Page 1

VARIABLE SPEED PUMPING SYSTEMS

INSTRUCTION MANUAL

™

Technologic

5500 Series

Variable Primary Pump and

INSTRUCTION MANUAL

S14334B

Valve Controller

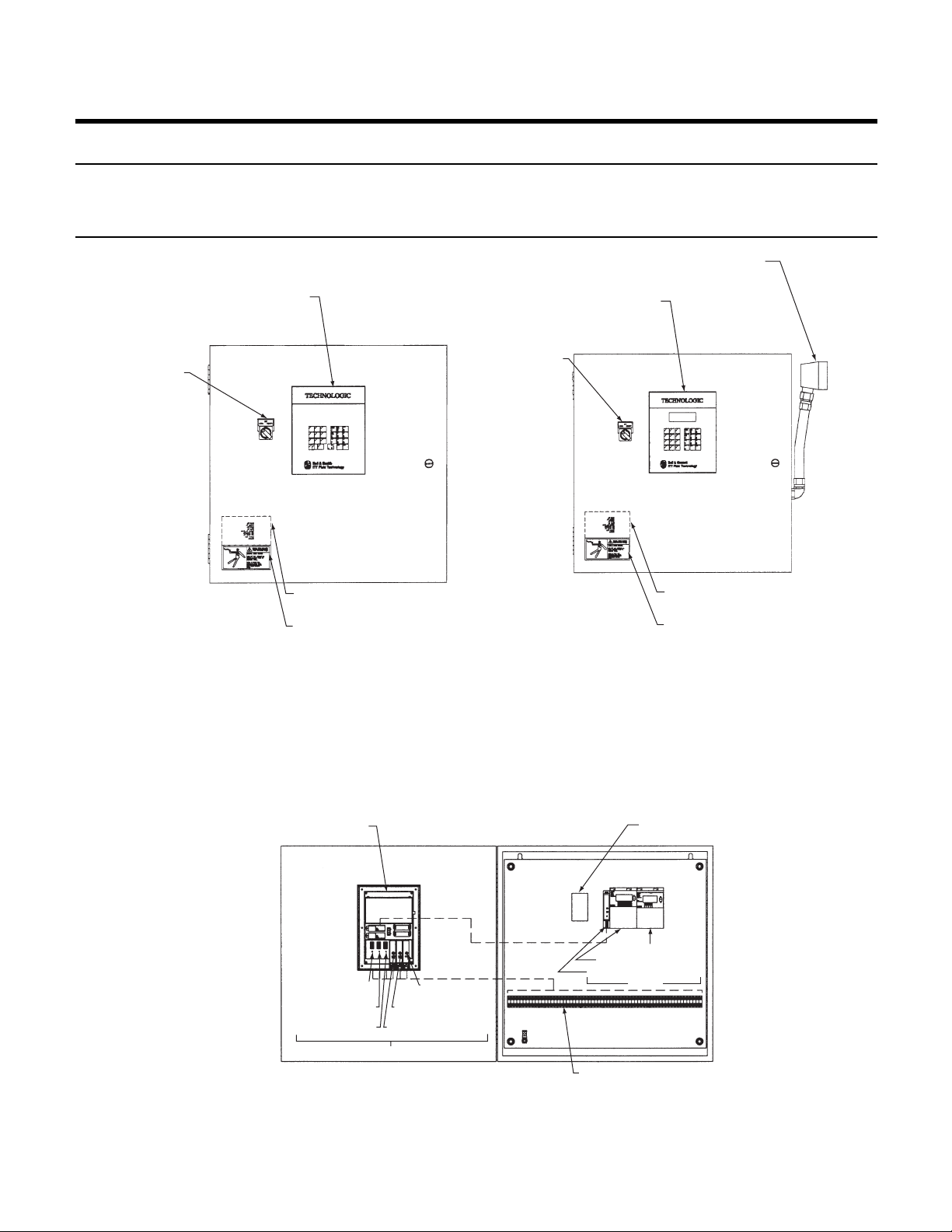

WARNING LABEL PART #S11550

INSTALLED IN THIS LOCATION.

IF MISSING IT MUST BE REPLACED.

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

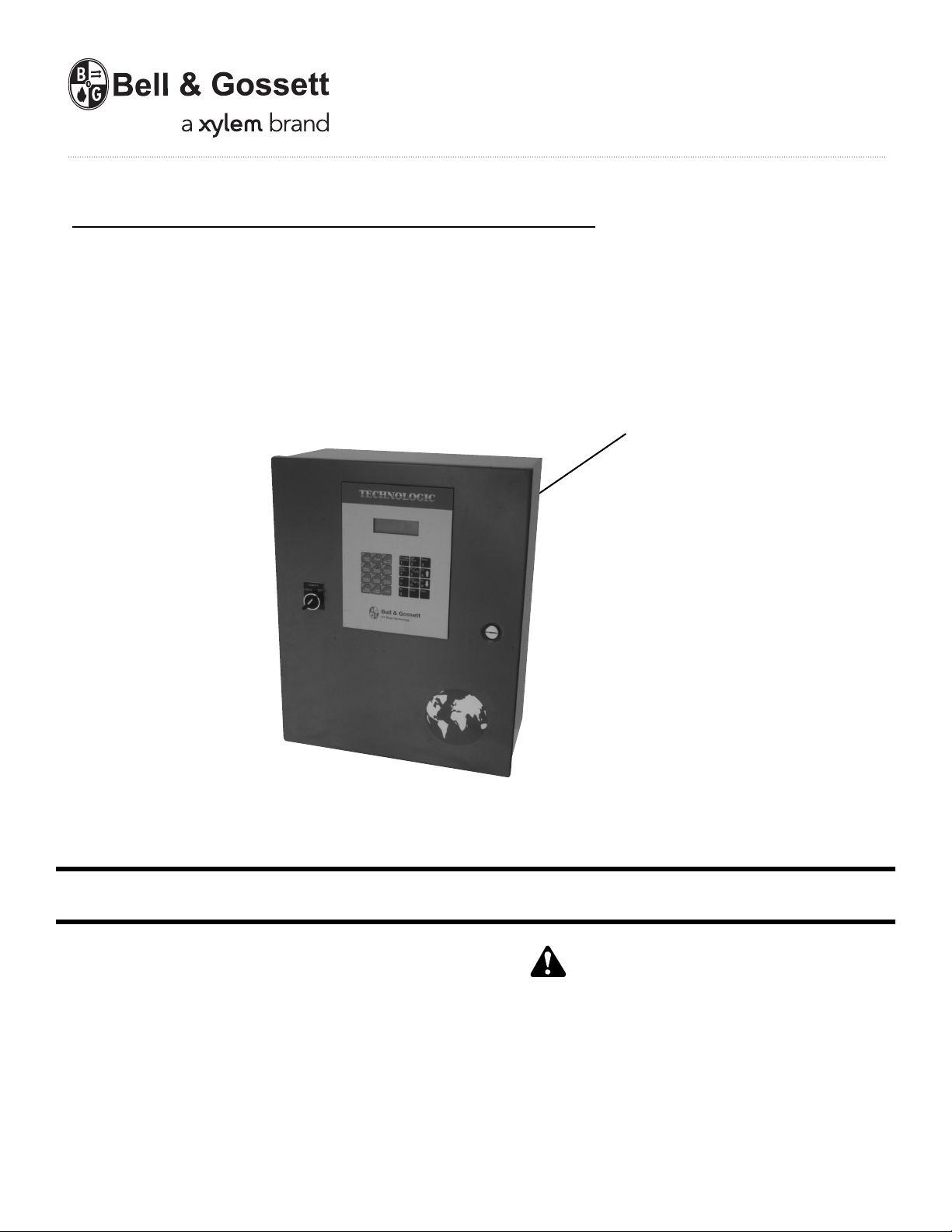

DESCRIPTION

Microprocessor based dedicated pump controller for variable

volume pumping systems. The control panel consists of the

following components: microprocessor, operator interface

with 4 line display and membrane key pad, and 24 VDC

power supply. Multi-pinned connecting cables for connection

to bypass panels are available as options.

OPERATIONAL LIMITS

See the control panel nameplate for operating voltage, current

draw, as well as information on the equipment to be connected to the control panel.

This safety alert symbol will be used in this manual and on the

Technologic 5500 Safety Instruction decal to draw attention to

safety related instructions. When used, the safety alert symbol

means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTION

MAY RESULT IN A SAFETY HAZARD!

SAFETY

INSTRUCTIONS

Page 2

2

Preface

The following manual describes the new microprocessor based Technologic 5500 Variable Primary Pump

Controller. This unit is in the tradition of the other

members of the Technologic Control Panels as it

incorporates many original, novel, and proprietary features that may only be found on B&G controllers.

Some of these features require special emphasis here.

The controller is best described as a specific purpose

programmable pump and valve controller. This means

that the hardware and software have been created for

the control and diagnostics of pumps and valves with

consideration for their inherent characteristics. This

results in an optimum pump controller without the cost

of general purpose control hardware. Software is dedicated and established for the unit only after extensive

testing. Changes to this software are not taken lightly

and must pass rigid version control.

The controller has the unique analog input protection

of other members of the control family. In the event of

a short circuit condition the current limit circuitry prevents failure of the analog input components.

This new controller has standard manual motor bypass

switches when a Bell & Gossett automatic bypass is

supplied. The manual motor bypass switches allow

the user to de-energize the programmable logic controller and take manual control of the pumping system.

This is helpful during system startup to confirm pump

rotation and to purge air from the system prior to

switching to automatic control.

Page 3

3

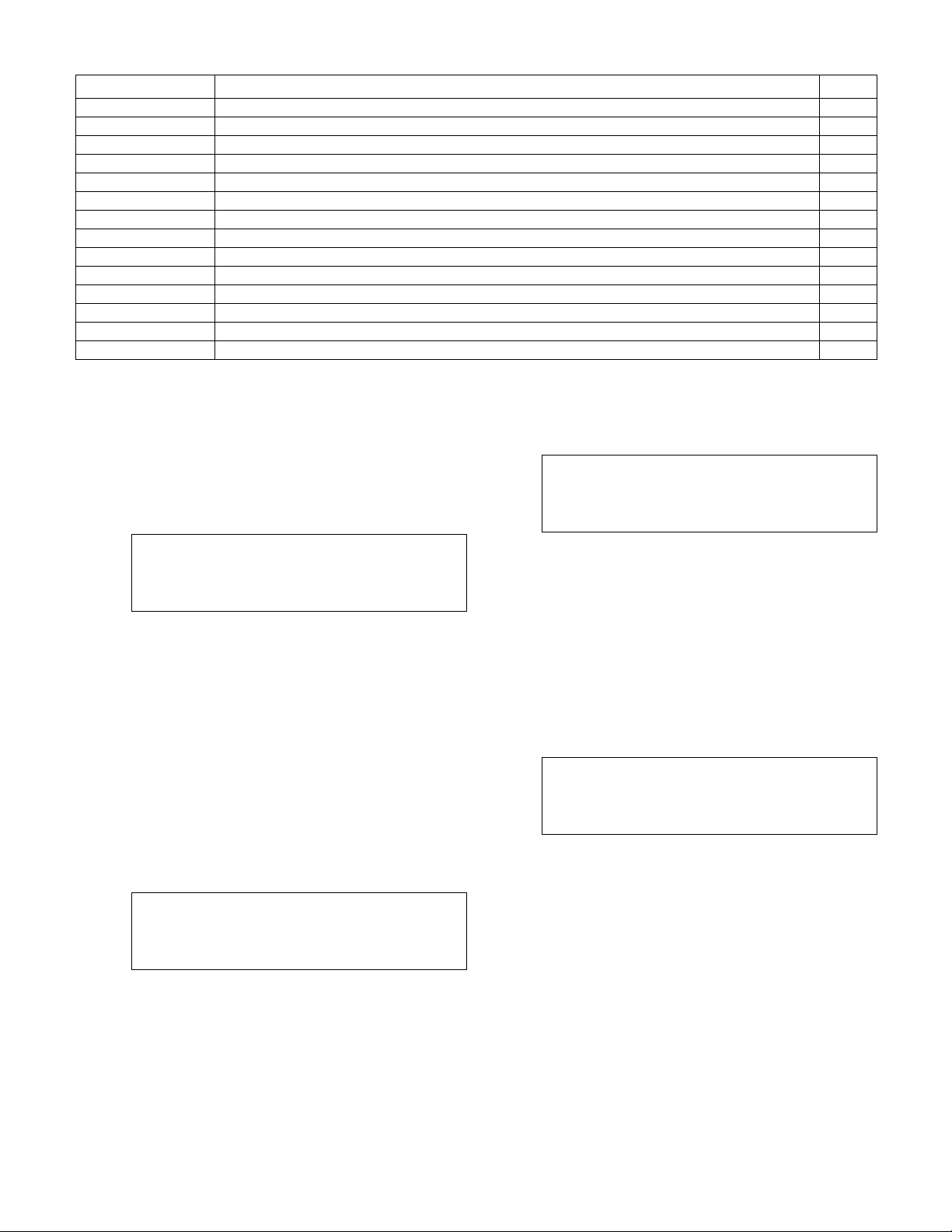

SECTION 1 - GENERAL Page

1.1 Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.1 Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.2 Safety Instruction Decal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.3 Motor Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.4 Motor Control Equipment Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.5 Temperature and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.6 Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7 Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.8 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.9 Output/Motor Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.10 Analog Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.11 Field Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.12 Sensor and Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.12.1 DP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.12.2 AFDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.12.3 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.4 Analog Inputs with External Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.5 Drive Speed Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.6 Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.7 Hardwire Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.7.1 Remote Start/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.7.2 Remote Alarm Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.12.8 User Configurable I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SECTION 2 - INSTALLATION AND STARTUP

