1080

MODEL

Abrusive

ABRASIVE BELT GRINDER OPERATING

TOSO

INSTRUCTIONS

AND PARTS LIST

Belt

Grinder

SPDCIFICATIONS:

OVERALL SIZE:

WORK TABLE

TABLE TILT ANGLLS:

MOTOR:

STANDABD

SPECIAL

ADJUSTABLE IDLER

SELF-ALIGNING UPPER WHEEL - AUTOMATICALLY ALIGNS

PRECISION

AUTOMATIC

QUICK

SEALED BALL BEARINGS

BELT

SURFACE:

FEATURES

_

ARM

GROUND TABLE

BELT TENSION

CHANGE

_

USES

IN

DRIVE WHEELS

USED

EASILY

_

FOR

BELT SUPPORT ON

LOCKED AT ANY ANGLE

INSURES LONG

I" X M"

ABRASIVE BELTS

AND

EVEN

PRECISION

BELT

8.5 INCHES WIDE

INCHES

I4.O

INCHES

22.0

INCHES

8.5

7.0 INCHES DEEP

20" BACK

FORWARD MAXIMUM

70"

I/4 HORSEPOWER

I75O

RPM

IIOV,

BELT WITH LOWER

_

ASSURES EVEN

WEAR

60 CYCLE AC

INSIDE WORK

DEEP

HIGH

WIDE

MAXIMUM

WHEEL

GRINDING

IIIACHINDRY

CO

liilol

Equitable

Bd.,

Bor 593

o

f,ansas Gity,-to. 6f1{1

1dffia

INDEX

INTRODUCTION

SAFETY RECOMMENDATIONS

GLOSSARY

PARTS

PARTS

r0B3

rOB4 MOTOR MOUNT

ASSEMBLY

BELT INSTALLATION

BELT

LIST

ITLUSTRAT1ON

(FLOOR

ALIGNMENT

ABRASIVE

CIRCUTAR

TOOTH

BACK

SHAPING

K)INTS .

BEVELING

SAW

TERMS

OF

STAND)

INSTRUCTIONS FOR IO8O BELT

BELTS

SAW SHARPENING

TEETH

PARTS

.

.

ON THE TOBO

rrST.

ON

GRINDER

TO8O

THE

BELT

BELT GRINDER .

AND TO83 FLOOR

GRINDER

STAND .

I

2

3

4

5

6

6

7

I

9

l0

tl

t2

r3

t4

SCISSORS

PINKING

SHEARS .

CHISELS.

SCREWDRIVER

ROTARY

AXES, HATCHETS,

GARDEN

HEDGE

HEDGE

SETNNG

SHARPENING

TAWNMOWER

TOOLS

TRIMMERS

SHEARS

UP FOR INSIDE

GENERAL

.

KNIVES USING THE

SHOP TIPS

BLADES

AND

CLEAVER WEDGES.

GRINDING .

#27I

KNIFE

SHARPENING FIXTURE

r6

t7

l8

r9

r9

2l

22

23

2/L

25

.

%

27

I

'1

l

l

l

INTRODUCTION

Belsaw

The

work.

Designed

artd

The

metals.

The

continuous

shipperin

and check

or

It will

clean

Model 1080

It's perfect

1080

missing

Abrasive

sharpen

for quick

Belt

scissors,

easy sharpening,

of burrs.

also be used

can

for

those

abrasive

use.

good condition.

your

parts

belt

has been

It

equipment carefully.

and

Grinder

will

mower

for cleaning,

inside

grinder

is

carefully

receiving

Upon

immediately

just

sharpen

blades,

belt

the

that

edges

heavyduty,

a

tested"

ginder

about

knives,

sanding,

are hard

rugged

inspected

your equipment,

Using the part

write the Customer

anything

chisels,

not

does

carving, polishing

to sharpen using

grinder,

and packed at our

inspect the shipping cartons

numbers

Services

in your shop,

drills,

burn

built

and description, make a

teeth

saw

your

-

and

other methods.

to

Department, Belsaw

and with

in less

virtually

-

finished work

shaping

industrial

time

all cutting

is

smooth,

wood,

of

standards

plastic,

for years

factory and was delivered

for

list

signs

any

of

of

Machinery

less

edges.

sharp,

and

of

to the

damage

damaged

Co.

We will

then

furnish

necessary

the

for returning the equipment

Your new Belsaw

parts. If

any

is guaranteed

part

should

need

MACHINDRY GO

repair parts and instructions

to our

for one

replacement,

factory

year from date of

for

exchange.

write our Customer Service

6801 Equitable

for filing dar.naSe

purchase against

Delnrhent.

Bor

Rd.,

claim,

or insfructions

faulty workmanship or defective

593

o

Kansas Gi$,

ltlo. 64141

6ffim

Pagc

1

SAFETY

RECOMMENDATIONS

1.

Before

operation

the

using

your

and

Belsaw

new

applications

the

gnnder

you

read

can

instruction

your

perform'

manual

carefully'

2.Alwaysmakesureyourmotorswitchisoffwhenplugginginpowercord.

operation'

3.

4.

5.

6.

Always

Remove

U.pLrg

sure

Be

wear

rings,

power

remove

to

safety

watches

cord

gtasses

and

before

adjusting

any

face

or

ties.

making

shield

Do

wrenches

when

wear

not

adjustments

the

loose-fitting

or

tools

or

grinder

changing

before

is in

clothing'

belts'

starting

equipment'

From

you'll

it

learn

z.

g.

g.

Keep

you

so

Never

Make

this

hands

don,t

operate

sure

manual

away

have

your

the

fron

to

belt

belt

abrasive

overreach

grinder

tracks

ProPeily

surface.

do

to

damp

a

in

the

on

Maintain

work.

wet

or

the

Pulley.'

control

proper

Keep

location.

work

your

of

footing

work

The

Adi'sment

times-

at'all

balance

and

drould

area

procedures

Position

all times'

at

well

be

included

are

yourself

lighted'

later

in

P*2

i

(

\

BEVEL

The

the

angle

purpose

GTOSSARY

a cutting

on

tool or

of the

TERMS

OF

surface

blade.

of a tool or

blade. A"d"

varies

depending on

I

CANNELL

EDGE

Rolled

objects.

edge on

digg"g tools

to reduce

nicking

rocks or

by

other

sharp

I

each tooth.

CHALK-LINE

BACK.CLEARANCE

FINISH.SHARPENING

.

FLAT-GRIND .

FREDHAND GRINDING

GUMMING

HOLLOW.GRIND

.

drawn

Line

basic shape

Refers

tooth

being

Achral

Refers

also

Grinding

Refers

sawblade.

Grinding

chisels

to

must

cut.

sharpening

to grinding

refers to grinding

a cutting surface

grinding,

to

the

similar

and

on wood table

of

beveling

or

face

the

the cutting

shaping

srrface

tools.

lower

b€ ground

cutting

guide

for

as a

back of tooth

the

than the tooth

of the

teeth on

of tooth on circular

surface

without use of

or increasing the depth of the gullet on

with

a slightly eoncave

sharpening

even

on circular

a sawblade.

flat as

a

guide.

point

blades without

opposed

of

sawblades.

it clears the

so

Back of

wood

angle. Can

to hollow grinding.

a circular

edge. Can be used

on

and

HONING

HOOK

ANGLE

.

