Page 1

INSTRUCTION MANUAL

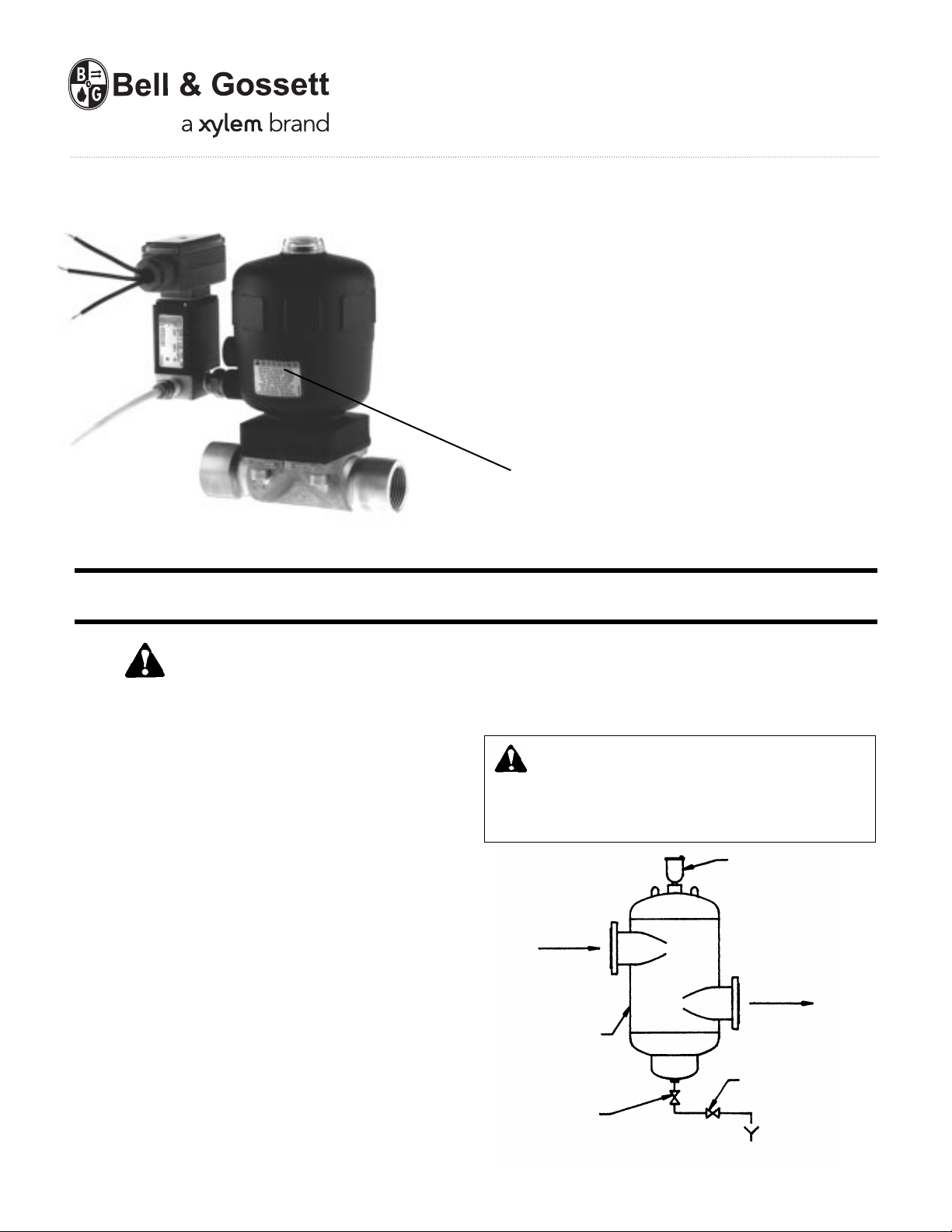

SRS

Pneumatic

Purge Valve

WARNING LABEL PART NO. V56845

INSTALLED IN THIS LOCATION.

IF MISSING, IT MUST BE REPLACED.

V57050B

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

DESCRIPTION

The SRS Pneumatic Purge Valve is an air-operated diaphragm

valve with programmable timer. It is used to purge sediment

from an open or closed loop hydronic system that is separated out and collected in the bottom of the SRS.

OPERATIONAL LIMITS

Maximum Fluid Operating Temperature: 250°F (121°C)

Maximum Fluid Operating Pressure: 150 PSI (1034 kPa)

Min/Max Ambient Temperature: 32-130°F (0-54°C)

Min/Max Control Air Pressure: 65-145 PSI (450-1000 kPa)

INSTALLATION INSTRUCTIONS

Connections Required To Valve/Timer:

120V AC (±10%) to timer 3-terminal strip.

