INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Installation, Operation and Maintenance Instructions

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on the

ZoneSav Safety Instruction decal to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTION

MAY RESULT IN A SAFETY HAZARD!

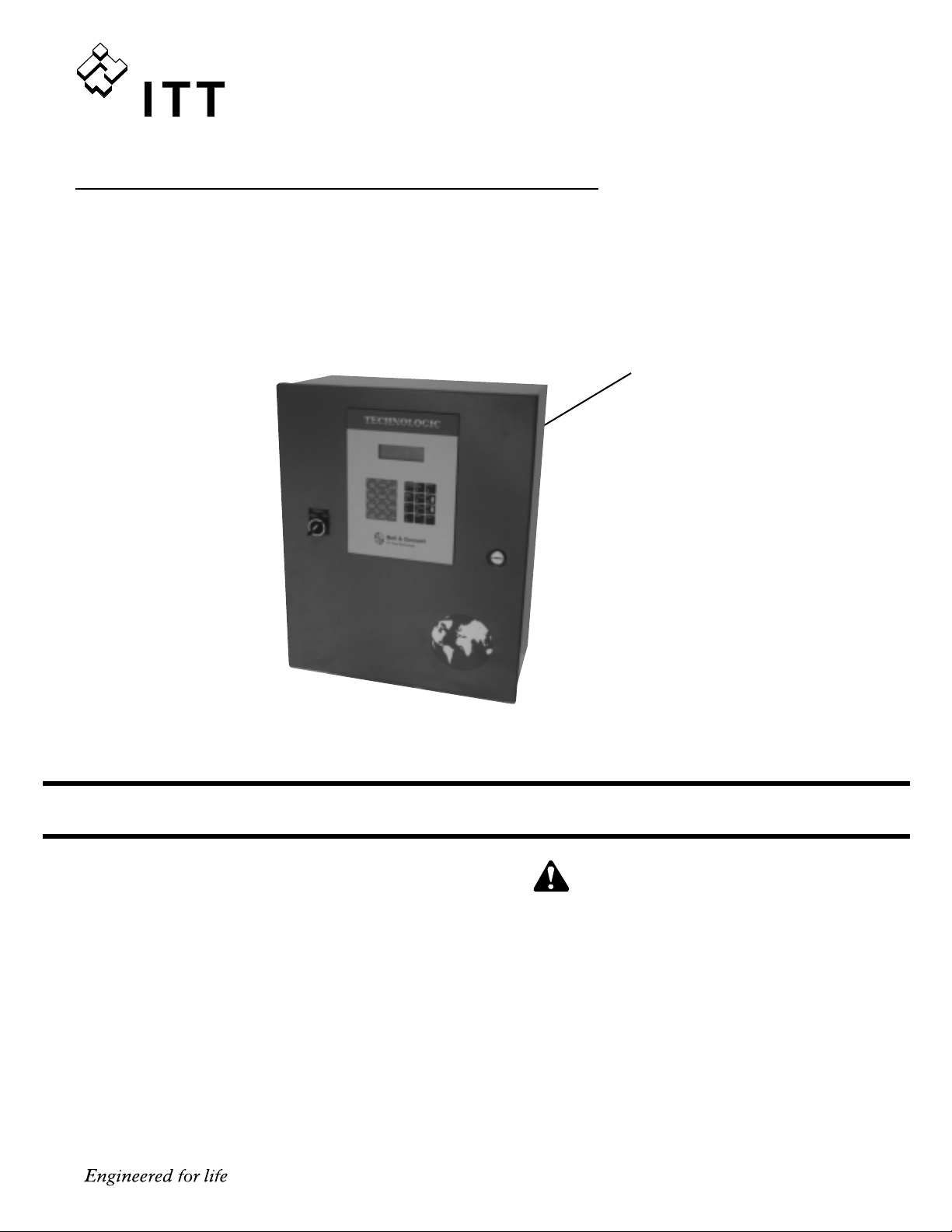

Technologic

™

5500 Series

ZoneSav Controller

WARNING LABEL PART #S11550

INSTALLED IN THIS LOCATION.

IF MISSING IT MUST BE REPLACED.

DESCRIPTION

Microprocessor based valve controller for HVAC systems.

The control panel consists of the following components:

microprocessor, operator interface with 4 line display and

membrane key pad, and 24 VDC power supply.

OPERATIONAL LIMITS

See the control panel nameplate for operating voltage, current

draw, as well as information on the equipment to be connected to the control panel.

VARIABLE SPEED PUMPING SYSTEMS

INSTRUCTION MANUAL

Bell & Gossett

Instruction Manual S14333

2

Preface

The following manual describes the microprocessor

based ZoneSav Controller. This unit is in the tradition

of the other members of the Technologic Control

Panels as it incorporates many original, novel, and

proprietary features that may only be found on B&G

controllers. Some of these features require special

emphasis here.

The controller is best described as a specific purpose

programmable valve controller. This means that the

hardware and software have been created for the control and diagnostics of valves with consideration for

their inherent characteristics. This results in an optimum valve controller without the cost of general purpose control hardware. Software is dedicated and

established for the unit only after extensive testing.

Changes to this software are not taken lightly and

must pass rigid version control.

The controller has the unique analog input protection

of other members of the control family. In the event of

a short circuit condition the current limit circuitry prevents failure of the analog input components.

