Page 1

Thermoglaze

Model TG 50

Operator’s Manual

For

Serial Number W04060001 on

Belshaw Bros., Inc.

1750 22nd Avenue South

Seattle, WA 98144-4590

Phone: (206) 322-5474 • Fax: (206) 322-5425

Email: service@belshaw.com • http://www.belshaw.com

Toll Free: 1-800-578-2547

Page 2

Page 3

Congratulations on buying a new

Thermoglaze from Belshaw Bros., Inc. Please

inspect the unit carefully for damage or

missing pieces immediately after receiving

your system. Belshaw cannot pay for shipping

damage, because the freight company has

accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, each crate should be

inspected before signing the Bill of Lading to

report any visible damage caused by the

trucker in transit, and account for the number

of crates.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

0805

MN-1716EN

Belshaw Bros., Inc.

1750 22nd Avenue South

Seattle, WA 98144-4590

Phone: (206) 322-5474 • Fax: (206) 322-5425

Toll Free: 1-800-578-2547

Email: service@belshaw.com • http://www.belshaw.com

Page 4

Page 5

Contents

1 Unloading and Uncrating 1

2 Identification 2

3 Installation 4

4 Assembly 5

5 Operation 8

6 Cleaning 9

7 Maintenance 22

8 Troubleshooting 23

9 Appendix 27

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN iii

Page 6

Preface

The operator of the Thermoglaze is expected to

behave safely, read this manual before operation,

and follow its instructions and warnings.

Study the instructions and warnings in this

manual carefully before operating the equipment.

A thorough understanding of how to install,

maintain, and safely operate the Thermoglaze

will prevent production delays and injuries. Prior

operation of the equipment before reading and

understanding the instructions in the manual will

void the warranties of the equipment.

To use the Thermoglaze safely, heed the

following warnings and all other warnings that

appear in this manual:

• To avoid damaging the Thermoglaze,

never use force to assemble,

disassemble, operate, clean, or maintain

it.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1716EN Thermoglaze 50

Page 7

1 Unloading and Uncrating

DO NOT LIFT EXCESSIVE

WEIGHT

Once the crate has been delivered,

immediately take the covers off the crate and

inspect for hidden damage. If damage is

found, please see the above information to

make a damage claim to the shipping

company. After inspection, cut the banding

and remove any other restrains from the

Thermoglaze unit. Remove the banding and

other packing material from the Thermolizer

unit. Roll the Thermolizer, carefully, off the

skid first and move it near the area where it

will be assembled. Roll the Thermoglaze

unit, carefully, off the skid and move it near

the area where it will be assembled.

Do not connect the Thermoglaze or the

Thermolizer to electrical power before

completing the assembly and placement of

the products.

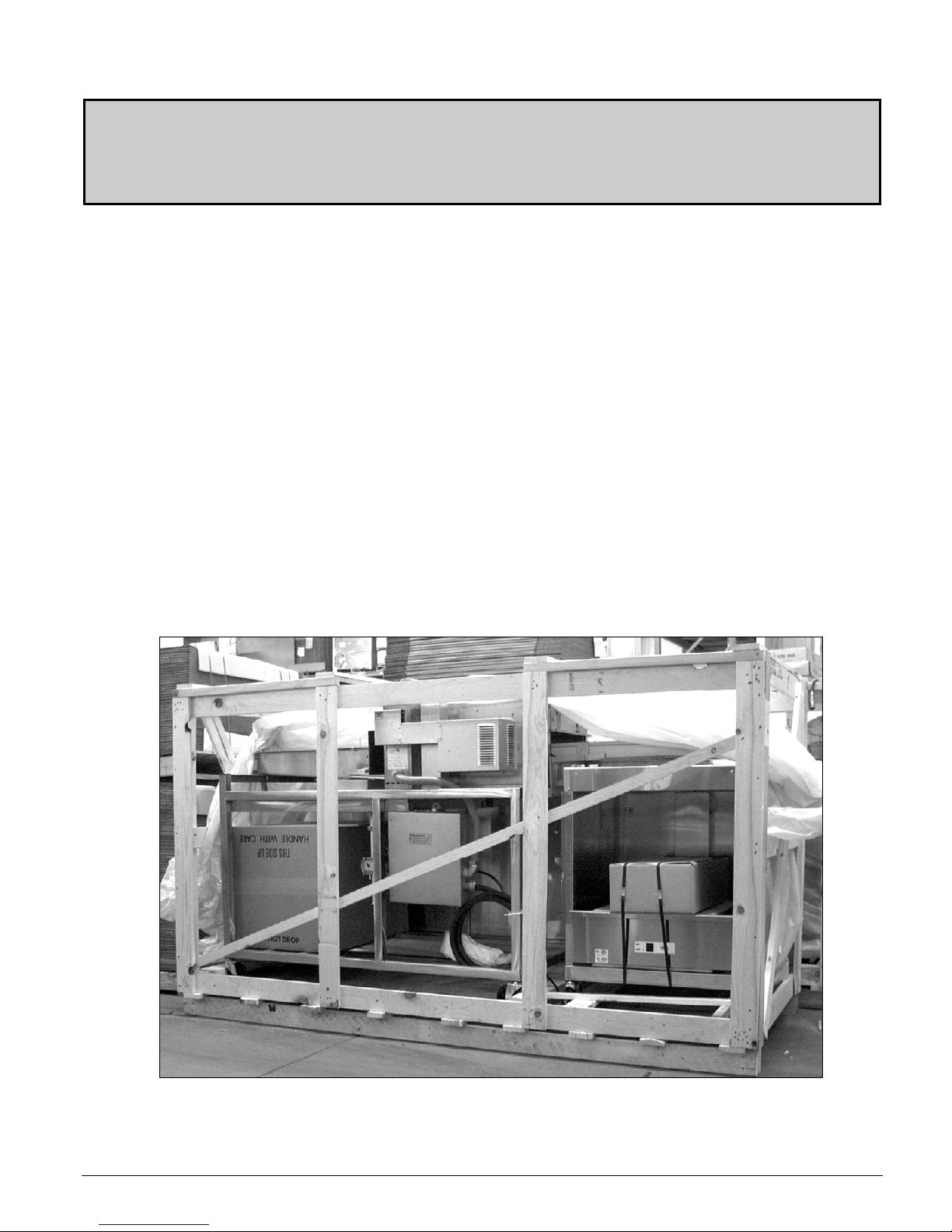

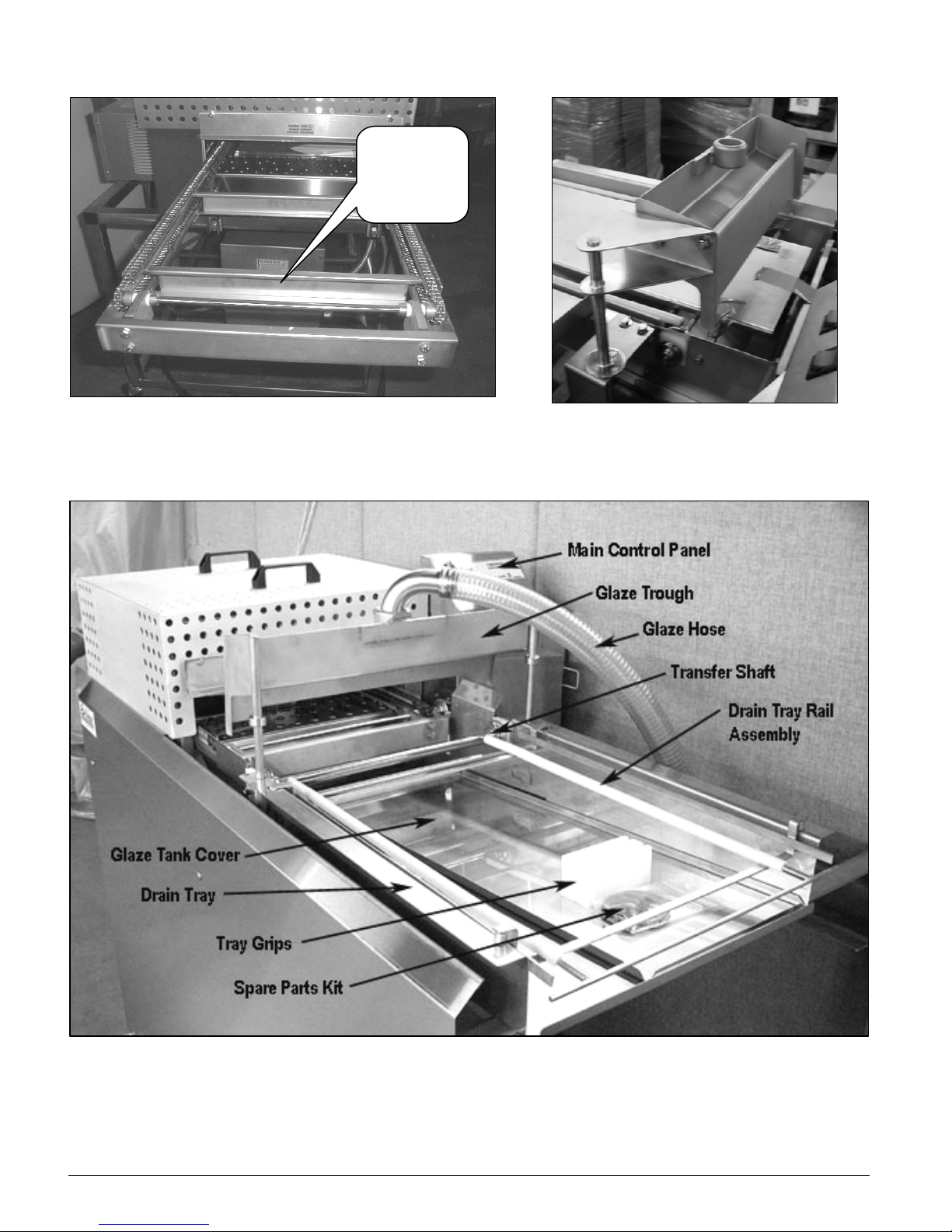

Figure 1-1 shows the system in the crate ready to

be unpacked. The cartons under the Thermoglaze

contain the glaze trough and oven guard. See

Section 4 to assemble the unit. The carton in the

Thermolizer contains the doors and other interior

parts. See Thermolizer manual for assembly

instructions.

The Thermoglaze system has been designed for

quick assembly and installation. Within a few

minutes of receiving the system, the installer can

have the Thermoglaze ready to make donuts if

the electrical connections are properly installed

and inspected by the prevailing local authorities.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 1

Figure 1-1

Page 8

Identification 2

This information is key to identification for

service or ordering parts on the ThermoGlaze.

When servicing the equipment, please have the

Model and serial number so the technician can

order the correct parts for you. To identify which

Thermoglaze system you have, please use the

following model number key:

THERMOGLAZE DESCRIPTION KEY

Model No: - Doz/hr: - Glaze Pump: Opt. Items: - Voltage: - Freq: - Phase: -

TG 50 G = Gear Pump V = End Cover -50 208 50 1

25 L = Lift Pump M = Mono -50 220/240 60 3

N = No Pump A = RF Oper. 400/230 3 w/N

B = LB Oper. 415/240

Location: C = LF Oper.

