Page 1

Installation, Operation

and Service Manual

™

Ultra Setter

Pressure

Independent Control

Valves

Page 2

Page 3

Table of Contents

Introduction and Safety..................................................................................................................2

Introduction..................................................................................................................................2

Safety.............................................................................................................................................2

Safety message levels............................................................................................................. 2

User safety................................................................................................................................ 3

Environmental safety...................................................................................................................4

Transportation and Storage.......................................................................................................... 5

Inspect the delivery.....................................................................................................................5

Inspect the package................................................................................................................5

Inspect the unit........................................................................................................................ 5

Product Description........................................................................................................................6

General description.................................................................................................................... 6

Operational limits.................................................................................................................... 7

Table of Contents

Installation........................................................................................................................................8

Installation precautions...............................................................................................................8

Installation guidelines.................................................................................................................8

Pipe hanging installations.......................................................................................................... 8

Install flanged connections........................................................................................................ 9

Install the actuator....................................................................................................................... 9

Attach insulation........................................................................................................................10

Operation.......................................................................................................................................11

Recommended operating procedures.................................................................................. 11

Maintenance..................................................................................................................................12

Precautions.................................................................................................................................12

Valve inspection........................................................................................................................ 12

Service P/T Ports........................................................................................................................12

Product warranty...........................................................................................................................14

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 1

Page 4

Introduction and Safety

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the

product can cause personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the

unit.

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Operating, installing, or maintaining the unit in any way that is not covered in this

manual could cause death, serious personal injury, or damage to the equipment. This

includes any modification to the equipment or use of parts not provided by Xylem. If

there is a question regarding the intended use of the equipment, please contact a

Xylem representative before proceeding.

• Do not change the service application without the approval of an authorized Xylem

representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result

in physical injury, damage, or delays.