Air connection to 1/4" FNPT port on solenoid

Valve. 1" FNPT inlet and outlet.

1. Reference Sediment Removal Separator Instruction Manual

A05767.

2. For best results, purge valve/timer should be installed upstream of any pipe bends.

3. The purge valve/timer can be installed in any orientation.

4. A manual gate or ball valve is recommended between the

SRS and the purge valve/timer in the event that the purge

valve needs repair. During normal operation, this manual

valve must remain fully open.

CAUTION: The use of PTFE impregnated pipe com-

pound and PTFE tape on pipe threads provides

lubricity which can lead to overtightening and breakage.

Do not overtighten. Failure to follow this instruction can

result in MODERATE personal injury from hot water and/or

property damage.

AUTOMATIC

Figure 1

INLET

FROM BOILER

CHILLER OR

CONVERTER

B&G SEDIMENT

REMOVAL

SEPARATOR

MANUAL

SHUTOFF

VALVE

AIR VENT

OUTLET

TO PUMP

SECTION

BLOW DOWN

VALVE

Page 2

5. Pipe as required to allow gravity flow of sediment and

water, and proper drainage.

6. Apply approximately 2 wraps of PTFE tape to the male end

of 1" field piping as it comes from the SRS and recommended service valve, and install into the inlet of the 1"

FNPT connection of the purge valve. Do the same for the

1" FNPT outlet and run the piping to a nearby drain.