D = RB Oper.

C = CE/Export T = LB Oper/SPL w/

D = Domestic/Nema (thermolizer cabinet)

B = Export/Non-CE

W = Domestic/Pin/Sleeve

E = Aust/NZ

Note: TG-50 is RF/LB Operate only, without Thermolizer - Screen 17” x 25”

TG-25 includes built in Thermolizer for 12 ½” x 17” Screen

Part No. Description Key Drawings

22080 OBS USE 22113, TG-25 JR. TJ-2004, TJ-4000 w/120V

22081 OBS USE 22114, TG-25 JR. TJ-2006, TJ-4000 w/120V

22082 OBS USE 22115, TG-25 JR. TJ-2005, TJ-4000 w/120V

22083 OBS USE 22116, TG-25 JR. TJ-2007, TJ-4000 w/120V

22113 TG-25-GA-208-60-1-D JR. TJ-2004, TJ-4002

22114 TG-25-GB-208-60-1-D JR. TJ-2006, TJ-4002

22115 TG-25-GC-208-60-1-D JR. TJ-2005, TJ-4002

22116 TG-25-GD-208-60-1-D JR. TJ-2007, TJ-4002

22117 TG-25-GA-220/240-60-1-D JR. TJ-2004, TJ-4002

22118 TG-25-GB-220/240-60-1-D JR. TJ-2006, TJ-4002

22119 TG-25-GC-220/240-60-1-D JR. TJ-2005, TJ-4002

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1716EN Thermoglaze 50

Page 9

Part No. Description Key Drawings

22120 TG-25-GD-220/240-60-1-D JR. TJ-2007, TJ-4002

22231 TG-25-GB-415-50-3w/N-C JR TJ-2006, TJ-4004 (415/240V)

22247 TG-25-GB-415-50-3w/N-E RVO TJ-2012, TJ-4005 (415/240V)

22010 TG-50-G-208-60-1-W STD TNG-2011, TNG-4008

22054 TG-50-GV-208-60-1-D STD TNG-2011, TNG-4008

22011 TG-50-GV-220/240-60-1-D STD TNG-2011, TNG-4008

22013 TG-50-GV-400/230-50-3-C STD TNG-2011, TNG-4012

22067 TG-50-GM-400/230-50-3-C SPL TNG-2012, TNG-4012

22251 TG-25-GT-208-60-1-D SPL TJ-2013, TJ-4002

Optional Line Items:

SL200-0004 Glazing Screen - 17” x 25” – TG-50

TJ-0001 Glazing Screen – 12 ½” x 17” – TG-25

TJ-1012 Front Shield Kit – TG-25

SK-1257 Spare Parts Kit – TG-50 (included)

SK-1258 Service Kit – TG-50 (208-220/240V-60H-1P-DOM)

SK-1280 Spare Parts Kit – TG-25 (included)

SK-1281 Service Kit – TG-25 (208-220/240V-60H-1P-DOM)

SK-1281CE Service Kit – TG-25 (415/240V-50H-3P-CE)

SK-1314 Service Kit – TG-50 (400/230V-50H-3P-CE)

TNGG-1011 Heater Assembly - Glaze Tank TG-50

TZ-6 & TZ-17 Thermolizer (order service kits separate)

TNGG-0079 Cover; Glaze Tank – TG-50 (included except 22010)

TNGV-2004 Oven Mod. Kit & Lincoln Oven Parts (208V-60H-1P-DOM)

TNGV-2005 Oven Mod. Kit & Lincoln Oven Parts (240V-60H-1P-DOM)

TNGV-2009 Oven Mod. Kit & Lincoln Oven Parts (400/230V-50H-3P-CE)

08/19/05

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 3

Page 10

Installation 3

Venting:

WARNING

To avoid electrocuting yourself or damaging

the Thermoglaze, never allow water, steam,

cleaning solution, or other liquid to enter the

electrical panels or connections

Local codes prevail. The authorities having

jurisdiction are stated in NFPA 96-1994

regarding requirements for the Thermoglaze.

Building Layouts:

Electrical:

Model Dimensions Power Requirements

88"L x 40W x

TG21586

Make sure that the power requirements of the

Thermoglaze, shown on the data plate, match

your power source.

Only plug in to power source that matches the

required voltage and current for the

Thermoglaze. (The Thermoglaze unit TG50

comes standard with a Hubbel 360P6W plug that

needs a 360C6W socket or equivalent for

electrical current.

Thermoglaze must be electrically grounded and

connected in compliance with the National

Electrical Code, ANSI-NFPA 70, and applicable

municipal building codes.

63"H

See data tag

Specification sheets and AutoCAD drawings for

use in developing architectural drawings can be

provided by request. Please call your Belshaw

Bros., Inc. representative for help in defining

your requirements.

Do not apply electrical power to the system until

the assembly has been completed. See Section 4

for the assembly of the Thermoglaze.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1716EN Thermoglaze 50

Page 11

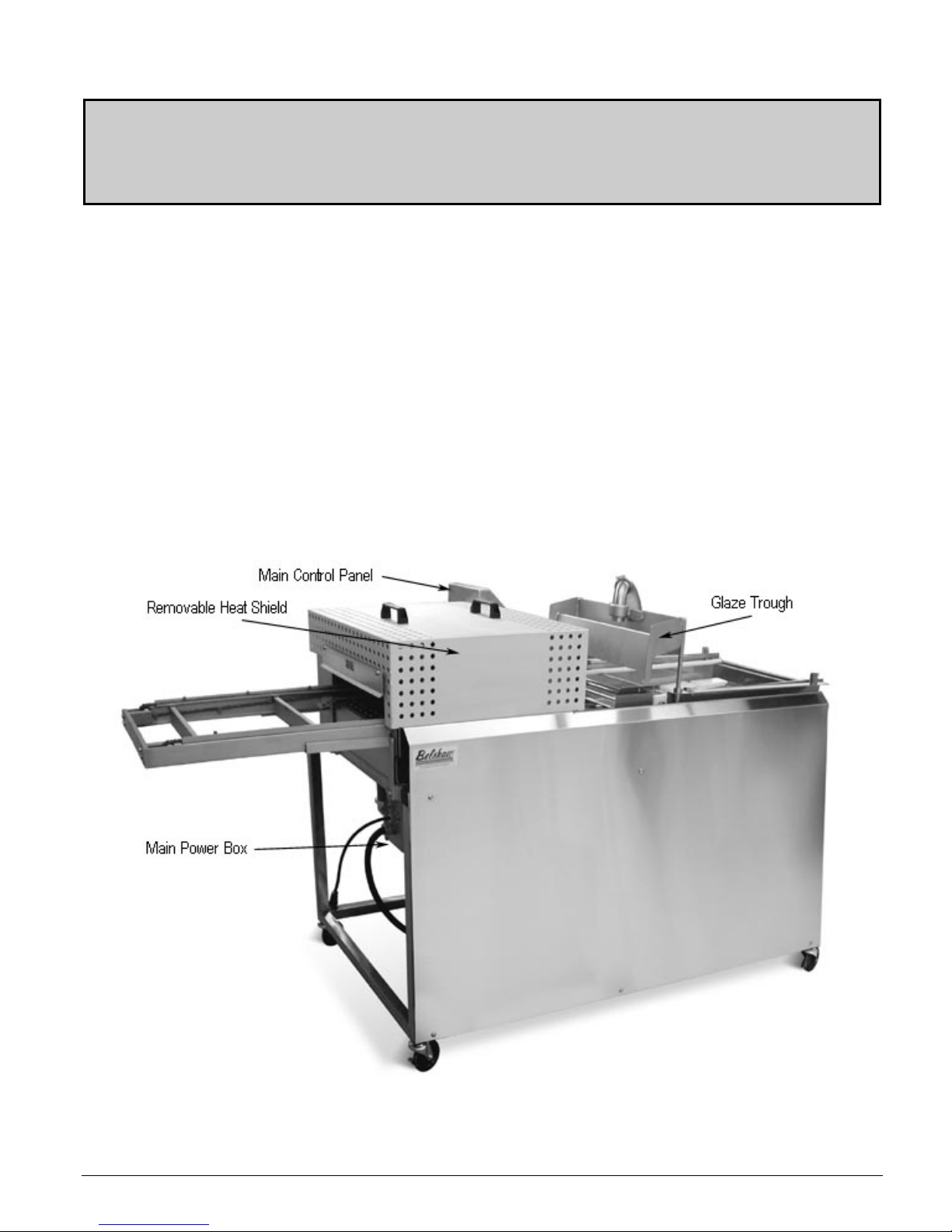

Assembly 4

Clean all parts with mild soap and water and

let dry before assembly and applying

electrical power to the equipment.

The Thermoglaze unit is design for ease of

assembly and use. The system is crated in a

manner so there are few pieces to put together

once the Thermoglaze is in place for production.

After unpacking the system per the uncrating

instructions, 2 items need to be placed on the

Thermoglaze to finish assembly, the glaze trough

and the heat shield. First, the Glaze trough slips

into the 2 holes on either side of the drain tray

with the waterfall headed toward the oven. See

figure 4-1 and 4-4 for help setting the trough in

place. After the trough is in place attach the glaze

hose to the trough by pushing it in the hose

mount in the center of the trough. Second is the

Heat Shield over the oven portion of the

Thermoglaze. Slip it over the oven using the

handles provided until the guard locks over the

back of the oven. See figure 4-1 for a photo of

the location of the heat shield.

To help familiarize you with your Thermoglaze,

please study the following photographs:

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 5

Figure 4-1 Front view:

Page 12

Transfer

Conveyor

Assembly

Figure 4-2 Infeed – Left hand view. Figure 4-3 Swing away glaze trough.

