1

CONTENTS

1. Declaration of conformity ЕС/ЕЕА 3

2. Intended use 4

3. General information 4

4. Main parameters 5

5. List of standard equipment 6

6. Basic components 7

7. Machine structure 12

8. Safety issues 13

9. Marking and packing 16

10. Setting-up procedures 17

11. Basic operations 22

12. Maintenance and repair 30

13. Troubleshooting 32

14. Storage 33

15. Transportation 33

16. Disposal 33

Warranty certificate 34

Acceptance certificate 36

2

This operating manual establishes machine service instructions and rules of safe operation.

Please read all instructions contained in this operating manual before using the machine.

The woodworking machines, if not operated safely, may endanger human life and health.

Hazardous exposure: noise, vibration, dust and cutting wastes, electricity.

Compliance with the requirements, specified in the operating manual, ensures safety while in

use and helps to avoid problems during operation and maintenance.

This operating manual does not reflects slight changes and modifications in machines, made

by the manufacturer after the publication of this manual, as well as changes in component

details and documentation attached to it.

1. DECLARATION OF CONFORMITY ЕС/ЕЕА

Joint limited liability company “Zavod Belmash” declares that multifunctional woodworking

machines

BELMASH SDM-2000

BELMASH SDM-2200

BELMASH SDM-2500

comply with the following requirements of EU Directives, including changes:

2006/42/EC Machinery (MD)

2004/108/EC Electromagnetic Compatibility (EMC)

2011/65/EURO HS Directive

A basis for concordance of the mentioned above devices with the EU Directives is their full

compliance with the applicable standards listed below:

EN 61029-1: 2009 + A11: 2011

EN 62233: 2008 (incl. Corr: 2008)

EN 55014-1: 2006 + A1: 2009

EN 55014-2: 1997 + A1: 2001+A2: 2008

EN 61000-3-2: 2006 + A1:2009+A2: 2009

EN 61000-3-3: 2008*

EN 61000-3-11: 2010**

01/222-1*

01/222-2**

_____________________________________________

* - for machines BELMASH SDM-2000

** - for machines BELMAS SDM-2200, BELMASH SDM-2500

Director _____________ D. V. Shorikov

Conformity certificates are stored at the address:

Zavod Belmash JLLC, Slavgorodskiy Proezd, 37 Republic of Belarus, 212000, Mogilev.

3

2. INTENDED USE

The machine relates to equipment for the domestic individual use.

The hand-fed machines are used for processing of wood and analogous hard materials

(cardboard, plywood, wood chip boards) by planing, cutting, milling and drilling in order to

give them the required shapes and sizes.

Do not use the machine for other purposes. It is not allowed to process metals, stone,

asbestos-cement materials, soft plastic and rubberlike materials

With appropriate adjustment the machine can perform the following types of processing:

planing (jointing) on surface or along ribs;

angular planing (jointing, along ribs);

longitudinal and cross cutting;

longitudinal angular cutting with the use of a ruler;

angular cross cutting with the use of device;

milling with disc cutters;

milling with end cutters;

drilling.

3. GENERAL INFORMATION

The machine can be operated outdoors, under cover, indoors, except for residential premises.

Climatic service conditions:

altitude above the sea level – up to 1000 m;

environment temperature from +5 to +40°С;

environmental relative humidity – up to 80%, at a temperature of +20°С.

It is not allowed to operate the machine under the impact of drops and splashes, as well as

outdoors during rain, fog, snowfall, strong wing, and storm.

The power of the machine is supplied by a single-phase AC with an earthed positive earth.

BELMASH SDM-2200 и BELMASH SDM-2500 machines shall be used in the electrical grids

with a nominal impedance z

sufficient for the mentioned above machines with Electric Inspection Service.

Type of engine – asynchronous, single-phase, with the working capacitor, intermittent

operating status – S6-40%.

The equivalent and maximum sound levels are as follows: 80 dBA and 90 dBA relatively.

The machine has a built-in disconnect device from the power supply during

engine overheating. Restarting of the machine can be performed after the electric motor has

cooled down to the ambient temperature.

=0,354 ohm. The user must agree on the rated load capacity

max

asynchronous

To connect the external exhaust units in order to collect dust and cutting wastes, the

woodworking machine has three pipes:

a pipe with 63 mm in diameter on casing for chip removing 24 (Fig. А);

a pipe with 38 mm in diameter on casing of saw blade 30 (Fig. А);

a pipe with 28 mm in diameter on fencing of saw blade 29 (Fig. А).

The external exhaust unit should be suitable for removing cutting wastes.

4

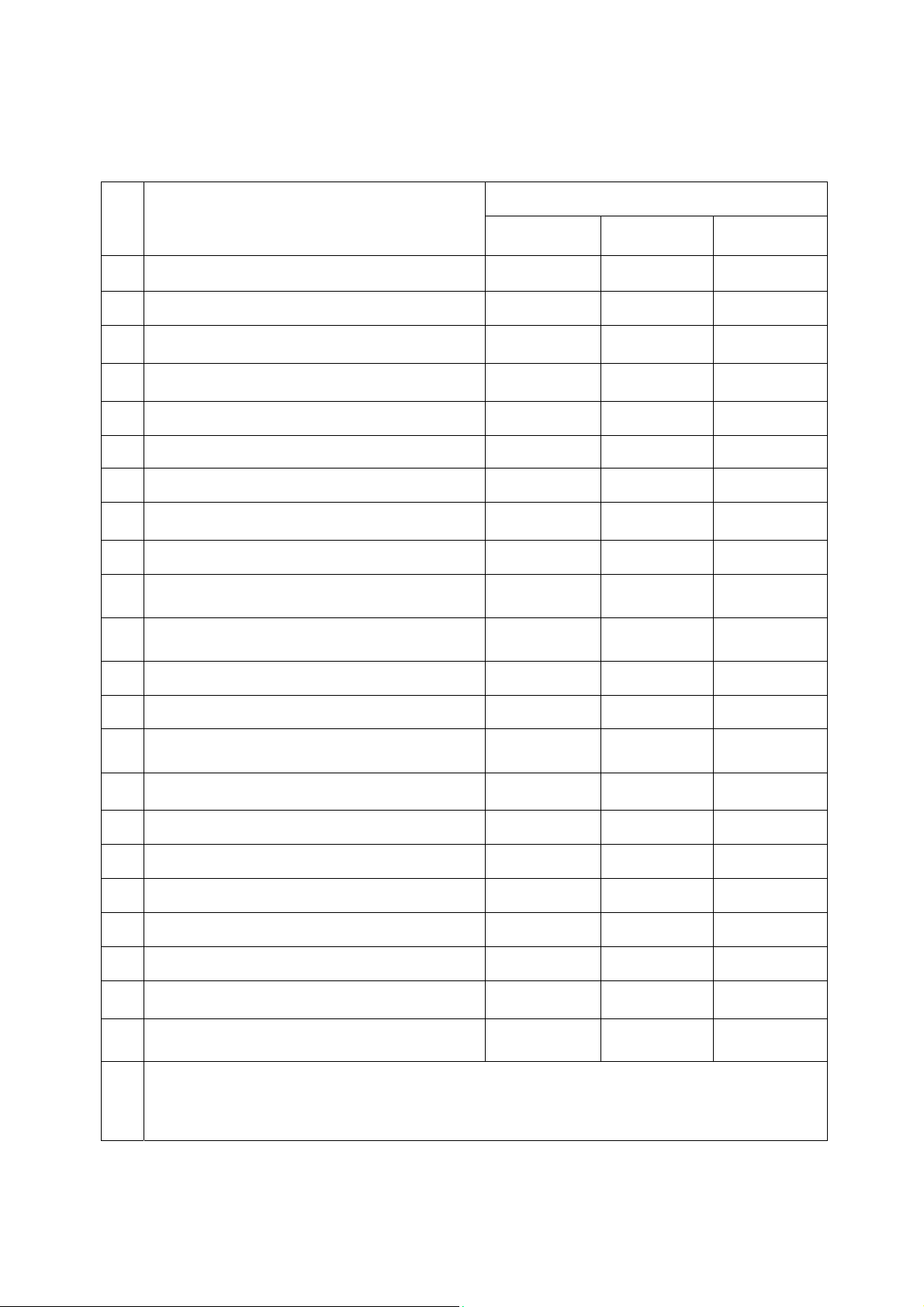

4. MAIN PARAMETERS

Main parameters are specified in the Table 1.

