Page 1

INSTRUCTION MANUAL

V59074B

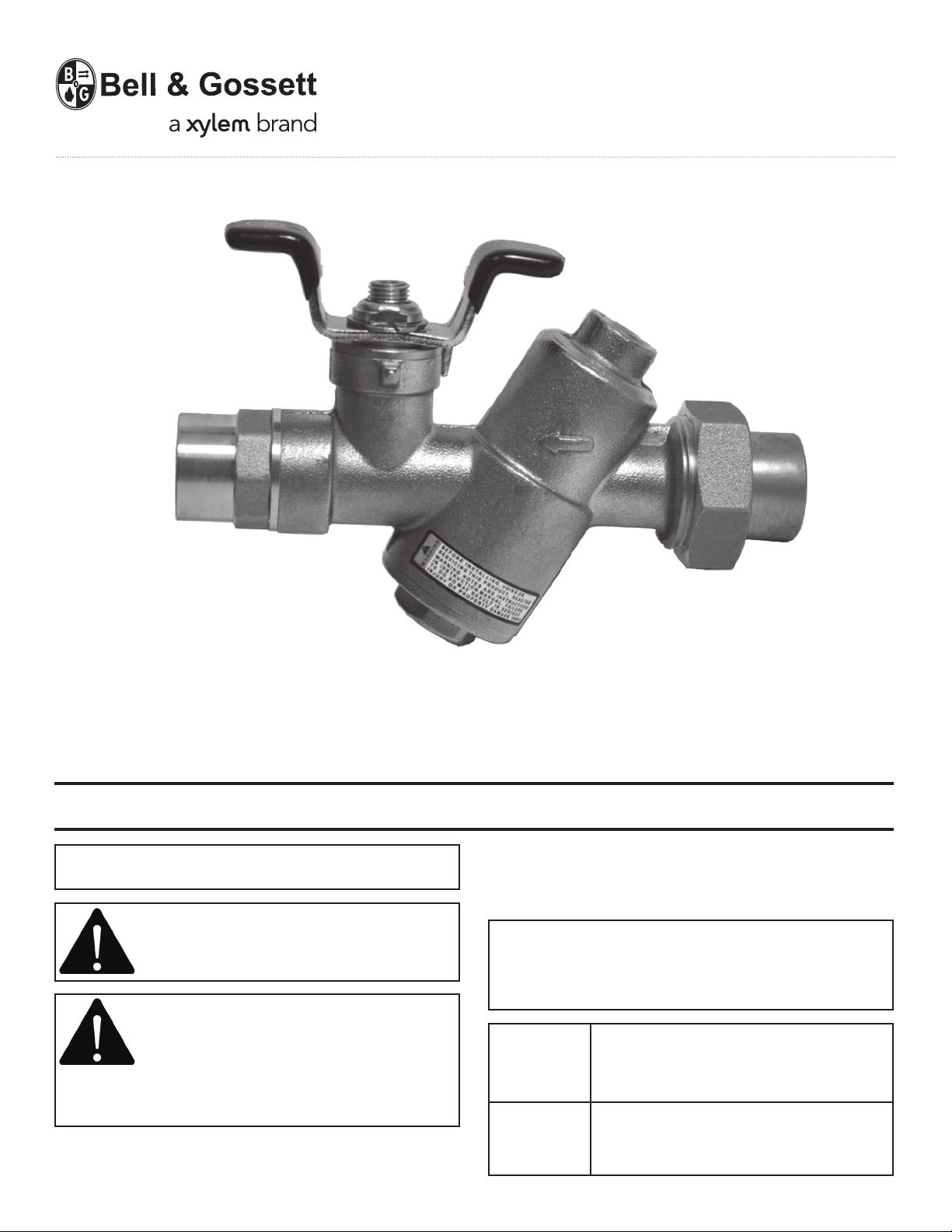

Low Flow Circuit Sentry

Model ACL Flow Limiting Valves

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

NOTE: This product is not intended for use in potable

water applications.

