Page 1

INSTRUCTION MANUAL

S14367

REVISION B

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Technologic® Constant Speed

Pump Controller

Page 2

NOTE: The information contained in this manual is intended to assist operating personnel by providing information on the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of accepted practices in the

installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation and maintenance of your Technologic Constant Speed Pump Controller

can be found in the instruction manuals for the associated equipment provided. See Section 1.1, Maintenance, for a list of

relevant manuals.

Page 3

Table of Contents

Section 1 — General

1.1 Purpose of Manual …………………………………………………………………………… 6

1.2 Safety …………………………………………………………………………………………… 6

1.2.1 Safety Alert Symbol …………………………………………………………………………… 6

1.2.2 Safety Instruction Decal ……………………………………………………………………… 6

1.2.3 Hazardous Voltage …………………………………………………………………………… 6

1.2.4 Pump/Motor Safety …………………………………………………………………………… 6

1.2.5 Closed System Safety Measures …………………………………………………………… 6

1.3 Storage ………………………………………………………………………………………… 6

1.4 Handling ………………………………………………………………………………………… 7

1.5 Foundation ……………………………………………………………………………………… 7

1.6 Leveling ………………………………………………………………………………………… 7

1.7 Location ………………………………………………………………………………………… 7

1.8 Piping …………………………………………………………………………………………… 7

1.9 Temperature and Ventilation ………………………………………………………………… 7

1.10 Incoming Power and Ground Wiring ………………………………………………………… 7

Section 2 — Operator Interface Panel

2.1 Key Functionality ……………………………………………………………………………… 8

2.2 LEDs …………………………………………………………………………………………… 8

2.3 I/O ……………………………………………………………………………………………… 9

2.3.1 Analog Inputs …………………………………………………………………………………… 9

2.3.2 Powered Analog Inputs ………………………………………………………………………… 9

2.3.3 RTD Inputs ……………………………………………………………………………………… 9

2.3.4 Digital Inputs …………………………………………………………………………………… 9

2.3.5 Relay and Power Monitor Rack ……………………………………………………………… 10

2.3.5.1 Digital Output Module ………………………………………………………………………… 10

2.3.5.2 Power Measurement Module ………………………………………………………………… 10

2.3.5.3 Current Transformer …………………………………………………………………………… 10

Section 3 — Operation

3.1 Power-Up ……………………………………………………………………………………… 10

3.2 Basics of Screen Navigation and User Setup ……………………………………………… 10

3.3 Pump Operation ………………………………………………………………………………… 11

3.3.1 Manual Pump Operation ……………………………………………………………………… 11

3.3.2 Automatic Pump Operation …………………………………………………………………… 11

3.4 Status Screens ………………………………………………………………………………… 11

3.4.1 Tech Status ……………………………………………………………………………………… 11

3.4.2 Pump Status …………………………………………………………………………………… 11

3.4.3 Sensor Status …………………………………………………………………………………… 12

3.4.4 Staging ………………………………………………………………………………………… 12

3.4.5 Timers …………………………………………………………………………………………… 12

3.4.6 Power …………………………………………………………………………………………… 12

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 3

Page 4

3.4.7 Optional Sensors ……………………………………………………………………………… 13

3.5 Alarms/Events ………………………………………………………………………………… 13

Section 4 — Setup Menu

4.1 Sensor Setup …………………………………………………………………………………… 15

4.2 Pump Setup Menu ……………………………………………………………………………… 15

4.2.1 Number of Pumps ……………………………………………………………………………… 15

4.2.2 Pump Nameplate Data ………………………………………………………………………… 15

4.3 System Setup Menu …………………………………………………………………………… 16

4.3.1 Stage Menu …………………………………………………………………………………… 16

4.3.1.1 Primary Staging ………………………………………………………………………………… 16

4.3.1.2 Secondary Staging …………………………………………………………………………… 17

4.3.1.3 Force Destage/Minimum Pump Run Time ………………………………………………… 17

4.3.2 Alternation ……………………………………………………………………………………… 17

4.3.3 Pump Exercise ………………………………………………………………………………… 18

4.3.4 Start/Stop ……………………………………………………………………………………… 18

4.3.5 Scheduling ……………………………………………………………………………………… 19

4.3.6 Date/Time ……………………………………………………………………………………… 19

4.3.7 Password ……………………………………………………………………………………… 19

4.3.8 Relay Outputs Setup …………………………………………………………………………… 19

4.3.9 Save/Load Menu ……………………………………………………………………………… 20

4.3.9.1 Save to Flash …………………………………………………………………………………… 20

4.3.9.2 Load from Flash ………………………………………………………………………………… 20

4.3.9.3 Load Defaults …………………………………………………………………………………… 20

4.3.10 Communications ……………………………………………………………………………… 20

4.3.10.1 BACnet MS/TP ………………………………………………………………………………… 20

4.3.10.2 Metasys N2 ……………………………………………………………………………………… 21

4.3.10.3 Modbus ………………………………………………………………………………………… 21

4.3.10.4 Lonworks ………………………………………………………………………………………… 21

4.3.10.5 Analog Input Override ………………………………………………………………………… 22

4.3.11 Tech 350 ………………………………………………………………………………………… 22

4.4 Test Menu ……………………………………………………………………………………… 22

4.4.1 Digital Input Test ……………………………………………………………………………… 22

4.4.2 Digital Output Test ……………………………………………………………………………… 22

4.4.3 Analog Input Test ……………………………………………………………………………… 22

4.4.4 LED Test ………………………………………………………………………………………… 22

4.4.5 Key Test ………………………………………………………………………………………… 23

4.4.6 Display Test …………………………………………………………………………………… 23

4.4.7 Comm Test ……………………………………………………………………………………… 23

4.5 Alarms/Events Menu …………………………………………………………………………… 23

4.5.1 Pump Failure …………………………………………………………………………………… 23

4.5.2 Low System Pressure ………………………………………………………………………… 23

Table of Contents

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 4

Page 5

Table of Contents

4.5.3 High System Pressure ………………………………………………………………………… 24

4.5.4 Low Suction Pressure ………………………………………………………………………… 24

4.5.5 High Suction Pressure ………………………………………………………………………… 24

4.5.6 No Flow Shutdown …………………………………………………………………………… 25

4.5.7 High Temperature Cutout ……………………………………………………………………… 25

4.5.8 Low Level ……………………………………………………………………………………… 26

4.5.9 Volts Tolerance ………………………………………………………………………………… 26

4.6 EZ-Start ………………………………………………………………………………………… 26

4.7 Log Menu ……………………………………………………………………………………… 27

4.7.1 Alarm Log ……………………………………………………………………………………… 27

4.7.2 Pump Log Menu ……………………………………………………………………………… 27

4.7.2.1 Pump State Log ………………………………………………………………………………… 27

4.7.2.2 Pump Runtime Log …………………………………………………………………………… 27

4.7.2.3 Reset Pump Runtime ………………………………………………………………………… 27

4.7.3 Data Log ………………………………………………………………………………………… 27

4.7.4 Data Log Rate ………………………………………………………………………………… 28

4.7.5 Operation Log Menu …………………………………………………………………………… 28

4.7.5.1 Operation Mode Changes Log ……………………………………………………………… 28

4.7.5.2 Power Cycles Log ……………………………………………………………………………… 28

4.7.5.3 Events Log ……………………………………………………………………………………… 28

4.7.5.4 Purge Log ……………………………………………………………………………………… 28

4.7.5.5 Exercise Log …………………………………………………………………………………… 29

4.7.5.6 Operating Hours ……………………………………………………………………………… 29

4.7.6 Totals …………………………………………………………………………………………… 29

4.7.7 Reset Totals …………………………………………………………………………………… 29

4.7.8 Log Book ………………………………………………………………………………………… 29

Section 5 — Maintenance

5.1 Battery …………………………………………………………………………………………… 30

5.2 Signal Generator (analyzer) - recommended ……………………………………………… 30

5.3 Field Repair …………………………………………………………………………………… 30

5.4 Program Updating ……………………………………………………………………………… 30

5.5 Info Screens …………………………………………………………………………………… 30

5.6 Troubleshooting ………………………………………………………………………………… 31

Section A — Parameter List ……………………………………………………………………………………………… 32

Section B — BACnet Protocol Implementation Conformance Statement for BACnet MS/TP …………………… 35

Section C — Serial Communications Points …………………………………………………………………………… 37

Section D — Procedure for Field Balancing 70E/70M PRVs ………………………………………………………… 39

Section E — Electrical Wiring and Control Settings – Final Check List ……………………………………………… 39

Section F — System Piping and Unit Installation - Final Check List ………………………………………………… 40

Section G — Quick Startup Check List ………………………………………………………………………………… 40

Section H — Drawings …………………………………………………………………………………………………… 42

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 5

Page 6

Section 1 — General

1.1 Purpose of Manual

This m a n u al describes the op e r a t i o n of the

Technologic® Constant Speed Pump Controller for

control of constant speed pump systems.

The control panel consists of an operator interface

panel (OIP), a disconnect switch, control transformer,

motor starters, motor branch circuit protection

including fuses or circuit breakers and thermal overloads, a 24VDC power supply, and terminal blocks

for customer connections.

Further information pertaining to the system can be

found in the following IOMs:

1. Bell & Gossett 1510 # P81673

2. Bell & Gossett 1531 # P81567

3. CLA-VAL Pressure Reducing Valve # TM90-01

4. McDonnell & Miller Series 750B and 750BM

Condu c tan c e Ac t u ate d L e v el Con t r ols #

MM-248(C)

5. McDonnell & Miller FS250 General Purpose

Liquid Flow Switch # MM-625

6. Squa re D Differe ntial Pres sure Switche s #

65013-009-32C

7. United Electric Cont rols 54 Series Pressu re

Switches # IMP54-03

1.2 Safety

1.2.1 Safety Alert Symbol

SAFETY INSTRUCTION

This safely alert symbol will be used in this manual to draw attention to safety related instructions.

When used, the safety alert symbol means

ATTENTION, BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO

FOLLOW THIS INSTRUCTION MAY RESULT

IN A SAFETY HAZARD.

1.2.2 Safety Instruction Decal

Your Technologic

should have a safety instruction dec al (part #

S11550) located on the front of the enclosure near

the disconnect switch. If the decal is missing or illegible contact your local B&G representative for a

replacement.

1.2.3 Hazardous Voltage

Only qualified electricians should perform electrical

service of any kind on the control panel or pumping

system. Visually inspect the control panel for loose or

stranded wires and for damaged components or wires

prior to performing electrical service. Never troubleshoot or perform service on a live control panel. Do

not turn the disconnect switch on while the enclosure

door is open. Live voltage is still connected to the

incoming side of the disconnect switch even when the

®

Constant Speed Pump Controller

disconnect switch is off. Turn off and lock out the

incoming power prior to troubleshooting or performing service on this control panel.

WARNING: High Voltage! Do not work

on live control panels. Disconnect the

incoming power prior to performing service on

this unit. FAILURE TO FOLLOW THIS

INSTRUCTION MAY RESULT IN DEATH OR

PROPERTY DAMAGE.

1.2.4 Pump/Motor Safety

All electrical installation or service on the motors

should be performed by a qualified electrician.

Ground fault protection should be sized properly.

Refer to local electrical codes for sizing and selection.

Refer to the I.O.M. for the motors for specific installation information. Even when the Pum ps are

stopped, they should be considered alive as long as its

controller is energized. Keep hands away from the

pumps until the power is disconnected from the

pump controller.