Parameters

№ Name

1 Max. planing width per pass, mm 230 250 270

2 Range of planing depth per pass, mm 0÷3 0÷3 0÷3

Max. height of the work piece pressed by a holding

3

down device, up to, mm

Max. uncut dimensions, length×width×height

4

(depth), mm

5 Range of cutting depth, mm 0÷85 0÷100 0÷117

6 Range of cutting depth per pass, mm 250 280 315

7 Diameter of disc cutter 125 125 125

Diameter of mounting bore of disc cutter/ saw

8

blade, mm

8 Diameter of end cutter, mm 612 612 612

BELMASH

SDM-2000

65 65 65

2000×230×85 2000×250×100 2000×270×117

32 32 32

BELMASH

SDM-2200

Table 1

BELMASH

SDM-2500

Range of longitudinal cutting angles and planing

9

with the use of a ruler, degrees

Range of cross cutting angles with the use of a

10

device, degrees

11 Cutting table dimensions, mm 732×456 802×492 872×532

12 Dimensions of tables during planing, mm 760×247 830×267 900×287

13 Milling table dimensions, mm 470×190 470×190 470×190

Rated idle RPM of a knife’s block and end cutter,

14

15 Rated idle RPM of a saw blade and disc cutter, min-1 2850 2850 2850

16 Rated consumed power, W 2000 2200 2500

17 Rated frequency, Hz 230 230 230

18 Rated frequency, Hz 50 50 50

19 Overall dimensions, L×B×H, mm 806×793×445 876×829×460 949×849×512

20

-1

min

Setting dimension, L

for the installation of the machine), mm

(min. the size of the site

1×B1

0÷45 0÷45 0÷45

–45÷45 –45÷45 –45÷45

7700 7700 7700

430×206 430×226 441×246

21 Weight of machine including devices (net/gross), kg 52,4/55,3 56,1/59,2 61,3/64,9

Limit deviations of linear and angular dimensions do not exceed ±5%

Limit deviation of the rotating frequency does not exceed ±5%

Limit deviation of the power consumption +15%

5

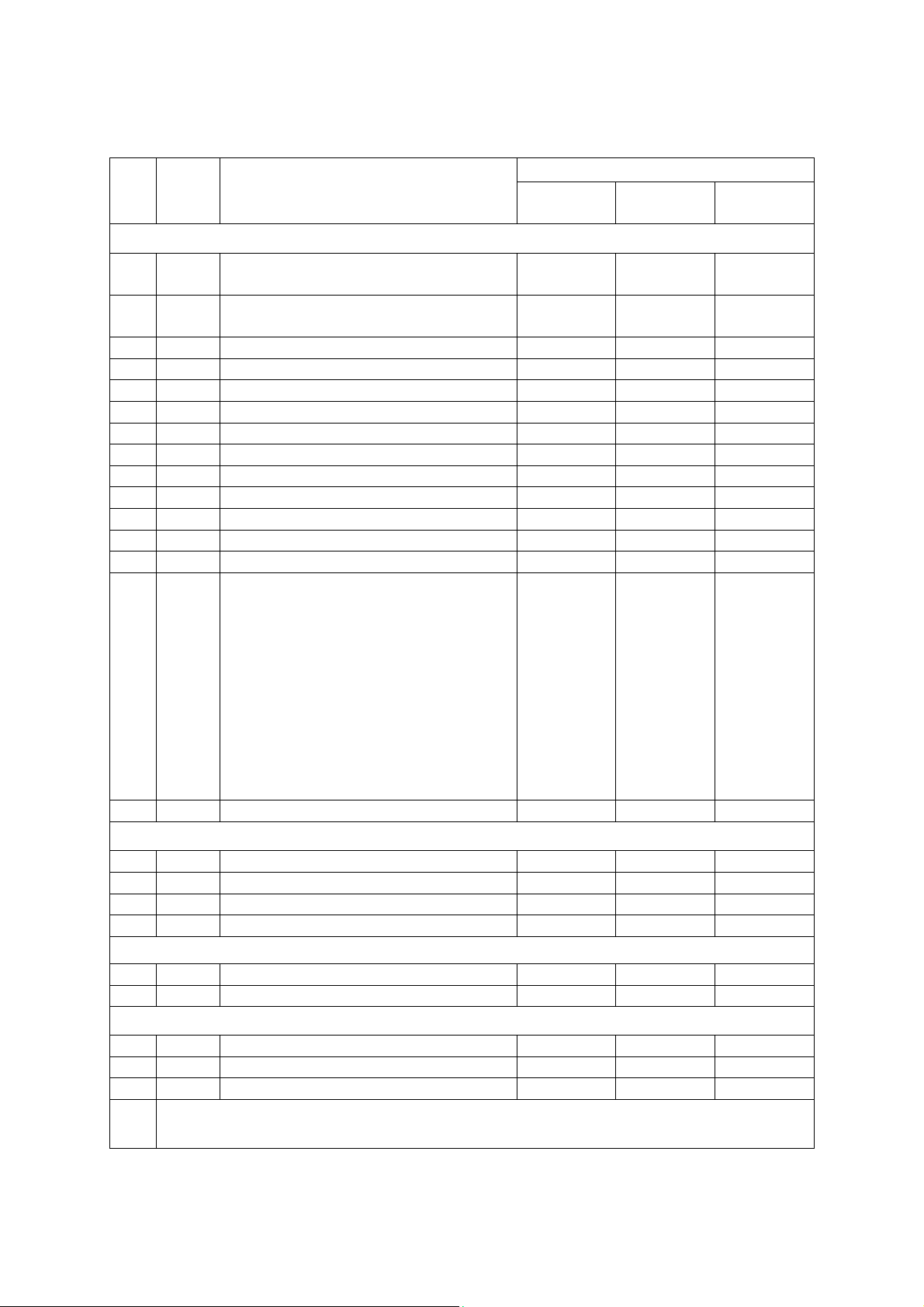

5. LIST OF STANDARD EQUIPMENT

Quantity, pсs

№ Item Name

Devices, tools, fencing

1 -

2 28, 29

3 11, 12 Angular bump as a set with a ruler 1 1 1

4 34 Device for angular cross cutting 1 1 1

5 41-44 Vertical holder 1 1 1

6 56 Chuck screw wrench 1 1 1

7 68 Hook wrench 1 1 1

8 7 Knife’s block fencing 1 1 1

9 8 Bracket 1 1 1

10 46 Milling table 1 1 1

11 51 End mill fencing 1 1 1

12 45 Insert for milling 1 1 1

13 24 Casing 1 1 1

14 22

74

75

76

77

78

79

23

80

81

23а

15 - Pusher 1 1 1

Standard articles

16** 25 Circular saw blade 1 1 1

17 55 Drilling chuck 13-М12×1,25 1 1 1

18** - Fixing arrangements 1 set 1 set 1 set

19 - Hex key 1 1 1

Documentation

20 - Operating manual 1 1 1

21 - Warranty certificate 1 1 1

Personal protective equipment

22 - Earplugs 1 set 1 set 1 set

23 - Protective goggles 1 1 1

24 - Mask 1 1 1

** – Fixing arrangements can be installed on the machine or its tools and devices

Portable multifunctional woodworking

machine

Fencing of saw blade and disc cutter

together with the splitting knife

Holding down device

Spring box

Right support

Left support

Rotation axis

Clamp axis

Clamp handle

Screw М5×12

Screw nut М8

Spring washer 5

Spring washer 8

BELMAS

SDM-2000

1 1 1

1 1 1

1

1

1

1

1

1

1

4

2

4

2

BELMASH

SDM-2200

1

1

1

1

1

1

1

4

2

4

2

Table 2

BELMASH

SDM-2500

1

1

1

1

1

1

1

4

2

4

2

6

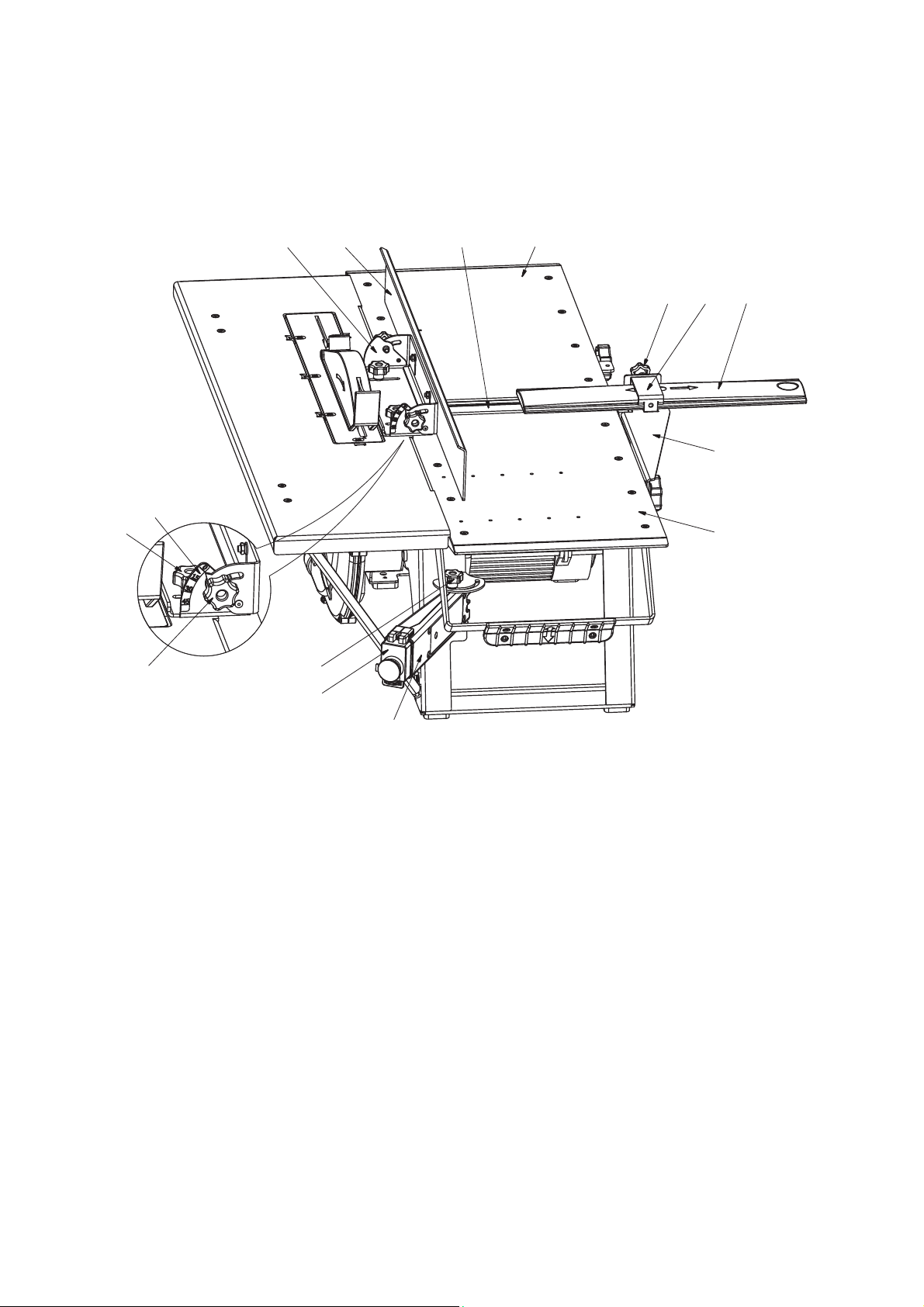

6. BASIC COMPONENTS

16

17

13

11

21

20

12

1

3

10 9 7

8

2

18

Fig. A

Planing function

1 – Knife block

2 – Loading table

3 – Outfeed table

7 – Knife’s block fencing

8 – Swing bracket for knife’s block fencing

9 – Clip for fixing of knife’s block fencing

10 – Flywheel for clip fixing

11 – Angular bump (vertical)

12 – Gib stick of angular bump (vertical)

13 – Cutting/planing angle scale (vertical)

16 – Flywheels for angular bump fixation (vertical)

17 – Flywheels for cutting/planning angle fixation (vertical)

18 – Swivel control panel

20 – Safety switch cover

21 – Flywheel for control panel fixation

7

В1

24

27

31

59

60 30

28

25

37

36353429 12

26

33

38

32

39

B2

25 67

32

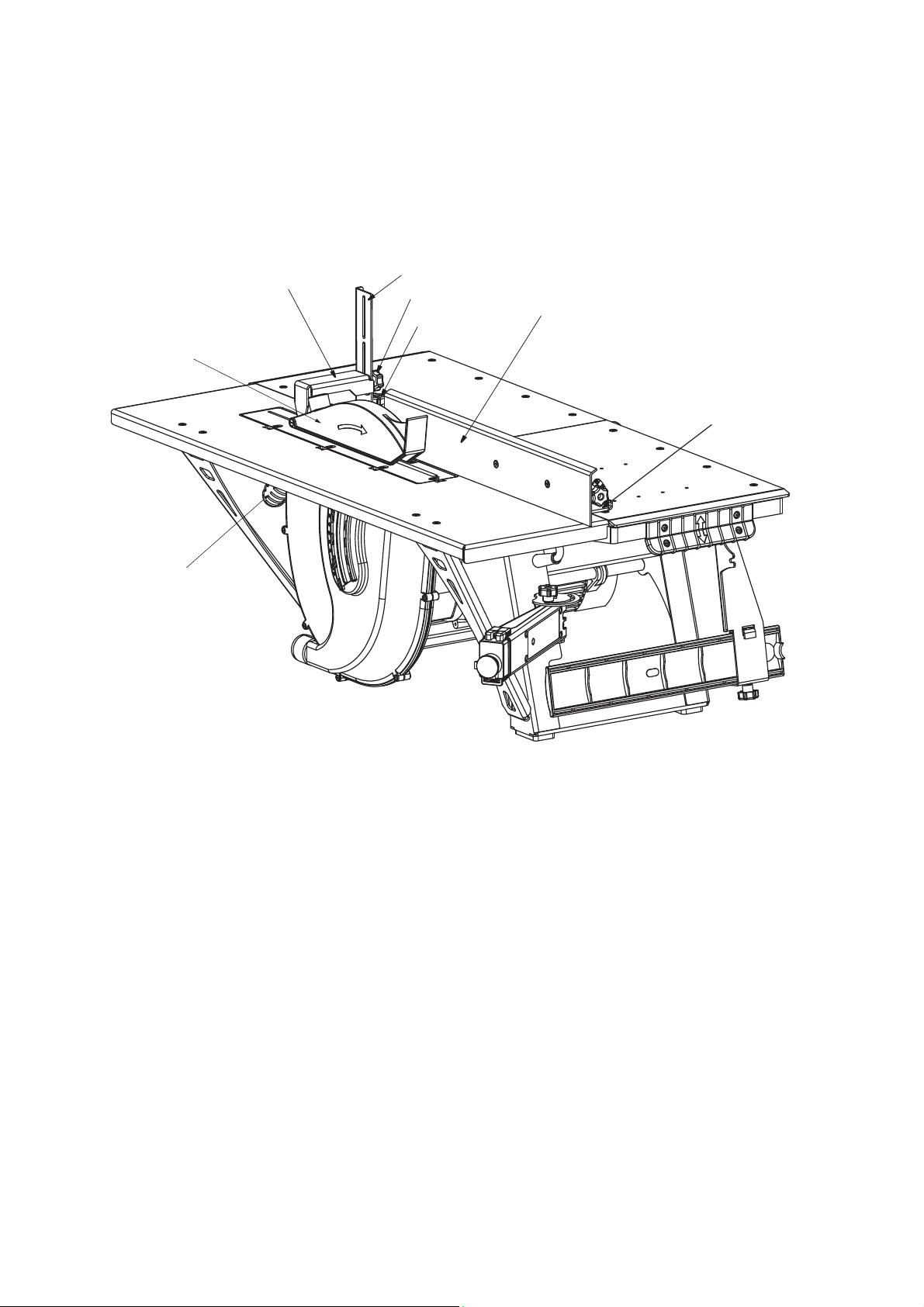

Fig. В1, B2

Cutting function

12 – Gib stick of angular bump (vertical)

24 – Pipe for cutting wastes

25 – Saw blade

26 – Cutting table

27 – Stick for lifting and lowering of saw blade

28 – Splitting knife

29 – Fencing of saw blade / disc cutter above the table

level

30 – Fencing of saw blade / disc cutter below the table

level

31 – Cutting table mounting

32 – Flywheel for fixation of saw blade / disc cutter

33 – Hold slide for angular cross cutting

34 – Device for angular cross cutting

67 40 45 32

35 – Angular cross cutting scale

36 – Flywheel for bum fixation

37 – Cutting depth scale

38 – Depth scale of milling with disc cutter

39 – Tool-slide indicating cutting/milling depth

40 – Disc cutter (not included in the scope

of delivery)