(Optional)

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

6 MN-1716EN Thermoglaze 50

Figure 4-4 Right Hand View:

Page 13

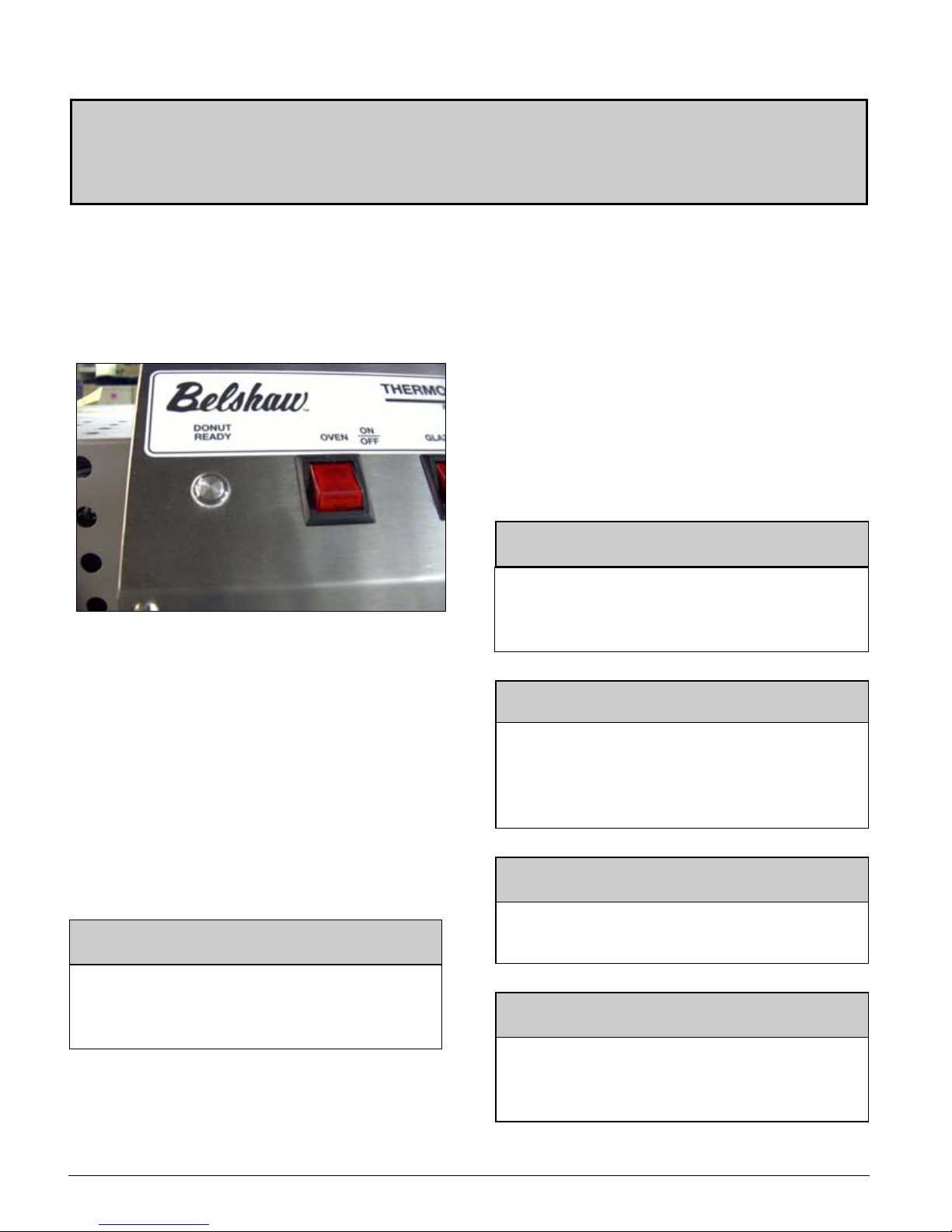

Figure 4-5 Control Panel View:

The Thermoglaze system consists of a Thermoglaze

unit and the Thermolizer. They are placed in unison

in the area located for the production of donuts. See

Figure 4-6 for Thermoglaze system.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 7

Figure 4-6 Thermoglaze System.

Page 14

Operation 5

• Turn on main power switch and allow to heat

to operating temperature. (Note: conveyor

will not move until the oven is up to

operating temperature and the donut

ready light is on. See Figure 5-1.)

Figure 5-1. Oven Ready Light.

• Turn on the Thermolizer and heat for 30

minutes to allow it to reach operating

temperature. See Thermolizer manual for

more operating instructions.

• Load glaze reservoir with 40 pounds (one

large bucket) of glaze and turn on the glaze

pump.

using the on switch located on the main

control panel.

• After the donuts are thawed, place a screen of

donuts from Thermolizer box to the infeed

end of the Thermoglaze conveyor and allow

the screen to travel through the oven and

glazer. This takes approximately 3 minutes.

• When the screen of donuts is through the

glazer and stopped forward travel, place the

glazed product on a rack for cooling using

the 2 delrin tray grips provided with the unit.

WARNING

To avoid burning yourself, never touch the

Thermoglaze unit, conveyor, or interior of the

oven while the machine is in use.

WARNING

Thoroughly clean and dry the floor if water or

other materials are spilled. Materials spilled

on the floor may cause serious injury and loss

of life.

• To swing the glaze trough back, turn off

glaze pump, lift up on the mount slightly and

rotate to the trough to the rear. (Optional

Equipment) See Figure 4-3.

WARNING

Do not operate glazer without glaze or water

in the pump. Doing so may cause permanent

damage to the pump.

• After the donuts have been in the

Thermolizer for at least 20 minutes (60

minutes for filled product), turn on glazer

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

8 MN-1716EN Thermoglaze 50

WARNING

Conveyor will automatically start when

Thermoglaze reaches operating temperature.

CAUTION!

Donut screens are hot after coming out of the

glazer and will burn you if you grab them

without the handles.

Page 15

Cleaning 6

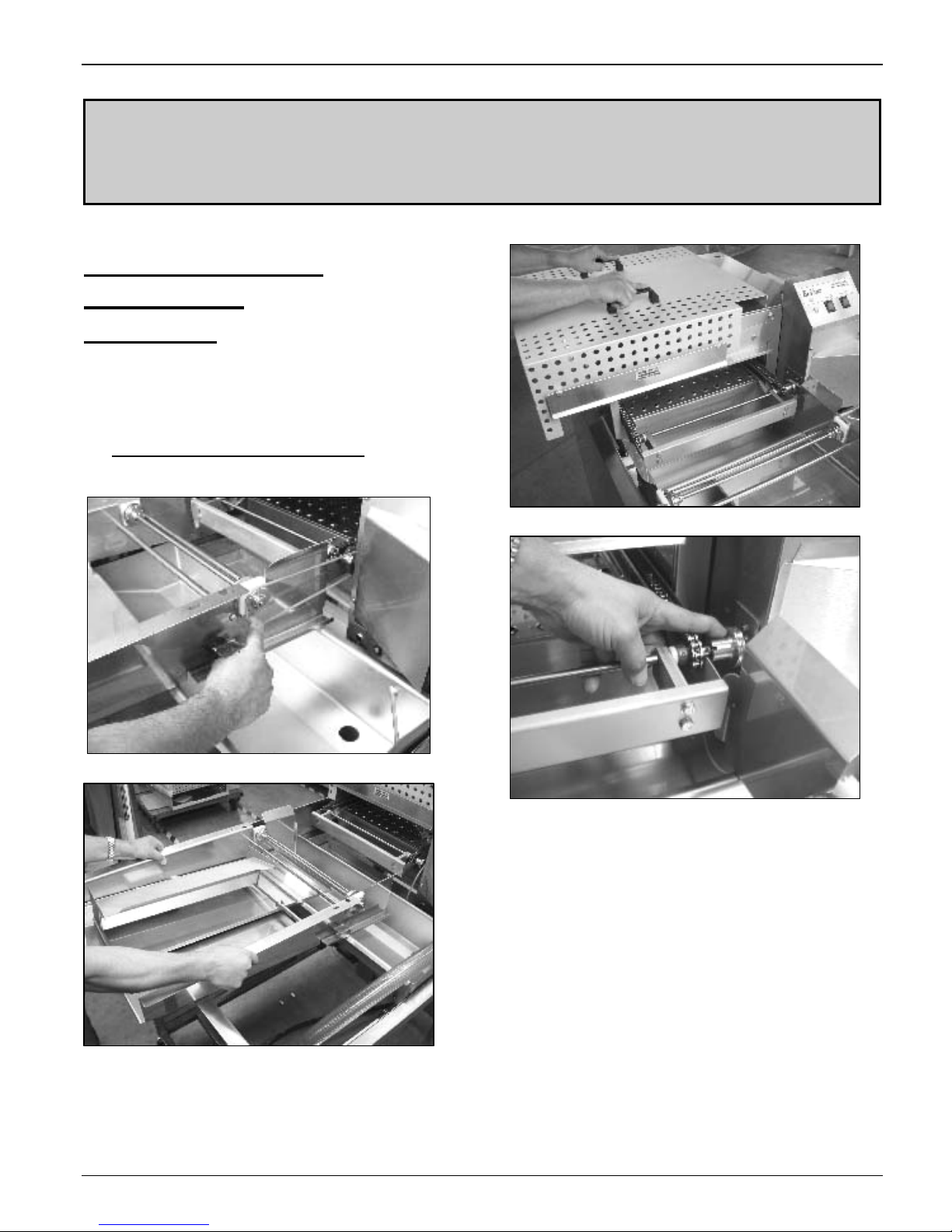

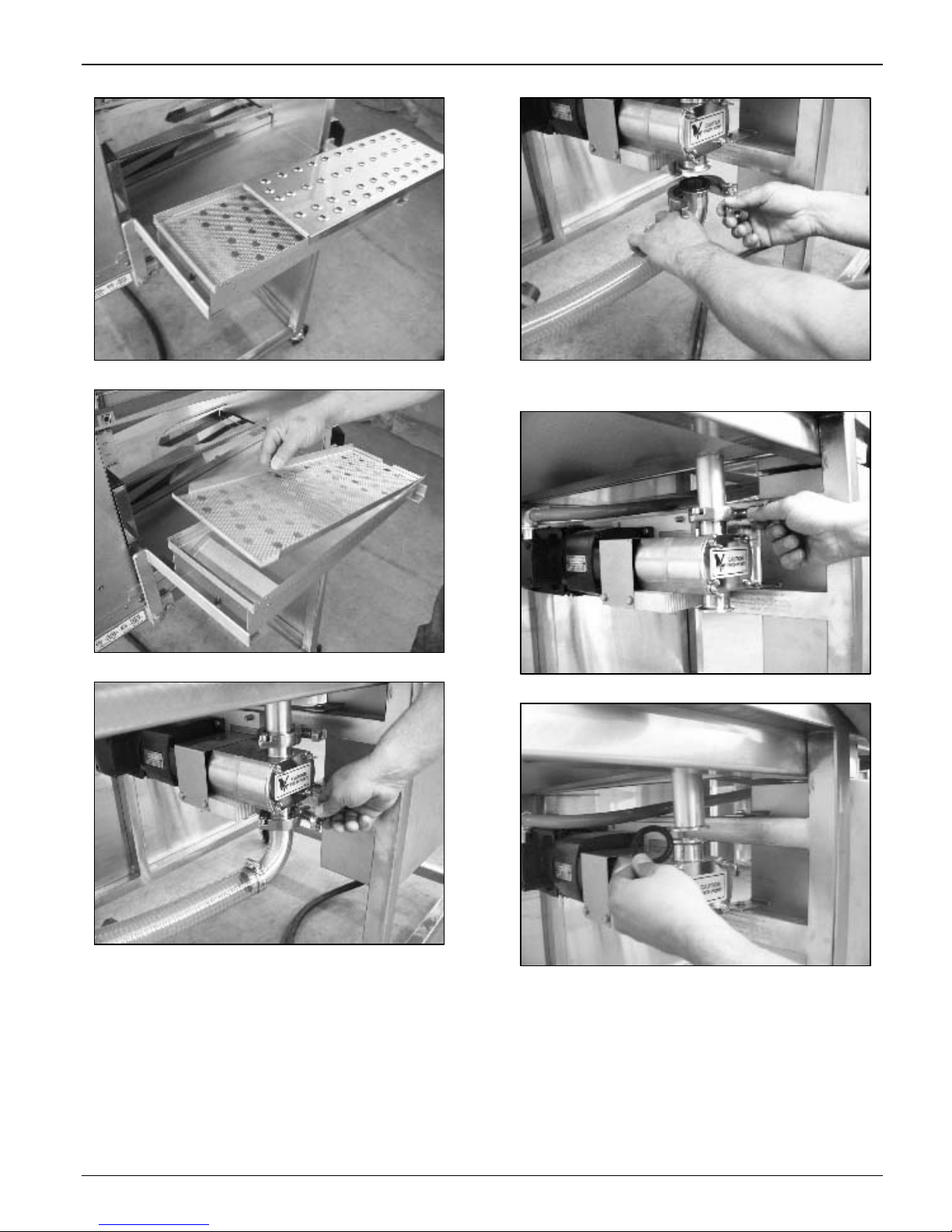

Daily TG Cleaning

Instructions

Disassembly

1. Allow the Thermoglaze to completely

cool. (All material must under 130º)