1.2.5 Motor Control Equipment Safety

Do not install and operate a pumping package in a

closed system unless the system is constructed with

properly sized safety and control devices. Such devices include the use of properly sized and located pressure relief valves, compression tanks, pressure controls, temperature controls and flow controls as

appropriate. If the system does not include these

devices, consult the responsible engineer or architect

before making pumps operational.

DANGER: The heating of water and

other fluids causes volumetric expansion.

The associated forces may cause failure of system

components and release of high temperature fluids. This will be prevented by installing properly

sized and located pressure relief valves and compression tanks. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN SERIOUS

PROPERTY DAMAGE AND SERIOUS

PERSONAL INJURY OR DEATH.

1.3 Storage

For long periods of storage, the pumping package

should be covered to prevent corrosion and contamination from dirt. It should be stored in a clean, dry

location between -20 and +60º C. The relative

humidity should not exceed 95%. The unit should be

checked periodically to ensure that no condensation

has formed. After storage, check that it is dry before

applying power.

1.4 Handling

Care should be taken to prevent damage due to drop-

ping or jolting when moving any panel or pumping

package. Transportation damage should be brought

to the carrier’s attention immediately upon receipt.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 6

Page 7

General

The unit should be unloaded and handled by qualified personnel. A pumping package that includes this

panel may be top heavy due to the position of the

motors. Lift the unit with slings placed under the unit

base rails. Be sure not to load the lifting mechanism

beyond its rated limits. Use the motor eyebolts to stabilize the unit while lifting to prevent overturning.

DANGER: Heavy load, may drop if

not lifted properly. Do not load cables,

chains or hoists beyond their rated limits.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS

PERSONAL INJURY, DEATH AND/OR

PROPERTY DAMAGE.

1.5 Foundation

A concrete base weighing at least 2.5 times the weight

of the pumping package is recommended. Check the

shipping ticket for the unit weight. Tie the concrete

pad in with the finished floor. Use foundation bolts

and larger pipe sleeves to give room for final bolt

location.

1.6 Leveling

Place the pumping package on its concrete founda-

tion, supporting it with steel wedges or shims totaling

1” in thickness. These wedges or shims should be put

on both sides of each anchor-bolt to provide a means

of leveling the base.

1.7 Location

Install the pumping package appropriately for ease of

inspection, maintenance and service. Observe local

electrical codes concerning control panel spacing.

1.8 Piping

Be sure to eliminate any pipe strain on the pumping

package. Support all pipes independently by use of

pipe hangers near the unit. Ordinary wire or band

hangers are not adequate to maintain alignment. It is

very important to provide a strong, rigid support for

the suction and discharge lines. A saddle hanger is

recommended. Do not attempt to force the suction

or discharge lines into position. Refer to the assembly

drawing for customer piping connections.

Inspect all unit piping connections. Joints may also

become loose during transit due to vibration and

shock. All joints should be checked for tightness.

Flanged joints should be checked for proper torque

of all flange bolts prior to filling the system with

fluid.

Eccentric increasers may be used in the suction lines

when increasing the pipe size, with the straight sides

of the increaser on top to eliminate air pockets.

For critical installations, equipment for absorbing

expansion and vibration should be installed in the

inlet and outlet connections of the unit.

Drain plugs are placed in a cloth bag and secured to

the unit prior to shipping from the factory. Reinstall

the drain plugs prior to filling the system with fluid.

On an open system with a suction lift, use a foot

valve of equal or greater area than the pump suction

piping. Prevent clogging by using a strainer at the

suction inlet next to the foot valve. The strainer

should have an area three times that of the suction

pipe. Provisions must be made to prime the pump

suction piping on start up. Do not start the pump

unless all suction piping is full of water.

A thermal relief valve is installed on the discharge

header to prevent potentially dangerous thermal

buildup in the package. This valve acts as a safety

device and it should never be removed or tampered

with. It is factory set to open and discharge when the

water temperature in the discharge header exceeds

125°F. The 3/8” NPT opening of this valve must be

piped to a floor drain.

Before starting, all pumps and motors should be

checked for proper lubrication.

1.9 Temperature and Ventilation

The operating temperature range for this unit is 0 to

50°C. The relative should be kept between 10% and

90% non-condensing. The unit should not be operated outside these extremes.

1.10 Incoming Power and Ground Wiring

A qualified electrician should bring incoming power

and ground wiring to the disconnect switch. If holes

are drilled in the control panel, be sure to not contaminate electrical components with metal filings. A

grounding terminal is provided next to the disconnect switch for an incoming ground wire connection.

Wire types and sizes must be selected according to

the National Electrical Code and all local codes and

restrictions. Refer to the input current and voltage as

listed on the nameplate on the enclosure door when

sizing the power wires. Only copper (Cu) wire rated

for 75°C (minimum) may be used for the power connections. The voltage tolerance is +10/-5% and

phase to phase voltage must not have an imbalance

greater than 5 VAC.

WARNING: Prevent electrical shocks.

Disconnect the incoming power supply to

the control panel before beginning installation.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR

PROPERTY DAMAGE.

WARNING: Conduit grounds are not

adequate. A separate ground wire must be

attached to the ground lug provided in the enclosure to avoid potential safety hazards. FAILURE

TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH AND/OR PROPERTY

DAMAGE.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 7

Page 8

1

Yes

2 3

Setup

4No5

Log

6

7 8

Info9Alt

Clear

0

Enter

Tec hnolog ic® Const ant Sp eed Pu mp Con troll er

NextPrev

GREEN = RUN

OFF = STOP

GRE EN = A UT O

OFF = M AN UA L

ON SOLID-PUMP RUNNING

OFF-PUMP DISABLED

FLASH SLOW-PUMP READY

FLASH FAST-PUMP FAILED

Start /

Stop

Pump 1

Enabled

Pump 2

Enabled

Pump 3

Enabled

Reset /

Silence

Auto /

Manual

Pump 4

Enabled

Pump 5

Enabled

Pump 6

Enabled

Help

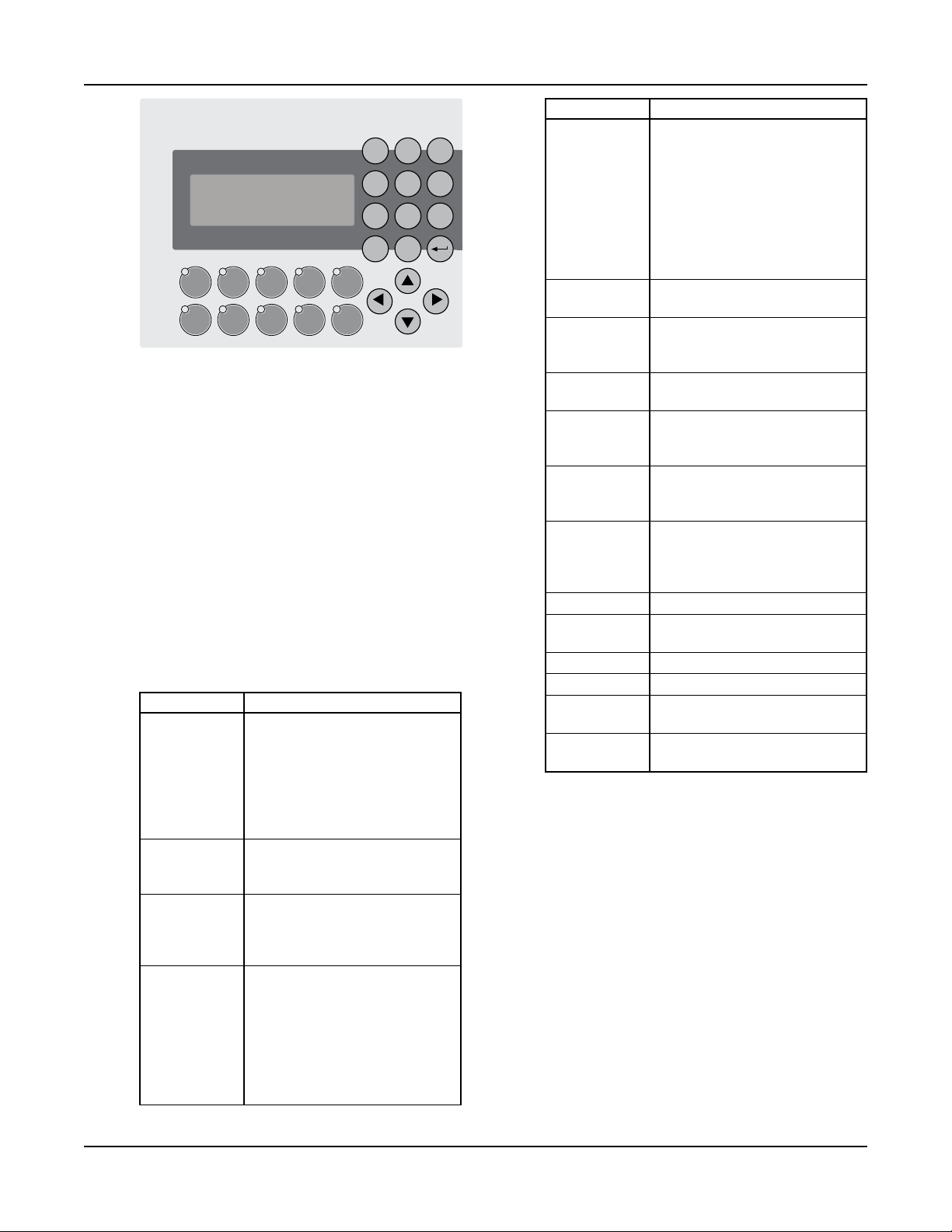

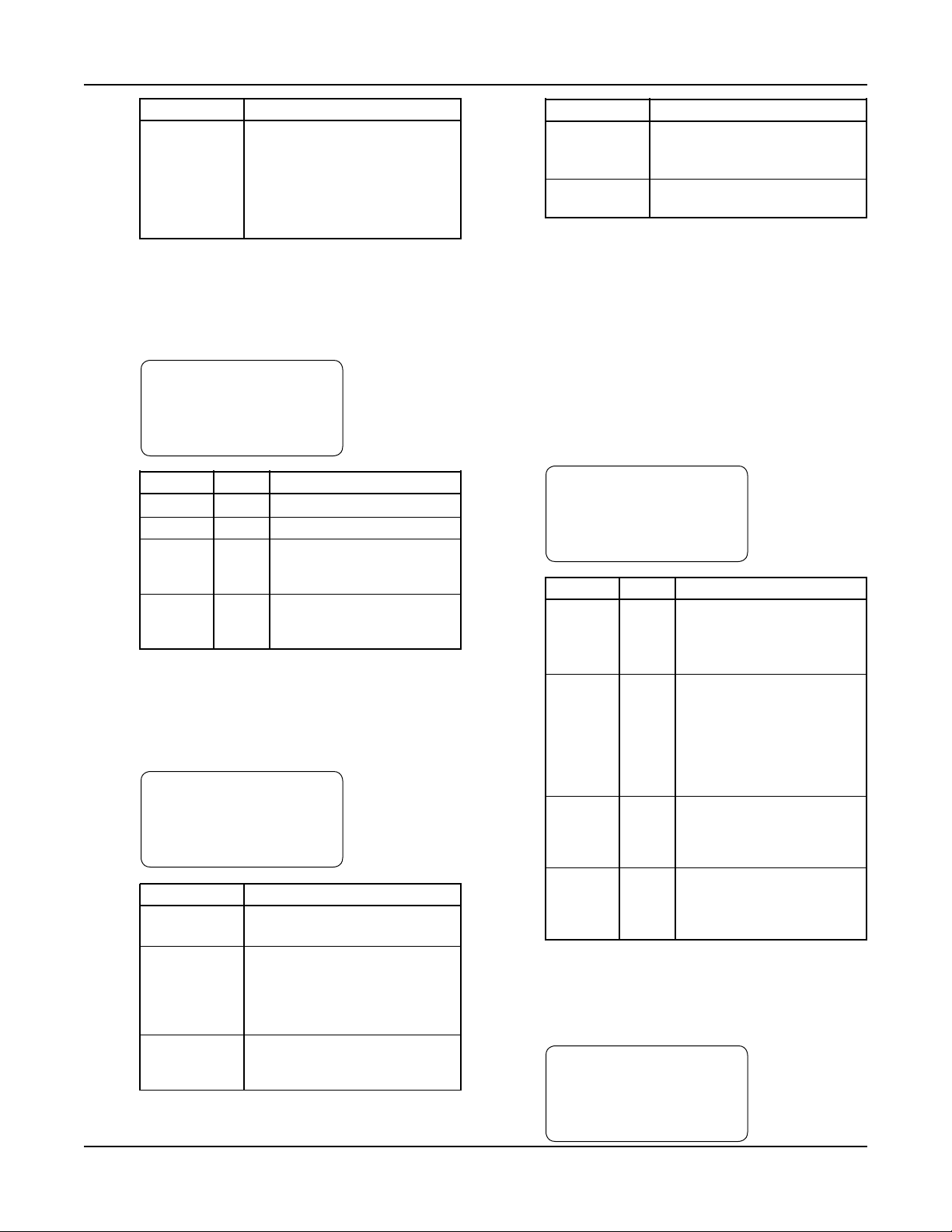

Section 2 — Operator Interface Panel

The OIP consists of a 4 x 20 character LCD screen

and a 26 button keypad with LEDs which display system status. It also is equipped with onboard I/O

