Page 1

®

Comfort-Trol

PATENT NO’S. 4,553,733 AND 4,560,140

Zone Control Valve

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

INSTRUCTION MANUAL

V01348H

WARNING LABEL PART NO. V56871

INSTALLED IN THIS LOCATION.

IF MISSING IT MUST BE REPLACED.

DESCRIPTION

A two wire heat motor operated valve designed for Hydronic Heating/

Cooling Systems.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw attention

to safety related instructions. When used, the safety alert symbol

means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOL LOW T HE INST RUCTION S MAY RESU LT IN A

SAFETY HAZARD.

PERFORMANCE CHARACTERISTICS:

Maximum differential shut off pressure: 35 PSIG

WORKING PRESSURE & TEMPERATURE LIMITS

(SOLDER TYPE LIMITS FOR ASTM STD. B16.18)

TYPE OF

SOLDER PRESSURE PSI TEMPERATURE °F

95-5

TIN- 125 240

ANTIMONY

CAUTION: Heat associated with the use of silver solder will

damage the Comfort-Trol and void the product warranty.

Use only the low temperature solder specified. Failure to follow

these instructions could result in property damage and/or moderate personal injury.

WARNING: Solder joints will fail if used at pressures or tem-

peratures above those listed in the above table. Do not

exceed the temperature and pressure limitations. Failure to follow

the above instruction can cause the joint to fail resulting in serious

personal injury and/or property damage.

Maximum ambient temperature: 125°F.

Electrical rating: 24 Volt 50/60 Cycle, 1Ø, 15VA AC

MAXIMUM LIMITATIONS

THERMOSTAT

24 Volt two wire with 0.6 ampere heat anticipator setting.

TRANSFORMER

115/24 volt rated at 40 VA for a maximum of three Comfort-Trol Zone

Valves. Note: This transformer must be dedicated to the Comfort-Trol

Zone Valves and not be used to power any other device.

WARNING: Hazardous conditions could occur if the following notes are not adhered to:

READ PRIOR TO INSTALLING COMFORT-TROL

1. Do not install Comfort-Trol in a dusty area or in an area where

the flow of air to the operator is restricted because erratic

operation or premature failure may occur.

2. Use 95-5 (Tin-Antimony) solder and a good grad of flux to

solder the Comfort-Trol valve body into the system.

NOTE: a. Remove the brass bonnet and retainer assembly

3. Do not install a jumper wire between terminals #1 and #2

because the thermostat heat anticipator may burn out when

the Comfort-Trol operator is energized.

4. Keep external wiring from contacting the Comfort-Trol operator

cover by securing the wiring to a nearby support.

5. Use only silicone grease to lubricate the valve gland pin and

O-ring seals. Do not use lubricants with a petroleum base. The

use of a petroleum base lubricant will cause swelling and failure of U-rings.

6. Do not insulate the Comfort-Trol Zone Valve Operator.

7. Use of additives to the system may be harmful to the Comfort-Trol.

Failure to follow these instructions could result in serious personal

injury or death and property damage.

from the valve body before applying heat to the

body. Failure to do so will damage the valve seals

and discs.

b. Excessive use of solder in a vertical installation may

result in damage to the valve seat.

c. Avoid excessive use of flux.

d. Heat associated with the use of silver solder may

damage the Comfort-Trol.

WARNING NOTES:

Page 2

INSTALLATION INSTRUCTIONS

The B&G Comfort-Trol Zone Valve can be installed horizontally or vertically. However, the following precautions should be taken: When

installing the valve in a vertical position, the electrical connections

must be at the top of the operator. On chilled water applications the

operat or should be above the pipe cen terline . If the valv es are

installed near the boiler, locate them a sufficient distance from the

breeching so they are not affected by flue temperatures.

4. Check solder connections for leaks. If resoldering is neede d,

remove the bonnet assembly and resolder.

5. Assemble the Comfort-Trol operator onto the valve body (the operator can be rotated 360° after it is installed) by pushing down on

the operator until the wire retainers into the operator frame (Fig. 3,

Item E) snap into the retaining groove on the brass bonnet (Fig. 3,

Item C).

6. Electrically wire the Comfort-Trol to the system as described in one

of the following wiring diagrams.

