Belshaw Brothers Mark Series General Manual

The worldwide leader in donut production equipment

+1.206.322.5474 ▪ info@belshaw.com ▪ www.belshaw.com

AUTOMATIC FRYERS

Donut Robot® Mark I – Mark IX

Donut Robot® Series Automatic Fryers deposit,

fry, turn, and dispense cake and yeast-raised

donuts - automatically - improving donut

quality and reducing costs. Training and labor

requirements are substantially reduced while

quality, repeatable donuts are produced time after

time. Additionally, Donut Robot® fryers have been

shown to reduce shortening use by up to 50%.

Donut Robot® Series Automatic Fryers are built

with exhibition style production in mind – improving

foot trafc and customer loyalty. For locations where

Donut Robot

exterior ventilation is impractical, the Insider ‘Clean-Air’ Cabinet, without exterior ducting, is the solution.

Belshaw offers several machines with capacity from 156 to 1350 donuts per hour. Production is even higher for miniature donuts.

If less production is needed at any time, a switch cuts cake donut production instantly by half (except Mark I).

Belshaw can also assemble a complete Donut Robot® system to your specic needs, including proofer, glazer, icer, feed table and

more, for production of both cake and raised donuts.

®

Mark II

Donut Robot

®

GAS Mark II

Donut Robot® Mark I

Donut Robot® Mark V

Donut Robot® Mark VIDonut Robot® Mark IX

BELSHAW BROTHERS, INC ▪ 814 44th St NW, Suite 103, Auburn, WA 98001 ▪ USA

Tel +1.206.322.5474 ▪ Fax +1.206.322.5425 ▪ Email info@belshaw.com ▪ www.belshaw.com

©2009 Belshaw Adamatic Bakery Group ▪ Product specications may be changed without notice.

Donut Robot

®

Mark I - Mark IX

Product Information

Electric heating is standard; Mark II and Mark II GP are available either ▪

gas-heated* or electric-heated. All models (including gas-heated models)

feature electrically powered conveyors. *Gas models not available in European Union

‘GP’ models designate mini donut specic machines, with hopper/plunger ▪

and conveyor adapted for rapid production of mini donuts.

‘Non-GP’ models can produce mini donuts with Mini Donut Conversion Kit. ▪

All models feature frying time and temperature adjustment. Mark II and ▪

above feature a switch that reduces automatic cake donut deposits to one

donut per conveyor row (normal is two donuts per row).

The Donut Robot ▪

®

automatic cake donut depositor is standard on Mark

I, II and V. It accomodates Donut Robot® plain, mini, star, or french cake

plungers and attachments. A 1-9/16” (40mm) star plunger is standard on

new machines.

Mark VI accomodates either Type ‘F’ (semi-automatic) or Donut Robot ▪

(automatic) cake donut depositors.

Type ‘N’ (automatic) depositor is standard on Mark IX. ▪

ETL certied to UL-197, CSA C22.2 and NSF-4

EXCEPTIONS:

1 Mark I certied CE only

2 Mark II Gas not certied

Donut Robot

C

® Mark I - IX

A B

Drawin g shows Donut R obot cake don ut deposito r. Mark VI may use

Type F depositor instead. M ark IX uses automatic Type N depo sitor.