2.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2 Installation of Skid Mounted Systems with Factory Supplied Pumps . . . . . . . . . . . . . . . . . . . . . .9

2.2.1 Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.2 Grout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.3 Closed System Safety Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.4 Eccentric Increasers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.5 Pipe Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.6 Expansion and Vibration Absorbtion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.7 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 Putting the Unit into Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.1 Pump Rotation, 3 Phase Motors Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.2 Joint Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SECTION 3 - OPERATOR INTERFACE

3.1 Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Technologic Pump Controller Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Key Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.4 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SECTION 4 - SETUP SELECTION MENU

4.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.1 Sensor Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.2 Edit/Copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.3 Sensor Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.4 Do Another . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.5 Sensor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.6 Sensor Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.7 Sensor Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.8 Sensor PV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.9 Sensor Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.10 Sensor Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.11 Sensor Setup Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.12 Sensor Setup Exit (not PV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.13 Copy Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.14 Chiller Sensor Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.15 Chiller Sensor Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.16 Chiller Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.17 Chiller Sensor Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Pump Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2.1 Enable/Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

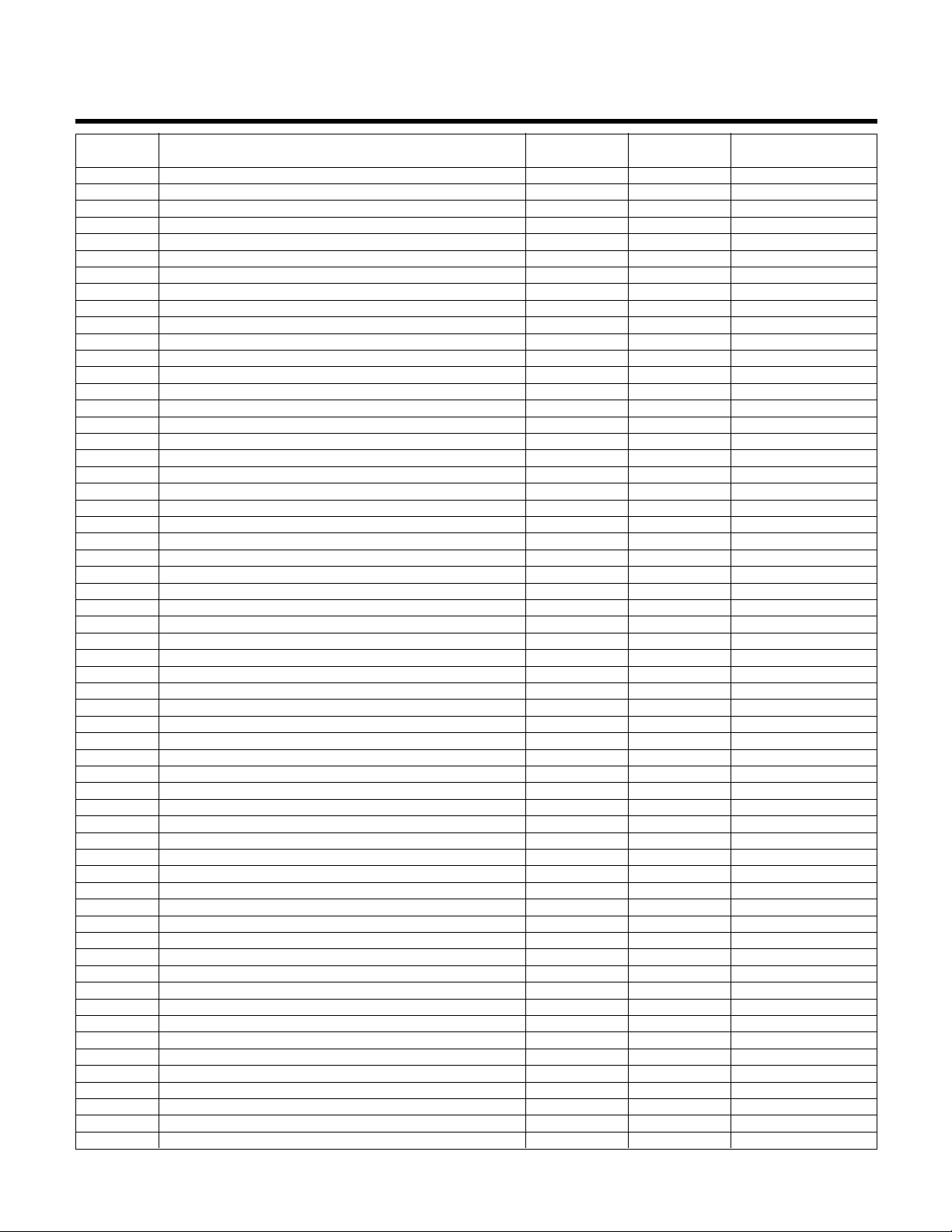

Index

Page 4

4

INDEX (continued)

4.2.2 Number of Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.3 Edit Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.4 Edit Pump Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.5 Enable/Disable Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.6 Do Another . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.7 Pump Off Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.8 Lag Pump Run Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.9 Low Load Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2.10 High Low Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 System Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.1 Stage/Destage Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.1.1 PV Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.1.2 PV Destage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.3.1.3 EOC Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.3.1.4 EOC Destage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3.2 PID Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3.3 Alarms Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3.4 Alternation Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3.5 Bypass Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.3.6 AFD Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.3.7 Date/Time Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.3.8 Password Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3.9 I/O Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3.9.1 DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3.9.2 DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3.9.3 AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3.9.4 AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3.10 Communication Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.10.1 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.10.2 Metasys N2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.10.3 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.10.4 BACnet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.11 Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.12 Brightness/Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.13 Save to Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.14 Load from Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4 Test Selection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.1 DI Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.2 DO Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.3 AI Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.4 AO Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.5 LED Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.6 Key Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.7 Disp Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.4.8 Comm Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.5 Default Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.6 Chiller Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.6.1 Enbl/Disbl Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.6.2 Chiller's Run Tmr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.6.3 Isolation Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.7 Bypass Valve Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.7.1 Bypass Valve Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.7.2 Bypass Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.7.3 Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SECTION 5 - OPERATION

5.1 Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.1 Technologic Pump Controller Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.2 Pump Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.3 Pump Speed Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.4 Chiller Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.5 Chiller Data Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.6 Active Values Data Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.7 Bypass Valve Signal Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.8 Manual Speed Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1.9 Active Values Seq Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.1.10 Bypass Valve Position Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.1.11 Sys. Temp Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.1.12 Isolation Valve Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Page 5

5

INDEX (continued)

5.2 Bypass Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.2.1 Manual Bypass Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.2.2 Auto Bypass Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.3 Manual Bypass Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.4 Hand Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.5 Hand Bypass Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.6 Setpoint Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.7 Process Variable Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.8 Request to Stage/Destage Chillers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.9 Alternation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.10 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SECTION 6 - MAINTENANCE

6.1 Technical Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.2 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.3 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.4 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.5 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.6 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.7 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.8 Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.9 Instruments and their Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.9.1 AC/DC Voltmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.9.2 Ohmmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.9.3 Milliamp Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.9.4 Signal Generator (analyzer) - recommended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.10 Field Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.11 Program Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.12 Controller Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.13 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.13.1 Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.13.2 Pump Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.13.2.1 Pump Run Time Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.13.2.2 Pump On/Off Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.13.3 Data Log Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.3.1 PV Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.3.2 KWH Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.3.3 Flow Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.4 Operation Log Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.4.1 System On/Off Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.4.2 Op Mode Changes Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.4.3 Alternations Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13.4.4 System Reset Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.13.4.5 Control Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.13.5 Power Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.13.6 Service Log Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.13.6.1 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.13.6.2 Operating Hours Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.14 Maintenance (Physical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.14.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.14.2 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

APPENDIX A System Check List – Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

APPENDIX B System Check List – Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

APPENDIX C Valid I/O Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

APPENDIX D BACnet MS/TP Protocol Implementation Conformance Statement . . . . . . . . . . . . . . . . .38

APPENDIX E BACnet IP Protocol Implementation Conformance Statement . . . . . . . . . . . . . . . . . . . . .39

APPENDIX F BACnet Communications Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40-42

APPENDIX G LonWorks Communications Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43-46

APPENDIX H Metasys N2 Communications Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47-49

APPENDIX I Modbus Communications Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-52

APPENDIX J Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53-54

Page 6

6

NOTE: The information contained in this manual is intended to assist operating personnel by providing information on the char-

acteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of accepted practices in

the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your Technologic 5500 series pump controller

can be found in the I.O.M.s for the associated equipment provided see Section 5, Maintenance, for a list of relevant manuals.

Glossary of Terms

AFD

Adjustable Frequency Drive; converts a constant power input

into a variable power output for the motor; a device for controlling motor speed

Alternation

Process of determining which pump will serve as lead pump

and which pump will serve as lag pump

Bypass

Controller bypasses the AFD, pumps stop running in variable

speed mode and run at constant speed (50 Hz / 60 Hz)

Bypass Valve

Modulating valve that controls the minimum flow required by

chillers

Destage

To turn off a lag pump

EOC

End of Curve; point at which a pump is staged or destaged

I.O.M.

Installation Operation Manual

Isolation Valve

Two way control valve that isolates flow from standby chillers

Lag pump

Standby pump that activates only when lead pump alone

cannot efficiently provide sufficient pressure or flow rate

Lead pump

Duty pump which runs continuously until a standby pump is

required

LED

Light emitting diode, located on OIP and controller

OIP

Operator Interface Panel

O.L.

Overload: device to protect a motor from overheating

PID

Proportional Integral Derivative; 3 variables required for error

control

Process Variable

Signal generated by a sensor that is set up to control the

system

Proof timer

Minimum time period before controller acknowledges an

input; time period for which a signal must be stable before it

is accepted by the controller as a sustained and valid signal

RTC

Real time clock

RTD

Resistive temperature device used to supply temperature

signals to the PLC

Stage

To start a lag pump

Page 7

7

1.1

Purpose of Manual

This manual is furnished to acquaint you with some

of the practical ways to install, operate, and maintain

this unit. Read it carefully before doing any work on

your unit and keep it handy for future reference.

Equipment cannot operate well without proper care.

To keep this unit at top efficiency, follow the recommended installation and servicing procedures outlined in this manual.

1.2

Safety

1.2.1 Safety Alert Symbol

SAFETY INSTRUCTION

This safely alert symbol will be used in this manual

and on the unit safety instruction to draw attention to

safety related instructions. When used the safety alert

symbol means

ATTENTION BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN A

SAFETY HAZARD.

1.2.2 Safety Instruction Decal

Your Technologic 5500 Series Variable Primary Pump

and Valve Controller should have a safety instruction

decal (part # S11550). If the decal is missing or

illegible contact your local B&G representative for a

replacement.

1.2.3

Motor Safety

Each motor must have a properly sized starter with

properly sized overload block to provide overload

and undervoltage protection. Ground fault protection

should be sized properly. Refer to local electrical

codes for sizing and selection. Refer to the motor

manufacturer's I.O.M. (Installation Operation Manual)

for specific installation information. Even when the

motor is stopped, it should be considered "alive" as

long as its controller is energized.

The use of motor disconnect switches is acceptable.

Consult the factory for proper interlocking with

adjustable frequency drives, AFD's. See section 1.9.

1.2.4

Motor Control Equipment Safety

Motor control equipment and electronic controls are

connected to hazardous line voltages. When servicing electronic controls, there will be exposed components at or above line potential. Extreme care should

be taken to protect against shock. Stand on an insulating pad and make it a habit to use only one hand

when checking components. Always use accurate

test meters when checking electrical components.

Always work with another person in case of an emergency. Disconnect power when performing maintenance. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electronic

control or rotating equipment.