Safety message levels

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

2 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 5

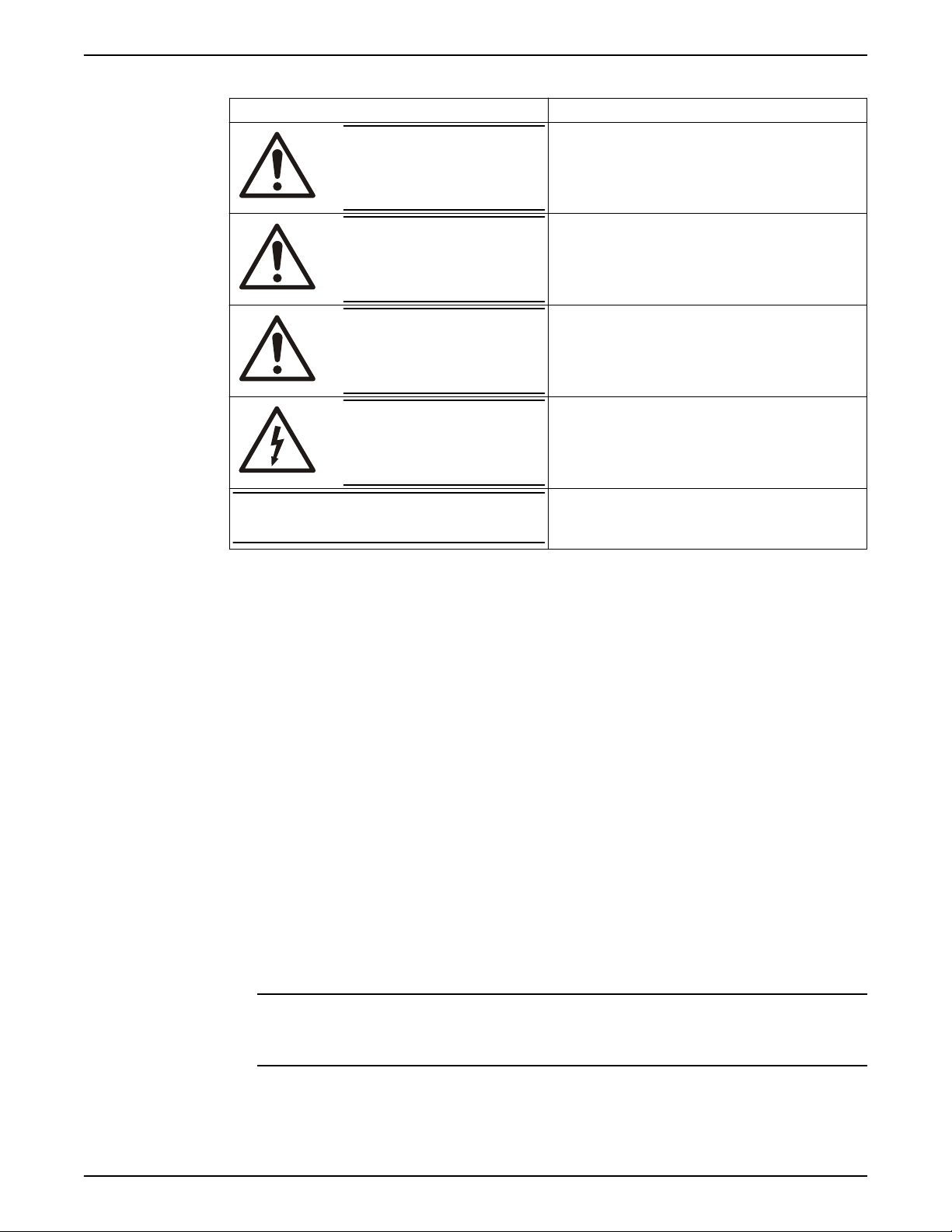

Definitions

Safety message level Indication

DANGER:

A hazardous situation which, if not avoided, will result in

death or serious injury

Introduction and Safety

User safety

General safety rules

WARNING:

CAUTION:

Electrical Hazard:

NOTICE:

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc

hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

A hazardous situation which, if not avoided, could result

in death or serious injury

A hazardous situation which, if not avoided, could result

in minor or moderate injury

The possibility of electrical risks if instructions are not

followed in a proper manner

• A potential situation which, if not avoided, could

result in undesirable conditions

• A practice not related to personal injury

flash

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

Electrical connections

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations. For more information about

requirements, see sections dealing specifically with electrical connections.

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 3

Page 6

Introduction and Safety

Precautions before work

Observe these safety precautions before you work with the product or are in connection

with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage

• Make sure that the lifting equipment is in good condition and is properly rated for the

• Use a lifting harness and safety line, as required.

• Allow all system and pump components to cool before you handle them.

• Make sure that the product has been thoroughly cleaned.

• Disconnect and lock out power before you install or service the actuator.

• Check the explosion risk before you weld or use electric hand tools.

Wash the skin and eyes

property.

load to be lifted.

Follow these procedures for chemicals or hazardous fluids that have come into

contact with your eyes or your skin:

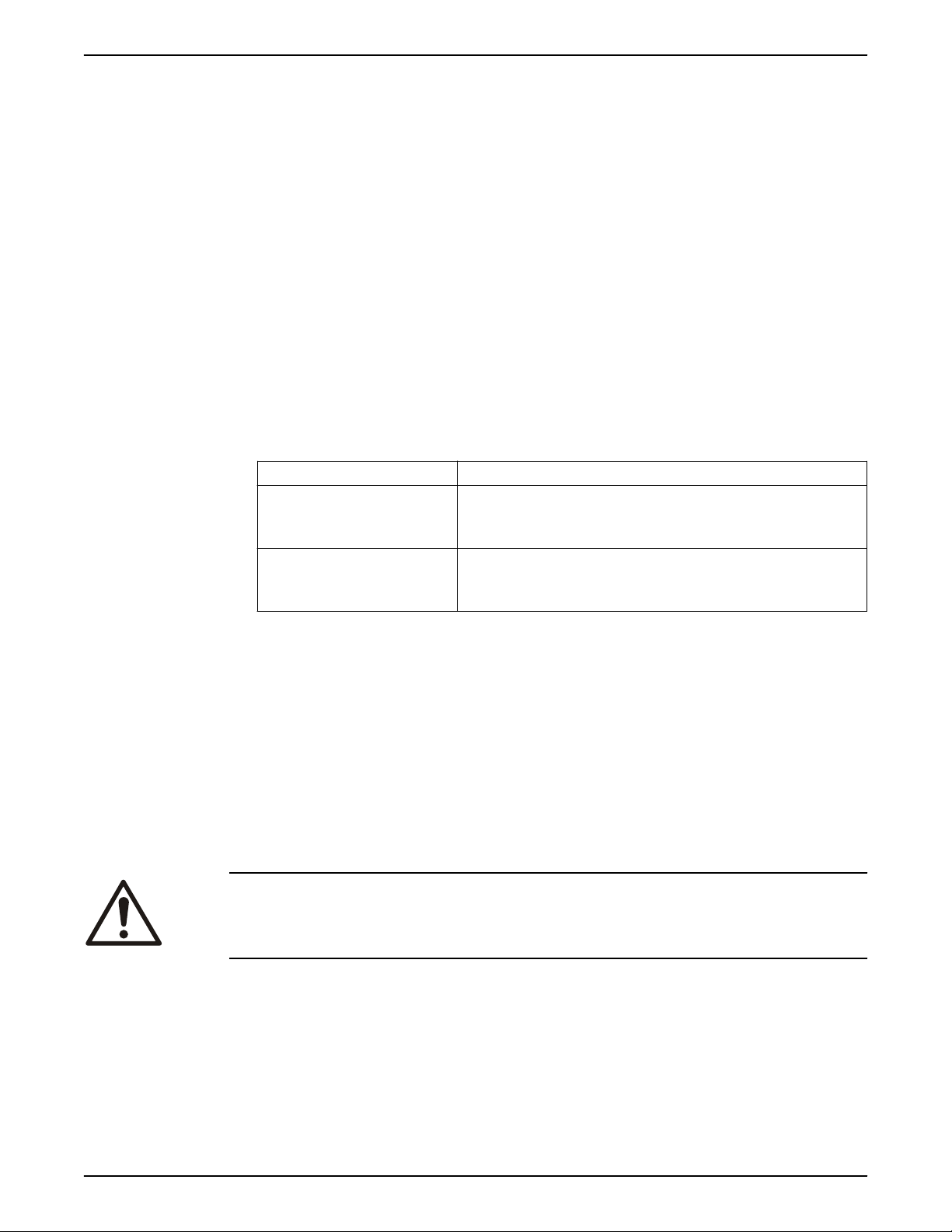

Condition Action

Chemicals or hazardous fluids in

eyes

Chemicals or hazardous fluids on

skin

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

Environmental safety

The work area

Always keep the station clean.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable

environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless

Xylem has been informed and appropriate actions have been agreed upon.

Electrical installation

For electrical installation recycling requirements, consult your local electric utility.

Recycling guidelines

Always follow local laws and regulations regarding recycling.

4 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 7

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

Parts included in package

• Ultra Setter™ Large Pressure Independent Control Valve

• Installation, Operation, and Service Manual (IOM)

• Operational instruction tag

Additional parts needed:

• Valve actuator

• Flange gaskets

• Nuts and bolts

Transportation and Storage

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact the local sales representative if there is any issue.

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 5

Page 8

Product Description

Product Description

General description

The Ultra Setter is a pressure independent combination temperature control, balance,

and commissioning valve for use in hydronic HVAC systems.

WARNING:

California Proposition 65 warning! This product contains chemicals known to the state of

California to cause cancer and birth defects or other reproductive harm.

NOTICE:

This product is not intended for potable water applications.

The innovative design of the Bell & Gossett Ultra SetterTM introduces a modulating control

component that retains 100% authority at all times. With the Ultra SetterTM, there are two

independent movements for the presetting and the modulating function. During

presetting, that is selecting the desired flow rate, the inlet area moves radially without

interfering with the length of the stroke. During modulating, the inlet area moves linearly

taking advantage of the full stroke.