Cleaning

A"d"

up

between a line

tooth point

JOINTING

Sometimes

It brings the blades to

LOADING

*

SETTING

SHAPING

SHINER

.

Befers

Describes

sawed eo that

Restoring origind

Flat spot

to build+p on abrasive

on point

resharpening

drawn

to

the center

cdled rounding,

a tme cutting circle

a

method of

the blade

ehape of teeth on blades or

of

circular

to a very fine edge.

along

hole.

dhe first step

belts, primarily from wood

providing

does not

bind in the cut.

sawblades

face

the

in

with every

clearance

left after

a

of

sawblade

resharpening circular

to a

line from

tooth the same

duminum.

or

in the cut of material

tools.

jointing.

the

sawblades.

length.

being

he. 3

t-

---"

l

PART

BC'.1

BG.2

Be*3

BCF4

BG-6

BG7

Bc-8

Be'-9

Bc'.lO

BCr.11

BC-12

BG13

BG-14

BCr15

BC-16

Bcr.17

BG-194

BG-20

Be*22

BG-26

BG-27

8G.29

BC-30

BC*31

BG'33

BC*38

BG41

Bc*46

BG-52

BG55

BG60

BG-61

z-77

7-85

Z-LL4

z-r15

z-rL6

Z.LT?

z-Lt$

Z-LLg

z-t20

z-tzL

z-r22

2-124

z-t25

7-126

NUMBER

ABRASIVE

ORDER

Column

RightBase

Base

Left

Mounting

Front

Backstop,

Cover

Upper

Upper

Plate

Arm

Axle

Spring,

Lower

Adaptor,

Hinge

Idler

ldler

Idler

Table

Table

Lower

Lower

End

Upper

Ball

?

3"

Table

Oilite

Spring

5/8

,.v"'Belt

Upper

Ball

Pin

Pulley

Axle,

Axle,

Adjusting

Ball

hrlley

Cap,

Pulley

Bearing

V-Belt

V-Belt

Bracket

Bearing

Clip

I.D.

Idler Arm

hrlley

Idler

Abrasive

.

Nuts

Lower

Nut,

Table

Nut,

Adjusting

Table

Screws

Screw,

Upper

Adjusting

Cap

End

Idler

Nut,

Screw,

10-24x

Back

Idler

Stop

5/1L18

Screws,

Ipwer

Pulley

Pulley

Washer,

Belt

Screw

1/4

i

Table

PART

BY

DESCRIPTION

.

Channel

for 1"

Flat

.

.

.

Arm.

Bearing

Ball

..

Upper

Lower

Bracket

Bearing

Upper

Arm

....

(1/2"

Pivot

for Idler

.

Iower

with

Guard

Axle

Idler

Adjusting

Bracket

Arm StoP

Screw,

.

Arm

Arm

Socket

Screws

glA

So"k"t

Adjusting

PARTS

BELT

Belts

Axle

&

Bearing

and

....

hole

'

Oilite

(OPtional)

Bracket

UPPer

Screw,

Set

Set

IIST

GRINDER

NUMBER

....

&

Axle

motor,

for

hrlleY

Axle

Idler

(BeFf4

Screw

Screw

PulleY

Idler

Scnew

Bracket

MODET

AND

Adaptors

not shown

..

BC-il8)

and

Arm

Lower

for

1080

DESCRIPTION

(BG'12)

drawing)

on

Pultey

and.t

BELSAW

EOUITABLE

6301

firfiitrJ"ffi,,

NUMBER

""""'

V-Pulley

MACHINERY

ROAD

MrssouR!

REQUIRED

1

I

""'

1

1

1

1

....

CO.

64141

Page

4

l

oA.

c

H

a

z

c

()

Ed

Ff

frl

c0

H

a

E

o

c

co

o

Ff

14

a

o

=

z

o

Fr

&

F

U)

Ff

Fl

a

F

c

I

\

KT

Ti

EI

lEl

\

ni

lSl-a

LJ

EI

tl.'\ i

EZ,,b

N:

I

e

e

**lil

r13

o

e

r?

=6

=6

.A

5

i

i

FI

llel

I lntl

-u

-t

-f

a9

cl

=

j

i5

v,

.E

at

(rg

-

a

GD

€tt

rl':,

x

ct

o

E

E

ct

-cl

6g

=

=

E

lrl

e

c:t

G'

o

C)

)r

fr

rt

2

t{

H

*t

C)

d

E

lr

l}'

