Page 1

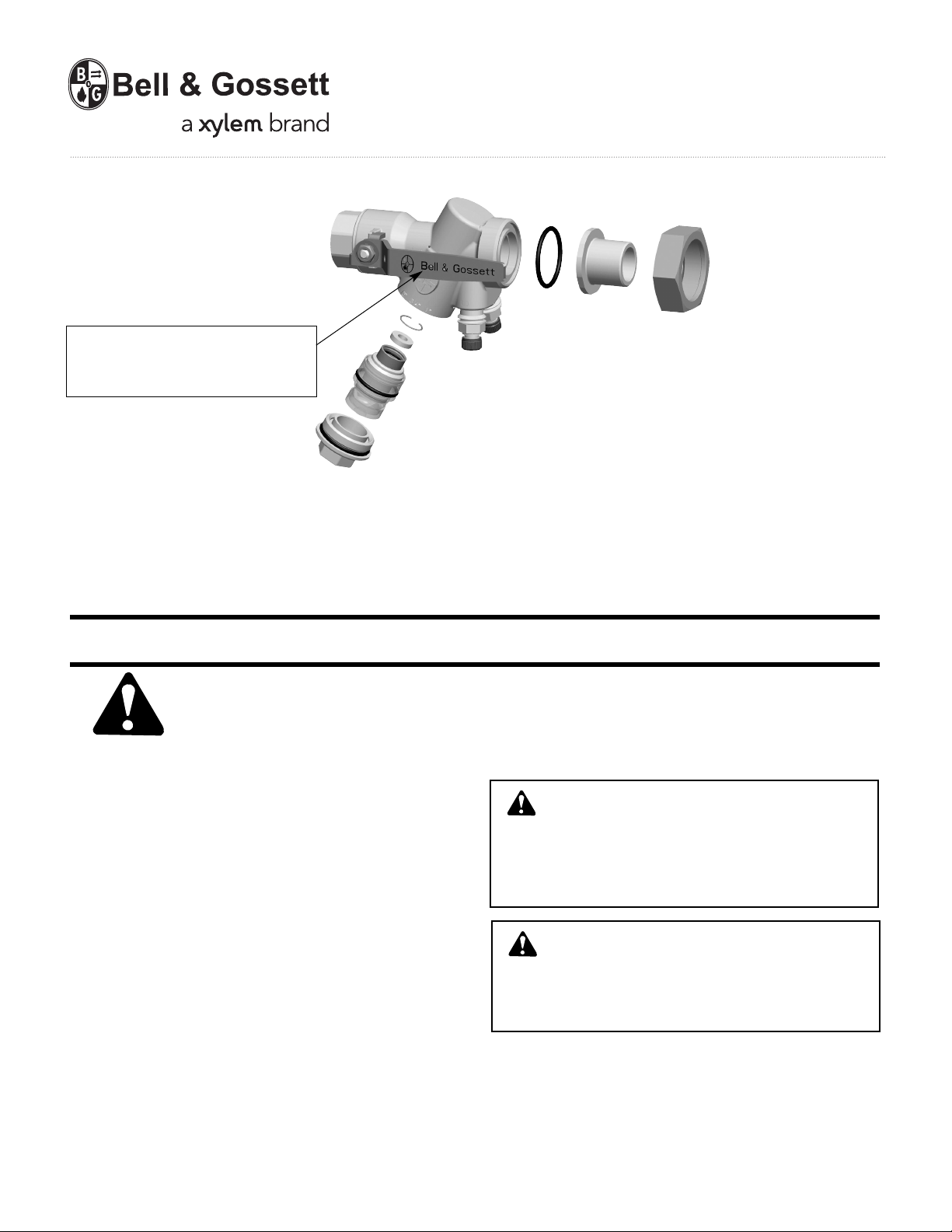

WA RNI N G LAB E L PAR T N O. V56 8 73

INSTALLED IN THIS LOCATION (UNDER

BELL & GOSSETT). IF MISSING IT MUST

BE REPLACED.

Circuit Sentry

INSTRUCTION MANUAL

V58044B

™

Automatic Flow-Limiting Valve

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

b) Install the unit so that the flow arrow on the body

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

The Bell & Gossett Automatic Flow Limiting Valves (AFLV) are

designed to automatically control the flow in piping system to

selected preset limit. As pressure differential increases, a

cartridge inside the valve body reduces the flow area to

accurately maintain the pre-selected flow rate.

Operational Limits

Maximum Operating Temperature: 250ºF (121ºC)*

Maximum Operating Pressure: 300 psig (206

Differential Pressure Flow Control

2 to 60 psig (14 to 414 kPa) nominal

INSTALLATION INSTRUCTIONS

1. For installing NPT Connections:

a) Install the AFLV in the piping system/circuit where it is

desired to maintain the flow at a preselected value.

