Page 1

Mechanical Installation, Operation,

and Maintenance Manual

10-001-287 Rev 4

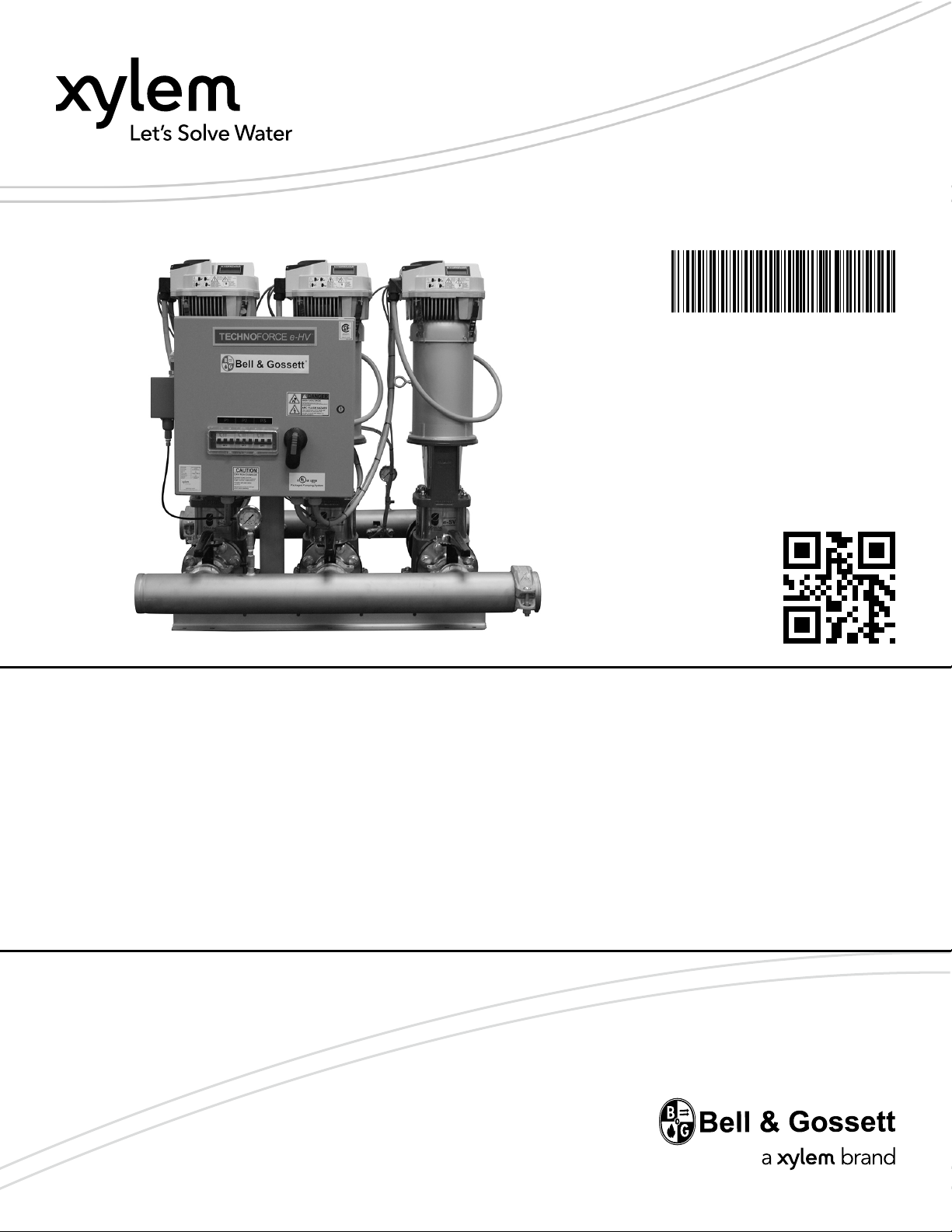

TECHNOForce e-HV

Page 2

Page 3

Table of Contents

1 Introduction and Safety..............................................................................................................3

1.1 Introduction.......................................................................................................................... 3

1.2 Safety..................................................................................................................................... 3

1.2.1 Safety terminology and symbols.................................................................................3

1.2.2 Protecting the environment.........................................................................................4

1.3 User safety.............................................................................................................................4

1.3.1 Wash the skin and eyes................................................................................................5

2 Transportation and Storage...................................................................................................... 7

2.1 Examine the delivery........................................................................................................... 7

2.1.1 Examine the package................................................................................................... 7

2.1.2 Examine the unit............................................................................................................7

2.2 Transportation guidelines...................................................................................................7

2.2.1 Lifting methods............................................................................................................. 7

2.3 Storage guidelines...............................................................................................................7

2.3.1 Long term storage........................................................................................................ 8

Table of Contents

3 Product Description................................................................................................................. 10

3.1 General description...........................................................................................................10

3.1.1 Operational limits....................................................................................................... 10

3.2 Nameplate information.....................................................................................................10

4 Installation................................................................................................................................. 12

4.1 Reference manuals............................................................................................................ 12

4.2 Field connections...............................................................................................................12

4.3 ground (earth) connections..............................................................................................12

4.4 Pump package location guidelines................................................................................. 12

4.5 Foundation requirements.................................................................................................13

4.6 Level the base on a concrete foundation ...................................................................... 13

4.7 Grout the baseplate...........................................................................................................14

4.8 Piping checklist.................................................................................................................. 14

5 Commissioning, Startup, Operation, and Shutdown.......................................................... 15

5.1 Preparation for startup...................................................................................................... 15

5.1.1 Prestartup checklist.................................................................................................... 15

5.1.2 Final installation checks............................................................................................. 16

5.1.3 Final adjustments........................................................................................................16

5.2 Pump station startup......................................................................................................... 16

5.2.1 Confirm the job site voltage......................................................................................16

5.2.2 Connect the storage tank.......................................................................................... 17

5.2.3 Optional water level control relay............................................................................ 17

5.2.4 Check for available suction water.............................................................................19

5.2.5 Start the package........................................................................................................19

5.2.6 Check the pump rotation...........................................................................................19

5.2.7 Set the system operating pressure...........................................................................19

5.2.8 Enter the setup menu.................................................................................................19

5.2.9 Test the package.........................................................................................................20

6 Maintenance..............................................................................................................................21

6.1 Precautions......................................................................................................................... 21

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 1

Page 4

Table of Contents

6.2 Monthly maintenance........................................................................................................21

7 Troubleshooting....................................................................................................................... 23

7.1 Pump station troubleshooting......................................................................................... 23

7.1.1 The pump station does not power up..................................................................... 23

7.1.2 The station powers up, but the pumps do not run.................................................23

7.1.3 The pumps run but do not build desired pressure................................................ 24

7.1.4 The pump station experiences excessive vibration............................................... 24

7.1.5 The pump station does not shut down and no water is used...............................25

7.1.6 The pump station cycles or hunts erratically...........................................................25

8 Technical Reference.................................................................................................................26

8.1 Pump station numbering system..................................................................................... 26

8.1.1 Pump station with e-SV pumps................................................................................. 26

9 Appendix................................................................................................................................... 28

9.1 Installation drawings..........................................................................................................28

10 Product warranty.................................................................................................................... 36

2 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 5

1 Introduction and Safety

1.1 Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the

product can cause personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the

unit.