Ir

"il

I

'lrl

t-

@

I

t4

Page

a

a

]t

H

n

5

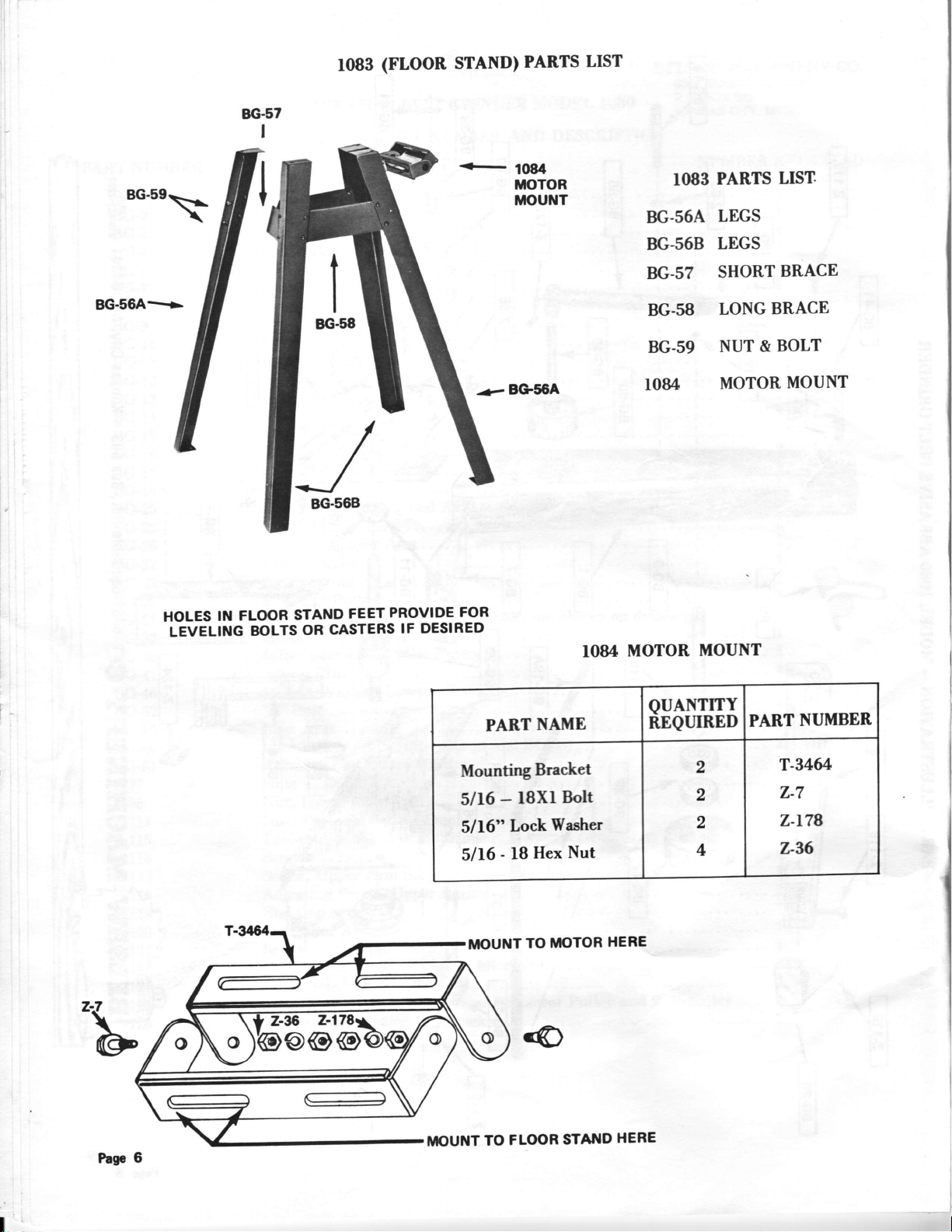

(FLOOR STAND)

1083

PARTS

LIST

8G.59

BG-56A-

HOLES

IN

LEVELING

FLOOR

BOLTS

STAND

CASTERS

OR

FEET

PROVIDE

IF DESIRED

FOR

-e

BG56A

IO83

BG.56A

BG-568

BG.s?

BG.58

BG-59

IO84

rO84 MOTOR

PARTS

LEGS

LEGS

SHORT

LONG

NUT &

MOTOR

MOUNT

LIST.

BRACE

BRACE

BOLT

MOUNT

Pas.6

Mounting

5116

5116"

5116

IIIOUNT

MOUNT

PART

lSXr

-

Lock

-

l8

FLq)R

TO

NAME

Bracket

Washer

Hex

TIIOTOR

TO

Boh

Nut

STATTID

HERE

HERE

QUANTITY

REQTIIRED

2

,

2

4

PART

T-346/!

z-7

z-t78

z-%

NUMBER

ASSEMBLY

GRINDER

INSTRUCTIONS

IO83

FLOOR

AND

FOR

IOSO

STAND

BELT

legs

l.

In an open

BG-568,

2. Using

Leg to

I

thcn connect

area, arrange

are on opposite

the

BG-59

Nuts and

a BG-56B

the two

Lcg,

assembled

four

the

corners.

Bolts

with BG-57

pair of legs

of the

The holes for

provided,

Short Brace.

floor stand

the

loosely assemble

Repeat

with

the

so

1084 Motor Mount

BG-58

each pair

of matching legs, BG-56A and

should

face

front and rear.

the

the floor stand connecting a BG-56A

the procedure

Long Braces.

with

the other pair of

legs;

t

Befort: tightening the

3.

nuts. The

two sections

floor stand. Do not attach motor

Floor

With the

4.

and

with

The ll4

5.

the

After aligning the

6.

wrench and screwdriver.

a

l0B3

attach with

a screwdriver

horsepower

motor

bracket,

four nuts

and

motor

hand-tight.

motor pulley

floor

of the

Stand

and bolts,

wrench.

stand,

put the l0B4

motor mount

until after

loosely

should

assembled, place

hand-tight.

be attached

with

Nlotor

should

llelt Grinder is attached

'l'hen,

to

the BG-30

pulley,

I\tount

swing

together using the shoulder

loosely.

Attach the motor mount to the

to the

the l0B0 Relt

tighten the

motor mount, tightening

the

tighten

Grinder on top

floor

the motor to the

floor

stand.

and belt grinder

stand

bolts and

of the

the nuts and bolts

motor mount

floor stand

in place

with

to

Place the

7.

proper belt tension.

the

B.

Once the

Table

screw to

2-126

the

so

that

will

angle.

hold

to

so that the table

The

9.

added

Screw and

beneath the

will

BG-27 Upp"r

V

belt over the

main

unit and

Bracket

Pivot

hold

the table

Table Adjusting

the BG-33 Table

for

turn

These

the table

optional

adjustment

screws should

in place,

angle can be

BG-61 Belt

by loosening the

positioned

be

placing

head of the screw.

Pulley.

the

BG-30

floor

and held

in place

Bracket Screws

Bracket

be tight

yet loose

Guard

Z-lI9

slot of

the

over

pulley

stand are assembled,

position with

in

on the BG-33 Table

Pivot

and

motor

of the table

enough

enough

moved easily.

may

be

End

Cap

the guard

The guard

top of the

the

pulley,

the

set

Bracket

letting the

BG-I9A

screw on the table.