While the actuator provides proportional modulation irrespective of the preset flow, the

automatic balancing cartridge guarantees that the flow never exceeds the maximum

preset flow. Regardless of pressure fluctuations in the system, the maximum flow rate is

kept constant once the minimum differential pressure listed in the product submittal is

met, up to 90 PSI (600 kPa).

The flow rate of the valve can be set according to the convenient GPM flow rate scale next

to the valve stem.

Select the appropriate size Ultra SetterTM pressure independent balancing control valve,

normally line size, for the required flow rate. Ideally, Ultra SetterTM valves should be

selected such that they operate at about 80% of their maximum flow, enabling them to

deliver spare capacity, if required.

The scale is for the adjustment of flow. If you want to close the branch line, use an isolation

valve in conjunction with the Ultra SetterTM valve.

Ultra Setter features

• Internal automatic balancing cartridge

• External control actuator (provided separately)

• 1/4” NPT readout ports

• 125# or 250# ANSI flanged connections

• Flow rate scale in GPM

Actuator

Model Actuator

Ultra Setter Analog Control Signal

(0-10V or 4-20mA)

6 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

3–Position Tri-State

Control Signal

Spring Return

Normally Open

Spring Return

Normally Closed

Page 9

Operational limits

Valve

Ultra Setter

Product Description

Maximum Limitations

Temperature ºF (ºC)

#125 Flange 32ºF (0ºC) to 250ºF (120ºC) —

Fluid

#250 Flange 360 PSI (2500 kPa)

34ºF (1ºC) to 122ºF (50ºC) —

Ambient

Max. working pressure PSI

(kPa)

175 PSI (1207 kPa)

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 7

Page 10

Installation

Installation

Installation precautions

WARNING:

Installation and maintenance must be performed by a qualified professional.

CAUTION:

• Make sure that all connecting pipe work is water tight.

Safety rules

• Service should not be performed on any valve in an active hydronic loop.

• Before attempting to make any required adjustments, properly isolate and drain the

branch loops or system that require service and allow the valves to reach a safe

handling temperature and zero pressure condition.

• Use proper safety equipment including gloves, goggles, or similar tools to avoid

contact with system fluids and common hazards.

• Use proper tools and lifting equipment when installing or servicing the valve. Be sure

it is properly supported at all times.

• Failure to follow these instructions could result in personal injury, death, and property

damage.

Installation guidelines

• The valve is uni-directional and can be installed in most attitudes. The preferred

installation is to mount the valve in the return piping.

• Installation of strainers and isolation valves is recommended.

• Valves can be used with up to 50% ethylene or propylene glycol mixtures.

• Be sure to install the valve with the arrow pointing in the direction of flow.

• Do not position the actuator below the horizontal axis of the pipe. See Install the

actuator (page 9)

• When installed in vertical pipes, be sure to position the valve with the actuator cable

connections facing downward.

• There must be a minimum of 8 in (200 mm) access space above the actuator.

• There must be a minimum of 4 in (100 mm) access space surrounding the actuator.

• Follow all instructions provided with the valve actuator for proper wiring and

connections.

NOTICE:

The hydronic system must be properly vented to remove all entrained air. Liquid media

containing debris or other particulates should be filtered to avoid damage to or

obstruction of the pressure independent control valve, which could cause the valve to

malfunction.

Pipe hanging installations

Be aware of water weight in the valve and connected piping when installing your system.

8 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 11

NOTICE:

Never use the valve as a form of piping support. Support the valves and piping according

to the local building code. Failure to follow these instructions may result in property

damage.

Install flanged connections

• Flanged Ultra SetterTM pressure independent control valves are not furnished with

companion

• Check and make sure the gaskets do not extend into the inside diameter of the pipe.

This will cause a blockage and affect the performance of the Ultra SetterTM.

• Check connections for leaks.

flanges, gaskets, nuts, and bolts.

Install the actuator

Installation

Figure 1: Actuator Positioning

NOTICE:

To install an actuator on a valve already in line, close the shutoff valves (upstream first,

then downstream) in the piping or turn off the pump. This procedure allows the

differential pressure in the valve to drop.

Before installing the actuator, set the flow rate on the Ultra SetterTM pressure independent

balancing control valve. Follow the curve information in the product submittal to find the

required minimum differential pressure for the desired flow rate.