45 – Insert for cutter guard below the tale level

56 – Box wrench

59 – Screw nut for splitting knife fixation

60 – Washer lock for splitting knife

67 – Screw nut for saw blade/ disc cutter fixation

68 – Hook wrench

68

56

8

27

29

42

41

44

43

12

11

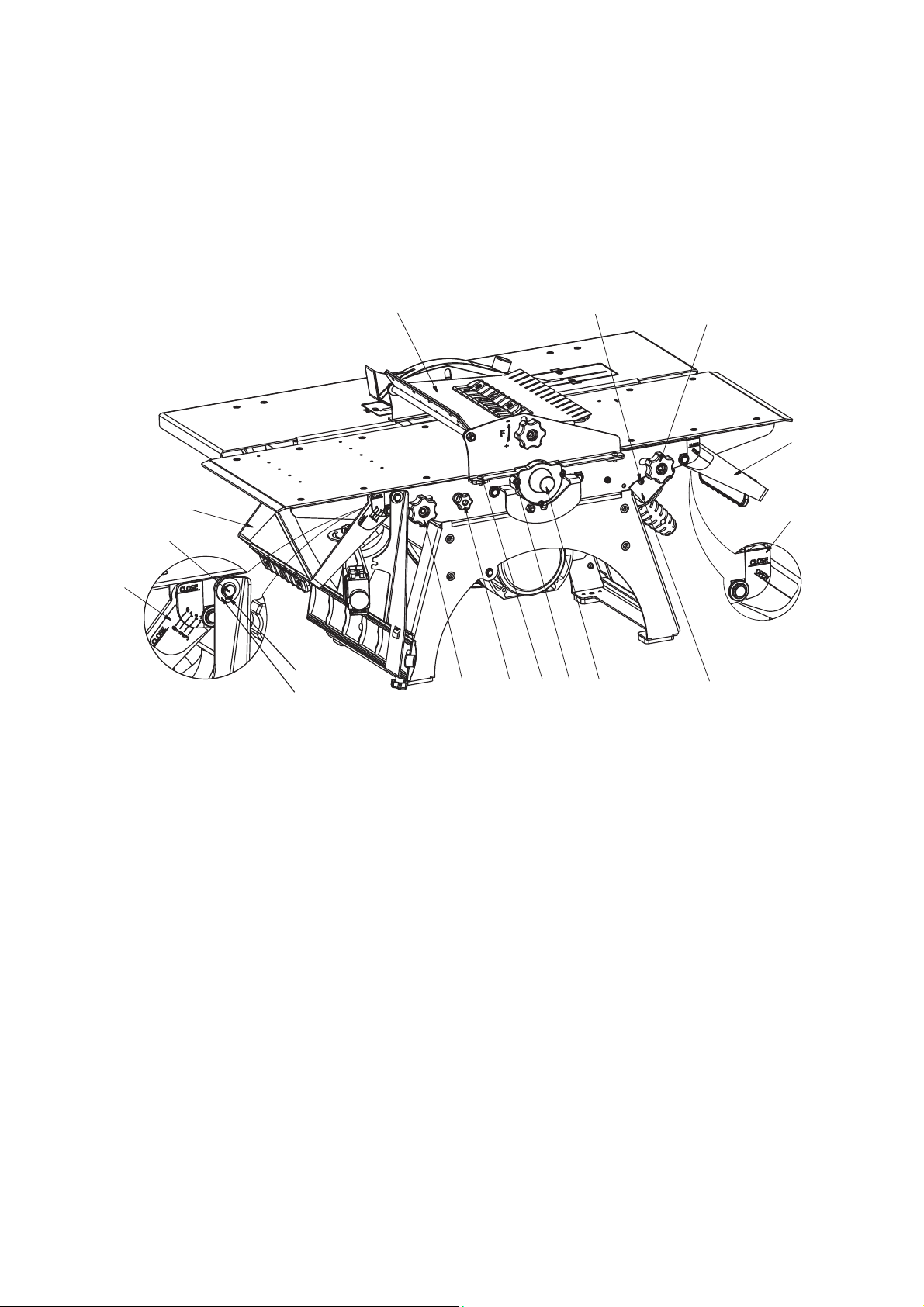

Fig. С

Milling with disc cutter

11 – Angular bump (vertical)

12 – Gib stick of angular bump (vertical)

27 – Stick for lifting and lowering of saw blade

29 – Fencing of saw blade / disc cutter above the table level

41 – Vertical rod for fencing of disc cutter

42 – Horizontal rod for fencing of cutter

43 – Flywheel for vertical rod fixing

44 – Flywheel for horizontal rod fixing

9

64

55

52

53

51

12

47

58

54

48 50 46 49

Fig. D

End milling function

11 – Angular bump (vertical)

12 – Gib stick of angular bump (vertical)

16 – Fixing handwheels of angular support (vertical)

46 – Milling table

47 – End milling cutter (not included in the scope of delivery)

48 – Brackets for cutter accessory

49 – Lever-stick for lifting/lowering/of milling table

50 – Flywheels for fixation of cutter accessory

51 – Fencing of end milling cutter

52 – Lock bracket for operating mode disabler

53 – Rod for operating mode disabler

54 – Fixing screws for brackets of cutter accessory

55 – Drill chuck

58 – Wrench for drill chuck

64 – Fixing screws for end mill fencing 51/knife’s end block fencing 65

16

11

10

14

63

22

4

62

6

19

61

23

64

66

65

24

6

5

15

Fig. Е

Planing with holding down device

4 – Lever-stick for lifting and lowering the loading table and transferring the machine

5 – Lever-stick for lifting and lowering the outfeed table and transfer machine

6 – Flywheels for fixing loading and outfeed tables

14 – Planing depth scale

15 – Loading table scale

19 – Handwheel for fixing bracket 8

22 – Holding down device

23 – Fixing screws for holding down device

24 – Pipe for cutting wastes

61 – Washer locks for swing bracket of knife’s block fencing

62 – Lock ring for swing bracket of knife’s block fencing

63 – Axis for bracket 8

64 – Fixing screws for end mill fencing 51/knife’s end block fencing 65

65 – Knife’s end block fencing

66 – Fixing screws for cutting wastes pipe 24

11

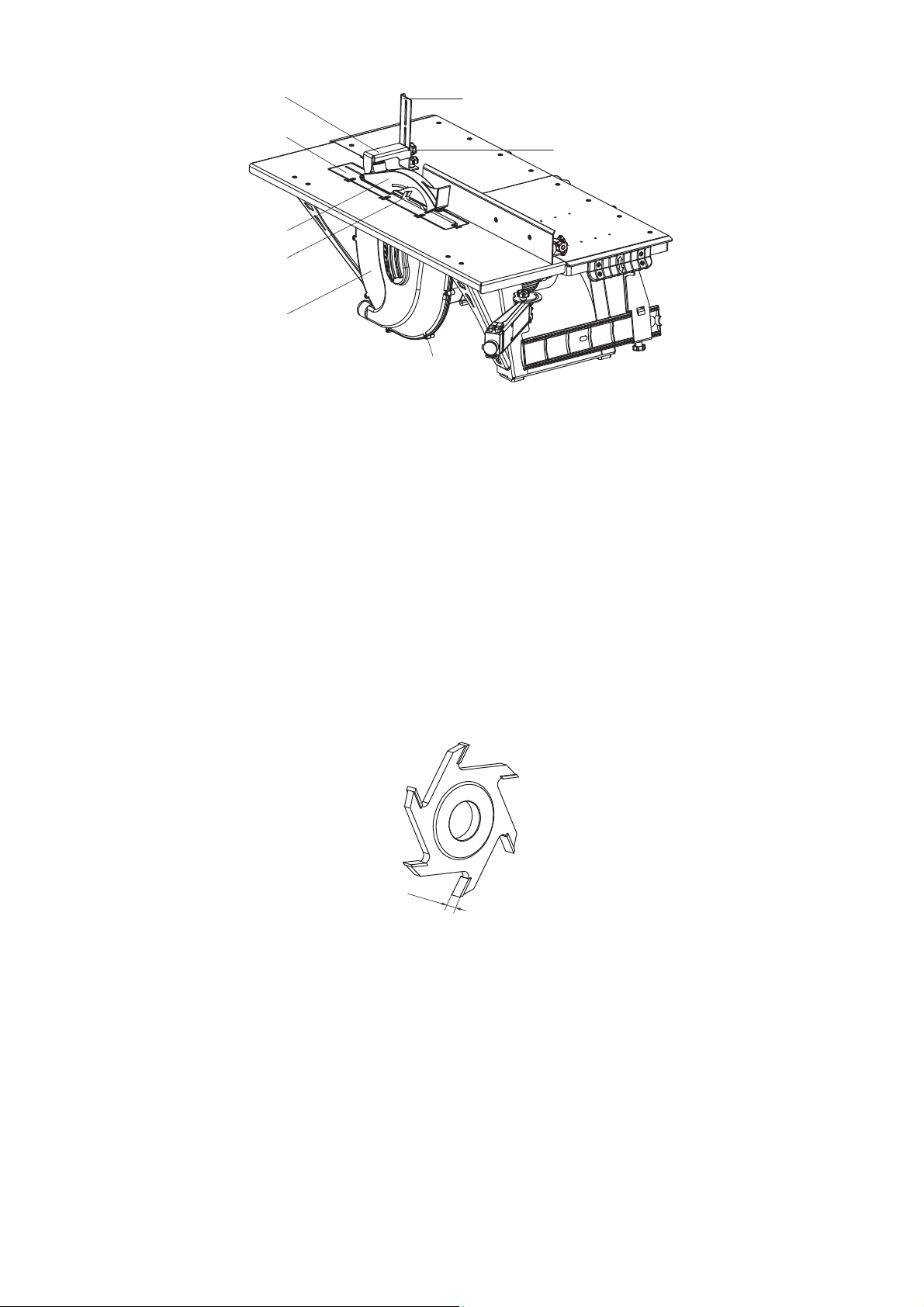

7. MACHINE STRUCTURE

The machine is an electromechanical device. The woodworking machines are powered with

the help of asynchronous electromotor. Rotation from the motor to the knife block (outlet

end of the knife block) and saw blade is performed with the help of multiple vee belt drive.

The belt covers driving pulley and two driven pulleys. The first of the driven pulleys generates

the rotation of the saw blade, and the other one generates the rotation of the knife block and

the end mill cutter. The belt tension is performed automatically as a result of the

electromotor and traction coil weight.

The woodworking machines are equipped with the interlocking devices, which allow

performing only one type of processing: cutting/milling with disc cutter or planning/milling

with end mill cutter.

The machine has a stationary table for cutting and two replaceable tables for planning

(outfeed and loading tables). Planing tables, when used in cutting mode, complement cutting

table.

In the planning mode, the loading and outfeed tables are mounted at the level of slicing

blade cut. Besides, the front table can move down below the level of the slicing blade cut.

That provides the necessary planning depth.

In the cutting mode, the planning tables are mounted at the level of cutting tables, forming a

single-piece area of cutting table. In this case, planning tables cover the rotating cutter block,

ensuring safe operating. Displacing of tables is performed with the help of the in-built leversticks. Such a construction helps to easily and quickly readjust the machine to the necessary

type of processing.

Machine stop has special protection from spontaneous shutdown. It is installed on the

mobile bracket, rotating to ensure accessible switch-on/switch-off of the machine.

The tables serve as a basic supporting surface for a workpiece.

The machine has an angular bump with a ruler and a device for angular cross cutting to

ensure the right location of the workpiece to a cutting tool and the forward, straight,

longitudinal motion.

In order to avoid saw blade jamming during cutting, there is a splitting knife in the machine

construction.

The woodworking machine is equipped with protection devices to prevent access to rotating

parts of the device.

The design includes portable hinged guard to prevent access to the cutter block.

To prevent access to a saw blade /disk cutter, stationary fencing is located below the cutting

table and movable fencing – above.

The design includes end mill fencing to prevent access to end mill/drill.

To prevent access to the end of the rotating cutter block (while the milling device is not

operated) – stationary protection device – end mill fencing.

The machine is equipped with measuring scales, indicating the cutting depth, milling with

disc cutters and planning depth.

12

8. SAFETY ISSUES

Before starting to use the machine the user shall take into account his physical state,

qualification and complexity of tasks. Persons operating the woodworking machines must be

at least 18 years of age and must study the operating manual.

IT IS FORBIDDEN:

to work under the influence of alcohol or other intoxicating substances;

to expose the machine to dripping and splashing, as well as using it outdoors during rain

and snowfall;

to leave the machine unattended while it is connected to the supply mains;

to provide access to the machine to people, who do not have any professional knowledge

in this sphere;

to use the machine for purposes other than that intended;

to process metals, stones, asbestos-cement materials, soft plastic and rubberlike materials.

IT IS FORBIDDEN to use the machine if any of the following problems occur during its

performance:

damage of plug-and-socket connection, power cord;

damage of ground circuit;

if you smell fume or odor, typically occurring during burning insulation;

failing operation of the switcher;

formation of loud noise, hammering, vibration;

damage or cracks in the basic parts, fencings, casings.

