Bell & Gossett WEHT0311M, WEHT0312M, WEHT0318M Installation, Operation And Maintenance Instructions

Page 1

INSTRUCTION MANUAL

IM249R03

High Temp Sump Pump

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

TABLE OF CONTENTS

SUBJECT PAGE

Introduction ............................................................................................................................................................................ 3

Safety Instructions .................................................................................................................................................................. 3

Performance and Motor Details ........................................................................................................................................... 3

Pre-Installation Checks .......................................................................................................................................................... 3

Lifting of Pump ....................................................................................................................................................................... 4

Optional Guide Rail or Lift-Out System ............................................................................................................................... 4

Piping ...................................................................................................................................................................................... 4

Wiring and Grounding .......................................................................................................................................................... 4

Selecting and Wiring Pump Control Panels and Switches ................................................................................................ 4

Installation ............................................................................................................................................................................... 5

Operation................................................................................................................................................................................ 5

Float Switch and Panel Chart ................................................................................................................................................ 6

Insulation Resistance Readings ............................................................................................................................................ 7

Engineering Data ................................................................................................................................................................... 7

Troubleshooting ..................................................................................................................................................................... 8

Typical Installations ................................................................................................................................................................ 9

Limited Warranty .................................................................................................................................................................. 12

Owner’s Information

Pump Model Number:

Pump Serial Number:

Control Model Number:

Dealer:

Dealer Phone No.

Date of Purchase: Installation:

Current Readings at Startup:

1Ø 3Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

2

Page 3

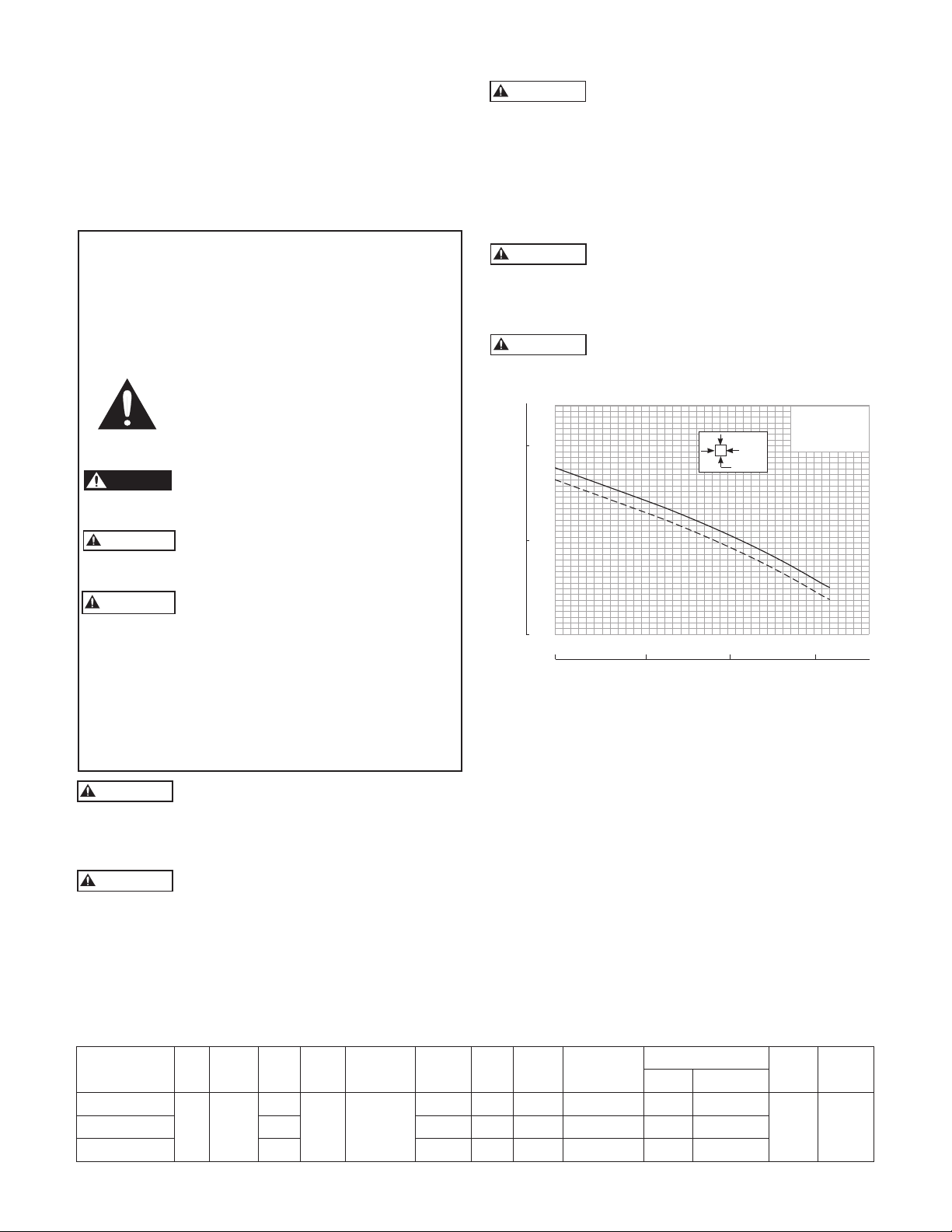

08

METERS FEET

TOTAL DYNAMIC HEAD

CAPACITY

Derate at

200ºF (93ºC)

68ºF (20ºC)

DANGER

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

INTRODUCTION

Bell & Gossett High Temperature 3885 Series Efuent

pumps are recommended for use in High Temperature

applications up to 200ºF. The High Temperature 3885 Pump

handles ¾” solids . Common applications include boiler

blow down and High Temperature condensate. Pump

should be operated with a High Temperature oat switch

sold separately.

aged equipment, provide unsatisfactory performance, and

may void manufacturer’s warranty.

Standard units are not designed for use in

swimming pools, open bodies of water,

hazardous liquids, or where ammable gases exist. These

uids and gases may be present in containment areas. Tank

or wetwell must be vented per local codes.

Only pumps specically Listed for Class 1, Division 1 are

allowable in hazardous liquids and where ammable gases

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT AND

MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or

in the manual, look for one of the following

signal words and be alert to the potential

for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause personal

injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS WHICH

ARE VERY IMPORTANT AND MUST BE

may exist. See specic pump catalog bulletins or pump

nameplate for all agency Listings.

Disconnect and lockout electrical power

before installing or servicing any electrical

equipment. Many pumps are equipped with automatic

thermal overload protection which may allow an overheated

pump to restart unexpectedly.

Do not use pump ammalde or explosive

liquids. Pump is for water only.

PERFORMANCE

40

35

10

30

WEHT03M

25

20

5

15

10

5

0

0

01020304050607

0

5

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND

WARNINGS PRIOR TO PERFORMING ANY WORK

ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

This product can expose you to chemicals

including Lead, which is known to the State

of California to cause cancer and birth defects or other

reproductive harm. For more information go to:

www.P65Warnings.ca.gov.

All electrical work must be performed by a

qualied technician. Always follow the National Electrical Code (NEC), or the Canadian Electrical Code,

as well as all local, state and provincial codes. Code questions should be directed to your local electrical inspector.

PRE-INSTALLATION CHECKS

Open all cartons and inspect for shipping damage. Report

any damage to your supplier or shipping carrier immediately.

Important: Always verify that the pump nameplate Amps,

Voltage, Phase and HP ratings match your control panel and

power supply.

This pump is oil-lled. If there are any signs of oil leakage

or if the unit has been stored for an extended period check

the oil level in the motor dome and the seal housing, if so

equipped.

Check the motor cover oil level through the pipe plug on

top of the unit. The motor chamber oil should just cover the

motor. Do not overll, leave room for expansion!

Failure to follow electrical codes and OSHA safety standards

may result in personal injury or equipment damage. Failure

to follow manufacturer’s installation instructions may result in

To check the seal housing oil level, where used, lay the unit

on its side with the ll plug at 12 o’clock. Remove the plug.

electrical shock, re hazard, personal injury or death, dam-

MODELS

Order

Number

WEHT0311M

HP Phase Volts RPM

115

0.33 1

WEHT0312M 230 6.1 16.5 J 54 11.7 5.6

Impeller

Dia. (In.)

1750 5.38

Max.

Amps

LRA

KVA

Code

Full Load

Motor Eff.

12.0 31.1 J 55 9.3 1.4

*Add P1 to the end of the order number to include an ultra hi-temp oat switch in the purchase.