3

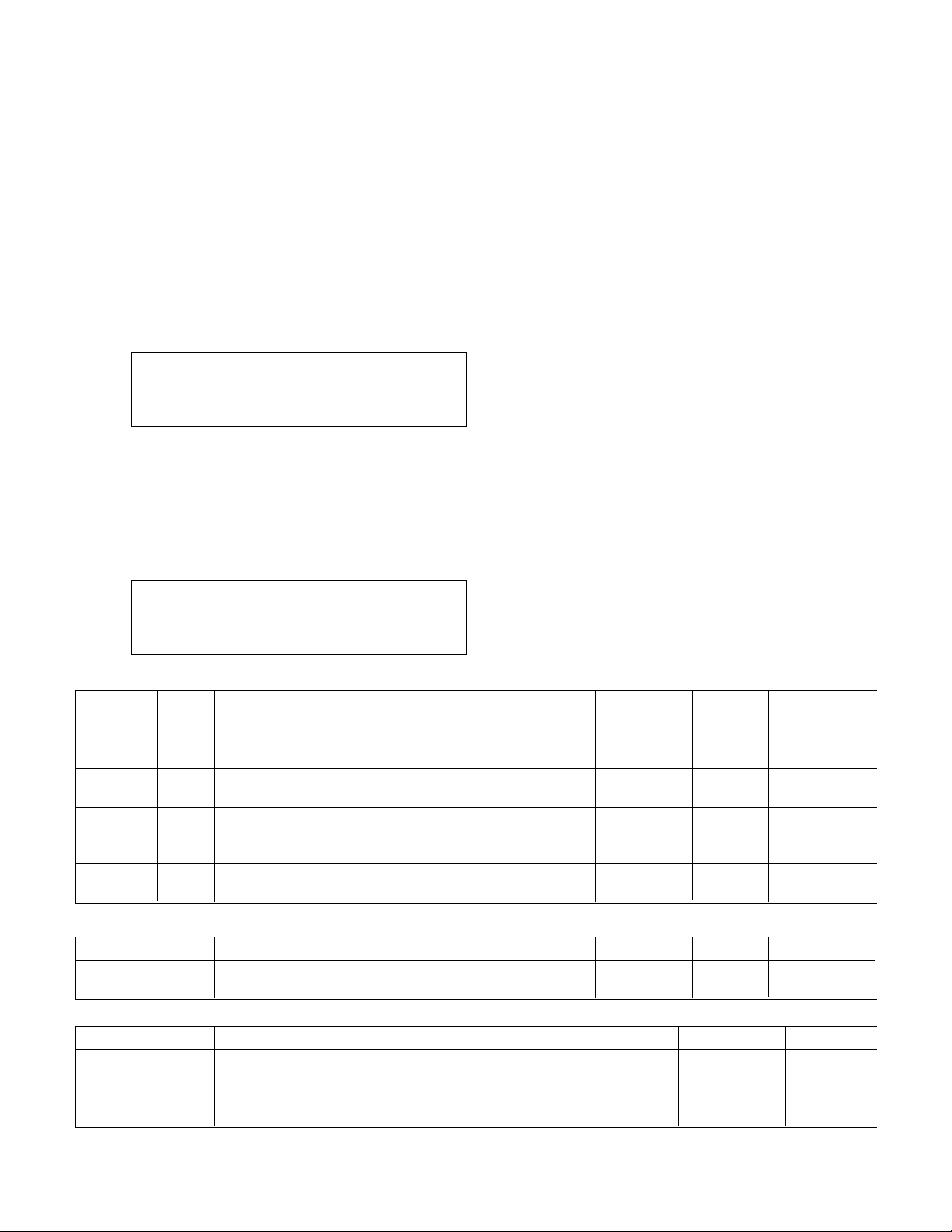

SECTION 1 - GENERAL Page

1.1 Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.1 Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.2 Safety Instruction Decal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.3 Valve Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.4 Closed System Safety Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6 Temperature and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.7 Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.8 Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.9 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.10 Analog Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.11 Field Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.11.1 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.11.2 Analog Inputs with External Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.11.3 User Configurable I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.11.4 Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.11.5 Local-Off-Remote Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SECTION 2 - OPERATION INTERFACE

2.1 Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 ZoneSav Controller Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 Key Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SECTION 3 - SETUP SELECTION

3.1 Sensor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.1 Sensor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.1.1 Sensor Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.1.2 Sensor Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.1.3 Sensor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.1.4 Sensor Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.1.5 Sensor Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.1.6 Sensor Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.1.7 Do Another . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1.2 Sensor Log Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Valve Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2.1 Valve Position Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.2.2 Valve Log Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.2.3 Valve Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3.1 System Temperature Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2 PID Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2.1 PID Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2.2 Setpoint Indexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2.3 Heat/Cool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.2.4 Auto Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.2.5 Optimize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.3 Alarms Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.4 Flow Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.5 System Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.6 Reset Totals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.3.7 Date/Time Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.3.8 Password Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.3.9 I/O Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3.9.1 DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3.9.2 DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3.9.3 AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.3.10 Communication Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.3.10.1 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.3.10.2 Metasys N2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3.10.3 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3.10.4 BACnet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3.11 Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.11.1 Summer/Winter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.12 Save to Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.13 Load to Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.14 Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Index

4

INDEX (continued)

3.4 Test Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.4.1 DI Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.2 DO Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.3 AI Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.4 AO Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.5 LED Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.6 Key Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.7 Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.8 Comm Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.5 Default Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

SECTION 4 - OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1 Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1.1 ZoneSav Controller Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1.2 Temperature Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1.3 Flow Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1.4 Valve Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2 Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2.1 Manual Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2.2 Auto Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3 Setpoint Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4 Process Variable Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.7 Log Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.7.1 Averages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.7.2 Totals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.7.3 Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.7.4 Valve Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.7.5 Data Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.7.6 Operation Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.7.7 Power Logl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.7.8 Service Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.7.8.1 System Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.7.8.2 Operating Hours Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.7.9 Auto-Tune Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SECTION 5 - MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.1 Technical Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.3 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.5 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.6 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.7 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.8 Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.9 Instruments and their Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.9.1 AC/DC Voltmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.9.2 Ohmmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.9.3 Milliamp Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.9.4 Signal Generator (analyzer) – recommended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.10 Field Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.11 Special Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.12 Program Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.13 Controller Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.14 Maintenance (Physical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.14.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.14.2 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