1 Introduction and Safety

1.2 Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Operating, installing, or maintaining the unit in any way that is not covered in this

manual could cause death, serious personal injury, or damage to the equipment. This

includes any modification to the equipment or use of parts not provided by Xylem. If

there is a question regarding the intended use of the equipment, please contact a

Xylem representative before proceeding.

• Do not change the service application without the approval of an authorized Xylem

representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result

in physical injury, damage, or delays.

1.2.1 Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product and its surroundings

• Product malfunction

Hazard levels

Hazard level Indication

DANGER:

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 3

A hazardous situation which, if not avoided, will result in

death or serious injury

Page 6

1 Introduction and Safety

Hazard level Indication

WARNING:

A hazardous situation which, if not avoided, could result

in death or serious injury

CAUTION:

NOTICE:

Special symbols

Some hazard categories have specific symbols, as shown in the following table.

Electrical hazard Magnetic fields hazard

Electrical Hazard:

1.2.2 Protecting the environment

Emissions and waste disposal

Observe the local regulations and codes regarding:

• Reporting of emissions to the appropriate authorities

• Sorting, recycling and disposal of solid or liquid waste

• Clean-up of spills

A hazardous situation which, if not avoided, could result

in minor or moderate injury

Notices are used when there is a risk of equipment

damage or decreased performance, but not personal

injury.

CAUTION:

Exceptional sites

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless

Xylem has been informed and appropriate actions have been agreed upon.

Recycling guidelines

Always follow local laws and regulations regarding recycling.

1.3 User safety

General safety rules

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

hazards.

4 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 7

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

Electrical connections

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations. For more information about

requirements, see sections dealing specifically with electrical connections.

Precautions during work

Observe these safety precautions when you work with the product or are in connection

with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is

• Never operate a pump without a properly installed coupling guard.

1 Introduction and Safety

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

control.

pressurized. Make sure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

1.3.1 Wash the skin and eyes

Follow these procedures for chemicals or hazardous fluids that have come into contact

with your eyes or your skin:

Condition Action

Chemicals or hazardous fluids in

eyes

Chemicals or hazardous fluids on

skin

Lockout/Tagout provisions

DANGER:

Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 5

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

Page 8

1 Introduction and Safety

WARNING:

• Always disconnect and lock out power to the driver before you perform any installation

The main station panel is equipped with a main station disconnect for completely

powering down the system. This panel also provides individual circuit breaker service

disconnects for each pump. These disconnects are accessible without disengaging the

main station disconnect to ensure that operation of the system is not interrupted during

individual pump service. In both situations (complete station or individual pump power

down), provisions for lockout / tagout capability have been provided.

The main station disconnect has a door interlocking feature that utilizes a handle that

allows for padlocking.

or maintenance tasks. Failure to disconnect and lock out driver power will result in

serious physical injury.

The individual circuit breaker disconnects are accessible through an inspection/service

window that has an integrated locking tab feature. The use of a lockout scissor clamp is

highly recommended to properly lockout any of these individual disconnects.

6 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 9

2 Transportation and Storage

2 Transportation and Storage

2.1 Examine the delivery

2.1.1 Examine the package

1. Examine the package for damaged or missing items upon delivery.

2. Record any damaged or missing items on the receipt and freight bill.

3. If anything is out of order, then file a claim with the shipping company.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

2.1.2 Examine the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. To determine whether any parts have been damaged or are missing, examine the

product.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

Use care around nails and straps.

4. If there is any issue, then contact a sales representative.

2.2 Transportation guidelines

2.2.1 Lifting methods

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support

this equipment can result in serious physical injury and/or equipment damage. Lift

equipment only at the specifically identified lifting points. Lifting devices such as

eyebolts, slings, and spreaders must be rated, selected, and used for the entire load

being lifted.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

and wear steel-toed shoes at all times.

• Tip over hazard. Do not use component eyebolts to lift the pump station. The eyebolts

are only designed to lift the components to which they are attached.

• Do not attach sling ropes to the panel stand.

2.3 Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and

vibrations.

NOTICE:

Protect the product against humidity, heat sources, and mechanical damage.

NOTICE:

Do not place heavy weights on the packed product.

2.3.1 Storage between use

Observe the following for long-term storage of a pump station.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 7

Page 10

2 Transportation and Storage

• Insure system is drained of any water.

• Remove transducers to ensure that they do not freeze.

• System may be top-heavy, brace to keep from tipping.

2.3.1 Long term storage

The following procedure applies to Boosters and HVAC Packages.

1. Customer furnished equipment and accessories that are not offered as standard or

optional by the factory must be handled in accordance with the respective

manufacturer's recommendations.

2. Storage longer than one month Is considered long term storage.

3. Pumps should be prepared for storage using the following procedure.

SAFETY

• Select a storage location that will prevent potential hazards to persons allowed access

to the storage area.

• Appropriate precautions should be taken to ensure safe on-site receipt and transit.

• Potential energy risk should be minimized. Keep product at ground level and prevent

stacking or other unsafe positioning that could result in falling, dropping, and/or

tipping.

LOCATION AND TREATMENT

• Indoor Storage

– Little extra preparation is needed if indoor storage area is dry and clean.

– Care should be taken to prevent extremes In temperature (below 32°F and above

110°F). Also, keep the pump out of direct sunlight and covered to protect it from

dust and dirt.

– Care should be taken to prevent moisture build-up around the pump, either by

allowing proper ventilation or tightly sealing the pump in the cover with a suitable

amount of desiccant to ensure dryness.

– If indoor storage area is humid or dirty, such as an unfinished building, treat the

pump as if it were to be stored outdoors.

– If exposure to condensation is expected, un-painted external steel or cast-iron

surfaces should be coated with rust-inhibiting oil such as Cortec’s VCI-329.

– Storage location should also provide minimal exposure to vibration and other

damage potentially transmitted from adjacent operating equipment.

– Product supplied in factory cartons, pallets or similar Xylem packaging should be

kept in ‘as-shipped’ condition where possible.

– Inspect suction and discharge manifold flange covers.

• Outdoor Storage

– Pump should be covered to protect it from weather and direct sunlight.

– All coverings should be property secured to withstand high wind.

– Care must be exercised in covering pumps to prevent moisture build-up under the

cover. This can be done either by allowing proper ventilation or tight sealing cover

with suitable amount of desiccant to ensure dryness.

– Extreme heat and cold are to be avoided, as rubber parts and seals could age

prematurely (below 32°F and above 110°F).

– Storage area should be inspected weekly, and after storms for damage to

protective covers.

– Inspect suction and discharge manifold flange covers.

• Installed But Not in Service

8 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 11

2 Transportation and Storage

– Preparation for storage under these conditions is the same as for indoor and

outdoor, except the suction and discharge piping will serve as flange covers.

– The suction and discharge valves must be tightly closed and all water removed

from the pump and attached piping. The interior of the pump and piping must be

thoroughly dried.

– Inspect un-painted external steel or cast-iron surfaces once a month for moisture

and replace volatile corrosion inhibitor at that time (see section 1.B.a.v)

EQUIPMENT PROTECTION

• Pumps

– Every 30 days, the pump and motor shaft should be rotated by hand (10-15 turns)

to prevent bearing damage and potential for binding. Be sure shaft comes to rest in

different positions.