1.3

Storage

For long periods of storage, the unit should be cov-

ered to prevent corrosion and contamination from

dirt. It should be STORED in a clean, dry location

between -20 and +60ºC. The relative humidity

should not exceed 85%. The unit should be checked

periodically to ensure that no condensation has

formed. After storage, again check that it is dry

before applying power.

NOTE: EXTENDED STORAGE OF AFDs MAY

REQUIRE SPECIAL ATTENTION PRIOR TO STARTUP. SEE MANUFACTURER'S I.O.M. FOR DETAILS.

1.4

Handling

Care should be taken to prevent damage due to

dropping or jolting when moving the Technologic Variable Primary Pump and Valve Controller. Transportation damage should be brought to the carrier's attention immediately upon receipt.

1.5

Temperature and Ventilation

All electrical equipment is susceptible to failure if

operated in ambient temperatures outside of its rating. The operating temperature range for this unit is

0 to 40°C. The relative humidity should not exceed

95% non-condensing. The unit should not be operated outside these extremes.

1.6

Input Voltage

The Technologic Variable Primary Pump and Valve

Controller was factory set to operate on the voltage

shown on the nameplate. Check the AFD nameplate

for the proper input and output voltages before wiring

the AFD.

The voltage tolerance is +10/-5% and phase to

phase voltage must not have an imbalance greater

than 5 VAC.

Section 1 - General

DANGER: Troubleshooting live control panels exposes

personnel to hazardous voltages. Only a qualified elec-

trician may do electrical troubleshooting.

FAILURE TO FOL-

LOW THESE INSTRUCTIONS MAY RESULT IN SERIOUS

PERSONAL INJURY, DEATH, AND/OR PROPERTY

DAMAGE.

WARNING: Motor can start automatically. Keep

hands away from output shaft until motor is completely stopped and input power is removed from the motor

control panel. Lockout main power switch while working

near the motor shaft.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAIL-

URE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 8

8

1.7

Ground Connections

A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the

National Electrical Code and local codes must be

followed.

1.8

Power Wiring

Power wire types and sizes must be selected based

upon conformance with the National Electrical Code

and all local codes and restrictions. In addition, only

copper (Cu) wire rated for 75°C (minimum) may be

used for the power connections. Refer to the input

current as listed on the nameplate on the enclosure

door when sizing wire.

1.9

Output/Motor Disconnect

It is necessary that any device that can disconnect

the motor from the output of the AFD be interlocked

to the emergency shutdown circuits of the AFD. This

will provide an orderly shutdown if the disconnecting

device is open circuited while the AFD is in operation.

Failure to provide this interlock may result in damaged components due to improper installation.

1.10

Analog Signal Wiring

Shielded cable (#22 AWG, Belden type 8762, Alpha

#2411, or equal) should be installed for all D.C. control wiring. The shield must be terminated in the

Technologic Variable Primary Pump and Valve

Controller panel.

Do not connect the shield at the

other end of the cable! Insulate the shield so that

no electrical connection is made at the other end

of the cable.

A twisted pair of #22 AWG conductors

(Belden 8442 or equal) can be used in place of

shielded cable. The cable length must be limited to

5,000 feet for #22 AWG wire.

1.11 Field Connection Diagrams

Refer to the pump I.O.M. for specific details unique to

the pump.

Refer to the flow sensor/transmitter I.O.M. for specific

details unique to the flow sensor/transmitter.

The Wiring Diagram(s), Dimensional Drawings and

Field Connection Diagram should be reviewed prior

to unit installation and operation.

1.12

Sensor and Control Wiring

The following sections are based on the installation of

standard Technologic 5500 product. Because customized software and hardware is available, the

installing contractor should base all wiring connections on the wiring diagrams that accompany each

controller. These sections are meant to complement,

not replace, those wiring diagrams.

1.12.1

DP Switches

Differential pressure switches sense the increase in

pressure between the pump suction and discharge

gauge taps. DP switches are used to determine

whether a pump is running. Each switch should be

wired from the normally closed contact.

1.12.2

AFDs

To monitor if an adjustable frequency drive is running,

it is necessary to wire from each AFD's normally

open "run" or "on" contact.

For the Technologic Variable Primary Pump and

Valve Controller to start and stop each AFD, it is necessary to wire to the remote start terminals in each

AFD.

Additional wiring to each of the adjustable frequency

drives may be required with certain types of controller programs. Refer to the wiring diagram for all

connection points.

With certain bypass and control methods, it is necessary to disable an adjustable frequency drive from

running. This is accomplished by wiring from the

Technologic 5500 terminals to each AFD's interlock

terminals. Should this wiring be required, any

jumpers which may be found on the AFD's interlock

terminals should be removed.

1.12.3

Analog Inputs

The Technologic 5500 control family has the capa-

bility to accept many analog inputs. Typically, all

analog inputs must be 4-20mA and powered by the

24VDC power supply in the Technologic 5500. All

shields must be grounded, only in the Technologic

5500, to prevent ground loops and improper signals.

To monitor system zones, it is not necessary for all

analog inputs to be used. It is necessary, however,

that all zone transmitters be connected consecutively

starting with zone 1. Optional transmitters (i.e., other

than zones) may be supplied.

CAUTION: Metal filings can create electrical short

circuits. Do not drill, saw, file or perform any operation on the AFD conduit entry plate while attached to the

AFD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN PROPERTY DAMAGE AND/OR

MODERATE PERSONAL INJURY.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the ground

lug provided in the enclosure to avoid potential safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAIL-

URE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 9

9

1.12.4

Analog Inputs with External Power

The following steps describe the general procedure

for rewiring an analog input sensor when the sensor's

power source is not the Technologic 5500 controller.

1) Turn off all power to the Technologic 5500 controller.

2) Refer to the appropriate controller wiring diagram

that was shipped with unit. Locate the analog

input sensors on the wiring diagram that will be

rewired. They are labeled AI X.

3) Remove the 24 VDC positive (+) wire from TB 40

for the respective analog input sensor connection.

This wire needs to be removed completely or terminated if used as a jumper. This will prevent any

accidental contact with a negative (-) voltage

source (i.e. control panel) and avoid becoming a

short circuit. Care should be taken to ensure that

24 VDC positive (+) voltage is still provided to any

remaining sensors that will be powered by the

Technologic 5500 controller.

4) Remove the 24 VDC negative (-) wire from TB 41

for the respective analog input sensor connection.

This wire needs to be removed completely or terminated if used as a jumper. This will prevent any

accidental contact with a positive (+) voltage

source and avoid becoming a short circuit. Care

should be taken to ensure that 24 VDC (-) negative

voltage is still provided to any remaining sensors

that will still be powered by the Technologic 5500

controller.

5) Terminate the negative (-) wire of the sensor to TB

41 of the respective analog input sensor connection. Terminate the positive (+) wire of the sensor

to the terminal block which is connected to the

positive (+) terminal shown on the Analog input

card.

NOTE: Be certain that the power supplied to other

terminal blocks has not been interrupted! The wires

that were removed in the preceding steps may have

been used as jumpers.

1.12.5 Drive Speed Signals

Drive speed (follower) signals must be wired from the

Technologic 5500 Controller to each of the adjustable

frequency drives. The AFDs must be configured to

accept a 0-10 VDC speed signal with the minimum

speed set for 30% (0 VDC) and maximum speed set

for 100% (10 VDC). All shields must be grounded,

only in the Technologic 5500, to prevent ground

loops and improper signals.

1.12.6

Valve

The Valve must be configured to accept a 4 - 20mA

signal with the closed position set for 4 mA and the

open position set for 20 mA. All shields must be

grounded, only in the Technologic 5500, to prevent

ground loops and improper signals.

1.12.7

Hardwire Communications

Hardwire communications refers to the capability of

the Technologic 5500 Controller to communicate with

an energy management system. Standard communication features such as remote start/stop and remote

alarm indications are listed below.

1.12.7.1

Remote Start/Stop

Install a switch as indicated on the wiring diagram.

With the LOCAL-REMOTE-OFF switch in the

REMOTE position, this contact closure will provide

the start signal.

1.12.7.2

Remote Alarm Indication

A digital output rated 8 amps at 115V is supplied.

This output closes to indicate an alarm condition

exists.

1.12.8

User Configurable I/O

The Technologic 5500 Controller comes equipped

with the capability to define the operation of any

unused input or output signal. Refer to Section 4.3.9

for detailed information on the I/O Setup Menu.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAIL-

URE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Section 2 - Installation and Startup

2.1 Location

Install the pumping unit appropriately for ease of

inspection, maintenance and service. Observe local

electrical codes concerning control panel spacing.

2.2

Installation of Skid Mounted Systems with

Factory Supplied Pumps

This unit is built to give you years of service if it is

installed properly with a suitable foundation.

2.2.1

Foundation

A base of concrete weighing 2-1/2 times the weight

of the unit is recommended. Check the shipping

ticket for unit weight. Tie the concrete pad in with

the finished floor. Use foundation bolts and larger

pipe sleeves to give room for final bolt location.

Place the unit on its concrete foundation, supporting

it with steel wedges or shims totaling 1" in thickness.

These wedges or shims should be put on both sides

of each anchor-bolt to provide a means of leveling

the base.

DANGER: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by the motor eyebolts. Lift

the unit with slings placed under the unit base rails.

FAIL-

URE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 10

10

2.2.2

Grout

After the frame has been leveled and securely bolted

to the pad, a good grade of grout should be installed

beneath the base. A suggested mixture for grout is:

one part Portland Cement and two or three parts

plain, sharp sand mixed with water until it will pour

easily. Commercial grout mixtures with suspended

iron particles are available. Wet the concrete base

before pouring grout. To hold wedges or shims in

place, allow the grout to flow around them and

beneath the entire length of the base flange.

2.2.3

Closed System Safety Measures

Important:

Do not install and operate the Bell &

Gossett Technologic 5500 Variable Primary pump

and valve controller in a closed system unless the

system is constructed with properly sized safety and

control devices. Such devices include the use of

properly sized and located pressure relief valves,

compression tanks, pressure controls, temperature

controls and flow controls as appropriate. If the system does not include these devices, consult the

responsible engineer or architect before making

pumps operational.

2.2.4 Eccentric Increasers

Eccentric increasers can be used in the suction lines

when increasing the pipe size, with straight sides of

the increaser on top to eliminate air pockets.

2.2.5

Pipe Support

Be sure to eliminate any pipe strain on the unit.

Support the suction and discharge pipes independently by use of pipe hangers near the unit. Line up

the vertical and horizontal piping so that the bolt

holes of the flanges match. DO NOT ATTEMPT TO

SPRING THE SUCTION OR DISCHARGE LINES

INTO POSITION. As a rule, ordinary wire or band

hangers are not adequate to maintain alignment. It is

very important to provide a strong, rigid support for

the suction line. A saddle hanger is recommended.

2.2.6

Expansion and Vibration Absorbtion

For critical installations, equipment for absorbing

expansion and vibration should be installed in the

inlet and outlet connections of the unit.

2.2.7

Lubrication

Before starting, all pumps and motors should be

checked for proper lubrication.

2.3

Putting the Unit into Service

2.3.1 Pump Rotation, 3 Phase Motors Only

It will be necessary to check for proper rotation for all

pumps in both variable speed and bypass. Run each

pump in AUTO and then in BYPASS, if so equipped,

and note the rotation in each.

If both rotations (AFD and bypass) are wrong, exchange the wiring on two motor phases. If the rotation is incorrect in the AFD mode, but it is correct in

the bypass mode, exchange the wiring on two of the

AFD output phases.

If the rotation is correct in the AFD mode, but it is

incorrect in the bypass mode, exchange the wiring on

two of the bypass input phases.

NOTE: Changing phase at AFD input does not change

output phasing.

2.3.2

Joint Check

While the unit may be hydro tested at the factory to

internal quality standards, there may be some joints

that are not pressure tested. Some joints may have

been loosened, to allow for draining of the system,

and not retightened. Thus, some joints may be loose

due to system drainage or shocks during the shipping process. All flanged joints are to be checked for

tightness and proper torque of the flange bolts prior

to filling the system with fluid.

DANGER: The heating of water and other fluids

causes volumetric expansion. The associated forces

may cause failure of system components and releases of

high temperature fluids. This will be prevented by installing

properly sized and located pressure relief valves and compression tanks.

FAILURE TO FOLLOW THESE INSTRUC-

TIONS CAN RESULT IN SERIOUS PROPERTY DAMAGE

AND SERIOUS PERSONAL INJURY OR DEATH.

CAUTION: Seal Damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation.

FAILURE TO FOLLOW THESE INSTRUC-

TIONS COULD RESULT IN PROPERTY DAMAGE

AND/OR MODERATE PERSONAL INJURY.

WARNING: Rotating shafts can catch loose clothing.