2. Pump the unused glaze back into a bucket.

3. Disconnect the TG from power!

4. Remove the glaze trough.

5. Remove the drive belt.

7. Remove the oven heat shield.

8. Disconnect the conveyor drive coupling.

6. Remove the glazer drain tray.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-544EN 9

Page 16

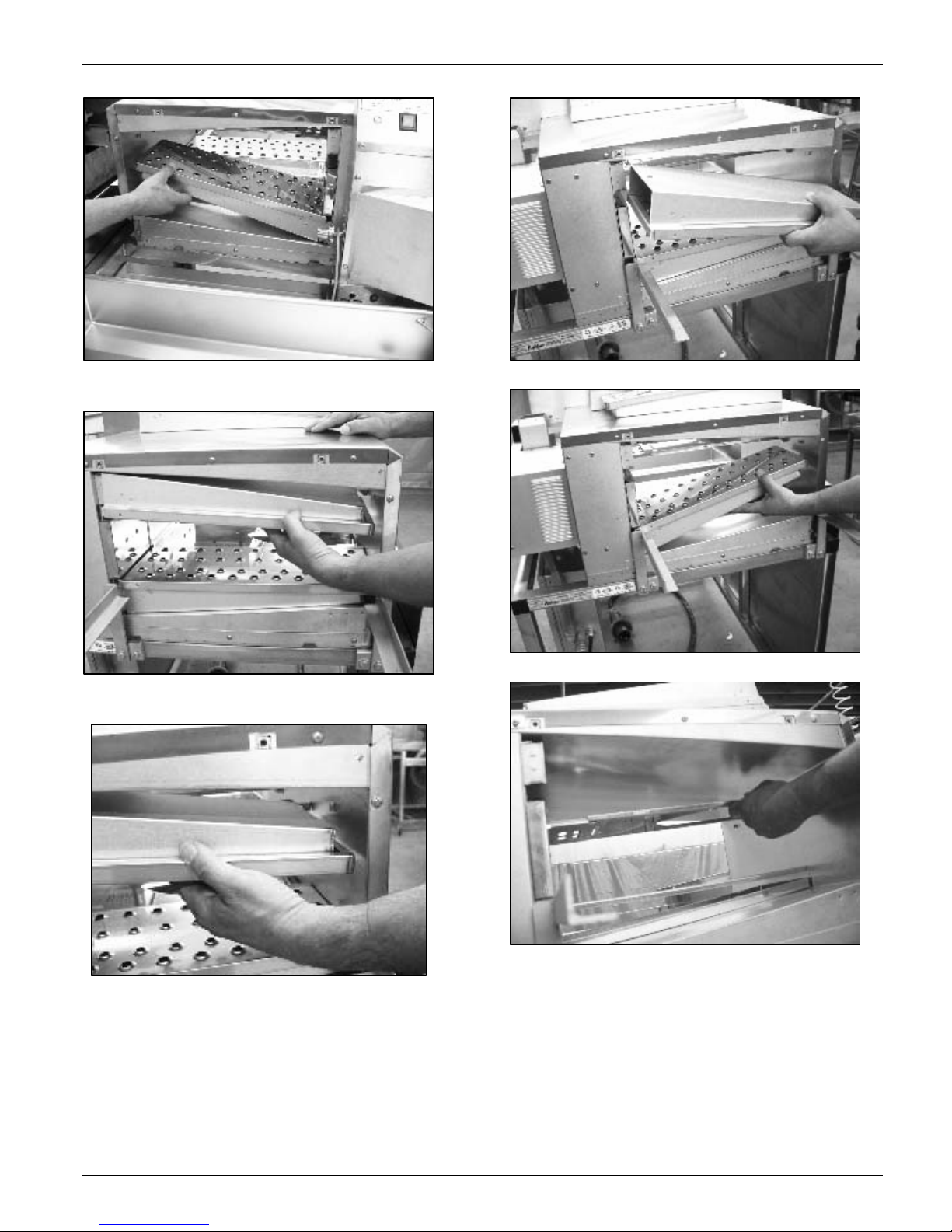

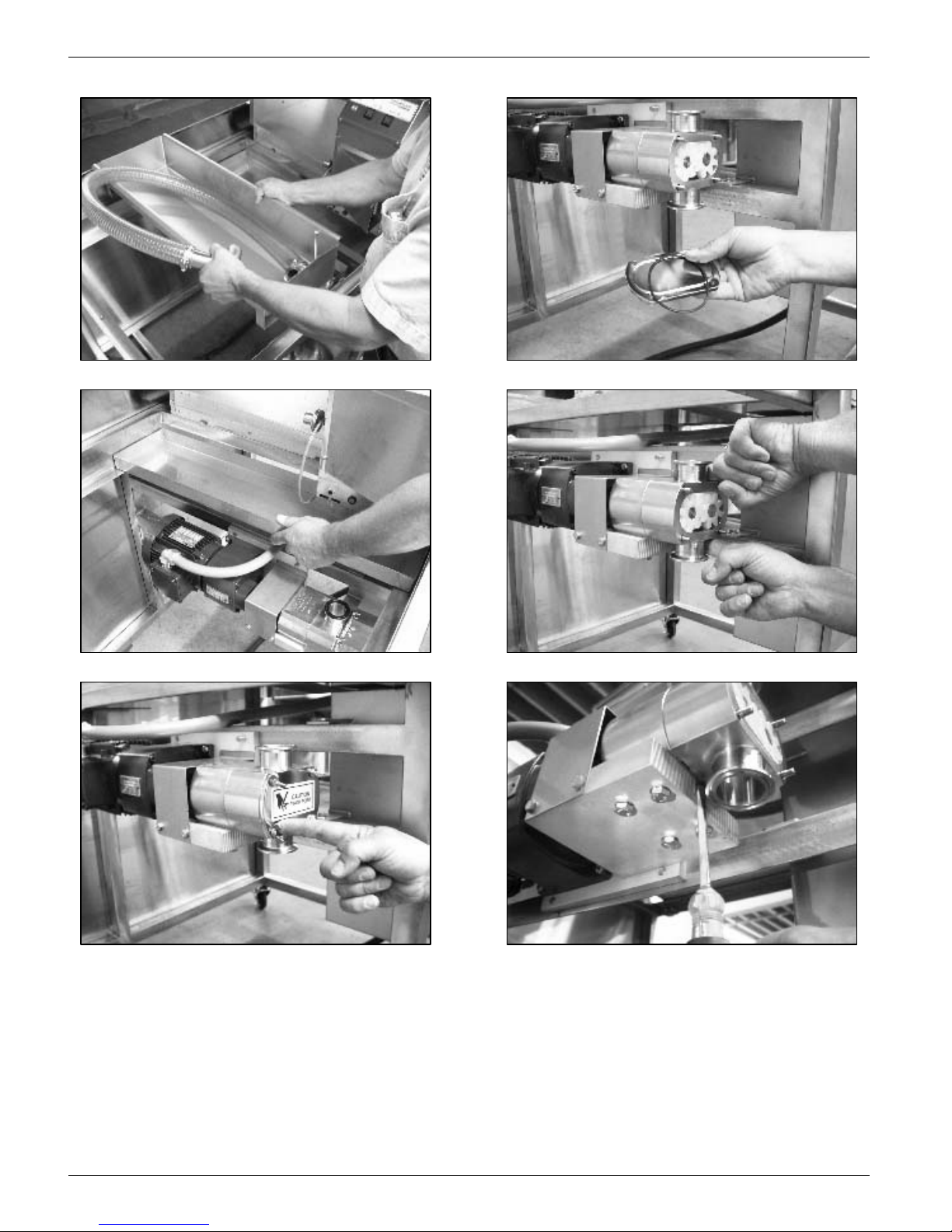

9. Remove the conveyor assembly through

the outfeed end of the oven.

10. Turn the end cover latches

counterclockwise.

12. Lift up on the outfeed upper finger housing and

slide it to the rear of the oven disengaging it

from the mounting bracket.

13. Lower the end of the finger assembly.

11. Remove the end covers.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

10 MN-1716EN Thermoglaze 50

14. Pull the finger assembly off the duct on the back

of the oven and remove it.

Page 17

15. Lift up on the outfeed lower finger

assembly and remove it.

16. Lift up on the infeed upper finger

assembly.

18. Remove the infeed upper finger assembly.

19. Remove the infeed finger assembly.

17. Slide the infeed upper finger assembly to

the rear of the oven.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 11

20. Lift up on the outside end of the upper air duct

panel.

Page 18

21. Remove the upper air duct panel

22. Lift up on the outside end of the lower air

duct panel.

24. Remove the oven crumb tray

25. Oven with all parts removed.

23. Remove the lower air duct panel.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

12 MN-1716EN Thermoglaze 50

26. Insert flat tip screwdriver into finger

assembly if it cannot be removed by hand.

Page 19

27. Remove the finger cover.

28. Remove the columnating plate.

30. Remove the lower glaze hose clamp and

gasket.

31. Remove the upper pump clamp.

29. Loosen the lower glaze hose clamp.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 13

32. Lift the glaze reservoir and remove the gasket

Page 20

33. Remove the glaze reservoir and hose.

34. Remove the drip pan.

36. Remove the glaze pump cover and “O” ring.

37. Remove the glaze pump body.

35. Remove unscrew the 4 glaze pump cover

wing nuts.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

14 MN-1716EN Thermoglaze 50

38. Insert a flat tip screw driver into the slot to

loosen the pump body if it can not be

removed by hand.

Page 21

39. Remove the pump body and impellers.

40. Remove the impellers from the pump body.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 15

Page 22

Cleaning

1. Hand wash all parts of the oven and

glazer with warm soapy water.

2. Do not use caustic cleaners on oven parts.

3. You may use an approved oven cleaner

on the stainless steel finger cover only.

(see step 27 of Disassembly)

4. Do not use oven cleaner on any other part

of the oven or glazer!

5. Do not hose/spray down any part of this

machine.

6. Glaze pump body and parts.

CAUTION

Failure to properly clean or lubricate glaze

pump may cause damage to the pump gear

impellors.

