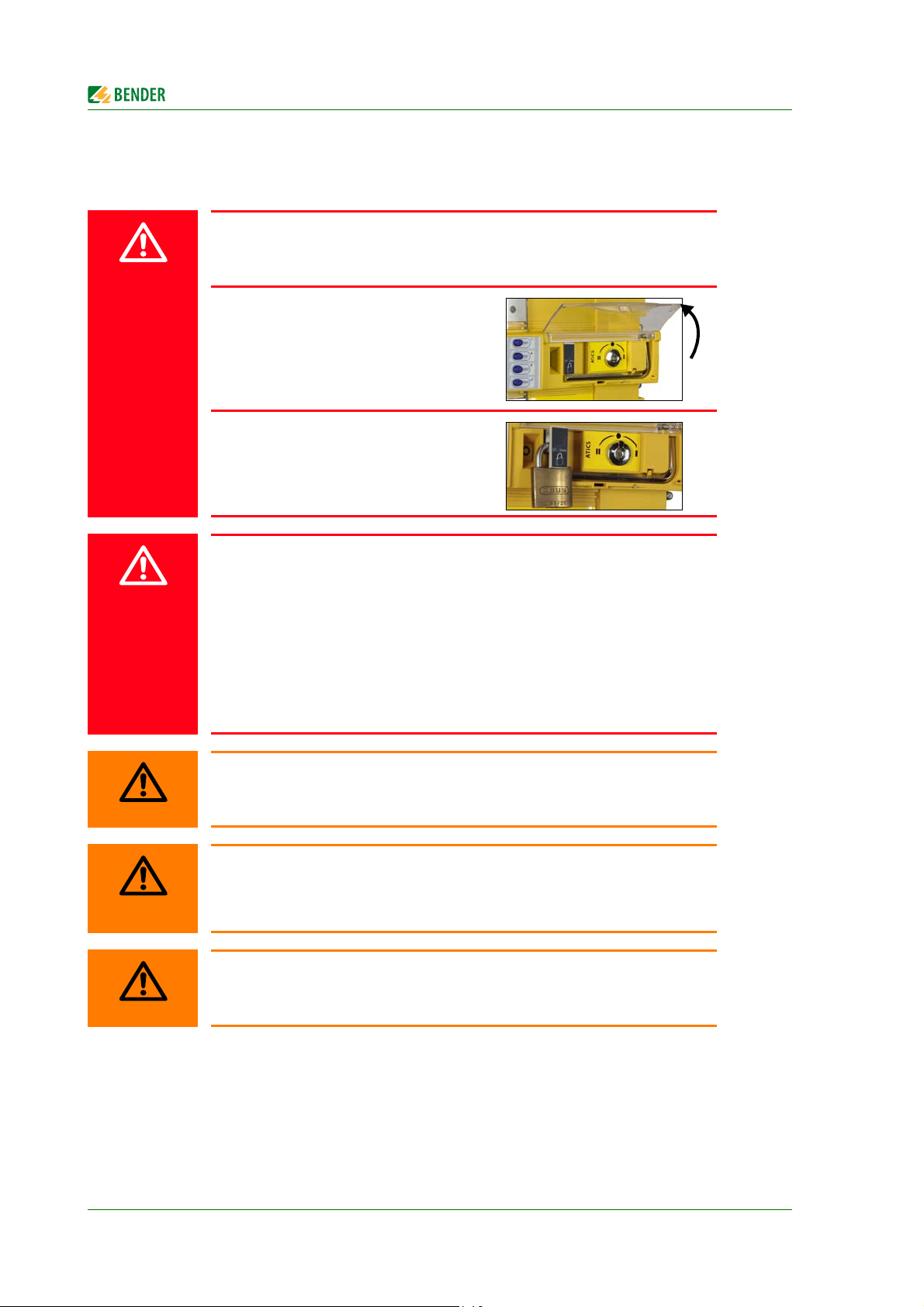

DANGER

DANGER

WARNING

WARNING

WARNING

Risk of fatal injury from electric shock

If any of the supplies are switched on, some of the parts of the system which are

not yet fully installed may be live.

