Nr. Documento

Revisione

Autore

Data stampa

Nr. pagine

M_S2014

01

32

PAG. 2/32

Contents

Contents ..................................................................................................... 2

Important Notice ........................................................................................ 3

1. SAFETY INSTRUCTIONS ...................................................................... 4

1.1 General .....................................................................................................4

1.2 Safety Instructions .....................................................................................5

2. DEVICE DESCRIPTION ........................................................................ 6

2.1 Introduction ..............................................................................................6

2.2 Area of application .....................................................................................7

2.3 Hardware ..................................................................................................8

2.3.1 Control elements and interfaces .......................................................... 8

2.3.2 Device connections: power and high voltage ....................................... 10

2.3.3 Device connections: control signals and interfaces ............................... 11

2.4 Software ................................................................................................. 13

2.4.1 Operating modes ............................................................................. 13

3. Description of the functionality ......................................................... 14

3.1 Soft Start ................................................................................................ 14

3.2 Droop Compensation ................................................................................ 14

3.3 ‘Keep alive’.............................................................................................. 15

3.4 Limiters .................................................................................................. 16

3.4.1 V/f Limiter ...................................................................................... 16

3.4.2 Minimum excitation current............................................................... 16

3.4.3 Maximum excitation current .............................................................. 17

3.4.4 Minimum capability .......................................................................... 17

3.4.5 Massima capability ........................................................................... 18

4. References and Regulations .............................................................. 19

4.1 Field Current Regulation (FCR) ................................................................... 20

4.2 Automatic voltage regulator (AVR) ............................................................. 20

4.3 Automatic Power Factor regulation (PF) ...................................................... 21

4.4 Automatic reactive power regulation (VAR) ................................................. 21

4.5 Digital reference adjust by calibrator (U/Down)............................................ 22

4.6 Digital reference adjust by analog (Pot/An. In) ............................................ 22

5. OPERATOR INTERFACE ..................................................................... 23

5.1 Control keypad and display ....................................................................... 23

5.2 Navigating the menus ............................................................................... 24

5.3 Parameters saving .................................................................................... 25

5.3.1 Menu d – Display ............................................................................. 26

5.3.2 Menu r – References and Regulators .................................................. 26

5.3.3 Menu I – Inputs and outputs ............................................................. 27

5.3.4 Menu P – Parameters ....................................................................... 27

5.3.5 Menù C........................................................................................... 28

6. MAINTENANCE AND FAULTS ............................................................. 29

6.1 Safety regulations .................................................................................... 29

6.2 Maintenance ............................................................................................ 29

6.3 Trouble shooting ...................................................................................... 29

6.4 Repair..................................................................................................... 30

7. General Data ..................................................................................... 31

PAG. 3/32

Important Notice

Our experience has shown that, if the information and recommendations contained in

this Operating Instructions are observed, the best possible reliability of our products is

assured.

The data contained herein purports solely to describe the product and it is not a

warranty of performance or characteristics. It is with the best interests of our

customers in mind that we constantly strive to improve our products and keep them

abreast of advances in technology. This may, however, lead to discrepancies between

a product and its "Technical Description" or "Operating Instructions".

This document has been carefully prepared and reviewed, however should in spite of

this the reader find an error, he is requested to inform us at his earliest convenience.

It is scarcely possible for the operating instructions for technical equipment to cover

every eventuality, which can occur in practice. We would therefore request you to

notify us or our agent in the case of all unusual behavior that does not appear to be

covered by these operating instructions.

It is pointed out that all local regulations must be observed when connecting and

commissioning this equipment in addition to these operating instructions.

We cannot accept any responsibility for damage incurred as a result of mishandling

the equipment regardless of whether particular reference is made in these operating

instructions or not.

We lay particular stress on the fact that only genuine spare parts should be used for

replacements.

All rights with respect to this document, including applications for patent and

registration of other industrial property rights, are reserved. Unauthorized use, in

particular reproduction or making available to third parties, is prohibited.

PAG. 4/32

1. SAFETY INSTRUCTIONS

1.1 General

The safety instructions shall be followed during installation, commissioning, operation and

maintenance of the excitation system. Read all instructions carefully before operating the

device and keep this manual for future reference.

Required Qualification

Personnel involved in installation work and commissioning of the S2014 must be familiar,

specially instructed and informed about the residual danger areas according to the regulations

currently in force.

Operating personnel is not permitted to work at the control system.

Specially instructed personnel must only carry out maintenance and repair work.

The maintenance personnel must be informed about the emergency shutdown measures and

must be capable of turning off the system in case of emergency.

The maintenance personnel must be familiar with the accident prevention measures at their

workplace and must be instructed in first aid and fire fighting.

It is the owner’s responsibility to ensure that each person involved in the installation and

commissioning of the S2014 has received the appropriate training or instructions and has

thoroughly read and clearly understood the safety instructions in this chapter.

PAG. 5/32

1.2 Safety Instructions

The safety instructions always appear at the beginning of each chapter and/or precede

any instruction in the context where a potentially dangerous situation may appear.