Replacement part numbers for oat: A2HT31 – 115V and A2HT32 – 208 and 230V (20' cord length).

Resistance

Start Line-Line

MODEL: WEHT03xxM

SIZE: 2" Discharge

RPM: 1750

HP: .33 HP

3

/4" Diameter

2 GPM

1 FT

10

SOLIDS:

Wt.

(Lbs.)

15

Cord

Length

0GPM

m3/hr

56 20'WEHT0318M 208 7.3 19.5 K 51 9.1 4.2

3

Page 4

WARNING

Hazardous

voltage

WARNING

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

The oil should be within ½” (13mm) of the top. If low, rell

with an ASTM 150 turbine oil. Replace the plug.

Oil is available in 5 gallon cans through our distributors. You

can also source oil locally at motor repair shops. Typical oil

brands are: Shell Turbo 32, Sunoco Sunvis 932, Texaco Regal

R&O 32, Exxon Nuto 32 and Mobil DTE Light.

Check the strain relief nut on power cable strain assemblies.

Power cables should be torqued to 75 in. lbs., cable supplied

is for high temp use.

Warranty does not cover damage caused by connecting

pumps and controls to an incorrect power source (voltage/

phase supply).

Record the model numbers and serial numbers from the

pumps and control panel on the front of this instruction

manual for future reference. Give it to the owner or afx it to

the control panel when nished with the installation.

FOR ALL SES PUMP INSTALLATIONS

LIFTING OF PUMP

DO NOT LIFT, CARRY OR HANG

PUMP BY THE ELECTRICAL CABLES.

DAMAGE TO THE ELECTRICAL

CABLES CAN CAUSE SHOCK, BURNS

OR DEATH.

Lift the pump with an adequately sized chain or cable attached to the lifting eye bolt. DO NOT damage electrical

cables while raising and lowering unit.

OPTIONAL GUIDE RAIL

OR LIFT-OUT SYSTEM

In many efuent and sewage basins or lift stations it is advisable to install the pump on a guide rail system or on a lift-out

adapter to facilitate installation and removal for inspection

and/or service. Most codes do not allow personnel to enter a

wetwell without the correct protective equipment and training. Guide rails are designed to allow easy removal of the

pump without the need for entry into the wetwell or need

to disturb piping. The guide rail or lift-out adapter should

locate the pump opposite the inuent opening preventing

stagnate areas where solids can settle. The basin or pit must

be capable of supporting the weight of the pump and guide

rail. The pit oor must be at.

NOTICE: FOLLOW THE INSTRUCTIONS THAT ARE

PROVIDED WITH THE GUIDE RAIL ASSEMBLY.

PIPING

Discharge piping should be no smaller than the pump

discharge diameter and kept as short as possible, avoiding

unnecessary ttings to minimize friction losses. Piping should

be rated for high temperatures if used in high temperature

applications.

Install an adequately sized check valve matched to the solids

handling capability of the pump to prevent uid backow.

Backow can allow the pump to “turbine” backwards and

may cause premature seal and/or bearing wear. If the pump

is turning backwards when it is called on to start the increased torque may cause damage to the pump motor and/

or motor shaft and some single-phase pumps may actually

run backwards.

4

Install an adequately sized gate valve AFTER the check valve

for pump, plumbing and check valve maintenance.

Important – Before pump installation. Drill a 3⁄16” (4.8mm)

relief hole in the discharge pipe. It should be located within

the wetwell, 2” (51mm) above the pump discharge but below the check valve. The relief hole allows any air to escape

from the casing. Allowing liquid into the casing will insure

that the pump can start when the liquid level rises. Unless a

relief hole is provided, a bottom intake pump could “air lock”

and will not pump water even though the impeller turns.

All piping must be adequately supported, so as not to impart

any piping strain or loads on the pump.

The pit access cover must be of sufcient size to allow for

inspection, maintenance and crane or hoist service.

WIRING AND GROUNDING

Important notice: Read Safety Instructions before

proceeding with any wiring.

Use only stranded copper wire to pump/motor and

ground. The ground wire must be at least as large as

the power supply wires. Wires should be color coded

for ease of maintenance and troubleshooting.

Install wire and ground according to the National Electrical Code (NEC), or the Canadian Electrical Code, as

well as all local, state and provincial codes.