APPENDIX A System Piping and Unit Installation – Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . .27

APPENDIX B Electrical Wiring and Control Settings – Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . .27

APPENDIX C Valid I/O Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

APPENDIX D BACnet Protocol Implementation Conformance Statement for BACnet IP . . . . . . . . . . . .29

APPENDIX E BACnet Protocol Implementation Conformance Statement for BACnet MS/TP . . . . . . . . .30

APPENDIX F BACnet Communications Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

APPENDIX G LonWorks Communication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

APPENDIX H Metasys N2 Communications Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

APPENDIX I Modbus Communications Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

APPENDIX J Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35-37

NOTE: The information contained in this manual is intended to assist operating personnel by providing information on the char-

acteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of accepted practices in

the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your ZoneSave Controller can be found in the

I.O.M.s for the associated equipment provided see Section 5, Maintenance, for a list of relevant manuals.

1.1

Purpose of Manual

This manual is furnished to acquaint you with some

of the practical ways to install, operate, and maintain

this unit. Read it carefully before doing any work on

your unit and keep it handy for future reference.

Equipment cannot operate well without proper care.

To keep this unit at top efficiency, follow the recommended installation and servicing procedures outlined in this manual.

1.2 Safety

1.2.1 Safety Alert Symbol

SAFETY INSTRUCTION

This safely alert symbol will be used in this manual

and on the unit safety instruction to draw attention to

safety related instructions. When used the safety alert

symbol means

ATTENTION BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN A

SAFETY HAZARD.

1.2.2 Safety Instruction Decal

Your ZoneSav Controller should have a safety

instruction decal (part # S11550). If the decal is

missing or illegible contact your local B&G representative for a replacement.

1.2.3 Valve Safety

Ground fault protection should be sized properly.

Refer to local electrical codes for sizing and

selection.

Refer to the valve manufacturer's I.O.M. for specific

installation information.

Even when the valve is stopped, it should be considered alive as long as its controller is energized. Keep

hands away from the valve until the power is disconnected from the valve controller.

1.2.4

Closed System Safety Measures

Important:

Do not install and operate the ITT Bell &

Gossett ZoneSav Controller in a closed system

unless the system is constructed with properly sized

safety and control devices. Such devices include the

use of properly sized and located pressure relief

valves, compression tanks, pressure controls, temperature controls and flow controls as appropriate. If

the system does not include these devices, consult

the responsible engineer or architect before making

pumps operational.

1.3

Location

Install the ZoneSav Controller appropriately for ease of

inspection, maintenance and service. Observe local

electrical codes concerning control panel spacing.

5

Section 1 - General

Glossary of Terms

I.O.M. – Installation Operation Manual

LED – Light emitting diode, located on OIP and controller

OIP – Operator Interface Panel

PID – Proportional Integral Derivative; 3 variables required

for error control

Process Variable – Signal generated by a sensor that is set

up to control the system

Proof timer – Minimum time period before controller acknowledges an input; time period for which a signal must be stable

before it is accepted by the controller as a sustained and

valid signal

RTC – Real time clock

RTD – Resistive temperature device used to supply tempera-

ture signals to the PLC

BAS – Building Automation System

DANGER: The heating of water and other fluids causes

volumetric expansion. The associated forces may

cause failure of system components and releases of high

temperature fluids. This will be prevented by installing properly sized and located pressure relief valves and compression

tanks.

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN SERIOUS PROPERTY DAMAGE AND

SERIOUS PERSONAL INJURY OR DEATH.

DANGER: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by the motor eyebolts. Lift the

unit with slings placed under the unit base rails.

FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD RESULT

IN SERIOUS PERSONAL INJURY, DEATH, AND/OR

PROPERTY DAMAGE.

6

1.4

Storage

For long periods of storage, the unit should be

covered to prevent corrosion and contamination from

dirt. It should be STORED in a clean, dry location

between -20 and +60ºC. The relative humidity should

not exceed 85%. The unit should be checked periodically to ensure that no condensation has formed.

After storage, check that it is dry before applying

power.

1.5

Handling

Care should be taken to prevent damage due to

dropping or jolting when moving the ZoneSav

Controller. Transportation damage should be brought

to the carrier's attention immediately upon receipt.

1.6 Temperature and Ventilation

All electrical equipment is susceptible to failure if

operated in ambient temperatures outside of its rating. The OPERATING temperature range for this unit

is 0 to 40°C. The relative humidity should not exceed

95% non-condensing. The unit should not be operated outside these extremes.

1.7

Input Voltage

The ZoneSav Controller can be set up to operate

across a broad range of voltages. It was factory set

to operate on the voltage shown on the nameplate.

The voltage tolerance is +10/-5% and phase to

phase voltage must not have an imbalance greater

than 5 VAC.

1.8

Ground Connections

A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the

National Electrical Code and local codes must be

followed.

1.9

Power Wiring

Power wire types and sizes must be selected based

upon conformance with the National Electrical Code

and all local codes and restrictions. In addition, only

copper (Cu) wire rated for 75°C (minimum) may be

used for the power connections. Refer to the input

current as listed on the nameplate on the enclosure

door when sizing wire.

