Page 1

INSTRUCTION MANUAL

WARNING: Label Part No. V56873

installed in this location (under

Bell & Gossett). If missing it must

be replaced.

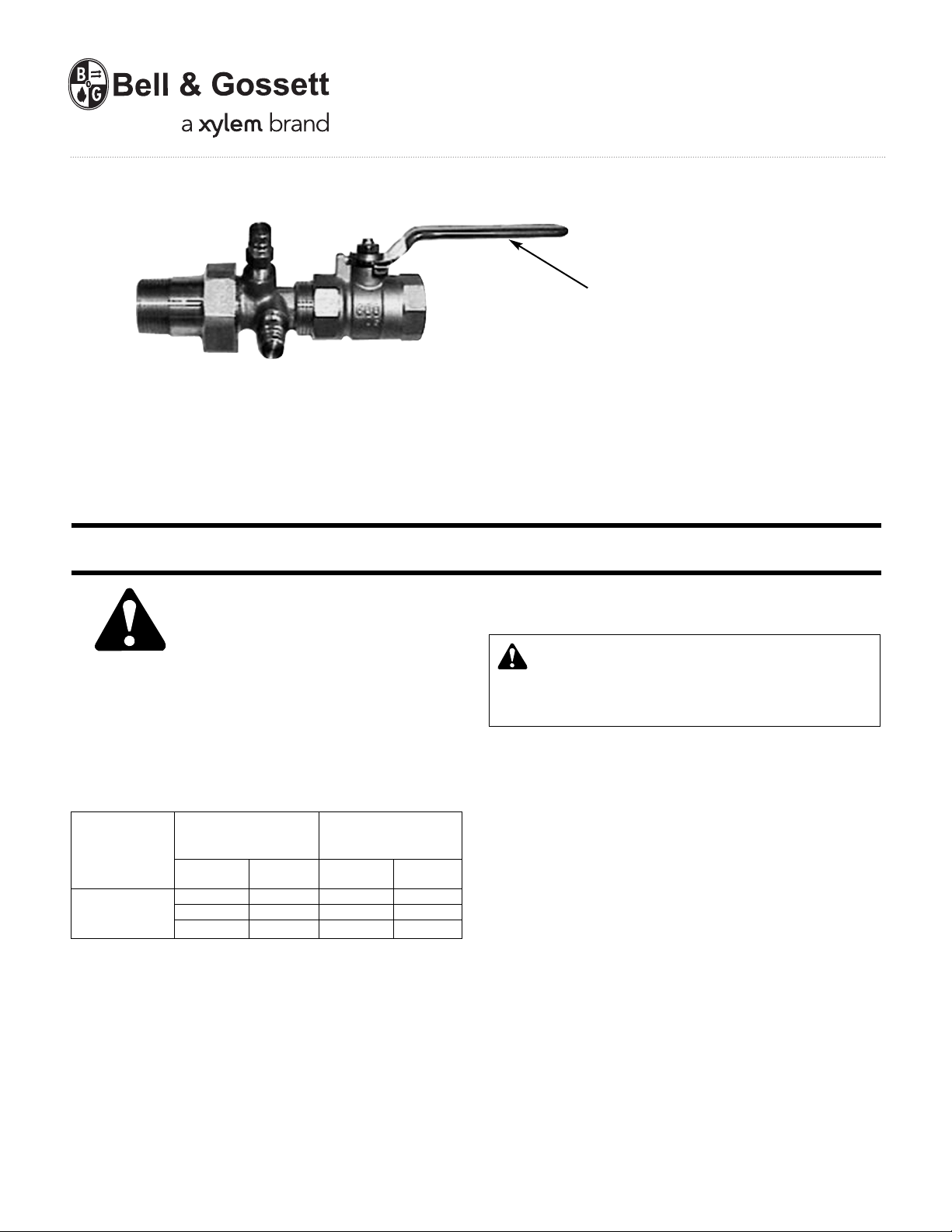

Venturi/Ball Valve Combination

V57895B

Model MV

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

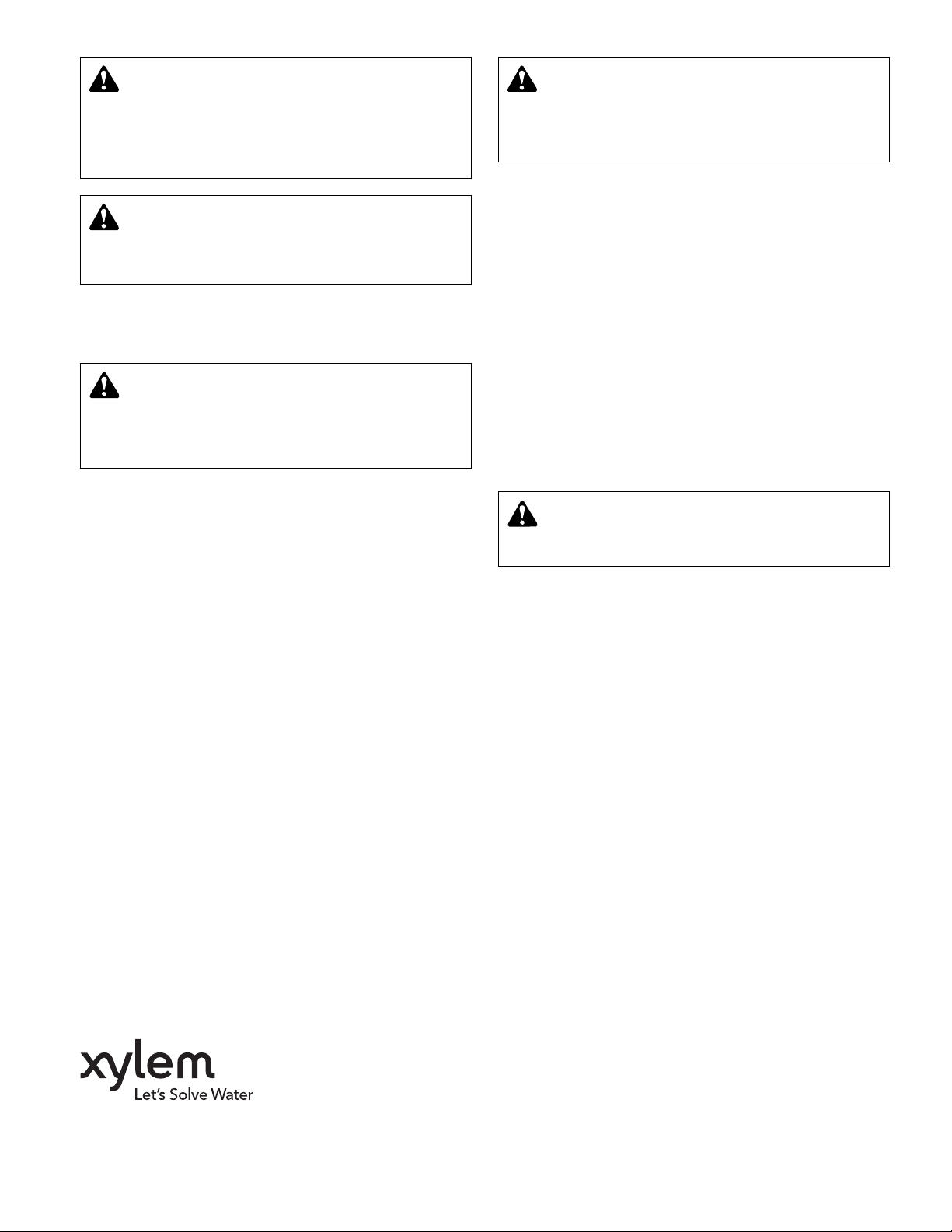

OPERATIONAL LIMITS

WORKING PRESSURE & TEMPERATURE LIMTS

(SOLDER TYPE LIMITS FOR ANSI STD. B.16.18)

MAXIMUM MAXIMUM

TYPE OF 1/2" – 1" 11/4" – 2"

SOLDER PRESSURE TEMP PRESSURE TEMP

95-5 300 (2069) 200 (93) 300 (2069) 175 (79)

TIN- 250 (1724) 225 (107) 250 (1724) 200 (93)

ANTIMONY 200 (1379) 250 (121) 175 (1207) 250 (121)

NPT

Maximum Operating Pressure 400 psig (2758 kPa)

Maximum Operating Temperature 250°F (121°C)

LIMITATIONS LIMITATIONS

PSI (kPa) °F (°C) PSI (kPa) °F (°C)

Venturi/Ball valve provides highly accurate flow measurement

capabilities.