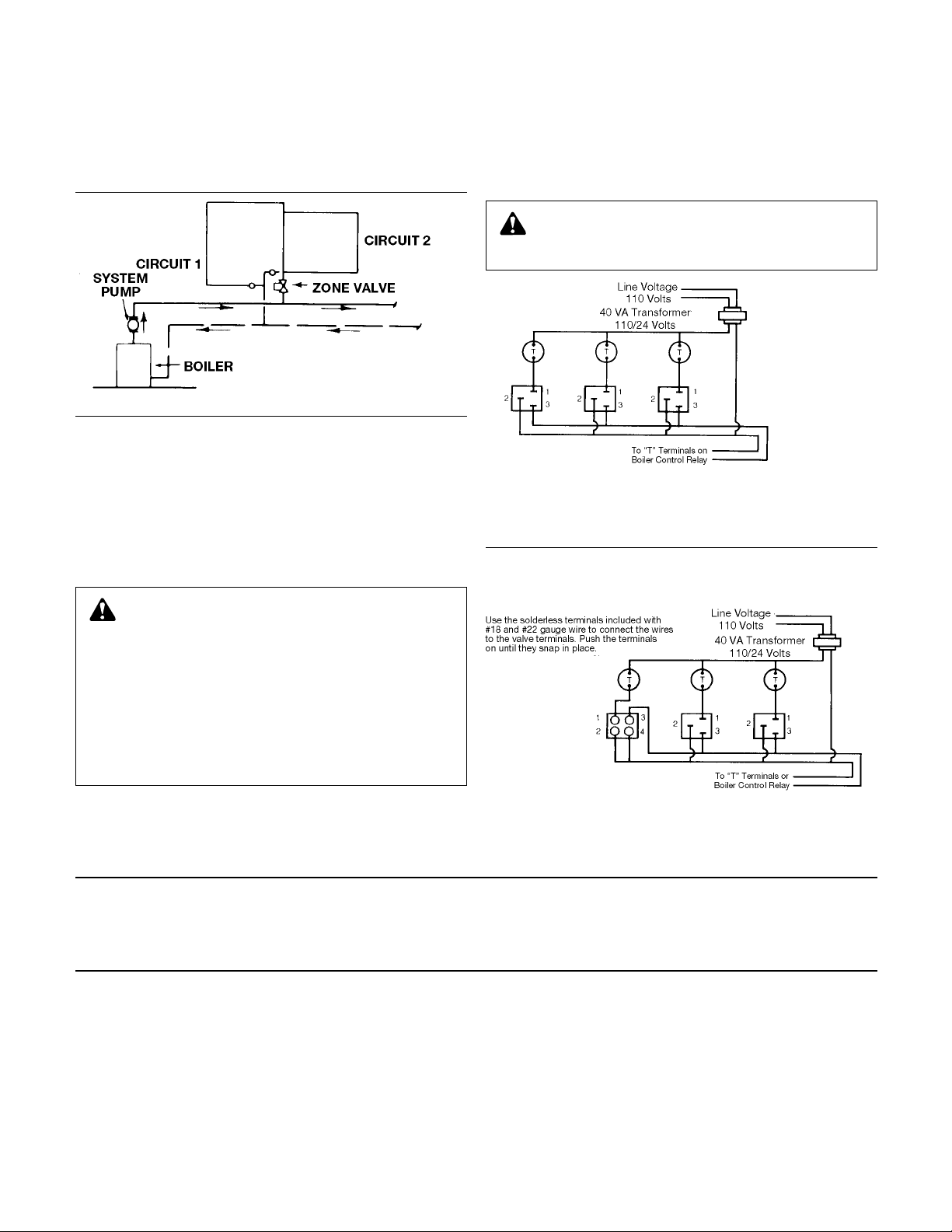

FIG. 1

ote: When two circuits are used in a

N

single zone, always join the circuits to

a common return as shown in Figure 1.

There can be no flow in circuit 1 or 2

hen the zone valve is closed.

w

1. Remove the brass bonnet and retainer assembly from the valve

body as shown in Figure 3.

NOTE: Model w it h flare connect or s can be left ass em bled if

Comfort-Trol is removed from piping before soldering connectors

in place.

2. Solder the valve body into position with the arrow on the body

pointing downstream.

a. Clean the tube ends and Comfort-Trol valve body connections

thoroughly.

b. Use 95-5 (Tin-Antimony) solder, a good grade of flux and a torch

with a sharp pointed flame.

WARNING: Damage to Comfort-Trol body or bonnet may

occur from improper installation, which can cause leakage

or failure of Comfort-Trol.

a. Avoid excessive use of flux and solder when installing Comfort-

Trol in a vertical position because damage to the valve seat

may occur.

b. When soldering the joints, direct the flame with care to avoid

subjecting the valve body to excessive heat.

c. Allow the valve body to cool below 100°F before installing the

bonnet and retainer assembly.

