Page 1

Shortening Filter

SF18/24/34

Operator’s Manual

and

Technical Supplement

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Tel: (206) 322-5474

Fax: (206) 322-5425

Toll Free (US): 1-800-578-2547

E-mail: service@belshaw.com

www.belshaw.com

Page 2

Shortening Filter

SF18,SF24 & SF34

Operator’s Manual

Belshaw Bros., Inc.

814 44TH ST NW Suite 103

Auburn, WA 98001 USA

Phone: 206-322-5474 • Fax: 206-322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 3

Page 4

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

To unpack the Shortening Filter and transport it

to the workstation:

1. In the kettle is a carton containing the motor.

Remove this carton and take it to the

workstation.

2. Remove the kettle from the frame assembly

and take it to the workstation.

3. Move the rest of the Shortening Filter to the

workstation.

4. Remove and discard all packing materials.

IMPORTANT

Keep this manual for future reference.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

052009

MN-1407EN

Belshaw Bros., Inc.

814 44TH ST NW Suite 103

Auburn, WA 98001USA

Phone: 206-322-5474 • Fax: 206-322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 5

Page 6

Contents

1 Operation 1

2 Cleaning 3

Daily Cleaning 3

Weekly Cleaning 3

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 OM MN-1407EN iii

Page 7

Preface

The Shortening Filter is designed to do the

following things:

• To filter shortening

• To pump filtered shortening into fryer

kettles

• To rinse fryer kettles with shortening

It is not designed to melt shortening or to filter or

pump anything other than shortening.

The machine is available with the following

electrical configurations:

• 115 volts, 1 phase, 50/60 hertz

• 220/240 volts, 1 phase, 50/60 hertz

The Shortening Filter is designed to be used on a

flat, dry floor, underneath the drain of a fryer

kettle. The operator must work safely at all

times and read this manual and follow its

instructions and warnings.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

Shortening Filter will prevent production delays

and injuries.

• Hot shortening can cause serious burns.

Make sure that proper protective gear

(face shield, gloves and apron) are worn

before filtering, disassembly and

cleaning.

• To avoid electrocution or other injury,

unplug the machine before attempting

any adjustment, repair, disassembly, or

cleaning.

• To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

• Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

• To prevent unintentional startup and

possible shortening spillage or fire,

unplug the machine if there is a local

power outage. When the power is

restored, it is safe to plug the machine in

again.

To use the Shortening Filter safely, heed the

following warnings and all other warnings that

appear in this manual:

• Never let water and hot shortening come

in contact with each other. Moisture

causes hot shortening to spatter, which

may cause serious burns.

• Do not overfill the kettle of the

Shortening Filter with shortening. If

shortening overflows the kettle, it could

cause serious burns or could cause

someone to slip on the floor and be

seriously injured.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1407EN SF 18/24/34 OM

• To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

• Make sure that all electrical cords are

routed so that no one will trip over them.