Open the transparent cover of the

device for manual mode selection and

wait until the display shows "Manual

mode".

Turn the Allen key to switch position "0".

Leave the transparent cover open and

lock the transfer switching device with a

padlock to prevent it from starting accidentally.

Installation and connection

Risk of fatal injury from electric shock

Connecting wires can come loose and fall out if the ferrules being used are too

short, the wire ends are tinned or the connection screws have not been tightened

enough.

Consider a stripping length of 20 mm and do not use ferrules when connecting

lines 1, 2 and 3.

Note the assignment of the terminals. Note especially that the two supplies are

always connected to the device from the top.

Use a torque wrench to tighten the terminal screws.

Check all the screws on a regular basis to make sure they are seated tightly.

Risk of destruction when insulation and voltage test are carried out

-> Disconnect the device from the mains for the duration of the test.

Risk of destruction in the event of phase failure in three-phase systems

If only one of the phases fails, it may result in overvoltages which can damage

the connected devices.

-> Install a device for all-pole disconnection in the event of phase failure.

Risk of destruction if connected incorrectly

-> The terminals labelled GND must not be connected to PE.

30

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 31

Installation and connection

III

1357

2468

1L 2N2L1N

NL

lNCNC

EN/EXIN1/

GND

IN1GNDk

grau

ANC 111214NCNCB

schwarz

21 IN3IN2443424

IN2-4

GND

IN4

weiß

ATICS-2-DIO terminals

Legend

1L, 1N Connection line 1 (input line)

2L, 2N Connection line 2 (input line)

L, N Connection line 3 (output line)

l, k Connection measuring current transformer T3 (STW3) for monitoring the load

current downstream of the transfer switching device (short-circuit monitoring)

GND, En/Ex Connection must not be used. Intended for Bender-internal purposes only (12

V).

IN1/GND, IN1 Digital input, configurable (see "Settings menu 5: Digital input" on page 75)

NC Not used

24, 34, 44, 21 3 alarm relays (1 N/O contact each), 21 = common connection for the three

alarm relays

IN2, IN3, IN4, IN2-4 GND 3 digital inputs

A, B BMS bus connection

14, 12, 11 Alarm relay, programmable function

ATICS-DIO_D00080_02_M_XXEN/08.2017

31

Page 32

ATICS-4-DIO terminals

WARNING

II

9111315

10 12 14 16

2L1 2N2L32L2

ANC 111214NCNCBNC NCNC

EN/EXIN1/

GND

IN1GNDNC

I

1357

2468

1L1 1N1L31L2

grau

NC l4l3l2l1

NC k4k3k2k1

schwarz

L1 NL3L2

21 IN3IN2443424

IN2-4

GND

IN4

weiß

ATICS-4-125A-DIO and ATICS-4-160A-DIO only:

High temperatures may affect the terminals

The terminals for the connection of line 1, 2, 3 are designed for the specified rated

operational current, at room temperature.

-> Avoid higher temperatures or ensure that the load current is reduced.

Installation and connection

Legend

1L1, 1L2, 1L3, 1N Connection line 1 (input line)

2L1, 2L2, 2L3, 2N Connection line 2 (input line)

L1, L2, L3, N Connection line 3 (output line)

NC Not used

GND, En/Ex Connection must not be used. Intended for Bender-internal purposes only (12

IN1/GND, IN1 Digital input, configurable (see "Settings menu 5: Digital input" on page 75)

24, 34, 44, 21 3 alarm relays (1 N/O contact each), 21 = common connection for the three

IN2, IN3, IN4, IN2-4 GND 3 digital inputs

A, B BMS bus connection

14, 12, 11 Alarm relay, programmable function

l1, l2, l3, l4,

k1, k2, k3, k4

V).

alarm relays

Connection measuring current transformer T1 … T4 for monitoring the load

current downstream of the transfer switching device (short-circuit monitoring).

Also refer to "Connection example: ATICS-4-DIO basic configuration" on

page 34.

