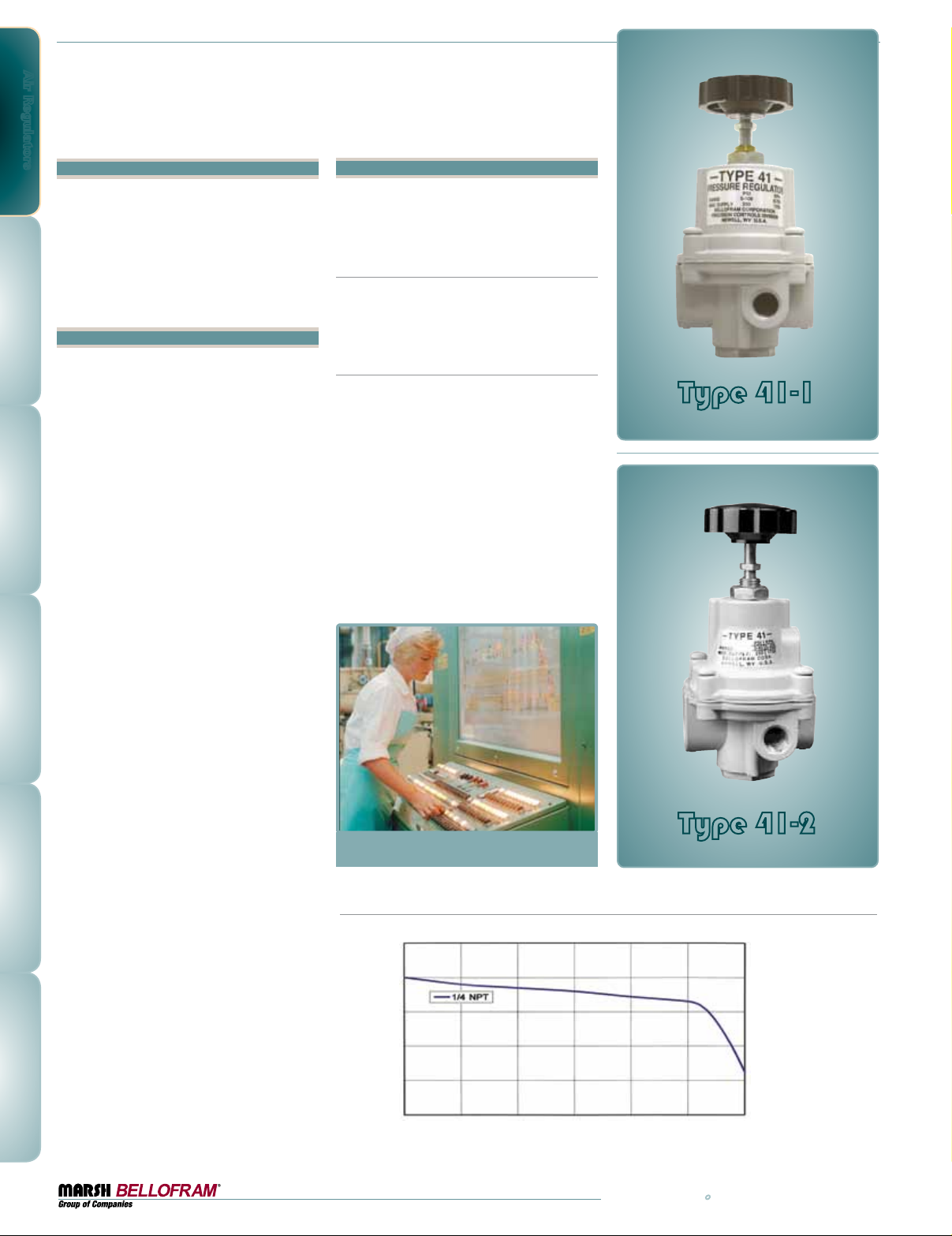

Bellofram Air Regulators Type 41-1, Air Regulators Type 41-2 Catalog Page

Air Regulators

Type 41-1 & Type 41-2

Pressure Regulator Series

Features

•Superior regulation characteristics

•Rugged, corrosion-resistant construction

•Excellent stability and repeatability

•Self-relieving of excess down stream pressure

•Low droop at high flow

•Mounting options available

Description

The Type 41 regulators are designed for applications requiring high flow capacity, low droop,

high accuracy, and fine adjustment sensitivity.