Table

Pivot,

you can then adjust the tension

weight

can be

After

of the

placed

tightening

motor provide

BG-33

the

on

set

thc

of

OPTIONAL 8G.61 BELT GUARD

MOUNTED ON GRINDER

Page 7

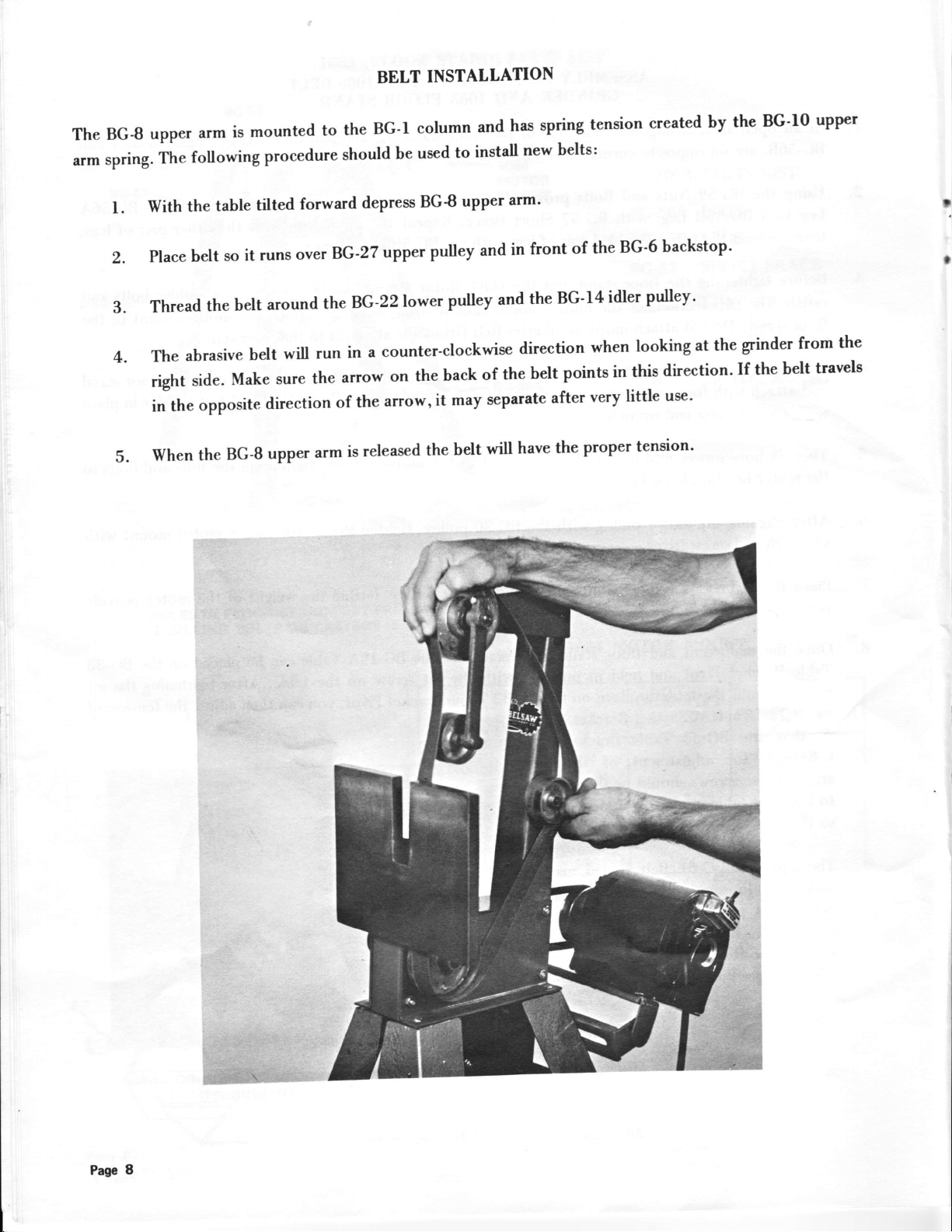

BELT

INSTATLATION

The

arm

BG-B

spring.

l.

2.

3.

4.

).

upper

The

the

With

Place

Thread

abrasive

The

right

inthe

when

is

arm

following

table

it

so

belt

belt

the

belt

Make

side.

opposite

BG-8

the

mounted

procedure

forward

tilted

over

runs

around

will

sure

direction

upper

the

to

should

BG-27

BG-22lower

the

in

run

arrow

the

of

is

arm

corumn

BG-r

used

be

depress

a

the

released

BG-B

the

on

arrow,

pulley

pulley

back

may

it

the

upper

counter-clockwise

and

install

to

upper

belt

has

arm'

in

and

and

direction

the

of

separate

have

will

spring

new belts:

of the

front

BG-f

the

points

belt

after

proper

the

tension

BG-6

4 idler

when

this

in

little

very

created

backstop'

pulley'

looking

direction.

use'

tension'

by

at the

BG'ro

the

grinder

If the

from

belt

upPer

t

the

travels

Page

:;t+:::\

8

BELT ALIGNMENT

REMOVED

you find

If

3.

l.

2.

your abrasive belt tracks to

that

Unplug power cord.

belt

If the

bottom, and loosen the

the

tracks

to the

If the belt tracks to

the

4. Tum on the equipment and check

final

5.

If

adjustments are necessay,

(THE

BG26

FOR

the

right, tighten

adjusting

left, reverse

belt

make

E'UD

I LLUSTRATIVE PURPOSESI

right

the

screw

procedure in step 2.

the

travel.

sure power cord is unplugged.

HAS

CAP

or left,

BEEI{

following

the

Z-ll8 adjusting screw

going through

the axle

adjustments

going through

from

the top.

may be

axle from

the

made:

he.

9

ABRASWE

BELTS

whenorderingabrasivebelts,weofferthefol|owinginfo'mationssaguideline.sin€eeschoPeretofusesa

different

which

COARSE

40"GRIT:

wood eince

such

MEDIUM.COARSE

.,touch",

iB best Buited

belt

removing

as

This ie the

belt

the

a trial

order

your needs,

to

courBest

will not tend

deep nicls

the

of each

i{e heve

b€lt

to..load".

in mower

and personal

belt

available.

bladee

Used

snd other

experience

Hobbyirts

on metal

should

6nd this the b€st

only when

general shaping'

fart removal of

be the

determining

belt

factot

for rough'ehaping

is required

stock

as to

I

I

a

from

as well

"loading"

60-GRIT:

plesticE.

you are

when

MEDIUM

on

Good

W€ suggest

grinding

wood, but

touching

eluminum.

al6o csn

moving

the

be used

b€lt

wide variety

on a

with candle

of metels

or paraffin to

wax

(including a.luminum)

ke€P the b€lt

B0-GRIT:Veryclos€intextuetothefamiliarMediumlfi)gritbelts,butthecoarsergritandheavier

backing

useful

will tend

for rough shaping

M[,DIUM.FINE

l00"cRIT:

of the

Good

g r has

NNE

lSocRIT:

the

up

fine

The

on cut

Hsving

finest

grit produces

gho8, which hobbyiste

to make

heavy

finbh sharpening

for

worn ftom the

the 6nest

cutting edges

almoet

the belt

wear longer

cutting

b€lt, msny

it dso

grit,

on tools

a honed

and handymen

such

than

such a6

tools

most cutting

experienced

has the lighteet

ss sciesors,

edge.

This belt

will find

the 100€dt'

axes, hatcheb

tools srch

ope.rtors

backing

pinking

worke

extremely

rs rotary

sct the belt

rnd

eheere,

cxtr€mely

us€ful'

Sharpening

or graE6

whiPs'

mower bl,erles.

aside for

will tend to

cutlery rnd

well for removing

operators

shop

once

fine'fini6h sharyening.

wesr fs5te..

other light

will find

the majority

used to

cutting

sharp edge

the

bring

tools

ae

it

Pre.

f0

A circular

CIRCULAR

grw

vrill cut clcrnly

SHARPENING

SAW

rnd earily only

ON

whcn it

THE

TOOO

is round and

BELT

sharP, md

GRINDER

the teeth hrvc

the

p.oP€r

I

I

gide

and beck cle&rnco.

circulrr srw

Before

f.

teeth in

eherpening

JOINTING

bringr

2. GUMMING

blarle,

aaw

SETTING - Terrdinolo6r

3.

material

Thc l08O bclt

leas time and

r sawblede

Sometimos cdled

-

the blade to

Refels

-

being sarved, 60

without h.viDg

on the bclt

r

cutting citcle

truc

to

grinding,

used to

thst the blade

grindcr

will enrble

to ttotty lbout

grinder, the

rounding,

the

vith evcry tooth

shaPing

descdhe

does not bind

you to bevel-grind,

following steps

first

8t€P

or increasing

e method

flat-grind

buming

in.4hrrPening

th€

the

the s'rv tcclh'

must l,€

6rme lcngth.

depth of the

accomPli6hed:

citculrr sawblade*

gull€t on . circular

of providing cleerence

in the cul.

end eharpen

It

in the cut of

these stepe

After

ectual eha4rning

have heen accomplirhe{

or beveling of the t€€th

you ,r€

on a sawbhde

now rcady to sherPen

is notmally

dre teeth on the

rdened to ra

sarvblade.

finirh+herpening.