Apply pipe joint compound sparingly to the male pipe

threads only.

9 kPa)*

2. For installing Sweat Connections:

* Refer to chart A for solder joints for limitations.

housing points in the direction

c) Supports both sides of the unit with wrenches during

instal lation to prevent putting stress on the joint

joining the two sections.

CAUTION: The generous use of pipe joint com-

pound when installing the AFLV will foul the valve

operating mechanism prevent ing it from functioning

properly. Pipe joint compound must be conservatively

appli ed to ma le threads only. Failure to f oll ow this

instruction can result in moderate personal injury and/or

property damage.

CAUTION: The use of PTFE impregnated pipe

compound and PTFE tape on pipe threads pro-

vides lubricity, which can lead to overtightening and

brea kage. Do n ot ov ertig hten. Fail ure t o fol low this

instruction can result in moderate personal injury and/or

property damage.

a) Clean tube ends and valve connections thoroughly

according to good piping practices with a fine grade

emery cloth or fine grit sandpaper.

of flow.

Page 2

b) For soldering, use 95-5 (Tin-Antimony) solder and a

good grade of flux.

c) Use a torch with a sharp pointed flame.

d) When sweating the j o i n t s , f i r s t adjusting the

Aut o m a tic F l o w -Limiti n g Valv e in t h e fu l l open

position, then wrap the valve with a cool wet rag and

then direct the flame with care to avoid subjecting

AFLV to excessive heat. Allow the valve to cool before

touching or operating.

e) Check the so

ldered connection for leaks.

WARNING: Use of improper procedures to sweat

valve model with union connection into system

can d a m a g e valve. Be f o r e installing sw eat union

connection to valve, remove the union nut and O-ring

from the valve body, the union tailpiece with nut must be

sweate d (soldered) into place. Failure to follow

this

in str uct ion co uld re sul t i n p rop erty damage and/or

moderate personal injury.

HOW TO USE AUTOMATIC FLOW-LIMITING

VALVE PRESSURE TAPS TO DETERMINE

PROPER FUNCTIONING OF VALVE.

1. Using Bell & Gossett Model RP-250 readout probes,

attach a Bell & Gossett differential pressure readout kit to

the readout valves on the Automatic Flow-Limiting Valve.

WARNING: Hot water leakage can occur from

readout valve during probe insertion and during

hookup of readout kit. Follow the instruction manual

supplied with readout probes and readout kits for safe

use. Failure to follow this instruction could result in

serious personal injury and/or property damage.

2. Read the differential pr

Limiting Valve. This can be compared to system pump

head to determine valve function, and system flo w

blockage.