1.10

Analog Signal Wiring

Shielded cable (#22 AWG, Belden type 8762, Alpha

#2411, or equal) should be installed for all D.C. control wiring. The shield must be terminated in the

Technologic Valve Controller panel.

Do not connect

the shield at the other end of the cable! Insulate

the shield so that no electrical connection is made

at the other end of the cable.

A twisted pair of #22

AWG conductors (Belden 8442 or equal) can be used

in place of shielded cable. The cable length must be

limited to 5,000 feet for #22 AWG wire.

1.11 Field Connection Diagrams

Refer to the valve I.O.M. for specific details unique

to the valve. Refer to the flow sensor/transmitter

I.O.M. for specific details unique to the flow sensor/

transmitter.

The Wiring Diagram(s), Dimensional Drawings and

Field Connection Diagram should be reviewed prior

to unit installation and operation.

The following sections are based on the installation of

standard ZoneSav product. Because customized

software and hardware is available, the installing contractor should base all wiring connections on the

wiring diagrams that accompany each controller.

These sections are meant to complement, not

replace, those wiring diagrams.

1.11.1

Analog Inputs

The ZoneSav Controller may be provided with the

capability to accept many analog inputs. Typically,

all analog inputs must be 4-20mA and powered by

the 24VDC power supply in the ZoneSav Controller.

1.11.2 Analog Inputs with External Power

The following steps describe the general procedure

for rewiring an analog input sensor when the sensor's

power source is not the ZoneSav Controller.

1) Turn off all power to the ZoneSav Controller.

2) Refer to the appropriate controller wiring diagram

that was shipped with unit. Locate the analog

input sensors on the wiring diagram that will be

rewired. They are labeled AI X.

3) Remove the 24 VDC positive (+) wire from TB 40

for the respective analog input sensor connection.

This wire needs to be removed completely or terminated if used as a jumper. This will prevent any

accidental contact with a negative (-) voltage

source (i.e. control panel) and avoid becoming a

short circuit. Care should be taken to ensure that

24 VDC positive (+) voltage is still provided to any

remaining sensors that will be powered by the

ZoneSav Controller.

4) Remove the 24 VDC negative (-) wire from TB 41

for the respective analog input sensor connection.

This wire needs to be removed completely or terminated if used as a jumper. This will prevent any

accidental contact with a positive (+) voltage

source and avoid becoming a short circuit. Care

should be taken to ensure that 24 VDC (-) negative

voltage is still provided to any remaining sensors

that will still be powered by the ZoneSav Controller.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the ground

lug provided in the enclosure to avoid potential safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

7

5) Terminate the negative (-) wire of the sensor to TB

41 of the respective analog input sensor connection. Terminate the positive (+) wire of the sensor

to the terminal block which is connected to the

positive (+) terminal shown on the Analog input

card.

Note: Be certain that the power supplied to other terminal blocks has not been interrupted! The wires that

were removed in the preceding steps may have been

used as jumpers.

1.11.3 User Configurable I/O

The ZoneSav Controller comes equipped with the

capability to define the operation of any unused input

or output. Table 1 below shows the amount of each

type that is available for user setup on the standard

ZoneSav Controller. This does not include optional

I/O modules or the signals that are required for correct operation. Refer to Section 3.3.9 for detailed

information on the I/O Setup Menu.