Failure to follow these instruction could result in serious personal

injury or death and property damage.

3. Insert the bonnet assembly with retainer into the valve body and

secure with the two retaining screws. Be careful not to damage the

O-ring seal when inserting the bonnet assembly (Fig. 3, Item A). If a

lubricant is required, apply silicone grease to the bonnet assembly

below the retainer. Do not use lubricants with a petroleum base.

CAUTION: Transformer overload. Do not wire more than

three Comfort-Trol or Modumate Zone Control Valves to

one 40 VA Transformer. Failure to follow these instructions could

result in property damage and/or moderate personal injury.

ote: This transformer

N

ust be dedicated to

m

omfort-Trol use only.

C

No other controls are

to be powered from it.

Improper operation of

omfort-Trol will result.

C

ote: Terminal 3 is not

N

sed if a continuously

u

perating pump is used.

o

FIGURE 2A

1, 2 OR 3 COMFORT-TROLS – SINGLE TRANSFORMER

INTERMITTENT PUMP OPERATION

IMPORTANT: Figure 2B is correct

only when the ModuMate was wired

per factory recommendations.

Note: Terminal 3 is not

used if a continuously

operating pump is used.

See Transformer

Note in Fig. 2A

FIGURE 2B

COMFORT-TROL AND MODUMATE WIRED

TO THE SAME TRANSFORMER

INTERMITTENT PUMP OPERATION

OPERATING INSTRUCTIONS

The Com fo rt-Trol is opened by a heat motor, therefore, the re is

approximately a two minute period between the time the thermostat

closes, calling for heat, and the time the Comfort-Trol opens. As long

MANUAL OPERATION

A power failure may necessitate manual operation of the Comfort-Trol.

If required, please follow these instructions:

1. Turn the switch bringing power to the Comfort-Trol operator to the

OFF position.

2. Squeeze the two formed wire release tabs together and lift up to

remove the operator. See Figure 3.

3. The valve is now fully o pe n and will allow g ra vi ty circulation

through the system.

2

as heat is required, the Comfort-Trol is kept in the open position by a

built in control switch, which meters small amounts of electricity to the

Comfort-Trol heat motor. When the thermostat opens, indicating that

the need for heat has been satisfied, a return spring in the ComfortTrol slowly closes the Comfort-Trol.

NOTE: After power is restored, return the Comfort-Trol to normal

operation by:

1. Assembling the operator to the valve by installing the operator over

the bonnet assembly and pressing down until the wire form tabs

both engage the slots on the bonnet assembly. This is the reverse

of the process used to remove the operator from the Comfort-Trol.

Do not squeeze the two formed release tabs when reassembling

the operator to the Comfort-Trol.

2. Turn the power switch for the Comfort-Trol to the ON position.

Page 3

SERVICE INSTRUCTIONS

Comfort-Trol Zone Control Valves are designed for fast and easy maintenance with a standard screwdriver and pliers. It is recommended

that the Comfort-Trol be inspected periodically for signs of leakage,

corrosion or other damage.

WARNING: Corrosion or leakage are indications that the

Comfort-Trol may be about to cause serious damage from

leakage or rupture. It should be periodically inspected and if noted

the Comfort-Trol must be serviced or replaced. Failure to follow

these instructions could result in serious personal injury or death

and property damage.

The exploded view of the Comfort-Trol in Figure 3 will aid in performing service or maintenance.

To inspect and service the Comfort-Trol follow the steps listed below:

CAUTION: Burn Hazard. Turn off the power to the Comfort-

Trol and allow Comfort-Trol operator to cool to 100°F or

less. This could take 10 to 30 minutes or longer depending on the

ambient temperature. The heat motor is surrounded by an electrical heater which can become very hot so care needs to be exercised to avoid being burned. Failure to follow these instructions

could result in property damage and/or moderate personal injury.

1. Identify the power leads (#1, #2 and #3 as shown in Fig. 2), and

disconnect them by pulling them off the blade type connectors.

2. Remove the Comfort-Trol operator by squeezing the formed wire

release tabs (Fig. 3) together and lifting up.

3. Remove the operator cover by spreading the cover at the bottom

to disengage the locking tabs and lifting up.

4. The following components can now be inspected and replaced if

required.