Do not operate the pump without all guards in place.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: Failure to check all joints for tightness

and all flange bolts for proper torque could result in

leaks and/or flooding.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

DANGER: High voltage 3 phase power can kill. Dis-

connect and lockout power prior to servicing unit.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 11

11

3.1

Power-up

Put LOCAL-REMOTE-OFF (LRO) switch in the

LOCAL position. Put the optional AUTO-OFF-HAND

switch in the AUTO position.

Turn main disconnect on.

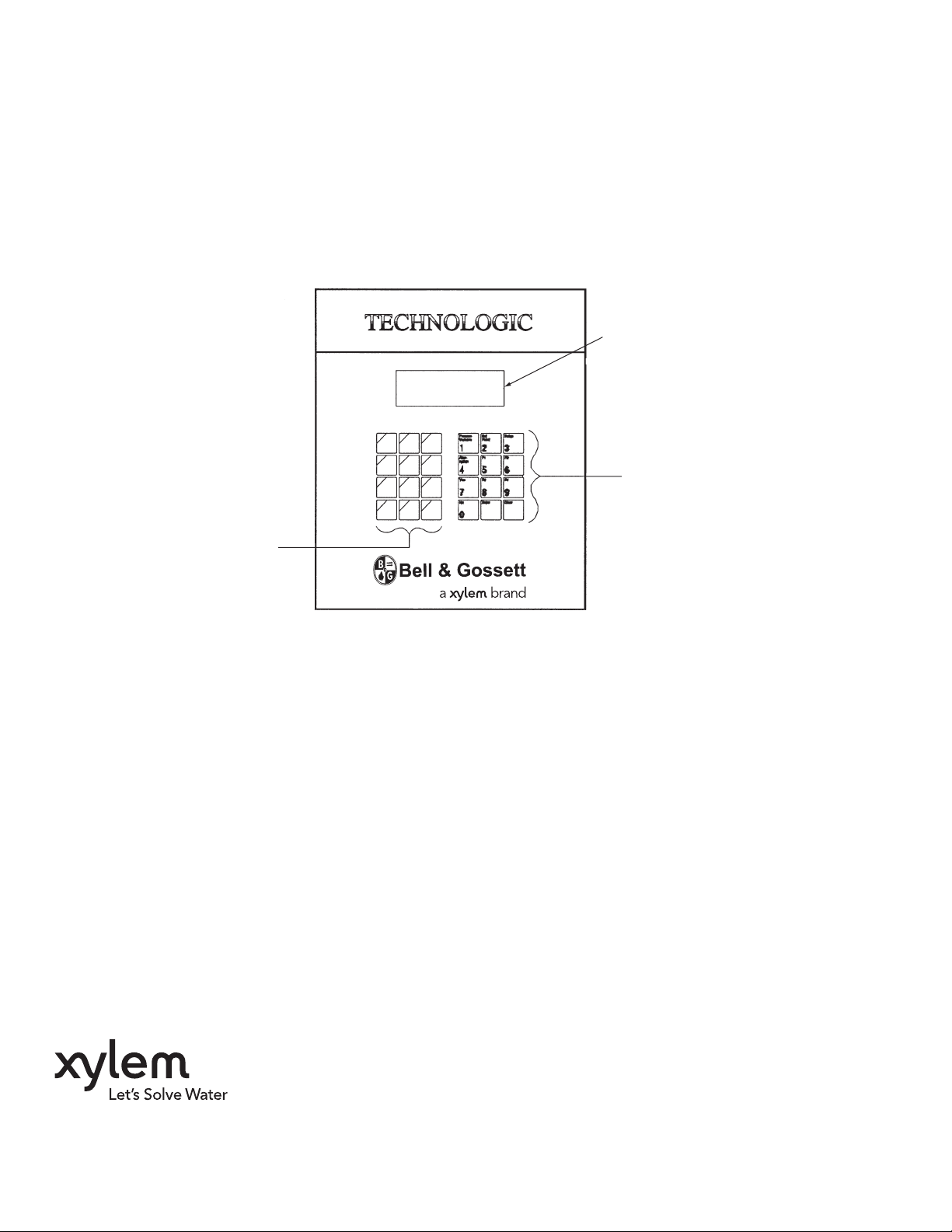

3.2

Technologic Pump Controller Screen

Upon powering up the controller, the display will light

and show the Technologic Variable Primary Pump

and Valve Controller default screen shown below:

Technologic Pump

Controller

MM/DD/YY HH:MM:SS A/P

Normal Manual

The current date and time will be displayed on the

third line.

3.3

Key Functionality

The names of the keys on the Operator Interface

Panel (OIP) are shown as CAPITAL LETTERS in this

manual. Table 1 shows the functionality of the keys

on the OIP.

3.4 LEDs

The START-STOP LED will be flashing. If the START-

STOP LED is not illuminated as described above,

press the START-STOP button once to light the LED.

The Auto-Manual LED should be green for auto operation. The display should also indicate MANUAL in

the lower right hand corner. If not, press the AUTOHAND key to enter the operation mode menu, press

the SET POINT/2 key, then the ENTER key to select

manual operation.

The PREV. SCREEN and NEXT SCREEN LEDs flash

when the keys can be used to navigate to neighboring screens.

The HELP LED flashes when HELP can be pressed to

obtain information.