2. Install the drive gear impeller. Line up

the flat on the shaft with the flat in the

impeller.

3. Install the lay gear impeller.

Assembly

NOTE

Lubricate the pump body, shaft “o” ring and

gear impellors with food grade mineral oil.

1. Install the glaze pump body.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

16 MN-1716EN Thermoglaze 50

4. Install the “O” ring into the glaze pump

cover. Make sure it stays in place and you

do not pinch it between the pump and

cover. The “O” ring may need to be

stretched before installing.

Page 23

5. Install the 4 wing nuts finger tight.

6. Set the upper gasket on top of the glaze

pump.

8. Install the upper clamp.

9. Install the lower gasket, hose and clamp.

7. Install the drip pan and glaze reservoir.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 17

10. Install the columnating plates.

Page 24

11. Install the finger covers.

12.

Install the oven crumb tray.

Install the upper air panel assemb ly.

14.

15.

Install the lower infeed finger assemb ly.

13.

Install the lower air duct panel.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

18 MN-1716EN Thermoglaze 50

16.

Install the upper infeed finger assem b ly

by slipping it over the duct on the back of

the oven.

Page 25

17. Then lift it up, slide it to the front of the

oven and hook it on the brackets.

Install the infeed end cover by lining up

20.

the slots at the bottom of the end cover

with the brackets on the oven and push in

on the latches and turn clock wise.

18.

Install the lower outfeed finger assemb ly.

19.

Install the upper outfeed finger assembly.

21.

Install the outfeed end cover same as the

infeed.

22.

Insert the conveyor through the outfeed

end of the oven.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 19

Page 26

23. Pull the drive coupling back and line it up

with the conveyor drive shaft.

24.

Install the glaze reservoir cover

26.

Install the glaze drain tray.

27.

Connect the drive belt.

25.

Glaze reservoir installed.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

20 MN-1716EN Thermoglaze 50

28.

Set the heat shield on top of the oven.

Page 27

29. Slide the heat shield over the oven.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 21

Page 28

Maintenance 7

The ThermoGlaze is engineered to need little

maintenance. By keeping the system clean, the

equipment will last for years. The only

maintenance that is required is the following:

When cleaning the donut system, check all

rubber gaskets for wear and replace when

necessary. Check for wear on impellers of the

glaze pump, replace when necessary. .

DO NOT spray machine with water or cleaning

agents to clean. Only wipe main unit off with

damp cloth.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

22 MN-1716EN Thermoglaze 50

Page 29

Troubleshooting 8

Call Belshaw Bros. at (206)322-5474, or (800)

578-2547. One of our customer support

representatives will be happy to help you. When

you call, please specify the following:

• The model name of the machine.

• The serial number of the machine.

• The voltage, phase, and hertz (cycle) of

the machine. This information can be

found on the small, rectangular data

tag/plate.

CAUTION

If you perform repairs yourself or have them

performed by anyone other than Belshaw

Bros. or a service technician authorized by

Belshaw Bros., you do so at your own risk.

Following is a troubleshooting chart to help you

identify and solve some basic problems.

WARNING

Disconnect the machine from the power

source before disassembling, repairing, or

wiring.

NOTE

See page 31 of the Maintenance Appendix for

oven troubleshooting.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 23

Page 30

CONVEYOR WILL NOT MOVE

Possible Causes What To Do

Oven not to correct temperature yet. Wait until the oven comes to temp.and the ready

light comes on.

Conveyor is jammed. Check for obstruction in conveyor and remove.

Motor circuit breaker is tripped. Push the black circuit breaker reset at bottom of

oven control panel.

GLAZER WILL NOT PUMP GLAZE

Glazer motor is not running. Check to make sure the motor is running.

(See Pump Motor Will Not Run)

Glazer pump impellers are worn. 1. Disconnect power.

2. Replace impellors.

GLAZE IS MISSING THE DONUTS ON ONE SIDE OF THE GLAZE SCREEN

Glazer or glaze trough is not level. Adjust level of glaze trough by moving set collar.

Glaze pump is running too slow. 1. Disconnect from power.

2. Open Electrical Enclosure.

3. Turn glazer speed control clockwise.

4. Close Electrical Enclosure.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

24 MN-1716EN Thermoglaze 50

Page 31

THE PUMP MOTOR WILL NOT RUN

Possible Causes What To Do

The connection of the power cord to the power

source is faulty.

Make sure the power cord is fully plugged in to a

proper power source.

The circuit breaker has been tripped. 1. Disconnect from power.

2. Open electrical enclosure.

3. Reset circuit breaker.

4. Close electrical enclosure.

THE FILL HOSE IS LEAKING

Possible Causes What To Do

Fill hose is leaking at the connection. Hose bracket needs adjusting or tightening.

Fill hose is leaking near the pump. Check for missing or damaged o-ring.

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 25

Page 32

Calibration Procedure for Temperature and Cook Time on

the Thermoglaze Model TG50

Turn off power to the TG50 before removing any

access covers. This procedure should be

performed only by qualified service technicians.

Remove the electrical box cover on the oven to

access the temperature and speed control

adjustment potentiometers. The following is a

Speed Control

Adjustment

photo of the location of the adjustment

potentiometers for the temperature and cooking

time for the Belshaw TG50 Thermoglaze.

Temperature

Adjustment

Speed control/cook time

adjustment:

Turn on the oven and allow it to heat for 30

minutes.

Put a glaze screen on the conveyor chains that

run through the oven. With the oven in operation,

time the leading edge of the screen as it enters

the oven until the leading edge just leaves the

exit end of the oven. Adjust the potentiometer

until the desired time/speed is found. To increase

the cook time, turn the potentiometer clockwise.

To decrease the cook time, turn the

potentiometer counterclockwise. The factory

setting for cook time for the TG50 is 1 ½

minutes.

Temperature Adjustment:

Measure the temperature from the lower baffle

on the exit end of the oven. Place a thermocouple

in the hole located on the baffle, 3

outside, 3

Note: The back side of the oven has a fan motor

extended from it. Adjust the temperature by

rotating the potentiometer located to the right of

the speed control, clockwise increases the

temperature, and counterclockwise decreases the

temperature. The factory setting is 400º F.

rd

hole from the back side of the oven.

rd

row from the

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

26 MN-1716EN Thermoglaze 50

Page 33

Appendix 9

Final Assembly Drawing TNG-2011

Parts Diagrams TNGG-1008

TNGG-0526

TNGG-1009

TNGV-2004

Wiring Diagram TNG-4008

Maintenance Appendix for ThermoGlaze Oven

Service Kit Parts List

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 27

Page 34

TNG-2011. THERMOGLAZE ASSEMBLY

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

28 MN-1716EN Thermoglaze 50

Page 35

TNG-2011. THERMOGLAZE ASSEMBLY

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 29

Page 36

TNG-2011. THERMOGLAZE ASSEMBLY

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

30 MN-1716EN Thermoglaze 50

Page 37

TNG-2011. THERMOGLAZE ASSEMBLY

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 31

Page 38

TNG-2011. THERMOGLAZE ASSEMBLY

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

32 MN-1716EN Thermoglaze 50

Page 39

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 33

Page 40

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

34 MN-1716EN Thermoglaze 50

Page 41

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 35

Page 42

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

36 MN-1716EN Thermoglaze 50

Page 43

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1716EN 37

Page 44

SK-1258 R5

REC. QTY PART NUMBER DESCRIPTION

1 EA #RLY-0008 RELAY (240V)

1 EA #SWT-0022-240 ILLUMINATED ROCKER SWITCH

1 EA #TDR-0015 TIME DELAY RELAY

5 EA 905-0242-7/8 HD SPRING PIN, 1/8 DIA X 7/8" LG

5 FT 905-0408-58

2 EA GL100-0116 GLAZE TUBE CLAMP

4 EA GL100-0171 GASKET

1 EA HG18-0031-4 CASTER 4"

1 EA HG18-0031B-4 CASTER W/BRAKE 4"

1 EA TNGG-0034C DRIVE GEAR

1 EA TNGG-0034D LAY GEAR

4 EA TNGG-0034M WING NUTS, PUMP COVER

2 EA TNGG-0034T COVER O-RING

2 EA TNGG-0034Z PUMP O-RING, SHAFT

4 EA TNGT-0009 SPACER, DELRIN, WHITE

2 EA TNGT-0079 BEARING BLOCK, TRANSFER SHAFT

1 EA TNGT-0080 TRANSER SHAFT

2 EA TNGT-0082

2 EA TNGT-0167 REPL. CHAIN ASS'Y

2 EA TNGT-0169 IDLER SPROCKET, 38B10

1 EA TNGT-0171 CONVEYOR DRIVE SHAFT, OUTFEED

2 EA TNGV-0060 TRAY GRIP

THERMOGLAZE

1 1/2 ID SUCTION HOSE (SPIRILITE) 58"

LG.

TRANSFER SHAFT DRIVE BELT,-

ORANGE

Belshaw Bros., Inc. • 1750 22nd Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

38 MN-1716EN Thermoglaze 50

Page 45

TROUBLESHOOTING GUIDE

IMPINGER CTI

SYMPTOM POSSIBLE CAUSE EVALUATION

Oven fan will not run

No main fan cool

down

Main fan continues to

run after cool down

No control box

cooling

Incoming Power Supply Check breakers, reset if required Check power plug

to be sure it is firmly in the receptacle (if applicable).

Measure the incoming power, call Power Co., if

needed

Oven Fan Fuses, 5 Amp Check and/or replace

Fuse Holder Check and/or replace

High Limit Thermostat

Control Box (

Limit not used in ovens

S/N 3000352)

Fan Switch Check continuity between switch terminals. Check

20 Minute Time Delay Check for supply voltage at terminal #1 to ground on

Main Fan Relay Check continuity of coil. Check for power to relay

Fan Motor Check for opens, shorts, or grounds. WITH POWER

Capacitor Check for opens, shorts, or grounds. WARNING

20-Minute Timer Check for supply voltage at terminal #2 and #3 while

20 Minute Timer

Fan Switch WITH POWER OFF: Close switch and check for

20 Minute Timer See "Main Fan Motor will not run."

Cooling Fan Check for voltages at the fan motor, if present,

Note

: High

Check for voltage on both sides of the switch.

Terminals are normally closed. If open, reset and

test oven for proper operation. If thermostat and

below.) will not hold and control box temperature is

not exceeding 140°F (60°C), replace thermostat.

and insure good wire connections

the 20-minute timer. If no voltage is present, trace

wiring back to power supply. If voltage is present at

terminal #1, check for supply voltage at terminal #2 to

ground. If no voltage is present, and the oven fan

switch is closed, replace the 20-minute timer.

coil. Visually check for contact pull in and contact

condition. Check for voltage across relay terminals.

OFF: Turn fan blade to check for locked rotor.

Capacitor has a stored charge, discharge before

testing.

main fan is running. Turn off fan switch and supply

voltage should continue to be present for 20 min. at

terminal #2. Replace as needed.