A. Seal Kit

In examining the valve seat at the top of the bonnet (Fig. 3, Item

B), look for evidence of leakage around the stem and on the

underside of the knurled head. If there is an indication of leakage, replace the seal. Failure to replace the seal may cause

erratic valve operation resulting in failure of the valve to open.

Comfort-Trol is a backseating valve which permits replacing the

seal without draining the system. Using a pliers, loosen and

remove the seal. Carefully insert the replacement seal kit without disturbing the spring loaded valve disc (Fig. 3, Item D) or

system fluid may be discharged from the valve.

WARNING: Accidental discharge of hot water fluid. Do not

jar or move the valve disc during replacement of the Seal

Kit. Backseating of valve disc is by spring load only. Failure to follow these instructions could result in serious personal injury or

death and property damage.

Tighten the seal kit, without excessive force, until it is reasonably

secure.

B. Heat motor (power pill with heater)

The large end of the heat motor is wrapped with a black material

which secures the heater element to the power pill. The normal

color of the power pill under the heater is copper. If it turns gray

or black and there appears to be leakage around the piston,

replace the heat motor. See the instructions for replacing the

heat motor.

C. Operator

If the heat motor or switches have failed the entire operator

may be replaced rather than replacing the components. This is

accomplished by simply placing a new operator on the valve

body and pressing down until the wire retainers inside the operator frame (Fig. 3, Item E) snaps into the retaining groove on the

brass bonnet (Fig. 3, Item C).

5. After servicing the Comfort-Trol, follow the steps below to return it

to operation.

a. Replace the cover on the Comfort-Trol operator so that the

wide section of the operator frame at the switch end of the

operator (Fig. 3, Item F) slips between the end cover and the

raised guides located inside and on both sides of the cover.

Push down on the cover until the two 3/16" long raised tabs at

the bottom of the cover lock over the underside of the operator.

b. Assemble the Comfort-Trol operator onto the valve body (the

operator can be rotated 360° after it is installed) by pushing

down on the operator until the wire retainers inside the operator

frame (Fig. 3, Item E) snap into the retaining groove on the

brass bonnet (Fig. 3, Item C).

c. Reconnect terminal leads #1, #2, and #3 as required by push-

ing the connectors onto the blade terminals until the locking

catch snaps into place.

d. Restore power.

INSTRUCTIONS FOR REPLACING THE HEAT MOTOR

Two versions of the operator frame can be encountered. The design is

identical except for a heat motor access hole at the switch end of the

frame.

UNITS WITH HEAT MOTOR ACCESS HOLE

1. Turn off power to the Comfort-Trol operator.

2. Disconnect power leads from the blade switch terminals.

WARNING: Burn Hazard. Do not touch the heat motor until

it has cooled to 100°F or less. This could take 10 to 30

minutes or longer depending on the ambient temperature. It is

heated by an electrical heater which can become very hot. Failure

to follow these instructions could result in serious personal injury

or death and property damage.

3. If the valve cover has cooled sufficiently, remove it by spreading

the cover at the bottom to disengage the locking tabs and lifting

up.

WARNING: Do not insert screwdrivers or other objects into

the operator body to pry the cover off. Movement in the leaf

springs will cause the operator to lose calibration and will cause a

failure in the Comfort-Trol.

4. Disconnect the heater leads at the solderless terminals on the

switch inside the operator (Fig. 4, Item 1).

5. Remove retaining clip (Fig. 4, Item 9).

6. Pull heat motor thru access hole.

7. Replace the heat motor with a V01370 replacement heat motor

and secure in place with the retaining clip.

8. Reattach the heater leads to the solderless terminals on the

switch assembly (Fig. 4, Item 1), making sure the leads do not

contact the operator frame.

9. Replace cover.

10. Restore power.

3

Page 4

{

05263:V01348 11/11/02 6/17/09 1:33 PM Page 4

FIG. 3

SQUEEZE

FORMED WIRE

RELEASE TABS

AND LIFT UP

TO REMOVE

OPERATOR

F

E

SPREAD COVER

AT BOTTOM TO

DISENGAGE

LOCKING TABS

AND LIFT UP TO

REMOVE COVER

POSITION

INDICATOR

COMFORT-TROL

OPERATOR

189139 (CARTON OF

6 V01372)

V01372

BONNET &

RETAINER

ASSEMBLY

COMFORT-TROL

VALVE BODY

B

SEAL GLAND

C

BONNET &

RETAINER

ASSEMBLY

LESS SEAL

GLAND

D

A

UNITS WITHOUT HEAT MOTOR ACCESS HOLE

1. Turn Off power to the Comfort-Trol operator.

2. Disconnect power leads from the blade switch terminals.

CAUTION: Burn Hazard. Do not touch the heat motor until

it has cooled to 100°F or less. This could take 10 to 30 minutes or longer depending on the ambient temperature. It is heated

by an electrical heater which can become very hot. Failure to follow these instructions could result in property damage and/or

moderate personal injury.

