Page 1

BELL & GOSSETT

INSTRUCTION MANUAL

*

*

*

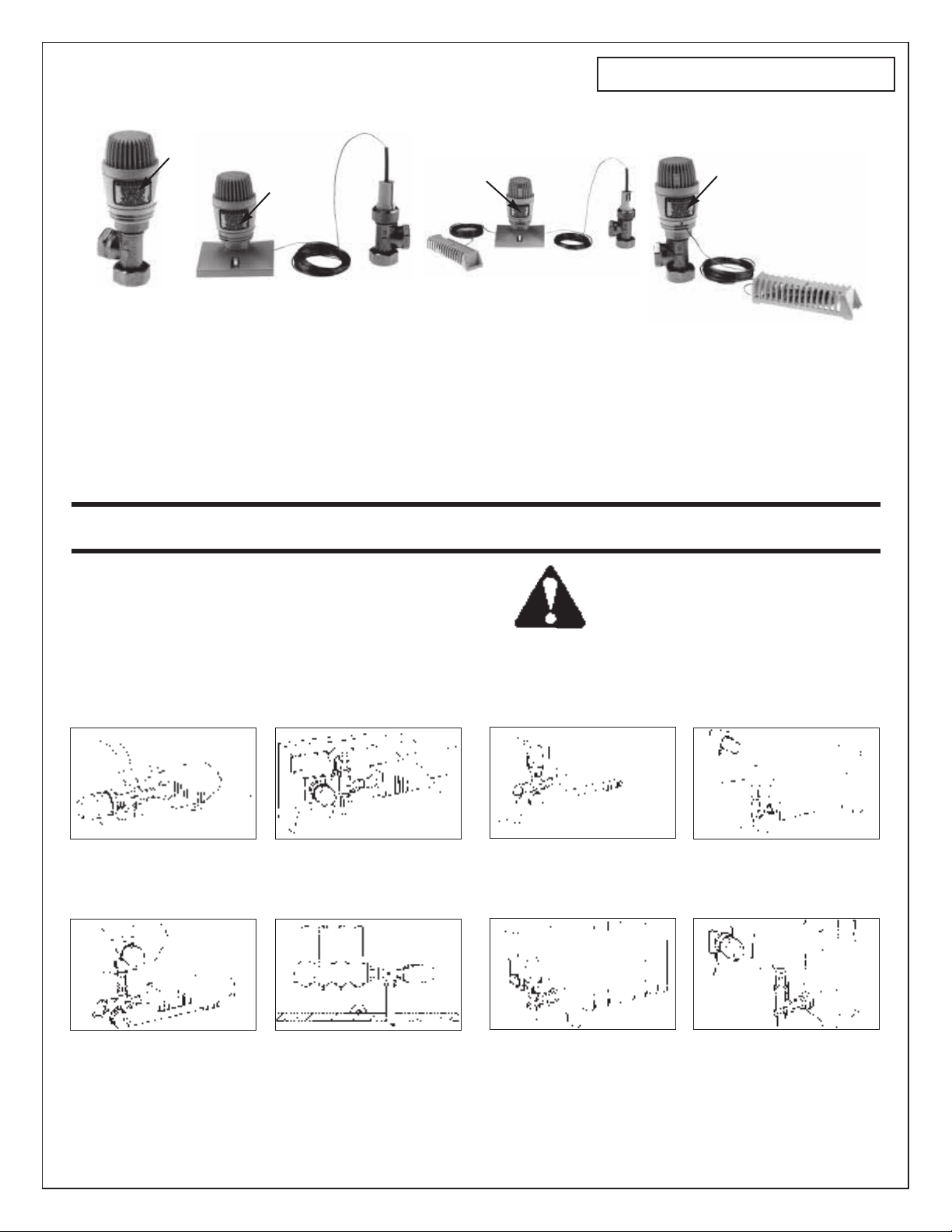

ThermoMate

*

®

* WARNING: Label Part No. V56871

must be installed in this location.

If missing, must be replaced.

Thermostatic Control Valves

Installation, Operation and Service Instructions

V02300

Revision D

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

ThermoMate Thermostatic Control Valves are silent, efficient,

energy saving non-electric control valves that provide reliable

temperature control for hydronic and low pressure steam terminal units. The temperature range of ThermoMate Control Valves

is adjustable between 46°F (7.8°C) and 79°F (26.1°C). A drop in

room temperature causes the operator to open the valve.

