Page 1

INSTRUCTION MANUAL

V58912B

PSH

Primary-Secondary Header

Flanged & Threaded Connections

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

The Bell & Gossett’s PSH is a device which makes the primary

and secondary circuits connected to it independent and can

be used on hot or chilled water systems.

The PSH is supplied with an air-vent and check valve assembly to permit automatic discharge of the air in the circuits. The

PSH is also equipped with a drain valve for removing any

impurities deposited in the bottom of the unit.

WARNING: State of California Residents

This product contains a chemical known by the State

of California to cause cancer. This product contains a

chemical known by the State of California to cause birth

defects or other reproductive harm.

The PSH should be sized according to the maximum flow rate

at the inlet. The selected value must be either that of the primary circuit or of the secondary, whichever is the greatest.

TECHNICAL SPECIFICATIONS

Threaded Connections: 1", 1-1/4", 1-1/2" FNPT with Unions

Flanged Connections: 2", 2-1/2", 3" & 4" ANSI150 CLASS

Materials: Body: Steel

Air Vent: Brass

Drain Valve: Brass

Insulation – Threaded: PEX

Insulation – Flanged: Polyurethane Foam

Medium: water, glycol solution non-hazardous, therefore

excluded from the guidelines of 67/548/EC Directive

Maximum Percentage of Glycol: 30% Threaded

50% Flanged

INSTALLATION INSTRUCTIONS

CAUTION: All work must be performed by qualified

personnel trained in the proper application, installation, and maintenance of systems in accordance with all

applicable codes and ordinances.

WARNING: System fluids are under pressure or temp-

erature can be hazardous. Be sure the pressure has

been reduced to zero and the system temperature is below

100°F (38°C). Failure to follow these instructions could

result in property damage and/or personal injury.

Connection Size 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4"

Flow Rate (gpm) 11 18 26 40 80 124 247

OPERATING DATA

With Insulation

Working Pressure: 150 psi

Operating Temperature – Threaded: 32°-210°F

Operating Temperature – Flanged: 32°-220°F

Without Insulation

Working Pressure: 150 psi

Operating Temperature – Threaded and Flanged: 32°-230°F

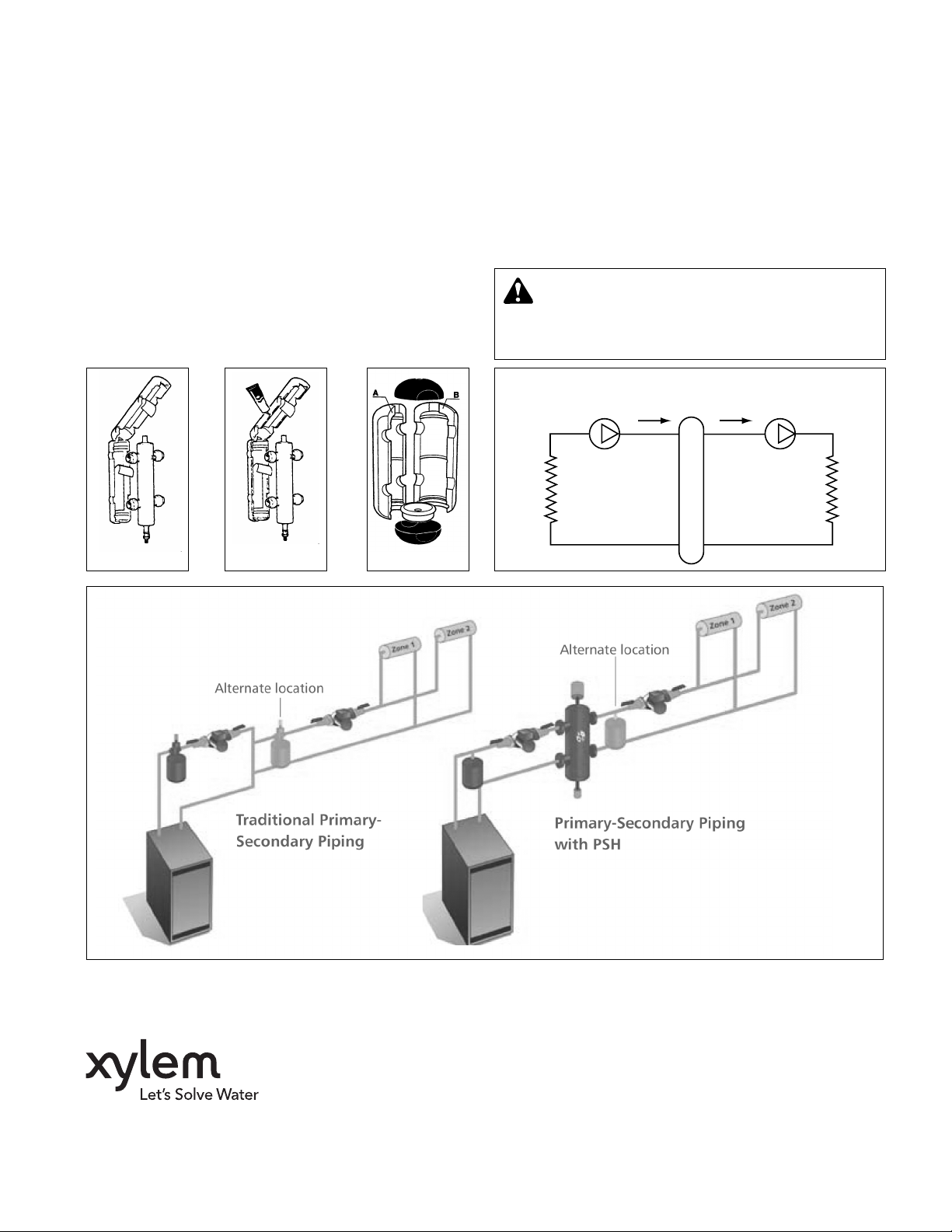

The hydraulic separator is installed between the primary and

secondary circuits, always in a vertical position.

Make sure that all connections are water-tight.

When making the water connections, take care not to overtighten the connections to the reducer. Failure to follow these

instructions could result in property damage and/or personal

injury.

During the installation, commissioning and maintenance of

hydraulic separators, all necessary steps should be taken to ensure that system water temperature does not cause danger to

people.

Page 2

Procedure for installation and insulation

assembly on threaded models

1. Remove the protective strip from the adhesive surface. Reclose the shells (See Illustration A).

2. If the hydraulic separator is used with chilled water spread

a thin layer of sealant on the edge of the insulation and

wait until the solvent evaporates (10 minutes approx.) and

then close it again (See Illustration B).

Procedure for installation and insulation

assembly on flanged models (up to 4")

1. Remove the two black head covers at the ends.

2. Open the two side sections and the lower cap.

3. Install the separator in the system.

4. Use the tape provided on insulation.

5. Reassemble the two side sections, fitting the lower cap

into one of the two sections and then connecting the other.

6. Finish the assembly with the adhesive tape provided in the

box.

7. Complete with the two black head covers.

8. Fit the automatic air vent and the drain valve.

Recommended sealant: Superclear mastic.

SERVICE INSTRUCTIONS

There is no service required for the PSH.

CAUTION: Corrosion or leakage of the PSH can cause

damage or injury. Periodically inspect the PSH for

signs of leakage or corrosion. If noted, PSH must be

replaced. Failure to follow these instructions could result in

property damage and/or moderate personal injury.

Illustration A Illustration B Illustration C

primary

circuit

Primary

Circuit

Flow

Secondary

Circuit

Flow

secondary

circuit

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V58912B May 2012

Loading...

Loading...