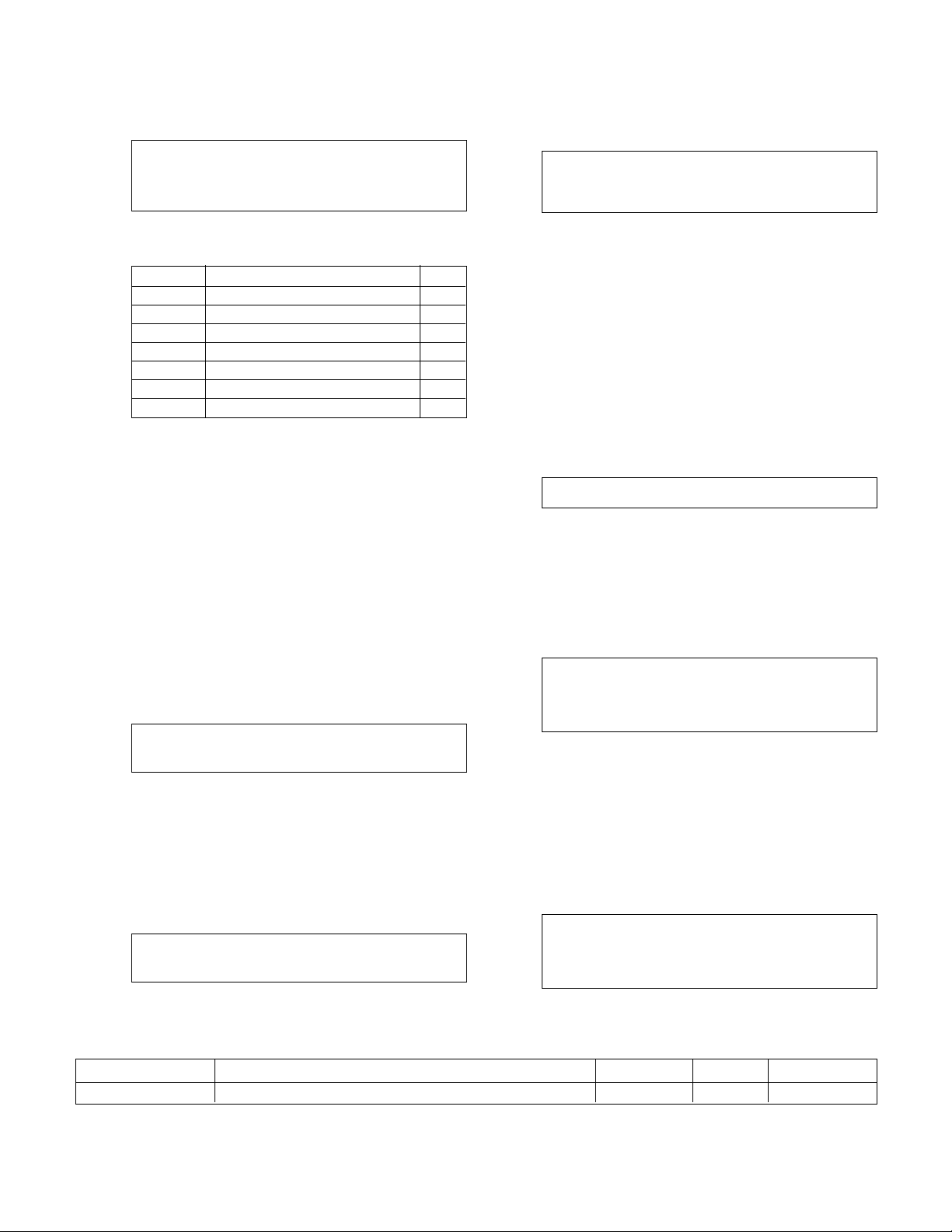

I/O Type Amount Available

Digital Input (24V) 9

Digital Output (24V) 8 + 1 relay

Analog Output 1

Table 1: User Configuration I/O

1.11.4 Valve

The ZoneSav Controller sends a 4 - 20mA or 0 - 10V

signal to the valve. This signal can also be reversed.

See section 3.2.3, Valve Signal, for instructions on

how to change the signal sent to the valve. The Valve

must be configured to accept a 4 - 20mA or 0 - 10V

signal. All shields must be grounded, only in the

ZoneSav Controller, to prevent ground loops and

improper signals.

1.11.5

Local-Off-Remote Switch

In the LOCAL position, the panel is always energized.

With the LOCAL-OFF-REMOTE switch in REMOTE, a

contact closure from a remote source will energize

the panel. This signal can be supplied through any of

the communications protocols used or through a 24V

digital input.

Section 2 - Operator Interface

2.1 Power-Up

Put LOCAL-REMOTE-OFF (LRO) switch in the

LOCAL position.

Turn main disconnect on.

2.2

ZoneSav Controller Screen

Upon powering up the controller, the display will light

and show the ZoneSav Controller default screen

shown below. See section 4.1 for more description

of this screen and the neighboring status screens.

ZoneSav Controller

Version: #.#

MM/DD/YY HH:MM:SS A/P

Stop Man Heat Manual

2.3 Key Functionality

The names of the keys on the Operator Interface

Panel (OIP) are shown as CAPITAL LETTERS in this

manual. Table 2, on the next page, shows the functionality of the keys on the OIP.

2.4

LEDs

Table 3, shown on the next page, gives the meaning

of the LED states.

WARNING: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING: Electrical shock hazard. Multiple power

sources. The off position of the LOCAL-REMOTEOFF switch does not disconnect all of the power sources in

the technologic panel. All power sources must be disconnected prior to entering the control panel.

FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH, AND/OR PROPERTY DAMAGE.

8

From the ZoneSav Controller screen, shown in section 2.2, press the SETUP key to get to the Setup

Selection screen shown below.

Setup Selection: 0

1 = Sensors 4 = Test

2 = Valve 5 = Default

3 = System 0 = Exit

Press the numeric key corresponding to the desired

Setup Selection submenu, and press ENTER.

3.1

Sensor Setup

From the Setup Selection Menu, shown in section 3,

press 1 and ENTER to get to the Sensor Setup

screen shown below.

Sensor Setup: #

1=Sensor Settings

2=Sensor Log Rate

0=Exit

Press the numeric key corresponding to the desired

Sensor Setup submenu and press ENTER.

3.1.1

Sensor Settings

3.1.1.1 Sensor Number

From the Sensor Setup screen, shown in section 3.1,

Press 1 and ENTER to get to the Sensor Number

screen shown below.

SENSOR NO: ##

Input the analog input number that will be modified,

and press ENTER.

3.1.1.2

Sensor Edit

After the analog input number is entered section

3.1.1.1, the Sensor Edit screen, shown below, will be

displayed.

Sensor# ## Type: (Type)

Span = 0 Zero = 0

Override:Y/N

Ok ? (Y/N)

Press YES and ENTER at the Ok prompt to accept

these values, and proceed to section 3.1.1.7. Press

NO and ENTER to modify these values, and go to

section 3.1.1.3.

Section 3 - Setup Selection

Key Name Functionality

START/STOP Starts and Stops System

AUTO/MANUAL Toggles operation mode

MANUAL VALVE Brings up the manual valve position screen. See section 4.2.1.

WARNING Brings up the active warnings if a warning exists (LED will blink when active)

PREV. SCREEN Navigates to neighboring screens (LED will blink when active)

NEXT SCREEN Navigates to neighboring screens (LED will blink when active)

HELP Brings up alarms. See section 4.5. If no alarm exists, help is available in every screen.