The use of Bellofram’s rolling diaphragm provides greater sensitivity and improved accuracy.

In addition, Type 41 regulators offer reduced

over-all size and several mounting options,

providing direct interchangeability with more

expensive competitors’ units.

Ruggedly designed and constructed, the Type

41 regulators have housings of precision-cast

aluminum. They are pressure tested, and

are chromate treated for internal corrosion

resistance. Every regulator is finished with vinyl

paint which resists scratching, weathering and

other physical abuse.

Careful design and quality materials throughout

assure long, trouble-free operation in the most

difficult industrial environments. A rubberized,

soft-seat valve stem provides stability and

“forgives” dirt and other foreign matter. An

aspirator maintains downstream pressure and

compensates for droop when high flow occurs.

The gauge port is convenient for gauge installation and can also be used as an additional full

flow outlet.

The design of these regulators is especially

well suited for panel applications due to ease of

mounting (only one panel hole required), small

size, adjustment sensitivity (32 threads per inch

on the adjusting screw), and knob.

Models

The Type 41 comes in two versions, Type 41-1

and Type 41-2. These two regulators offer the

same performance in two slightly different

packages.

Type 41-1

This unit comes standard with 1⁄4 NPT ports

and a knob, and can be panel mounted using

either the center nut or the threaded shoulder

holes, spaced 1.5 in. (38.1 mm) center-to-center.

Type 41-2

This unit comes standard with 1⁄4 NPT ports,

a knob and a bonnet vent port which can be

tapped for a 1⁄4 NPT fitting if desired. It can

be panel mounted using either the center nut

or the threaded shoulder holes, spaced 1.25 in.

(32.7 mm) center-to-center.