: On/Off operation of fan switch will reset timer

NOTE

to 20 minutes. If timer is accidentally reset, turn off

main breaker to cancel. If voltage continues to be

present at terminals 2 and 3 after 20 minutes, verify

fan switch contacts have opened, replace timer as

needed.

continuity across switch terminals.

replace defective fan motor.

November 1999 31 COUNTER TOP IMPINGER

Page 46

Oven will not heat

Main Oven Fan Check if main oven fan is working. If not, refer to

"Oven Fan Will Not Run".

Temperature Control

Board

Check for voltage input at the board. Turn the

temperature adjustment knob to the maximum

temperature position and check for voltage at the load

terminal. If present, and unit is not heating, refer to "Air

pressure switch" for next check. If no voltage is

present, proceed.

Thermocouple Sensor Check terminals, wiring, and proper location of the

sensor bulb. It must be in its spring holder located in

the inside, rear, lower right hand corner (viewed from

front) behind Finger #4. The thermocouple is a type J

and has one red lead (Neg.) and one white lead

(Pos.).WITH POWER ON AND THERMOCOUPLE

LEADS ATTACHED TO THE TEMPERATURE

CONTROL BOARD: Measure the D.C. millivolt output

of these leads. Refer to thermocouple chart in Section

D for proper readings. If these readings are not

achieved, replace the thermocouple.

Temperature Set

Potentiometer

Disconnect the potentiometer leads from the board.

Place ohm meter test leads on the blue and green pot.

leads. Reading should be 1 K ohms. Place meter leads

across the blue and purple pot. leads and rotate knob

from high to low. Repeat on green and purple leads.

Check for even rise and fall of ohms reading to insure

that there are no open or dead spots in the

potentiometer. Check each lead to ground for shorts.

Replace Pot. if it does not meet the above test.

Hi Limit ThermostatOven Cavity

Terminals are normally closed, open at 660°F (350°C).

If open, push in reset button and retest. If thermostat

will not hold for maximum oven temperature, and oven

is not exceeding temperature dial setting, check for

proper location of capillary bulb in its spring holder. If

above checks okay, replace hi-limit thermostat.

Air Pressure Switch Check for voltage on both sides of the switch, if voltage

is present on one side only, check for air tube

blockage, adjust air switch, if above fails, replace

switch.

Heating Element Relay Check for voltage to the Relay coil and contacts. If

voltage is present and contactor will not activate,

replace the contactor. Check for voltage across relay

terminals.

Heater Element Check the amperage draw on each hot leg for proper

load. Check the rating plate for rating information. If

amp draw is low or high, check element for opens and

shorts.

November 1999 32 COUNTER TOP IMPINGER

Page 47

Conveyor will not run

S/N 4000480 and Below

Conveyor speed

varying or intermittent

Fan Switch Check continuity between switch terminals. Replace

as needed.

Conveyor Control

Transformer

Check for supply voltage at primary of transformer. If

no voltage is present, trace wiring back to fan switch.

Check for 24VAC at transformer secondary. If no

voltage is present, replace transformer.

Speed Adjustment

Potentiometer

This is a 5K ohm potentiometer. WITH POWER OFF:

Remove the leads from the motor control board at

terminals P1, P2, P3. With a digital meter, check the

ohm reading across the red and black leads. This

reading should be 5K ohms (± 10%) as the pot. is

rotated from low to high. Place meter leads on red

and white lead. Rotating the pot. slowly from low to

high, the meter reading should show an even

transition from 0 to 5K ohms (± 10%). There should

be no dead or open spots throughout the rotation of

the pot. Check all three (3) leads to ground. There

should be no continuity to ground. If any of the above

checks fail, replace the pot.

Conveyor Control Board Check for 24 VAC input to conveyor control. If no

voltage is present, trace wiring back to transformer. If

voltage is present at L1 and L2, check for D.C. output

at terminals A+ and A-. If there is AC voltage input,

but no D.C. voltage output, replace conveyor control

board.

Conveyor Gear Motor If there is D.C. voltage output from the conveyor

control, but the motor does not run, check the mini-

breaker (0.7 Amp). Check motor leads for opens,

shorts or continuity to ground. If motor fails above

test, replace motor.

Conveyor Check conveyor drive coupling to be sure that it is

tight. Also check to see that coupling is engaged with

conveyor drive shaft. Check for any mechanical

misalignment or improper adjustment, also check for

worn bearings. A conveyor belt that is too tight will

cause excessive bearing wear and sometimes-

irregular speed.

Power Supply Check for steady supply voltage to oven. If voltage is

unsteady, contact power company.

Transformer Check for steady A.C. voltage output from transformer

and replace as needed.

Conveyor Control Check for steady D.C. voltage output from conveyor

control. If D.C. voltage output is unsteady, check

conveyor potentiometer (see "Speed Adjustment

Potentiometer" under Conveyor will not run). If the

potentiometer checks good, and the D.C. voltage is

unsteady, replace conveyor control.

D.C. Gearmotor Check motor brushes for excessive arching and/or

unusual wear. Replace brushes or gearmotor as

needed.

November 1999 33 COUNTER TOP IMPINGER

Page 48

Conveyor will not run

(S/N 3000481 & Above)

Conveyor speed

varying or intermittent

Fan Switch WITH POWER OFF: Check continuity between switch

terminals. Check and insure good wire connections.

Conveyor Control

Transformer

With the fan switch on, check for supply voltage at the

primary of the transformer. Check for voltage on the

secondary side of transformer (24 VAC) at J4 and J5 on

the conveyor control board. Replace as needed.

Speed Adjustment Pot This is a 50 K ohm potentiometer. WITH POWER OFF:

Remove the leads from the motor control board at

terminals P1, P2, P3. With a digital meter, check the

ohm reading across the red and black leads. This

reading should be 50K ohms (± 10%) as the pot. is

rotated from low to high. Place meter leads on red and

white lead. Rotating the pot. slowly from low to high, the

meter reading should show an even transition from 0 to

50 K ohms (±10%). There should be no dead or opens

spots throughout the rotation of the pot. Check all three

(3) leads to ground. There should be no continuity to

ground. If any of the above checks fail, replace the pot.

Conveyor Control

Board

Check for 24 VAC input to the control board at terminals

J4 and J5. If not present, check wiring back to control

transformer, if voltage is present at J4 and J5, check the

VDC output at terminals J2 (+) & J3 (-) (0-18 VDC). If

24 VAC is present at J4 and J5, but VDC is not present

at J2(+) & J3(-) replace board.

Conveyor Gear Motor If D.C. voltage is present at J2(+) and J3(-) and the

motor does not run, first check the mini breaker (.7Amp).

Check the leads to the motor for evidence of any shorts

or opens, and each lead to ground. If the motor fails the

above tests, replace motor.

Conveyor Check for any mechanical misalignment or improper

adjustment, also check for worn bearings. A conveyor

belt that is too tight will cause excessive bearing wear

and sometimes, irregular speed.

Power Supply Check for steady supply voltage to oven. If voltage is

unsteady, contact Power Company.

Transformer Check for steady AC voltage output from transformer

and replace as needed.

Conveyor Control Check for steady D.C. voltage output from conveyor

control. If D.C. voltage output is unsteady, check

conveyor potentiometer (See Speed Adjustment

Potentiometer" under Conveyor will not run). If the

potentiometer checks good, and the D.C. voltage is

unsteady, replace conveyor control.

D.C. Gearmotor Check motor brushes for excessive arching and/or

unusual wear. Replace brushes or gearmotor as

needed

Magnet Check to insure that the magnet (cemented to shaft of

conveyor drive motor) has not been damaged, or come

loose from motor shaft. Replace as needed.

Hall Effect Sensor Check for any physical damage to Hall Effect Sensor

(mounted on conveyor motor). Check all wiring and

connections or damage. Check all connections for

tightness or proper location and check all wiring or

visible damage. Replace as needed.

November 1999 34 COUNTER TOP IMPINGER

Page 49

REMOVAL, INSTALLATION, AND ADJUSTMENT

MODEL SERIES 1300

CAUTION!

BEFORE REMOVING OR INSTALLING ANY COMPONENT IN THE IMPINGER

OVEN BE SURE TO DISCONNECT ELECTRICAL POWER SUPPLY

SWITCH, ON-OFF

1. Remove conveyor and oven side panels.

2. Remove two (2) screws from ends of control panel and remove panel.

3. Disconnect four (4) wires from switch assembly. Mark wires for reinstallation.

4. Depress clips on side of switch and remove from panel.

5. Reassemble in reverse order and check operation.

POTENTIOMETER, CONVEYOR CONTROL

1. Remove conveyor and oven side panels.

2. Remove two (2) screws from ends of control panel and remove panel.

3. Unplug potentiometer at the wire harness (push on connectors).

4. Loosen set screws on control knob and remove knob.

5. Remove retaining nut from potentiometer shaft and remove pot.

6. Reassemble in reverse order and check operation, recalibrate if needed.

POTENTIOMETER, TEMPERATURE CONTROL

1. Remove conveyor and oven side panels.

2. Remove two (2) screws from ends of control panel and remove panel.

3. Unplug potentiometer at the wire harness (push on connectors).

4. Loosen set screws on control knob and remove knob.

5. Remove retaining nut from potentiometer shaft and remove pot.

6. Reassemble in reverse order and check operation, recalibrate if needed.

CIRCUIT BREAKER, 0.7 AMP

1. Remove control box cover.

2. Remove two (2) wires from mini-breaker.

3. Remove knurled nut and remove breaker.

4. Reassemble in reverse order and check operation.

FUSE HOLDER

1. Remove control box cover.

2. Remove two (2) wires from fuse holder.

3. Remove two (2) screws and remove holder.

4. Reassemble in reverse order and check operation.

November 1999 35 COUNTER TOP IMPINGER

Page 50

THERMOSTAT, OVEN CAVITY HI-LIMIT

1. Remove control box cover.

2. Remove oven back assembly. (See OVEN BACK)

3. Remove two (2) wires from thermostat.

4. Remove retaining nut from the front of thermostat and remove thermostat.

5. Remove capillary tube from wire form in back of oven and remove assembly out through control

box side.

6. Reassemble in reverse order. Check for proper routing through insulation. Be sure capillary tube is

held securely in the wire form and the reset button has been pushed in and set.

: All excess capillary tubing should be brought back into control box area. Be certain to

NOTE

replace insulation seal when oven back is re-installed.

7. Check operation.

AIR PRESSURE SWITCH - REPLACEMENT

1. Remove control box cover.

2. Remove two (2) wires.

3. Remove air tube (note location).

4. Remove four (4) screws and replace air switch.

5. Reassemble in reverse order and check operation.

NOTE:

Make sure to use rubber grommets when installing air switch.

ADJUSTMENT SCREW

AIR PRESSURE SWITCH - ADJUSTMENT

1. Apply power to oven, turn temperature control potentiometer to max. and allow 30-minutes preheat

for temperatures to stabilize.

2. Remove air tube and with a volt meter verify that contactor for heater elements opens.

3. WITH POWER ON: Re-connect tube and check voltage across the air switch making sure that

there is no voltage drop and it remains steady. Adjust as needed. (See Picture, verify adjustment

screw has not vibrated out).