including (16) 24VDC digital inputs, (4) 4-20mA

analog inputs, (2) PT100 RTD inputs, and an RS232/

RS485 serial port for communications all mounted

on the back of the OIP. The OIP communicates

through a CAN bus to the relay and power monitor

rack.

2.1 Key Functionality

The names of the keys on the Operator Interface

Panel (OIP) are shown as CAPITAL LETTERS in this

manual. Table 1 shows the functionality of the keys

on the OIP.

Note: The contrast can be adjusted from any screen

by pressing the UP and DOWN arrows while holding

the ENTER key.

Key Name Functionality

START/STOP Starts or stops the system. When

the Start/Stop method is not

“Keypad”, pressing the START/

STOP key will toggle between

“Ready” and “Stop”. “Ready”

indicates the system is waiting

for a remote signal to start.

AUTO/ Toggles the operation mode. The

MANUAL system must be stopped to

change the operation mode.

PUMP 1-6 Enables or disables the

ENABLE corresponding pump. Pumps

cannot be disabled while they

are failed.

RESET/ This key is used to reset pumps

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 8

SILENCE and alarms. When the A/V Alarm

relay output (section 4.3.8) is

set, initial pressing of this key

opens the relay to silence the

horn or turn off the pilot light.

Pressing a second time resets the

pumps and alarms.

Key Name Functionality

HELP Press the HELP button, from the

status screens, to view alarms or

events while the HELP LED is

flashing. While in the Alarm

screen, press the HELP button

again to view help messages for

active alarms. Press HELP any

other time to view screen

specific help messages.

YES/1 Press YES at OK prompts to

accept values and proceed

SETUP/3 Press SETUP, from the status

screens, to bring up the Setup

Menu shown in section 4

NO/4 Press NO at OK prompts to edit

the parameters

LOG/5 Press LOG, from the status

screens, to bring up the Log

Menu, shown in section 4.7

INFO/8 Press INFO, from the status

screens, to bring up the Info

screens, shown in section 5.5

ALT/9 Press ALT, from the status

screens, to manually alternate

the pump staging sequence, see

section 4.3.2

ENTER Confirms entries

CLEAR Clears entries or used to exit

some screens

PREV (←) Navigates to neighboring screens

NEXT (→) Navigates to neighboring screens

UP (↑) Used to modify values and

navigate to neighboring screens

DOWN (↓) Used to modify values and

navigate to neighboring screens

Table 1: Key Functionality

Page 9

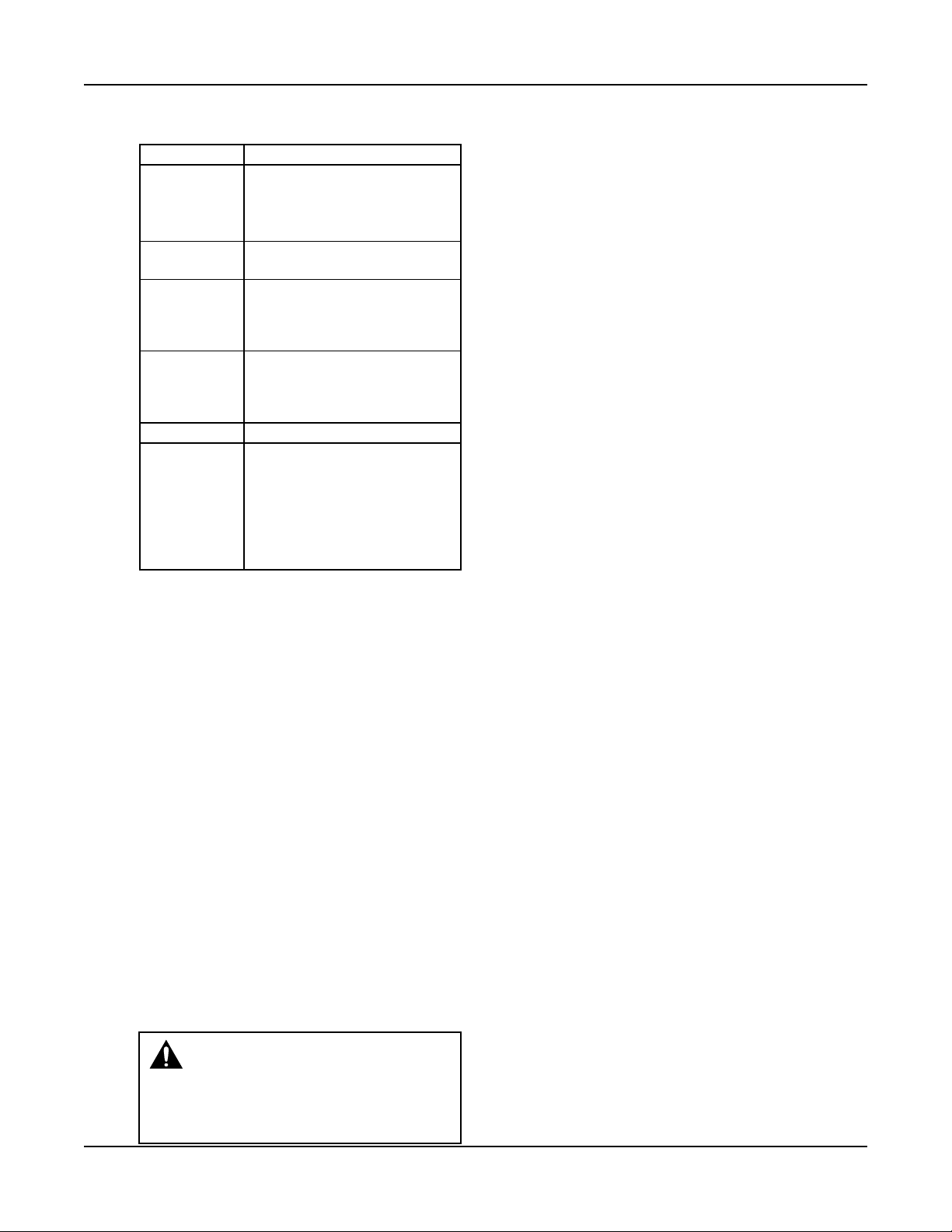

2.2 LEDs

Table 2 gives the meaning of the LED states.

LED Description

START/STOP On = Start

Off = Stop

Blink Slow = Ready (waiting for

remote method)

AUTO/ On = Auto

MANUAL Off = Manual

PUMP 1-6 On = Pump On

Off = Pump Disabled

Blink Slow = Pump Ready

Blink Fast = Pump Failed

RESET/ Off = OK

SILENCE Blink Slow = Reset Required

Blink Fast = A/V Alarm output

is active

LED Description

HELP Off = OK

Blink Slow = Event (press HELP

from the status

screens to view)

Blink Fast = Alarm (press HELP

from the status

screens to view)

Table 2: LED Functionality

2.3 I/O

2.3.1 Analog Inputs

The Technologic

is equipped with 4 analog input channels. The analog

inputs must provide a 4-20mA signal. Typically, analog inputs will be powered by the 24V power supply

within the panel. For analog inputs which source

their own power, see the following section. See section 4.1 for more information on sensor setup.

Shielded 22 AWG cable should be installed for all

analog input wiring. The shield must be terminated

in the Technologic

Do not connect the shield at the other end of the

cable! Insulate the shield so that no electrical connection is made at the other end of the cable. A twisted

pair of #22 AWG conductors can be used in place of

shielded cable. The cable length must be limited to

5,000 feet for #22 AWG wire.

®

Constant Speed Pump Controller

®

Constant Speed Pump Controller.

Operator Interface Panel

1) Turn off all power to the Technologic

Speed Pump Controller.

2) Refer to the appropriate controller wiring diagram

that was shipped with unit. Locate the analog

input sensors on the wiring diagram that will be

rewired. They are labeled AI1 – AI4.

3) Remove the 24 VDC positive (+) wire from TB 40

for the respective analog input sensor connection.

This wire needs to be removed completely or terminated if used as a jumper. This will prevent any

accidental contact with a negative (-) voltage

source (i.e. control panel) and avoid becoming a

short circuit. Care should be taken to ensure that

24 VDC positive (+) voltage is still provided to

any remaining sensors that will be powered by the

Technologic

®

Constant Speed Pump Controller.

4) Remove the 24 VDC negative (-) wire from TB 41

for the respective analog input sensor connection.

This wire needs to be removed completely or terminated if used as a jumper. This will prevent any

accidental contact with a positive (+) voltage

source and avoid becoming a short circuit. Care

should be taken to ensure that 24 VDC (-) negative voltage is still provided to any remaining sensors that will still be powered by the Technologic®

Constant Speed Pump Controller.

5) Terminate the negative (-) wire of the sensor to TB

41 of the respective analog input sensor connection. Terminate the positive (+) wire of the sensor

to the terminal block which is connected to the

positive (+) terminal shown on the Analog input

card.

Note: Be certain that the power supplied to other

terminal blocks has not been interrupted! The wires

that were removed in the preceding steps may have

been used as jumpers.

2.3.3 RTD Inputs

®

The Technologic

Constant Speed Pump Controller

is equipped with (2) PT100 RTD input channels. (2)

RTDs will be shipped with standard units. The system RTD will be factory mounted, on the suction

header, unless the control panel is sold separate from

the pump package. The suction RTD will be shipped

loose inside the control panel and will need to be

field mounted upstream of the suction header.

®

Constant

2.3.2 Powered Analog Inputs

The following steps describe the general procedure

for wiring an analog input when the sensor’s power

source is not the Technologic

®

Constant Speed Pump

Controller.

2.3.4 Digital Inputs

The Technologic

is equipped with (16) 24VDC digital input channels.

This signal voltage must be obtained from the 24VDC

power supply mounted to the subpanel. It is not rec-

®

Constant Speed Pump Controller

ommended that other power sources be used without

WARNING: Prevent electrical shocks.