The safety instructions are divided into five categories and emphasized by the use of

the following layout and safety signs:

DANGER!

This symbol indicates an imminent danger resulting from

mechanical forces or high voltage. A non-observance leads to

life-threatening physical injury or death.

WARNING!

This symbol indicates a dangerous situation. A non-observance

may lead to bad or life-threatening physical injury or death.

CAUTION!

This symbol indicates a dangerous situation. A non-observance

may lead to physical injury or cause damage to the converter.

NOTICE!

This symbol emphasizes important information. A nonobservance may cause damage to the converter or to objects

close to it.

IMPORTANT!

This symbol indicates useful information. Not to be used to

indicate dangerous situations.

PAG. 6/32

2. DEVICE DESCRIPTION

2.1 Introduction

S2014 is an automatic voltage regulator of the latest design for controls alternators

excitation. The unit contains the most advanced microprocessor technology together

with SCR semiconductor technology (Silicon Controlled Rectifier).

A practical and simple-to-operate panel on the unit is used for all control operations.

In addition, user friendly software facilitates commissioning allows optimization of

operation.

The mechanical construction is compact and robust.

PAG. 7/32

2.2 Area of application

This advanced-design automatic voltage regulator is used for the excitation of

synchronous machines. This unit is only suitable for this one area of application.

The regulator can also be switched over to function as a automatic voltage regulator,

power factor or reactive power regulation.

SM= Synchronous Machine

E = Exciter

PMG = Permanent-Magnet-Generator

Generator excitation from generator

output

Generator excitation with

PMG or external supply.

Replacement of voltage regulators for

generators with direct-current

excitation machines.

PAG. 8/32

2.3 Hardware

Structure:

The device is built into a plastic casing, depending on the nominal output current some

models have an aluminum base for cooling.

The connection terminals are integrated on top of the circuit boards.

Power electronics:

The power part is fitted with SCR semiconductors.

The average value of the output voltage is always positive. The output is protected

against short-circuit by a fuse.

Control elements:

The operating keys and the display are located on the circuit board.

The connector of the communication port it is located on the regulator.

Installation:

The site of installation must be dry and free of dust.

Mounting:

The regulator must be installed inside the machine or inside the control panel in order

to be protected against accidental contacts. For fastening the regulator, 4 MA throughscrews should be tightened with self-locking nuts in two corners holes.

It is recommended to bind the regulator back on a metal plate for better dissipation.