FIG. A

Baseboard radiation with Model TM42 angle pattern

valve body and Model TM51 self-contained thermostatic operator. (Thermostatic operator mounted thru

the side panel of the terminal unit cover.)

FIG. B

Baseboard radiation with Model TM12 angle pattern

valve body and Model TM51 self-contained thermostatic operator attached to the TM91 remote mounting base a nd sen sing element. (Remote mounting

base and operator mounted thru the front panel of the

terminal unit cover.)

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

Convector with Model TM21 straight pattern valve

body and Model TM61 thermostatic operator with

remote sensing bulb. (Mounted inside the terminal

unit cover.) Solder adaptor not furnished with valve.

D .GIFC .GIF

Convector with Model TM12 angle pattern valve body

and Model TM51 self-contained thermostatic operator

attached to the TM91 remote mounting base and

sensing element. (Remote mounting base and operator mounted on the wall outside of the terminal unit.)

FIG. E

Convertor with Model TM21 st raight pattern valve

body and Model TM61 t hermostatic operator with

remote sensing bulb attached to the TM91 remote

mounting base. (Remote mounting base and the operator mounted thru the front panel of the terminal unit

cover.)

© COPYRIGHT 1981, 1995

FIG. F

Free standing radiator with Model TM42 angle pattern

valve body and Model TM51 self-contained thermostatic

operator mounted on the radiator.

Free standing radiator with Model TM12 angle pattern

valve body and Model TM61 thermostatic operator

with remote sensing bulb mounted on the wall alongside of the terminal unit.

FIG. HFIG. G

Free standing radiator with Model TM12 angle pattern

valve body and Model TM61 thermostatic operator

with r emote sensing bulb attached to the TM91

remote mounting base. (Remote mounting base and

the operator are mounted on the wall alongside of the

unit.)

Bell & Gossett

Morton Grove, IL, U.S.A.

Page 2

MAXIMUM OPERATING LIMITATIONS

Temperature: 250°F (121°C)

Steam Pressure: 15 PSI (103.43 kPa)

Working Pressure: 200 PSI (1,379 kPa)

Differential Pressure:

1

/2" Valves 25 PSI (172.38 kPa)

3

/4" Valves 20 PSI (137.90 kPa)

1" Valves 15 PSI (103.43 kPa)

5. As shown in Figures C and G, the TM61 remote sensing

bulb may be installed inside the terminal unit below the

radiation or on a wall. Remove the plastic housing protecting the remote sensing bulb by pulling gently on the housing while holding the mounting base. Carefully remove the

sensing bulb from the mounting base and mount the base

to a wall or terminal unit. Replace sensing bulb and cover.

Coil excess capillary tubing and protect it from damage.

INSTALLATION INSTRUCTIONS

1. Fig. A through Fig. H shows the various ways the ThermoMate may be installed. Install the ThermoMate valve body

by attaching each end to the mating NPT pipe thread using

a pipe joint compound and tighten with a wrench. If a

sweat connection is used, outlet union connection should

be sweated to the terminal unit before union nut is connected to the ThermoMate.

CAUTION: The generous use of pipe joint com-

pound will foul the operating mechanism and prevent the ThermoMate from functioning properly. When

piping ThermoMate valve bodies to the system, apply

pipe compound to male threads only. Failure to follow

this instruction could result in property damage and/or

moderate personal injury.

CAUTION: The heat from supply piping of terminal

unit, solar heat or drafts from windows can cause the

temperature sensing element of the TM51 or TM61 to misinterpret the need for heat. If the TM51 operator is to be

used, it must be installed so that it is in a horizontal position or is protected from convection currents rising up the

supply pipe. Failure to follow this instruction could result in

property damage and/or moderate personal injury.

CAUTION: Overtightening and breakage can be

caused by the use of Teflon impregnated pipe compound or Teflon tape on pipe threads. Use caution when

tightening pipe joints with Teflon materials applied.

Failure to follow these instructions could result in property damage and/or moderate personal injury.

2. If heat is not immediately required from the terminal unit,

and the valve operator is to be installed at a later date,

leave the red plastic protective cap tightly assembled to

the valve to isolate the terminal unit and protect the operating mechanism. However, temporary heating can be provided by loosening the protective cap which allows the

ThermoMate Valve to Stay Open.