Disconnect the power supply before begin-

ning installation. FAILURE TO FOLLOW

factory approval. All digital inputs are automatically

assigned based on Table 3. See the typical wiring diagram in Appendix H.

THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH AND/

OR PROPERTY DAMAGE.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 9

Page 10

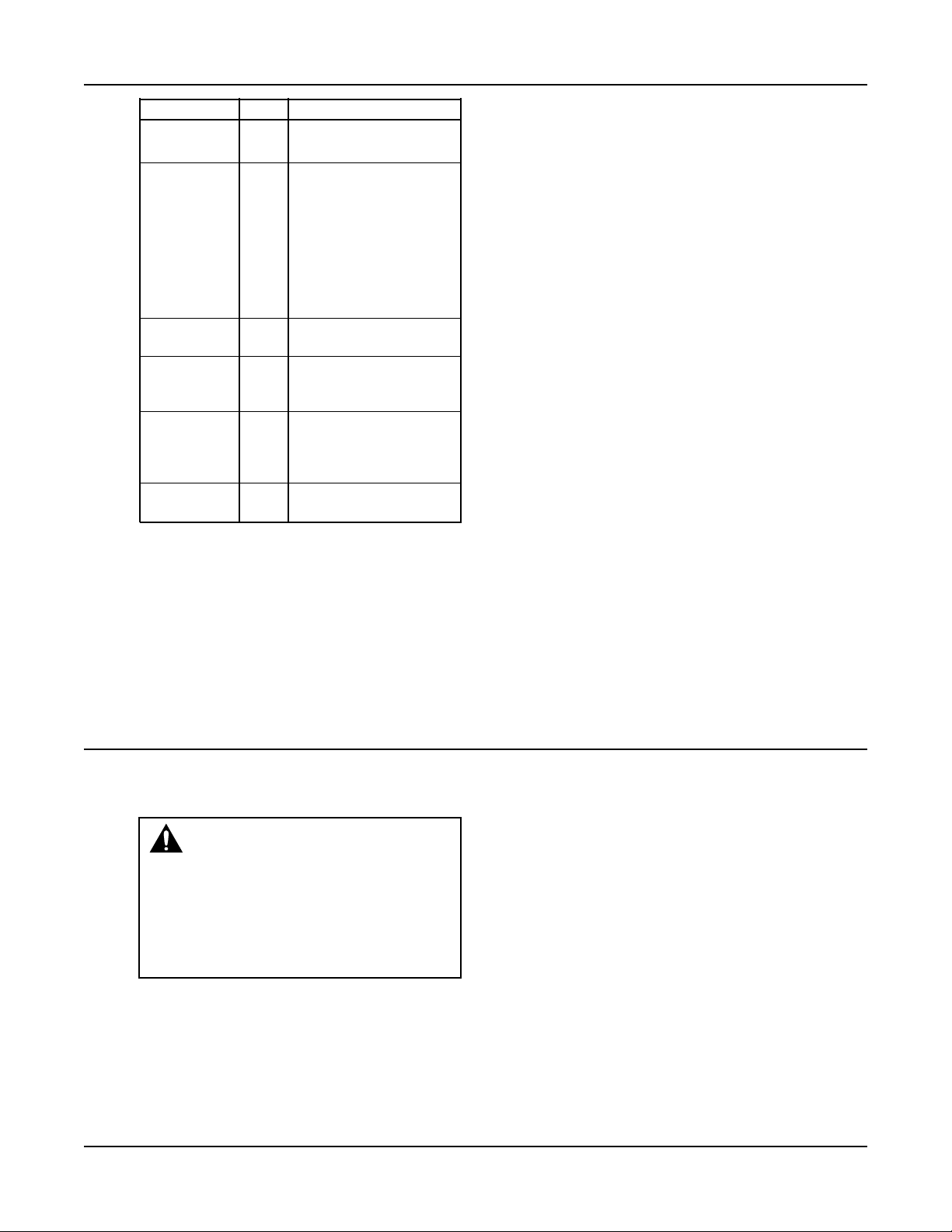

Operator Interface Panel

Functionality DI # Description

1M-6M 1-6 Motor starter feedbacks

Feedback (generate overload alarm)

Start/Stop Sw 7 Remote contact can be

used to start/stop the

system. The start/stop

method must be set to

Remote. See section 4.3.4.

“Rem” will be displayed in

the Tech Status screen

shown in section 3.4.1

when this method is active.

Flow Switch 8 Used for no flow shut-

down, see section 4.5.6.

Pressure Sw 9 Used to detect low suction

pressure alarm or event,

see section 4.5.4.

Low Level 10 Low level relay to sense a

low level condition in a

tank. All pumps will stop

when active.

DP 1-6 11-16 Differential pressure

switches

Table 3: Digital Inputs Functionalities

# 22 AWG cable should be installed for all field wir-

ing to digital inputs.

2.3.5 Relay and Power Monitor Rack

The relay and power monitor rack consists of an

EX270 CAN bus controller, a DO722 digital output

module and an AI984 power measurement module.

2.3.5.1 Digital Output Module

The digital output module consists of 8 normally

open single pole single throw relays rated at 2.5A at

either 240VAC or 24VDC. One relay will be used to

energize the coil of each motor starter. These will be

factory wired. Customer connections are made directly to the terminals mounted on the digital output

module. If a relay is defective, the digital output

module must be replaced. Refer to section 4.3.8 for

relay output setup.

2.3.5.2 Power Measurement Module

The power measurement module calculates total

power by measuring the incoming voltage and the

total current from the current transformer.

2.3.5.3 Current Transformer

The current transformer (ct) comes in three different

sizes measuring up to 40A, 150A, or 400A. It plugs

directly into the AI984 module on the relay and

power monitor rack. The ct measures the total amp

draw of all motors in the system. The four digit hex

numbers displayed on the label on the current transformer are calibration values, unique to each ct, that

have been input into the controller prior to shipment.

See section 5.5 to view the values used.

Section 3 — Operation

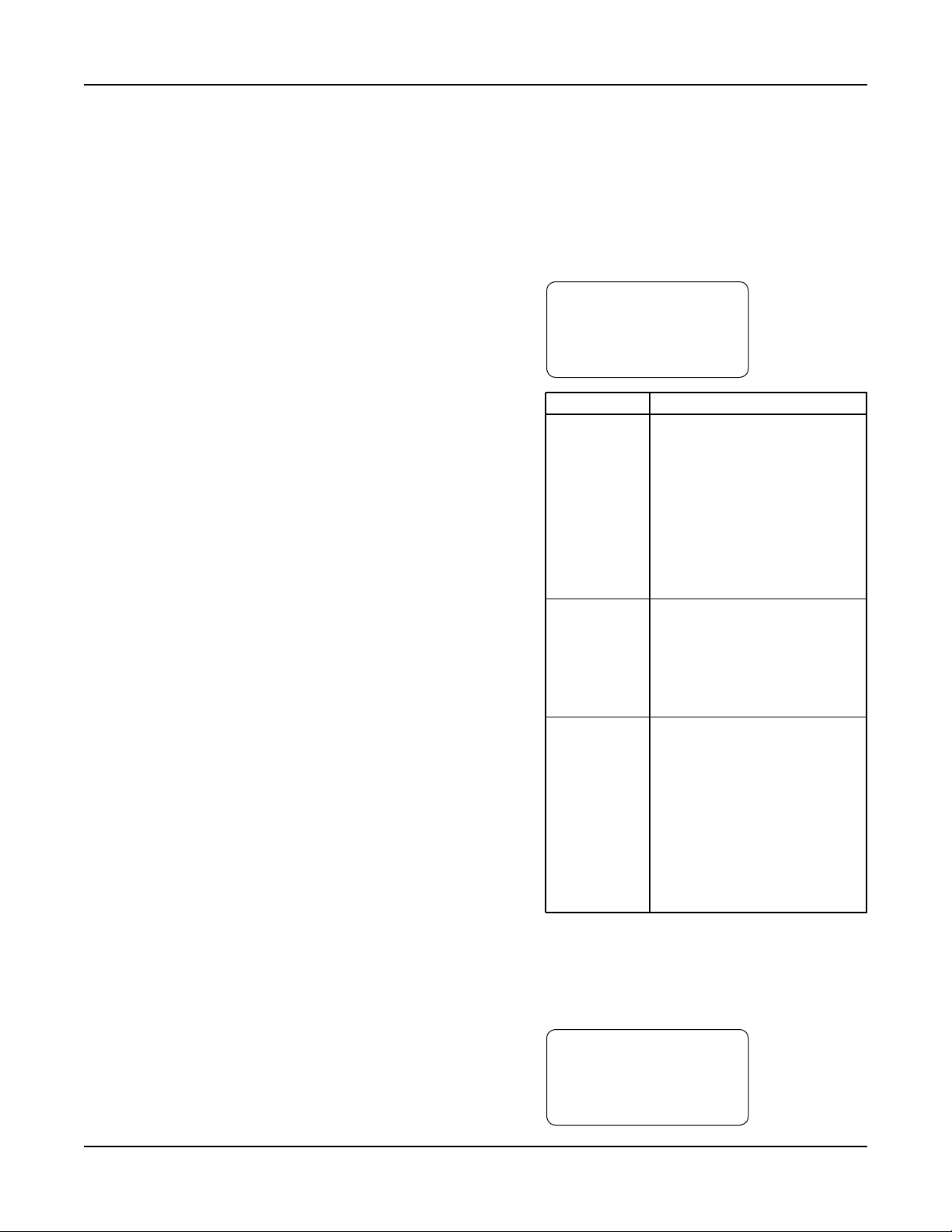

3.1 Power-Up

Turn the disconnect switch “ON” to power up the controller.

WARNING: Electrical shock hazard.

Inspect all electrical connections prior to

powering the unit. Wiring connections must be

made by a qualified electrician in accordance with

all applicable codes, ordinances and good practices. FAILURE TO FOLLOW THESE INSTRUC-

TIONS COULD RESULT IN SERIOUS

PERSONAL INJURY, DEATH AND/OR

PROPERTY DAMAGE.

In order to recover from a power loss, the controller

will start up in the operating mode that it was in

prior to the last shutdown. On power up, the controller will display the Tech Status screen shown in

section 3.4.1.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 10

3.2 Basics of Screen Navigation and User

Setup

Numeric inputs (represented by the # symbol) must

be input from the numeric keypad. Text fields (represented by the $ symbol) must be modified by using

the UP and DOWN arrow keys. For numeric or text

fields, ENTER must be pressed to confirm values.

The arrow keys are also be used to navigate to neigh-

boring screens. Flashing arrows shown on the display

indicate when the corresponding arrow keys are

active.

An OK prompt is used in most user setup screens.

Press NO (the number 4 key) followed by ENTER at

the OK prompt to edit the parameters shown, or

press YES (the number 1 key) followed by ENTER to

accept the values and exit the screen.

The YES/1 and NO/4 keys are also used for text

inputs for some parameters. They will appear as “Y”

or “N” when a text input is required.

Page 11

Operation

The CLEAR key is also used to exit some screens

including: Log screens, Test screens, Info screens, and

the Alarm screen.

3.3 Pump Operation

The pumps can be controlled manually or automati-

cally. See the following sections for instructions on

both types of operation.

3.3.1 Manual Pump Operation

To manually control the pumps with the controller,

the operation mode must be set to Manual by pressing the AUTO/MANUAL key. Note that this key is

not allowed unless the system is stopped. The Auto/

Manual LED will be off to indicate manual operation. The system must also be started by pressing the

START/STOP key. The Start/Stop LED will be on to

indicate the system is started.

Pumps are automatically disabled when operation

mode is changed to manual. Press the corresponding

PUMP ENABLE keys to start or stop pumps. The

corresponding LED will turn solid green to indicate a

pump is on.