– Close-coupled pumps may have minimal access to exposed shaft areas. In those

cases, care must be taken to avoid damage to the shaft though use of channel-lock

pliers or similar tools.

– If removal of the coupling guard is required for hand-rotation of the pump and

motor shafts, this guarding must be reinstalled prior to removal of lock-out tag-out

and start-up.

• Control Panels, VFDs, and Electronics

– For storing electrical control panels, drives and other electrical items for more than

3 months, insertion of moisture absorbing packets within the enclosure by be

necessary. Periodically replace as required. Remove packets prior to equipment

start-up.

• Package Enclosures

– Housing vents and/or openings will be sealed with plastic wrap and waterproof

tape.

– Condensation protection shall be provided in accordance to instructions previously

noted.

PREPARATION FOR OPERATION

• Remove all rust inhibitor from exposed machined surfaces using the method

described by the supplier.

• Remove all corrosion protection devices or material from package.

• Remove flange covers, tape, and all unnecessary pipe plugs.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 9

Page 12

3 Product Description

3 Product Description

3.1 General description

Description

A pump station is a pre-engineered and fabricated line of packaged booster systems that

provides:

• Energy efficiency

• System protection

• Hydraulic capability up to 780 GPM

• Boost pressures up to 270 PSI

Intended applications

WARNING:

This product can expose you to chemicals including Lead, which is known to the State of

California to cause cancer and birth defects or other reproductive harm. For more

information go to: www.P65Warnings.ca.gov.

The pump station is intended for these applications:

• High rise buildings

• Industrial plants

• Municipal and rural water districts

• Agriculture / irrigation

• General water pressure boosting

3.1.1 Operational limits

Pressure

This table describes the pressure ratings for a pump station using the pump model shown

Pump system type Max. discharge pressure

e-SV Pumps 270 PSI

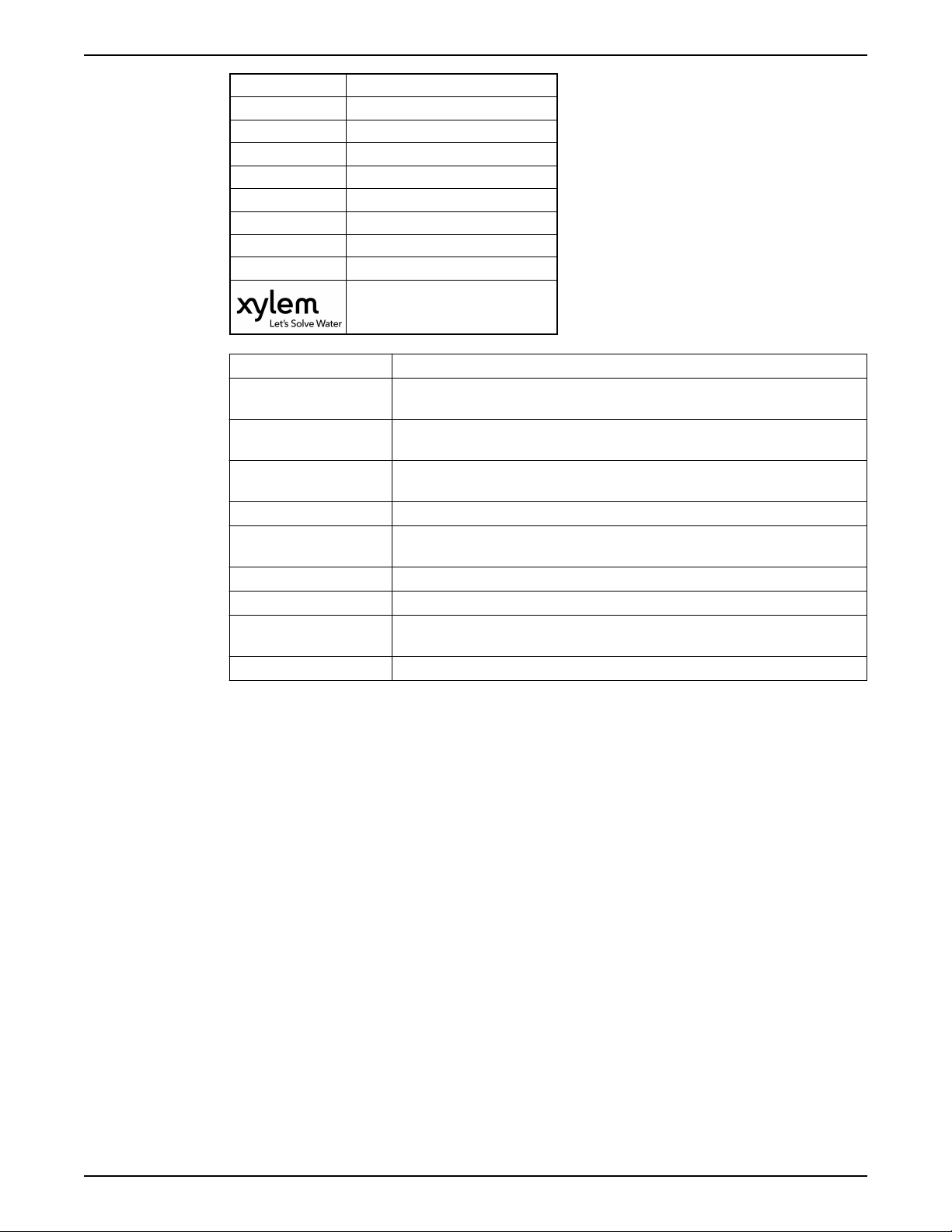

3.2 Nameplate information

Important information for ordering

Every pump station has a nameplate that provides information about the pump station.

The pump station nameplate is located on the inside of the control enclosure door.

When ordering spare parts, be prepared to identify the nameplate information when

contacting the factory.

• Model

• Size

• Serial number

• Item numbers of the required parts.

10 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 13

Date Code

Pump Boost

Station Flow

Largest Motor HP

SCCR

System FLA

Station Voltage

Serial Number

Model Number

Applied Water Solutions

Dallas, Texas, U.S.A

Customer Service 1.800.786.7480

3 Product Description

Nameplate field Explanation

Model number The manufacturer's number to indicate the particular type of product which has been

acquired.

Serial number A set of characters that uniquely identifies a single unit and can be used for traceability

and warranty purposes.

Station voltage The rated voltage at which the station has been designed for. Should match the

application site supply voltage.

System FLA The full-load-amperage at which the station can operate.

SCCR “Short-Circuit Current rating”. Represents the maximum level of short-circuit current

that a component or assembly can withstand.

Largest motor HP The rated HP for the largest pump in the system.

Station flow The designed duty point, in GPM, LPH, etc.

Pump boost The difference between the input side of the pump station and the output side of the

pump station.

Date code Marking of products to indicate their date of manufacture.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 11

Page 14

4 Installation

4 Installation

4.1 Reference manuals

Additional installation information

For information on installing controllers, use the following IOM:

• Hydrovar - Instruction Manual

• Hydrovar - Overview Software Parameters

4.2 Field connections

Diagrams

Actual equipment manufacturers/models installed are system specific. Refer to specific

manufacturer Installation, Operation, and Maintenance manuals for details unique to each

component. The pump instruction manual is supplied with the system.