1. Grip the flats of the valve stem with a 7mm wrench and turn until the flow rate on the

adjacent GPM dial is in line with the indicator on the valve body.

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 9

Page 12

Installation

NOTICE:

Must disconnect all actuator stem connections and anti-rotation devices that may be

found on the actuator before rotating the actuator. Failure to do so will change the

maximum GPM flow rate setting of the valve.

2. Assemble actuator to valve and wire connections per actuator manufacturer's

instructions.

Attach insulation

To maximize energy savings, attach insulation to the valve after the system has been

balanced. Tape or other acceptable means can be used to secure the insulation to the

valve. The insulation must not cover the actuator.

10 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 13

Operation

Recommended operating procedures

WARNING:

• Burn hazard. Water temperatures higher than 100°F (38°C) can be dangerous. Take

all necessary precautions to prevent water or steam leakage.

• Hot water leakage can occur from readout valves during probe insertion and during

hookup of readout kit. Follow the safety instructions supplied with readout probes

and readout kits.

• Installation and maintenance must be performed by a qualified professional.

CAUTION:

Avoid pipe strain. This can cause breakage and water loss over time.

Safety rules

• Service should not be performed on any valve in an active hydronic loop.

• Before attempting to make any required adjustments, properly isolate and drain the

branch loops or system that require service and allow the valves to reach a safe

handling temperature and zero pressure condition.

• Use proper safety equipment including gloves, goggles, or similar tools to avoid

contact with system fluids and common hazards.

• Failure to follow these instructions could result in personal injury and property

damage.

1. Ensure that the GPM scale is set for the desired flow rate and that the valve is fully

open.

2. Using Bell & Gossett RP250-B Readout Probes, attach a Bell & Gossett differential

pressure readout kit to the readout valves (P/T ports) on the desired valve.

3. Measure the pressure differential across the readout valves (P/T ports) on the valve

flanges. Confirm that the value of the pressure differential obtained is greater than the

minimum value indicated in the product submittal required to achieve the desired

flow rate.

4. Repeat the process for all valves on the branch, if required.

5. Measure the flow rate indicated at the flow measurement device on the branch, if

available. Confirm that the value recorded is equal to the desired flow. If it is not, then

investigate the causes and if necessary, report to the designer.

6. When a flow measurement device is not present on the branch, measure the

differential pressure across the valve and verify the minimum differential pressure

listed in the submittal to ensure the valve can achieve the desired flow rate.

7. Repeat this procedure as needed until all valves in the system have been set and

differential pressure has been verified.

Operation

NOTICE:

Make sure the valve is fully open when flushing or pressure testing the hydronic

system. Strong pressure impacts, or water hammer, can damage closed valves.

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 11

Page 14

Maintenance

Maintenance

Precautions

WARNING:

• All procedures must be performed by qualified personnel.

• When the process fluid is hazardous, thermal (hot or cold), or corrosive, take extra

precautions. Employ the appropriate safety devices and be prepared to control a

process media leak.

• Always wear protective clothing and equipment to safeguard the eyes, face, hands,

skin, and lungs from the particular fluid in the line.

Valve inspection

Periodically inspect the valve for signs of leakage or corrosion.

WARNING:

Risk for property damage, serious personal injury or death. You must replace the valve if

corrosion or leakage is found.

Service P/T Ports

The P/T readout ports and drain plugs come pre-assembled with a leading industrial

thread sealant, Loctite, and are tightened to appropriate levels. Any

factory installed components breaks the original thread seal and could cause leakage.

This adjustment necessitates the removal, cleaning, and resealing of those parts per the

following instructions.

1. Remove the desired component from the valve.

2. Clean off all of the old thread sealant using a wire brush and gentle abrasion if

necessary.

If the component or valve appears to have been damaged, replace it.

3. Starting with the second thread of the NPT male valvecomponent, apply a 360º bead

of Loctite 567 thread sealant/lubricant as shown. Follow Loctite handling precautions

as noted on the product label.