PROCESS VARIABLE/1 Brings up the Process Variable screen, shown in section 4.4, or used as a numeric key

SET POINT/2 Brings up the Set Point screen, shown in section 4.3, or used as a numeric key

SETUP/3 Brings up the Setup screen, shown in section 3, or used as a numeric key

F1/LOG/5 Brings up the Log Menu, shown in section 4.7, or used as a numeric key

F2/6 Used as a numeric key or an up arrow

YES/7 Used as a numeric key or YES

F3/INFO/8 Shows controller information screen, shown in section 5.13, or used as a numeric key

F4/9 Used as a numeric key or a down arrow

NO/0 Used as a numeric key or NO

ENTER Used to confirm entries and to advance to the next item if there are multiple fields

CLEAR Used to clear entries and to exit some screens

Table 2: Key Functionality

LED Description

START/STOP On = Start, Blinking = Stop

AUTO/MANUAL On = Auto, Blinking = Manual

MANUAL VALVE Blinks when system is on and in manual and in status screens to indicate it is active

WARNING Blinks when a warning exists and in status screens to indicate it is active

PREV. SCREEN Blinks when button is active

NEXT SCREEN Blinks when button is active

HELP Off = Brings up Help screen when pressed, Blinking = Brings up alarms when pressed.

Table 3

9

3.1.1.3

Sensor Type

If NO was selected in the Sensor Edit screen, shown

in section 3.1.1.2, the following will be displayed.

Sensor # ## Type: (Type)

1 = SysT 2 = ZST 3 = ZRT

4 = Flw 5 = Tmp 6 = VFbk

0 = None

Table 4, shown below, gives a description and the

units of each sensor type.

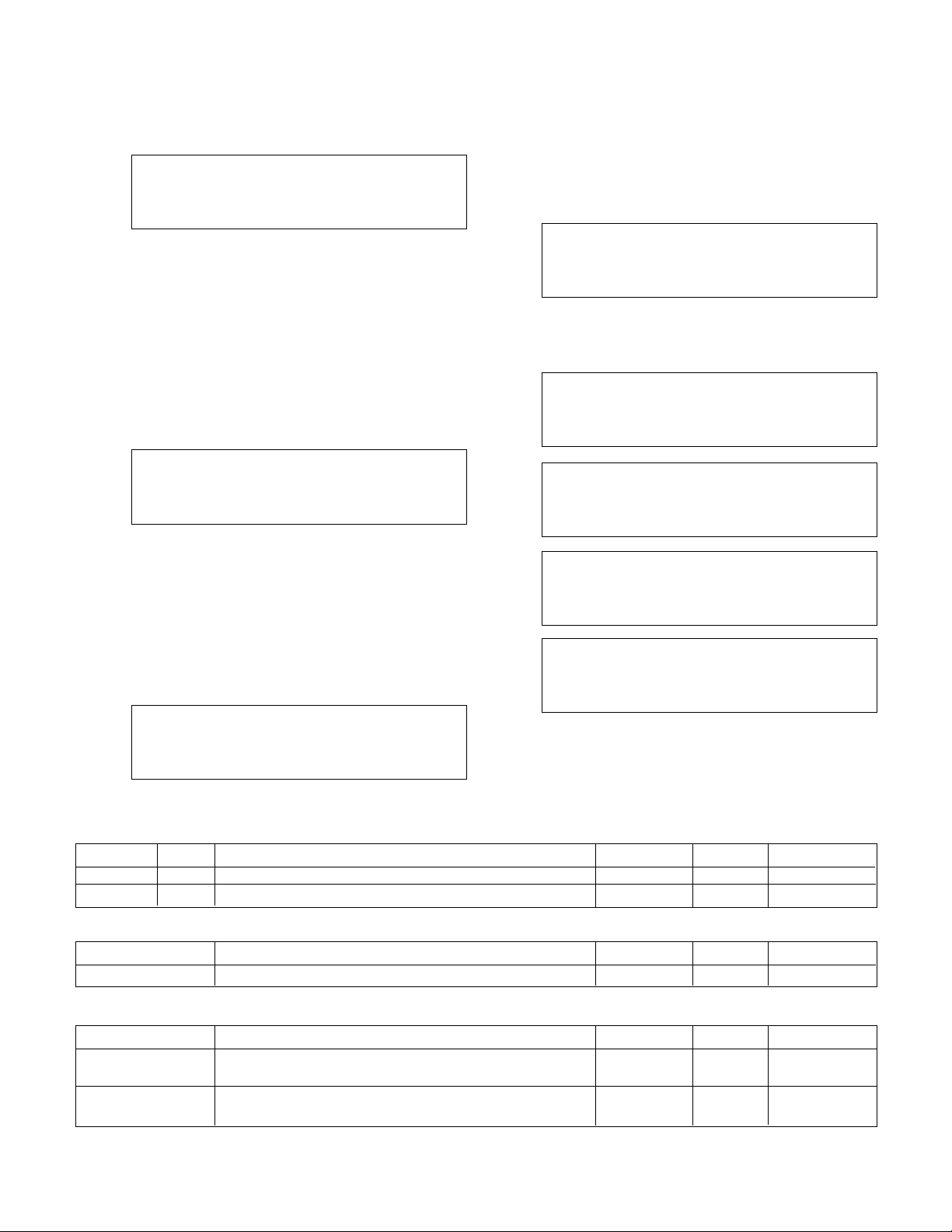

Selection Description Units

1=SysT System Temperature ˚F

2=ZST Zone Supply Temperature ˚F

3=ZRT Zone Return Temperature ˚F

4=Flw *Flow GPM

5=Temp Temperature (for display only) °F

6=VFbk Valve Feedback (for display only) %

0=None No Sensor N/A

Table 4: Sensor Types

Enter the numeric key corresponding to the type of

sensor you are setting up. The abbreviation for the

sensor type will appear in the upper right corner of

the display in the following screens. The ZoneSav

controller does not allow more than one sensor to

have types 1, 2, 3, 5, or 6.