3. The TM51 or TM61 operators are installed as follows: Remove the red plastic protective cap from the valve body.

While pushing the operator down on the brass hex packing

nut, rotate it until mating slots in the operator engage the

hex nut. Secure the union nut onto the ThermoMate valve

body while continuing to push down on the operator. The

installation of the operator is simplified by setting the operator to the #6 temperature setting.

4. As shown in Figure B and D, the TM91 remote mounting

base and sensing element can be mounted either on the

terminal unit cover or a wall. Use the remote sensing element as a template to mark the location of mounting holes.

If mounted on a terminal unit, drill a 1

centered between the two mounting holes. This will allow

the operator to pass through and be mounted on the valve

body. Coil the excess capillary tube and secure so that it

does not get damaged.

5

/16" diameter hole

OPERATING INSTRUCTIONS

1. The room temperature can be changed by rotating the cap

(Fig. J) on the operator until the desired number on the cap

lines up with the index pointer in the bezel window. The

number on the operator cap correspond to temperature

settings as shown in fig. H.

2. Using memory feature (day/night temperature)

a) Turn cap to desired day temperature number setting.

Example: Set pointer to #4 for 68°F or 20°C daytime

temperature.

b) Pull the night set back ring up off of the bezel.

c) You will note that the night set back ring has a sun sym-

bol and a moon symbol. The sun symbol indicates the

daytime temperature setting and the moon the night

time setting. The night time setting will be 5.4°F (3°C)

lower than the daytime temperature. Replace the night

set back ring so that the sun symbol lines up with the

pointer on the bezel. For night time setting, rotate the

cap so that the moon symbol lines up with the pointer.

3. Limiting the maximum set temperature

a) Rotate the cap so that the indicator points to the

position.

b) Pull the shroud down from the bezel.

c) Note that numbers are molded into the bezel diameter

which is covered by the shroud. These numbers from 10

to 28 correspond to maximum temperature in °C. Fig. I

shows this relationship in °F. Beneath these numbers

are slots that correspond to the numbers. The lock and

range lever is inserted into one of the slots. To change

the maximum temperature set point pull the locks range

lever out of its slot and insert into the new maximum

temperature slot.

d) Reassemble the shroud to the bezel. The small notch on

the shroud must be on the opposite side of the bezel cut

out indicator where the setting is displayed. Another way

to line up the shroud to reassemble it to the bezel is to

line up the notch in the shroud with the long slot in the

bottom of the bezel which is just past the number 28.

4. Locking set temperatures

a) Set the desired temperature at the pointer in the bezel

window. For example, a setting of 4 is equal to 68°F

(20°C). Refer to Fig. H for other settings.

b) Slide the shroud down off the operator which will reveal

numbers molded into the bezel which was covered by

the shroud. To lock the set temperatures to 68°F (20°C)

put lock and range levers in slots 20 and 22. Refer to

Fig. K for other settings.

c) Reinstall the shroud by lining up the notch in the shroud

with the long slot in the bottom of the bezel which is just

past the number 28.

0 123456

Approx. 0 8 11 14 17 20 23 28 °C

32 46 52 57 63 68 73 79 °F

FIG. H

2

Page 3

Max Temp. °C

(Adj 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Setting)

Max Temp. °F

46 48 50 52 53.6 55.3 57 59 61 63 64.6 66.3 68 69.6 71.3 73 75 77 79

Min. Temp °F

46 48 46 46 46 46 46 46 46 46 46 46 46 46 46 46 46 46 46

FIG. I

123456

11, 13 14, 16 17, 19 20, 22 23, 25 26, 28

FIG. K

ADJUSTMENT RANGE

b) Remove the bonnet and gland assembly by turning the

chrome plated bonnet hex nut in a counterclockwise

direction.

c) Inspect the valve seat and remove any foriegn material

that might prevent the ThermoMate from providing positive shut off. If the valve seat is corroded, the valve

body must be replaced.

d) Install the new bonnet and gland assembly and tighten

securely.

e) Return system to normal operation.

f) Inspect the bonnet and gland assembly for leaks and

tighten additionally if necessary.

g) Reassemble the ThermoMate operator to the valve

body by pushing it down on the brass hex gland and

rotating the operator until you feel the slots in the actu-

ator engage the gland nut. While continuing to push

down, engage and tighten the knurled union nut to

the valve body. It is helpful if the operator is set to the

highest temperature.

2. Replacement of Gland Assembly

a) If the gland assembly is leaking it can be replaced while

the ThermoMate is still pressurized if the valve disc is in

good condition and is backseating properly.

b) Remove the valve operator as in 1(a) above.