Review the wiring diagrams and dimensional drawings provided with the station before

you install and operate the unit.

Electrical precautions

WARNING:

Electrical shock hazard. The electrical supply must match the control panel nameplate

specification. Incorrect voltage can cause a fire, which damages the electrical components

and voids the warranty. Failure to follow these instructions could result in serious personal

injury or death, or property damage.

NOTICE:

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local rules.

4.3 ground (earth) connections

WARNING:

Electrical shock hazard. Conduit grounds are not adequate. You must attach a separate

ground (earth) wire to the ground (earth) lug provided in the enclosure in order to avoid

potential safety hazards. Failure to follow these instructions can result in serious personal

injury, death, or property damage.

A grounding terminal is provided for a dedicated ground (earth) wire connection. You

must follow all provisions of the National Electrical Code and local codes.

4.4 Pump package location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this

equipment can result in serious physical injury and/or equipment damage. Lift equipment

only at the specifically identified lifting points. Lifting devices such as eyebolts, slings, and

spreaders must be rated, selected, and used for the entire load being lifted.

Guideline Explanation/comment

Make sure that the space around the pump package is

sufficient.

12 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

This facilitates ventilation, inspection, maintenance, and

service.

Page 15

Guideline Explanation/comment

If you require lifting equipment such as a hoist or tackle,

make sure that there is enough space above the pump

package.

Use traditional lifting equipment (safety belt, sling, or

chain) to secure assembly. Corner holes in base have

been provided for installation of an approved lifting

eyebolt and nuts (not furnished with package).

Protect the unit from weather and water damage due to

rain, flooding, and freezing temperatures.

Do not install and operate the equipment in closed

systems unless the system is constructed with properlysized safety and control devices.

Take into consideration the occurrence of abnormal noise

and vibration.

This makes it easier to properly use the lifting equipment

and safely remove and relocate the components to a safe

location.

Prevention against overturning the package

This is applicable if nothing else is specified.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices, consult the

engineer or architect in charge before you operate the

pump.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil underneath.

4 Installation

Figure 1: Rigging examples

4.5 Foundation requirements

Requirements

• The foundation must be able to absorb any type of vibration and form a permanent,

rigid support for the unit.

• Provide a flat, substantial concrete foundation in order to prevent strain and distortion

when you tighten the foundation bolts.

• Sleeve-type and J-type foundation bolts are most commonly used. Both designs allow

movement for the final bolt adjustment.

• See Appendix A for base mounting hole patterns.

4.6 Level the base on a concrete foundation

1. Place the pump package on its concrete foundation.

2. Place 1.00 in./(25.40 mm) thick steel shims or wedges on both sides of each anchor

bolt in order to support the pump package.

Make sure that you also place the shims or wedges midway between the bolts.

This also provides a means of leveling the base.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 13

Page 16

4 Installation

4.7 Grout the baseplate

Required equipment:

• Cleaners: Do not use an oil-based cleaner because the grout will not bond to it. See

the instructions provided by the grout manufacturer.

• Grout: Non-shrink grout is required.

1. Clean all the areas of the baseplate that will come into contact with the grout.

2. Build a dam around the foundation.

3. Thoroughly wet the foundation that will come into contact with the grout.

4. Pour grout around the baseplate.

To hold wedges or shims in place, allow the grout to flow around them.

Follow grout manufacturer's instructions for removing air pockets from grout during

pour.

5. Allow the grout to set.

The grout needs to set for at least 48 hours. Follow any additional instructions from the

grout manufacturer.

6. Tighten the foundation bolts.

4.8 Piping checklist

WARNING:

• The heating of water and other fluids causes volumetric expansion. The associated

forces can cause the failure of system components and the release of hightemperature fluids. In order to prevent this, install properly sized and located pressurerelief valves. Failure to follow these instructions can result in serious personal injury or

death, or property damage.

• Avoid serious personal injury and property damage. Make sure that the flange bolts

are adequately torqued.

NOTICE:

Never force piping to make a connection with a pump.

Check Explanation/comment Checked

Check that the suction and discharge pipes are

supported independently by use of pipe hangers near

the pump station.

Check that there is a strong, rigid support for the

suction and discharge lines.

Check that the suction or discharge lines are not

forced into position.

Check that fittings for absorbing expansion are

installed in the system when considerable

temperature changes are expected.

This eliminates pipe strain on the pump station.

As a rule, ordinary wire or band hangers are not

adequate to maintain proper alignment.

Component failure will result if suction or

discharge lines are forced into position.

This helps to avoid strain on the pump.

14 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 17

5 Commissioning, Startup, Operation, and Shutdown

5 Commissioning, Startup,

Operation, and Shutdown

5.1 Preparation for startup

DANGER:

Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

WARNING:

• Failure to follow these precautions before you start the unit will lead to serious

personal injury and equipment failure.

• Do not operate the pump below the minimum rated flows or with the suction or

discharge valves closed. These conditions can create an explosive hazard due to

vaporization of pumped fluid and can quickly lead to pump failure and physical injury.

• Always disconnect and lock out power to the driver before you perform any installation

or maintenance tasks. Failure to disconnect and lock out driver power will result in

serious physical injury.

• Operating the pump in reverse rotation can result in the contact of metal parts, heat

generation, and breach of containment.

NOTICE:

• Verify the driver settings before you start any pump.

You must follow these precautions before you start the pump:

• Flush and clear the system thoroughly to remove dirt or debris in the pipe system in

order to prevent premature failure at initial startup.

• Verify controller settings match site conditions and motor nameplate data before

starting station.

5.1.1 Prestartup checklist

CAUTION:

Risk of leaks or flooding. Make sure to reinstall the drain plugs properly. Check all joints

for tightness and flange bolts for the proper torque.

Checks Checked

Check that the pump is properly aligned. Refer to these manual numbers for more

information:

• eSV pumps = IM228

Check that the drain plugs are installed before filling system.

Inspect all piping joints for tightness.

Joints can become loose during transit due to vibration and shock.

Check all flanged joints for the proper torque.

Check that the system is full of liquid.

Check that all high points in the piping system are vented in order to remove trapped

air.

Check that all pumps and drivers are properly lubricated.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 15

Page 18

5 Commissioning, Startup, Operation, and Shutdown

Checks Checked

Check that the piping is clean and has been flushed.

5.1.2 Final installation checks

Installation checklist

CAUTION:

Serious damage to the pump may result if it is started dry. Make sure that the pump is

completely filled with liquid before it is started.

Check Checked

Check that the unit base is properly leveled, grouted, and secured.

Check that all lubrication points are properly lubricated.

Check that the outlet side of the high-temperature relief valve assembly (if option is

purchased) is connected to the drain with tubing or pipe sized 1/2 in. or greater.

Check that the shut-off valves to the transmitters are open.

Check that the stop cocks for the check feature on the PRV are open. They must never

be completely closed during normal operation. Throttle the cock if you note any

check slamming (constant speed stations only).

Check that the system is purged of debris and air.

Check that the pump and motor shafts are properly aligned.

Check that the pump rotation is correct.