Page 8

1 Operation

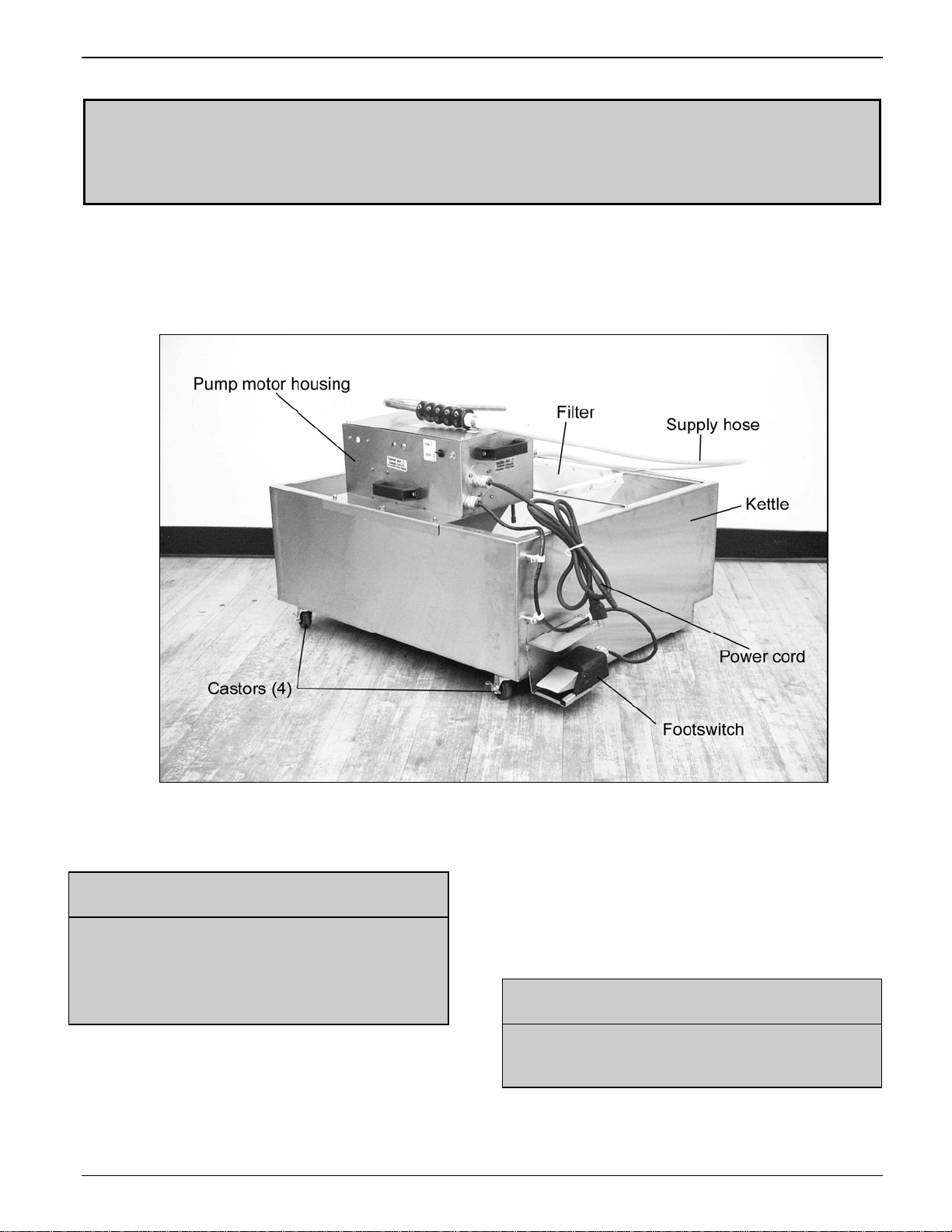

To help familiarize yourself with the basic parts

of the Shortening Filter, please study the

photograph below.

Figure 1-1. Shortening Filter, Model SF34.

2. Wait for the shortening to cool to the right

WARNING

Be careful with hot shortening. Always

wear proper protective gear (face shield,

apron and gloves) when filtering,

disassembling and cleaning

Read each step completely before doing what it

tells you to do.

1. Turn off the fryer (heat/thermostat).

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 OM MN-1407EN 1

temperature for filtering, as indicated by the

fryer’s thermometer.

Shortening should be cooled to 250°F/121°C.

WARNING

Maximum filtering temperature is

325°F/163°C

Page 9

Because hot shortening is dangerous,

FILTER SHORTENING AT THE LOWEST

TEMPERATURE THAT WORKS. Hot

shortening may also trip the pump motor.

WARNING

Be careful with hot shortening. It can cause

serious burns.

3. When the shortening has cooled to the right

temperature for filtering, position the

Shortening Filter so its filter bag is directly

underneath the drain of the fryer.

4. Place the outlet nozzle of the hose into the

fryer kettle.

5. Connect the Shortening Filter to an

appropriate power source, as specified on the

data plate.

9. When you are done rinsing the fryer kettle,

turn off the filter pump and allow the fryer

kettle to drain into the Shortening Filter.

10. When all the shortening has drained into the

Shortening Filter, close the fryer’s drain

valve.

11. Being sure that the nozzle of the hose is in the

fryer’s kettle, turn on the filter pump and

depress the footswitch to transfer the filtered

shortening to the fryer.

12. When you are done transferring shortening,

turn off the filter pump.

13. Unplug the machine.

WARNING

Make sure the filter is directly under the

fryer’s drain valve before you open the

valve. If it is not, shortening will get on the

floor, possibly resulting in slips, falls, injury,

or even death. If the shortening is hot,

someone could be seriously burned.

6. Slowly open the fryer’s drain valve. The

shortening will drain into the Shortening

Filter. Note: Do not open the valve

completely, as shortening may splash.

7. To rinse the fryer kettle with shortening, grasp

the hose by the black handle, direct the nozzle

into the fryer kettle, and turn on the filter

pump.

8. After the power has been turned on, the

footswitch (see Figure 2-1) must be depressed

in order to start the pump.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1407EN SF 18/24/34 OM

Page 10

2 Cleaning

5. Back wash the filter bag with hot soapy water

WARNING

to remove food particles trapped in filter.

Be careful with hot shortening. Always

wear proper protective gear (face shield,

apron and gloves) when filtering,

disassembling and cleaning

When preparing to clean the shortening filter,

always follow these steps before cleaning.