essure across the Automatic Flow-

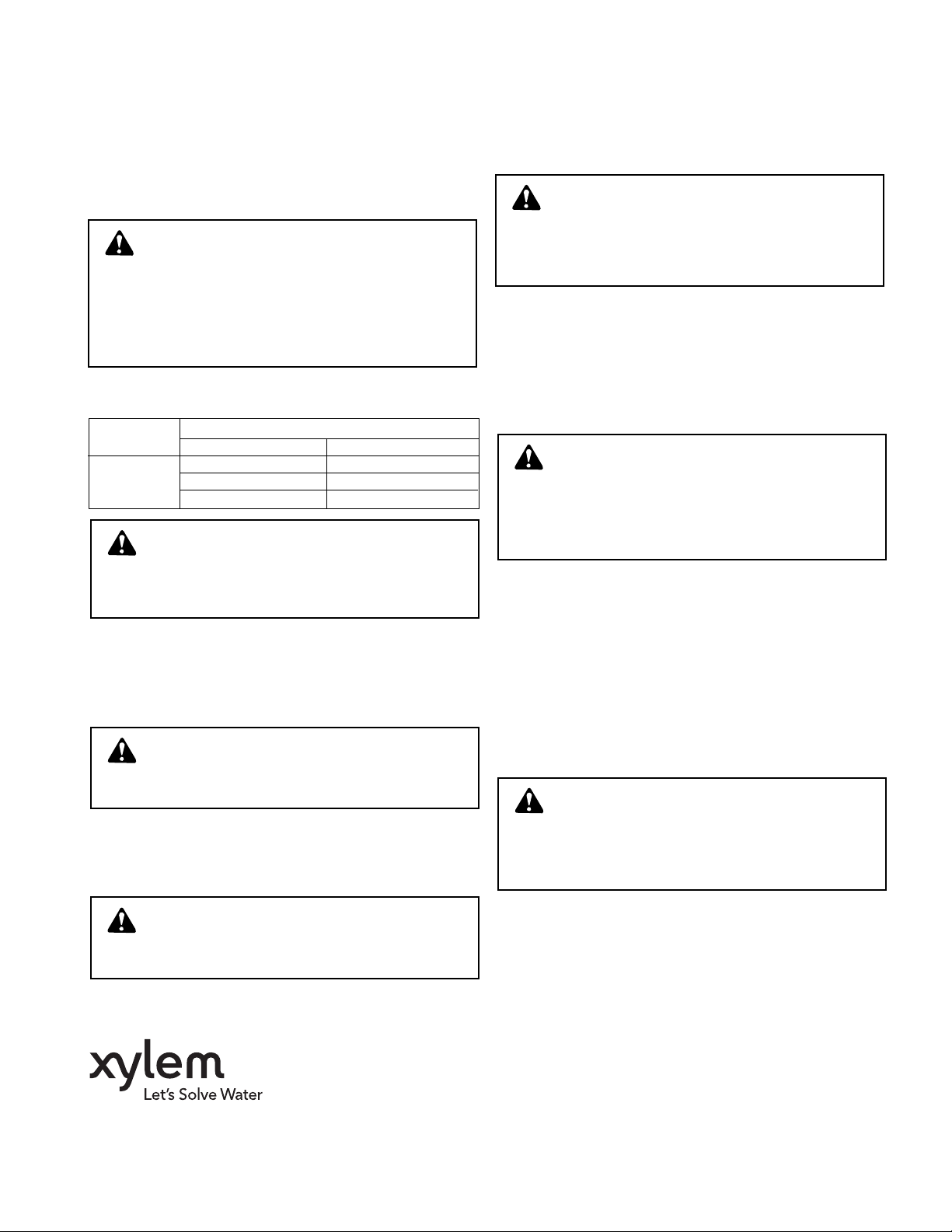

Chart A

(SOLDER TYPE LIMITS PER ASTM STD. B16.22-1989)

TYPE OF MAXIMUM LIMITATIONS

SOLDER PRESSURE PSIG TEMPERATURE ºF

95-5 300 175

TIN- 250 200

ANTIMONY 175 250

CAUTION: Heat associated with the use of silver

solder may damage an Automatic Flow-Limiting

valve and void the product warranty. Do not use silver

solder. Failure to follow these instructions could result in

property damage and/or moderate personal injury.

OPERATING INSTRUCTIONS

Oper ation of the Automatic Flow-Limiting V alve is fully

automatic and does not require any adjustment. It automatically maintains the selected flow over the designed

differential pressure range.

CAUTION: Hot uninsulated surfaces can cause

burns to the skin. Do not touch hot surfaces.

Fa i lure to fol l ow these in s truc t ions cou ld r esul t in

moderate personal injury.

Before the system start up, remove cartridge from the valve.

Flush the hydronic system and then reassembl

the valve and make sure cap is tightened properly. Start the

system and check for the AFLV leak.

e cartridge into

SERVICE INSTRUCTIONS

Should the Automatic Flow-Limiting Valve require cleaning or

changing the orifice, follow the following instructions.

WARNING: System fluid under pressure and/or at

high temperature can be very hazardous. Before

servicing, reduce system pressure to zero or isolate the

pressure reducing from the system. Leave drain valve

open. Allow system to cool below 100ºF (38ºC). Failure to

follow these instructions could result in serious personal

injury or death and property damage.

1. Loosen and remove the bonnet (cap) from the valve body.

2. Pull the cartridge assembly from t he valve body for

cleaning or

cartridge by pushing the orifice washer in to the cartridge

housi n g for s e v e r a l times t o make s u r e spring i s

functional.

3. If you design to changing the orifice washer (for more or

less flow rate). With a screwdriver, remove the clip ring

from inside the cartridge housing. Pull the orifice washer

out and re place wi th the n ew orifi ce that you h ave

preferred.

4. Rei

nstall, or replace the clip ring in the cartridge housing

groove and reassemble the bonnet with the O-ring.

about to cause serious damage from leakage or rupture.

It must be periodically inspected and if noted, it must be

replaced. Failure to follow these instructions could result

in serious personal injury or death and property damage.

change the new flow cartridge. Checking the

WARNING: Corrosion or leakages are indications

that the Automatic Flow Control Valve may be

CAUTION: Hot uninsulated surfaces can cause

burns to the skin. Do not touch hot surfaces.

Fa i lure to fol l ow these in s truc t ions cou ld r esul t in

moderate personal injury.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V58044B September 2012

Loading...

Loading...