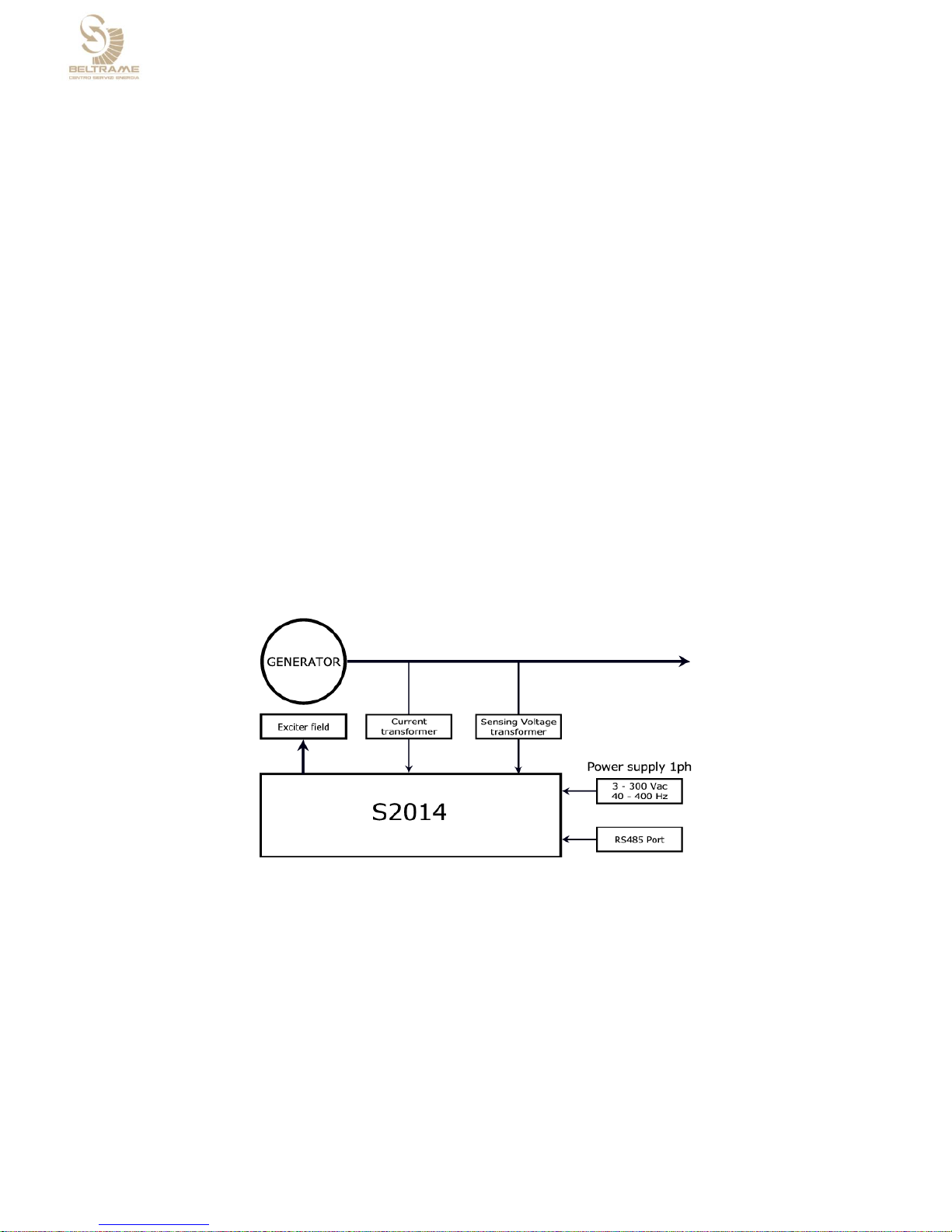

Connection diagram:

2.3.1 Control elements and interfaces

Carrying out settings on the unit

The displays and the four keys are sufficient to allow complete operation.

All settings can be carried out directly on the unit without additional equipment.

Configuration of inputs and outputs;

Parameter setting;

Display of important measuring values.

PAG. 9/32

Interface with PC

Parameter setting and also optimization is possible using the user-friendly software

S2014 Config for Microsoft Windows.

Connection cable with RS-485 Half-Duplex (two wire)

Configuration of inputs and outputs;

Parameter setting;

Display of important measuring values;

Parameter File upload or download.

Note: The interface is not isolated from the power supply

In order to connect with a pc or other devices an interface isolator

must be used

Terminal blocks

Overview of the device connections

PAG. 10/32

CN2 – RS 485 Serial Interface

CN3 – Control connections

1

GND

C1

Common

2

GND

C2

Up reference adjust

3

--RESERVED-

C3

Down reference adjust

4

LINK –

C4

Feedback Parallel

5

LINK +

C5

±5V reference adjust

6

--RESERVED-

C6

Potentiometer reference adjust 1Kohm

7

--RESERVED-

C7

+6V Aux

8

--RESERVED-

C8

N.C.

Note: the reserved pins have to be

left unconnected

C9

OUT (E)

C10

OUT (C)

FX1 - Power connections

FX2 - Current sensing inputs

AUX

AUX

S1

C.T. input

COM

Common

S2

C.T. input

+Ecc

Excitation output +

-Ecc

Excitation output –

Vsense

Voltage sensing input

PE

PE

2.3.2 Device connections: power and high voltage

Terminal

designation

Signal

Specifications

Power electronics

supply

AC input voltage

single-phase

80÷300 Vac

40÷500 Hz

Measurements inputs

1 Generator voltage

0÷500 Vrms

Not isolated: one terminal

common with power supply

1 Generator current

0÷5 Arms

galvanic isolation

Excitation output

Excitation voltage

3÷300 VDC

Excitation current

0÷8 A (16 A for 10 s)

PAG. 11/32

2.3.3 Device connections: control signals and interfaces

Terminal

designation

Signal

Specifications

Digital inputs

3 programmable

digital inputs

4mA

Up / Down / programmable function

not isolated from power supply

Digital outputs

1 programmable

digital output

Load Max 65mA 24Vdc

PAG. 12/32

Analog inputs

2 analog inputs

input ±5V for reference adjust

not isolated from power supply

● potentiometer 1KΩ 5% for ref. adjust

● not isolated from power supply

Communication

1 RS485

Modbus RTU and proprietary protocols

half duplex

not isolated from power supply

PAG. 13/32

2.4 Software

2.4.1 Operating modes

Bump less changeover between all modes of operation

Automatic voltage regulator (Auto)

Regulates the terminal voltage of the

synchronous machine.

Note: Current measurement is optional:

used only for droop compensation

PF or Var regulation (PF, Var)

Regulates the power factor or reactive

power of the synchronous machine.

PAG. 14/32

3. DESCRIPTION OF THE FUNCTIONALITY

3.1 Soft Start

Thanks to the configuration of the following parameters, it is possible to set up the excitation

ramp of the alternator as follows:

Parametro

Descrizione (short)

Descrizione

P.100

Gen rate voltage

Generator rated voltage [V]

P.101

Max Gen. voltage

Generator maximum voltage [%]

R.002

Ramp slope

Ramp slope [%/s]

A soft start is done only in the AVR mode

3.2 Droop Compensation

The compensation function (K> 0) is used in order to cancel the voltage drop in the possible

transformer, which is downstream connected with the alternator.

The ‘droop’ function (K<0) is to be used if you are operating with more generators in parallel.

It is applied a voltage reduction according to the output of the reactive power.

This function is enabled only in AVR mode. The input must be configured as follows:I00x = 4.