The machine must be disconnected using the switch in case of spontaneous stop (during

rotating parts jamming, etc.). Always place the appropriate cover over the switch during work

breaks.

When connecting the machine it is recommended to use automatic safety fuse or fuse with a

rated current equal to 16А.

Use the plug to disconnect the machine from the supply system:

while changing the working tool (disc cutter, knifes, etc.), installing accessories or

adjusting;

while transferring the machine from one working place to another;

during work breaks, when the work is completed;

during technical maintenance;

while removing cutting wastes.

Power cord of the machine must be protected from accidental damage (it is recommended

to hang it). Direct contact of the electrical cord with hot and oily surfaces is forbidden.

While working outdoors it is permitted to use the original, app

cord.

Always make sure that the workpiece does not contain nails or foreign objects.

When processing short and narrow pieces use a secure workpiece infeed (paragr. 8.6).

ropriately marked extension

Do not wear too loose clothing and jewelry. They can get to the moving parts of the machine.

When working outdoors it is recommended to use gloves and slip-resistant footwear. Wear

appropriate personal protective equipment and head covering.

13

To ensure high-quality and safe operation, the cutting part of the working tool must be sharp

and clean. Follow the instructions to replace the accessories.

8.1 Workplace requirements

The workplace should be determined taking into account the location of the workpieces ,

direction of their movement, and junkyard location;

Space around the entire perimeter of the working tables should be empty. Working

clearance is necessary for direction, infeeding and unloading of workpieces taking into

account their overall dimensions and weight;

The floor must not be slippery or have any obstacles;

Keep the machine and workplace clean;

The workplace should be well lit by natural sunlight or artificial light. Using fluorescent

lighting causes stroboscopic effect that may lead to incorrect identification of rotating

direction of moving machine parts;

Ensure proper ventilation when working indoors, for example, with the help of air vent or

by proving air supply;

Do not work in the rooms with explosive or chemical environments;

Comply with safety regulations when working indoors. A fire extinguisher is a must.

8.2 Additional safety measures

Keep children and unnecessary persons away from a working area;

Ensure you always have a firm and safe footing. Do not attempt to reach the object that

are out of distance;

When working avoid contact with grounded devices (for example: pipelines, electric

cookers, refrigerators );

Do not stand in the area of the plane of saw blades. Keep to the left or to the right side

from them;

Please attend, mind what you do, do not use the machine when tired;

Do not use damaged or distorted saw blades and knives;

Use the saw blades, knives, cutters and equipment, recommended by the manufacturer;

Notice that the choice of the saw blade depends on the work material;

Use the splitting knife and adjust it in the appropriate manner;

Use head guard (casing) of the saw blade and adjust its location appropriately;

Do not overload the machine;

Do not process too small and too short workpieces;

Replace the plastic insert of the saw blade when it is worn out.

8.3 Operational hazards

The following types of hazards may appear even if the machine operates properly:

Risk of injury from a flown away workpiece;

Risk of injury from breaking parts of the workpiece;

Risk of noise and dust;

Danger of electric shock due to improper laying of the power cord.

To reduce the noise impact, when operating at the machine, always wear personal protection

equipment to prevent hearing damage (earplugs). It is recommended to use a dust mask to

protect the respiratory tract from dust particles.

14

The figures of equivalent and ceiling sound level (p. 3) are the levels of radiations but are not

necessarily the safe operating levels. Despite there is a correlation between levels of radiation

and noise impact, they can be reliably used to determine if further protection measures will

be required.

Factors that influence on the actual level of noise impact on the user include not only the

characteristics of working space (open air, under cover, enclosed space and its sizes), but also

other noise sources, namely, the noise from the other related processes. This information

allows the user of the machine to make a risk assessment and take care of the necessary

safety precautions.

Precautionary measures herein refer to the reducing of the noise dose by cutting time spent

in the work area, using of individual protective equipment such as earplugs, hearing

protectors, etc.

Allow only qualified persons to inspect and service the machine and use only original spare

parts.

8.4 Workpiece requirements

The workpiece weight must not exceed 50 kg.

The maximum workpiece dimensions are listed in Table 1. When processing workpieces of

greater length, it is necessary to use special trays that should be installed under the hanging

end of the workpiece, or work in a pair with someone. The minimum height of the workpiece

during planing or sawing should be not less than 5 mm.

Workpiece should be checked for the presence of metallic or mineral inclusions (nails,

staples, splinters, stones etc.) Do not process materials containing cracks, black knots, rot of

wood or other wood defects.

IT IS FORBIDDEN: to cut flat the workpiece (“round wood”) without a special carriage (not

included in the scope of delivery).

When crosscutting the “round wood”, supply is performed by moving the workpiece along

the table, rather than by rolling.

The workpiece shall not be wet. The recommended humidity should be up to 12%.

8.5 Working stance and workpiece supply

The proper working stance of the user is standing position. To supply workpieces to the

machine, the user should stand aside, next to the workpiece.

When jointing, move the workpiece along the loading table, pressing it by ruler. It is

necessary to keep the fingers together and hold the workpiece with both palms at the top.

Proper hand position is when one hand is on the upper workpiece sawn face, above the

loading table.

It is necessary to plane the workpieces along the full length without moving it back over the

rotating knife block. The workpieces with a thickness less than 50 mm should be planed with

the help of the holding-down device (p. 10.1.6).

When sawing and millingб the workpiece should be kept with fingers and moved smoothly

along the loading table, without cramping it, with the help of the ruler and cross cutting

device.

15

Keep your hands at a safe distance from the cutting place.

The workpiece supply should be steady (without jerks). The table speed should provide the

smooth running of the machine to avoid overloading.

To process short workpieces (with length less than 300 mm), use special devices for secure

workpiece supply (pushers).

8.6 Devices for secure supply of the workpiece

To ensure secure supply, use wooden pushers that are designed to fit the specific workpiece.

The pushers are made by the user himseft. The minimal length of the pushing part should be

at least 400 mm.

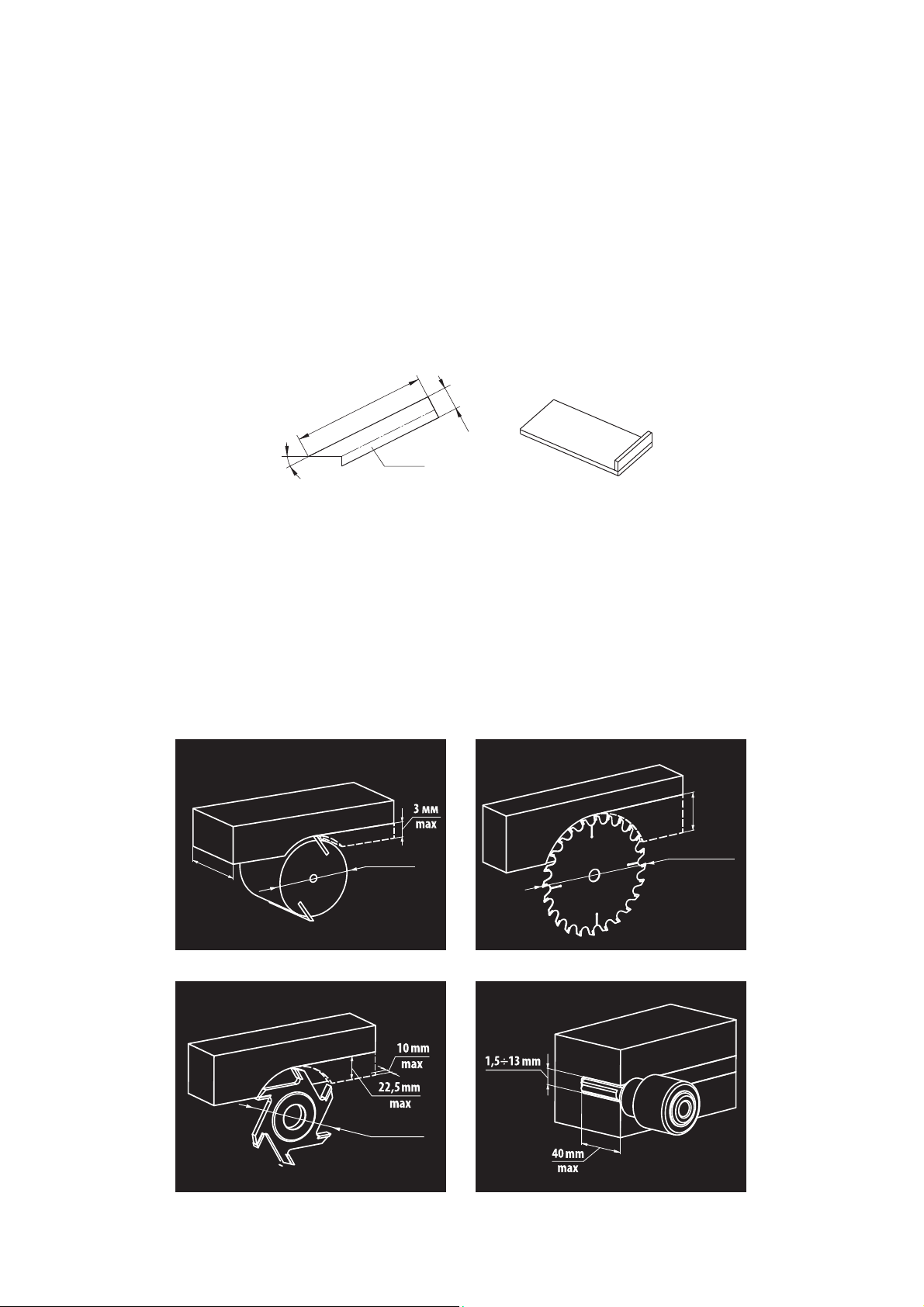

The examples of the pushers are shown in the Fig. F.

50

400

90˚

25˚±5˚

S=25

Fig. F

Pushing rails

9. MARKING AND PACKING

There is a plate with information about the parameters of the power supply on the machine

stand. It is recommended to comply with these requirements when connecting the machine

to the network.

It is necessary to observe the symbols on the packaging during transportation and storage.

85÷117 mm

Ø

250÷315 mm

230÷270 mm

Ø

55 мм

Ø

125 mm

16

Consider the tool sizes and do not use adapters for them. Use the tool recommended by the

manufacturer. When working, consider the maximum allowable finished dimensions.

Information on the types of processing is listed on the label on the fencing of the 30 (Fig. B1)

saw blade below the table level.

There is a threat-warning label on the swivel control panel 18.

Do not put your hands in the working area the machine is switched on. It

may result in risk of injury due to rotating parts.

Use a dust mask.

Always wear personal protection equipment to prevent hearing damage. The

noise exposure can cause permanent hearing loss.

Wear eye-protection goggles.

Never dispose this tool together with unsorted municipal waste. In

accordance with the European Directive 2002/96/EC on waste electrical and

electronic equipment and its implementation into national law,

nonfunctioning power tools must be collected separately and recycled in an

environmentally suitable manner.

There is an icon on the lever 27 showing moving direction when lifting or

lowering the saw blade.

The machine is packed in an individual carton box with two handles.

10. SETTING-UP PROCEDURES

During setting-up procedures it is necessary to perform:

assembly;

installation;

knife setting;

startup.

10.1 Assembly

First of all, you must set up the machine on the table and assemble the auxiliary machinery

and fencing included in the scope of delivery.

Adjust the saw blade insert (p. 10.1.1);

17

Install fencing of saw blade together with the splitting knife (p. 10.1.2);

Install the device for angular cross cutting (p. 10.1.3);

Install the knife’s block fencing together with the bracket (p. 10.1.4);

Install the milling table (p. 10.1.5), in case you are going to perform planning with end mill

cutter or drilling;

Assemble the holding down device (p. 10.1.6).