Install an all leg disconnect switch where required by

code.

Disconnect and lockout electrical power before performing any service or installation.

The electrical supply voltage and phase must match

all equipment requirements. Incorrect voltage or

phase can cause re, motor and control damage, and

voids the warranty.

All splices must be waterproof. If using splice kits follow manufacturer’s instructions.

Select the correct type and NEMA grade

junction box for the application and location. The junction box must insure dry, safe

wiring connections.

Seal all controls from gases present which

may damage electrical components.

FAILURE TO PERMANENTLY GROUND

THE PUMP, MOTOR AND CONTROLS

BEFORE CONNECTING TO POWER

CAN CAUSE SHOCK, BURNS OR DEATH.

SELECTING AND WIRING

PUMP CONTROL PANELS AND SWITCHES

FLOAT SWITCH TYPES

High Temp oats can be purchased for High Temp applications. They are normally open (NO) for pump down operations.

These wide-angle, pump down switches may be used as

direct connected pump switches or as control switches.

Page 5

SETTING THE FLOAT SWITCHES

WARNING

Hazardous voltage

can shock, burn or

cause death.

DANGER

Hazardous Machinery

!

There are no absolute rules for where to set the oat switches, it varies from job to job.

Suggested Rules to Follow:

All oats should be set below the Inlet pipe!

Off Float: Best: set so the water level is always above the top

of the pump (motor dome). Next Best: set so the water level

is not more than 6" below the top of the pump.

On Float: set so the volume of water between the On and

Off oats allows pumps of 1½ HP and under to operate for 1

minute minimum. Two (2) HP and larger pumps should run

a minimum of 2 minutes. Basin literature states the gallons of

storage per inch of basin height.

Lag/Alarm Float(s): should be staggered above the Off and

On oats. Try to use most of the available storage provided

by the basin, save some space for reserve storage capacity.

See Diagrams and Charts in Float Switch Chart Section.

PANEL WIRING DIAGRAMS

Our control panels are shipped with instructions and wiring

diagrams. Use those instructions in conjunction with this

IOM. Electrical installation should be performed only by

qualied technicians. Any problem or questions pertaining

to another brand control must be referred to that control

supplier or manufacturer. Our technical people have no

technical schematics or trouble shooting information for

other companies' controls.

ALARMS

We recommend the installation of an alarm on all Wastewater pump installations. Many standard control panels come

equipped with alarm circuits. If a control panel is not used,

a stand alone high liquid level alarm is available. The alarm

alerts the owner of a high liquid level in the system so they

can contact the appropriate service personnel to investigate

the situation.

SINGLE PHASE PUMPS

Single phase (1Ø) pumps may be operated using a piggy-

back or hard wired oat switch, a contactor, or a Simplex or

Duplex control panel. See Figures 1 and 4.

All 1/3 and ½ HP, 115 or 230 volt pumps, and some ¾ and 1

HP pumps, are supplied with plug style power cords. They

may be plugged into piggyback oat switches for simple

installations. It is allowable to remove the plugs in order to

hardwire or connect to a Simplex or Duplex controller. Removing the plug neither voids the warranty nor violates the

agency Listings. See Figure 4.

Pumps with bare lead power cords can be hard-wired to a

oat switch, wired to a 1Ø contactor, a Simplex controller or

a Duplex controller. Always verify that the oat switch is rated

for the maximum run amperage, maximum starting amperage, and the HP rating on the pump. Single-phase wastewater pumps contain on-winding overloads, unless noted on

the pump nameplate. See Figure 1.

PLUG-CONNECTED UNITS MUST

BE CONNECTED TO A PROPERLY

GROUNDED, GROUNDING TYPE

RECEPTACLE.

ON NON-PLUG UNITS, DO NOT

REMOVE CORD AND STRAIN RELIEF.

DO NOT CONNECT CONDUIT TO PUMP.

SINGLE PHASE CONTROL PANELS:

Control panels are available as Simplex (controls 1 pump) or

Duplex (controls 2 pumps). Our standard SES Series Panels

are available with many standard features and can be built

with our most popular options. We also custom build panels

which offer many more design options than the SES panels.

Custom control panels are available in many different con-

gurations. Custom panel quote requests may be forwarded

to Customer Service through any authorized distributor.