Note: Insert the plug until it noticeably clicks into place

32

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 33

Installation and connection

CAUTION

4.2.3 Connection example: ATICS-2-DIO basic configuration

Risk of destruction if connected incorrectly

The terminals marked "*" are intended for Bender-internal purposes only. If this

is ignored, the ATICS® transfer switching device may be damaged.

ATICS-DIO_D00080_02_M_XXEN/08.2017

33

Page 34

4.2.4 Connection example: ATICS-4-DIO basic configuration

CAUTION

Risk of destruction if connected incorrectly

The terminals marked "*" are intended for Bender-internal purposes only. If this

is ignored, the ATICS® transfer switching device may be damaged.

Installation and connection

34

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 35

Installation and connection

CAUTION

4.2.5 Connection example: ATICS-2-DIO with bypass switch

Risk of destruction if connected incorrectly

The terminals marked "*" are intended for Bender-internal purposes only. If this

is ignored, the ATICS® transfer switching device may be damaged.

ATICS-DIO_D00080_02_M_XXEN/08.2017

35

Page 36

4.2.6 Connection example: ATICS-2-DIO with bypass switch

CAUTION

Risk of destruction if connected incorrectly

The terminals marked "*" are intended for Bender-internal purposes only. If this

is ignored, the ATICS® transfer switching device may be damaged.

Installation and connection

36

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 37

Installation and connection

4.2.7 Instructions for connection

4.2.7.1 BMS bus

Ex works, the terminals A and B are available for connecting BMS-enabled devices. Alarm indicator

and test combinations, alarm indicator and operator panels or other bus-enabled Bender devices

can be connected. The bus line must be terminated at both ends with resistors (120 Ω, 0.25 W).

Please note the information in the "BMS bus" manual.

4.2.7.2 MK… alarm indicator and test combination and TM… alarm indicator and operator

panels

MK2430, MK800 and TM800 are used. They have the following capabilities:

Displaying messages of the ATICS® transfer switching device

Mutual monitoring for failure

4.2.7.3 SCADA systems (Supervisory Control and Data Acquisition)

If messages from the ATICS® transfer swit ching d evice a re to be forwarded to a SCADA system, the following possibilities exist:

Protocol converters (gateways, e.g. COM465…)

Common alarm via the ATICS® relay output

Alarms via interconnected signal converters SMO480-12 or SMO482-12.

TM800, SMO480-12 and SMO482-12 convert serial signals from Bender devices into potentialfree relay contact alarms.

4.2.7.4 Bypass switch (optional)

The ATICS-BP-… bypass switch makes it possible to test and change the two-pole ATICS® transfer

switching device without interrupting the power supply to the line downstream of the transfer

switching device. Adjusting the settings: see "Operation with bypass switch" on page 92.

ATICS-DIO_D00080_02_M_XXEN/08.2017

37

Page 38

Installation and connection

AB

C

D

4.2.8 Fastening, inserting and securing connections

Connect the terminals to the plug connectors (A, B) and the connector plugs (C, D) according to the

wiring diagram.

Connect the lines 1, 2 and 3 to the plug connectors (A, B). Consider a stripping length of 20 mm

and do not use ferrules. Use a Torx® screwdriver T20 or a slotted screwdriver of 6.5 x 1.2 mm.

Tightening torque: 2.5 Nm (≤ 25 mm²) or 4.5 Nm (≥ 25 mm²).

Connect the three connector plugs (C) with a slotted screwdriver of 2.5 x 0.4 mm. Stripping

length: 7 mm. Tightening torque: 0.22…0.25 Nm.

Insert bottom green plug connector

(B) and secure with mounting screws.

AT IC S - 2- D I O: After that, insert top

green plug connector (A) and secure

with mounting screws.

AT IC S - 4- D I O: Only then insert the

two top green connector plugs and

secure them with mounting screws.

Insert the three connector plugs (C).

ATICS -4- D IO o n l y:

Insert the connector plug (D) of the

measuring current transformers

T1…T4 (D).

Note:

The plug must noticeably click into

place!

38

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 39

Installation and connection

CAUTION

4.3 Other functions

4.3.1 Sealing the transparent cover of the transfer switching device

4.3.2 Manual mode

The transparent cover can only be sealed

when it is closed (automatic mode).

