Page 1

INSTRUCTION MANUAL

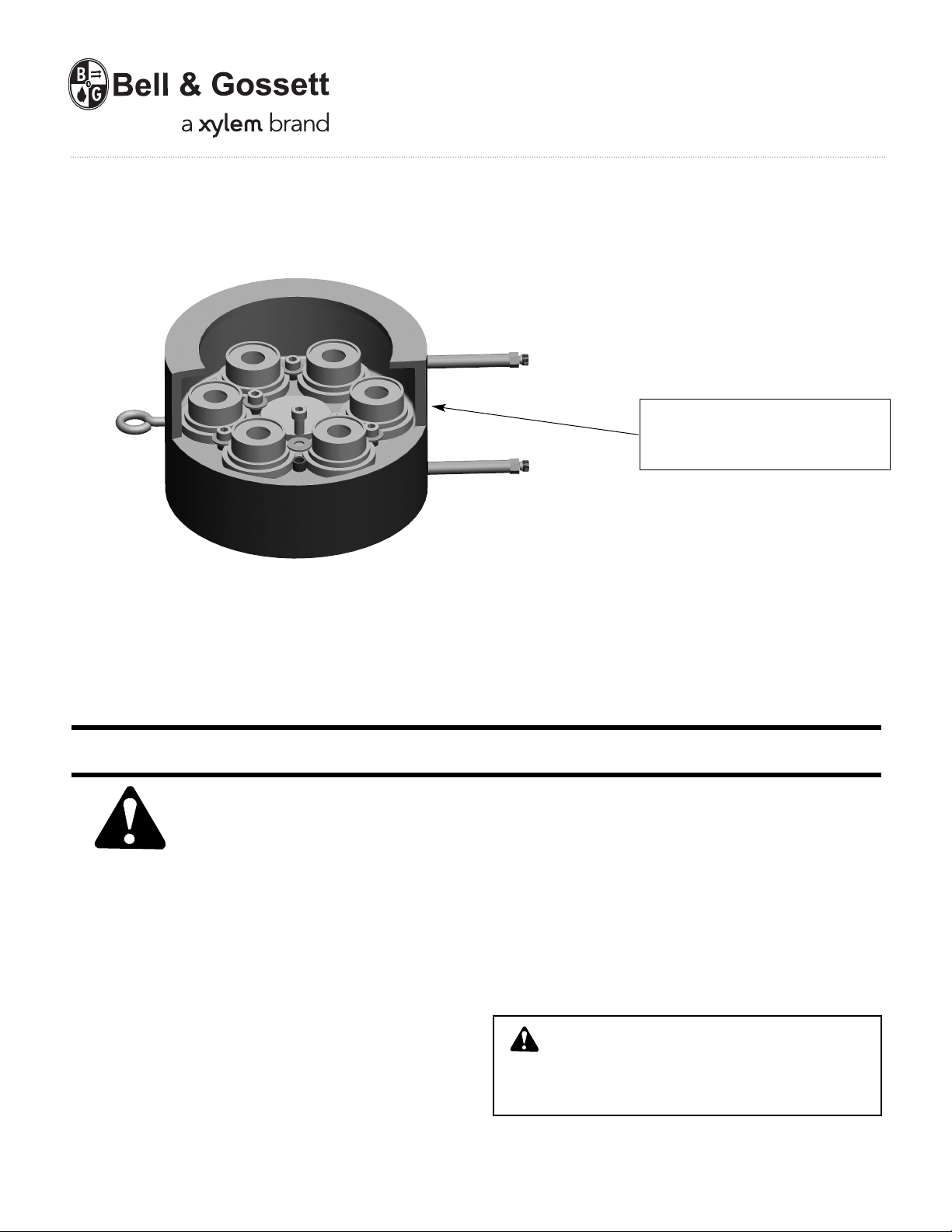

V58046B

WA RN IN G LABEL P AR T NO. V5 6871

INSTALLED IN THIS LOCATION (UNDER

BELL & GOSSETT). IF MISSING IT MUST

BE REPLACED.

Wafer Valve

Automatic Flow-Limiting Valve

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

INSTALLATION INSTRUCTIONS

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

The Bell & Gossett WAFER Valve is designed to fit between

two 150 lb. ASME flanges and to automatically control the

flow in a piping system to a selected preset flow requirement.

As pressure differential increases, a cartridge inside the valve

body reduces the flow area to accurately maintain the preselected flow rate.