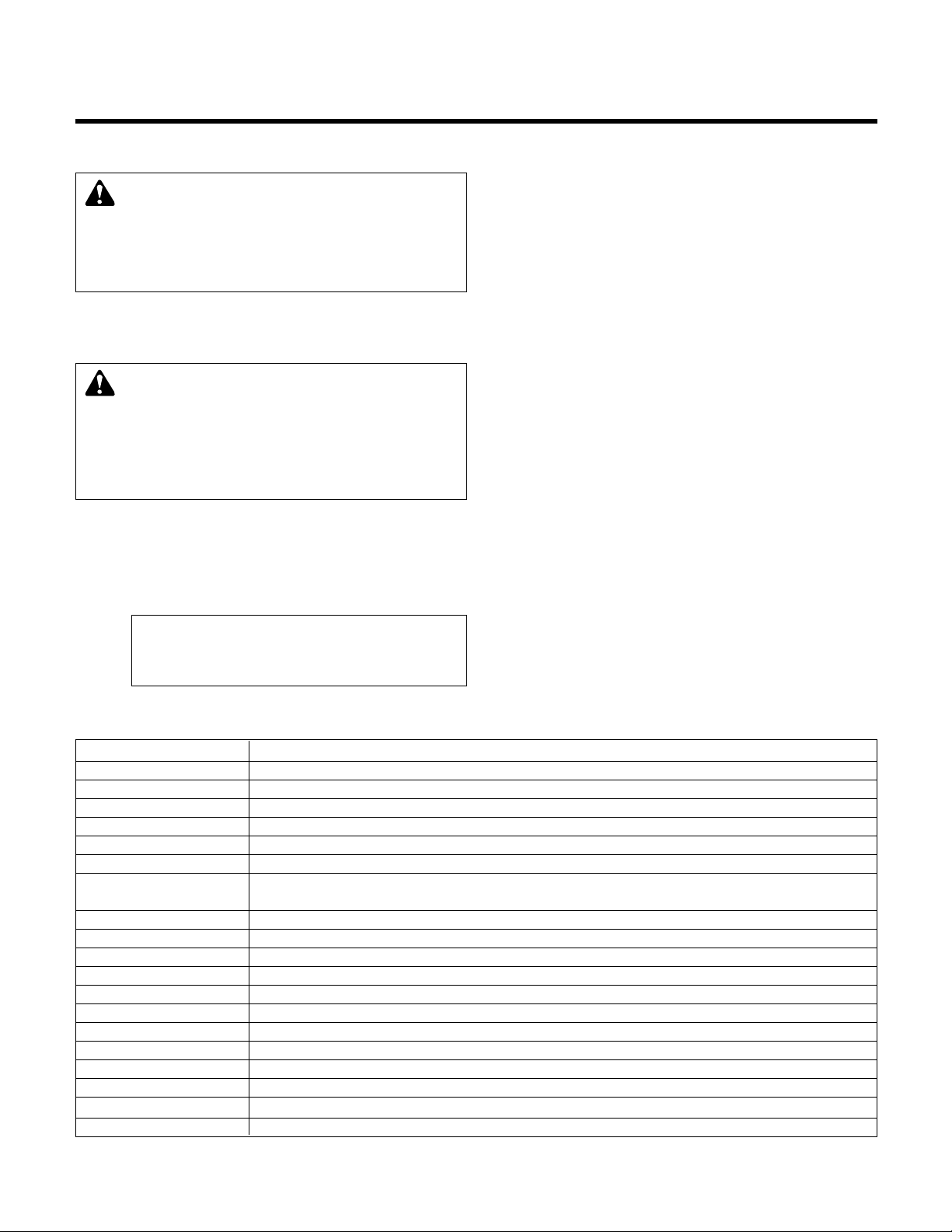

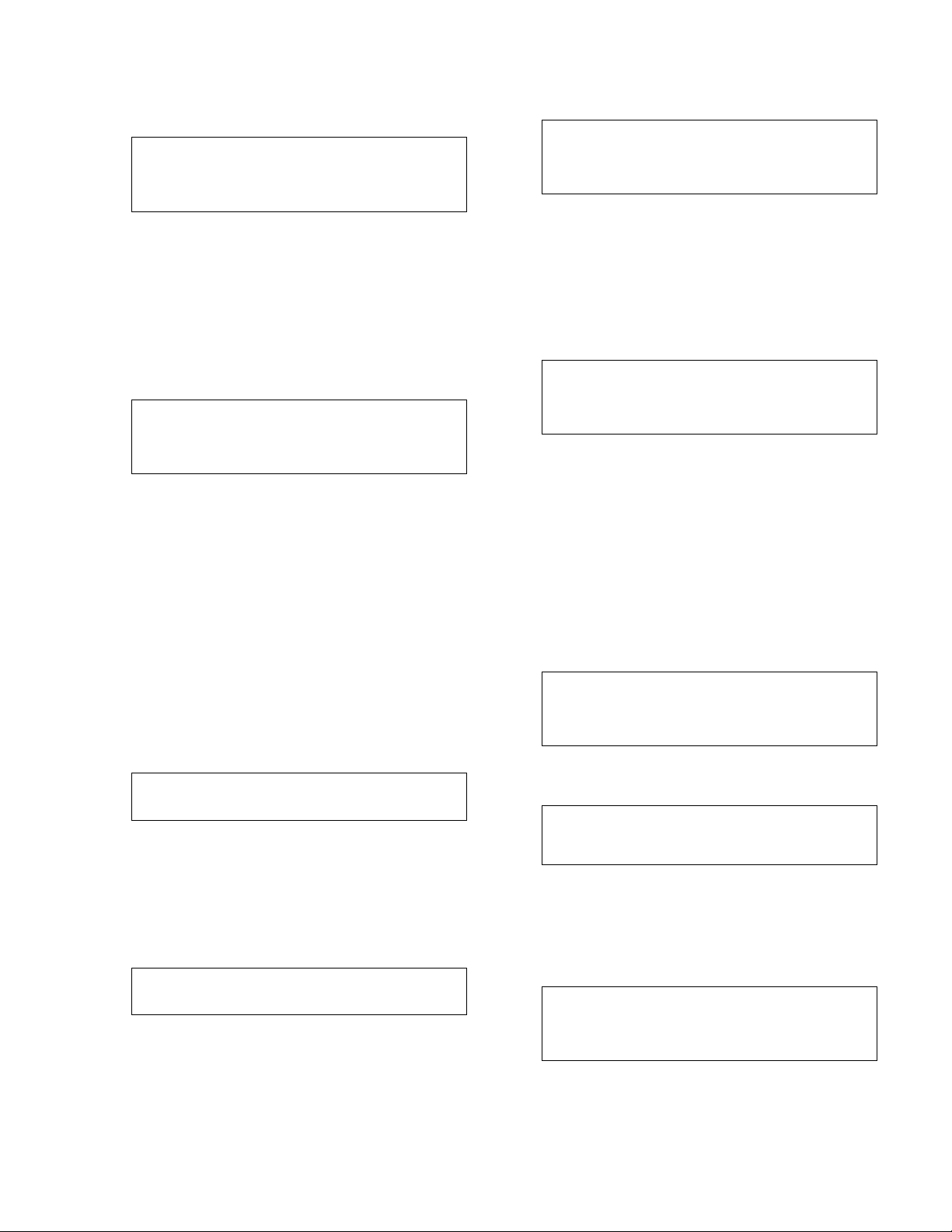

Section 3 - Operator Interface

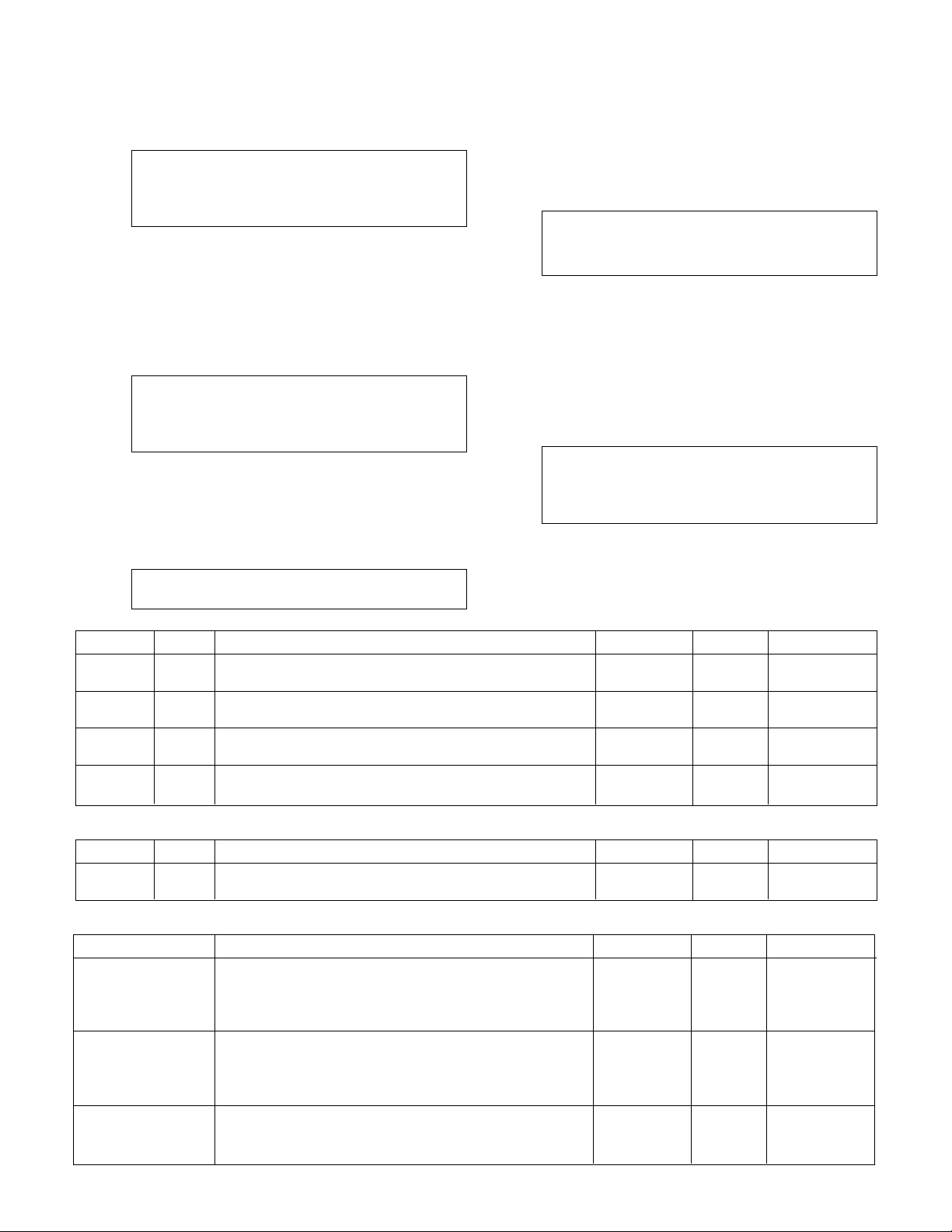

Key Name Functionality

Start/Stop Starts and Stops System

Reset Resets System

Auto/Manual Brings up the Operation Mode screen shown in section 5.5

Pump 1-6 On/Off Turns the corresponding Pump on or off

PREV. SCREEN navigates to neighboring screens if its green led is flashing

NEXT SCREEN navigates to neighboring screens if its green led is flashing

HELP gives details on alarm conditions (see section 5.11) / if used in conjunction with a function key it

will give a detailed explanation of the function key application

PROCESS VARIABLE/1 Brings up the Process Variable screen, shown in section 5.9, or used as a numeric key

SET POINT/2 Brings up the Set Point screen, shown in section 5.8, or used as a numeric key

SETUP/3 Brings up the Setup screen, shown in section 4, or used as a numeric key

ALTERNATION/4 Brings up the Alternation screen, shown in section 5.10, or used as a numeric key

F1/LOG/5 Brings up the Log Menu, shown in section 6.13, or used as a numeric key

F2/6 Used as a numeric key or an up arrow for manual control of pumps or bypass valve

YES/7 Used as a numeric key or YES

F3/INFO/8 Shows controller information screen, shown in section 6.12, or used as a numeric key

F4/9 Used as a numeric key or a down arrow for manual control of pumps or bypass valve

NO/0 Used as a numeric key or NO

ENTER Used to confirm entries and to advance to the next item if there are multiple entries

CLEAR Used to clear entries and to exit some screens

Table 1: Key Functionality

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUC-

TIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Electrical shock hazard. Multiple power

sources. The off position of the LOCAL-REMOTEOFF switch does not disconnect all of the power sources in

the technologic panel. All power sources must be disconnected prior to entering the control panel.

FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

Page 12

From the Technologic Pump Controller screen,

shown in section 3.2, press the SETUP/3 key to get

to the Setup Selection Menu shown below.

Setup Selection: 0

1 = Sensors 4 = Test

2 = Pumps 5 = Default

3 = System 0 = Exit

Press the NEXT SCREEN key to view the neighboring

page, which is shown below. Press PREV. SCREEN

to return to the screen shown above.

Setup Selection: 0

6 = Chillers

7 = Bypass Valve

0 = Exit

Press the numeric key that corresponds to the

desired Setup Menu and then press ENTER.

4.1

Sensors

From the Setup Selection Menu, shown in section 4,

press PROCESS VARIABLE/1 and ENTER, to get to

the Sensors screens.

4.1.1

Sensor Number

The first of the Sensors screens is the Sensor Number

screen. The display will show:

Sensor No: #

Press the numeric key(s) for the sensor you wish to

setup. The sensor number is limited to the maximum

number of sensors allowed, typically 16. Press the

ENTER key to proceed.

4.1.2 Edit/Copy

After entering the sensor number, the display will show:

Sensor No: #

1 - Edit 2 - Copy : #

0 - Exit

Press PROCESS VARIABLE/1 and then the ENTER

key to edit the sensor setup. See section 4.1.3.

Press SET POINT/2 and then the ENTER key to copy

from an existing sensor. See section 4.1.13.

4.1.3

Sensor Edit

If 1-Edit was selected in section 4.1.2, the display will

show:

Sensor No ## (Type)

Span = 0 Zero = 0

*PV:Y/N *Set Point No: #

*Override:Y/N Ok ? (Y/N)

*PV, Set Point No, and Override will only appear if

the sensor was previously set up to be a process

variable.

Press YES/7 and then ENTER to accept these values,

and proceed to section 4.1.4. Press NO/0 and

ENTER to modify these values, and skip to section

4.1.5.

4.1.4

Do Another

If YES/7 was selected in the Sensor Edit Menu,

shown in section 4.1.3, the display will show:

DO ANOTHER ? (Y/N)

Press YES/7 and then ENTER to set up another sen-

sor, or press NO/0 and ENTER to return to the Setup

Selection Menu shown in section 4.

4.1.5

Sensor Type

If NO/0 was selected in the Sensor Edit Menu, shown

in section 4.1.3, the following is displayed:

No: ## Sensor Type: #

1 = DP, 2 = PR, 3 = Flow

4=KW, 5 = Temp, 6 = DT

7 = SyDp, 8 = SyKW, 0 = None

To view the neighboring screen, Press the NEXT

SCREEN key. The following will be displayed:

No: ## Sensor Type: #

9 = Chi Flow, 10 = Chi DP

11=S Temp, 12 = R Temp

13 = Bep V Fb, 0 = None

Table 2, shown on next page, gives a description and

the units of each sensor type.

Enter the numeric key followed by ENTER for the

type of sensor you are setting up. The abbreviation

for the sensor type will appear in the upper right corner of the display in the following screens.

*If the sensor type is Chi Flow or Chi DP, then see

section 4.1.14.

4.1.6

Sensor Span

The display will now show the selected sensor type

and prompt the user for the sensor span as shown

below.

Sensor No ## (Type)

Span = #####

Obtain the span of the sensor from the nameplate on

the sensor. Enter the span by pressing the appropriate numeric keys followed by the ENTER key.

4.1.7 Sensor Zero

The display will now prompt the user for the zero of

the sensor as follows:

Sensor No ## (Type)

Span = ##### Zero = #####

12

Section 4 - Setup Selection Menu

Page 13

13

Typically the variable value is zero at 4mA for many

sensors. An exception would be for a temperature

sensor. Enter the desired zero value by pressing the

appropriate numeric keys followed by the ENTER

key.

4.1.8

Sensor PV

The display will now show the following:

Sensor No ## (Type)

Span = ##### Zero = #####

PV: ? (Y/N)

Press the YES/7 key if the selected sensor will con-

trol the system by supplying a process variable feedback signal. Typical process variable signals are

supplied by one of the following: Pressure, Differential Pressure, Temperature, or Differential Temperature sensors. Continue to section 4.1.9

Press the NO/0 key for all sensors that supply optional signals. Typical optional signals are supplied by

any of the following: System Differential Pressure,

System Differential Temperature, Flow, and KW

Sensors. If NO/0 was selected, skip to section 4.1.12.

4.1.9

Sensor Set Point

If YES was selected in section 4.1.8, the display will

now prompt the user for a Set Point NO as shown

below.

Sensor No ## (Type)

Span = ##### Zero = #####

PV: Y Set Point No: ##

Enter a setpoint number by using the numeric key-

pad. See section 5.8 for more information on how to

modify setpoints.

4.1.10

Sensor Override

The display will now show:

Sensor No ## (Type)

Span = # Zero = #

PV: Y/N Set Point No: ##

Override: Y/N

The controller is capable of accepting sensor input

either through a 4-20mA analog input or through the

RS-485 communication port. The communication

port must be set up properly and connected to an

external building automation system.

Press the YES/7 key to receive the sensor signals via

the RS-485 port. Press the ENTER key.

Press the NO/0 key to receive the sensor signals via

the analog input card. Press the ENTER key

4.1.11

Sensor Setup Exit

The display will now show:

Sensor No ## (Type)

Span = # Zero = #

PV: Y/N Set Point No: ##

Override: Y/N Ok? (Y/N)

If correct, record your sensor setup information on

the wiring diagram that was included with the unit.

Press YES/7 and then ENTER to accept all of the

values shown and return to section 4.1.4.

Press NO/0 and ENTER to return to section 4.1.5 and

modify the sensor.