The

h!

1l

TOOTH

POINTS

to concentrate

Plan

the

bevel up

The

face,

tooth.

sharpened

combination

A

on

have a

With the

face on

straight

while a cutoff

motor

across

blade

25 degrees

to

turned

the

on

most

so

a

has

bevel

off, place

of

face

saw

rip

has

it

of 5-10

or crosscut

on the

face.

the saw

the saw

blades

bevel-

no

degrees

saw

may

on

work table

the

is

tooth

belt.

the

Draw

tb

each tooth.

is parallel

This

hook

a chatk

serve

angle already

as

the teeth

anglc.

hook

the

TOPVIEWOF

so

to

insure that

will

line around

a guide, to

each tooth

As

against

the

abrasive surface

the

you

the

insure

is sharpened,

chalk

TABLE

into

blade

equal

line to

gound

are not

the sawblade.

far enough

grinding

of the

face

the

that

saw

of the

changing

on

bring

maintain

a

t

I

I

It

CTIALK "GUIDE

BE19A

Oil

iIARK"

TABLE

t

I

I

degrees. On

the table

rip saw

l,t

I

i

On

table

grind all teeth set

12

Pqe

bladeso

to match

sharpen

face bevel,

in

all teeth

sharpen

the opposite

with

teeth

all

direction.

at

arc set

that

Do not

90

in

change

the same

the anglc

combination

direction.

of the tablc.

and crosscut blades,

over,

Turn the

blade

tilt

and

t

i

BEVEL TOP OR

TO

Beveling

angle

slightly

until

the top or back of a

required on the

in back of

the bevel

just

to be out of round.

THE

top

the tooth point. After the sawblade

extends to the tooth

Grind

BACK

TOOTH POINT

saw

or back of

this

bevel so the end of

A general guide to the amount of

JUST

BACK.BEVELING

tooth

the tooth.

can

also be

point.

metal to be

BEVEL

accomplished on grinder. Adjust the table

Plan

to make

has contacted the

Do

not

the bevel

removed is the

grind

curves

the

off

size

SHOULD CURVE

INTO BACK OF TOOTH

first contact of the tooth

belt, use

the tooth

smoothly

of the

point, as

flat or

pressure

into the back of the tooth.

shiner

SMOOTHLY

to the

against the belt

to grind

will cause the saw

this

left

jointing.

by

bevel

the top

If

the

large

shiner

is small, you can complete

shiner,

Almost any

to adjust the

it is better

blade

style

angle and

table

the sharpening

in one

around the blade.

pass

If

there

to make several passes around the blade.

be

can

sharpened on the

experiment with a sawblade before actually sharpening it on the belt grinder.

abrasive belt

grinder.

If the style is new to you, it's best

is a relatively

Page

13

SHAPING

SAW

TEETH

ON THE

IOSO

BEIT

GRINDER

After

several

a

saw

times,

has

The coolness

reshaping,

as

been

the saw

the

of

it enables

filed

teeth

l0B0

you

hand,

by

need

may

makes

to stay

or

reshaping.

it ideal

on the

ground

for

tooth'

bringing

about

shaping

with

overheating

table

it back

to shape

or bluing

of saw teeth

flat at

kept

should

degrees

90

without

the

worrying

tooth.

Basic

be accomplished

the bilt.

to

I

I

belt

The

entire

sharpened

is parallel

Page

top

14

grinder

of

sawblades.

to

is

the tooth

belt.

the

especially

in one pass.

With the

Mark the

shaping

useful

for

Also, this

motor

circumference

turned

Style

step

set the

off,

of the

teeth,

C

gives

sawblade

sawblade

as the

you the

back clearance

on the

with a chalk

one-inch

table

line.

wide belt

required

that the

so

lets you

for properly

of the

top

do

tooth

the

I

I

Using the chalk

line as

a

guide,

sharpen

each tooth

the same

to

back clearance.

T

t

teeth

Saw

the saw

evenly.

and

with curved

grind

to

backs

down the back

can

be shaped. Start

also

of the tooth

to

bring

grinding

the curve

just

in back of the

into the

back

point.

tooth

rounded gullet

Turn

smoothly

I

t

Cutoff saws

Style S

back of the tooth.

the

blade on the

and

blades

grinder, tilt the table

combination

some

will have a bevel

When shaping

blades such as

all

way down

the

this type

to the recom-

mended

belt. In this

accomplished on the sawblade,

to

bevel,

remove an

rather

way, when the final bevel ginding

excessive amount of metal.

than

at

degrees to the

90

will

you

not

is

have

Pagc 15

Although

scissors,

like many

other

tools,

SCISSORS

,

can be

sharpened,

without a holder,

we recommend

using

the

holder until

tool

#264

with the

across the

curve of the blade.

beveled

belt,

removing

edge

familiar

down.

Tilt the

only enough

with

basic

the

table

metal to

operation.

to the

create

desired

a sharp

Clamp

(3 degree to 5

the blade

cutting edge. Grind

to be sharpened

degree)

angle and

in the

make a

free hand matching

holder,

light pass

any

I

I

P!e.

I

16

PINKING

SHEARS

I

Sharpened

to sharpen

attempt

to sharpen

in a manner

only the beaeled

similar to scissors,

V-grooues. If the grooves

the

cutting edge.

plan

Neuer

I

have previously

shears

for

Reproduce

possible.

or

match

light

necessary. Taking

should

factory

Place

in the tool

the bevel of the shears.

across

pass

been filed or sharpened, the

be returned to

service.

original bevel as closely as

the

the shears

holder,

positioning

the manufacfurer

on the work table

After making a

abrasive belt, visually inspect

the

light

passes,

follow

the table

the natural

to

area

the

contour of the

being

sharpened

and readjust table

blade. Remove

only the

tilt

minimum

if

I

amount

You may

more

shears

to

nut can be made

t

bottle cap

picture

be sure

their

and

of metal for a

find it necessary and

convenient to disassemble the

prior to sharpening.

remove the

at

special

opener as shown in the

right. After

all parts

original

applylight machine oil sparingly.

order.

type fulcrum

from a common

are

replaced in

Clean

edge.

sharp

A

tool

sharpening

all

parts

For maximum cutting efficiency, adjust

the tension

of the

fulcrum nut after final sharpening.