3.3.2 Automatic Pump Operation

To automatically control the pumps with the control-

ler, the operation mode must be set to Auto by pressing the AUTO/MANUAL key. Note that this key is

not allowed unless the system is stopped. The Auto/

Manual LED will be on to indicate automatic operation. The system must also be started by pressing the

START/STOP key. The Start/Stop LED will be on to

indicate the system is started.

During automatic pump operation, the pumps will

turn on or off based on the primary staging method.

If more pumps are required to meet the system

demand, they will stage on as required. When the

system demand is met, and the minimum pump run

timer is met, the pumps will destage until only one

pump is running. When there is no demand in the

system, the no flow shutdown alarm or event will

occur, shutting down the last running pump. During

this sequence, alarms may occur that shut down a

specific pump or all of the pumps. Various automatic

pump alternation methods may be used to alternate

the pump sequence at any time.

View the status screens, shown in section 3.4, to get

system information including on/off or auto/manual

status, pump status, sensor values, or staging status.

3.4 Status Screens

The status screens are the main level in screen naviga-

tion and show most of the relevant system information. The status screens can be scrolled by pressing

PREV or NEXT.

The Setup Menu(3), Log Menu(5), Info screens(8),

Ma n ua l Al t er na ti on scr ee n( 9) , and Ala r m

screen(HELP) are only accessible from the status

screens.

All of the status screens will display “Alm”, “Evt”, or

“NFSD” in the lower right corner if an alarm or

event or NFSD condition exists. If this message is

flashing, press the HELP key for more details.

3.4.1 Tech Status

The Tech Status screen, shown below, is the first of

the status screens. This screen is displayed on power

up. See Table 4 below for a description of the Tech

Status variables.

← TECH STATUS →

HH:MMam MM/DD/YY

Stop :(Method)

Manual Alm

Variable Description

Start/Stop/ Stop: System is stopped. Pumps

Ready will not start.

Start: System is started. The

pumps can be controlled manually

or automatically.

Ready: System is waiting for

remote start/stop method,

see section 4.3.4.

Press the START/STOP button

to toggle.

Method System Start/Stop Method, see

section 4.3.4.

Key: Keypad

Rem: Remote contact

Sch: Scheduled start/stop

Ser: Serial Communications

Auto/Manual Manual: System is in manual

operation mode. The user can

manually start and stop the pumps

by pressing the corresponding

Pump On/Off key.

Auto: The system is in automatic

operation mode. The pumps will

be controlled automatically based

on the user setup info.

Press the AUTO/MANUAL key

to toggle.

Table 4: Tech Status Variables

3.4.2 Pump Status

Pressing NEXT, the controller will display the Pump

Status screen shown below. See Table 5 for a description of the Pump Status variables.

← PUMP STATUS →

1:On 2:On 3:Off

4:Rdy 5:Fail 6:Rdy

Alm

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 11

Page 12

Operation

Variable Description

P1-P6 On: pump is running

Off: pump is disabled from the

keypad

Rdy: pump is enabled but not

running

Fail: pump is failed

Table 5: Pump Status Variables

3.4.3 Sensor Status

Pressing NEXT, the controller will display the Sensor

Status screen shown below. See Table 6 for a description of the Sensor Status variables.

←Suc Press= ###→

Sys Press= ###

Suc Temp=###.#

Sys Temp=###.# Alm

Variable Units Description

Suc Press PSI Suction Pressure

Sys Press PSI System (discharge) Pressure

Suc Temp °F Suction Temperature

(mounted upstream of the

suction header)

Sys Temp °F System Temperature

(mounted on the suction

header)

Table 6: Sensor Status Variables

3.4.4 Staging

Pressing NEXT, the controller will display the Staging

screen shown below. See Table 7 for a description of

the Staging variables.

←STAGING: (Type)→

Stg Seq:1-2-3-4-5-6

Dstg: #### Stg: ####

Actual: ###.# Alm

Variable Description

Type Type will display the active staging

method.

Stg Seq Pump staging sequence from left

to right. A 0 indicates that a pump

is failed or disabled. See section

4.3.2 for information on alternat ing the staging sequence.

Stg Next staging value (N/A indicates

end of staging sequence or no

staging values set up)

Variable Description

Dstg Next destaging value (N/A indi-

cates end of destaging sequence

or no destaging values set up)

Actual Current value of the staging

variable

Table 7: Staging Variables

Note: “Stg” and “Dstg” will be displayed in units of

the active staging method shown in the “Type” field.

To change the staging type or values, see section

4.3.1.

3.4.5 Timers

Pressing NEXT, the controller will display the Timers

screen shown below. The numeric values on the left

are elapsed times, and the numeric values on the right

are the limits that they must reach prior to performing their respective action. See Table 8 for a description of the Staging variables.

←Pump MnRn:##/##m→

NFSD MnRn:###/###m

Stg PT:##/##

Dstg PT:##/## Alm

Variable Units Description

Pump Min Minutes Pump minimum run time,

Run see section 4.3.1.3. When the

timer reaches its limit pumps

will be allowed to destage.

NFSD Minutes No flow shutdown minimum

MnRn run time, see section 4.5.6.

When the timer reaches its

limit, a no flow shutdown

will be allowed to occur. Note

that the timer immediately

resets to zero after expiring.

Stg PT Seconds Staging proof timer, see

section 4.3.1.1. When the

timer reaches its limit,

another pump will stage on.

Dstg PT Seconds Destaging proof timer, see

section 4.3.1.1. When the

timer reaches its limit, a

pump will stage off.

Table 8: Timers Variables

3.4.6 Power

Pressing NEXT, the controller will display the Power

screen shown below.

← POWER→

HP= ###.# PF= #.##

Volts= ###.#

Amps = ###.# Alm

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 12

Page 13

Operation

Variable Units Description

HP Horse- Total power measured by

power the power module

Volts Volts Average voltage measured by

the power module

Amps Amps Total current measured by the

power module

PF N/A Power factor measured by the

power module

Table 9: Power Variables

3.4.7 Optional Sensors

Pressing NEXT, the controller will display the

Optional Sensors screen shown below if any optional

sensors are set up. If they are not, the Optional

Sensors screen will be skipped. See section 4.1 for

information on sensor setup.

←OPTIONAL SENSORS→

Temp =### Flow=#####

Diff Temp= ###

Pressure = ### Alm

Variable Units Description

Temp °F Optional temperature

Diff Temp °F Optional differential

temperature

Pressure PSI Optional pressure

Flow GPM Optional flow

Table 10: Optional Sensor Variables

3.5 Alarms/Events

Some conditions can be defined as alarms or events,

while others are predefined to be alarms. See section

4.5 for alarm setup. Alarms are logged in the Alarm

Log and events are logged in the Events Log. See section 4.7 for logging. An alarm triggers the General

Alarm serial communications point and the A/V

Alarm relay output. An event will not trigger either

of these. See Appendix C for the serial communications points list and section 4.3.8 for relay outputs

setup.

Some alarms or events will cause one or all of the

pumps to shut down. For Low System Pressure, the

user can define if the pumps will shut down or not.

All alarms or events require either a manual or auto-

matic reset. The RESET/SILENCE LED will flash

when a manual reset is required. Press the RESET key

to manually reset the system.

The values in parentheses in Table 11 are the default

values.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 13

Page 14

Operation

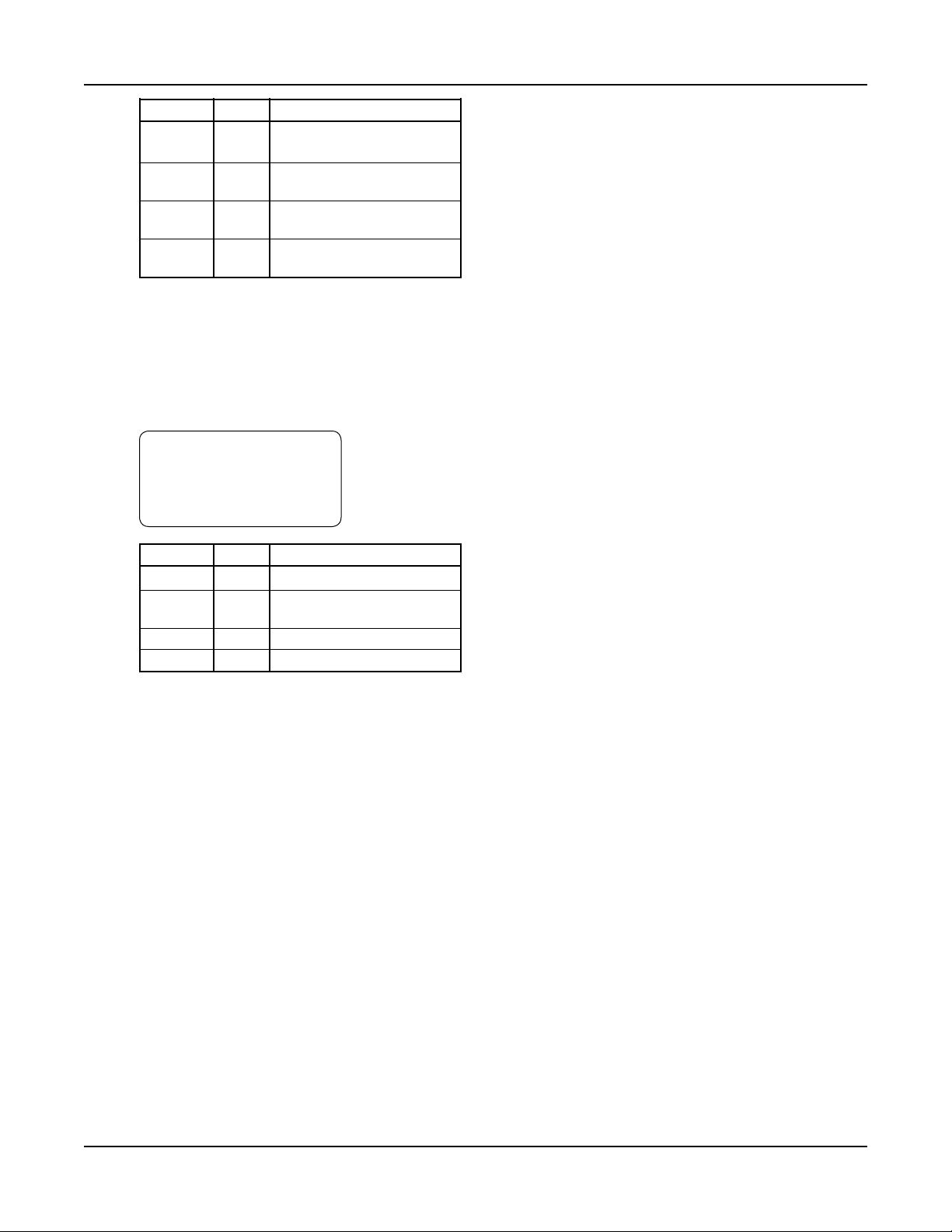

Description Alarm or Event Pump Shutdown Reset Conditional Upon Help Message

Pump 1-6 DP Alarm Individual Manual Started Check DP switch, im Fail peller, coupler, motor

Pump 1-6 Alarm Individual Manual Started Check motor amp

Overload Fail draw and use manual

reset if ok

Low System User Defined User Defined (No) Auto always active, Started and Auto Check PRV setting

Pressure (Event) Manual reset is and trip point

allowed if Stop

Pumps or Alarm is

set to “Y”

High System Alarm Yes Manual Started and Auto Check PRV setting

Pressure and trip point

Low Suction User Defined Yes Manual always Started and Auto Check suction pressure