10.1.1 Adjusting the saw blade

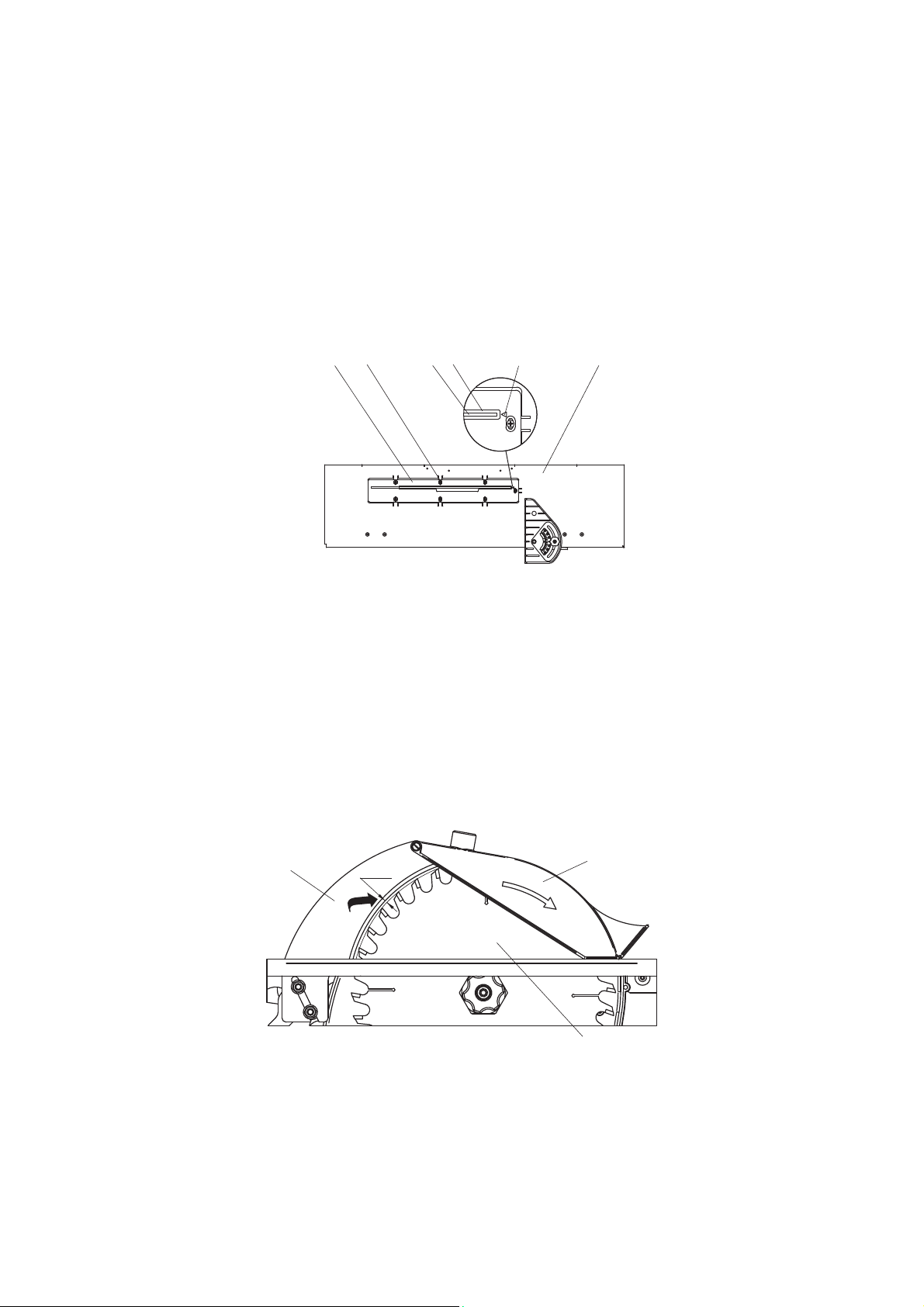

The saw blade insert 31 must be adjusted so that the mark “▼” 31b (Fig. G) shall coincide

with the center of the saw blade 25, and the slot 31 shall be parallel to the plane of the saw

blade 25. It requires releasing the screws 31c, adjusting the insert 31 and setting it back.

25

31c31

31a

31b

26

Fig. G

Adjusting the saw blade insert

25 – saw blade, 26 – cutting table; 31 – cutting table insert; 31а – slot; 31b – mark; 31c – screws

10.1.2 Installing the fencing of saw blade with the splitting knife

In order to install the fencing of saw blade with the splitting knife it is necessary to pull its

end with the sweep slot to the slotted hole of the insert and push on two threaded rods until

the sweep slot is positioned between the washers 60 and screw nuts 59 (Fig. B), pre-installed

on the threaded rods.

Next, you need to adjust the position of the splitting knife.

28

5 mm min

Fig. H

Radial distance

25 – saw blade, 28 – splitting knife; 29 – fencing of saw blade

18

25

29

This requires inserting the saw blade to the maximum cutting depth. The splitting knife shall

be placed symmetrically in the center in the plane of the saw blade, providing radial distance

between the splitting knife 28 and the crown of the saw blade equal to 5 mm (Fig. H). It is

achieved by moving the washers with screw nuts 59, 60 (Fig. B1) and the splitting knife 28

with a sweep slot along the threaded rods 59.

Fencing of saw blade shall be mounted on the machine during all types of processing.

10.1.3 Installing the device for angular cross cutting

Installation of the device for angular cross cutting 34 (Fig. В) is carried out by putting it into

the cam with a flange of the cutting table 26, which serves as a guideway for supplying the

workpiece along the cut line. To remove the device from the machine, perform the

mentioned above actions in the inverse order.

10.1.4 Installing the knife’s block fencing together with the bracket

9310

62

781963 61

Fig. I

Installing the knife’s block fencing together with the bracket

3 – outfeed table; 7 – fencing; 8 – bracket; 9 – clip; 10 – flywheel for clip fixation; 19 – flywheel for bracket fixation,

63 – axis; 61 – washer, 62 – lock ring

To install the knife’s block fencing, insert the fencing 7 (Fig. I) between the bracket 8 and the

clip 9 and then fix it with the help of the flywheel 10.

The bracket with the fencing should be installed on the axis 63 and fixed with the help of the

washer 61 and the lock ring 62.

The fencing should be installed on the plane of the outfeed table 3 and fixed with the

flywheel 19.

10.1.5 Installing the milling table

The install the milling table 46, fix it to the machine stand with cap screws 19 (Fig. D).

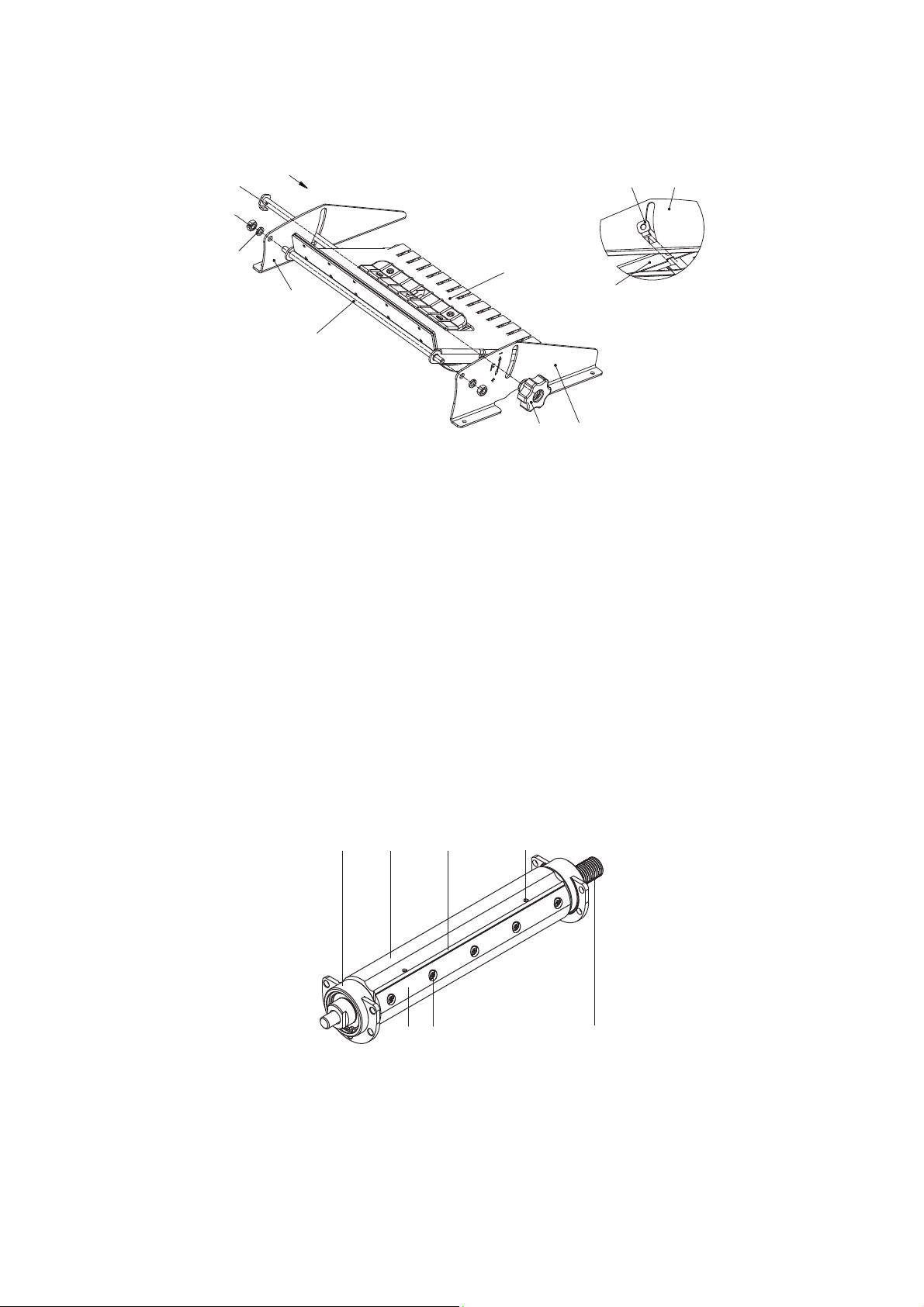

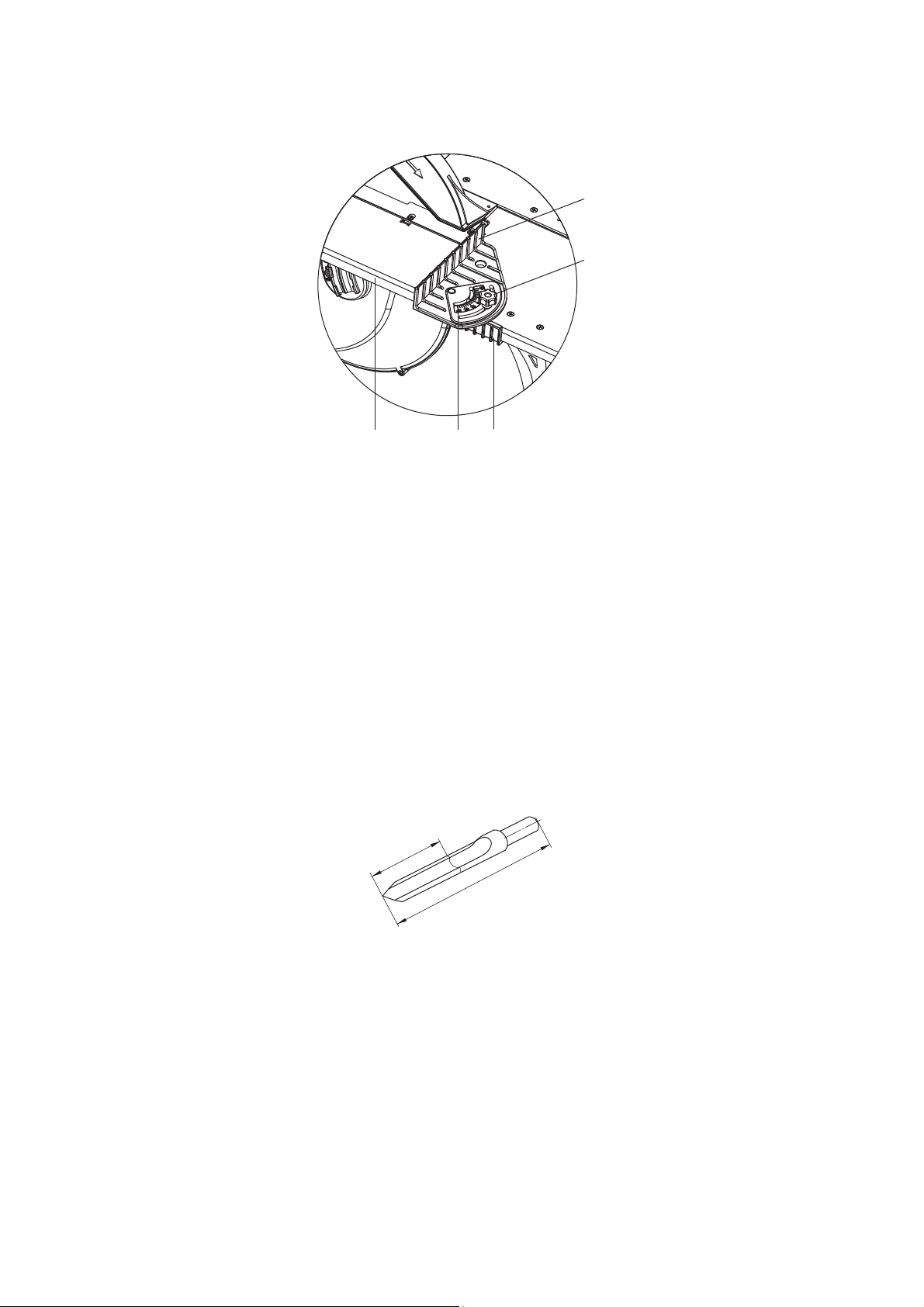

10.1.6 Assembling the holding down device

The holding down device 22 (Fig. E) is designed for safe processing of the workpieces with

19

the thickness less than 60 mm. It is shipped dismounted. The kit of parts (Table 2) is packed

A

A

in a separate box. The assembly of the holding down device is performed as shown in the

Figure J. To fix the holding device, use screws 23 and 8-mm washers.