Parametro

Descrizione (short)

Descrizione

P.400

Voltage comp K

Voltage comp [%]

PAG. 15/32

3.3 ‘Keep alive’

This feature allows to maintain a minimum excitation current even when the alternator

frequency drops below the minimum (P.130).

The parameter P.250 is the one, where the minimum excitation current must be set up; this

setting must be done based on the power source (set up to 0 if the power is from PMG or

auxiliary).

The AVR S2014 works to maintain an input auxiliary voltage of 60V in order to feed itself.

Parameter

Description (short)

Description

P.250

KeepAlive min I

Keep Alive minimum I

P.130

Gen. V/f min freq

Generator V/f minimum frequency

Having P.250 = 0 under the alternators minimum frequency the output will be

disabled.

PAG. 16/32

3.4 Limiters

3.4.1 V/f Limiter

The V / Hz limit is active during the voltage control phase. It works by limiting the alternator

voltage as the frequency falls below the maximum frequency set in parameter P.131. This

operation can avoid an alternator over-flushing in case of a reduction of laps.

Parameter

Description (short)

Description

P.100

Gen. rated V

Generator rated voltage [V]

P.130

Gen. V/f min freq

Generator V/f minimum frequency [Hz]

P.131

Gen. V/f Max freq

Generator V/f maximum frequency [Hz]

P.132

V/f slope

Generator V/f slope

3.4.2 Minimum excitation current

The limit of minimum excitation current is only active when the machine is in parallel with

Main.

It represents the minimum excitation current below which the machine cannot work.

Parameter

Description (short)

Description

P.002

F. UE Lim

Field UE Lim. [%]

r.900

OE/UE Lim reg KP

OE/UE Lim. Reg. KP

r.901

OE/UE Lim reg TI

OE/EU Lim. Reg. TI

PAG. 17/32

3.4.3 Maximum excitation current

The limit of maximum excitation current operates a limitation on the maximum excitation

current.

Parameter

Description (short)

Description

P.000

F. rated I

Field rated I [A]

P.001

F. OE Lim

Field OE Lim. [%]

P.032

F. OE Lim time

Field OE Lim time [s]

r.900

OE/UE Lim reg KP

OE/EU LIM reg KP

r.901

OE/UE Lim reg TI

OE/EU LIM reg TI

3.4.4 Minimum capability

The curve of minimum capability represents the reactive power limit absorbed by the machine.

It is determined by interpolating 5 data:

Parameter

Description (short)

Description

P.160

Q – lim @ P 0%

Limit Q- a P=0%

P.161

Q – lim @ P 25%

Limit Q- a P=25%

PAG. 18/32

P.162

Q – lim @ P 50%

Limit Q- a P=50%

P.163

Q – lim @ P 75%

Limit Q- a P=75%

P.164

Q – lim @ P 100%

Limit Q- a P=100%

3.4.5 Massima capability

The curve of maximum capability represents the reactive power limit delivered by the machine.

It is determined by interpolating 2 data:

Q+ limit a P=0% P.170 [%]

Q+ limit a P=100% P.171 [%]

Parameter

Description (short)

Description

P.170

Q + lim @ P 0%

Limit Q+ a P=0%

P.171

Q + lim @ P 100%

Limit Q+ a P=100%

PAG. 19/32

4. REFERENCES AND REGULATIONS

AVR [Automatic Voltage Regulator]

FCR [Field Current Regulation]

PF/VAR Control

PAG. 20/32

4.1 Field Current Regulation (FCR)

This functioning mode allows to control the regulator output

current. In this case the regulator controls only the output current

to the regulator excitation terminals without considering what

happening externally.

This functioning mode could become useful during the regulator

commissioning phase or in case of the eventual failure search.

Parameter

Description

Note

r.000

F. I digital

% compared to P.000

r.002

Ramp slope [s]

%/s

r.250

Field I Reg KP

r.251

Field I Reg TI

r.010

Delta Ref calibrator

%

r.011

Delta Ref analog

%

r.012

Delta ramp slope

%/s

4.2 Automatic voltage regulator (AVR)

The regulator controls automatically the output voltage to generator terminals.

This is the main functioning mode.

The AVR function is active when the parameter P300 = 1 is set and when the configured input

I00X = 4 is closed.

Parameter

Description

Note

P.100

Generator rated voltage

V rms

r.002

Ramp slope [s]

%/s

r.350

Generator V Reg KP

r.351

Generator V Reg TI

r.010

Delta Ref calib

%

r.011

Delta Ref analog

%

r.012

Delta ramp slope

%/s

PAG. 21/32

4.3 Automatic Power Factor regulation (PF)

The regulator controls in automatic mode the power factor at generator terminals.

The AVR function is active when the parameter P300 = 1 is set and when the configured input

I00X = 5 is closed.

Parameter

Description

Note

r.400

Generator PF digital ref

r.402

Ramp slope

r.450

PF/VAR Reg KP

r.451

PF/VAR Reg TI

r.410

Delta Ref calibrator

r.411

Delta Ref analog

r.412

Delta ramp slope

4.4 Automatic reactive power regulation (VAR)

The regulator controls in automatic mode the reactive power at generator terminals.