4. If Loctite is not available, it is recommended that you use RectorSeal No. 5 pipe thread

sealant for all non-glycol based applications, or any PTFE thread sealing tape. Be sure

to follow the manufacturer-specific handling precaution and application instructions

as noted on the product label.

5. Thread component into the valve until it is finger tight.

6. Apply torque to the following specification:

field adjustment of

Size Type Torque

1/4” NPT P/T Readout Port, drain plug 9.0 ft-lbs. + 3.0 ft-lbs. / 0

12 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 15

Maintenance

NOTICE:

The use of thread sealants and lubricants on threads also provides lubricity. Overapplication of torque can damage to the valve port or component.

7. Properly assembled valve components will immediately seal to moderate pressure

(100 PSI or less). For maximum pressure resistance, allow the Loctite 5671 or

RectorSeal No. 52 thread sealant to cure for 24 hours. PTFE tape typically does not

require curing to achieve maximum pressure resistance.

1

Loctite and Loctite 567 are registered trademarks of Henkel Ag & Co.

2

RectorSeal No.5 is a registered trademark of RectorSeal Corporation.

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 13

Page 16

Product warranty

Product warranty

Commercial warranty

Warranty. For goods sold to commercial buyers, Seller warrants the goods sold to Buyer

hereunder (with the exception of membranes, seals, gaskets, elastomer materials,

coatings and other "wear parts" or consumables all of which are not warranted except as

otherwise provided in the quotation or sales form) will be (i) be built in accordance with

the specifications referred to in the quotation or sales form, if such specifications are

expressly made a part of this Agreement, and (ii) free from defects in material and

workmanship for a period of one (1) year from the date of installation or eighteen (18)

months from the date of shipment (which date of shipment shall not be greater than thirty

(30) days after receipt of notice that the goods are ready to ship), whichever shall occur

first, unless a longer period is specified in the product documentation (the “Warranty”).

Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer,

either repair or replace any product which fails to conform with the Warranty provided

Buyer gives written notice to Seller of any defects in material or workmanship within ten

(10) days of the date when any defects or non-conformance are first manifest. Under

either repair or replacement option, Seller shall not be obligated to remove or pay for the

removal of the defective product or install or pay for the installation of the replaced or

repaired product and Buyer shall be responsible for all other costs, including, but not

limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to

the method or means of repair or replacement. Buyer’s failure to comply with Seller’s

repair or replacement directions shall terminate Seller’s obligations under this Warranty

and render the Warranty void. Any parts repaired or replaced under the Warranty are

warranted only for the balance of the warranty period on the parts that were repaired or

replaced. Seller shall have no warranty obligations to Buyer with respect to any product or

parts of a product that have been: (a) repaired by third parties other than Seller or without

Seller’s written approval; (b) subject to misuse, misapplication, neglect, alteration,

accident, or physical damage; (c) used in a manner contrary to Seller’s instructions for

installation, operation and maintenance; (d) damaged from ordinary wear and tear,

corrosion, or chemical attack; (e) damaged due to abnormal conditions, vibration, failure

to properly prime, or operation without flow; (f) damaged due to a defective power

supply or improper electrical protection; or (g) damaged resulting from the use of

accessory equipment not sold or approved by Seller. In any case of products not

manufactured by Seller, there is no warranty from Seller; however, Seller will extend to

Buyer any warranty received from Seller’s supplier of such products.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY AND ALL OTHER

EXPRESS OR IMPLIED WARRANTIES, GUARANTEES, CONDITIONS OR TERMS OF

WHATEVER NATURE RELATING TO THE GOODS PROVIDED HEREUNDER, INCLUDING

WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY EXPRESSLY DISCLAIMED

AND EXCLUDED. EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYER’S EXCLUSIVE

REMEDY AND SELLER’S AGGREGATE LIABILITY FOR BREACH OF ANY OF THE

FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT

AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID BY THE BUYER FOR THE

DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY OTHER FORM

OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL,

CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE,

LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF

OPPORTUNITY OR LOSS OF REPUTATION.