Risk of injury from rotating Allen key

When the transparent cover is closed, ATICS® is in automatic mode. ATICS® detects this by means of the button being pressed under the transparent cover.

When the transparent cover is opened, the button is no longer pressed and ATICS® switches to manual mode.

When the transparent cover is open, make sure that this button is not pressed accidentally. Check and make sure that the message "Manual mode" appears on

the display. Only then can the Allen key be used to set the changeover switch to

manual mode.

Manual mode can be enabled in the following ways:

Open the transparent cover

Set the digital input. "M/A" function

must be set (see "Settings menu 5:

Digital input" on page 75).

Manual mode:

Put the handle on the Allen key

Use the Allen key to change over

The switching device can be held in

switch position "0" and locked with a

padlock.

ATICS-DIO_D00080_02_M_XXEN/08.2017

39

Page 40

Installation and connection

4.3.3 Locking the transfer switching device with a padlock

It is only possible to lock the selector switch in manual mode (transparent cover open). The locking

device can only be locked in switch position "0".

Padlock shackle diameter: 4 mm … 8 mm (3/16” … 5/16”)

Locking the transfer switching device:

1. Pull out locking device

2. Thread in padlock and close it

The switch position cannot be changed until the lock has been removed and the locking device has

been pushed in.

40

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 41

5. Commissioning, settings and testing

CAUTION

CAUTION

5.1 Design and installation

Risk of missing or false messages on the display on MK..., TM... or FTC...

MK… alarm indicator and test combinations, TM... alarm indicator and operator panels or BMS Ethernet gateways COM465…, which, together with ATICS®,

are connected to a BMS bus must be loaded with the latest operating software

(e.g. MK800/TM800/MK2430 V 4.03 or higher).

Older MK…, TM… or FTC… cannot interpret the alarms of ATICS® because the

text modules required for ATICS® are not integrated yet. These devices must either be updated or replaced.

The TMK-SET configuration software must also be the latest version.

Risk that ATICS® does not switch

ATICS® requires enough current (2 pulses of 17 A for 30 ms) for a changeover. If

there are several ATICS® in one system it is possible that the current is insufficient,

especially when feeding from a battery-powered power supply.

Set the delay time t(start) on the devices in such a way that after voltage recovery

the devices switch to the preferred supply one by one.

Observe the relevant standards and regulations for installation and connection as well as the

operating manual of the respective device.

Provide at least two places for MK… alarm indicator and test combinations or TM… alarm indi-

cator and operator panels. These panels display messages from the ATICS® automatic transfer

switching device and monitor each other for failure. This is an essential part of the safety

concept (functional safety, SIL2).

Application examples of MK… or TM… in hospitals:

– Medical locations

– Continuously manned area (e.g. nurses' station)

– Technical area

Provide a fail-safe power supply for the MK… or the TM…

The TM... and MK... for the medical and technical area must be supplied with power from differ-

ent lines and sources.

Example:

The MK… or the TM… in medical locations is supplied from line 3 of the transfer switching

device. The MK… in technical areas is supplied from a fail-safe line backed up by battery.

ATICS-DIO_D00080_02_M_XXEN/08.2017

41

Page 42

Commissioning, settings and testing

5.1.1 Configure MK… or TM…

Configure MK… or TM… in a meaningful way

In addition to the alarm, also configure a brief message of what to do or who to

notify. Examples:

- Failure line 1. Call building services Tel. -123.

MK… or TM… must display at least the following faults detected by ATICS®:

Failure line 1, failure line 2

Device error, device failure ATICS®

Failure of the other MK… or TM…

Device error with complete text or error code

5.1.2 ATICS-2-DIO: Messages on the BMS bus (channel use)

BMS

chan

nel

Entry in the menu

1.Alarm/meas.