The AVR function is active when the parameter P300 = 1 is set and when the configured input

I00X = 5 is closed.

Parametro

Descrizione

Note

r.401

Generator VAR digital reference

% compared to P.100 xP.110

r.402

Ramp slope

r.450

PF/VAR Reg KP

r.451

PF/VAR Reg TI

r.410

Delta Ref Calibrator

r.411

Delta Ref analog

r.412

Delta ramp slope

PAG. 22/32

4.5 Digital reference adjust by calibrator (U/Down)

Thanks to the programmed digital inputs (I00X = 1 increase, IOOX = 2 decrease) it is possible

to vary the reference in a range between the maximum and the minimum of parametrized

delta.

4.6 Digital reference adjust by analog (Pot/An. In)

Via the analog inputs (potentiometer or input ±5V) it is possible to vary the reference in a

range between the maximum and the minimum of parametrized delta.

AVR/FCR

PF/VAR

AVR/FCR

PF/VAR

PAG. 23/32

5. OPERATOR INTERFACE

In this chapter, it is described how parameters are managed by using the

programming keypad.

5.1 Control keypad and display

M Scroll menu`: allows to change parameter menu’ (d, r, I, P)

E key Enter: used to begin parameter setting and/or to confirm value

+ key UP: used to increase displaying parameter and/or numerical value

- key DOWN: used to decrease displaying parameter and/or numerical value

PAG. 24/32

5.2 Navigating the menus

While the S2014 is working the parameter d000 is shown automatically in the Display

menu.

PAG. 25/32

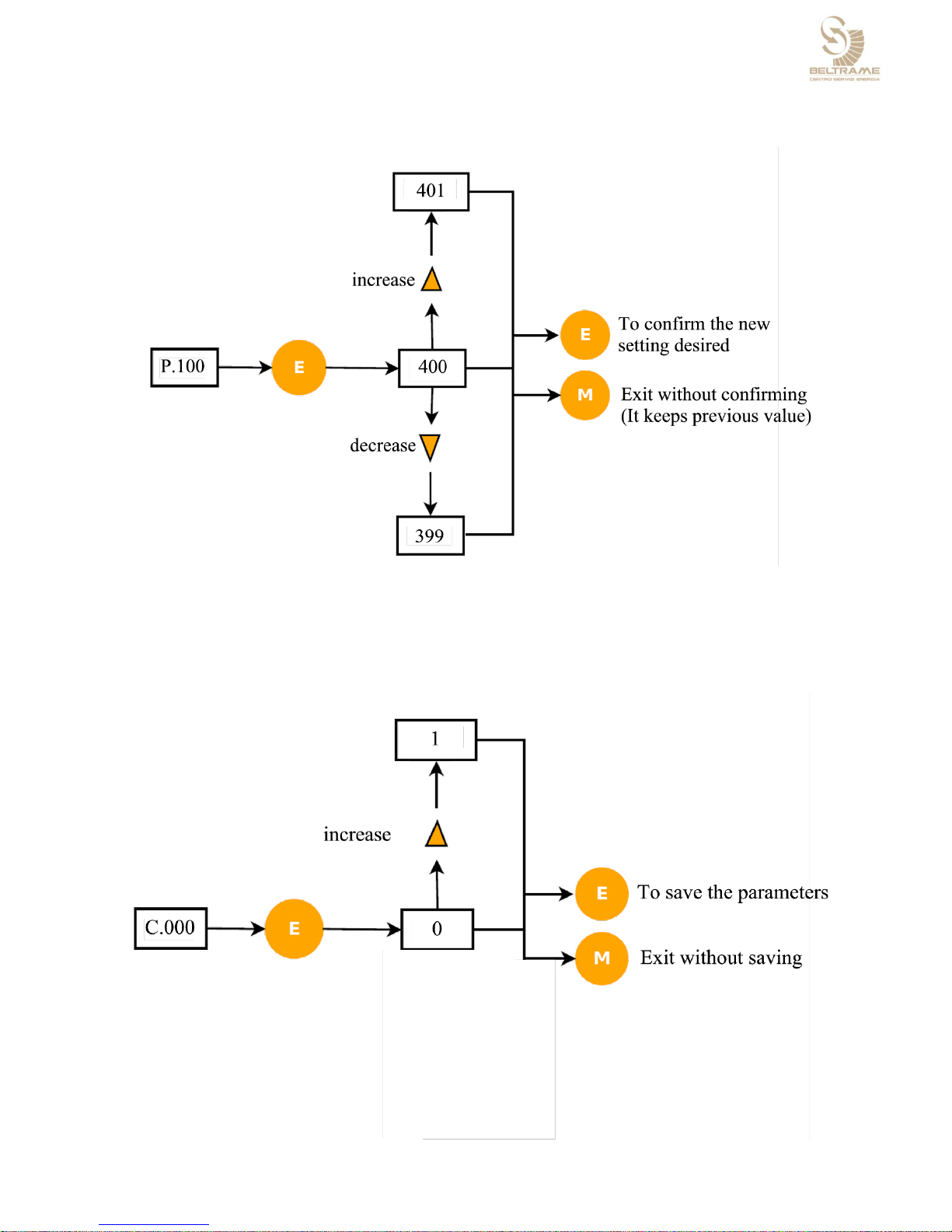

Example: how to change a Rated voltage generator reference

5.3 Parameters saving

When a parameter is modified, the action is immediate. However the saving is not automatic

and needs to be done through a specific saving action, using the command “C.000” [save the

parameters].