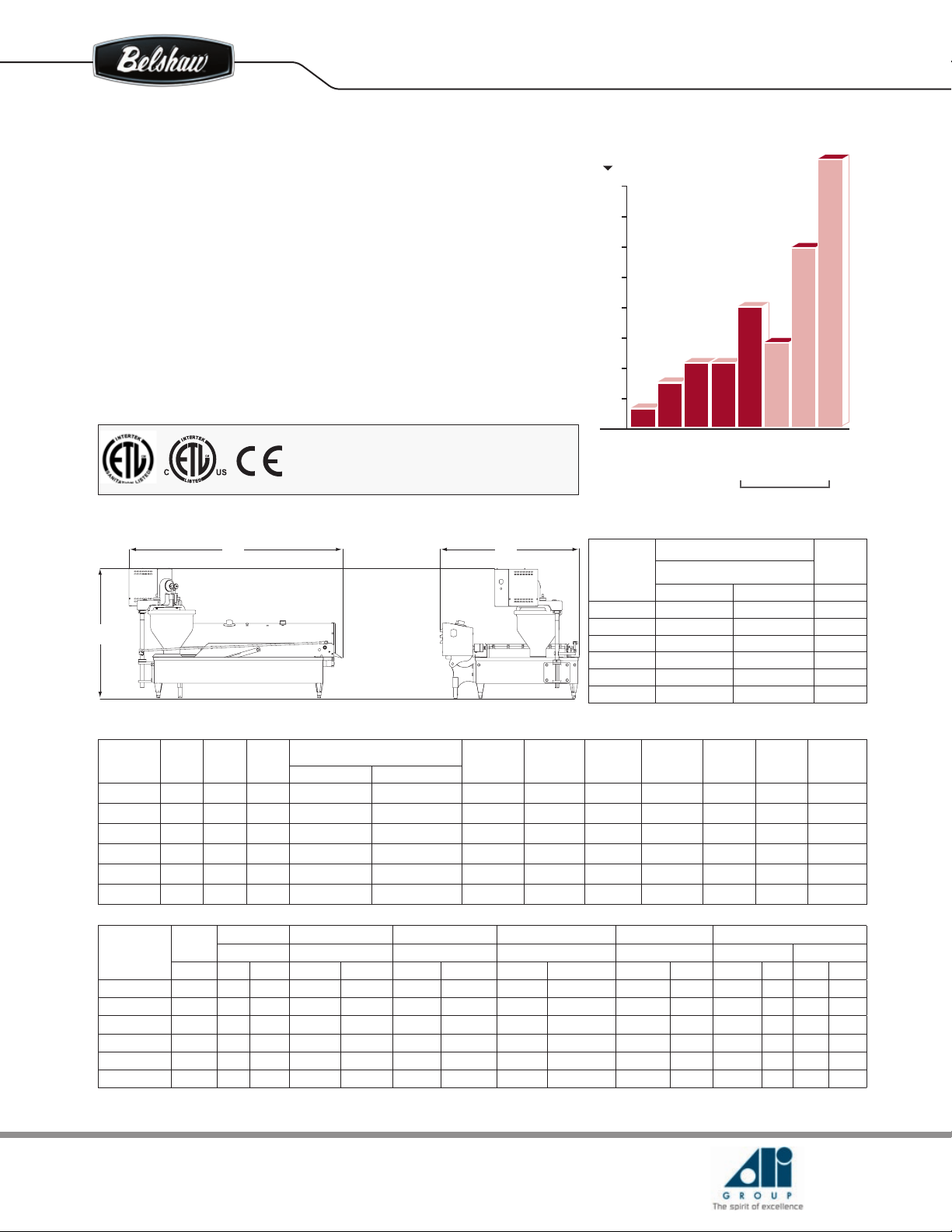

Donut Robot

Dozens Per

Hour

200

®

Production Chart

Based on frying times of 95

seconds for standard donuts

and 60 seconds for mini

donuts. Production will vary

depending on product size,

frying temperature and

composition of donut.

175

150

125

100

®

75

226

153

112

50

25

37

56

56

74

13

Mark I

Mark II

Mark V

Mark IX

Mark VI

Mark I GP

FOR MINI DONUTS ON LY

Mark V GP

Mark II GP

Dimensions and weight

A x B x C

MODEL

MARK I 35 x 14 x 23 89 x 34 x 57 100/45

MARK II 41 x 21 x 25 104 x 52 x 62 145/66

MK II Gas 41 x 23 x 30 104 x 58 x 76 210/95

MARK V 52 x 20 x 24 133 x 52 x 62 183/83

MARK VI 52 x 28 x 24 133 x 71 x 62 294/133

MARK IX 53 x 21 x 35 133 x 52 x 89 250/113

Length x Depth x Height

in cm lbs/kg

APPROX

SHIPPG

WEIGHT

Features

MODEL

MARK I

MARK II

MK II Gas

MARK V

MARK VI

MARK IX

● STANDARD ○ OPTIONAL

Electric

Heat

Gas

Heat

● ○

● ○

● ○

● ○

●

●

GP

model

Conveyor row spacing

Std model GP model

3.75” (95mm) 2.25in (57mm)

3.75” (95mm) 3in (76mm)

3.75” (95mm) 3in (76mm)

3.75” (95mm) 3in (76mm)

3.75” (95mm) N/A

3.75” (95mm) N/A

(Note 1)

Donut

Robot

Depositor

Type F

Depositor

Automatic

Type N

Depositor

Feed Table

(for raised

donuts)

Multiple

Turners

Drain

with cap

●

● ○ ● ○

● ○

● ○ ● ○

○ ○ ○ ○ ● ○

● ○ ○ ● ○

Electrical and Gas

MODEL

MARK I

MARK II

MK II Gas

MARK V

MARK VI

MARK IX

Notes 1 Distance between bars, taken center-to-center. Each bar is 3/8in (9.5mm) diameter. Consult factor y if 4.5” spacing is require d

2 For dimensions of Mar k VI with Type F depositor, ask for Mar k VI syste m layout from a Belshaw representative.

OIL

lbs/kg KW A KW A KW A KW A KW A BTU/hr kPa NG LP

14/6.4 1.2 10.0 1.5 7.4/6.4

35/16 4.3/5.7 21.0/24.0 4.5/5.7 12.5/14.2 4.4/5.2 6.7/7.3 5.8/6.8 7.6/8.2

35/16 0.36 3.0 0.37/0.44 1.7/1.8 40,000 12.9 3.5 in 10 in

50/23 7.3/9.4 35.2 7.3/9.4 20.3/23.0 7.9/9.4 11.9/13.8

106/48 12/15.2 33.6/37.1 12/14.2 18.0/20.9 15.3/18.7

50/23 7.6/9.8 36.5/40.8 7.6/9.8 21.1/24.4 8.3/9.8 12.5/14.6

120 V 208/240 V 208/240 V 380/415V (Export) 440/480 V GAS

50/60Hz/1 50/60Hz/1ph 50/60Hz/3ph 50/60Hz/3ph 50/60Hz/3ph OUTPUT WATER COL

BELSHAW BROTHERS, INC ▪ 814 44th St NW, Suite 103, Auburn, WA 98001 ▪ USA

Tel +1.206.322.5474 ▪ Fax +1.206.322.5425 ▪ Email info@belshaw.com ▪ www.belshaw.com

©2009 Belshaw Adamatic Bakery Group ▪ Product specications may be changed without notice.

11” drain

valve

Loading...

Loading...