Description

values

1 1. Line 1: 228V Line 1 Voltage Voltage* ---

2 2. Line 2: 183V Line 2 Voltage Voltage* ---

3 3. Position:1 Switch position 0, 1, 2 --- ---

4 4. t(2->1):--

or

SwitchBackLock

5 5. Automatic mode Manual/Automatic

6 6. Status Device error --- Error code (see

7 7. I(3):35A Load current

8 8. Digital input: Digital input 1 - - ** Alarm text** ---

9 9. Digital input: Digital input 2 - - ** Alarm text** ---

10 10. Digital input: Digital input 3 - - ** Alarm text** ---

11 11. Digital input: Digital input 4 - - ** Alarm text** ---

12 without function

Return transfer

delay time is

enabled, counting

backwards or

switching back

interlocking

function

mode

TN system

Operational

status

message

Seconds --- ---

--- Manual

Current Current Connect. fault

Alarm

message

mode

Error

---

chapter "8.1.2 ")

CT

* Message dependent on the parameter assignment in the "Settings menu 1: Changeover" -> "System" (for

details see "Settings menu 1: Changeover" on page 69)

** Message dependent on the input parameter assignment (for details see "Messages for alarm on the

digital input" on page 44)

42

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 43

Commissioning, settings and testing

5.1.3 ATICS-4-DIO: Messages on the BMS bus (channel use)

BMS

chan

nel

Entry in the menu

1.Alarm/meas.

Description

values

1 1. Line 1: 228V Line 1 Voltage Voltage* Phase sequence

2 2. Line 2: 183V Line 2 Voltage Voltage* Phase sequence

3 3. Position:1 Switch position 0, 1, 2 --- ---

4 4. t(2->1):--

or

SwitchBackLock

5 5. Automatic mode Manual/Automatic

6 6. Status Device error --- Error code (see

7 7. I(3):35A Load current on the

8 8. I(3):35A Load current on the

9 9. I(3):35A Load current on the

10 10. I(3):35A Load current in the

11 11. Digital input: Digital input 1 - - ** Alarm

12 12. Digital input: Digital input 2…4

Return transfer

delay time is

enabled, counting

backwards or

switching back

interlocking

function

mode

TN system on phase

L1

TN system on phase

L2

TN system on phase

L3

TN system on neutral conductor

(common alarm)

Operation

al

status

Alarm

message

Error

message

left,

unbalance

left,

unbalance

Seconds --- ---

--- Manual

mode

Current Current Connect. fault CT

Current Current Connect. fault CT

Current Current Connect. fault CT

Current Current Connect. fault CT

text**

- - ** Alarm

text**

---

chapter "8.1.2 ")

---

---

* Message dependent on the parameter assignment in the "Settings menu 1: Changeover" -> "System" (for

details see "Settings menu 1: Changeover" on page 69)

** Message dependent on the input parameter assignment (for details see "Messages for alarm on the

digital input" on page 44)

ATICS-DIO_D00080_02_M_XXEN/08.2017

43

Page 44

Commissioning, settings and testing

Messages for alarm on the digital input

The following operational status and alarm messages may appear depending on the settings in the

"Settings menu 5: Digital input":

Menu

setting

off Digital input switched off No alarm -

M/A Enabling manual mode Alarm "Manual mode" 5

Bypass Bypass enabled Alarm "Manual mode" 5

no2->1 Enable switching back interlocking

1<->2 Change preferred line No alarm

TEST TEST- carry out changeover No alarm

ALARM ATICS-2-DIO:

ALARM ATICS-4-DIO:

Function of digital input Alarm on BMS bus BMS channel

Operational status mes-

function

Convert message at digital inputs 1…4

into alarms on the BMS bus

Convert message at digital inputs 1…4

into alarms on the BMS bus.

Channel 11 = DigIn 1

Channel 12 = Common alarm DigIn

2…4

The common alarm code corresponds

to the first message, which has triggered the common alarm.

sage "Switch-back lock"

Alarm "Digital input" 8, 9, 10, 11

Alarm "Digital input" 11, 12

4

5.1.4 Tests, decommissioning

Abide by the relevant local or national regulations for periodic verifications on electrical instal-

lations.

If you notice changes on ATICS®, you must immediately start checking the transfer switching

device.