PAG. 26/32

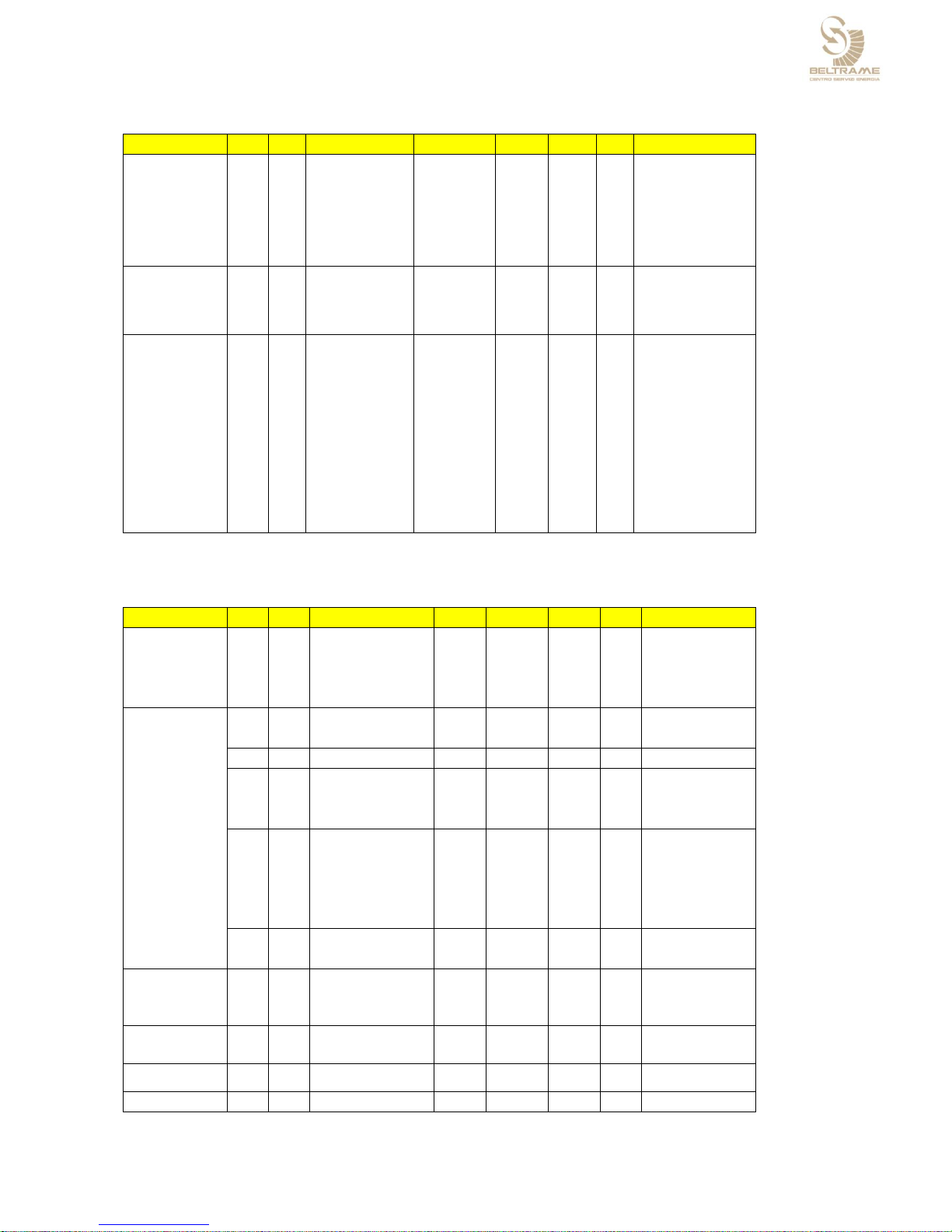

Menu

5.3.1 Menu d – Display

DISPLAYS

Name

IPA

Description

[U.M.]

Min

Default

Max

Notes, values

-1

Field

d.000

0

Field Current

%

0,0 - 200,0

% of P.000

d.020

1

Out Duty Cycle

%

0,0 - 100,0

1

Generator output

d.100

2

Gener. V

%

0,0 - -

% of P.100

d.104

3

Gener. Freq.

Hz

0,00 - 99,99

d.110

4

Gener. Current

%

0,0 - -

% of P.110

d.111

5

Gener. PowerFact

-

0,25 c - 0,25 i

Capacitive / Inductive

d.120

6

Gener. Power S

%

0,0 - -

% of P.100xP.110

d.121

7

Gener. Power P

%

-d.120 - d.120

% of P.100xP.110

d.122

8

Gener. Power Q

%

-d.120 - d.120

% of P.100xP.110

Excitier

d.950

9

FW ver. & rev.