1. Turn off the filter pump, unplug the machine.

2. Slide the Shortening Filter out from under the

fryer.

CAUTION

If debris are picked up by the Shortening

Filter’s pump, the pump or motor might

fail or be seriously damaged. To keep this

from happening, clean the Shortening

Filter at least once a week.

6. Wash filter bag using commercial dishwasher

(water temperature 150°F/65°C minimum)

7. Dry the filter bag completely before

reinstalling over the kettle.

Weekly Cleaning

Clean the Shortening Filter unit once a week, as

follows:

WARNING

Turn off the filter pump before you

disconnect the hose. If you fail to do so,

you may be splattered with hot shortening.

1. Perform daily cleaning as previously

described.

WARNING

Daily Cleaning

1. Disconnect the filter hose assembly while

still hot and drain any remaining shortening

back into the filter kettle to prevent

shortening from hardening in the hose.

2. Store the hose hanging vertically with the

lower end of the hose in a metal container to

catch any shortening that may drip.

3. Remove the filter frame assembly, with the

filter bag attached, from the kettle.

4. Turn the filter bag upside down and empty

the sediment from the bag into a waste

container.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 OM MN-1407EN 3

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor may

cause serious injury and loss of life.

2. Remove any remaining shortening from the

kettle.

3. Remove the pump/motor housing assembly:

b) Remove the footswitch from the

bracket (See Figure 2-1).

c) Detach the cord from the plastic

retainer clips (See Figure 2-1).

d) Remove the hex bolt (See Figure 2-2).

e) Lift the pump/motor housing off of the

locating pins (See Figure 2-2).

Page 11

WARNING

You must dry all parts thoroughly. Failure

to dry the kettle completely will cause an

eruption. Shortening will overflow the

sides of the filter and may result in fire,

injury or death.

Figure 2-1. Footswitch.

Figure 2-2. Pump motor housing.

2. Wash the kettle with household dishwashing

detergent, rinse, and dry thoroughly.

3. Wipe the pump/motor housing and

footswitch with a damp cloth. Never wash

down the pump/motor housing or the

footswitch. Dry thoroughly.

4. Reassemble the footswitch and housing.

CAUTION

Never allow water, steam, or any other

liquid to enter the pump motor.

5. Dry all parts thoroughly.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1407EN SF 18/24/34 OM

Page 12

Shortening Filter

SF18,SF24 & SF34

Technical Supplement

Belshaw Bros., Inc.

814 44TH ST NW Suite 103

Auburn, WA 98001 USA

Phone: 206-322-5474 • Fax: 206-322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 13

Page 14

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

To unpack the Shortening Filter and transport it

to the workstation:

1. In the kettle is a carton containing the motor.

Remove this carton and take it to the

workstation.

2. Remove the kettle from the frame assembly

and take it to the workstation.

3. Move the rest of the Shortening Filter to the

workstation.

4. Remove and discard all packing materials.

IMPORTANT

Keep this manual for future reference.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

011108

MN-1408EN

Belshaw Bros., Inc.

814 44TH ST NW Suite 103

Auburn, WA 98001USA

Phone: 206-322-5474 • Fax: 206-322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 15

Page 16

Contents

1 Installation 1

Initial Cleaning 2

Assembling the Shortening Filter 3

2 Troubleshooting 4

3 Appendix 7

Parts List Drawing Insert Page Insert

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 TS MN-1408EN iii

Page 17

Preface

The Shortening Filter is designed to do the

following things:

• To filter shortening

• To pump filtered shortening into fryer

kettles

• To rinse fryer kettles with shortening

It is not designed to melt shortening or to filter or

pump anything other than shortening.

The machine is available with the following

electrical configurations:

• 115 volts, 1 phase, 50/60 hertz

• 220/240 volts, 1 phase, 50/60 hertz

The Shortening Filter is designed to be used on a

flat, dry floor, underneath the drain of a fryer

kettle. The operator must work safely at all

times and read this manual and follow its

instructions and warnings.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

Shortening Filter will prevent production delays

and injuries.

• Hot shortening can cause serious burns.

Make sure that proper protective gear

(face shield, gloves and apron) are worn

before filtering, disassembly and

cleaning.

• To avoid electrocution or other injury,

unplug the machine before attempting

any adjustment, repair, disassembly, or

cleaning.

• To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

• Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

• To prevent unintentional startup and

possible shortening spillage or fire,

unplug the machine if there is a local

power outage. When the power is

restored, it is safe to plug the machine in

again.

To use the Shortening Filter safely, heed the

following warnings and all other warnings that

appear in this manual:

• Never let water and hot shortening come

in contact with each other. Moisture

causes hot shortening to spatter, which

may cause serious burns.