14 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 17

Consumer warranty

Product warranty

Warranty. For goods sold for personal, family or household purposes, Seller warrants the

goods purchased hereunder (with the exception of membranes, seals, gaskets, elastomer

materials, coatings and other "wear parts" or consumables all of which are not warranted

except as otherwise provided in the quotation or sales form) will be free from defects in

material and workmanship for a period of one (1) year from the date of installation or

eighteen (18) months from the product date code, whichever shall occur first, unless a

longer period is provided by law or is specified in the product documentation (the

“Warranty”).

Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer,

either repair or replace any product which fails to conform with the Warranty provided

Buyer gives written notice to Seller of any defects in material or workmanship within ten

(10) days of the date when any defects or non-conformance are first manifest. Under

either repair or replacement option, Seller shall not be obligated to remove or pay for the

removal of the defective product or install or pay for the installation of the replaced or

repaired product and Buyer shall be responsible for all other costs, including, but not

limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to

the method or means of repair or replacement. Buyer’s failure to comply with Seller’s

repair or replacement directions shall terminate Seller’s obligations under this Warranty

and render this Warranty void. Any parts repaired or replaced under the Warranty are

warranted only for the balance of the warranty period on the parts that were repaired or

replaced. The Warranty is conditioned on Buyer giving written notice to Seller of any

defects in material or workmanship of warranted goods within ten (10) days of the date

when any defects are first manifest.

Seller shall have no warranty obligations to Buyer with respect to any product or parts of a

product that have been: (a) repaired by third parties other than Seller or without Seller’s

written approval; (b) subject to misuse, misapplication, neglect, alteration, accident, or

physical damage; (c) used in a manner contrary to Seller’s instructions for installation,

operation and maintenance; (d) damaged from ordinary wear and tear, corrosion, or

chemical attack; (e) damaged due to abnormal conditions, vibration, failure to properly

prime, or operation without flow; (f) damaged due to a defective power supply or

improper electrical protection; or (g) damaged resulting from the use of accessory

equipment not sold or approved by Seller. In any case of products not manufactured by

Seller, there is no warranty from Seller; however, Seller will extend to Buyer any warranty

received from Seller’s supplier of such products.

THE FOREGOING WARRANTY IS PROVIDED IN PLACE OF ALL OTHER EXPRESS

WARRANTIES. ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE (1) YEAR FROM THE DATE OF INSTALLATION OR

EIGHTEEN (18) MONTHS FROM THE PRODUCT DATE CODE , WHICHEVER SHALL

OCCUR FIRST. EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYER’S EXCLUSIVE

REMEDY AND SELLER’S AGGREGATE LIABILITY FOR BREACH OF ANY OF THE

FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT

AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID BY THE BUYER FOR THE

DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY OTHER FORM

OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL,

CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE,

LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF

OPPORTUNITY OR LOSS OF REPUTATION.

Some states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual 15

Page 18

Product warranty

To make a warranty claim, check first with the dealer from whom you purchased the

product or call the following number for the name and location of the nearest dealer

providing warranty service. For Goulds Water Technology contact 315-568-7123. For all

other products, contact 847-966-3700.

16 Ultra Setter™ Pressure Independent Control Valves Installation, Operation and Service Manual

Page 19

Page 20

Xylem |’zīləm|

1) The tissue in plants that brings water upward from the roots

2) A leading global water technology company

We're 12,500 people unified in a common purpose: creating innovative

solutions to meet our world's water needs. Developing new technologies that

will improve the way water is used, conserved, and re-used in the future is central

to our work. We move, treat, analyze, and return water to the environment, and

we help people use water efficiently, in their homes, buildings, factories and

farms. In more than 150 countries, we have strong, long-standing relationships

with customers who know us for our powerful combination of leading product

brands and applications expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, IL 60053

USA

Tel: 1-847-966-3700

Fax: 1-847-965-8379

www.bellgossett.com

Visit our Web site for the latest version of this document

and more information

The original instruction is in English. All non-English

instructions are translations of the original instruction.

©

2014 Xylem Inc

Bell & Gossett is a trademark of Xylem Inc or one of its

subsidiaries.

V1000840

Loading...

Loading...