*Note: A total of three flowmeters can be set up. The

smallest analog input number that has type "Flw" will

be the Zone Flow. It will be used for flow limit operation. See section 3.3.4 to set up a flow limit. The

other two flows will not be used in control algorithms.

They are for display only.

3.1.1.4

Sensor Span

After entering the sensor type in section 3.1.1.3, the

display will prompt the user for the sensor span as

shown below.

Sensor No ## Type: (Type)

Span = #####

Enter the span by pressing the appropriate numeric

keys and ENTER. Obtain the span of the sensor from

the nameplate on the sensor. The span is the numeric

value that corresponds to a 20mA signal.

3.1.1.5 Sensor Zero

After entering the sensor span in section 3.1.1.4, the

display will prompt the user for the zero of the sensor

as shown below.

Sensor No ## Type: (Type)

Span = ##### Zero = #####

Enter the desired zero value by pressing the appropriate numeric keys and ENTER. The Zero corresponds to the numeric value of the sensor at 4mA.

3.1.1.6

Sensor Override

After entering the sensor zero in section 3.1.1.5, the

display will prompt the user for Override (Yes/No) as

shown below.

Sensor No ## Type: (Type)

Span = # Zero = #

Override: Y/N

The controller is capable of accepting sensor input

either through a 4-20mA analog input or through the

communication port. See section 3.3.10 for available

protocols. The communication port must be set up

properly and connected to an external building

automation system (BAS).

Press YES and ENTER to receive the sensor signals

via the communication port. Press NO and ENTER to

receive the sensor signals via the analog input card.

After the selection is made, the controller will return

to the Sensor Edit screen shown in section 3.1.1.2.

3.1.1.7

Do Another

If YES was selected in the Sensor Edit screen, shown

in section 3.1.1.2, the display will show the following.

DO ANOTHER ? (Y/N)

Press YES and ENTER to set up another sensor, or

press NO and ENTER to return to the Sensor Setup

screen shown in section 3.1.

3.1.2

Sensor Log Rate

From the Sensor Setup screen, shown in section 3.1,

Press 2 and ENTER to get to the Sensor Log Rate

screen shown below.

Sensor Log Rate: #

0=None 2=Hr 4=Week

1=Min 3=Day 5=Month

OK ? (Y/N)

Press YES and ENTER to accept the current Sensor

Log Rate, or press NO and ENTER to edit the Sensor

Log Rate. See section 4.7.5 for more information on

the Data Log. See Table 5 for a description of the

Sensor Log Rate.

3.2

Valve Setup

From the Setup Selection screen, shown in section 3,

press 2 and ENTER to get to the Valve Setup screen

shown below.

SELECTION: # 0 = EXIT

1 = Valve Pos. Limit

2 = Valve Log Rate

3 = Valve Signal

Push the numeric key corresponding to the desired

Valve Setup submenu, and press ENTER to proceed.

Variable Description Default Value Range Field Value

Sensor Log Rate One data point is taken at the end of the interval 0 0-5

Table 5: Sensor Log Rate Variable

10

3.2.1

Valve Position Limit

From the Valve Setup screen, shown in section 3.2,

Press 1 and ENTER to get to the Valve Position Limit

screen shown below.

Valve Pos. Limit

Minimum: ###%

Maximum: ###%

0% = Closed OK ? (Y/N)

Press YES and ENTER to accept the values and

return to the Valve Setup screen, shown in section

3.2, or press NO and ENTER to edit the fields. See

Table 6 for a description of the Valve Position Limit

variables.

Note: The minimum and maximum valve position limits are ignored in manual operation mode.

3.2.2

Valve Log Rate

From the Valve Setup screen, shown in section 3.2,

Press 2 and ENTER to get to the Valve Log Rate

screen shown below.

Valve Log Rate: #

0=None 2=Hr 4=Week

1=Min 3=Day 5=Month

OK: ? (Y/N)

Press YES and ENTER to accept the current Valve

Log Rate, or press NO and ENTER to edit the Valve

Log Rate. See section 4.7.4 for more information on

the Valve Log. See Table 7 for a description of the

Valve Log Rate variables.

3.2.3

Valve Signal

From the Valve Setup screen, shown in section 3.2,

Press 3 and ENTER to get to the Valve Signal screen

shown below.

Valve Signal Type: #

1=4-20mA 2=0-10V

Signal Reversed: Y/N

OK: ? (Y/N)

Press YES and ENTER to accept the configuration

and return to the Valve Setup screen shown in section 3.2. Press NO and ENTER to edit the fields. See

Table 8 for a description of the Valve Signal variables.

3.3 System Setup

From the Setup Selection screen, shown in section 3,

press the 3 and ENTER to get to the System Setup

screens shown below.

Selection: # 0 = Exit

1 = System Temp Limit

2 = PID

3 = Alarms

Press NEXT SCREEN key or PREV. SCREEN to view

neighboring screens. There are five screens in this

menu. The remaining screens are shown below.

Selection: # 0 = Exit

4 = Flow Limit

5 = System Purge

6 = Reset Totals

Selection: # 0 = Exit

7 = Date, Time

8 = Password

9 = I/O Setup

Selection: # 0 = Exit

10 = Communication

11 = Special Function

12 = Save to Flash

Selection: # 0 = Exit

13 = Load From Flash

14 = Set Contrast

Press the numeric key corresponding to the desired

System Setup sub-menu, and press ENTER.