• Do not overfill the kettle of the

Shortening Filter with shortening. If

shortening overflows the kettle, it could

cause serious burns or could cause

someone to slip on the floor and be

seriously injured.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1408EN SF 18/24/34 TS

• To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

• Make sure that all electrical cords are

routed so that no one will trip over them.

Page 18

1 Installation

To help familiarize yourself with the basic parts

of the Shortening Filter, please study the

photograph below.

Figure 1-1. Shortening Filter, Model SF34.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 TS MN-1408EN 1

Page 19

Initial Cleaning

Before using your new Shortening Filter, clean it

as follows:

1. Remove all packing materials.

2. Remove the pump/motor housing assembly:

a. Remove the footswitch from the bracket

(See Figure 1-2).

b. Detach the cord from the plastic retainer

clips (See Figure 1-2).

c. Remove the hex bolt (See Figure 1-3).

d. Lift the pump/motor housing off of the

locating pins (See Figure 1-3).

CAUTION

Never allow water, steam, or any other

liquid to come into contact with the pump

motor.

3. Wash the kettle with household dishwashing

detergent, rinse, and dry thoroughly.

4. Wipe the pump/motor housing and

footswitch with a damp cloth. Never wash

down the pump/motor housing or the

footswitch. Dry thoroughly.

5. Reassemble the footswitch and housing.

WARNING

You must dry all parts thoroughly.

Moisture causes hot shortening to splatter,

which could cause serious burns.

Figure 1-2. Footswitch.

Figure 1-3. Pump motor housing.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1408EN SF 18/24/34 TS

Page 20

Assembling the Shortening

Filter

1. Install the filter bag as follows:

2. With the filter frame in hand, take the filter

bag and attach it to the frame using the snaps.

See Figure 1-4.

Figure 1-5. Installing the filter frame.

4. Install the filter hose assembly. Thread the

coupling nut onto the end of the hose

assembly as shown in Figure 1-6.

Figure 1-4. Installing the filter bag.

3. Install the filter assembly (the frame with the

filter bag attached) onto the kettle. See

Figure 1-5.

Figure 1-6. Installing the filter hose.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 TS MN-1408EN 3

Page 21

2 Troubleshooting

If you have problems with your Shortening

Filter, call your dealer or another qualified

technician.

If your dealer cannot help you, please call

Belshaw at 206-322-5474. When you call,

please specify the following:

• The model number of the machine.

• The serial number of the machine.

• The voltage, phase, and cycle of the

machine.

CAUTION

If you perform repairs yourself or have

them performed by anyone other than a

service technician authorized by Belshaw

Bros., you do so at your own risk.

If your dealer or another local, qualified

technician cannot provide service for your

machine, Belshaw can provide factory service.

First call us for a return goods authorization.

Then send your machine to us, freight prepaid,

with your instructions for service, your phone

number, and the name of the person for us to

contact when we have made a cost estimate. In

most cases, the machine can be shipped back,

freight collect, within five days.

To avoid down time, call us to see whether we

have a machine we can loan to you while your

machine is being serviced.

Ship machines in need of servicing to:

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

On the following page is a troubleshooting chart

to help you identify and solve some basic

problems.

WARNING

Disconnect the machine from the power

source before disassembling, repairing, or

wiring.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1408EN SF 18/24/34 TS

Page 22

THE PUMP MOTOR WILL NOT OPERATE.

Possible Causes What To Do

The power cord is not connected to the power

supply.

The power supply does not match the power

requirements of the machine as specified on the

data plate.

The circuit breaker has been tripped. Push the reset button.

The wiring is faulty. Correct the wiring. Call Belshaw for help.

The power switch is defective. Repair or replace the power switch.

The motor is defective. Repair or replace the motor.

Connect the power cord to the power supply.

Connect the machine to a proper power supply.

WARNING

Before doing the following, turn off the

machine, allow it to cool, and disconnect it

from the power source.

THE SHORTENING FLOW THROUGH THE SYSTEM IS SLOW OR

RESTRICTED.

Possible Causes What To Do

The hose is crimped. Straighten the hose.

Solid shortening is building up inside the hose and

pump

Filter shortening at a higher temperature.

WARNING

The hose is plugged. Clean the hose.

The pickup tube is plugged. Clean the pickup tube.

The bleeder tube is plugged. Clean the bleeder tube.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 TS MN-1408EN 5

Before doing any of the following, turn off the

machine and allow it to cool.

Page 23

Page 24

3 Appendix

Parts List Drawing Insert Page

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

SF 18/24/34 TS MN-1408EN 7

Loading...

Loading...