: Allow 30 minutes preheat.

NOTE

THERMOSTAT, CONTROL BOX HI-LIMIT

1. Remove control box cover.

2. Remove two (2) wires.

3. Remove two (2) screws and replace

4. Reassemble in reverse order and check operation.

: Make sure reset button has been pushed and set.

NOTE

November 1999 36 COUNTER TOP IMPINGER

Page 51

MAIN FAN RELAY

1. Remove control box cover

2. Remove wires from relay and mark wires for reinstallation.

3. Remove two (2) screws and replace relay.

4. Reassemble in reverse order and check operation.

TIME DELAY RELAY

1. Remove control box cover.

2. Remove wires from relay and mark wires for reinstallation. CAUTION: Resistor should be

jumpered across terminals #2 and #3 on some of the early models (SN 3000352 and below) this

jumper was installed across terminals #1 and #3 which may cause failure of the timer. Correct

when replacing timer.

3. Remove screw and replace relay.

4. Reassemble in reverse order and check operation.

NOTE:

Do not overtighten mounting screw as this could damage timer.

RELAY CONTACTOR

1. Remove control box cover.

2. Remove wires and mark wires for reinstallation.

3. Remove four (4) mounting screws and replace contactor.

4. Reassemble in reverse order and check operation.

TRANSFORMER - CONVEYOR

1. Remove control box cover.

2. Disconnect wires from primary and secondary of transformer. Mark wires for reinstallation (#23-blue208V connection/#24-red-240V connection).

: Wire nut one not being used.

NOTE

3. Remove two (2) mounting screws and replace.

4. Reassemble in reverse order and check operation.

CONVEYOR DRIVE MOTOR

1. Remove conveyor (see Installation and Operations Manual).

2. Remove screw from center of coupling sleeve assemby. and slide coupling assembly off motor

shaft.

3. Remove control box cover.

4. Disconnect motor leads and mark wires for reinstallation and conveyor direction.

5. Remove four (4) motor mounting screws and replace motor.

6. Reassemble in reverse order and check operation.

: Check to insure coupling and conveyor shaft are aligned.

NOTE

: Starting with SN 3000481 all conveyor drives will be a closed loop system. The drive

NOTE

motor assembly will include a hall effect sensor board and magnet. No calibration required.

S/N 3000480 and Below

--Check calibration of conveyor control board (See "Conveyor control board

calibration")

S/N 3000481 and Above

--Attach correct magnet to conveyor motor assembly.

November 1999 37 COUNTER TOP IMPINGER

Page 52

ASSEMBLY OF MAGNET TO MOTOR

FOR OVENS WITH 1-12 MINUTE CONVEYOR DRIVE SYSTEM

1. Apply 1 or 2 drops of adhesive (supplied) to magnet. Mount magnet on motor shaft. Be sure

to keep adhesive away from motor bearings.

Use magnet marked "8"

Note:

FOR OVENS WITH 1-24 MINUTE CONVEYOR DRIVE SYSTEM

1. Apply 1 or 2 drops of adhesive (supplied) to magnet. Mount magnet on motor shaft. Be sure

to keep adhesive away from motor bearing.

Use magnet marked "16"

Note:

CONVEYOR CONTROL BOARD - REPLACEMENT

1. Remove control box cover.

2. Disconnect and mark all wires from the control board.

3. Remove two (2) screws from mounting bracket at rear wall and remove assembly.

4. Depress nylon clips and remove circuit board from mounting bracket.

5. Reassemble in reverse order and check operation.

CONVEYOR CONTROL BOARD CALIBRATION (S/N 3000480 AND BELOW)

(NOTE:

S/N 3000481 & ABOVE, NO CALIBRATION REQUIRED)

1. Remove control box cover.

2. Connect digital meter to A+ & A-.

3. With conveyor running at maximum speed, adjust max pot on board to 21.5 to 22 VDC.

4. With conveyor running at minimum speed, adjust min pot on board to 3 to 4 VDC.

5. Check conveyor belt timing (leading edge in to leading edge out) at 5 min. and adjust,

potentiometer knob if necessary to compensate (S/N 3000481 & above, no calibration required).

ELECTRONIC TEMPERATURE CONTROL BOARD - REPLACEMENT

1. Remove control box cover.

2. Disconnect wires and molded connector and mark wires for reinstallation.

3. Remove two (2) screws from mounting bracket and remove assembly.

4. Depress nylon clips and remove circuit board from mounting bracket.

5. Reassemble in reverse order and check operation.

ELECTRONIC TEMPERATURE CONTROL - CALIBRATION

1. Turn oven on, allow 30 minutes preheat for temperatures to stabilize in oven cavity.

2. Remove control box cover.

3. Place temperature probe in bottom finger #4 (lower right), 3rd row from outside edge, 3rd hole

from the rear.

: Make sure probe is not touching any metal surfaces. (Measure air temperature only)

NOTE

4. Turn temperature control knob fully clockwise and adjust so the knob indicator is aligned with the

mark past 550°F (288°C) on the dial. (See diagram Pg. 13)

November 1999 38 COUNTER TOP IMPINGER

Page 53

177C/350F 240C/400F

149C/300F

121C/250F

93C/200F

550F/288C

CALIBRATION MARK

450F/232C

500F/260C

5. Turn the temperature control knob to 500°F (260°C) and calibrate the temperature control board.

Adjust the top potentiometer only

(see diagram Pg. D5) so the unit cycles at 500°F ± 10°F (490°F -

510°F).

6. Turn the temperature control knob to 550°F and verify that the oven will cycle at 550°F (288°C) ±

10°F.

7. Replace the control box cover and check operation.

TEMPERATURE

CONTROL BOARD

CONVEYOR

DRIVE MOTOR

CONTROL BOX

HI-LIMIT

AIR SWITCH

TRANSFORMER

November 1999 39 COUNTER TOP IMPINGER

Page 54

COOLING FAN, CONTROL BOX

1. Remove control box cover.

2. Remove four (4) screws.

3. Lift off fan guard and finger guard.

4. Disconnect two wires and replace fan.

5. Reassemble in reverse order and check operation.

NOTE:

Check to insure that control box high limit switch is not tripped. Reset if needed.

CAPACITOR, MOTOR

1. Remove six (6) acorn nuts from motor cover and remove.

CAUTION: DISCHARGE CAPACITOR BEFORE REMOVING.

2. Remove wires from capacitor and mark wires for reinstallation.

3. Loosen clamp around capacitor and remove.

4. Reinstall in reverse order and check operation.

OVEN BACK ASSEMBLY

1. Remove six (6) acorn nuts and remove motor cover.

2. Disconnect all wiring from motor and heating element.

3. Remove four (4) nuts holding oven back and remove oven back.

4. Reassemble in reverse order. NOTE: Be certain to replace insulation seal each time oven back

is removed.

MAIN FAN

1. Remove six (6) acorn nuts holding motor cover and remove.

2. Remove four (4) acorn nuts holding oven back assembly and remove.

3. Loosen two (2) screws on fan hub and slide fan off of motor shaft. (Note location of hub on motor

shaft for reinstallation. Approximately 3/16" from back wall.)

4. Reinstall in reverse order and check system operation. Allow 30 minute preheat and verify that

fan is not rubbing.

NOTE:

Be certain to replace insulation seal each time oven back is removed.

November 1999 40 COUNTER TOP IMPINGER

Page 55

THERMOCOUPLE

1. Remove control box cover.

2. Remove six (6) acorn nuts holding motor cover and remove.

3. Remove four (4) acorn nuts holding oven back assembly and remove oven back.

4. Remove thermocouple bulb from wire form in rear of oven cavity.

5. Disconnect and mark wires from temperature control board (red=neg., white=pos.) and remove

thermocouple.

6. Reassemble in reverse order and check operation. NOTE: Be certain to replace insulation seal

each time oven back is removed.

INFORMATION:

When two wires composed of dissimilar metals are joined together and one of the ends is heated,

a continuous current flow is generated. We use an iron constant (Type J) thermocouple. The

iron wire increases the number of dissimilar junctions in the circuit.

It is possible to check a thermocouple with a properly calibrated D.C. millivolt meter. At 32°F, the

millivolt reading should be 0.00. This can be checked by inserting the thermocouple into an ice

bath. The millivolt reading at 72°F should be 1.134.

When using the following chart, the temperature at the terminal connections must be noted. This

temperature is called the Junction Temperature.

The following chart lists the thermocouple millivolt readings from 200°F to 600°F.

J U N C T I O N T E M P E R A T U R E

90°F 3.26 4.77 6.30 7.06 7.83 9.37 10.14 10.91 12.46 14.00 15.53

88°F 3.32 4.83 6.36 7.12 7.89 9.43 10.20 10.97 12.51 14.05 15.59

86°F 3.37 4.88 6.41 7.17 7.94 9.49 10.26 11.03 12.57 14.11 15.65

84°F 3.43 4.94 6.47 7.23 8.00 9.54 10.31 11.09 12.63 14.19 15.71

82°F 3.49 5.00 6.53 7.29 8.06 9.60 10.37 11.14 12.69 14.23 15.76

80°F 3.55 5.06 6.59 7.35 8.12 9.66 10.43 11.20 12.74 14.28 15.82

78°F 3.60 5.11 6.64 7.40 8.17 9.72 10.49 11.26 12.80 14.34 15.86

76°F 3.66 5.17 6.70 7.46 8.23 9.77 10.55 11.32 12.86 14.40 15.94

75°F 3.69 5.20 6.73 7.49 5.26 9.80 10.57 11.35 12.89 14.43 15.97

74°F 3.72 5.23 6.76 7.52 8.29 9.83 10.60 11.37 12.92 14.46 15.99

72°F 3.78 5.29 6.82 7.58 8.35 9.89 10.66 11.43 12.97 14.51 16.05

70°F 3.83 5.34 6.87 7.63 8.40 9.95 10.72 11.49 13.03 14.57 16.11

68°F 3.89 5.40 6.93 7.69 8.46 10.00 10.78 11.55 13.09 14.63 16.17

66°F 3.95 5.46 6.99 7.75 8.52 10.06 10.83 11.61 13.15 14.69 16.23

64°F 4.01 5.52 7.05 7.81 8.58 10.12 10.89 11.66 13.20 14.74 16.28

62°F 4.06 5.57 7.10 7.86 8.63 10.18 10.95 11.72 13.26 14.80 16.34

60°F 4.12 5.63 7.16 7.92 8.69 10.24 11.01 11.78 13.32 14.86 16.40

200°F 250°F 300°F 325°F 350°F 400°F 425°F 450°F 500°F 550°F 600°F

O V E N T E M P E R A T U R E

November 1999 41 COUNTER TOP IMPINGER

Page 56

HEATING ELEMENT

(Color Coded on the Cold Zone)

PART# 369418

PART# 369419

PART# 369450

PART# 369455

PART# 369456

PART# 369457

PART# 369475

PART# 369476

PART# 369477

PART# 370104

PART# 370105

Heating Element 208V Red

Heating Element 240V Blue

Heating Element 220V Yellow

Heating Element 200V Orange

Heating Element 380V Violet

Heating Element 415V Green

Heating Element 200V 3 PH Orange

Heating Element 380V 3 PH Violet

Heating Element 415V 3 PH Green

Heating Element 400V 3 PH Brown

Heating Element 400V 1 PH Brown

1. Remove six (6) acorn nuts holding motor cover and remove

2. Remove connectors from element.

3. Remove four (4) acorn nuts holding oven back assembly and remove.

4. Remove three (3) screws from heating element brackets and slide element out of back assembly.

5. Reassemble in reverse order. Verify by color code, dot or band on element that correct element is

being installed. Refer to chart above:

NOTE:

Be certain to replace insulation seal each time oven back is removed.