7. Run air for the valve in accordance with local code. Be certain that the minimum and maximum control pressure for

the air are complied with. Purchase a 1/4" air hose adapter,

apply PTFE tape to the threads, and insert into the 1/4" air

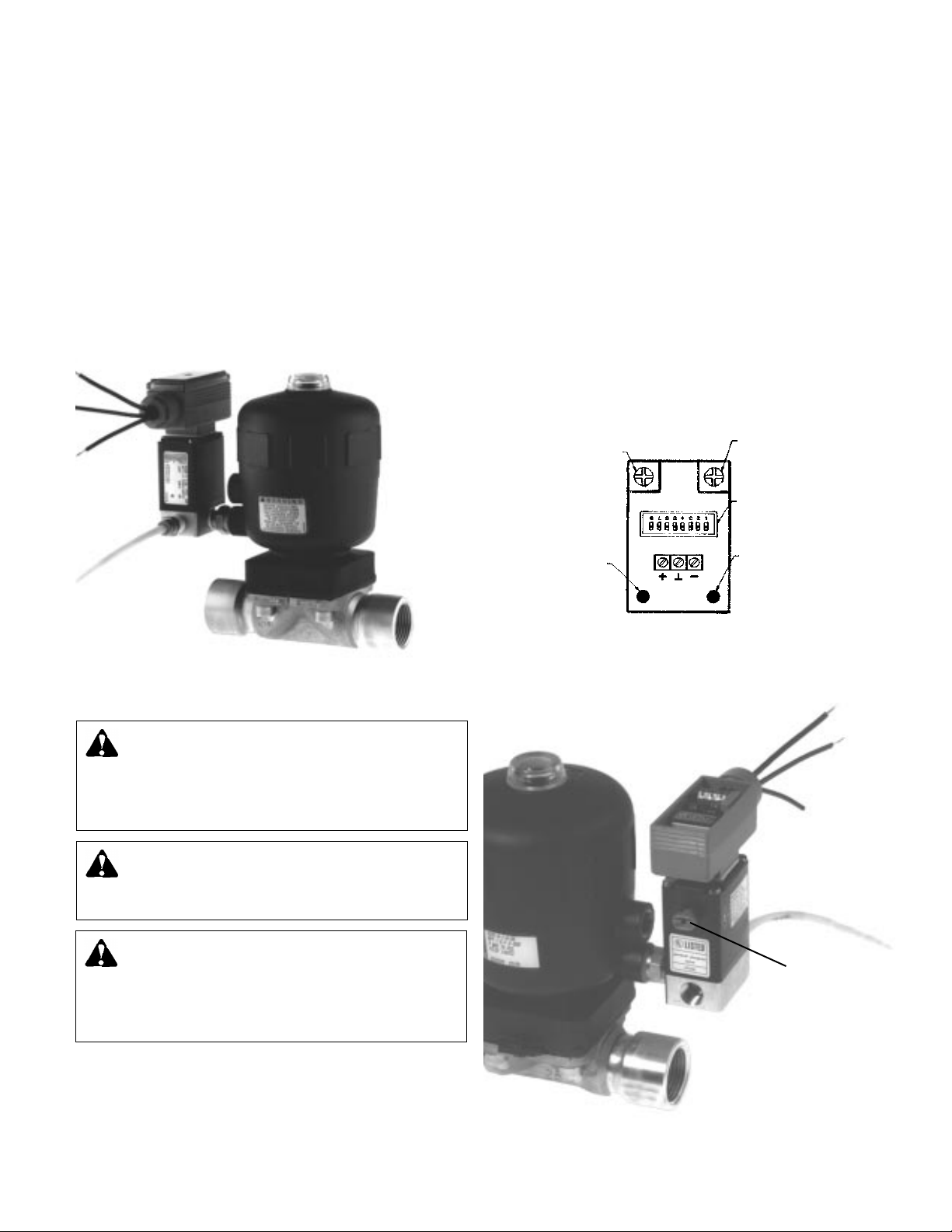

port on the side of the solenoid valve as shown in Figure 2.

Then attach tubing.

Timer

OPERATING INSTRUCTIONS

The timer is factory set as follows:

Cycle Time (how often the valve opens): 4 hrs.

Purge Duration (how long valve remains open per cycle): 10 sec

At start-up, the valve can be manually purged by depressing

the button located on the side of the solenoid. (See Figure 4).

We recommend manually purging the valve approximately

every 30 minutes for 2 hours to determine if the factory setting

is sufficient to handle the sediment problem in the system.

Keep in mind that the first hour of start up will typically have a

greater concentration of sediment than that found after several

hours of operation.

If the factory setting is insufficient, adjustment is made by a

series of DIP switches in the timer. The switches are accessed

by removing the cover of the timer. Figure 3 is a sketch of the

timer assembly, and Figure 5 is a diagram of the DIP switches

and the range of settings available.

TIMER CONNECTIONS & ADJUSTMENTS

Valve

Actuator

Pilot Valve

Figure 2

WARNING: Water at temperatures above 100°F

(38°C) can be very hazardous. Piping from valve to

drain should be such that there is no risk of exposure of

hot water to personnel or equipment. Failure to follow

these instructions could result in serious personal injury or

death and property damage.

WARNING: Electrical shock and potential circuit

damage. Disconnect power before beginning installation. Failure to follow these instructions could result in

serious personal injury or death and property damage.

Cycle Time

Potentiometer

Output

Led

Figure 3

Duration of

Purge Time

Potentiometer

Dip

Switches

Power

Led

WARNING: Improper wiring and wire can cause

electrical shock and fires. Wiring connections must

be made in accordance with all applicable electrical codes

and ordinances. Use copper wire only. Failure to follow

these instructions could result in serious personal injury or

death and property damage.

8. Install 120V AC to the timer per local code. Remove the

timer cover to expose the 3 terminal strip. Connect 120V

AC to the terminal strip. Attach the middle terminal to

ground. These connections provide the power for the solenoid and timer. See Figure 3.

2

Manual

Purge

Button

Figure 4

Page 3

t

on

tmin tmax 1 2 3 456 7 8

.5 s 10 s down down down down up down down down

1.5 s 30 s down down up down up down down up

5 s 100 s down up down down up down up down

.5 min 10 min down up up down up down up up

1.5 min 30 min up down down down up up down down

5 min 100 min up down up down up up down up

12 min 240 min up up down down up up up down

.5 h 10 h up up up down up up up up

t

off

CAUTION: Changing the #4 and #5 setting can result

in excessive water loss. Do not change these settings.

Failure to follow this instruction can result in property damage.

POTENTIOMETERS

Figure 5

decrease

cycle

increase

cycle

decrease

purge

increase

purge

As indicated in Figure 5, there are 8 ranges to choose from.

The potentiometers below the DIP switches are used to adjust

the settings within the desired range. DIP switches 1-3 are

used to adjust the duration. DIP switches 6-8 are used to

adjust the cycle. Note that setting of time is proportional, e.g.

8 sec in the .5 s - 10 s range becomes 8 h when changed to

the .5 - 10 h range. Adjustment is as follows:

DANGER: ELECTRICAL SHOCK HAZARD:

Disconnect or otherwise interrupt power to the timer

before programming the unit. Failure to follow these instructions will result in serious personal injury or death.

1. Disconnect or otherwise interrupt power to the timer before

programming the unit.