- - - - xx.yy(hex)

d.952

10

SN

- - - - y.nnn

d.997

11

Heatsink Temp.

°C

-5 - 110

d.999

12

AUX V

V

0,0 - -

5.3.2 Menu r – References and Regulators

REFERENCES &

REGULATORS

Name

IPA

Description

[U.M.]

Min

Default

Max

Notes, values

199

Primary regulator

r.000

200

F. I digital ref

% 0 0,0

P.001

% of P.000

r.002

201

Ramp slope

%/s

0,1

50,0

999,9

r.010

202

Delta Ref calib

%

0

20

200

r.011

203

Delta Ref analog

%

0

20

200

r.012

204

Delta ramp slope

%/s

0,1

1,0

10,0

Field current

regulator

r.250

205

F. I Reg KP

-

0,01

0.50

99,99

r.251

206

F. I Reg TI

1/(2*AuxF)

0,1

20,0

100,0

related to Aux supply period

Generator voltage

regulator

r.350

207

G. V Reg KP

-

0,01

0.50

99,99

r.351

208

G. V Reg TI

1/(2*GenF)

0,1

20,0

100,0

related to generator period

206

Secondary

regulator

r.400

209

G. PF dig. ref

-

0,50c

1,00

0,50i

Capacitive / Inductive

r.401

210

G. VAR dig. ref

%

-100 0 100

% of P.100xP.110

r.402

211

Ramp slope

%/s

0,1

1,0

100,0

r.410

212

Delta Ref calib

%

0

20

100

r.411

213

Delta Ref analog

%

0

20

100

r.412

214

Delta ramp slope

%/s

0,1

1,0

10,0

PF/VAR

r.450

215

PF/VAR Reg KP

-

0,01

0,50

99,99

r.451

216

PF/VAR Reg TI

10/(2*GenF)

0,1

20,0

100,0

related to generator period

Aux voltage

regulator

r.650

217

AuxV Reg KP

-

0,01

0,50

99,99

r.651

218

AuxV Reg TI

1/(2*AuxF

0,1

20,0

100,0

related to Aux supply period

Limiters Regulator

r.900

219

OE/UE LIM Reg KP

-

0,01

0,25

99,99

r.901

220

OE/UE LIM Reg TI

1/(F reg)

0,1

40,0

100,0

related to generator period

PAG. 27/32

5.3.3 Menu I – Inputs and outputs

I/Os

Name

IPA

Description

[U.M.]

Min

Default

Max

Notes, values

Digital inputs

I.000

600

Dig inp 1 cnf

-

0 1 6

0 NONE

1 SET RAISE

2 SET LOWER

3 MANUAL FCR

4 GRID PAR (VDC)

5 GRID PAR (PF)

6 GRID PAR (VAR)

I.001

601

Dig inp 2 cfg

-

0 2 6

I.002

602

Dig inp 3 cfg

-

0 5 6

Digital outputs

I.100

603

Dig out 1 cnf

-

0 3 4

0 NONE

1 FAULT

2 NOT FAULT

3 LIMIT

4 NO LIMIT

RS485

I.400

604

RS485 config

-

0 0 4

0 custom protocol

1 Modbus RTU 8N1

2 Modbus RTU 8E1

3 Modbus RTU 8O1

4 Modbus RTU 8N2

I.401

605

RS485 bitrate

-

0 2 5

0 4800

1 9600

2 19200

3 38400

4 57600

5 115200

I.402

606

RS485 node ID

-

1 1 247

I.404

607

RS485 delay

s

0,000

0,001

0,100

5.3.4 Menu P – Parameters

PARAMETERS

Name

IPA

Description

[U.M.]

Min

Default

Max

Notes, values

Field excitation

data

P.000

1000

F. rated I

A dc

1,0

5,0

10,0

P.001

1001

F. OE Lim

%

100

150

250

% of P.000

P.002

1002

F. UE Lim

%

0 5 50

% of P.000

P.032

1003

F. OE Lim time

s

1

10

240

Generator data

P.100

1004

G. rated V

V rms

50

100

500

P.101

1005

G. max V

%

105

120

120

% of P.100

P.110

1006

G. rated I

A rms

0,20

2,50

5,00

P.130

1007

G. V/f min freq

Hz

20

30

150

P.131

1008

G. V/f max freq

Hz

P.130

45

250

P.132

1009

G. V/f slope

-

1,0

2,0

4,0

P.160

1010

Q – lim @ P 0%

%

-100

-40

-5

% of P.100 x P.110

P.161

1011

Q – lim @ P 25%

%

-100

-35

-5

% of P.100 x P.110

P.162

1012

Q – lim @ P 50%

%

-100

-30

-5

% of P.100 x P.110

P.163

1013

Q – lim @ P 75%

%

-100

-25

-5

% of P.100 x P.110

P.164

1014

Q – lim @ P 100%

%

-100

-20

-5

% of P.100 x P.110

P.170

1015

Q + lim @ P 0%

%

5

80

100

% of P.100 x P.110

P.171

1016

Q + lim @ P 100%

%

5

60

100

% of P.100 x P.110

Power supply

P.250

1017

KeepAlive min I

%

5

50

2

% of P.000

set 0 for PMG or

other independent

Power Supply

Control mode

P.300

1018

Primary reg.