Page

17

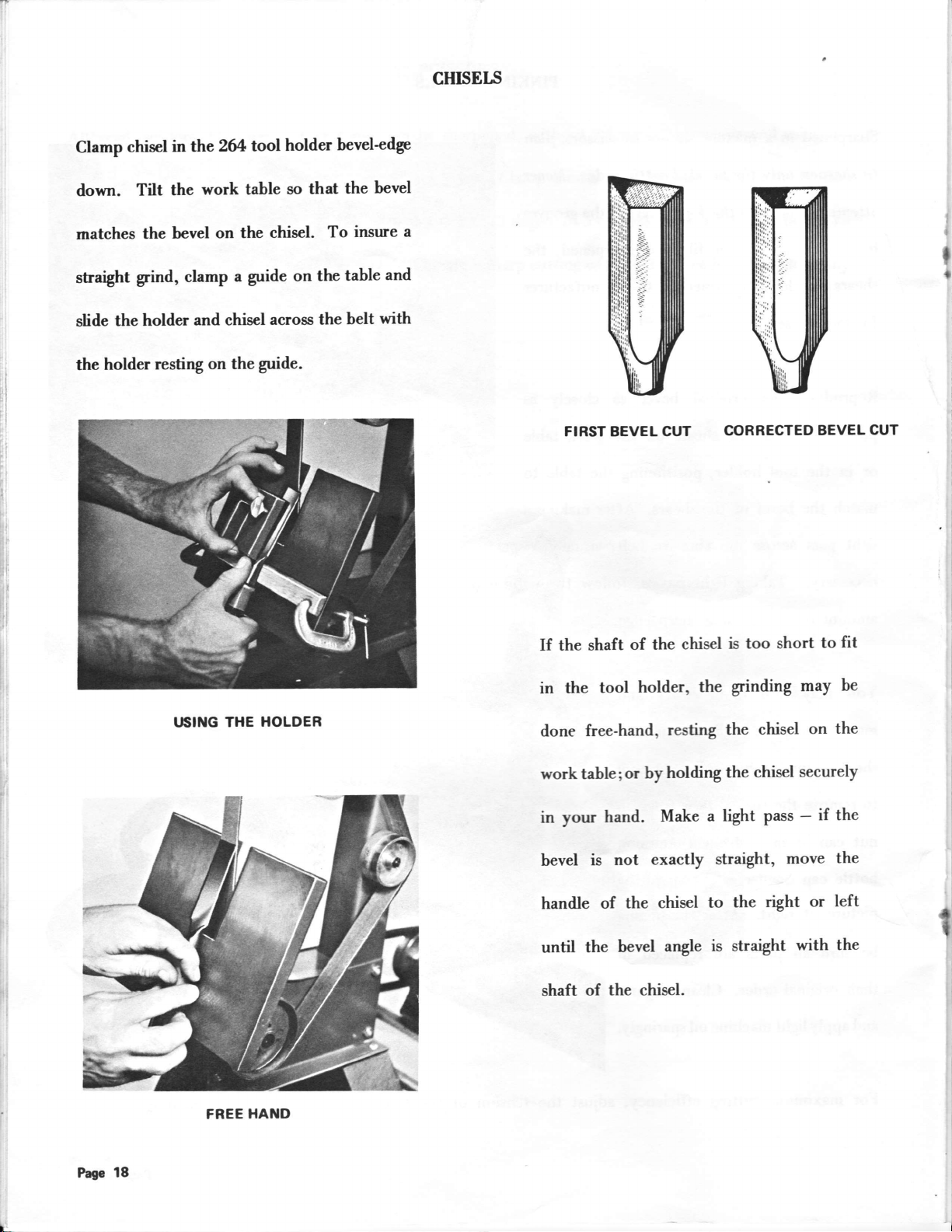

CHITIEI,s

Clamp

chisel

down.

rnatches

straight

the holder

slide

holder

the

Tilt

the

grnd,

resting

264 tool

the

in

work

the

bevel on

clamp

and chisel

on

holder

table so

the chisel.

a guide

the guide.

on the

across the

bevel-edge

that

To

the

insure

table

belt

bevel

and

with

I

a

I

t

I

FIRST BEVEL CUT

CORRECTED

BEVEL

CUT

t,SIlTG THE

HOLDER

If the

in

done

work table;or

in

bevel

handle

until

shaft

the

free-hand,

your

is

the

shaft of

tool

hand.

not exactly

of the

bevel

the chisel.

chisel

the

of

holder,

resting

by holding

Make

chisel

angle

too short

is

grinding

the

the chisel

the chisel

light pass

a

straight,

the

to

is straight

to

may

on

securely

if the

-

move

right or

with

fit

be

the

the

left

the

t

Page

18

FREE

HAI{D

SCREWDRIVER

Clamp

with

Line

face

the

driver

is

edge

screwdriver

the

work table

the

the

up

of the belt

lightly

formed.

in the

at a

90

of the screwdriver

tip

and push

the belt until

into

tool holder

degree

angle.

the screw-

a straight

with

ROTARY

Due to

the length of rotary

LAWNMOWER BLADES

mower blades,

it's necessary to sharpen them with a

freehand

t

already

grind. Grind

on

the blades. Blades with straight

to match the bevel

I

cutting

straight,

edges

even

p:rsses

can be sharpened making

across the belt.

SHARPENING

EDGE BLADE

STRAIGHT

Page

19

If

you

have

a blade

with multi-

cutting

level

sharpening

mend

lower

backstop

Thecurved

without

belt

possible

surfaces

the

(see

before

allows

the

edges,

photo

(see

area

backstoP

photo

that

one

is flexible.

and

belt

both

against

at right).

be

can

below,

has been

to

we recom-

and

uPPer

the

sharPened

fine

a

using

right)

used

This

bend

and

if

match

Don,t

to check

way

cutting

the

curve

the

forget

to

the

edge.

of the

balance

balance.

blade.

the

after

blade

Balancing

sharpening.

should

be

done

our

by

rotary

#277

removing

blade

metal

balancer

from

the

provides

back

of

the

a

quick

blade,

easy

never

PaSe

2()

All of these tools

have a

AXES, HATCHETS AND

standard

bevel of 15 degrees.

CLEAVER

Axes and cleaver

ryEDGES

wedges

should

be

ground

with

a

curved cutting

prevent

burning.

edge.

Hatchets have a

straight edge.

Take several passes

to remove large

nicks in order to

Pw

21

GARDEN

TOOLS

Many tools

should

tools

Tools

This edge

for digging

any sharp edges.

off

Roud

You'll

enablcs you

find sharpcning

SHARPENING

as hoes, shovels,

such

be sharpened

havc

b" fo.-ed

""n

see the edge

to

HOE

THE

spades

free-hand.

cunnell or rolled

a

the belt

using

and gardcn

lawn

being sharpened

digging

and

edgc

which prevcnts

without the

tools a

lot easier

much more

tools can

hackstop,

if thev

casil\

'

. . . THE

be sharpened

nicking

so

that

by rocks

bclt

the

arc cleaned

using

v,'ill

prior to

SHOVEL

belt

the

or

cun'e around

grinder.

hard objects.

other

sharpening.

These

the edge.

This

Page 22

...

THE

LOPPING

SHEAR

...

OTHER

SIDE

OF

LOPPING

SHEAR

HEDGE TRIMII{ERS

are

Trimmers

position

will not

Sharpening

slightly

to drarv

a6 illustrated. This guide

that each tooth is

slop€

as well as the correct bevel.

easi€sl to sharpen

four

by

dislodge motor

depending on manufacturer€rind to existing

screws

can be done quickly

going inlo the base through

parts.)

a guide on the tilting table

will assure

ground to the same

Grind each tooth until the

forms a

edge

across rhe face of the tooth.

smooth

cutting edge

iI you remove

and esily

heveled

lhe blades

tilting tlle

by

from

the electric motor-

base of the tool.

the

table to a 30 d€gre€

angte to insure top

(Use

when removing

care

angle.

performance.)