Type 41: Regulated Pressure VS. Flow

PSIG BAR

25 1.7

Type 41-1

Pressure Regulator Series

Type 41-2

Pressure Regulator Series

10

20 1.4

15 1.0

10 0.7

Regulated PRessuRe

5 0.3

0 0

SCFM 0 5 10 15 20 25 30

LPM 0 142 283 425 566 708 850

FoRwaRd Flow

800.727.5646 • www.marshbellofram.com

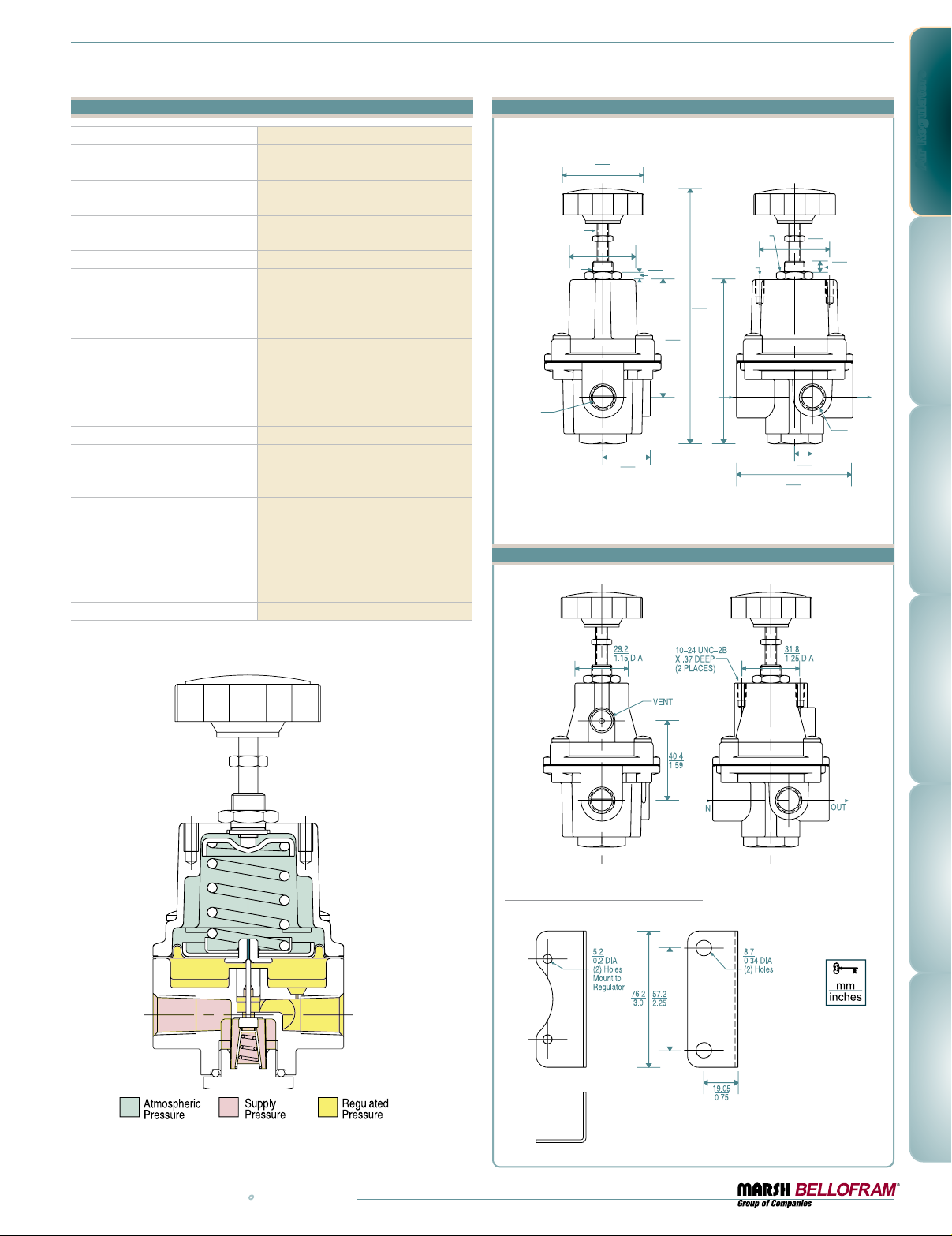

44.5

1.75 DIA

35.6

1.40

DIA

1/4–32 UNEF–3A

7/16–20 UNF–2A

1/4–18 NPT

IN & OUT PORTS

25.4

1.0

63.5

2.5

146.1

5.75

88.6

3.49

11/16 HEX PANEL

MOUNTING NUT

10–24 UNC–2B X .37

DEEP (2 PLACES)

4.8

0.19

10.2

0.4

38.1

1.5

1/4–18 NPT

GAUGE PORTS

9.4

0.37

63.5

2.5

IN

OUT

T41 Regulator Specifications

Sensitivity 1" Water Column (2.5 cm)

Flow Capacity @ 100 psig (6.9 BAR)

Supply and 20 psig (1.4 BAR) outlet

Effect of Supply Pressure Variation

(25 psig/1.7 BAR) on Outlet Pressure

Exhaust Capacity 5 psig (0.35 BAR)

above 20 psig set point

Max Supply Pressure 250 PSIG (17.2 BAR)

Effect of Changes in Flow on

Regulated Pressure

(100 psig / 6.9 BAR Supply)

Output Pressure Ranges

Temperature Range 0-160˚F (-18 to 71˚C)

Total Air Consumption

@ Maximum Output

Port Size 1/4 NPT, BSPT

Materials of Construction

Mounting Options Pipe, Panel or Bracket

25 SCFM (700 LPM)

±0.35 PSIG

(24 mBAR)

0.1–0.45 SCFM Typical 2.8 - 12.7 LPM

1 psig (0.07 BAR) over flow

of 10 SCFM (0-30 psig / 0-2.1 BAR

range, 1/4 NPT, 20 psig / 1.4 BAR set

point)

0-2 PSIG (0-0.14 BAR)

0-10 PSIG (0-0.69 BAR)

0-30 PSIG (0-2.1 BAR)

0-60 PSIG (0-4.1 BAR)

0-100 PSIG (0-6.9 BAR)

6 SCFH (2.8 LPM)

Body: Die cast aluminum with vinyl paint

Adjusting Screw: Plated steel

Trim: Plated steel, brass, acetal resin

Diaphragm: Buna-N polyester fabric

Knob: Phenolic Plastic

Spring: Music wire

Type 41-1 Dimensional Drawing

Air Regulators

Type 41-2 Dimensional Drawing

www.marshbellofram.com • 800.727.5646

Optional Mounting Bracket

607-000-057

11

Loading...

Loading...