Check that the piping is properly supported. This prevents strains on the unit.

5.1.3 Final adjustments

Make the final adjustments on these adjustable devices in order to match the exact system

requirements.

Thermal relief valve

An optional thermal relief valve is installed on the pump discharge in order to prevent

potentially dangerous thermal pressure buildup. The valve automatically opens on a

temperature increase and closes on a temperature decrease. This valve acts as a safety

device; do not remove or plug it. It is factory set to open and discharge when the water

temperature in the discharge header reaches between 125°F to 135°F (51°C to 57°C).

Make sure that the 1/2 in. NPT opening of this valve assembly is piped to a floor drain in

accordance with local codes.

After long periods of operation, the valve seat and disc can become worn or pitted. This

allows leaks through the valve in the closed position. You can replace internal parts, if

desired.

Low suction pressure switch

Adjust the setting to 10 psi below the rated suction pressure.

5.2 Pump station startup

5.2.1 Confirm the job site voltage

1. Check these items before you apply power or close the disconnect:

16 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 19

a) Check all of the power wiring connections and secure them as required.

b) Confirm with the owner/installing contractor if there are plans for any required

building automation or remote connections.

c) Inspect and/or install any customer remote terminations.

2. Make note of the design data supplied on the data label. The label is located on the

inside of the control panel door.

3. Use a volt meter to check the voltage on the incoming power terminals at the

disconnect.

4. Compare the voltage to the data on the nameplate.

5.2.2 Connect the storage tank

DANGER:

Explosion hazard. Prevent tank explosion. Do not install the tank when the system shut-off

pressure exceeds the tank pressure rating.

DANGER:

Explosion hazard. Prevent tank explosion. Install a pressure relief valve on the tank inlet

with a set point no greater than tank rating.

5 Commissioning, Startup, Operation, and Shutdown

1. Precharge the storage tank before you connect it to the system.

The air precharge needs to be 5 to 10 psi less than the system operating pressure.

2. If the storage tank has already been installed and not precharged, then disconnect the

system piping from the tank and equalize it to atmospheric pressure. If an isolation

valve and drain are provided, then use them.

3. Apply air pressure to the tank through the air charging valve and pressurize to field

conditions.

This needs to be equal to the NFSD restart pressure of 5 to 10 psi below the operating

pressure.

4. Reconnect the tank to the system piping. Tank should be installed on the discharge

side of the system.

5.2.3 Optional water level control relay

The Level Sensing Probes, which are not provided, are required for the water level control

relay (Crouzet - 84870700) to work properly. The connection diagram for the level sensing

probes from the relay manufacturer is as follows.

Figure 2: Connection diagram for probes

The relay signal is connected to the Hydrovar drive. If the level sensing probes are not

connected, then the relay will give an unhealthy signal (“NO” – Normally Open) and the

Hydrovar drive will give an error message as “Lack of Water.” The terminals X1:1 – X1:3

are provided in the Electrical Control Panel to connect these probes.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 17

Page 20

1

5 Commissioning, Startup, Operation, and Shutdown

Figure 3: Terminals for probes connection

1. Level sensing probes connection to terminals X1:1 X1:3

Option-I: How to use or connect this relay to run the Hydrovar properly

1. Connect the level sensing probes to the terminals X1:1, X1:2, X1:3 (Min., Max. and

Common).

2. Relay (BL1) will need to use Pin No. 11 and 14 to connect to the Hydrovar drive.

Remove the connected wire from Relay (BL1) Pin No. 12 and connect it to Pin No. 14.

3. Once the swapping of the wires and connection of the probes is complete and the

water level is reached to set point, then the relay (BL1) will give a healthy signal (“NC”Normally Closed) to the Hydrovar drive. This signal will be maintained until the water

level falls out of the set point range.

4. When the water level is above or below the set point range, then the relay gives an

unhealthy signal to the Hydrovar drive, which results in an error message as “Lack of

Water.”

Option-II: How to by-pass this relay to run the Hydrovar properly

1. If the level sensing probes are not available or level sensing is not required, we need

to By-pass the relay to run the Hydrovar smoothly. (As a default, the system is already

set-up in a By-pass mode. If you have been running the system with the level control

and would like to now by-pass this feature, continue with the following instructions.)

2. For By-pass mode, relay (BL1) will need to use Pin No. 11 and 12 to connect to the

Hydrovar drive. Remove the connected wire from Relay (BL1) Pin No. 14 and connect it

to Pin No. 12.

3. When these connections are complete, the relay gives a healthy signal continuously

and the level sensing feature will get bypassed.

18 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 21

5.2.4 Check for available suction water

1. Open all supply, discharge, and pump isolation valves. Also open any other package

valves.

2. Close the bypass valve if it is installed in the piping by others.

3. Inspect the capillary tubing from the pump discharge to the suction header:

a) Open the petcocks that feed the tubing.

b) Make sure that the plastic tubing does not touch any metal surface. Protect the

tubing with insulation in order to prevent abrasion where it can possibly touch

metal.

4. Use the pump vent plugs and/or the vent cocks on the main PRV in order to prove that

there is available water from the suction.

5. Open a faucet in order to create a demand for water on the system pressure piping.

6. Observe the suction pressure and confirm that it is equal to or greater than the suction

pressure listed on the nameplate. System is designed for a specific suction pressure.

Deviation results in degraded system performance. Contact factory if suction pressure

varies from design specifications.

5.2.5 Start the package

1. Close the disconnect in order to apply power to the package.

2. Turn the panel switch to the local position.

3. Watch the screen as the boot-up progresses and note the serial number of the unit.

This is the password that you use for the setup menu.

4. If the unit starts, press the Stop button in order to stop the unit.

5 Commissioning, Startup, Operation, and Shutdown

5.2.6 Check the pump rotation

1. Select the hand mode on the controller.

2. Enable the pump with the blinking green light.

Do not select any of the other pumps (no green light).

3. Press the start button and spin the first pump.

4. Immediately press the Stop button.

5. Observe the spinning shaft for rotation.

6. Repeat steps 1 through 5 for each pump.

7. If all pumps run backwards, reverse the two leads of the incoming power.

8. If only one of the pumps run backwards, reverse the two leads on the pump motors

that are incorrect.

5.2.7 Set the system operating pressure

1. Open a faucet or some other demand for water from the discharge of the package.

This can be anywhere in the building being served by the package.

2. In hand, run one pump.

5.2.8 Enter the setup menu

1. For each pump, confirm the settings entered for the pump motor data.

2. Review all settings for the compatibility with the installed application.

3. Make sure that these settings are in place:

– Auto alt. prd. - 24 or 168 hours

– Forced destage timer - 10 to 15 minutes

– NFSD restart psi - Enter a value 5 to 10 psi less than the site-adjusted discharge

pressure

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 19

Page 22

5 Commissioning, Startup, Operation, and Shutdown

– NSFD minimum run timer - 5 minutes

– NFSD test PR timer - 20 seconds

4. Adjust any other settings in order to meet the needs of your system.

5.2.9 Test the package

1. Exit the setup menu.

2. Stop the package.

3. Press the Auto key and then Start.

4. Observe the pressures and temperatures for normal operation.

5. Press the Alternation key and observe the operation of each pump.

6. Close the running water faucet.

It is assumed that no demand for water is required. For example, no flow.