WARNING: Damage to the Venturi/Ball valve or failure

of solder sealing joints may occur it these operational

limits are exceeded. This can result in water leakage.

Failure to follow this instruction can cause serious personal injury and/or property damage.

INSTALLATION INSTRUCTIONS

1. For installing Sweat Connections:

a) Clean tube ends and valve connections thoroughly per

good piping practices with a fine grade emery clot

fine grit sandpaper.

b) For soldering, use 95-5 (Tin-Antimony) solder and a

good grade of flux.

c) Use a torch with a sharp pointed flame.

d) When sweating the joints, first adjusting the valve in the

full open position, then wrap the valve with a cool wet

rag and then direct the flame with care to avoid subjecting the valve to excessive heat. Allow the valve to cool

before touching or operating.

e) Chec

k the soldered connection for leaks.

h or

DESCRIPTION

The Bell & Gossett Model MV is a combination calibrated balance, commissioning and positive shutoff valve for use in

HVAC systems. An efficient brass venturi design provides

accurate flow balancing with minimal system pressure loss.

Valves are furnished with two readout valves (pressure and

temperature p

stop, and a hanging ID tag for commissioning. A variety of

end connections are available on both the fixed and union

ends.

orts), standard port ball valve with memory

Page 2

WARNING: Use of improper procedures to sweat

valve model with union connection into system can

damage valve. Before installing sweat union connection to

valve, remove the union nut and O-ring from the valve

body, then union tailpiece with union nut must be sweated

(soldered) into place. Failure to follow this instruction could

result in property damage and/or moderate personal injury.

CAUTION: Heat Associated with the use of silver

solder may damage a Venturi/Ball valve and void the

product warranty. Do not use silver solder. Failure to follow

these instructions could result in property damage and/or

moderate personal injury

2. For installing NPT connections:

Apply pipe compound conservatively to male connecting

fittings only.

CAUTION: The use of PTFE impregnated pipe

compound and PTFE tape on pipe threads provides

lubricity. Care should be taken to prevent overtightening

which may damage the valve body. Failure to follow these

instructions can result in moderate personal injury and/or

property damage.

After installation check all joints for leakage and retighten

where necessary.

OPERATION INSTRUCTIONS

1. Energiz e the zone, c ircuit a nd/or sy stem pump(s) as

applicable.

2. Using Bell & Gossett Model RP-250B Readout Probes,

sequentially attach a Bell & Gossett differential pressure

readout kit to the readout valves on each Venturi/Ball

valve.

WARNING: Hot water leakage can occur from readout valves during probe insertion and during hookup

of readout kit. Follow the instruction manuals supplied with

readout probes and readout kits for safe use. Failure to

follow these instructions could result in serious personal

injury or death and property damage.

3. Read the differential pressure across the orifice of the

Venturi/Ball valve.

4. Using the differential pressure data sheet #EP-600 of the

Venturi/Ball valve to read actual GPM.

Example: The Venturi/Ball valve model 3/4" L. If the differential pressure across the orifice read at 46" W.C. the

flow rate is 4 GPM.

HOW TO USE THE MEMORY STOP FEATURE

1. Make the final degree

of closure setting.

2. Loos en the handle nut and rot ate memory st op un til

against the body locking.

3. Tighten the handle nut.

SERVICE INSTRUCTIONS

Periodically inspect the Venturi/Ball for signs of leakage or

corrosion.

WARNING: Corrosion or leakage is indication, that

the Venturi/Ball must be replaced. Failure to follow

these instructions could result in serious personal injury or

death and property damage.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V57895B September 2012

Loading...

Loading...