Pressure (AI) (Event) active, auto reset is and trip point

allowed if “Auto

Reset” is set to “Y”

Low Suction User Defined Yes Manual always Started and Auto Check suction pressure

Pressure (Sw) (Event) active, auto reset is and trip point

allowed if “Auto

Reset” is set to “Y”

High Suction User Defined Yes Auto Started and Auto Check suction pressure

Pressure (Event) and trip point

No Flow Shut User Defined Yes Auto Started and Auto and NFSD is active, check

Down (AI) (Event) only 1 pump on restart pressure

No Flow Shut User Defined Yes Auto Started and Auto and NFSD is active, check

Down (Sw) (Event) only 1 pump on restart pressure

High Alarm Yes Auto Started and Auto Check water temp Temperature erature and trip point

Low Level Alarm Yes Auto Started and Auto Check water level in

holding tank

AI 1-4 Fail Alarm No Auto Always active Check wiring, piping,

polarity and continuity

RTD 1-2 Fail Alarm No Auto Always active Check wiring and

continuity

Battery Alarm No Auto Always active Replace OIP battery

CAN Fail Alarm No Auto Always active Set EX270 switches

C (top), 2 (bottom),

check wiring

Volt Tol. Alarm Yes Auto Always active Check voltage reading

and trip point

Voltage Alarm No Auto Always active Check AI984 connec tion and voltage inputs

Table 11: Alarms/Events

The LED on the HELP key will flash to indicate that an alarm or event exists. The Status screens will also flash “Alm”,

“Evt”, or “NFSD” in the lower right corner to indicate that an alarm or event exists. Pressing the HELP key, while in the

status screens, will display all of the active alarms or events as shown in the screen below. Blinking arrows will indicate

UP/DOWN can be pressed to view more alarms or events. Press CLEAR to exit this screen, or press HELP again while in

the Alarms screen to view help messages for each alarm.

Pump1 Ovld Press ↑

AI#1 Fail Clear to

Pump2 Fail Exit

Hi Sys Pr ↓

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 14

Page 15

Section 4 — Setup Menu

From the status screens, shown in section 3.4, press

the SETUP key to get to the Setup Menu shown

below. Field values columns are provided to record

user setup information for future reference. For the

remainder of this manual, the path to navigate to a

particular screen will be given as follows: Path: Status

Screens/Setup(3).

Setup Menu: # 0=Exit

1=Sensors 4=Test

2=Pumps 5=Alrm/Evt

3=System 6=EZ-Start

4.1 Sensor Setup

Path: Status Screens / Setup (3) / Sensors (1)

← Sensor Setup→

AI#:# (Type)

Span= #### Zero=####

OK? $ (Y/N)

While the left and right arrows are flashing, press

PREV or NEXT to scroll through all of the analog

inputs and RTDs that can be set up. Press UP/DOWN

to modify the sensor type when it is flashing. Input

the span (the sensor value that corresponds to a

20mA signal), then input the Zero (the sensor value

that corresponds to a 4mA signal). Table 12 shows

the default values for each analog input or RTD.

Table 13 shows all of the possible analog input or

RTD types.

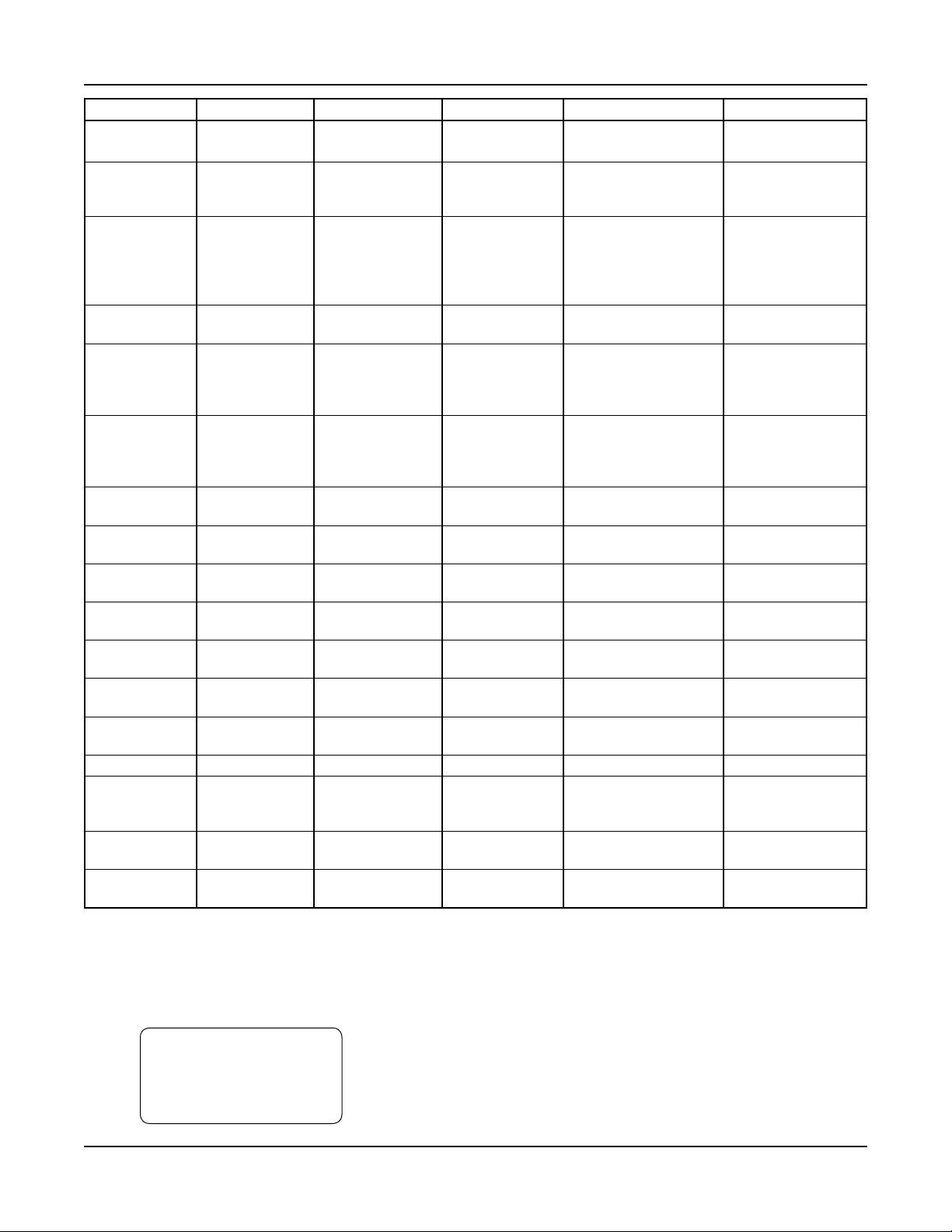

Sensor Default Default Default Field Field Field

Number Type Span Zero Type Span Zero

AI #1 Suc Press 100 0

AI #2 Sys Press 300 0

AI #3 None 0 0

AI #4 None 0 0

RTD #1 Suc Temp N/A N/A

RTD #2 Sys Temp N/A N/A

Table 12: Sensor Setup Variables

Analog Input Types RTD Types

None None

Suc Press Suc Temp

Sys Press Sys Temp

Flow Sup Temp

Temp Ret Temp

Press

Diff Temp

Table 13: Possible Sensor Types

Note: Only one sensor of each type can be set up. If

a type is chosen that is already used for another sen-

sor or RTD channel, the other sensor or RTD input

will be given a type of “None”.

4.2 Pump Setup Menu

Path: Status Screens / Setup (3) / Pumps (2)

Pump Menu: # 0=Exit

1=Number of Pumps

2=Nameplate Data

3=Reset Pmp Runtime

4.2.1 Number of Pumps

Path: Status Screens / Setup (3) / Pumps (2) / Number

of Pumps(1)

Total # Pumps: #

# Jockey Pumps: #

# Standby Pumps: #

OK? $ (Y/N)

See Table 14 for a description of the variables.

Variable Description

Value Value

Total # The total number of 3 1-6

Pumps pumps in the system.

# Jockey pumps will always 0 0-5

Jockey be first in the staging

Pumps sequence. Alternation will

not change this designation.

Jockey Pumps will be

assigned to the lowest

pump numbers starting

with Pump # 1.

# A standby pump will only 0 0-5

Standby operate if a duty pump

Pumps fails. The last pumps in the

staging sequence will be

designated as the standby

pumps.

Table 14: Number of Pumps Variables

4.2.2 Pump Nameplate Data

Path: Status Screens / Setup (3) / Pumps (2) /

Nameplate Data (2)

← Pump# 1 Data →

HP : ###.#

Amps: ###.#

GPM : #### OK? $

Press PREV or NEXT to scroll though all of the

pumps. See Table 15 for a description of the variables.

Default

Range

Field

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 15

Page 16

Setup Menu

Variable Description

Value Value

HP Enter the horsepower from Actual 0 the nameplate of the motor. 999.9

These values are required

for power staging.

Amps Enter the full load amps 0 0 from the motor nameplate. 999.9

These values are required

for amps staging.

GPM Enter the maximum GPM 0 0 from the pump nameplate. 999.9

These values are required

for flow staging.

Table 15: Pump Nameplate Data Variables

Note: All values will be copied to the next screen by

pressing NEXT. They will only be copied the first

time the screens are visited.

Default

Range

Field

4.3 System Setup Menu

Path: Status Screens / Setup (3) / System (3)

System Menu: # ↑

0=Exit

1=Staging

2=Alternation ↓

System Menu: # ↑

3=Exercise

4=Start/Stop

5=Scheduling ↓

System Menu: # ↑

6=Date/Time

7=Password

8=Relay Outputs ↓

System Menu: # ↑

9=Save/Load

*10=Communications

*11=Tech 350 ↓

Press UP/DOWN to view the entire menu.

*Note: depending on factory setup, menu items 10

and 11 may or may not be available

4.3.1 Stage Menu

Path: Status Screens/Setup(3)/System(3)/Staging(1)

Stage Menu:# 0=Exit

1=Primary Staging

2=Secondary Staging

3=Force Dstg/Min Run

4.3.1.1 Primary Staging

Path: Status Screens / Setup (3) / System (3) / Staging

(1) / Primary Staging (1)

Pri Stg Mthd: Method

Stg :###(U) PT: ##s

Dstg:###(U) PT: ##s

Dynamic Stg:$ OK? $

See Table 16 for a description of the Primary Staging

variables

Variable Units Description

Value Value

Pri Stg N/A Primary staging Power Power,

Mthd method. Power, Amps, Amps,

and flow staging Press,

require nameplate D Temp,

data to be set up. See Flow,

section 4.2.2. Temp

Stg (U) The value at which 80 0-999

pumps will stage on.

The units depend on the

staging type. This is the

stage 1-2 value and will

be used for each staging

occurrence unless Dy namic Stg is set to “Y”.

Dstg (U) The value at which 72 0-999

pumps will stage off.

The units depend on

the staging type. This is

the destage 2-1 value

and will be used for

each destaging occurr-

ence unless Dynamic

Stg is set to “Y”.

PT Sec- The proof timer that

onds will elapse before

staging pumps on/off. 5 5-99

Dynamic N/A Select “Y” for Dynamic N Y/N

Stg Stg to choose different

staging and destaging

values for each staging

occurrence. A separate

screen will be displayed

to allow for these inputs.

Table 16: Primary Staging Variables

If “Y” was selected for Dynamic Stg, the screen

shown below will be displayed.