3. If the valve cover has cooled sufficiently, remove it by spreading the

cover at the bottom to disengage the locking tabs and lifting up.

WARNING: Do not insert screwdrivers or other objects into

the operator body to pry the cover off. Movement in the leaf

springs will cause the operator to lose calibration and will cause a

failure in the Comfort-Trol.

4. Disconnect the heater leads at the solderless terminals on the

switch assembly inside the operator (Fig. 4, Item 1).

5. The operating spring (Fig. 4, Item 2) is under load and requires

caution when unloading it. Disconnect the spring legs from the

lever by alternately gripping the legs with a pliers (be careful not to

score the spring with the pliers) and forcibly lift them out of their

notch on the lever (Fig. 4, Item 4) lowering them to the frame. In

this position the spring legs will rest on the operator frame outside

of the coated ends of the lever (Fig. 4, Item 3).

6. Disengage the switch plate locking feature (Fig. 5, Item 5) by placing a common screwdriver under the bottom of the overlapping

tab and lifting up.

CAUTION: Disassembly of the Comfort-Trol Operator will

likely cause the operator to come out of calibration. Replacement of the power pill should be done by a professional with

proper calibration equipment.

7. Before disassembling the operator, note the position of the bottom of the heat motor retaining bracket to the coated ends of the

operating lever (Fig 4, Item 10).

8. Remove the heat motor and bracket assembly.

9. Rotate the heat motor until the notch in the side of the unplated

retaining clip is exposed beyond the plated bracket. Remove the

retaining clip by placing a common screwdriver in the notch and

twisting the screwdriver until the retaining clip pops off.

10. Replace the heat motor with a V01370 replacement heat motor.

The small end of the heat motor must point in the same direction

as the two support legs near the bottom of the plated bracket.

Secure the heat motor by attaching the unplated retaining clip to

the heat motor (Fig, 4, Item 6) on the side of the plated bracket

opposite the large end of the heat motor.

11. Raise the coated ends of the lever, position the heat motor and

bracket assembly so that the small end of the heat motor appears

in the cutout of the main operator assembly (Fig. 4, Item 7

the heat motor bracket support legs are situated under the coated

ends of the lever (Fig. 4, Item 10).

12. Attach the switch plate assembly by sliding the side of the assembly to which the switch is attached between the formed wire

release tabs and the main operator assembly until the locking

tabs engage the slots in the switch plate assembly.

13. Complete assembly of the Comfort-Trol operator by closing the

switch plate assembly to the main operator assembly and noting

the following:

a. The two pins or screws under the switch must engage the two

holes in the bottom of the main operator assembly.

b. The finger on one coated end of the lever must be situated

between the two contact arms on the switch (Fig. 4, Item 11).

c. The tab at the bottom of the heat motor retaining bracket must

be seated in the mating seat slot on the bottom of the main

operator assembly (Fig. 4, Item 8).

d. The top of the heat motor retaining clip must be in the top verti

cal position (Fig. 4, Item 9).

e. The spring legs must be outside the coated ends of the lever

(Fig. 4, Item 3).

14. Squeeze both sections of the operator together until the locking

tabs at the top of the switch plate assembly lock over the mating

tab section at the top of the main operator assembly (Fig. 4, Item 5).

15. Attach the heater leads to the solderless terminals on the switch

assembly inside the operator (Fig 4, Item 1), making sure the leads

do not contact the operator frame.

16. Load the valve spring by alternately gripping the legs with a pliers

(be careful not to score the spring with the pliers) and forcibly lifting them off the frame and placing them in their notch in the lever

(Fig. 4, Item 4).

17. Replace the cover by placing the cover on the operator so that

the wide section of the operator frame at the switch end of the

operator (Fig 3, Item F) slips between the end of the cover and the

raised guides located inside and on both sides of the cover. Push

down on the cover until the 3/16" long raised tabs at the bottom

of the cover lock over the underside of the operator.

18. Connect power leads to the blade terminals on the Comfort-Trol

operator by pushing the connectors onto the blades until the locking catch snaps into place.

19. Restore power.

) and

FIG. 4

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. V01348H April 2012

Loading...

Loading...