WARNING: Hot system fluid can be hazardous.

Allow the system to cool to 100°F (37.8°C) or below

before removing the gland assembly. Failure to follow this

instruction could result in serious personal injury or death

and property damage.

FIG. J

SERVICE INSTRUCTIONS

WARNING: Leakage or corrosion of ThermoMate

are signs of an impending serious failure of the

ThermoMate. Periodically inspect the ThermoMate for

signs of leakage or corrosion. If noted, the failed part or

assembly must be replaced. Failure to follow this instruction could result in serious personal injury or death and

property damage.

1. Replacement of Bonnet and Gland Assembly

WARNING: Hot system fluid can be hazardous.

Allow the system temperature to cool to 100°F

(37.8°C) or below before attempting any service. Isolate

the ThermoMate from the system or drain system. If system is not drained, relieve pressure from the ThermoMate.

Leave drain open during servicing. If servicing a steam

system, make sure that all electrical power is disconnected.

Failure to follow this instruction could result in property

damage and/or moderate personal injury.

a) Remove the valve operator by pushing down on the

operator and turning the knurled union nut counterclockwise.

c) Slowly loosen the brass hex gland nut and check for

leakage.

WARNING: If fluid escapes it is a sign that the valve

disc is not backseating properly and a hazardous

condition exists. If leakage is found, STOP. Isolate the

ThermoMate or drain the system before proceeding.

Failure to follow this instruction could result in serious

personal injury or death and property damage.

d) Finish removing the gland assembly.

e) Inspect the bonnet assembly for signs of damage or

corrosion. Replace the bonnet assembly as noted in 1 if

damage is found.

f) Install the new gland assembly and tighten securely.

g) Return the system to normal operation.

h) Check the gland assembly for leakage. Tighten addi-

tionally if necessary.

i) Replace the operator as in 1(g) above.

3. Replacement of Operator

a) Move the operator to the highest temperature setting.

Push down on the operator and unscrew the knurled

union nut (counterclockwise) that attaches the operator

to the valve body.

b) Examine the valve stem and gland assembly for signs of

leakage, if foun replace the gland assembly.

c) Install the new operator by pushing operator down on

the brass hex gland nut while slowly rotating the opera-

tor until you feel the slots in the operator engage the

hex of the gland nut. While continuing to push down,

engage and tighten the knurled nut to the valve body.

d) Set the operator to the desired temperature setting.

3

Page 4

INSTALLATION INSTRUCTIONS

FOR TAMPER PROOF COVER (See Fig. L)

1. Remove the night set back ring and the shroud from the

operator. The set back ring is removed by pulling it up and

the shroud is removed by pulling it down. To remove the

shroud operator must be removed from the valve body.

2. Mount the operator on the valve body and set to desired

temperature. If it is desired to lock the set temperature

refer to Section 4 under operating instructions.

3. Place the tamper proof cover over the operator so that the

window lines up with the temperature scale.

4. Place the tamper proof cover retaining collar halves over

the valve body, operator nut and tamper proof cover lip.

Notch in retaining collar must be fitted over lug on valve

body.

5. Hold the two halves of the retaining collar together and

lock in place with two supplied screws. Two sets of screws

are supplied. A standard set of machine screws and a set

of screws which require drilling out to remove if you want

to make it more difficult to remove tamper proof cover.

OPERATING INSTRUCTIONS

WITH TAMPER PROOF COVER

Once tamper proof cover is installed changes in temperature

setting can only be made by removing cover.

SERVICE INSTRUCTIONS

WITH TAMPER PROOF COVER

1. The tamper proof cover can be removed to service the

valve or the operator by removing the two screws holding

the two halves of the retaining collar together and then

removing the cover by pulling it up. If the permanent type

screws were used, they will have to be drilled out to remove

the retaining collar.

2. To complete the servicing of the ThermoMate refer to the

service instructions elsewhere in this manual.

TAMPER PROOF COVER

RETAINING

COLLAR

NIGHT

SET BACK

RING

SHROUD

SCREW

VALVE BOOT

NOTCH

FIG. L

PRINTED IN U.S.A. 8-95

For further information, contact Bell & Gossett, 8200 N. Austin Avenue, Morton Grove, IL 60053,

Phone (847) 966-3700 – Facsimile (847) 966-9052.

Bell & Gossett

Morton Grove, IL, U.S.A.

Loading...

Loading...