78

80

81

76

77

74

79

78

74

75

76

Fig. J

Holding down device

74 – spring box, 75 – right support, 76 – left support, 77 – rotating axis, 78 – clamp axis, 79 – clamp handle,

80 – screw nut М8, 81 – washer spring

10.2 Setting up the machine

Install the machine on a freely accessible, sturdy, level surface. It is useful to additionally

scerw the machine with the help of mounting bolts (not included in the scope of delivery).

The holes in the bearing surface of the machine feet serve for mounting.

Check the intactness of the basic parts; fastening security of the separate parts; bolts, screws

and nuts tightening; locking; integrity of the supply cord, plug and socket; availability of the

safety fencing.

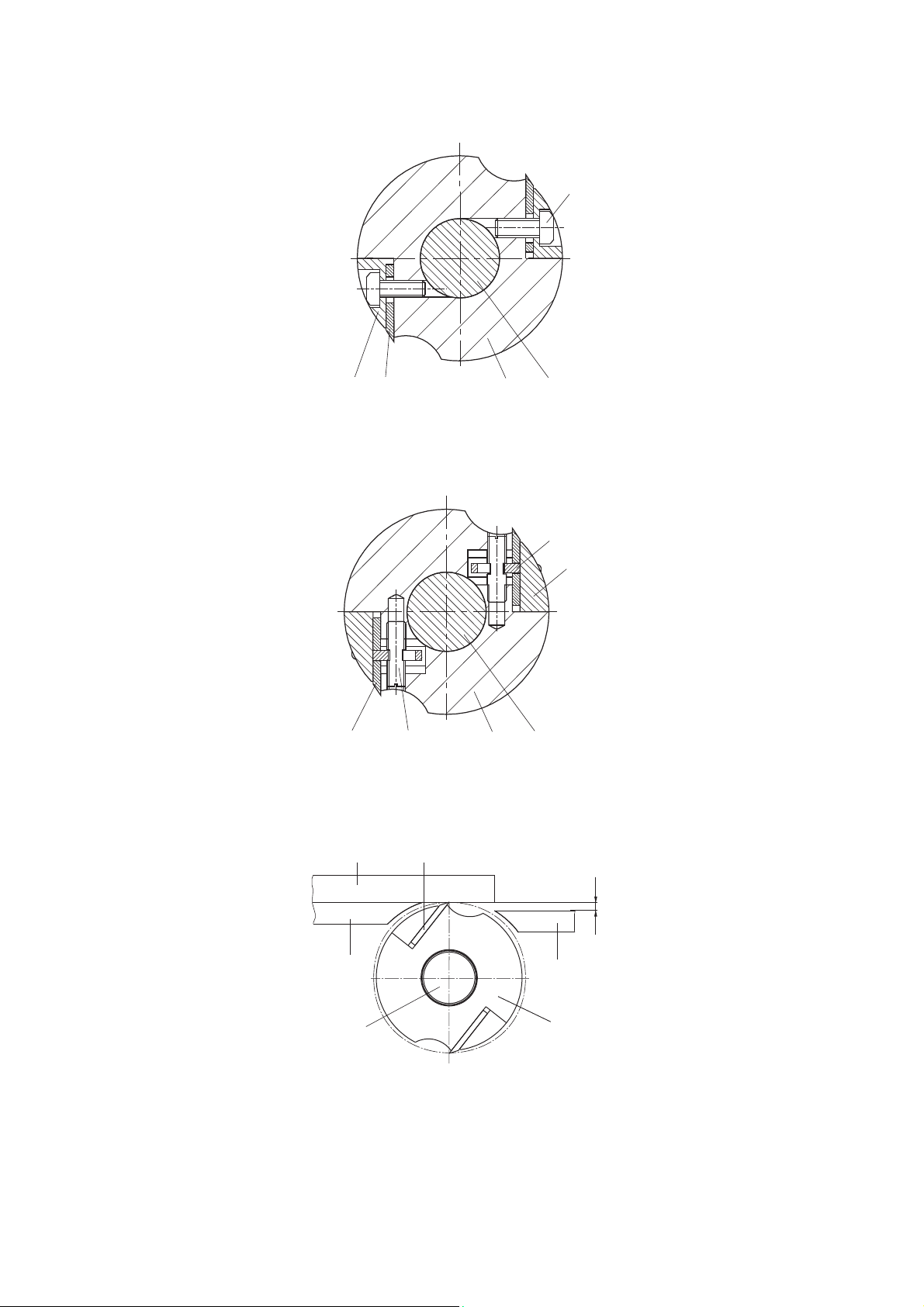

10.3 Installing and adjusting the knives

The knife adjustment is performed by consistent installation of each blade. It is necessary to

loosen the knife 70 by removing five screws 71 in advance. (Fig. K).

1a1b

70 72

69 71

1

Fig. K

The cutter block construction

1 – cutter block; 1а – block casing; 1b – end shields; 69 – knife holder; 70 – slicing blade;71 – fixing screw for the

knife holder; 72 – adjusting device

20

Adjust the knives by tightening / unscrewing the screws 71 so that the knife edge touch the

ruler 12, mounted on the receiving table 3 (Fig. N)

71

1a69 70 1

Fig. L

Knife mounting

1 – cutter block; 1а – block casing; 69 – knife holder; 70 – slicing blade; 71 – fixing screw for the knife holder

73

69

1a7270 1

Fig. M

Adjusting device

1 – cutter block; 1а – block casing; 69 – knife holder; 70 – knife; 72 – adjusting screw; 73 – flag

12 70

H

3

1

2

1a

Fig. N

Scheme of knife adjustment

1 –cutter block; 2 – loading table; 3 – infeed table; 12 – ruler; 70 – knife; Н – required milling depth

Fix the knife by tightening the binding screws 71. After that check the proper knife

21

installation. If required, repeat the installation again.

The cutting edge of properly installed knives should touch (up to 0,1 mm) the lower edge of

the ruler 12 during cutting block rotation.

10.4 Machine startup

Machine startup is performed with the help of the switcher after adjusting the processing

type. The switcher is located on the swivel control panel 18 (Fig. A) that has two positions:

1 position – to operate in the jointing and cutting mode. The swivel control panel with the

switcher is installed on the accessible area from the left side of the outfeed table 3;

2 position – to operate in the milling mode. The swivel control panel with the switcher is

turned and installed all the way to the right in the accessible work area.

To change the switcher position, release the flywheel 21, turn the swivel control panel with

the switcher and fix it again with the flywheel.

To start up the machine it is necessary:

to connect the machine’s plug to the mains;

to unlock and open the switch cover, push the green button.

To switch off the machine it is necessary to:

push the red button;

or close the switch cover.

The start-up time of the machine is less than 5 seconds. In case the machine fails to start, turn

it off with the switcher. If the problem remains, restarting is performed in no event sooner

than 1 min.

After the end of work, the switch cover must be shut off.

11. BASIC OPERATIONS

11.1 Рlaning (jointing) on surface, along ribs and at an angle (along ribs)

Before starting, it is recommended to make the following adjustments:

to install the planing table;

to adjust the planing depth;

to adjust and install the fencing;

to install the ruler;

to install the holding device (for workpieces with thickness less than 50 mm).

To switch to the planing mode it is necessary to lower the saw blade below the table level

until the indicator needle will be in line with the mark "min" on the cutting depth scale

(p.11.2.2).

22

11.1.1 Installing the planning table

The loading 2 and outfeed 3 tables should be installed at the level of the slicing blade cut (Fig. O).

To get that done:

loose the flywheels 6;

pull the locking clip 52 (horizontally) by holding it from the bottom, and lower the tables

by moving the lever-sticks 4 and 5 down against stop;

the bracket 8 with fencing 7 should be mounted on the plane of the outfeed planing table

3 and fixed with the help of the flywheel 19.

9362

5

4

7819 5214a14 6

Fig. O

Installing planning tables

2 – loading table; 3 – outfeed table; 4 – lever-stick of the loading table; 5 – lever-stick of the outfeed table;

6 – flywheels for loading and outfeed table fixation;7 – knife’s block fencing; 8 – swinging bracket; 9 – fixation clip;

14 – scale, 14а – survey-line of the planning depth; 19 – flywheel for bracket fixation; 52 – locking clip.

11.1.2 Adjusting the planing depth

To adjust the planning depth, perform the following (Fig. O):

unscrew the flywheel 6 of the loading table 2;

move the table to the desired planing depth (0÷3 mm) by moving up/down the lever-stick

4, aligning the survey-line 14a on the loading table with the appropriate value on the scale

14;

fix the loading table 2 in this position by tightening the flywheels 6 of the loading table.

11.1.3 Adjusting the fencing

The fencing 7 is designed to close those parts of the rotating cutter block which are not

located in the cutting area (inactive parts of the knife (cutter) block) while the machine is

running. (Fig. P).

While half-width planning, the fencing 7 should be moved to the required planning width.

To move the fencing 7 into the necessary position it is required:

to loosen the flywheel;

to move the fencing 7 along the cutter block in the direction of arrows 7а;

to tighten the flywheel.

23

When the work is completed and during work breaks, the fencing 8 should totally close

the cutter block.

10 7a

7

65

Fig. P

Using the fencing

7 – fencing; 7а – arrows; 10 – flywheel for clip fixation, 65 – knife’s end block fencing

11.1.4 Installing the ruler in the planning mode

The ruler 12 ready-fitted with the angular bump 11 is designed for positioning of the workpiece

relative to the cutter block. It provides the linear motion of the workpiece and performing the

planing operations at an angle to the edge of the workpiece.

The angular bump 11 is fixed to the cutting table with two flywheels 16. The ruler 12 can be

installed both perpendicularly to the table and angularly (Fig. Q).

16 11b

13

3

11c

11a

11

12

2

2а

17

Fig. Q

Using the ruler in the planning mode

2 – loading table, 2а – hole, 3 – outfeed table, 11а – slot; 11b – slot, 11с – screws with nuts; 12 – ruler, 13 – scale;

16 – flywheel; 17 – flywheel

24

To install the ruler 12 at an angle, it is necessary to loosen two flywheels 17, install the ruler

along the scale 13 at the desirable angle, and tighten the flywheels 17.

The ruler 12 should to be adjacent to the outfeed 3 table (at any turning angle). It requires

loosening the screws with nuts 11c, moving the ruler along the slots11a of the angular

bumps 11 to the necessary extent, tightening the screws with nuts 11c.

11.1.5 Installing the holding down device

The holding down device is used for workpieces with thickness equal to 5-60 mm.

Install the assembled (p. 10.1.6) holding-down device on the machine as shown the Figure E.

First, install the knife's block fencing 7 with the bracket 8 under the loading planing table 2

(Fig. R)

Before operating the holding down device, it is necessary to set the pressing force of the

workpiece. The pressing force is set by moving the pressure plate up/down.

Loosen the holder 79.

Move the pressure plate, holding its handle, at the height of the workpiece thickness.

Set the appropriate pressing force (so that the workpiece is not detached from the planing

tables and provides a normal pressing force to supply the workpiece to the work zone).

Fix the position of the pressing plate with the help of the holder 79.

11.2 Longitudinal and cross cutting

Before starting, it is recommended to make the following adjustments:

To install tables.

To adjust the cutting depth.

11.2.1 Installing the cutting table

3

26

2

4

8

7

Fig. R

The bracket position with fencing under the loading table

2 – outfeed table; 3 – loading table; 4 – lever-stick, 8 – bracket;7 – knife’s block fencing; 26 – cutting table

To install the cutting table, it is necessary to perform the following:

place the knife's block fencing 8 under the loading planing table 2. To do so, unscrew the

flywheel 19 (Fig.Е), fixing bracket, and place them under the table 2 (Fig. R) by turning the

bracket with fencing around the axis;

bring together the loading 2 and outfeed planing 3 tables, install them on the same level

25

with the cutting table 26 (the lines "close" on scale will coincide). To do so, unscrew the

flywheels 6, lift the lever-stick 4 and 5 (Fig. E), and then tighten the flywheels again 6. The

locking clip 52 will automatically block the planing tables 2 and 3.