7. Observe the No Flow Shutdown sequence. All minimum run timers must elapse for this

sequence to occur.

8. Demand water from the system and observe the restart of the package.

If you encountered no problems, then you are done.

20 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 23

6 Maintenance

6.1 Precautions

DANGER:

Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

WARNING:

• This manual clearly identifies accepted methods for disassembling units. These

methods must be adhered to. Trapped liquid can rapidly expand and result in a violent

explosion and injury. Never apply heat to impellers, propellers, or their retaining

devices to aid in their removal.

• Make sure that each pump and the package are isolated from the system and that

pressure is relieved before you disassemble the pump, remove plugs, open vent or

drain valves, or disconnect the package piping.

• Always disconnect and lock out power to the package and the driver before you

perform any installation or maintenance tasks. Failure to disconnect and lock out driver

power will result in serious physical injury.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

and wear steel-toed shoes at all times.

• Rotating shaft. Make sure that the packing adjustment is performed by qualified

personnel only.

6 Maintenance

CAUTION:

Equipment damage hazard. Silt buildup is a sign of problems with the wet well and/or

intake screen. Failure to follow these instructions indicates a potentially hazardous

situation, which, if not avoided, may result in property damage.

6.2 Monthly maintenance

Control panel checks

• Verify that all of the operator interface keys and LEDS operate properly (see controller

manual).

• Review the station operation, fault history, and data log for station operation.

• Verify that all surge devices are visually sound, where applicable.

– Check the surge device for the station which is mounted on the back of the control

panel.

– Black soot on or around the device indicates that it has taken a surge and needs to

be replaced.

Motor lubrication checks

• For grease-filled bearings, make sure that grease is not all over the inside of the motor

and in the bottom of the motor. This could be a sign of overfilling. Refer to the

lubrication instructions from the motor manufacturer.

Sound and visual checks of the whole station

• Listen for any odd sounds that rub or grind, electrical arcing, and check for anything

that is binding or unusual. These conditions can indicate a serious problem.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 21

Page 24

6 Maintenance

Station skid

Note that there is going to be some harmonic vibration with the pumps and motor.

Listen for excessive vibration or noise as this requires immediate service. Do not

operate the pump if there is excessive vibration.

• Confirm that the building cooling and ventilation systems are operating and clear of all

obstructions. The maximum operating range for equipment is 104°F (40°C).

• Verify that water, grease, oil, and hardware are not leaking or loose on the pump

station.

• Visually inspect for leaks in the station piping, valves, and other components.

• Visually inspect the piping and skid for any stress cracks in the welds.

• Visually inspect the station for loose or damaged paint or areas of rust.

22 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 25

7 Troubleshooting

7.1 Pump station troubleshooting

DANGER:

• Personal injury hazard. Troubleshooting a live control panel exposes personnel to

hazardous voltages. Electrical troubleshooting must be done by a qualified electrician.

Failure to follow these instructions will result in serious personal injury, death, and/or

property damage.

• Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

WARNING:

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local rules.

Note that some troubleshooting procedures apply to only constant speed systems or only

variable speed systems.

Use this Installation, Operation, and Maintenance manual for more information:

• e-SV pumps = IM228

7 Troubleshooting

7.1.1 The pump station does not power up

Cause Remedy

The site voltage does not match the pump station

voltage.

Line-to-line voltage is not balanced. Check incoming voltage and amperage. Line-to-line

The power fuses are blown or breakers are tripped. Check power fuses and breakers. Breakers are shipped in

The pump station is not properly grounded (earthed). Check that proper grounding (earthing) techniques have

There is a fault. Check for fault codes or fault lights on the Hydrovars.

7.1.2 The station powers up, but the pumps do not run

Cause Remedy

Pumps are not enabled. Check the PLC to make sure that the pumps are enabled.

The desired pressure is satisfied. Check to see if the desired pressure is satisfied. If the

There is a fault. Check for fault codes or fault lights on the Hydrovars.

The motor is tripped. Check for a tripped motor thermal protector. Allow motor

The fuses are blown or breakers are tripped. Check circuit breaker and fuses.

Transducer isolation valves are closed. Make sure that the transducer isolation valves are in the

Make sure that the site voltage matches the pump station

design voltage.

voltage should be balanced. Line-to-ground voltage

should also be balanced.

the OFF position. Replace blown fuses.

been used for the pump station.

Correct the fault.

Check for faults. Correct any faults.

actual pressure is greater than the set point pressure,

then the pumps are automatically stopped.

Correct the fault.

to cool, and then reset the thermal protector.

open position.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 23

Page 26

7 Troubleshooting

Cause Remedy

Automatic mode is faulty. Check to see if the pump can be run in Manual mode on

The impeller is bound. Check to see if you can turn the pump by hand. Check for

A pressure transducer is faulty. Replace faulty pressure transducers.

Motor wiring is loose. Make sure that motor wiring is securely connected.

Motor windings have lost insulation strength. Test the motor leads with a megger in order to check the

Variable speed drive is wired incorrectly. Check corresponding variable speed drive. Make sure

Motor is defective. Repair or replace motor.

7.1.3 The pumps run but do not build desired pressure

Cause Remedy

Pumps are running off their design curve. Check the application. Is the system running in an open

Pumps are running at less than full speed. Check to see if the pumps are running at full speed. If

The inlet pressure does not match the project

specifications.

A pipe is broken. Check for broken pipes.

The transducer isolation valves are closed. Check to be sure that the transducer isolation valves are

The NPSH is insufficient. Check the NPSH. Are proper flooded conditions or

The pump station has lost its prime. Check to be sure that the pump station has been primed

The pump rotation is incorrect. Check the pump rotation. Proper rotation is indicated on

A suction or discharge valve is closed or clogged. Check the isolation valves and check valves. Are all

The motor is not operating at the rated RPM. Check the voltage and amperage. Check for possible

The impeller is worn or plugged. Take the pump to an authorized pump repair facility.

The pump bearings are worn. Take the pump to an authorized pump repair facility.

the Hydrovars.

a bound impeller.

motor windings.

drive is wired correctly.

discharge condition (excessive flow rate)? For example, is

the system filling a large irrigation line for the first time

of the season?

they are running less than full speed, they could be

experiencing electrical issues. Check the panel for power

status.

Check to see if the inlet pressure matches the project

specifications. Variations in inlet pressure can have

detrimental effects on performance.

in the open position.

positive pressure being delivered to the pump station?

Check for air in the supply lines. Check for properly filled

supply tanks (if applicable). Excessive suction lift or

piping losses will limit the life expectancy of the pumps.

properly. Make sure that all pumps and components are

properly filled with water.

the pump volute. (See the pump IOM.)

suction/discharge valves open? Could any valves be

plugged? Could the pumps be plugged?

phase loss to the motor.

7.1.4 The pump station experiences excessive vibration

Cause Remedy

The motor, pump, or piping is loose. Make sure that all fasteners and components are properly

tightened.

24 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 27

Cause Remedy

Pump station vibration dampers are missing or

improperly installed.

Pumps are running off their design curve. Check the application. Is the system running in an open

Air or gases are present in the pumped liquid. Check water supply lines and tanks. Check for air or gases

Discharge piping is plugged. Check discharge piping/valves. Could the piping be

Supply piping has excessive suction/lift conditions or

friction loss.