WARNING: This product may contain a

chemical known to the State of California

to cause cancer, or birth defects or other

reproductive harm.

SAFETY INSTRUCTION: This safety alert

symbol will be used in this manual to draw

attention to safety related instructions.

When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

OPERATIONAL LIMITS

WORKING PRESSURE & TEMPERATURE LIMITS

(SOLDER TYPE LIMITS FOR ANSI STD. B.16.18)

COIL HOOKUP VALVE TEMP °F (°C) PRESSURE PSI (KPA)

Union Ended Ball

Valve (NPT) 250° (121°) 400° (2758°)

Union Ended Ball Based on solder type ASTM Std.

Valve (sweat) B16.18

TYPE OF

SOLDER

95-5

TINANTIMONY

MAXIMUM LIMITATIONS 1/2” - 3/4”

PRESSURE

PSI (kPa)

300 (2069) 200° (93°)

250 (1724) 225° (107°)

200 (1379) 250° (121°)

TEMP

° F (° C)

Page 2

DESCRIPTION

Low Flow Circuit Sentry Model ACL valve is designed to

automatically control the flow in piping systems to a

selected preset limit. As pressure differential increases, a

cartridge inside the valve body reduces the flow area to

accurately maintain the preselected flow rate.

CAUTION: Heat associated with the use of

silver solder may damage valve components

and void the product warranty. Do not use

silver solder. Failure to follow these

instructions could result in property damage and/or

moderate personal injury.

Flow Operating Range: 0.25 – 3.8 GPM

INSTALLATION INSTRUCTIONS

Low Flow Circuit Sentry Model ACL Flow Limiting Valves

are uni-directional valves and can be installed in most

orientations; Low Flow Circuit Sentry valves should be

mounted in the return pipe where temperatures are

lower and where the sealing gland is less affected by pipe

strain. Installation of strainers and isolation ball valves

is recommended. Be sure to install the Low Flow Circuit

Sentry ACL valve with the arrow pointing in the

direction of flow. Provide enough space around the

valve to ensure the flow cartridge can be removed for

flow adjustment or system commissioning.

LOW FLOW CIRCUIT SENTRY MODEL ACL VALVES

WITH SWEAT CONNECTIONS

For installing sweat connections, make sure that the flow

limiting cartridge has not yet been installed in the valve.

When confirmed, proceed as follows:

a) Clean tube ends and valve connections thoroughly per

good piping practices with a fine grade emery cloth or

fine grit sandpaper.

CAUTION: Excessive use of solder or flux

may result in damage to the shutoff valve

seat and ball. Do not use excessive solder or

flux. Failure to follow these instructions can

result in moderate personal injury and/or property

damage.

LOW FLOW CIRCUIT SENTRY MODEL ACL VALVES

WITH NPT CONNECTIONS

Apply pipe compound conservatively to male connecting

fittings only. After installation, check all the joints for

leakage and re-tighten if necessary.

CAUTION: The use of PTFE impregnated

pipe compound and PTFE tape on pipe

threads provides lubricity. Care should be

taken to prevent over tightening which may

damage the valve body. Failure to follow these

instructions can result in personal injury and/or

property damage.

LOW FLOW CIRCUIT SENTRY MODEL ACL VALVES

FLOW LIMITING CARTRIDGE INSTALLATION

b) For soldering, use 95-5 (Tin-Antimony) solder and a

good grade of flux.

c) Use a torch with a sharp pointed flame.

d) When sweating the joints, adjust the valve to the full

open position, then wrap the valve with a cool wet rag

and then direct the flame with care to avoid subjecting

the valve to excessive heat. Allow the valve to cool before

touching or operating.

e) Check the soldered connection for leaks.

WARNING: Use of improper procedures to

sweat valve model with union connection

into system can damage valve. Before

installing sweat union connection to valve,

remove the union nut and O-ring from the valve body,

then union tailpiece with union nut must be sweated

(soldered) into place. Failure to follow these

instructions could result in property damage and/or

moderate personal injury.