Our “SES” Duplex panels feature a solid-state printed circuit

board design with standard high level alarm circuits. Other

standard features are: an auxiliary dry alarm contact for

signaling a remote alarm and oat switch position indicator

lights.

INSTALLATION

Connect the pump(s) to the guide rail pump adapters or to

the discharge piping. Slide rail bases should be anchored to

the wetwell oor.

Complete all wiring per the control panel wiring diagrams

and NEC, Canadian, state, provincial and/or local codes.

This a good time to check for proper rotation of the motors/

impellers.

DO NOT PLACE HANDS IN PUMP

SUCTION WHILE CHECKING

MOTOR ROTATION. TO DO SO WILL

CAUSE SEVERE PERSONAL INJURY.

Always verify correct rotation. Correct

rotation is indicated on the pump casing.

Three phase motors are reversible. It is

allowable to bump or jog the motor for a

few seconds to check impeller rotation. It

is easier to check rotation before installing

the pump. Switch any two power leads to

reverse rotation.

Lower the pump(s) into the wetwell.

Check to insure that the oats will operate freely and not

contact the piping.

OPERATION

Once the piping connections are made and checked you

can run the pumps.

Piggyback Switch Operation – Plug the piggyback switch

into a dedicated grounded outlet and then plug the pump

into the switch. Test the pump by lling the wetwell until the

pump goes On. If the pumps run but fail to pump, they are

probably air locked, drill the relief holes per the instructions

in the Piping Section.

Check the operating range to insure a minimum one minute

run time and that the pump goes Off in the correct position.

Control Panel Operation – Fill the wetwell with clear water.

Use the pump H-O-A (Hand-Off-Automatic) switches in

Hand to test the pumps. If they operate well in Hand proceed to test Automatic operation. If the pumps run but fail to

pump, they are probably air locked, drill the relief holes per

the instructions in the Piping Section.

Place Control Panel switch(es) in Automatic position and

thoroughly test the operation of the ON, OFF, and Alarm

5

Page 6

oats by lling the wetwell with clear water. Important:

Inlet

Alarm SW3

Pump On SW2

Pump Off SW1

Discharge

Inlet

Alarm SW4

Lag Pump On

SW3

Pump Off

SW1

Discharge

Lead Pump On

SW2

Failure to provide a Neutral from the power supply to a 1Ø,

230 volt Control Panel will not allow the panel control circuit

to operate. The Neutral is necessary to complete the 115

volt control circuit.

Check voltage and amperage and record the data on the

front of this manual for future reference. Compare the amperage readings to the pump nameplate maximum amperage. If higher than nameplate amperage investigate cause.

Operating the pump off the curve, i.e. with too little head or

with high or low voltage will increase amperage. The motor

will operate properly with voltage not more than 10% above

or below pump nameplate ratings. Performance within this

range will not necessarily be the same as the published

FLOAT SWITCH AND PANEL CHART

The purpose of this chart is to show the required switch

quantities and the function of each switch in a typical wastewater system. The quantities required vary depending on

the switch type, single-action or wide-angle. Switch quantities also vary by panel type: simplex with and without alarms,

and duplex with alarms.

Duplex Panels using single-action switches:

Three Float Panel Wiring

SW1 Bottom Pumps Off

SW2 Middle 1st Pump On

SW3 Top 2nd Pump & Alarm On

performance at the exact rated nameplate frequency and

voltage. Correct the problem before proceeding. Three

phase unbalance is also a possible cause. See Three Phase

Power Unbalance and follow the instructions.

Reset the Alarm circuit, place pump switch(es) in the Automatic position and Control Switch in ON position. The

system is now ready for automatic operation.

Explain the operation of the pumps, controls and alarms to

the end user. Leave the paperwork with the owner or at the

control panel if in a dry, secure location.