Operational Limits

Maximum Operating Temperature: 250ºF (121ºC)

Maximum Op

Flow Control, Differential Pressure:

2 to 60 psig (14 to 414 kPa) nominal

erating Pressure: 250 psig (1724 kPa)

1. For installing Wafer Valves:

a) Install the Wafer valve in the piping system/circuit

where it is desired to maintain the flow at a preselected value. The lifting lug (eye-bolt) provided (from

4" thru 20") will make handling of the valve easier.

In stall the lifting lu

between two identical 150 lb. ASME flanges. Use long

threaded rods to connect the two flanges together

and secure the wafer valve and mating gasket in full

contact with the flanges. Torque each nut on the

threaded rod to specified torque value necessary for

typical flange torque connections.

CAUTION: Use unit lifting eyes only to lift unit as

shipped from factory. Unit must be empty and

disconnected from pipe, and other restraints. Use proper

rigging procedures. Failure to follow these instructions

could result in injury or property damage.

b) Install the unit so that the flow arrow on the body

housing points in the directio

g i nt o t he valve body. Install

n of flow.

Page 2

c) Install the pressure readout fittings into the valve

body using the extension adapters first. Then install

the pressure and temperature access port onto the

extension adapter

1

/4 inch NPT end.

SERVICE INSTRUCTIONS

Should the Wafer Valve require cleaning or changing the

orifice, consult the following instructions.

CAU TI O N: The gen erous us e of pi pe jo int

compound when installing the adapter or P/T will

foul the valve operating mechanism preventing it from

functio ning properly. Pipe joint compound must be

conservatively applied to male threads only. Failure to

follow this instruction can result in moderate personal

injury and/or property damage.

CAUTION: The use of PTFE impregnated pipe

compound and PTFE tape on pipe threads

provides lubricity, which can lead to overtightening and

breakage. Do n ot overtighten. Failure t o follow this

instruction can result in moderate personal injury and/or

property damage.

OPERATING INSTRUCTIONS

Operation of the Wafer Valve is fully automatic and does not

re qu ir e a ny ad ju stment. It a utomatically maintains the

selected flow over the designed differential pressure range.

CAUTION: Hot uninsulated surfaces can cause

burns to the skin. Do not touch hot sur faces.

Fa il ure to foll ow these instruct io ns could result in

moderate personal injury.

HOW TO USE AUTOMATIC FLOW-LIMITING

VALVE PRESSURE TAPS TO DETERMINE

PROPER FUNCTIONING OF VALVE.

1. Using Bell & Gossett Model RP-250 readout probes,

attach a Bell & Gossett differential pressure readout kit to

the readout valves on the Automatic Flow-Limiting Valve.

WAR NING: Hot water leakage can occur from

readout valve during probe insertion and during

hookup of readout kit. Follow the instruction manual

supplied with readout probes and readout kits for safe

use. Failure to follow this instruction could result in

serious personal injury and/or property damage.

WARNING: System fluid under pressure and/or at

high temperature can be very hazardous. Before

servicing, reduce system pressure to zero or isolate the

pressure reducing from the system. Leave drain valve

open. Allow system to cool below 100ºF. Failure to follow

these instructions could result in serious personal injury

or death and property damage.

1. Re move the valve body from the piping syste m b y

unbolting it from the two flanges on either side. Use the

lifting lug (eye-bolt for 4" thru 20") to handle/carry the

valve.

2. Pull the cartridge assembly from the valve body for

cleaning or change to new flow cartridge. The cartridge is

secured

to the mid-plate of the housing by means of 2 or

3 allen head screws. Remove the screws first. Then pull

the cartridge out of the mid-plate bore. Checking the

cartridge by pushing the orifice washer in to the cartridge

housing against the spring force for several times to

make sure spring is functional. Inspect the interior of

cartridge for broken spring or any particles stuck inside

that may prevent fr

ee movement of the cartridge housing.

3. To change the orifice washer (for different flow rate),

remove the clip ring from inside the cartridge housing

with a screwdriver. Pull the orifice wa sher out and

replace it with the new orifice (orifice part number should

be facing upward). Push the new orifice in until it seats all

the way to the bottom of the shelf.

4. Reinstall, or replace the clip ring in the c

artridge-housing

groove and make sure that it is holding the new orifice

disk securely in place.

5. Reassemble the cartridge into the mid-plate bore and

secure with the allen head screws.

WARNING: Corrosion or leakages are indications

th at the Wafer Valve ma y b e about to cause

serious damage from leakage or rupture. It must be

periodically inspected and if noted, it must be replaced.

Failure to follow these instructions could result in serious

personal injury or death and property damage.

2. Read the differential pressure across Wafer Valve. This

can be compared to system pump head to determine

valve function, and system flow blockage.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V58046B September 2012

Loading...

Loading...