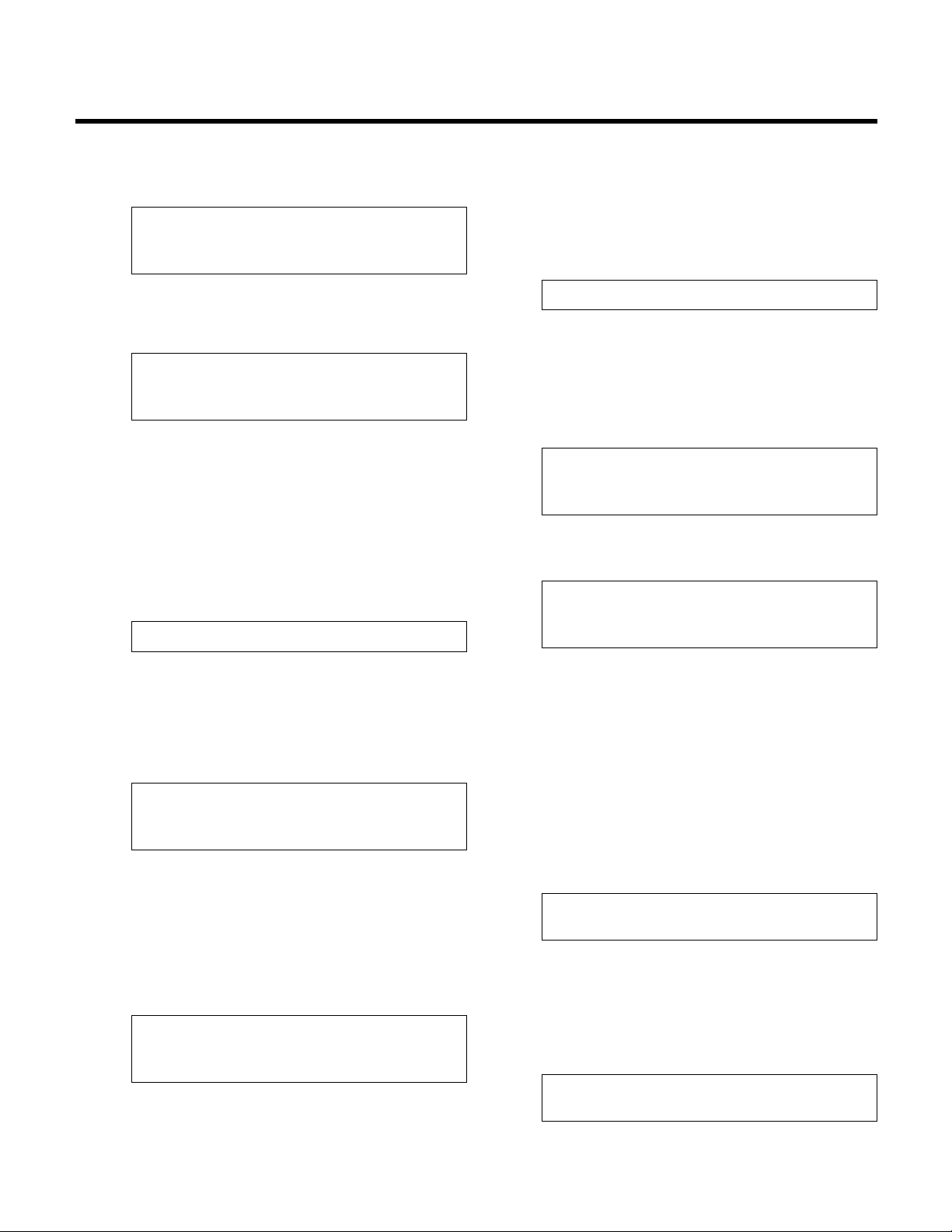

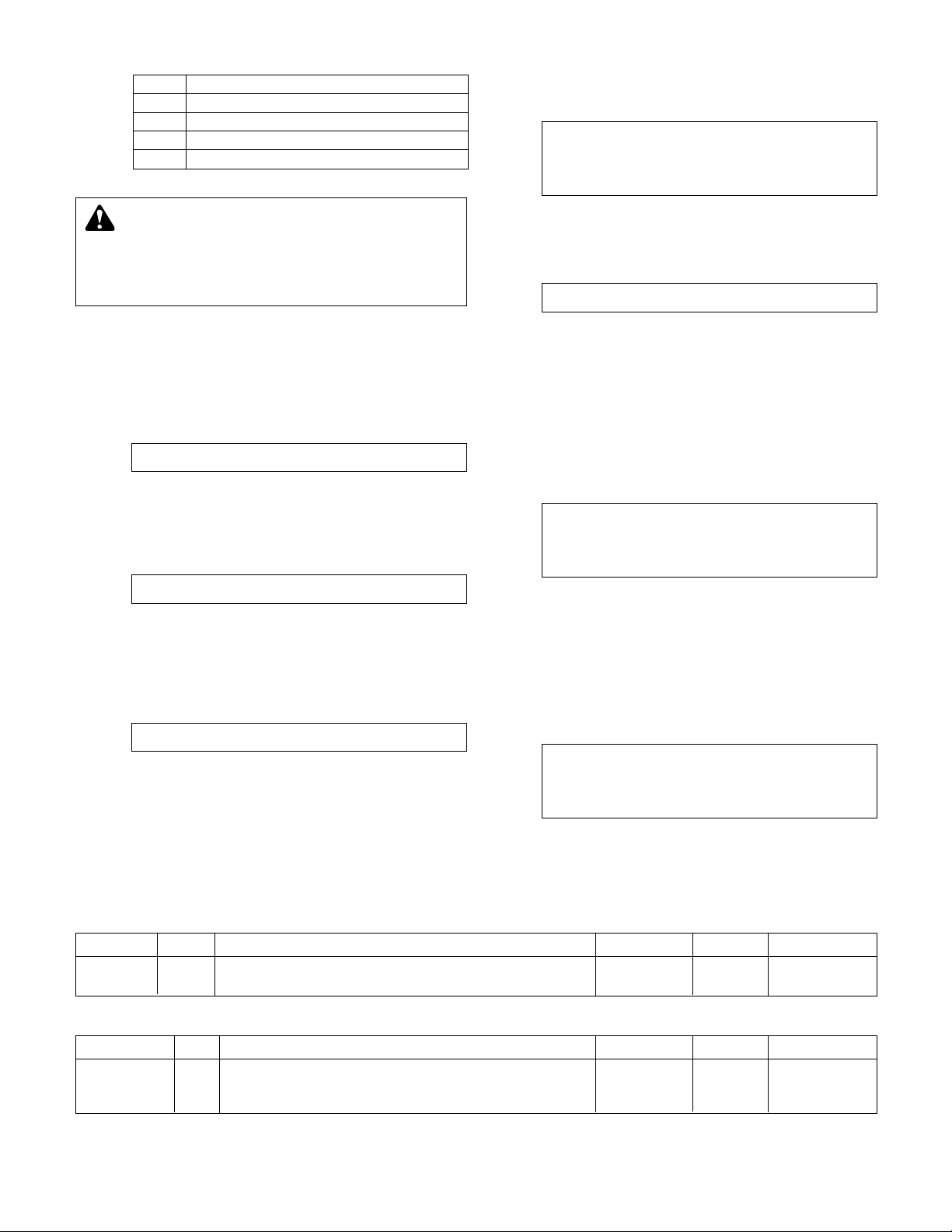

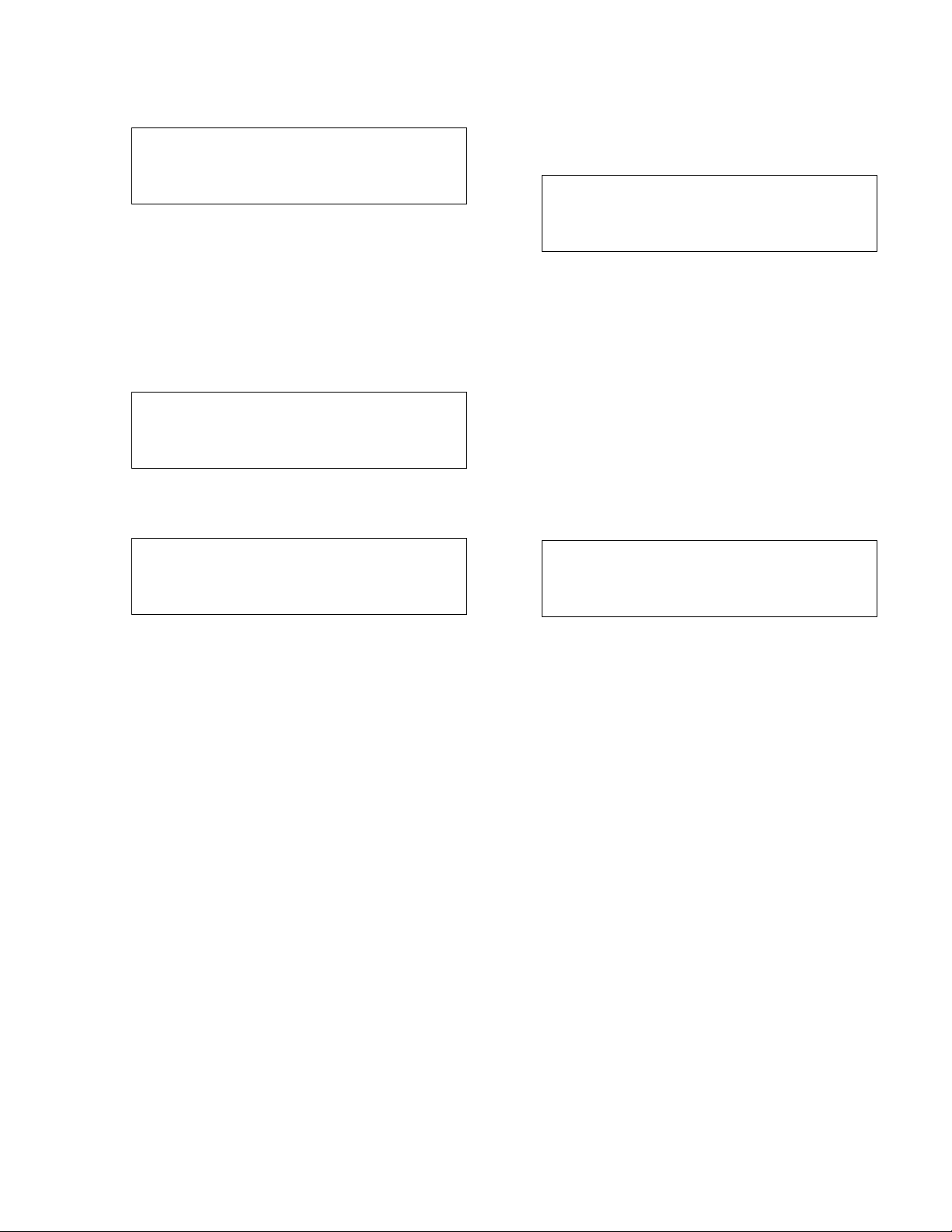

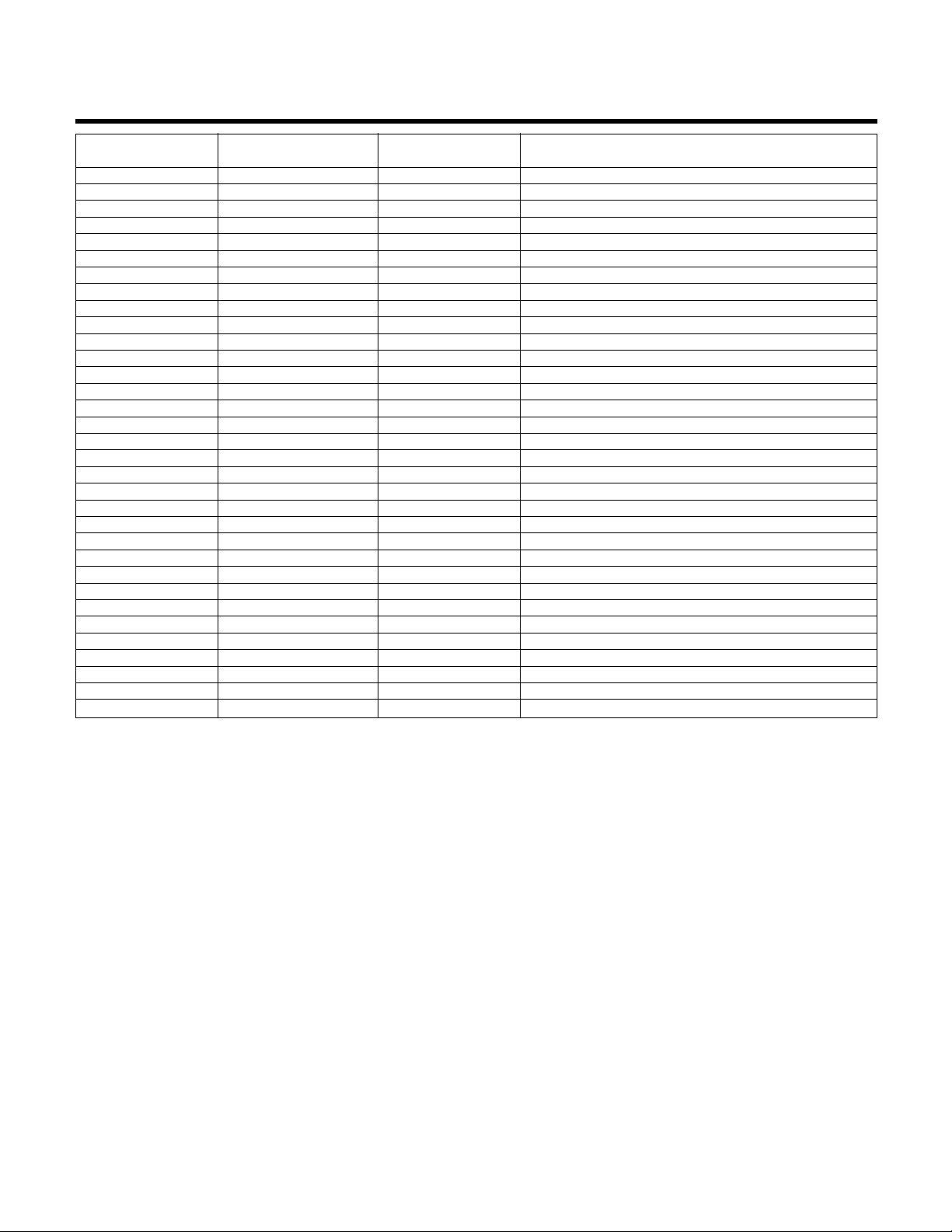

Selection Description Units

1=DP Differential Pressure PSID

2=PR Pressure PSI

3=Flow Flow Rate GPM

4=KW Power, from each AFD, totalized in controller. KW

5=Temp Temperature °F

6=Delta T Differential Temperature °F

7=SysDP System Differential Pressure PSID

8=SysKW System Power, from KW transmitter at single point power connection KW

*9=Chi Flow Chiller Flow GPM

*10=Chi DP Chiller Differential Pressure PSID

11=S Temp System Temperature °F

12=R Temp Return Temperature °F

13=BYP V FB Bypass Valve Feedback %

0=None Non-standard transmitter N/A

Table 2: Sensor Types

Page 14

14

4.1.12

Sensor Setup Exit (not PV)

If NO/0 was selected in section 4.1.8 (the sensor

does not provide a PV), the display will show:

Sensor No ## (Type)

Span= # Zero= #

Ok? (Y/N)

If correct, record your sensor setup information on

the wiring diagram that was included with the unit.