-

0 1 1

0 FCR

1 AVR

Voltage Droop

Compensation

P.400

1019

Voltage comp K

%

-10,0

0,0

10,0

% of P.100 @ Q =

100%

Access control

P.981

1020

Password

-

0 1 9999

0 --> no password

PAG. 28/32

5.3.5 Menù C

DISPLAYS

Name

IPA

Description

[U.M.]

Min

Default

Max

Notes, values

-1

Utility commands

C.000

1600

Params save

-

0 0 1

C.002

1601

Params reload

-

0 0 1

C.200

1602

Test step

-

-8192 0 8192

8192=100%

C.201

1603

Test step type

-

0 1 3

0= Field I ref

1= Generator V ref

2= Generator PF ref

3= Generator VAR ref

PAG. 29/32

6. MAINTENANCE AND FAULTS

6.1 Safety regulations

WARNING!

The secondary voltage of the excitation transformer and the rotor field

voltage are fed into the excitation cabinet.

These components present a great danger of electric shocks.

Maintenance work shall only be carried out on the

electrical installation if the system has been switched off and protective

grounds installed.

6.2 Maintenance

When the system is at a standstill, check the fastening of faston terminals on the

regulator.

6.3 Trouble shooting

The following instructions are supposed to assist in localizing a fault within the

excitation system as a whole. However, it is not possible to deal with all eventualities

in full.

List of possible faults

Possible causes

Checks, action

Machine is not excited

Field circuit interrupted

Field circuit-breaker does not close

Check wiring for break

Check field circuit-breaker

No electronics supply

Measure power supply Aux – Com

Check for tripped protective circuit-breaker

Check builtin fuse

Set point error

Check operating mode

Check programmable digital input setting and

connection

Check set point

Overvoltage during build-up

Overvoltage caused by voltage regulator

Generator voltage present (measure voltage sensing

input at terminals Vsens and Common Aux)

Check system data

Check set point

Check overvoltage threshold

Check regulator settings

Machine voltage not stable in no-load operation

PAG. 30/32

Regulator error

Check operating mode.

Check programmable digital input setting and

connection

Check set points

Check parameters of voltage regulator

Set point error

Higher, lower inputs unstable

Externally input set point adjust unstable

Control element fault

Check wiring, loose contact V generator, Excitation

current

Parallel operation with grid unstable.

Periodic oscillation of reactive and possibly active power

Regulator settings incorrect

Were changes made to the grid configuration?

Are additional outputs, loads etc. installed?

Yes: re-set regulator

No: check parameters of Auto and PF, Var regulator

Irregular instability, i.e. sporadic over - or under excitation which is not

caused by grid

Droop influence of the voltage regulator

ineffective or CT measurement defective

Check droop compensation setting

Check external current transformer circuit

Gen CB Closed Status not active

Check programmable digital input setting and

connection

Machine within inadmissible operating range

(normally protected by limiters)

Bring machine into normal operating range by

adjusting the set point.

Check setting of limiters

Operating point cannot be adjusted

Set point error

Check operating mode.

Check programmable digital input setting and

connection

Check set point

Limiter active

Bring machine into normal operating range by

adjusting the set point.

Check setting of limiters

External controls faulty

No external control voltage

Measure control

voltage

Check wiring

Configuration of the digital or analog inputs are not

correct

Check configuration

6.4 Repair

A defective unit should be sent back for repair.

PAG. 31/32

7. GENERAL DATA

Ordering information

Device designation S2014

Mechanical data

Weight max 600 g

Protection class IP00 (limited by faston-type terminals, IP50 if terminals are protected

by an external isolation screen)

Dimensions (LxWxH) 138x58x55 mm

Climatic stability

Temperature range for operation: 0 to 55 °C

Temperature range for storage: -20 to +80 °C

Vibration: 5 mm, 2 G, 5<f<150 Hz

Electrical data

Power electronics supply: 80÷300Vac, 40 to 500 Hz

Excitation output: - maximum continuous current 8 A

- current reduction for ambient

temperatures >50 °C 1 A/degree

- overload (maximum 10 s) 16 A

Frequency range of measuring values Vgen and Igen 10 to 100 Hz

Accuracy: Voltage regulation <0.25%

Test voltage: power electronics supply against case 2500 Vdc, 2 s

Voltage measurement inputs Vgen, without galvanic separation

Relevant standards, CE conformity

EMC directive: 89/336/EEC

Generic emission standard EN 50081-2 (IEC 61000-6-4)

Generic immunity standard IEC/EN 61000-6-2

PAG. 32/32

Note:

Loading...

Loading...