11.2.2 Installing the cutting depth

25

27

29 12

37

32

Fig. S

Installing the cutting depth

12 – ruler of the angular bum; 25 – saw blade; 27 – lever for lifting and lowering the saw blade; 29 – fencing of saw

blade; 32 – flywheel for saw blade/cutter disc fixation; 37 – cutting depth scale

Cutting depth installation is performed only when the cutting and planing tables are

brought together and set to the same level.

Adjusting the cutting depth is made with the help of the lever 27 by moving it up/down, after

releasing the flywheel 32. The depth of cutting is set on the scale 37 and fixed by the flywheel

32.

11.3 Longitudinal angular cutting with the use of a ruler

The ruler 12 with an angular bump 11 (Fig. Q, S) is fixed to the planing loading table with the help

of the flywheels.

The distance between the saw blade and the ruler can be measured by moving the lower part

of the angular bump in slots and moving the holes 2a of the loading table 2. Thus, you can

set any cutting width.

The ruler is installed both perpendicularly to the table and angularly (p. 11.1.4) and should fit

to the table at any rotating angle.

11.4 Angular cross cutting with the use of device

To install the device, it is necessary to set the slide 33 (Fig. T) through the open edge of the

table so that the hoop on the bottom covered the leading edge 5 of the cutting table.

The bump 34 can be rotated relative to the slide 33, setting and fixing it perpendicularly to

the cut of the saw blade or angularly (–45° to +45°) to make the beveling cut. Install the

desired cutting angle, rotating the bump 34 and fixing it by the flywheel 36. Pressing the

26

workpiece to the bump 34, move the device along the guideway 26a in the direction of the

saw blade.

34

36

26а 35

33

Fig. Т

The device construction for angular cross cutting

26а – leading edge; 33 – bump slide; 34 – bump; 35 – scale; 36 – flywheel for bump fixation

11.5 Milling with end cutters/drilling

Before starting, it is recommended to make the following adjustments:

To bring together the loading 2 and outfeed planing 3 tables, install them on the same

level with the cutting table 26 as described in the paragraph 11.2.1;

To lower the saw blade 25 to the lower position «min» on the cutting depth scale 37;

To install the cutting tool;

To adjust the table;

To install the ruler 12 with the angular bump 11.

11.5.1 Installing the end mill cutter/drill

End mill cutters are used as a cutting tool as shown in the Fig. U.

40 mm

70 mm

Fig. U

End mill cutter

To install end mill cutter/drill, it is required to perform the following:

To remove knife’s block fencing 65 (Fig. Е);

To install the drill chuck 55(Fig. V) on the cutting surface of the knife block end;

To install and fix the end cutter47 or drill to the drill chuck 55;

To install fencing 51 of the end cutter 47 and fix it with screws 64.

The end mill cutter fencing has a sprung security cap 51a, which moves into the casing when

pressing the workpiece on the cap in the axial direction, opening the working part of the end

mill 47.

27

When the drill chuck is removed, install the knife’s end block fencing 65 (Fig. E).

64

51 51a

55

47

12

16

11

50 46 49

Fig. V

The construction of the machine in the end milling mode

11 – angular bump; 12 – ruler; 16 – flywheel; 46 – milling table; 47 – end mill; 49 – lever-stick for lifting/lowering of

milling table; 50 – flywheels for milling table fixation; 51 – fencing of end milling cutter; 51а – protective cap;

55 – drill chuck; 64 – screws for fixing of end mill fencing

11.5.2 Adjusting the milling table

Adjust the table 46 (Fig. V) for height relative to the cutter 47. To do so, lower the flywheels 50.

Adjust the desired height by switching the lever-stick 49 up/down and tighten the flywheels 50.

11.5.3 Installing the ruler with angular bump

The workpiece feeding is performed manually along the table 46 (Fig. V). For parallel motion

use the ruler 12 with angular bump 11. The angular bump is fixed with the flywheels 16 to the

milling table 46 through the screwed holes in the table.

11.6 Milling with disc cutters

Before starting, it is recommended to make the following adjustments (Fig. W):

Install the disc cutter 40;

Install the fencing 29;

Adjust the milling depth.

28

42

41

31

29

40

30

30a

44

Fig. W

The structure of the machine in the milling with the cutter disk mode

29 – Fencing of saw blade/cutter above the table level; 30 – Fencing of saw blade/cutter below the table level;

30а – screws; 31 – cutting table insert; 41 – vertical rod of saw blade fencing; 40 – cutter disk; 42 – horizontal rod of

cutter disk fencing; 44 – flywheel for vertical rod fixation; 45 – insert for milling

11.6.1 Installing the cutter disc

It is recommended to use slot milling cutters for wood (Fig. X).

To install the disc cutter 40, perform the following actions:

remove the saw blade fencing 30, by loosening the screws 30а;

unscrew the lock nut of the saw blade 25 (Fig. В1, B2) with the help of a wrench 56;

remove the saw blade 25;

install the disc cutter 40, with it with the nut 67 backside;

install the insert 45;

install the cutter disc casing 30, fix it with the screws 30а.

10 mm

Fig. X

Slot milling cutter for wood

11.6.2 Installing the fencing

To install the fencing of the disc cutter 40 it is necessary to remove the fencing of saw blade

29 from the machine 25 with the help of the splitting knife 28.

It is necessary to install the vertical rod 41 in place of the splitting knife.

Fix the vertical rod with the fencing on the table with the flywheel 43.

Then adjust the insert 31 and fencing 29 position of the saw blade relative to the disc cutter

40. They should be installed symmetrically around the center of the disc cutter. The height of

29

the fencing is adjusted by moving the horizontal rod 42 along the vertical rod 41.

11.6.3 Adjusting the milling depth

The milling depth of the disc cutter is installed similarly as in the case of saw blade (p. 11.2.2).

The milling depth scale 38 is located from the right side of the casing 30 of the saw blade

(Fig. B).

12. MAINTENANCE AND REPAIR

In order to maintain the machine in a permanent technical efficient and working condition, it

is necessary to service the machine each time before using it. It includes the following:

Performing exterior check;

Checking the fixing security of slicing blades;

Cleaning the machine.

The exterior check includes cable test, integrity of security fencing test.

Checking the fixing security of slicing blades is performed by tightening the screws 71 with

the wrench (Fig.К).

Cleaning includes removing dust, cuttings, wood particles with a brush or a vacuum cleaner

from the machine surface.

12.1 Replacing the slicing blades

Periodically, it is required to resharpen or replace the slicing blades, whenever they has dulled

noticeably (Fig. Y).

The cutting edge of the blade should be sharp and clean. There should not be any notches,

rough guide lines and cracks.

70а 70а

40°± 5°

20

2

Fig. Y

Slicing blade

70a – slot

To the replace the knives, it is necessary to perform the following action:

remover the holder 69, by loosening the crews 71 (Fig. K);

replace the knife 70, installing it so that, the knife slots 70a fit the flags 73 (Fig. M);

install the holder 69 and fix it with the screws 71.

When installing the new blades, replacing fixing parts, and after resharpening, the difference

of the total mass of the knife kit with the fixing parts should not exceed 1 gram.

Adjust the knives as it is described in the paragraph 10.3.

30

12.2 Replacing the saw blade

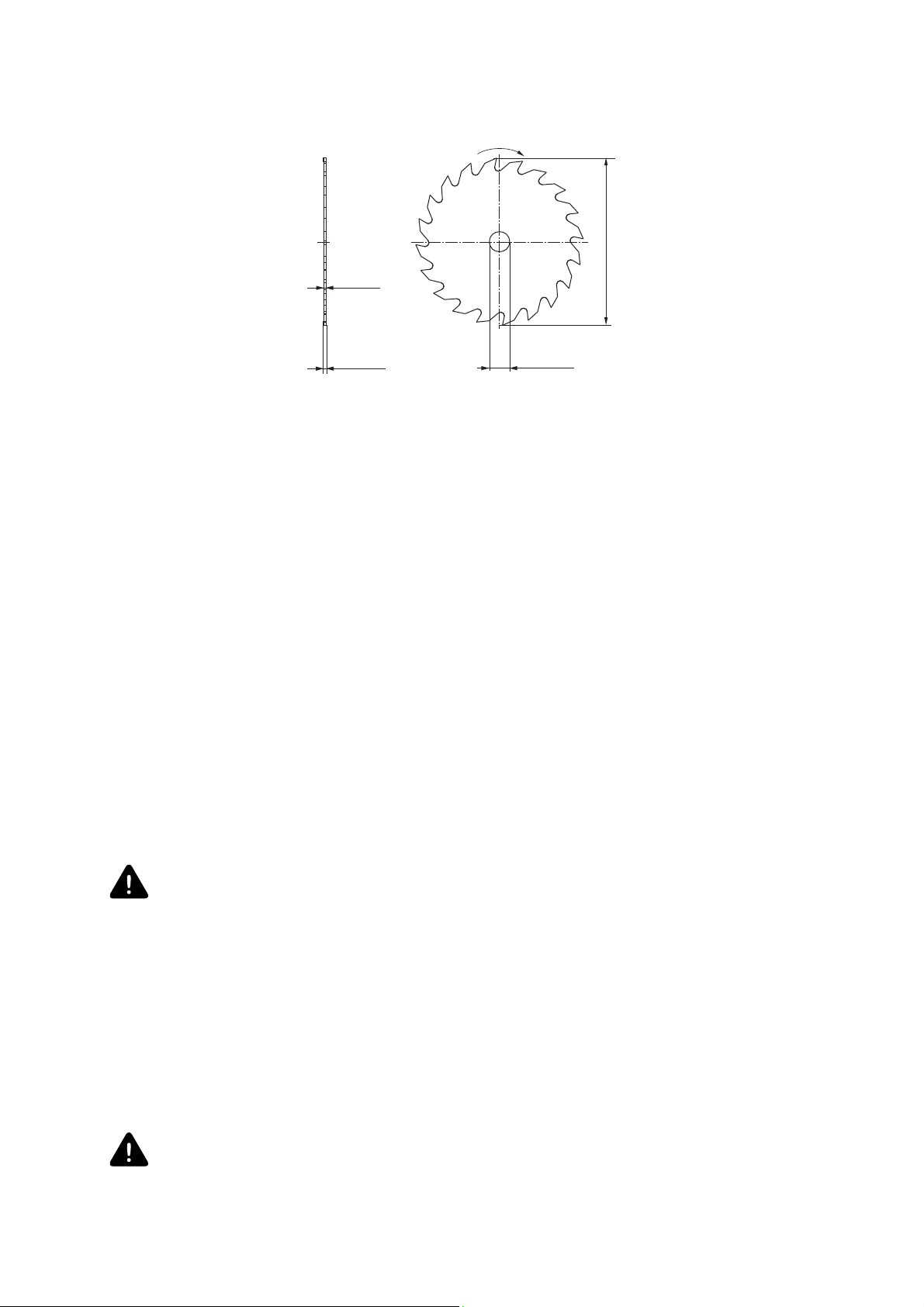

It is recommended to apply the saw blades with carbide blades for this machine (Fig. Z).

ØD mm

2÷2,2mm

3,2mm

Ø32 mm

Fig. Z

Saw blade

When installing the saw blade it is necessary to observe the rotating direction. Installing

process is similar to the one described in the paragraph 11.6.1. The direction of the teeth

should coincide with the arrow direction on the security casing that protects the saw blade

above the work table.

12.2.1 Dismounting the saw blade/ cutter

Lower the saw blade 25 (cutter 40) with the help of the lever 27 (Fig. В2) to the down

position.

Unscrew the flywheel to fix the position of the saw blade/cutter 32.

Remove the cover of the saw blade (cutter) fencing 30with the help of the screw driver.

Install the flywheel 32 to its place.

Lift the saw blade/cutter to the uppermost position and fix it with the flywheel 32.

Put the wrench 68 into the gap between the saw blade/cutter and the insert hole of the

cutting table 31, fix the position of the flange of the saw blade/ cutter.

With the help of the box wrench 56, hold the wrench 68 unscrew the union joint of the nut 67

and flange of the saw blade/cutter.

Mind the left union joint of the nut 67. Tightening is performed counterclockwise,

loosening – clockwise.

Unfix the flywheel 32 and lower the saw blade/cutter to the down position.

Unscrew the flywheel 32.

Remove the nut 67 and the saw blade 25 (cutter 40).

12.2.2 Installing the saw blade/cutter

If necessary, clean all the parts before installation.

Install a new saw blade/cutter на on the bearing flange, set the nut 67.

Do not use saw blades of the smaller size. The distance between a saw blade and

a splitting knife should be up to 5 mm.

31

Make sure that the direction of the cutting teeth (arrow on the saw blade) coincided with

the direction of the arrow on the fencing of the saw blade 29.