Simplex Panel using wide-angle switches:

Simplex Panel with Alarm

SW1 Bottom Pump On/Off

SW2 Top Alarm On/Off

Simplex Panel with No Alarm

SW1 Pump On/Off

Four Float Panel Wiring ➁

SW1 Bottom Pumps Off

SW2 2nd 1st Pump On

SW3 3rd 2nd Pump On

SW4 Top Alarm On

Duplex Panels using wide-angle switches:

Three Float Panel Wiring

SW1 Bottom 1st Pump On/Both Off

SW2 Top 2nd Pump & Alarm On

Four Float Panel Wiring

SW1 Bottom 1st Pump On/Both Off

SW2 Middle 2nd Pump On

SW3 Top Alarm On

Simplex Panel using single-action switches:

Simplex Panel with Alarm ①

SW1 Bottom Pump Off

SW2 Middle Pump On

SW3 Top Alarm On/Off

Simplex Panel with No Alarm

SW1 Bottom Pump Off

SW2 Top Pump On

Simplex ①

6

Duplex ➁

Page 7

INSULATION RESISTANCE READINGS

6" (15.3 cm)

6" (15.3 cm)

8" (20.3 cm) TURN ON LEVEL

WEIGHT

Normal Ohm and Megohm Values between all leads and ground

Condition of Motor and Leads Ohm Value Megohm Value

A new motor (without drop cable). 20,000,000 (or more) 20 (or more)

A used motor which can be reinstalled in well. 10,000,000 (or more) 10 (or more)

Motor in well. Readings are for drop cable plus motor.

New motor. 2,000,000 (or more) 2 (or more)

Motor in good condition. 500,000 - 2,000,000 .5 - 2

Insulation damage, locate and repair. Less than 500,000 Less than .5

Insulation resistance varies very little with rating. Motors of all HP, voltage and phase ratings have similar values of

insulation resistance.

Insulation resistance values above are based on readings taken with a megohmmeter with a 500V DC output.

Readings may vary using a lower voltage ohmmeter, consult factory if readings are in question.

ENGINEERING DATA

Engineering data for specic models may be found in your catalog and on our website (address is on the cover).

Control panel wiring diagrams are shipped with the control panels. Please use the control panel drawings in

conjunction with this instruction manual to complete the wiring.

Minimum Submergence

Continuous

Duty

Pumpmaster and Pumpmaster Plus - Hard Wired

Determining Pumping Range

Fully Submerged

Figure 1

PUMP OPERATION

Continuous

Operation

Single-Action Float Switch

Maximum Fluid Temperature

200º F 93º C

"Typical" Installation

Figure 3

Wide-Angle Float Switch

Pump plug

Piggyback

switch plug

Figure 2

Pumping

range

Figure 4

7

Page 8

TROUBLESHOOTING

WARNING

Hazardous

voltage

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL

POWER BEFORE ATTEMPTING ANY SERVICE CAN CAUSE

SHOCK, BURNS OR DEATH.

SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION

MOTOR NOT RUNNING Motor thermal protector tripped. Allow motor to cool. Insure minimum pump

submergence. Clear debris from casing and impeller.

NOTE: If circuit breaker

Open circuit breaker or blown fuse. Determine cause, call a qualied electrician.

“OPENS” repeatedly,

DO NOT reset. Call

Pump impeller binding or jammed. Check motor amp draw. If two or more times higher

qualied electrician.

than listed on pump nameplate, impeller is locked,

a) Manual operation Power cable is damaged. motor bearings or shaft is damaged. Clear

Resistance between power leads and ground should

b) Automatic operation No neutral wire read innity. If any reading is incorrect, call a

connected to control panel. qualied electrician.

Inadequate electrical connection Inspect control panel wiring. Call a qualied

in control panel. electrician.

NOTE: Check the pump in

Defective liquid level switch. With switch disconnected, check continuity while

manual mode rst to con-

activating liquid level switch. Replace switch, as

rm operation. If pump

required.

operates, the automatic

Insufcient liquid level to Allow liquid level to rise 3" to 4" (76 mm - 101 mm)

control or wiring is at fault.

activate controls. above turn-on level.

If pump does not operate,

Liquid level cords tangled. Untangle cords and insure free operation.

see above.

PUMP WILL NOT Liquid level cords tangled. Untangle cords and insure free operation.

TURN OFF

Pump is air locked. Shut off pump for approximately one minute, then

restart. Repeat until air lock clears. If air locking

persists in a system with a check valve, a 3⁄16" (4.8 mm)

hole may be drilled in the discharge pipe approximately

2" (51 mm) above the discharge connection.

Inadequate electrical connection

in control panel.

debris from casing and impeller, consult with dealer.

Inuent ow is matching pump’s Larger pump may be required.

discharge capacity.