Press YES/7 and then ENTER to accept all of the

values shown and return to section 4.1.4.

Press NO/0 and ENTER to return to section 4.1.5 and

modify the sensor.

4.1.13

Copy Sensor

If 2-Copy was selected in section 4.1.2, the display

will show:

Copy to Sensor No: #

From Sensor No: #

Copy? (Y/N)

Exit? (Y/N)

The Copy to Sensor No refers to the sensor number

for which the setup is being performed. The

From

Sensor No

refers to the sensor from which the infor-

mation will be copied.

Select NO/0 and ENTER, in the

Exit field, to modify

the variables. In the

From Sensor No field, enter the

numeric value of the sensor from which you want to

copy. In the

Copy field, press YES/7 and ENTER to

confirm copying. In the Exit field, press YES/7 and

ENTER to exit. Proceed with section 4.1.11 if the

sensor will provide a PV, and proceed to section

4.1.12 if the sensor will not provide a PV.

4.1.14 Chiller Sensor Span

If 9 = Chi Flow or 10 = Chi DP was selected for the

sensor type in section 4.1.5, then the display will

show:

Sensor No ## (Type)

Span = #####

The span is the sensor value that corresponds to a

20mA signal. Obtain the span of the sensor from the

nameplate on the sensor. Enter the span by pressing

the appropriate numeric keys followed by the ENTER

key.

4.1.15

Chiller Sensor Zero

The display will show:

Sensor No ## (Type)

Span = ##### Zero = #####

The zero is the sensor value that corresponds to a

4mA signal. Typically the variable value is zero at

4mA for many sensors. An exception would be for a

temperature sensor. Enter the desired zero value by

pressing the appropriate numeric keys followed by

the ENTER key.

4.1.16

Chiller Number

The display will show:

Enter the Chiller

No ##

OK ? (Y/N)

Press NO/0 and ENTER to edit the chiller number.

Press the numeric key and ENTER for the chiller you

wish to set up. The chiller number is limited to the

maximum number of chillers allowed, typically 9.

Press YES/7 and ENTER keys to proceed with the set

up.

4.1.17

Chiller Sensor Exit

The display will now show:

Sensor No ## (Type)

Span = ##### Zero = #####

Chill No. #

Ok ? (Y/N)

If correct, record your chiller setup information on the

wiring diagram that was included with the unit. Press

YES/7 and ENTER to accept the values and return to

section 4.1.4.

Press NO/0 and ENTER to return to section 4.1.5 to

modify the sensor.

4.2

Pump Setup Menu

From the Setup Selection Menu, shown in section 4,

Press SETPOINT/2 and ENTER to get to the Pump

Setup Menu shown below. Record your pump setup

information on the wiring diagram that was included

with the unit.

Selection: # 0 = Exit

1 = Enable/Disable

2 = Pump Off Delay

3 = Lag Pump Run Timer

To view the neighboring screen, press the NEXT

SCREEN key. The following will be displayed:

Selection: # 0 = Exit

4 = Hi Load Transfer

5 = Lo Load Transfer

Push the desired numeric key and ENTER to proceed.

4.2.1

Enable/Disable

From the Pump Setup Menu, shown in section 4.2,

Press PROCESS VARIABLE/1 and ENTER to get to

the Enable/Disable screen shown below.

# PUMPS = #

P1: * P2: * P3: *

P4: * P5: * P6: *

OK ? (Y/N)

*The pump status will be displayed for each defined

pump. Table 3, on the next page, shows the possible

pump states.

Page 15

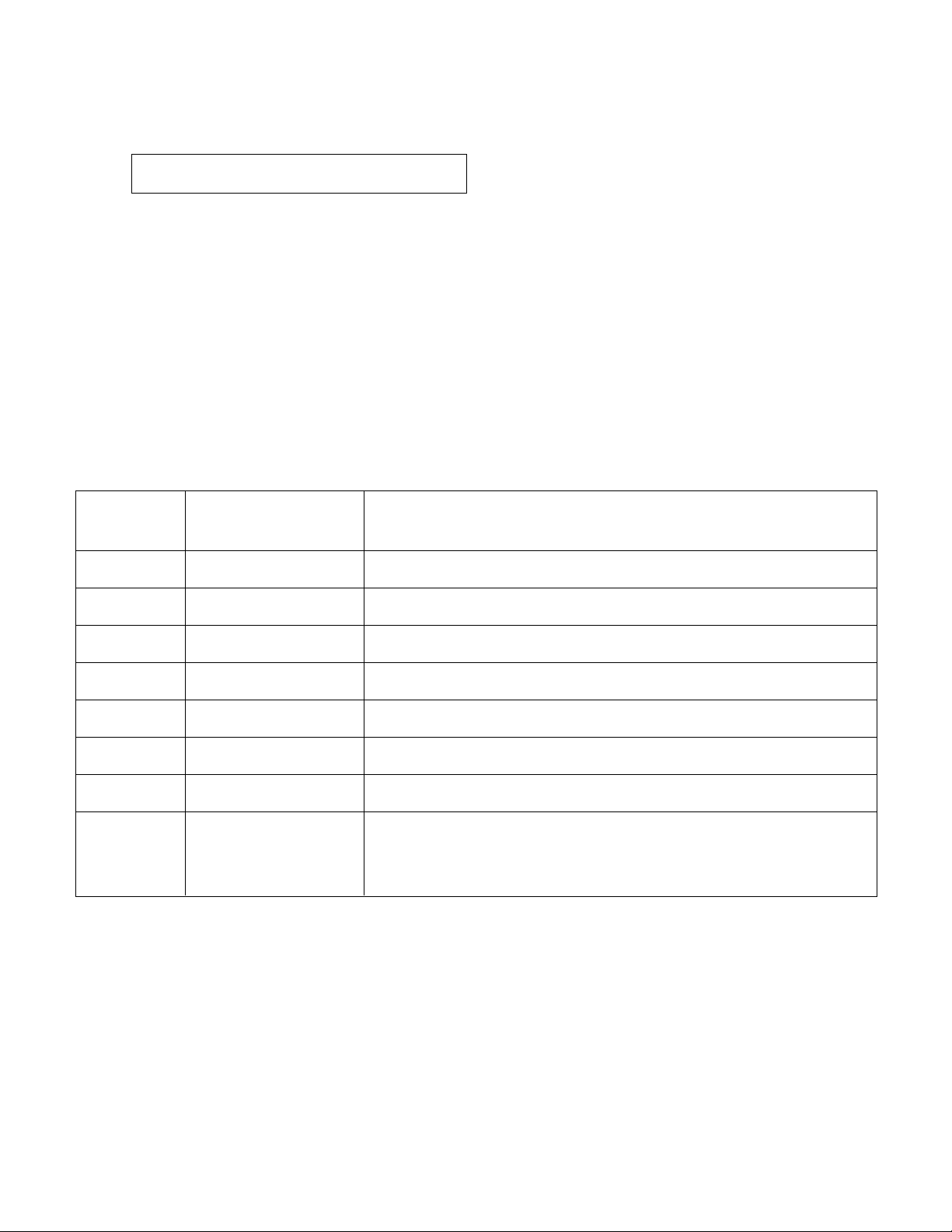

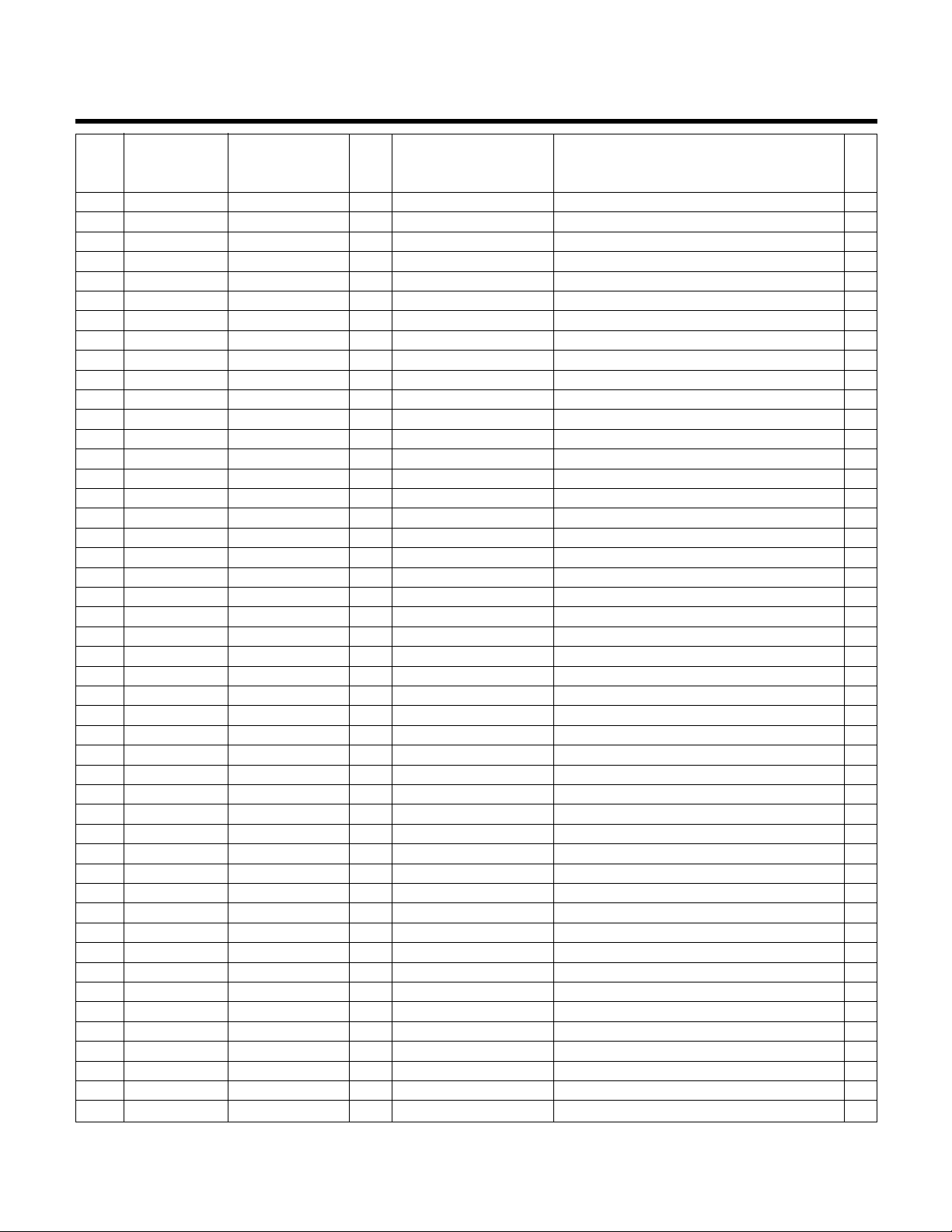

Table 4: Pump Off Delay Variables

15

State Description

N/A pump not available as defined by setup

Rdy pump available, not running

On pump is running

Off pump disabled, will not be allowed to start

Table 3: Pump States

Press YES/7 and ENTER to accept pump configura-

tion and return to setup selection screen.

Press NO/0 and ENTER to setup any pumps.

4.2.2

Number of Pumps

If NO was selected in section 4.2.1, the following

displayed:

Total # Pumps = #

Press the numeric key for the total number of pump

(1 to 6 pumps). Press ENTER to continue.