2. Remove cover of timer (using a screw driver to remove the

screw in the center of the cover).

3. Calculate the percentage of the cycle range required.

4. Change the DIP settings 1-3 and/or 6-8 to a lower range.

5. Adjust potentiometers as labeled in Figure 5 to fine-tune to

desired setting:

Counter clock-wise (CCW) = decrease

min is maximum CCW setting)

(t

Clock-wise (CW) = increase

(t

max is maximum CW setting)

6. Connect the power to the timer and observe the results.

Determine if additional adjustment of the potentiometer is

necessary. If additional adjustment is required then disconnect or interrupt power to the timer and repeat from Step 4,

if not proceed to Step 7.

7. Return DIP settings to desired range.

8. Replace cover on the timer.

9. Supply power to the timer.

EXAMPLE

An example will help illustrate the procedure:

Desired setting: Cycle every 8 hours with 20 sec purge dura-

tion per cycle.

Current factory setting: Cycle every 4 hours with 10 sec purge

duration per cycle.

Step 1: Disconnect or interrupt the power to the timer.

Step 2: Remove the cover to the timer by removing the screw

on the face of the coverplate.

Step 3: 8 hours is 8/10 of the present range.

Step 4: Since settings are proportional, adjustment can be

made in shorter time ranges to enable observation of the

results of the changes in a shorter period of time. Adjust the

cycle time by setting the DIP switches to the .5 s - 10 s range

(6-8 are all set down). Now the valve will cycle every 4 seconds (instead of 4 hours).

Step 5: Adjust the potentiometer located below the 6-8 DIP

switches CW to increase the cycle time to the desired 8 seconds. Turn on the power briefly to confirm that the desired

setting is attained, then disconnect or interrupt the power

before further adjustments are made or before proceeding.

Once complete, set the DIP switches to a range which will

facilitate the setting of the purge duration. In our example, 20

sec falls within the 1.5 s - 30 s range. Since t

max and tmin are

obtained by potentiometer adjustment fully CW and CCW

respectively, adjust the potentiometer under DIP settings 1-3

to a setting between these two values. Turn on the power

briefly to confirm that the desired setting is attained, then disconnect or interrupt the power before further adjustments are

made or before proceeding.

Step 6: Return the cycle time setting to the .5 h - 10 h range

by adjusting the DIP settings 6-8 all up, and the purge setting

to the 1.5 s - 30 s range by adjusting DIP settings 1-3 down,

down and up respectively.

Step 7: Replace cover to the timer.

Step 8: Turn on the power to the timer.

SERVICE INSTRUCTIONS

These valves are designed for sediment service. It is possible,

particularly in abrasive service, that sediment may become

lodged in valve seat upon valve closure which results in leaking. If the valve is leaking, manually purge the valve by depressing the button on the side of the solenoid valve until the water

appears relatively clear. See Figure 4.

Then release your finger from the button to stop the purge. If

leaking continues, this may be a sign that the valve seat is

damaged and in need of replacement. The following is a procedure to replace the diaphragm. Other parts in need of

replacement or repair shall be done at the factory.

3

Page 4

DIAPHRAGM REPLACEMENT (See Figure 6)

WARNING: System fluid under pressure and/or at

high temperature can be very hazardous. Before servicing, reduce system pressure to zero or close the upstream shutoff valve (See No. 4 Installation Instruction

Section). Leave purge valve in open position, and allow

system fluid trapped between the shutoff valve and the

drain to drain completely. Failure to follow these instructions could result in serious personal injury or death and

property damage.

Required parts: EPDM screwed-in diaphragm part no. V57051

1. Turn valve to stand on the cover

18

2. Unfasten the 4 body screws 24

3. Remove body 22 and screws 24

4. Unscrew and remove old/defective diaphragm 21

5. Slightly grease screw threads in the actuator housing 11

(NOTE: use lithium grease ZETGE M 51)

CAUTION: Diaphragm and all diaphragm connecting

parts must be kept free of petroleum based lubricat-

ing fluids and greases.

6. Align the diaphragm with the actuator. Mold seam of diaphragm must be perpendicular to the flow direction.

7. Put body 22 back on. Press down on body to start screws

24 into the actuator thread.

8. Switch actuator on and off twice, fasten screws

24 cross-

wise in unpressurized condition (torque at 5 N-m).

9. Examine valve to make sure it is operating properly and

there are no leaks.

21

20

5

19

18

12

11

1

22

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V57050B December 2012

23

24

Figure 6

Loading...

Loading...