Default

Range

Field

←Method Value Time→

Stg1-2: ###(U) ##s

Dst2-1: ###(U) ##s

OK? $ (Y/N)

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 16

Page 17

Setup Menu

The staging method chosen will be displayed in the

upper left corner. Press PREV or NEXT to scroll

through each staging occurrence. The staging num-

bers will increment to indicate which occurrence is

being shown. Set the value and the proof time for

each staging occurrence.

4.3.1.2 Secondary Staging

Path: Status Screens / Setup (3) / System (3) / Staging

(1) / Secondary Staging (2)

Sec Stg Mthd: Method

Stg :###(U) PT: ##s

Dstg:###(U) PT: ##s

Dynamic Stg:$ OK? $

See Table 17 for a description of the Secondary

Staging variables

Variable Units Description

Value Value

Sec Stg N/A Secondary staging Pressure Power,

Methd method. This will be Amps,

used if the sensor for Press,

the primary method D Temp,

fails. Power, Amps Flow,

and flow staging Temp

require nameplate

data to be set up.

See section 4.2.2.

Stg (U) The value at which System 0-999

pumps will stage on. Pressure

The units depend on the – 10

staging type. This is the

stage 1-2 value and will

be used for each staging

occurrence unless Dy namic Stg is set to “Y”.

Dstg (U) The value at which System 0-999

pumps will stage off. Pressure

The units depend on the – 3

staging type. This is the

destage 2-1 value and

will be used for each

destaging occurrence

unless Dynamic Stg is

set to “Y”.

PT Sec- The proof timer that 5 5-99

onds will elapse before

staging pumps on/off.

Dynamic N/A Select “Y” for Dynamic “N” Y/N

Stg Stg to choose different

staging and destaging

values for each staging

occurrence. A separate

screen will be displayed

to allow for these inputs.

Table 17: Secondary Staging Variables

Default

Range

Field

If “Y” was selected for Dynamic Stg, the screen

shown below will be displayed.

←Method Value Time→

Stg1-2: ###(U) ##s

Dst2-1: ###(U) ##s

OK? $ (Y/N)

The staging method chosen will be displayed in the

upper left corner. Press PREV or NEXT to scroll

through each staging occurrence. The staging numbers will increment to indicate which occurrence is

being shown. Set the value and the proof time for

each staging and destaging occurrence.

4.3.1.3 Force Destage/Minimum Pump Run Time

Path: Status Screens / Setup (3) / System (3) / Staging

(1) / Force Dstg / Min Run (3)

Force Dstg/Min Run

Force Dstg Tmr=##Min

Min Run Timer =##Min

OK? $ (Y/N)

See Table 18 for a description of the Force Destage/

Minimum Pump Run Time variables.

Variable Units Description

Value Value

Force Min- Maximum time a lag 60 0-99

Dstg utes pump will run prior

Tmr to destaging auto matically, a value of 0

disables forced

destaging. See section

3.4.5 for display of

timer status.

Min Min- Minimum time a lag 5 0-99

Run utes pump must run prior

Timer to destaging, a value

of 0 effectively dis ables the minimum

run timer. See section

3.4.5 for display of

timer status.

Table 18: Force Destage/Minimum Pump Run Time Variables

4.3.2 Alternation

Path: Status Screens / Setup (3) / System (3) /

Alternation (2)

Default

Range

Field

Alt Method: $$$$$

Basis:$$$$$ Dur:##s

Time:##:## Day: ##

Period:###Hrs OK? $

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 17

Page 18

Setup Menu

The pump staging sequence, which is shown in sec-

tion 3.4.4, may be alternated automatically or manu-

ally. To manually alternate the sequence, press ALT

from the status screens, then press “Y” and ENTER

at the prompt. Automatic and manual alternation

methods use the Basis and Dur variables shown

be low. See Table 19 for a d escrip t ion of t he

Alternation variables.

Variable Units Description

Value Value

Alt N/A Automatic Alter- None None,

nation Method Timed,

None: disables Daily,

automatic alternation Weekly,

Timed: alternates Monthly

based on the “Period”

Daily: alternates daily

based on the “Time”

Weekly: alternates

weekly based on the

“Time” and the “Day”

Monthly: alternates

monthly based on the

“Time” and the “Day”

Basis N/A Seq: the next pump in Seq Seq,

the sequence will Pmp

become the lead pump Tm

after alternation

Pmp Tm: the pump

with the lowest run time

will become the lead

pump after alternation

Dur Sec- Amount of time that 10 0-99

onds the running pumps will

remain on during

alternation

Time N/A Time, in 24hr format, 0:00 0:00 at which the pumps will 23:59

be alternated for daily,

weekly, or monthly

alternation

Day N/A Day of the week (1= 1 1-28

Monday…7=Sunday)

or month (day of month)

on which the pumps

will be alternated

Period Hours Time between pump 168 0-999

alternations when using

“Timed” alternation

Table 19: Alternation Variables

4.3.3 Pump Exercise

Path: Status Screens / Setup (3) / System (3) /

Exercise (3)

Default

Range

Field

Pump Exercise

Period : ###Hr

Duration : ###Sec

OK? $

Pump exercising will ensure that no pumps go for

long periods of time without running. Note that

automatic alternation can also provide this functionality. Pump exercising will only occur when the system is started and in automatic operation. All pumps

which need exercising will exercise on startup. All

exercising events will be logged in the Exercise Log

shown in section 4.7.5.5. See Table 20 for a description of the Exercise variables.

Variable Units Description

Value Value

Period Hours Amount of time between 0 0-999

automatic exercising of

the pumps, a value of 0

disables pump exercising

Dur- Sec- Amount of time pumps 0 0-999

ation onds will be exercised, all

pumps which have not

run in the last period

will be exercised

simultaneously

Table 20: Pump Exercise Variables

4.3.4 Start/Stop

Path: Status Screens / Setup (3) / System (3) / Start /

Stop (4)

Default

Range

Field

Start/Stop

Method: $$$$$$$$$

OK? $

The controller can be started or stopped in a variety

of ways. This method will always be displayed next

to the start/stop/ready status in the Tech Status screen

shown in section 3.4.1. See Table 21 for a description

of the Start/Stop Methods.

Variable Description

Value Value

Method Keypad: Use the keypad to Keypad Keypad,

start and stop the system Remote,

Remote: Use “Start/Stop

Sw” tied to DI #7

Serial: Use “System Start/

Stop” shown in appendix C

Scheduled: Use scheduling

to start and stop the system,

see section 4.3.5

Default

Table 21: Start/Stop Variables

Range

Serial,

Sched-

uled

Field

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 18

Page 19

Setup Menu

Note: When the Start/Stop Method is anything other

than “Keypad”, the START/STOP key must be

pressed to set the system “Ready” prior to using the

desired method. When the chosen method is active,

the START/STOP key can be pressed to start or stop

the system. If the chosen method is inactive, the

Start/Stop Method must be set back to “Keypad” to

start the system from the keypad.

4.3.5 Scheduling

Path: Status Screens / Setup (3) / System (3) /

Scheduling (5)

← Scheduling →

Day

ON @ : ##:##AM

Off @: ##:##AM OK? $

Press PREV or NEXT to change the day for which

scheduling will be set up. See Table 22 for a descrip-

tion of the Scheduling variables.

Variable Description

ON @ Time at which the system will

automatically start. Set the hour to

0 to prevent the system from starting

on this day.

Off @ Time at which the system will

automatically stop. Set the hour to

0 to prevent the system from stopping

on this day.

AM/PM Press UP/DOWN to select AM/PM

Table 22: Scheduling Variables

Note: Scheduling must be set up as the start/stop

method, for it to take effect. See section 4.3.4 for

more information on the start/stop method. Also, the

controller must be powered up at the specified times,

or it will remain in the previous state until the next

scheduled on or off time.

4.3.6 Date/Time

Path: Status Screens / Setup (3) / System (3) /

Date/Time (6)

Date: MM/DD/YYYY

Time: HH:MM:SS am/pm

Daylite Saving Tm:$

OK? $ (Y/N)

Variable Description

MM Current month (two digits), example:

Jan. should be created as 01

DD Current date (two digits), example:

the 6th should be entered as 06

YYYY Current year using all 4 digits

HH Hours

MM Minutes

am/pm Use UP/DOWN to toggle am/pm

Daylite Enter “Y” for automatic set back

Saving Tm during daylight saving time.

Table 23: Date/Time Variables

4.3.7 Password

Path: Status Screens / Setup (3) / System (3) /

Password (7)

Enable Password

For Setup Menu?: $

OK? $ (Y/N)

If the above is set to YES, the user will be prompted

to input a password prior to entering the Setup

Menu. Upon exiting the above screen, the user will

be prompted to define and confirm a new password.

The password must be a numeric value (0-99999).

Record it here or somewhere else!

_______________________

4.3.8 Relay Outputs Setup

Path: Status Screens / Setup (3) / System (3) /

Relay Outputs (8)

← Digital Outputs →

DO# 1 Locked

(Functionality)

OK? $

Press PREV or NEXT to scroll through the digital

outputs. Its output number and functionality will be

displayed. If a digital output is “Unlocked”, it may be

modified. Use UP or DOWN to modify the functionality. Multiple outputs may have the same functionality.

See Table 23 for a description of the Date/Time Setup

variables.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 19

Page 20

Setup Menu

Functionality Description

1M-6M Relay used to energize motor starter

Output coil or can be used as pump run

status

General Relay closes to indicate an “alarm”

Alarm condition exists (will not indicate

an “event”)

System On Relay closes when the system is

started

System Auto Relay closes when the system is in

automatic mode

A/V Alarm Relay closes to indicate an “alarm”

condition exists (will not indicate an

“event”), this output is intended to

be connected to a pilot light or a

horn. When this output is active,

the RESET/SILENCE LED will blink

fast to indicate it should be pressed

to deactivate this output. Once this

output is deactivated, the RESET/

SILENCE key will function

normally to reset pumps and alarms.

Table 24: Optional Digital Outputs

Note: 1M-6M outputs will be automatically assigned

to digital outputs according to the appropriate wiring

diagram depending on the number of pumps that are

set up. These outputs will always be “locked” and

cannot be modified.

4.3.9 Save/Load Menu

Path: Status Screens / Setup (3) / System (3) /

Save/Load (9)

Sav/Ld Menu:# 0=Exit

1=Save to Flash

2=Load from Flash

3=Load Defaults

4.3.9.1 Save to Flash

Path: Status Screens / Setup (3) / System (3) /

Save/Load (9) / Save to Flash (1)

PREVIOUS SAVED

DATA WILL BE

OVERWRITTEN!

Proceed? $

Press YES and ENTER to save all of the user setup to

the flash memory. Saving to flash will overwrite any

data that was previously saved. A load from flash will

have to be performed to recover this saved data. See

the following section.

4.3.9.2 Load from Flash

Path: Status Screens / Setup (3) / System (3) /

Save/Load (9) / Load from Flash (2)

ALL USER SETUP

DATA WILL BE

LOADED FROM FLASH

Proceed? $

Press YES and ENTER to overwrite all of the current

user setup information with the data that was previously saved to the flash memory.

4.3.9.3 Load Defaults

Path: Status Screens / Setup (3) / System (3) /

Save/Load (9) / Load Defaults (3)

ALL USER SETUP

DATA WILL BE

OVERWRITTEN BY

DEFAULTS! Proceed? $

Press YES and ENTER to overwrite all of the current

user setup information with the factory defaults.

4.3.10 Communications

Selecting 10 from the System Setup Menu will dis-

play the appropriate communications setup screen

shown in the following sections. If no communications were set up by the factory, this menu option

will not be available. If the communication type displayed is not the type of communications desired, call

your Bell & Gossett representative for assistance in

changing it.