AIR PUMP

1. Remove six (6) acorn nuts holding motor cover and remove.

2. Disconnect motor, capacitor, and element leads and mark wires for reinstallation.

3. Remove four (4) acorn nuts holding oven back assembly and remove.

4. Remove main fan. (Note location, approximately 3/16" from back wall on motor shaft.)

5. Remove heating element.

6. Remove five (5) screws from inner back assembly and lift off.

7. Loosen two screws on air pump hub and slide off shaft. (Note location for reinstallation

(approximately 3/64" clearance from back wall).

8. Reinstall in reverse order and check operation. Allow 30 minute preheat and verify that fan is not

rubbing.

NOTE:

Be certain to replace insulation seal each time oven back is removed.

MAIN FAN MOTOR

1. Remove six (6) acorn nuts holding motor cover and remove.

2. Disconnect motor, capacitor, and heating element and mark wires for reassembly.

3. Remove four (4) acorn nuts holding oven back assembly and remove.

4. Remove heating element (See "heating element removal").

5. Remove main fan, NOTE position ("See fan removal").

6. Remove five (5) screws from inner back and separate.

7. Remove air pump assembly

location.

NOTE

8. Remove four (4) screws from motor mount pedestal and lift motor and pedestal off outer back

assembly.

9. Remove four (4) nuts from front motor studs and remove mounting pedestal.

10. Reassemble in reverse order and check operation.

: Be certain to replace insulation seal each time oven back is removed

NOTE

November 1999 42 COUNTER TOP IMPINGER

Page 57

GENERAL – 1300 SERIES

LETTER P/N DESCRIPTION

A 369434 Air Duct Panel, Upper

B 369442 Finger Housing S/N 3002167 & Below

C 369436 Columnating Plate #2 (UR) – S/N 3002167 & Below

D 369445 Finger Cover, Upper Right – S/N 3002167 & Below

E 369441 Finger Cover, Lower Right – S/N 3002167 & Below

F 369439 Columnating Plate #4 (LR) – S/N 3002167 & Below

G 369435 Air Duct Panel, Lower

H 369438 Columnating Plate #3 (LL) – S/N 3002167 & Below

I 369444 Finger Cover, Lower Left – S/N 3002167 & Below

J 369446 Finger Cover, Upper Left – S/N 3002167 & Below

K 369437 Columnating Plate #1 (UL) – S/N 3002167 & Below

L 369916 Top / Front Cover Panel

M 369484 Cover Panel Assy

N 369407 Fastener & Split Ring Retainer

O 369447 Cover Panel Assembly, Right

P 369953 Flat Washer, S/S

Q 369460 Compression Spring

R 369410 Coupling Sleeve

S 370106 Flat Washer, .156 x .430

T 350259 Screw, THMS 6-32 x 3/8

U 369413 Drive Key

V 369373 Receptacle, Snap-In

W 369461 Leg, 4”

X 369945 Control Panel

Y 369429 Knob, Control

Z 369432 Switch, On – Off

AA 369449 Temperature Control Pot. Assembly

BB 369433 Potentiometer Control, Conveyor S/N 3000480 & Below

369468 Potentiometer Control, Conveyor S/N 3000481 & Above

CC 350224 Lens, Yellow

DD 369448 Cover Panel Assembly, Left

EE 369467 Pilot Light & Harness – S/N 3000481 & Above

FF 369495 Conveyor Baffle

GG 369211 Thumb Screw

HH 369451 Mounting Ring Assy.

JJ 369491 Finger Cover – S/N 3002168 & Above (4 required)

KK 369490 Columnating Plate – S/n 3002168 & Above (4 required)

LL 369488 Finger housing – S/n 3002168 & Above (4 required)

MM 369932 Facia 1-12 Minute Bake Time

370096 Facia 2-24 Minute Bake Time

370018 Facia 1-24 Minute Bake Time

NN 370095 Control Guard

OO 370097 Screw 10-32 x ¼”

November 1999 43 COUNTER TOP IMPINGER

Page 58

GENERAL – 1300 SERIES PARTS BLOW-UP

November 1999 44 COUNTER TOP IMPINGER

Page 59

CONTROL COMPARTMENT – 1300 SERIES

LETTER P/N DESCRIPTION

A 369426 Cooling Fan – S/N 3000399 & Below

369378 Cooling Fan – S/N 3000400 & Above

B 369428 Finger Guard – S/N 3000399 & Below

369331 Finger Guard – S/N 3000400 & Above

C 369415 Conveyor Control S/N 3000480 & Below

369464 Conveyor Control – S/N 3000481 to 3007663

Except Models 1301-5, 1302-5, 1304-5, 1308-5

370017 Conveyor Control S/N 3007664 and Above and

All S/N for Models 1301-5, 1302-5, 1304-5, 1308-5

D 369431 Thermostat, Control Box Hi-Limit S/n 3000352 & Above

E 369430 Air Switch

F 369422 Relay SPST, 240V

G 369417 Time Delay Relay

H 369425 Relay Contactor Single Phase

369479 Relay Contactor 3 Pole 3 Phase

I 369427 Transformer, Conveyor Control

370241 Transformer, Conveyor Control Models 1312,1313,1314

J 369416 Electronic Temperature Control S/N 3000480 & Below

369465 Electronic Temperature Control S/N 3000481 & Above

K 369129 Fuse Holder, Model 1300,1301,1302,1307

L 369424 Conveyor Drive Motor S/N 3000480 & Below

369923 Conveyor Motor Assy. Models 1301-5,1302-5,1304-5,1308-5

369466 Conveyor Motor Assy (Assy. Includes Q,R)

S/N 3000481 & Above Except 1301-5,1302-5,1304-5,1308-5

369841 Brushes (For 369466 Motor)

M 369154 Circuit Breaker - .7Amp

N 357067 Thermostat, Capillary

O 369483 Housing Assy.

P 369482 Fan Housing

Q 369822 Magnet, 8 Pole (For 1-12 Minute Conveyor System)

370065 Magnet, 16 Pole (For 1-24 Minute Conveyor System)

R 369823 Hall Effect Sensor

S 369421 Fuse 5A, Model 1300,1301,1302,1307

T 370100 Conveyor Motor Plate, Inner

U 370040 Hall Effect Cable

V 370099 Conveyor Motor Plate, Outer

W 369414 Power Cord 30A S/n 3007818 & Below (Model 1301,1302)

370019 Power Cord 50A S/N 3007819 & Above (Model 1301,1302)

X 369536 Cooling Fan Cordset

Y 369085 Junction Box

Z 369376 Terminal Block 3 Pole

369584 Terminal Block 4 Pole

AA 369698 Cover, Junction Box

BB 369856 Stand-off, Support

CC 357107 Fuseholder

DD 369492 Fuse 5A

EE 369131 Thermocouple

November 1999 45 COUNTER TOP IMPINGER

Page 60

CONTROL COMPARTMENT – 1300 SERIES BLOW - UP

November 1999 46 COUNTER TOP IMPINGER

Page 61

BACK – 1300 SERIES

LETTER P/N DESCRIPTION

Color Coded on The Cold Zone

A 369418 Heating Element - 208V Red

369419 Heating Element - 240V Blue

369450 Heating Element - 220V Yellow

369455 Heating Element - 200V Orange

369456 Heating Element - 380V Violet

370105 Heating Element - 400V 1 PH Brown

369457 Heating Element - 415V Green

369475 Heating Element - 200V 3 PH Orange

369476 Heating Element - 380V 3 PH Violet

370104 Heating Element - 400V 3 PH Brown

369477 Heating Element - 415V 3 PH Green

B 369409 Main Fan

C 369408 Air Pump

D 369440 Nut, S/S ¼ - 20

E 369192 Capacitor

F 369457 Nut, 10-32

G 370041 Duct Assy

H 370020 Motor Cover Assy

I 370102 Bottom Cap, Flue Duct

J 369453 Flue Duct Assembly

K 369423 Motor, Main Fan S/N 3002137 & Below – All 1301-4,1302-4

369485 Motor, Main Fan 60 Hz S/N 3002168 & Above

370179 Motor, Main Fan 50 Hz – Models 1304-4,1305-4,1308-4

369480 Motor, Main Fan 50 Hz S/n 3002168 & Above

L 369940 Motor Mount

M 370093 Motor Plate Assy

N 369474 Insulation, Air Pump Panel

O 369936 Plenum Barrier Panel

P 369473 Insulation, Plenum Panel

Q 369935 Cover Plate, Plenum

R 369470 Insulation Seal

S 369497 Bracket, Thermostat, Left Side

T 369496 Bracket, Thermostat, Right Side

U 369459 Motor Cover Assy

November 1999 47 COUNTER TOP IMPINGER

Page 62

BACK – 1300 SERIES BLOW - UP

November 1999 48 COUNTER TOP IMPINGER

Page 63

STANDARD CONVEYOR – 1300 SERIES

LETTER P/N DESCRIPTION

369443 Standard Complete Conveyor Assy. (31” Length)

A 369462 Idler Axle

B 369515 Drive Sprocket

C 369516 Conveyor Bearing

D 369463 Drive Axle

E 369471 Roll Pin, 5/32 x 7/8”

F 1343 Entry Shelf – 12”

1344 Entry Shelf – 4”

G 369412 Conveyor Splice Clip

H 369411 Conveyor Belting

370185 Conveyor Belting (1 foot section)

I 1341 Exit Shelf – 12”

1342 Exit Shelf – 4”

J 370094 Conveyor Frame Assembly

November 1999 49 COUNTER TOP IMPINGER

Page 64

EXTENDED CONVEYOR – 1300 SERIES

LETTER P/N DESCRIPTION

369909 Extended Conveyor Assy. (49 ¾” Length)

A 369462 Idler Axle

B 369515 Drive Sprocket

C 369516 Conveyor Bearing

D 369463 Drive Axle

E 369471 Roll Pin, 5/32 x 7/8”

F 369943 Conveyor Frame, Extended

G 369412 Conveyor Splice Clip

H 369481 Conveyor Belting – Extended Conveyor

370185 Conveyor Belting (1 Foot Section)

I 369920 Retainer

J 369921 Roller, Slider Bed

K 369954 Pop Rivet S/S

L 369922 Support Rod

M 1345 Pan Stop

N 369489 Crumb Pan Assembly

November 1999 50 COUNTER TOP IMPINGER

Loading...

Loading...