Page 3

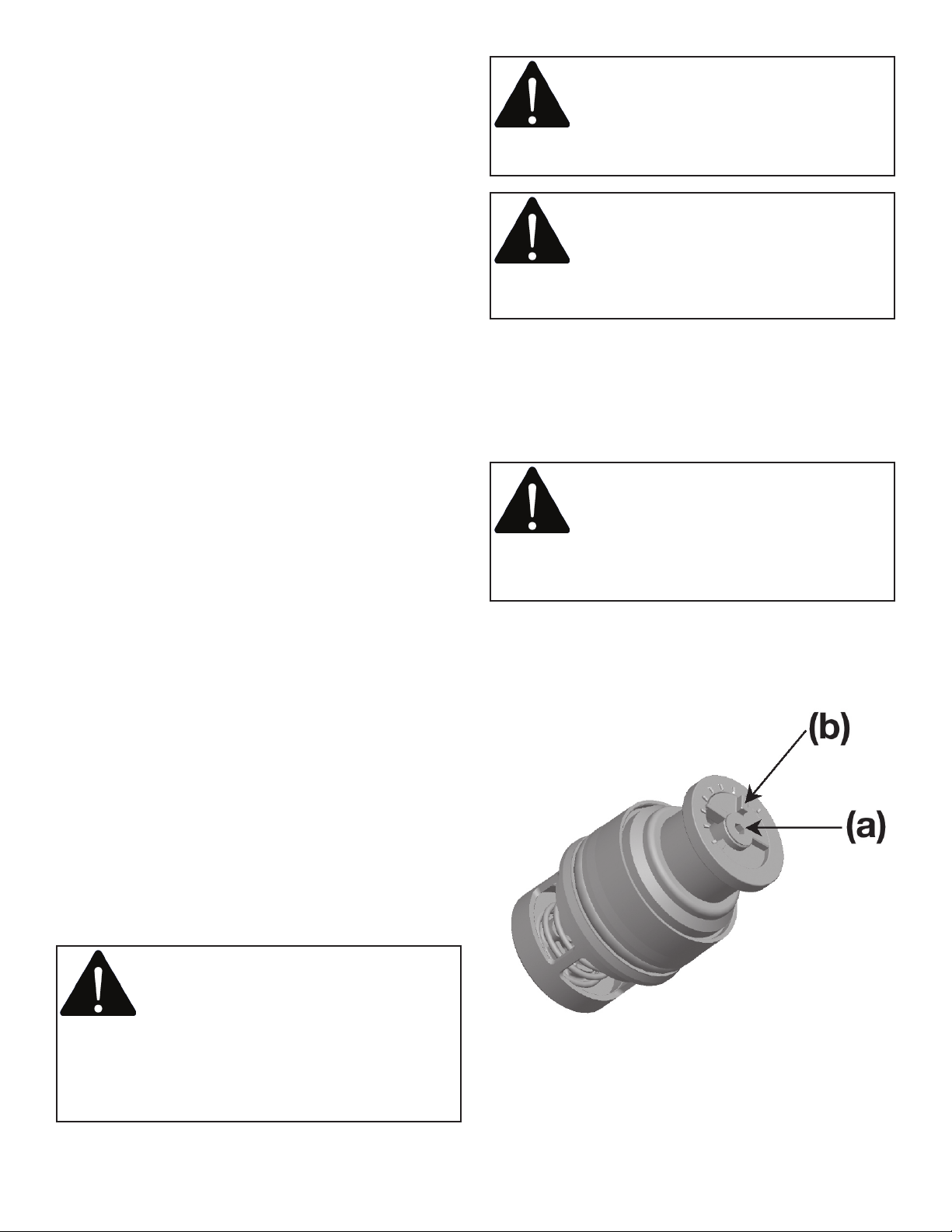

Prior to coil commissioning and operating the Flow

Limiting Valve, adjust cartridge to the desired flow rate

between 0.25 GPM to 3.8 GPM.