The blade

(Angle

Use a magic marker

is held in

so you

vary

may

Before

tool, ch€ck

dust,

that may

ening. Danage

removed

Maks sure to use

on

replacing the

rcplacing the blade on the

and remove any grinding

metal shavings, or rolled

have occuned during sharp-

wi result if this is not

before assernbling the blade,

a good coat of oil

each s€ction of the blade belore

blad€ on th€ tool.

edges

?.F

23

HEDGE SHEARS

Before

should

of the shears.

to obtain

down the entire

It's easiest

Belt

down toward the

this

sharpening

separate

an even beveled

to tilt the

Grinder so

way, the

This

length of the

weight of the shear

h"dg" shears

two portions

the

will enable you

blade.

table of

that it

abrasive belt.

is sloping

you

angle

the

In

.

will

provide

for grinding.

side of the

You'll have

a properly

letting

belt,

After

even support

ground

the

sharpening

the proper

Grind

blade on

weight of the

with the flat

cutting

both portions

pressure

the table.

insure

to

edge.

blade

grinding at the

Begin

determine

of the

the pressure

blade in

handle

end

against the belt.

this manner, be

of the

blade - guide

sure to clean

the tool

across

and oil the blade.

the

Page 24

SETTING

FOR INSIDE GRINDING

UP

a

are

Axles

on either the

here show

In drawing

moving

normal

In drawing

Move

the belt

provided

the two

"A"

BG-14 idler pulley to the

position

"B"

BG-14 idler pulley

around

lower pulley.

shown.

Push

front base or rear column.

Place

BG-60

for

using

ways the belt can be

the belt is placed like a triangle,

for most

the

sharpening.

belt is set up

the large upper pulley

belt inside

idler pulley in

until the two sides of the

ment

Z-l2I idler

the idler arm can

to

arm screw. This will

the lower idler pulley

The drawinp

positioned.

position, the

#l

for

inside

to the

position. Loop

#2

and

position

are parallel.

belt

be made

towards

and

#2

by loosening

give you

by

grinding.

large

#3

belt

the

Adjust-

two

as

DRAIYITTG

A

ginding surfaces

tion of the

arrows.

with

the belt running in

For inside grinding remove

Upper

want

the

Pulley,

run the

to sand or grind, and

large

upper pulley.

belt through the opening you

the belt from

replace

then

direc-

the

large

the

the belt

on

DRAW|TTG

8

Ptga

6

SHARPENITTG

KNIVES

USING

THE

#27I

KNIFE

SHARPENING

FIXTURE

Set up

your

outlined.

at rear of

C-clamp

the desired

Use the

fast

For

Turn

operators

belt

Medium-Fine

removal

finish

on

and

Belt Grinder

Fixture

The

worktable

and tilt

angle.

bevel

of metal

work, use

motor.

right,

backstop

for inside

is

then

as

shown.

downward

table

100-grit

(such as

Fine

the

With handle

blade

draw

fixture

of

placed

Secure

to

abrasive

removing

150'grit

of

between

left

from

grinding

in position

with

produce

for

belt

nicks).

belt.

knife to

abrasive

right.

to

as

backstop.

blade

sure

Be

Check

a

tilting

for desired

table

For best results,

strokes.

the

pressure

cause

removal

by

Reverse procedure

Use

desired

or hesitation

discoloration

of

dipping

knife handle

left.

to

lays

bevel

as necessary.

always

as many

metal

water.

is obtained.

is required,

finish

in

for opposite

to left,

Passes

during

of

draw

use

metal.

against

flat

the

readjust

angle

and

light, continuous

necessary

:rs

Using

excessive

the stroke

When

keep blade

blade

of

side

blade

from

until

may

heavy

cool

-

right

Page 26

GENERAL

inspected

BG-6 backstop

The

l.

periodically.

form if the

same

the

definite

a

cause

a

grinding,

a sharp

Wear-grooves

sharpentrg

point

groove

tearing

should

the backstop.

of

in the

bend

in the belt

belt.

the

be

or

always

is

backstop,

ridges can

done on

If there

it wiil

during

SHOPTIPS

GRITTIDER

ABRASIVE

BEVEL

is

GAUGE

FOR

BELT

Backstops

placed.

stop

one

work across

and

Always

2.

a

climate,

to

abrasive

bulb.

extend

a cake

Use the

3.

Use your

great

lighter

work.

is

a

work. Once

arvay;

the same

are inexpensive

If there

should

spot

longer

dry

make a storage

be replaced.

on the belt,

the belt,

belt

sure your

make

area. If you

may find it

you

belts. Install

Its heat will

life. A bread box

their

dish is

deal

Belts can

no reason to

heavier belt

you can use

ideal for this use.

right belt

heavier

of

for

belts

should have been used

a belt is

work

and easily

wear-grooyes, the back-

are

Avoid

instead

inzuring

life.

are stored

belts

live in

a

worth

compartment

a low

keep the belts

for the

grit belts

material

touch-up

be changed

wear out

worn, don't throw

worn

a

as a new belt

wattage

or a

job

you

when

be removed;

to

and

quickly. There

a

light belt because

heavier

a finer grit.

of

using

move the

even

yery

humid

your

for

dry and

lid from

are doing.

there

finishing

on the

belt to

re-

only

\rear

in

while

your

light

a

is

it

do

DRAilI{G

4.

The Abrasive

sindins

i.*cisr"gi.ding

i"g" *t"l

to-the

An B-inch

of the

positiorithe

sindins

i"n line

dotted

the

a ruler

table

ruler. This

exact

For

top

f5 degrees.

as

sho-wn

on the table,

at approximately

Next

B-1.

at

B-2.

made the

belt

machine.

how"a

Abrasive

ruler

grinder

table

belt.

"with

the

lines.

is held

it should

position

degrees.

90

bevel

Utittg

in drawing

the

make

Other

s:rme

A

customers

are

scale

Grinder.

bolted to

be

it is

of

a piece

against

with the

up

is basically

required

in

at right

of

the

grinder

For

angles

be"vel

Belt

can

as shown

so

bottom

The

bottom

If

flush

line

would be

grinding

most saws

a small

table can

12 to l5

a permanent

protector,

With the

B.

be adjusted

frequently used

way.

DRAilITG B

a free-hand

feel more

who

these

easily

can

upright

the

drawing

the ruler

table

of flat stock

the

A-

angles

should

as

shown

bottom

bottom

for grinding

require

tilt the

protractor

to

degrees

as shown

on the

mark

angles can

be

mch

line up

draw-

added

post

First

to the

be

by

the

of

the

of

12 to

table

flat

ruler

be

as

at

at

To determine

against

it lines up

to the

it is

the bottom

column-

neoessar)r

not

with the

desired

the

of the table

mark

Once these

to use

just

angle

on the scale

angles are established

the pro&actor.

lay

and tilt

attached

P4n

a ruler

it until

5.