Install the flywheel 32 and lift the saw blade / cutter in the uppermost position.

Fix the position with the flywheel 32.

Screw the nut 67 with the box wrench 56 holding the flange with the wrench 68.

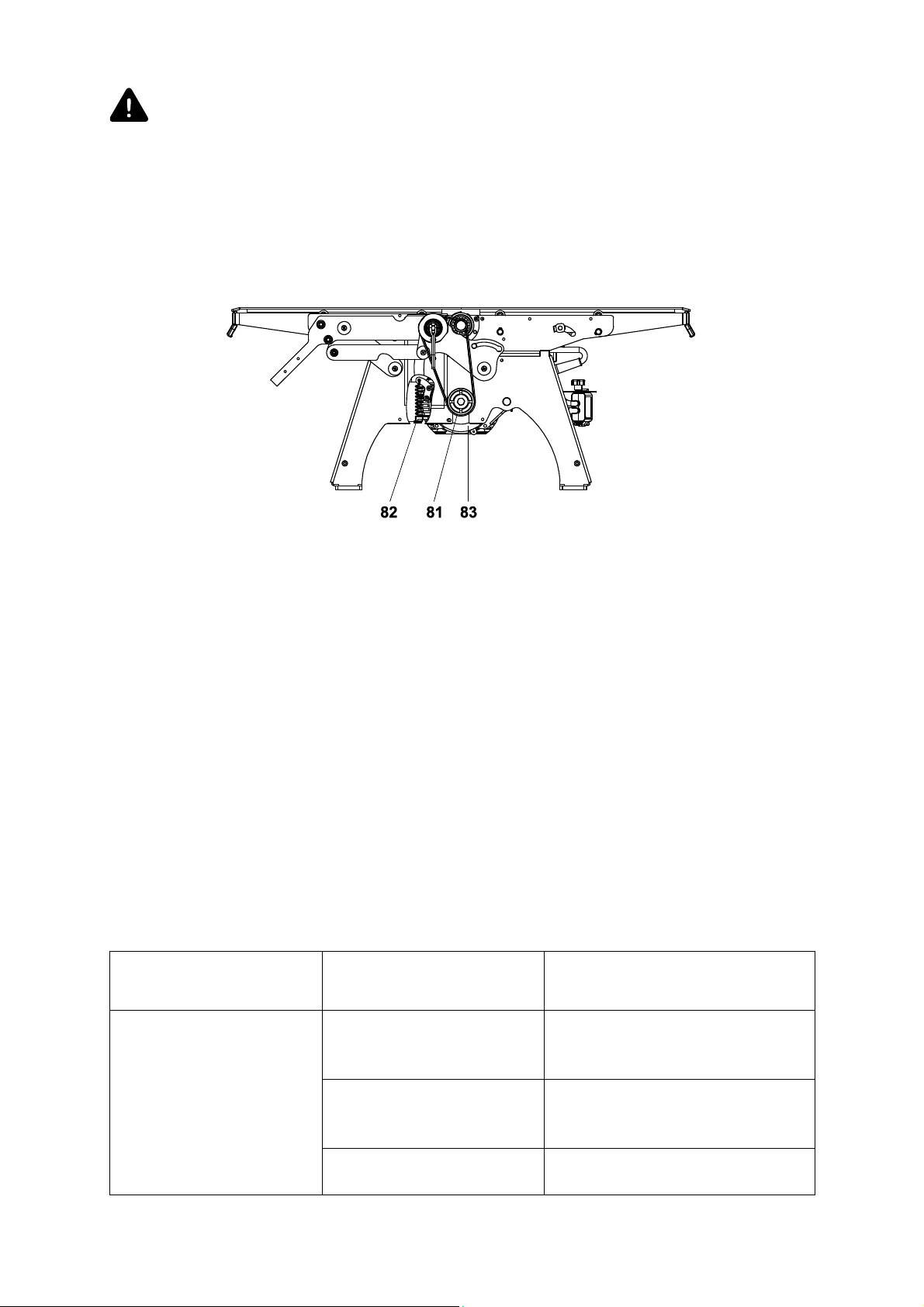

12.3 Replacing the drive belt

Fig. ZA

Installing the drive belt

81 – belt; 82 – spring; 83 – motor

To replace the drive belt, perform the following actions:

remove the saw blade as described in the paragraph11.6.1;

remove the back side of the casing 30 of the saw blade, by loosening the screws 30a with

a 3 mm hex wrench;

loosen the belt tension 82, by pushing the motor up 83, or by removing the tension spring

83;

install new belt;

assemble all the parts in reverse order.

The machine can be repaired only by a specialized enterprise.

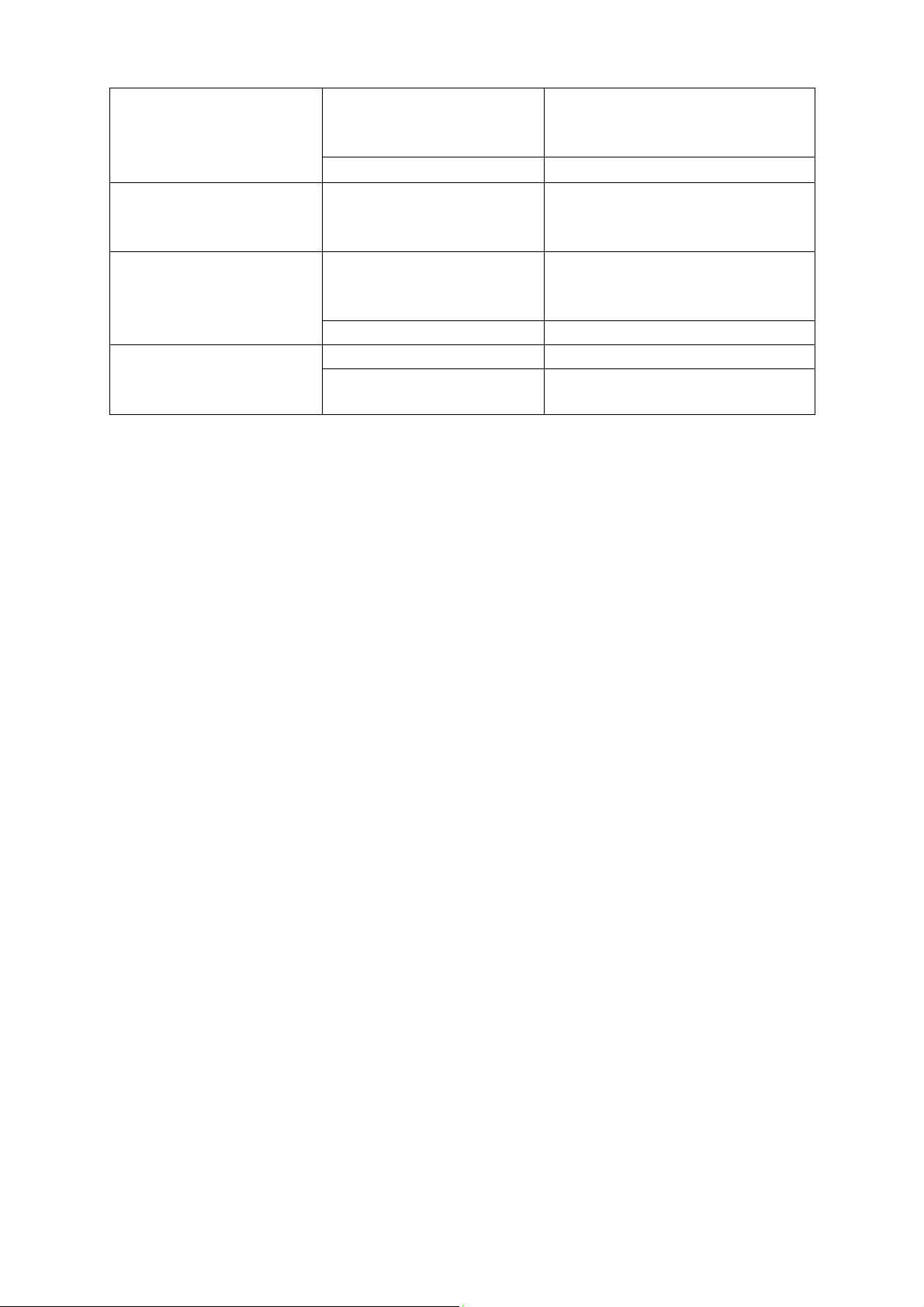

13. TROUBLESHOOTING

The list of the possible malfunctions and troubleshooting methods is described in the Table 3.

Type of malfunction Probable reason Troubleshooting method

Check the main socket voltage

The machine connected

to the mains does not

operate

There is no supply voltage

There is no contact in the

outlet with the patch cable

plug

The switcher is broken

with other known-good,

household appliance

Correct the fault or replace the

plug

Replace the switcher at the

service center

Table 3

32

The continuous feed of the

process material should be

reduced

Install the knives and holding

element with the appropriate

weight, adjust their position

Restart the machine in 15-20 min.

Electric motor becomes

overheated

The motor operates but

the cutter block is not

rotating

The work machine

vibrates

The machine has

suddenly stopped during

operation

The machine is overloaded

because of the high-feed

operation

The wood material is wet Replace the workpiece

The belt is torn Replace the belt

The knives are incorrectly

matched and installed in

the improper way

The saw blade is deformed Replace the saw blade

There is no voltage Check the voltage

The thermal protection

shield was activated

14. STORAGE

Machines are designed for storage in closed or other naturally ventilated rooms without

artificially controlled climatic conditions where variations in temperature and air humidity is

substantially less than in the open air (such as stone, concrete, metal heat-insulated, and

other unheated warehouses, located in macroclimatic areas with moderate and frigid

climates).

It is necessary to pay attention to the labeling requirements on the individual packaging.

Keep the machine out of children’s reach.

15. TRANSPORTATION

The transportation of the machines is performed in closed vehicles.

The transportation of the machines is performed by two persons, holding the handles of the

package.

It is necessary to comply with the labeling requirements on individual packaging.

16. DISPOSAL

Never dispose this machine and its parts together with unsorted municipal waste.

The machine parts made of aluminum and plastics are labeled. That allows sorting and

recycling wastes.

Devices and tools of the machine, which have reached the end of their working life, must be

collected and disposed of separately from household waste material.

The list of the details, which do not meet the terms of this limited warranty:

saw blade;

belt;

slicing blades;

drill chuck;

plastic insert of the saw blade;

33

saw blade fencing;

end mill fencing.

The service life of the machine is no less than five years from the date of sale, under adherence

to the operating conditions and regular maintenance.

WARRANTY CERTIFICATE

Read this Warranty Certificate carefully; make sure that it is filled in.

Thoroughly check the product visual appearance and completeness. Claims on the visual

appearance and completeness shall be made immediately at the time of the product

acceptance.

If during the guarantee period any defects are detected, excluding the defects arising after

the handover of the products to the consumer due to violation of the transportation, storage

or use instructions by the latter, as well as actions of third parties or

one's reasonable control, we shall be obliged to satisfy the claims of the consumers in

conformity with the law and under the conditions as follows:

The product warranty period is 24 (twenty-four) months from the date of the sale of the

product by the trading organization.

This Warranty covers only the products used for private, household or domestic purposes,

unrelated to business activities.

Claims on the machine quality are accepted if the defects are detected within the warranty

period.

circumstances beyond

During the warranty period, the defects arising due to the fault of the manufacturing plant

shall be eliminated free of charge.

List of the machine damages, due to which the warranty obligations are cancelled:

disregard of operation instructions;

mechanical damage, damages caused by aggressive environments, high temperatures,

ingress of foreign bodies;

connection to the incorrect supply voltage;

damages arising due to the reasons beyond the manufacturer’s control: power line

instability;

the machine has been dismantled by the customer;

self-directed replacement of units and parts, the design change;

overload performance;

damages due to improper storage (metal parts corrosion), severe contamination and

negligent operation;

use of the machine for purposes other than intended;

damages due to the circumstances beyond one's reasonable control (accident, fire, flood,

lightning stroke, etc.).

List of the parts not covered by the Warranty:

circular saw blade;

strap;

planer knives;

drill chuck;

saw table plastic insert;

34

circular saw blade locking;

end-milling cutter locking.

The machine operating life is no less than five years from the date of sale by the trading

organization, if the working conditions requirements are observed and the maintenance

procedures are carried out regularly.

The Service Department is ready to answer all the questions regarding the repair and

maintenance of the machines, as well as regarding the spare parts. See the full information on

www.belmash.by.

The manufacturer’s address:

Zavod Belmash, JLLC, 212000, 37, Slavgorodskiy Proezd, Mogilev, Republic of Belarus.

E-mail: info@belmash.by.

35

36

Loading...

Loading...