1. Loosen screw (a) position.

2. Rotate plastic dial (b) to the desired flow rate.

Increments marked on variable orifice are in GPM.

3. Re-tighten screw (a) with dial set at the desired

flow rate.

4. Install the cartridge as shown below.

Installed P/T Port (A)

Isolation Valve

Flow Cartridge

Optional P/T

Port (B)

Before system start up, remove the flow limiting cartridge

from the valve, if previously installed. Flush the hydronic

system as part of commissioning and then reassemble

cartridge into the valve. Make sure the valve cap is

tightened properly. Start the system and inspect the Low

Flow Circuit Sentry ACL valve for leakage.

HOW TO USE PRESSURE TAPS (P/T PORTS) TO MEASURE

SYSTEM OPERATING CONDITIONS

Using Bell & Gossett Model RP-250B, readout probes,

attach Bell & Gossett differential pressure readout kit to

the readout valves (P/T ports) on the Low Flow Circuit

Sentry ACL valve.

WARNING: Hot water leakage can occur

from readout valves (P/T ports) during probe

insertion and during hookup of readout kit.

Follow the instruction manuals supplied

with readout probes and readout kits for safe use.

Failure to follow these instructions could result in

serious personal injury or death and property damage.

Read the differential pressure from the coil inlet

isolation valve (typically strainer) to coil isolation valve

(typically a flow limiting balancing valve). The

differential value minus the pressure drops across the coil

and installed control valves should be less than 60 psi for

proper flow control.

If more accurate readings are desired, a pressure readout

valve (B&G P/N V58050) may be installed (B) in the barrel

above the cartridge chamber of the flow limiting valve.

Pressure readings should then be taken from the P/T valve

located in the isolation valve (A) and the P/T valve located

in the barrel of the cartridge (B). The differential valve

should be less than 60 psi for proper control.

CAUTION: Make sure Valve Cap is properly

assembled. Failure to follow these

instructions can result in personal injury and/

or property damage.

OPERATION INSTRUCTIONS

HOW TO USE BELL & GOSSETT LOW FLOW CIRCUIT

SENTRY MODEL ACL FLOW LIMITING VALVES FOR

PRE-SET FLOW BALANCING

Operation of the Flow Limiting Valve is fully automatic.

It automatically maintains the selected flow over the

designed differential pressure range.

CAUTION: Hot un-insulated surfaces can

cause burns to the skin. Do not touch hot

surfaces. Failure to follow these instructions

could result in personal injury.

SERVICE INSTRUCTIONS

Periodically inspect the Low Flow Circuit Sentry Model

ACL Flow Limiting Valve for signs of leakage or corrosion.

Replace valve cap o-ring (V57754), if necessary

WARNING: Corrosion or leakage are

indications that the Low Flow Circuit Sentry

Model ACL Flow Limiting Valve must be

replaced. Failure to follow these

instructions could result in serious personal injury or

death and property damage.

Due to the different types of material used, the Low Flow

Circuit Sentry Model ACL Flow Limiting Valve must be

disassembled prior to disposal. Special handling of

certain valve components may be required by law or may

be sensible from an ecological point of view.

Page 4

Should the Flow Limiting Valve require cleaning or

changing the flow rate, follow the instructions below:

1. Loosen and remove the cap from the valve body.

2. Pull the cartridge assembly from the valve body

for cleaning or flow adjustment.

3. Check the cartridge by pushing the orifice washer

into the cartridge housing several times to make

sure spring is functional and to dislodge any

possible debris. Rinse with water if necessary.

4. Once clean, return flow cartridge to valve

following installation instructions above.

5. Replace with a new flow cartridge (V58564) if

necessary.

INSULATION

Bell & Gossett recommends that insulation be attached

to the Low Flow Circuit Sentry Model ACL Flow Limiting

Valve after the system has been balanced.

NOTE: Tape or other acceptable means should be used

to secure the insulation to the Low Flow Circuit Sentry

Model ACL Flow Limiting Valve.

Patent Pending

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V59074B September 2012

Loading...

Loading...