Refer to Appendix C for the list of serial communica-

tions points that are available for each protocol.

4.3.10.1 BACnet MS/TP

Path: Status Screens / Setup (3) / System (3) /

BACnet (10)

Enable BACnet: $

Baud,8,1,1,N Slave

MAC=### Inst=###

AI Ovrd: $ OK?$

The Technologic® Constant Speed Pump Controller

communicates using 8 bit data packets, 1 stop bit, 1

sta r t bit a nd n o p ar i ty. See t he P r ot o co l

Implementation Conformance statement in appendix

D for details on the supported objects and services.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 20

Page 21

Setup Menu

Variable Description

Value Value

Enable This must be set to “Y” to Y Y/N

BACnet utilize RS-485 communi cations. It should only be

set to “N” to upload

software upgrades.

Baud The baud rate is user 9600 9600,

adjustable 19200,

38400

MAC The MAC address or node 10 1-255

Address number should be supplied

by the BMS.

Inst Unique instance numbers 100 0-9999

should be assigned for

every device on a BACnet

network.

AI Select “Y” to override N Y/N

Ovrd analog inputs through the

communications port.

See section 4.3.10.5.

Table 25: BACnet MS/TP Variables

4.3.10.2 Metasys N2

Path: Status Screens / Setup (3) / System (3) /

JC N2 (10)

Default

Range

Field

Enable Metasys N2: $

9600,8,1,1,N VND

Node=###

AI Ovrd: $ OK?$

See Table 26 for a description of the Metasys N2

variables.

®

The Technologic

communicates using 9600 bps baud rate, 8 bit data

packets, 1 stop bit, 1 start bit and no parity.

Constant Speed Pump Controller

4.3.10.3 Modbus

Path: Status Screens / Setup (3) / System (3) /

Modbus (10)

Enable Modbus: $

9600,8,1,1,N VND

Node=###

AI Ovrd: $ OK?$

See Table 27 for a description of the Modbus vari-

ables.

®

The Technologic

communicates using 9600 bps baud rate, 8 bit data

packets, 1 stop bit, 1 start bit and no parity.

Variable Description

Value Value

Enable This must be set to “Y” to Y Y/N

Modbus utilize RS-485 communi cations. It should only be

set to “N” to upload

software upgrades.

Node The node number should 10 0-255

be supplied by the BMS.

AI Select “Y” to override N Y/N

Ovrd analog inputs through the

communications port.

See section 4.3.10.5.

Table 27: Modbus Variables

4.3.10.4 Lonworks

Path: Status Screens / Setup (3) / System (3) /

Lonworks (10)

Constant Speed Pump Controller

Default

Range

Field

Enable Lonworks: $

AI Ovrd: $

OK?$

Variable Description

Value Value

Enable This must be set to “Y” to Y Y/N

Metasys utilize RS-485 communi N2 cations. It should only be

set to “N” to upload

software upgrades.

Node The node number should 10 0-255

be supplied by the BMS.

AI Select “Y” to override N Y/N

Ovrd analog inputs through the

communications port.

See section 4.3.10.5.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 21

Default

Table 26: Metasys N2 Variables

Range

Field

See Table 28 for a description of the Lonworks vari-

ables.

®

The Technologic

communicates using Modbus over RS-232 media

through a gateway, supplied with the panel, which

converts the protocol to Lonworks.

Note: Lonworks requires additional hardware.

Variable Description

Value Value

Enable This must be set to “Y” Y Y/N

Lon- to enable Lonworks

works communications.

AI Select “Y” to override N Y/N

Ovrd analog inputs through the

communications port.

See section 4.3.10.5.

Table 28: Lonworks Variables

Constant Speed Pump Controller

Default

Range

Field

Page 22

Setup Menu

4.3.10.5 Analog Input Override

If “Y” was entered for “AI Ovrd” in any of the com-

munication setup screens above, the following screen

will be automatically displayed.

AI Override

Suc P:$ D Temp:$

Sys P:$ Press:$

Flow :$ Temp:$ OK?$

Enter a “Y” next to each analog input type that will

be overridden through the communications port.

4.3.11 Tech 350

Path: Status Screens / Setup (3) / System (3) /

Tech 350 (11)

Tech 350

Purge Time: ##Min

Purge Num Pumps: #

App Type: $$$$ OK?$

This setup menu will only be available for closed sys-

tems. If purging is enabled, purging will occur every

time the system is started in automatic mode. Every

time purging occurs it will be logged. See section

4.7.5.4 for purge logging. See Table 29 for a descrip-

tion of the Tech 350 variables.

Variable Units Description

Value Value

Purge Min- Time that the pumps 10 0-30

Time utes will run immediately

after starting the

system in automatic

mode, a value of 0

disables purging

Number N/A Number of pumps 1 0-6

of that will turn on when

Pumps purging is active

App N/A The application type Cool Heat,

Type is required if staging Cool

will be based on

temperature.

Table 29: Tech 350 Variables

Default

Range

Field

4.4.1 Digital Input Test

Path: Status Screens / Setup (3) / Test (4) / DI (1)

Digital Input Test

1234567890123456

################

Press Clear to Exit

The 0 below each corresponding input will change to

a 1 upon receiving a 24VDC digital input on that

channel. Press CLEAR to exit the test.

4.4.2 Digital Output Test

Path: Status Screens / Setup (3) / Test (4) / DO(2)

Digital Output Test

12345678

########

Enter DO# # (0=Exit)

Press the numeric key corresponding to the digital

output for which the state is to be changed, and then

press ENTER to change it. Pressing ENTER multiple

times will toggle between 0 and 1. A 1 indicates that

the corresponding relay is closed. When the relay is

closed, the corresponding LED on the digital output

module will be lit. Press 0 and ENTER to exit the

test.

Note: Motors will start if the corresponding relay is

actuated.

4.4.3 Analog Input Test

Path: Status Screens / Setup (3) / Test (4) / AI (3)

Analog Input Test

AI1=###% AI4 =###%

AI2=###% RTD1=###.#F

AI3=###% RTD2=###.#F

The signal received on the corresponding analog input

channel will be indicated in percent next to each

input. 0mA = 0%, and 20mA = 100%. Analog inputs

1-4 are 4-20mA inputs. RTD1 and RTD2 are for

PT100 resistive temperature devices. RTD1 and RTD2

are displayed in °F. Press CLEAR to exit the test.

4.4 Test Menu

Path: Status Screens / Setup (3) / Test (4)

Test Menu: #

0=Exit 3=AI 6=Disp

1=DI 4=LED 7=Comm

2=DO 5=Key

Press the numeric key corresponding to the desired

sub-menu, and press ENTER.

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 22

4.4.4 LED Test

Path: Status Screens / Setup (3) / Test (4) / LED (4)

LED Test

*** LED ON ***

*** LED OFF ***

*** LED BLINK ***

All of the LED’s on the keypad will turn on, off, and

then flash. The current status will be displayed on the

screen. The LED test is self terminating.

Page 23

Setup Menu

4.4.5 Key Test

Path: Status Screens / Setup (3) / Test (4) / Key (5)

Key Test

Press a key to test

Press clear to exit

Press any key except for the CLEAR key, and the dis-

play will confirm that the key is working by display-

ing the key name. Press CLEAR to exit.

4.4.6 Display Test

Path: Status Screens / Setup (3) / Test (4) / Disp (6)

The display will show all black characters. Press

CLEAR to exit.

4.4.7 Comm Test

Path: Status Screens / Setup (3) / Test (4) / Comm (7)

Comm Test

ITT Read: ####

ITT Write: ####

Press Clear to Exit

If the controller is communicating properly with the

building automation system, both numbers will con-

tinue increasing in value. For Modbus protocol, the

read and write numbers should be equal and increas-

ing with every poll. For BACnet, both numbers

should be increasing, but they will not be equal. The

write value will increase even when not connected.

For the Metasys N2 protocol, both numbers should

be increasing but may not be equal. This test feature

is not supported for Lonworks. If both numbers are

not increasing in value, the controller is not commu-

nicating properly. Check the wiring at the terminal

blocks. See section 4.3.10 for more information on

communications setup. Press CLEAR to exit this test.

4.5 Alarms/Events Menu

Path: Status Screens / Setup (3) / Alrm/Evt (5)

Alarm Menu: # 0=Exit

4=Low Suction ↑

5=High Suction ↓

6=NFSD

Alarm Menu: # 0=Exit

7=High Temp ↑

8=Low Level ↓

9=Volts Tolerance

Press UP/DOWN to view the entire menu.

4.5.1 Pump Failure

Path: Status Screens / Setup (3) / Alrm/Evt (5) /

Pump Failure (1)

Pump Failure

DP Switch Pr Tm: ##s

OK? $ (Y/N)

See Table 30 for a description of the Pump Failure

variables.

Variable Units Description

Value Value

DP Sec- Proof timer prior to 10 0-99

Switch onds setting a pump fail

Pr Tm alarm after receiving

a continuous high sig nal from a DP switch

Table 30: Pump Failure Variables

4.5.2 Low System Pressure

Path: Status Screens / Setup (3) / Alrm/Evt (5) /

Low System (2)

Default

Range

Field

Low Sys Press: ##PSI

Low Sys Pr Tm: ##s

Alarm:$ Stop Pumps:$

OK? $ (Y/N)

See Table 31 for a description of the Low System

Pressure variables.

Alarm Menu: # 0=Exit

1=Pump Failure ↑

2=Low System ↓

3=High System

Technologic® Constant Speed Pump Controller Installation, Operation and Maintenance Manual 23

Page 24

Setup Menu

Variable Units Description

Value Value

Low PSI The pressure below ½ 0-999

Sys which an alarm or System

Press event will be set Pressure

Low Sec- The proof timer prior 0 0-255

Sys onds to setting an alarm or

Pr Tm event. A value of 0

disables this alarm or

event.

Alarm N/A Set this value to “Y” N Y/N

to consider low system

pressure an alarm, or

set it to “N” to

consider it an event.

Stop N/A Set this value to “Y” N Y/N

Pumps to stop all pumps in

the event of a low

system pressure alarm

or event. Set it to “N”

to continue operation

normally during this

alarm or event.

Table 31: Low System Pressure Variables

4.5.3 High System Pressure

Path: Status Screens / Setup (3) / Alrm/Evt (5) /

High System (3)

Default

Range

Field

High Sys Press: ##

High Sys Pr Tm: ##s

OK? $ (Y/N)

See Table 32 for a description of the High System

Pressure variables.

Variable Units Description

Value Value

High PSI The pressure above 1.5 x 0-999

Sys which an alarm will System

Press be set Pressure

High Sec- The proof timer prior 20 0-255

Sys onds to setting an alarm.

Pr Tm A value of 0 disables

this alarm.

Table 32: High System Pressure Variables

4.5.4 Low Suction Pressure

Path: Status Screens / Setup (3) / Alrm/Evt (5) /

Low Suction (4)

Default

Range

Field

Low Suct Press: ##

Pr Tm: ##s Alarm:$

Auto Reset: $

Reset Press: ## OK?$

See Table 33 for a description of the Low Suction

Pressure variables.

Variable Units Description

Value Value

Low PSI The pressure below 5 0-999

Suct which an alarm or

Press event will be set for

the analog input

method

Pr Tm Sec- The proof timer prior 20 0-255

onds to setting an alarm or

event. A value of 0

will disable this alarm.

Used for analog input

and pressure switch

methods.

Auto N/A Select “Y” to allow Y Y/N

Reset this alarm or event to

be automatically reset.

The analog input

method resets using

the “Reset Press”. The

pressure switch

method resets on a

low signal on the low

suction pressure