4.2.3

Edit Pump

The display will now show the following:

Edit Pump ? (Y/N)

Press YES/7 and ENTER to set up any pumps. Press

the NO/0 and ENTER keys to return to the Pump

Setup Menu shown in section 4.2.

4.2.4 Edit Pump Number

The display will now show the following:

Edit Pump # #

Press the numeric key(s) for the pump you wish to

setup. The pump number is limited to the maximum

numbers of pumps. Press the ENTER key to proceed

with the setup.

4.2.5

Enable/Disable Pump

The display will now show the following:

Pump # #

Enable/Disable: #

1 = Enable 0 = Disable

Press PROCESS VARIABLE/1 and ENTER to enable

the pump. Press NO/0 to disable a pump.

4.2.6

Do Another

The screen will now display:

Do Another ? (Y/N)

Press YES/7 and ENTER to setup another pump.

Return to section 4.2.4 and repeat for all remaining

pumps.

Press NO/0 and ENTER to return to the Pump Setup

Menu, shown in section 4.2.

4.2.7

Pump Off Delay

From the Pump Setup Menu, shown in section 4.2,

press SET POINT/2 and ENTER to edit the pump off

time delay. The display will show:

Pump Off Time Delay

# Min.

Exit ? (Y/N)

Press NO/0 and ENTER to edit the value. Press

YES/7 and ENTER to return to the Pump Setup Menu

shown in section 4.2. See Table 4 for a description of

the Pump Off Time Delay. Note: This time delay only

applies to dedicated pump to chiller systems.

4.2.8

Lag Pump Run Timer

From section 4.2, press SETUP/3 and ENTER to edit

the lag pump run timer. The display will show:

Lag Pump Full Speed

Minimum run time

# Sec.

Exit ? (Y/N)

Press NO/0 and ENTER to edit the value. Press YES/7

and ENTER to return to section 4.2. See Table 5 for a

description of the variable. Note: This variable only

applies to dedicated pump to chiller systems.

Variable Unit Description Default Value Range Field Value

Pump off min The delay prior to turning a pump off after losing the 1 0-99

time delay chiller start signal.

Table 5: Lag Pump Run Timer Variable

Variable Unit Description Default Value Range Field Value

Lag pump s The amount of time a pump will run at full speed when 0 0-999

full speed an additional chiller is turned on. 0 disables this function.

min run time

DANGER: High voltage 3 phase power can kill.

Pumps can start automatically. Disconnect and lock-

out power prior to servicing pumps.

FAILURE TO FOL-

LOW THESE INSTRUCTIONS WILL RESULT IN SERIOUS

PERSONAL INJURY, DEATH, AND/OR PROPERTY

DAMAGE.

Page 16

16

4.2.9 Low Load Transfer

From section 4.2, press 4 and ENTER to get to the

Low Load Transfer screen shown below.

Low Load Transfer

Point ### % Speed

Enable?

Exit (Y/N)

See Table 6 for a description of the Low Load Trans-

fer variables.

4.2.10

High Load Transfer

From section 4.2, press 5 and ENTER to get to the

High Load Transfer screen shown below.

High Load Transfer

Point ### % Speed

Enable?

Exit (Y/N)

See Table 7 for a description of the HIgh Load Trans-

fer variables.

4.3

System Setup Menu

From the Setup Selection Menu, shown in section 4,

press the SETUP/3 key and ENTER to get to the

System Setup Menu shown below.

Selection: # 0 = Exit

1 = Stage/De-stage

2 = PID

3 - Alarms

Press NEXT SCREEN key or PREV. SCREEN to view

the neighboring pages in the System Setup Menu.

There are five screens in this menu. The remaining

screens are shown below.

Selection: # 0 = Exit

4 = Alternation

5 = Bypass

6 = AFD

Selection: # 0 = Exit

7 = Date/Time

8 = Password

9 = I/O Setup

Selection: # 0 = Exit

10 = Communication

11 = Special Functions

12 = Set Bright/Constr

Selection: # 0 = Exit

13 = Save to Flash

14 = Load from Flash

Use the appropriate numeric key to select the setup

menu desired, and press the ENTER key.

4.3.1

Stage/Destage Menu

From the System Setup Menu, shown in section 4.3,

press PROCESS VARIABLE/1 and ENTER to get to

the Stage/Destage Menu shown below.

Selection: #

1 = PV Stg 2 = PV Destg

3 = EOC Stg 4 = EOC Dest

0 = Exit

Press the appropriate numeric key and ENTER to

complete the setup, or press NO/0 to exit back to the

System Setup Menu, shown in section 4.3.

Note: No pump staging will occur on dedicated pump

to chiller systems.

4.3.1.1

PV Stage

From the Stage/Destage Menu, shown in section

4.3.1, press PROCESS VARIABLE/1 and ENTER to

get to the PV Stage screen shown below.

Stg Spd: ##%

Stg Proof Timer: ##s

Stab Timer: ##s

Ok ? (Y/N)

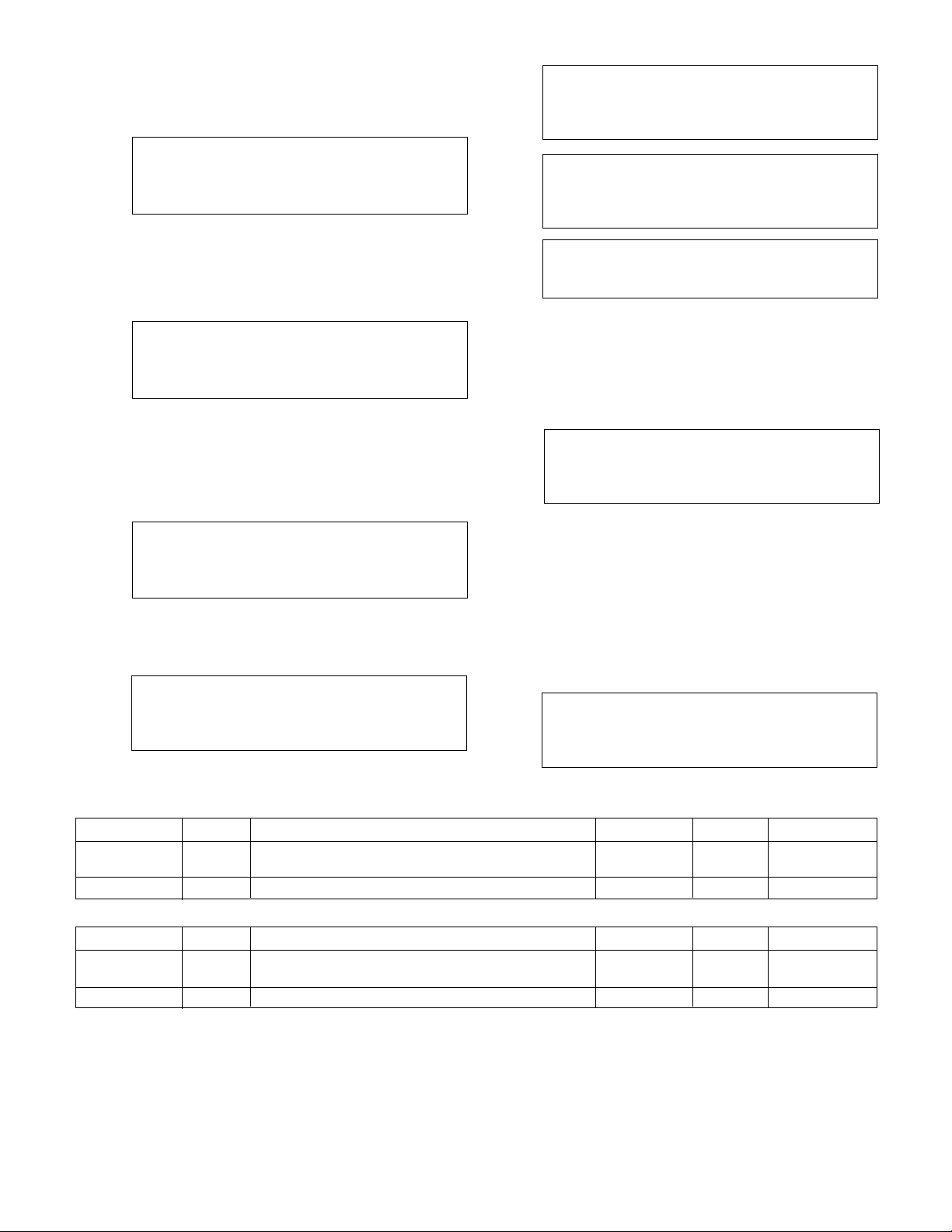

Table 6: Low Load Transfer Variables

Variable Unit Description Default Value Range Field Value

Low Load % Percentage of pump speed at which load will 0 0-100

Tranfer Point be transferred

Enable Select Y to enable or N to disable N Y/N

Variable Unit Description Default Value Range Field Value

High Load % Percentage of pump speed at which load will 0 0-100

Tranfer Point be transferred

Enable Select Y to enable or N to disable N Y/N

Table 7: High Load Transfer Variables

Page 17

17

Press NO/0 and ENTER to edit the fields. To return

to the Stage/Destage Menu, shown in section 4.3.1,

press YES/7 and ENTER. See Table 8 below for a

description of the PV Stage variables.

4.3.1.2

PV Destage

From the Stage/Destage Menu, shown in section

4.3.1, press SET POINT/2 and ENTER to get to the

PV Destage screen shown below.

Destage: ##%

Destg Pr Timer: ##s

HD Spd: ##%

HD Pr Tm: ##s Ok ? (Y/N)

To edit the fields, press NO/0 and ENTER. To return

to the Stage/Destage Menu, shown in section 4.3.1,

press YES/7 and ENTER. See Table 9 below for a

description of the PV Destage variables.

4.3.1.3

EOC Stage

From the Stage/Destage Menu, shown in section

4.3.1, press SETUP/3 and ENTER to get to the EOC

Stage screen shown below.

Pump Max Flow: #

Stage Proof Tm: ##s

Flow Offset: #

Ok ? (Y/N)

To edit the fields, press NO/0 and ENTER. To return

to the Stage/Destage Menu, shown in section 4.3.1,

press YES/7 and ENTER. See Table 10 below for a

description of the EOC Stage variables.

Variable Unit Description Default Value Range Field Value

Destage % Percentage of the stabilized speed at which the lag pump 85 0-100

will stop

Destg s Proof timer prior to stopping lag pump 30 0-999

Pr Timer

HD Spd % Lowest speed at which parallel pumps will operate prior 50 0-100

to destaging the lag pump

HD Pr Tm s Proof timer prior to destaging the lag pump when 30 0-999

operating below the HD speed

Table 9: PV Destage Variables

Variable Unit Description Default Value Range Field Value

Pump GPM Maximum flow allowable prior to starting a lag pump 0 0-9999

Max Flow

Stg Proof s Proof timer prior to end of curve staging 30 0-999

Tm

Flow GPM Flow rate of constant speed pump supplying variable 0 0-999

offset speed pump; input only required on series pumping

applications. The flow rate of the constant speed pump is

deducted from the total system flow rate in order to pro-

vide end of curve protection for the variable speed pump

Table 10: PV EOC Stage Variables

Variable Unit Description Default Value Range Field Value

Stg Spd % Maximum speed at which the lead pump will operate 95 0-100

prior to starting a lag pump

Stg Proof s Proof timer prior to starting lag pump 30 0-999

Timer

Stab s Staging stabilization time, delay prior to calculating 60 0-999

Timer destage value

Table 8: PV Stage Variables

Page 18

18

Variable Unit Description Default Value Range Field Value

AFD Fail s Proof timer prior to setting the AFD fail alarm 20 0-999

Pr Tm

Pump Fail s Proof timer prior to setting the pump fail alarm 30 0-999

Pr Tm

O.L. Fail s Proof timer prior to setting the O.L. fail alarm 3 0-999

Pr Tm

Reset Tm s Time delay between pressing the RESET key and 10 0-999

restarting the pumps in variable speed mode, allows

for pump deceleration

Table 13: Alarm Variables

4.3.1.4 EOC Destage

From the Stage/Destage Menu, shown in section

4.3.1, press ALTERNATION/4 and ENTER to get to

the EOC Destage screen shown below.

Destage Flow: ##%

Destage Pr Tm: ##s

Tm Forced Destg: #m

Ok ? (Y/N)

To edit the fields, press NO/0 and ENTER. To return

to the Stage/Destage Menu, shown in section 4.3.1,

press YES/7 and ENTER. See Table 11 below for a

description of the EOC Destage variables.

4.3.2

PID

From the System Setup Menu, shown in section 4.3,

press SETPOINT/2 and ENTER to get to the PID