Heed the alarms on the transfer switching device. ATICS® reports in good time when testing or servicing is necessary or if safe operation of the device according to IEC 61508 is no longer guaranteed

(e.g. due to component failure) and action must be taken.

44

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 45

Commissioning, settings and testing

5.2 Setting and testing according to the checklist

The settings made at the factory take into account a total changeover period t ≤ 0.5 s and switching

back to the preferred supply within 10 seconds on voltage recovery.

The response delay t(on), the dead time t(0), the delay on release t(off) and the return transfer delay

time t(2->1) of ATICS® are configurable and must be adjusted to the requirements of the specific application case and the requirements of DIN VDE 0100-710 (VDE 0100 Part 710) for automatic changeover devices. If the current monitoring (short-circuit detection) is deactivated in the menu "Settings"

> "Current", an additional short-circuit current calculation and configuration of the response time

t(on) is required.

The total turn-off time (from the point at which the fault occurs until the arc in the overcurrent

protective device is cleared) must be less than the minimum delay for the changeover of the

automatic transfer switching device.

Setting: Response delay t(on)

If several automatic transfer switching devices are connected in series in a power supply sys-

tem, it is recommended that they are time-graded.

Setting: Response delay t(on), return transfer delay time t(2->1) and delay on release t(off).

As part of the response delay (to be custom-set), you must, at the very least, take into account

the periods of time when the circuit experiences short interruptions, and the response times of

the short-circuit protection equipment upstream or downstream. Regardless of this, a switchover pause corresponding to the installation location should be taken into account, in order to

avoid switching overvoltages.

Setting: Response delay t(on), dead time t(0) and return transfer delay time t(2->1).

The factory settings and system-specific settings of the ATICS® DIO transfer switching device are

documented on the checklist. Please carry out all the work outlined in the list and log each test step.

Keep the checklist with this manual near to the device.

ATICS-DIO_D00080_02_M_XXEN/08.2017

45

Page 46

Commissioning, settings and testing

5.3 Addressing example

Insert terminating resistors correctly

Communication via the BMS bus is only guaranteed when there is a terminating

resistor at the beginning and at the end of the BMS bus. Other terminating resistors cause malfunctions and must not be used. Please note the information in

the "BMS bus" manual.

An automatic transfer switching device with two MK…

Device Parameter Address settings for an automatic transfer switching device

AT IC S ®

MK…

MK…

Bus address 3

Address 1

Alarm address 3, 2*

Address 2

Alarm address 3, 1*

* These alarm addresses are used for MK… or TM… to monitor one another for device failure

46

ATICS-DIO_D00080_02_M_XXEN/08.2017

Page 47

6. Operation

1 2 ALARM COM

21345

6

7

8

9

This chapter can also be used as a quick reference guide by technical operating personnel.

6.1 Operating and display elements

LED and LCD

1 Illuminated graphic LCD

2 LED "1" lights up when line 1 is ready

3 LED "2" lights up when line 2 is ready

4 LED "Alarm" lights up when there is an alarm message

5 LED "COM" flashes during communication via the BMS bus

The buttons have the following functions:

6 "INFO" Calls up standard information

7 "TEST" Calls up test menu

8 "RESET" Resets alarm and fault messages, unlocks switching back interlocking function

9 "MENU" Toggles between the standard display, alarm display and "MENU"

ESC Exits the menu function without changing parameters

Parameter changes, scrolling

Parameter changes, scrolling

↵ Confirms parameter changes (Enter button)

ATICS-DIO_D00080_02_M_XXEN/08.2017

47

Page 48

6.2 Quick reference guide

228V

50.0Hz

1 0 2 231V

50.0Hz

14:11

12.10.2010

1423

6.2.1 ATICS-2-DIO: Display under normal operating conditions

There is no alarm message. The LCD shows the standard information.

Example:

Legend

Operation

1 Line 1: Measured values of mains voltage and frequency

2 Switch position of the transfer switching device

3 Date and time

4 Line 2: Measured values of mains voltage and frequency

The device shows the alarm status for each measured value

No alarm

Alarm

Alternative displays in the bottom line of the display