LITTLE OR NO LIQUID Check valve installed backwards, Check ow arrow on valve and check valve

DELIVERED BY PUMP plugged or stuck closed. operation.

Excessive system head. Consult with dealer.

Pump inlet plugged. Inspect and clear as required.

Improper voltage or wired Check pump rotation, voltage and wiring.

incorrectly. Consult with qualied electrician.

Pump is air locked. See recommended action, above.

Impeller is worn or damaged. Inspect impeller, replace as required.

Liquid level controls defective Inspect, readjust or replace as required.

or improperly positioned.

PUMP CYCLES Discharge check valve inoperative. Inspect, repair or replace as required.

CONSTANTLY

Liquid level controls defective or Inspect, readjust or replace as required.

improperly positioned.

Inuent excessive for this size Consult with dealer.

pump.

8

Sewage containment area too small. Consult with dealer.

Page 9

TYPICAL INSTALLATIONS

Typical Efuent, Sewage and

Dewatering Pump Installations

9

Page 10

NOTES

10

Page 11

NOTES

11

Page 12

LIMITED CONSUMER WARRANTY

For goods sold for personal, family or household purposes, Seller warrants the goods purchased hereunder (with the exception of membranes,

seals, gaskets, elastomer materials, coatings and other “wear parts” or consumables all of which are not warranted except as otherwise provided

in the quotation or sales form) will be free from defects in material and workmanship for a period of one (1) year from the date of installation or

eighteen (18) months from the product date code, whichever shall occur rst, unless a longer period is provided by law or is specied in the product

documentation (the “Warranty”).

Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer, either repair or replace any product which fails to conform

with the Warranty provided Buyer gives written notice to Seller of any defects in material or workmanship within ten (10) days of the date when any

defects or non-conformance are rst manifest. Under either repair or replacement option, Seller shall not be obligated to remove or pay for the

removal of the defective product or install or pay for the installation of the replaced or repaired product and Buyer shall be responsible for all other

costs, including, but not limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to the method or means of repair

or replacement. Buyer’s failure to comply with Seller’s repair or replacement directions shall terminate Seller’s obligations under this Warranty and

render this Warranty void. Any parts repaired or replaced under the Warranty are warranted only for the balance of the warranty period on the parts

that were repaired or replaced. The Warranty is conditioned on Buyer giving written notice to Seller of any defects in material or workmanship of

warranted goods within ten (10) days of the date when any defects are rst manifest.

Seller shall have no warranty obligations to Buyer with respect to any product or parts of a product that have been: (a) repaired by third parties other

than Seller or without Seller’s written approval; (b) subject to misuse, misapplication, neglect, alteration, accident, or physical damage; (c) used in a

manner contrary to Seller’s instructions for installation, operation and maintenance; (d) damaged from ordinary wear and tear, corrosion, or chemical

attack; (e) damaged due to abnormal conditions, vibration, failure to properly prime, or operation without ow; (f) damaged due to a defective

power supply or improper electrical protection; or (g) damaged resulting from the use of accessory equipment not sold or approved by Seller. In any

case of products not manufactured by Seller, there is no warranty from Seller; however, Seller will extend to Buyer any warranty received from Seller’s

supplier of such products.

THE FOREGOING WARRANTY IS PROVIDED IN PLACE OF ALL OTHER EXPRESS WARRANTIES. ALL IMPLIED WARRANTIES, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE (1)

YEAR FROM THE DATE OF INSTALLATION OR EIGHTEEN (18) MONTHS FROM THE PRODUCT DATE CODE , WHICHEVER SHALL OCCUR FIRST.

EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYER’S EXCLUSIVE REMEDY AND SELLER’S AGGREGATE LIABILITY FOR BREACH OF ANY OF THE

FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT

PAID BY THE BUYER FOR THE DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY OTHER FORM OF DAMAGES, WHETHER

DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL, CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT NOT LIMITED

TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE, LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF

OPPORTUNITY OR LOSS OF REPUTATION.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above exclusions may not apply to you. This warranty gives you specic

legal rights, and you may also have other rights which may vary from state to state.

To make a warranty claim, check rst with the dealer from whom you purchased the product or visit www.xyleminc.com for the name and location of

the nearest dealer providing warranty service.

Xylem Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xylem.com/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2019 Xylem Inc. IM249 Revision Number 3 March 2019

Loading...

Loading...