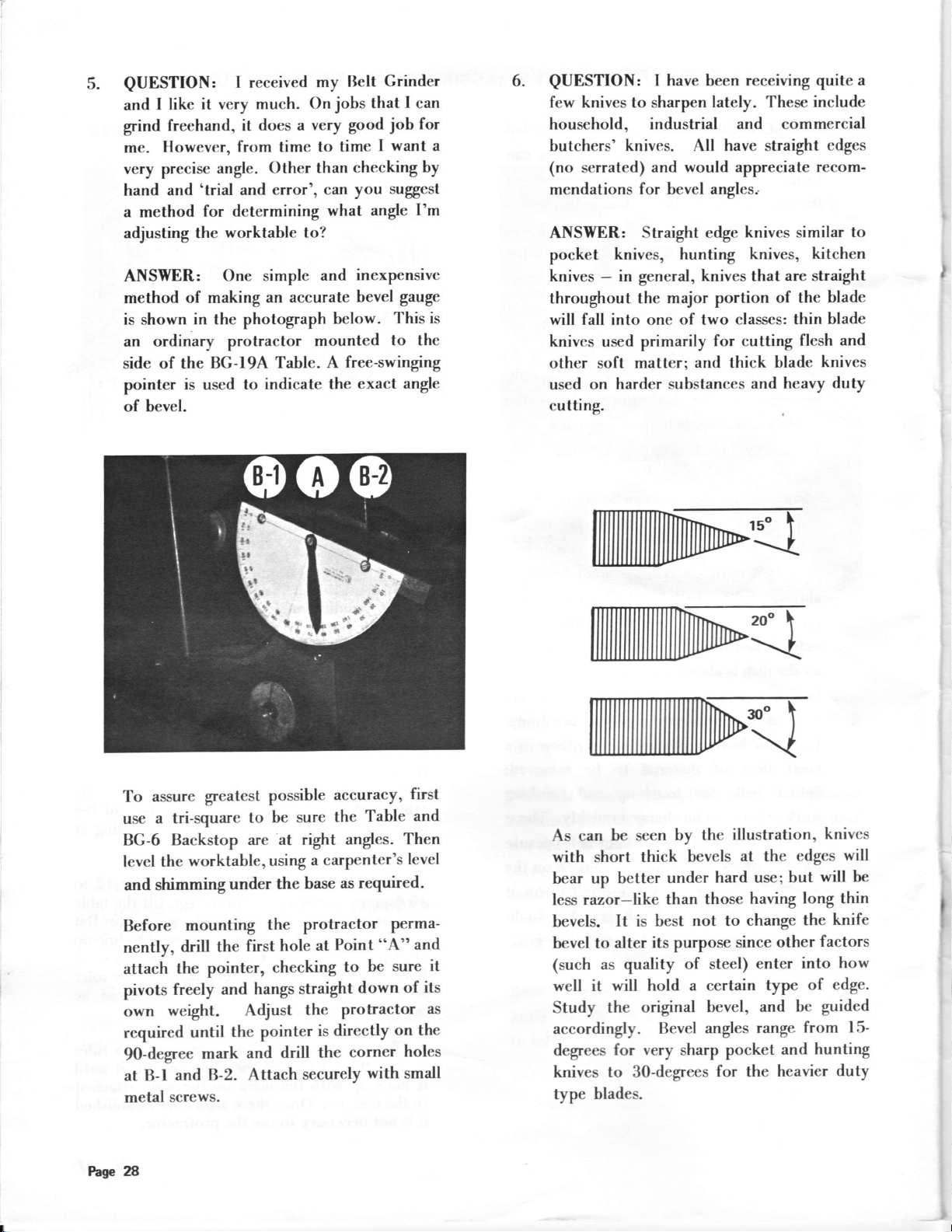

QUESTION:

like it very

I

and

freehand, it

grind

Howevt:r,

me.

very precise

and

hand

a method

adjusting the

angle.

'trial

for determining

worktable to?

ANSWER: One

method

is shown.in

of making

the photograph

an ordinary protractor

is

used

BG-l94,

side of the

pointer

of bevel.

I received

much.

does a

from time

Other

error', can you

and

simple

an accurate

Table. A

to indicate

my llelt

jobs

On

good

very

to time

checking by

than

what

inexpensive

and

bevel

below.

mounted

free-swinging

exact angle

the

Grinder

that

job

want

I

suggest

angle

gauge

'l'his

to the

I

can

for

I'm

6.

QUESTION:

few knives to sharpen lately. These

I have been

household, industrial

a

butchers'

(no

mendations

ANSWER:

pocket

knives

throughout

is

will fall into one

knives

other soft matter;

used

cutting.

knives.

serrated)

and

for bevel angles..

Straight edge

knives, hunting

in general,

-

the major portion

primarily

used

harder substances

on

All

would appreciate recom-

of

and thick

receiving quite a

and commercial

have

straight

knives similar

knives,

knives

two

that

of the

classcs: thin

for cutting

blade

and

include

cdges

kitchen

are straight

blade

blade

and

flesh

knives

heavy

duty

to

assure

To

a tri-square

use

BG-6 Backstop

level the

and shimming

Before

nently,

attach

pivots

own

required

90-degree

at B-l

metal

greatest

worktable

under

mounting

the

drill

the pointer,

freely

and hangs

weight.

the

until

mark

B-2.

and

screws.

possible

to be sure

are at right

a carpenter's

using

,

base

the

the protractor

at

hole

first

checking

straight

pointer

drill the

securely

the

is directly

Adjust

and

Attach

accuracy,

Table

the

angles.

required.

as

perma-

"A"

Point

be sure

to

down

protractor

on the

corner

with small

first

and

Then

level

and

its

of

holes

as

W

M

ffi

edges

will be

long thin

the

factors

into

of edge.

bc guidcd

from

hunting

and

knives

will

knife

how

l5-

duty

As can

be seen

with short

bear up

less

bevels.

bevel to

it

(such as quality

well it

Study

better

razor-like than

It is best

alter its purpose

will hold a certain

the

by the

thick bevels

under

of steel)

original

accordingly. Bevel

degees

knives to 30-degrees

type

for very

blades.

sharp

illustration,

at

hard use; trut

having

those

not to

change

since

enter

bevel, and

pocket

for

the

range

angles

the

other

type

heavier

FaSe 28

a

V€ }now

h.yc

lhc l0BO Bcl6.w

qu€rfiioru .hoot the uee

Abrrrive Bdt gdnd,er

of

equipment do not Ito6;tate to

tfte

uin he e profitrble

ril€ our Cudomer Scrvicc

edditi,on to your froP.

If yor cvcr

DcPldmetrl.

I

belance of tf,is prge

the

-

frR yo'

cET ALONG

'orn'

hes beca

t{otes ud importent rletr lf,rt r

Shop

providcd

WITEOUT" erpeoiry n..hinc.

recrioa wilhin ym Bdt

a r

l rftl in

rarlhg

Grintla lthmrrl rhcrr

yo Gliarlcr rn rheohrtc

ydr c.n

"CAIIT

I

hNr zg

Loading...

Loading...