The impeller is bound or worn. Take the pump to an authorized pump repair facility.

Pumps and pipes are not properly aligned. Correct the alignment between pumps and pipes.

Check for properly installed pump station vibration

dampers.

discharge condition (excessive flow rate)? For example, is

the system filling a large irrigation line for the first time

of the season?

in liquid. Bleed the lines.

plugged? Could the pump be plugged? Are the isolation

valves open? Clear any clogs.

Check for excessive suction/lift conditions or friction loss

on supply piping.

7.1.5 The pump station does not shut down and no water is used

Cause Remedy

The pump station is in Hand or Manual mode. Put the system in the AUTO position.

The system pressure is set beyond capability of the

station.

There are leaks or broken pipes. Check for broken pipes or leaks. Does the system

The diaphragm tank is faulty. Check for a properly installed diaphragm tank. Has the

The pressure transducers are faulty. Check the pressure transducers. Does the actual

A check valve is malfunctioning. Check for malfunctioning check valves. Does the system

Check the system set pressure. Is this duty point beyond

the capability of the pump station?

pressure decrease if the pump station is turned off?

tank failed? Has the tank been charged to the proper

operating pressure before installation? (~10 psi below

the desired set point)

mechanical gauge pressure match the pressure displayed

on the VFDs and the PLC?

hold pressure when the pump package is shut down?

Replace faulty valves.

7 Troubleshooting

7.1.6 The pump station cycles or hunts erratically

Cause Remedy

The pumps are oversized for the current demand. Check the application. Possibly increase the size of the

bladder tank for low demand situations.

The inlet pressure is fluctuating. Check the application. Possibly increase the size of the

bladder tank for low demand situations.

There are leaks or broken pipes. Check for broken pipes or leaks. Does the system

pressure decrease when the pump station is turned off?

The diaphragm tank is faulty. Check for a properly installed diaphragm tank. Has the

tank failed? Has the tank been charged to the proper

operating pressure before installation? (~10 psi below

the desired set point)

The pressure transducers are faulty. Check the pressure transducers. Does the actual

mechanical gauge pressure match the pressure displayed

on the VFDs.

A check valve is malfunctioning. Check for malfunctioning check valves. Replace faulty

valves.

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 25

Page 28

8 Technical Reference

8 Technical Reference

8.1 Pump station numbering system

The pump station label located on the inside of the control enclosure door identifies the

product code number for the various versions of the pump systems. This number is also

the catalog number for the pump station. The pump station numbering systems describe

the meaning of each digit.

Not all combinations are possible.

8.1.1 Pump station with e-SV pumps

Example product code

HVL 3 D 4 — 15 SV 4 G H 4 F 6 0 — 4 B M

Numbering system definitions

First character: Variable or constant speed

HVL = e-HV with 5th Generation Hydrovar

Second character: Number of pumps

2, 3, or 4

Third character: Supply voltage

D = 460 V / 3 PH / 60 Hz

L = 208-230V / 3 PH / 60 Hz

Fourth character: Header size

2 = 2 in. 4 = 4 in.

3 = 3 in. 6 = 6 in.

Fifth character: Pump series

3 = 3SV 15 = 15SV

5 = 5SV 33 = 33SV

10 = 10SV

Sixth character: Pump type

SV = eSV

Seventh character: Stages / impeller size

1 = 1, 2 = 2, 3 = 3, and so forth

Eighth character: Pump configuration option

G = CI-304

Ninth character: HP rating

D = 1.5 H = 7.5

E = 2 J = 10

F = 3 K = 15

G = 5

26 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 29

Tenth character: Pole-Hz-Phase

4 = 2-60-3

Eleventh character: Motor voltage

C = 230-460 F = 208-230/460

Twelfth character: Motor enclosure

6 = TEPE (Premium TEFC)

Thirteenth character: Seal material

0 = Carb-SilCar-Viton

Fourteenth character: Pump split

1 = 100 + Standby 4 = 33/33/33

2 = 50/50 5 = 33/33/33 + Standby

3 = 50/50 + Standby 6 = 25/25/25/25

Fifteenth character: Brand

B = B&G (Bell & Gossett)

8 Technical Reference

Sixteenth character: Communication option

D = Disabled

M1 = Modbus ASCII

M2 = Modbus RTU

B = BACnet MS/TP

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 27

Page 30

7.01

TYP

25.24

TYP

.81

TYP

1.12

TYP

3/8

TYP

9 Appendix

9 Appendix

9.1 Installation drawings

Duplex (208–230/3 and 460/3 Volt): 3SV to 5SV

28 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 31

Duplex (208–230/3) 10SV2 to 10SV8, 15SV1 to 15SV-4; Duplex (460/3): 10SV2 to 15SV5

14.57

TYP

22.05

TYP

1.57

TYP

.71

TYP

1/2

TYP

9 Appendix

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 29

Page 32

26.38

TYP

34.65

TYP

1.57

TYP

1.18

TYP

1/2

TYP

9 Appendix

Duplex (208–230/3): 33SV10, 33SV11, 33SV22; Duplex (460/3): 15SV6 to 33SV

30 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 33

Duplex (208–230/3): 10SV11, 15SV5 to 15SV8, 33SV20, 33SV21, 33SV31, 33SV32

1.57

TYP

26.38

TYP

1.18

TYP

38.58

TYP

1/2

TYP

9 Appendix

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 31

Page 34

14.57

TYP

1.57

TYP

.71

TYP

1/2

TYP

36.02

TYP

9 Appendix

Triplex (208–230/3) 3SV to 10SV8, 15SV1 to 15SV4; Triplex (460/3) 3SV to 15SV5

32 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 35

Triplex (208–230/3): 33SV10, 33SV11, 33SV22; Triplex (460/3 Volt): 15SV6 to 33SV

51.97

TYP

1.57

TYP

26.38

TYP

1.18

TYP

1/2

TYP

9 Appendix

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 33

Page 36

1.57

TYP

26.38

TYP

1.18

TYP

59.84

TYP

1/2

TYP

14.57

TYP

1.97

TYP

.71

TYP

21/32

TYP

1/2

TYP

49.80

TYP

14.57

TYP

14.57

TYP

14.57

TYP

3.05

TYP

9 Appendix

Triplex (208–230/3): 10SV11, 15SV5 to 15SV8, 33SV20, 33SV21, 33SV31, 33SV32

Quadplex (208–230/3): 3SV to 10SV8, 15SV1 to 15SV4; Quadplex (460/3 Volt): 3SV to 15SV5

34 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 37

Quadplex (208–230/3): 33SV10, 33SV11, 33SV22; Quadplex (460/3 Volt): 15SV6 to 33SV

70.87

TYP

26.38

TYP

1.18

TYP

1.57

TYP

1/2

TYP

82.68

TYP

1.57

TYP

26.38

TYP

1.18

TYP

1/2

TYP

9 Appendix

Quadplex (208–230/3): 10SV11, 15SV5 to 15SV8, 33SV20, 33SV21, 33SV31, 33SV32

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 35

Page 38

10 Product warranty

10 Product warranty

Commercial warranty

Warranty. For goods sold to commercial buyers, Seller warrants the goods sold to Buyer

hereunder (with the exception of membranes, seals, gaskets, elastomer materials,

coatings and other "wear parts" or consumables all of which are not warranted except as

otherwise provided in the quotation or sales form) will be (i) be built in accordance with

the specifications referred to in the quotation or sales form, if such specifications are

expressly made a part of this Agreement, and (ii) free from defects in material and

workmanship for a period of one (1) year from the date of installation or eighteen (18)

months from the date of shipment (which date of shipment shall not be greater than

ndythirty (30) days after receipt of notice that the goods are ready to ship), whichever shall

occur first, unless a longer period is specified in the product documentation (the

“Warranty”).

Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer,

either repair or replace any product which fails to conform with the Warranty provided

Buyer gives written notice to Seller of any defects in material or workmanship within ten

(10) days of the date when any defects or non-conformance are first manifest. Under

either repair or replacement option, Seller shall not be obligated to remove or pay for the

removal of the defective product or install or pay for the installation of the replaced or

repaired product and Buyer shall be responsible for all other costs, including, but not

limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to

the method or means of repair or replacement. Buyer’s failure to comply with Seller’s

repair or replacement directions shall terminate Seller’s obligations under this Warranty

and render the Warranty void. Any parts repaired or replaced under the Warranty are

warranted only for the balance of the warranty period on the parts that were repaired or

replaced. Seller shall have no warranty obligations to Buyer with respect to any product or

parts of a product that have been: (a) repaired by third parties other than Seller or without

Seller’s written approval; (b) subject to misuse, misapplication, neglect, alteration,

accident, or physical damage; (c) used in a manner contrary to Seller’s instructions for

installation, operation and maintenance; (d) damaged from ordinary wear and tear,

corrosion, or chemical attack; (e) damaged due to abnormal conditions, vibration, failure

to properly prime, or operation without flow; (f) damaged due to a defective power

supply or improper electrical protection; or (g) damaged resulting from the use of

accessory equipment not sold or approved by Seller. In any case of products not

manufactured by Seller, there is no warranty from Seller; however, Seller will extend to

Buyer any warranty received from Seller’s supplier of such products.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY AND ALL OTHER

EXPRESS OR IMPLIED WARRANTIES, GUARANTEES, CONDITIONS OR TERMS OF

WHATEVER NATURE RELATING TO THE GOODS PROVIDED HEREUNDER, INCLUDING

WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY EXPRESSLY DISCLAIMED

AND EXCLUDED. EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYER’S EXCLUSIVE

REMEDY AND SELLER’S AGGREGATE LIABILITY FOR BREACH OF ANY OF THE

FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT

AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID BY THE BUYER FOR THE

DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY OTHER FORM

OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL,

CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE,

LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF

OPPORTUNITY OR LOSS OF REPUTATION.

36 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 39

Limited consumer warranty

Warranty. For goods sold for personal, family or household purposes, Seller warrants the

goods purchased hereunder (with the exception of membranes, seals, gaskets, elastomer

materials, coatings and other "wear parts" or consumables all of which are not warranted

except as otherwise provided in the quotation or sales form) will be free from defects in

material and workmanship for a period of one (1) year from the date of installation or

eighteen (18) months from the product date code, whichever shall occur first, unless a

longer period is provided by law or is specified in the product documentation (the

“Warranty”).

Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer,

either repair or replace any product which fails to conform with the Warranty provided

Buyer gives written notice to Seller of any defects in material or workmanship within ten

(10) days of the date when any defects or non-conformance are first manifest. Under

either repair or replacement option, Seller shall not be obligated to remove or pay for the

removal of the defective product or install or pay for the installation of the replaced or

repaired product and Buyer shall be responsible for all other costs, including, but not

limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to

the method or means of repair or replacement. Buyer’s failure to comply with Seller’s

repair or replacement directions shall terminate Seller’s obligations under this Warranty

and render this Warranty void. Any parts repaired or replaced under the Warranty are

warranted only for the balance of the warranty period on the parts that were repaired or

replaced. The Warranty is conditioned on Buyer giving written notice to Seller of any

defects in material or workmanship of warranted goods within ten (10) days of the date

when any defects are first manifest.

Seller shall have no warranty obligations to Buyer with respect to any product or parts of a

product that have been: (a) repaired by third parties other than Seller or without Seller’s

written approval; (b) subject to misuse, misapplication, neglect, alteration, accident, or

physical damage; (c) used in a manner contrary to Seller’s instructions for installation,

operation and maintenance; (d) damaged from ordinary wear and tear, corrosion, or

chemical attack; (e) damaged due to abnormal conditions, vibration, failure to properly

prime, or operation without flow; (f) damaged due to a defective power supply or

improper electrical protection; or (g) damaged resulting from the use of accessory

equipment not sold or approved by Seller. In any case of products not manufactured by

Seller, there is no warranty from Seller; however, Seller will extend to Buyer any warranty

received from Seller’s supplier of such products.

THE FOREGOING WARRANTY IS PROVIDED IN PLACE OF ALL OTHER EXPRESS

WARRANTIES. ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE (1) YEAR FROM THE DATE OF INSTALLATION OR

EIGHTEEN (18) MONTHS FROM THE PRODUCT DATE CODE , WHICHEVER SHALL

OCCUR FIRST. EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYER’S EXCLUSIVE

REMEDY AND SELLER’S AGGREGATE LIABILITY FOR BREACH OF ANY OF THE

FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT

AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID BY THE BUYER FOR THE

DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY OTHER FORM

OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL,

CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE,

LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF

OPPORTUNITY OR LOSS OF REPUTATION.

Some states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which may

vary from state to state.

10 Product warranty

TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual 37

Page 40

10 Product warranty

To make a warranty claim, check first with the dealer from whom you purchased the

product or visit www.xyleminc.com for the name and location of the nearest dealer

providing warranty service.

38 TECHNOForce e-HV Mechanical Installation, Operation, and Maintenance Manual

Page 41

Page 42

Page 43

Page 44

Xylem |’zīləm|

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re a global team unified in a common purpose: creating advanced

technology solutions to the world’s water challenges. Developing new

technologies that will improve the way water is used, conserved, and re-used in

the future is central to our work. Our products and services move, treat, analyze,

monitor and return water to the environment, in public utility, industrial,

residential and commercial building services settings. Xylem also provides a

leading portfolio of smart metering, network technologies and advanced

analytics solutions for water, electric and gas utilities. In more than 150 countries,

we have strong, long-standing relationships with customers who know us for our

powerful combination of leading product brands and applications expertise with

a strong focus on developing comprehensive, sustainable solutions.

For more information on how Xylem can help you, go to www.xylem.com

Xylem Inc.

Visit our Web site for the latest version of this document

and more information

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

USA

Tel: (844) XYL-PUMP [844-995-7867]

Fax: (888) 322-5877

www.xylem.com/bellgossett

The original instruction is in English. All non-English

instructions are translations of the original instruction.

©

2019 Xylem Inc

Bell & Gossett is a trademark of Xylem Inc or one of its

subsidiaries.

10-001-287_4_en.US_2019-03_IOM_TECHNOForce e-HV

Loading...

Loading...