Variable Unit Description Default Value Range Field Value

Minimum % Minimum valve position in automatic operation mode 0 0-100

Maximum % Maximum valve position in automatic operation mode 100 0-100

Table 6: Valve Position Limit Variables

Variable Description Default Value Range Field Value

Valve Log Rate One data point is taken at the end of the interval 0 0-5

Table 7: Valve Log Rate Variables

Variable Description Default Value Range Field Value

Valve Signal Select 1 if the valve accepts a 4-20mA signal or select 1 1-2

Type 2 if it accepts a 0-10V signal

Signal Reversed Select N if the valve is closed at 4mA or 0V. Select Y if N Y/N

the valve is open at 4mA or 0V

Table 8: Valve Signal Variables

11

3.3.1

System Temperature Limit

From the System Setup Menu, shown in section 3.3,

press 1 and ENTER to get to the System Temperature Limit screen shown below.

System Temp Limit

Temp Limit = ###

Valve Opening = ###%

Timer = ###m OK ? (Y/N)

Press NO and ENTER to modify the fields, or press

YES and ENTER to exit back to accept the current

values and return to the System Setup screen, shown

in section 3.3. See Table 9 for a description of the

System Temperature Limit variables.

3.3.2

PID Setup

From the System Setup Menu, shown in section 3.3,

press 2 and ENTER to get to the PID Setup screen

shown below.

PID Selection: #

1 = Values 4 = AutoTune

2 = Index 5 = Optimize

3 = Heat/Cool 0 = Exit

Press the numeric key corresponding to the desired

PID Setup sub-menu, and press ENTER. Press 0 and

ENTER to return to the System Setup screen shown

in section 3.3.

3.3.2.1 PID Values

From the PID Setup screen, shown in section 3.3.2,

press 1 and ENTER to get to the PID Values screen

shown below.

(Type) PID VALUES

P = ###

I = ###

D = ### Ok ? (Y/N)

There is a different set of values for the zone supply

temperature, zone return temperature and flow.

Press NEXT SCREEN or PREV. SCREEN to change

the type of analog input.

The user should contact B&G if assistance is needed

in tuning the ZoneSav Controller's gains. Also see

section 3.3.2.4 for Auto-Tuning. To edit the fields,

press NO and ENTER. Press YES and ENTER to

accept the values. See Table 10 for a description of

the PID values variables.

3.3.2.2

Setpoint Indexing

From the PID Setup screen, shown in section 3.3.2,

press 2 and ENTER to get to the Setpoint Indexing

screen shown below.

Setpoint Indexing

Sup Idx = # ZSTmr = ## s

Ret Idx = # ZRTmr = ## s

Ok ? (Y/N)

Variable Unit Description Default Value Range Field Value

Temp °F If heating system, this is the low system temperature limit 55 0-999

Limit If cooling system, this is the high system temperature limit

Valve % Valve opens to this position when system temperature 50 0-100

Opening limit is exceeded

Timer minutes Valve will remain at the Valve Opening for the duration 1 0-99

of the timer

Table 9: System Temperature Limit Variables

Variable Description Default Default Default Field Field Field Range

Value Value Value Value Value Value

(ZS) (ZR) (FL) (ZS) (ZR) (FL)

Type ZS = zone supply N/A N/A N/A N/A N/A N/A N/A

ZR = zone return

FL = flow

PID-P Proportional value 400 400 20 1-999

PID-I Integral value 100 100 20 0-999

PID-D Derivative value 0 0 0 0-999

Table 10: PID Values

12

Setpoint Indexing is implemented when the system

supply temperature degrades to the point where it is

impossible to meet the setpoints in the system. In

this condition, the valve would normally go to the

wide open position to try to meet the setpoints.

However, if setpoint indexing is used, the ZoneSav

Controller can modify the setpoints in order to remain

in control. A warning is generated while the controller

is in this mode of operation.

To edit the fields, press NO and ENTER. Press YES

and ENTER to accept the values. See Table 11 for a

description of the Setpoint Indexing variables.

3.3.2.3

Heat/Cool

From the PID Setup Menu, shown in section 3.3.2,

press 3 and ENTER to get to the Heat/Cool screen

shown below.

Application Type: #

1:Heating

2:Cooling

Ok ? (Y/N)

Press YES and ENTER to accept the values and

return to the PID Setup Menu shown in section 3.3.2,

or press NO and ENTER to edit the field.

3.3.2.4

Auto Tune

From the PID Setup Menu, shown in section 3.3.2,

press 4 and ENTER to get to the Auto Tune screen

shown below.

Auto-Tune Select: #

ZS: (Message) 1=Start

ZR: (Message) 0=Stop

FL: (Message) Ok ? (Y/N)

Press YES and ENTER to return to the PID Setup

Menu shown in section 3.3.2. Press NO and ENTER

to edit the field. See Table 13 for a description of the

Auto Tune variables.

Auto-Tuning is used to find the optimal P, I, and D

values for the system being tuned. When the

process is started, the valve will be forced wide open.

It will remain there until the zone supply setpoint is

met. Then the valve will be forced closed. It will

remain there until the setpoint is no longer met. This

cycle will repeat 5 times. The message will change

from "Tune" to either "Comp" or "Err" indicating completion. Tuning of the zone return and flow values will

then commence. If an error occurs, auto tuning will

be aborted. The valve position and process variables

can be viewed in other screens during auto tuning.

The optimal P, I, and D will automatically be used.

These gains can be viewed or modified from the PID

Gains screen shown in section 3.3.2.1.

The controller must be stopped and in manual operation mode to begin the auto tuning process. Also,

make sure the zone return and zone supply setpoints

are set up and that they are realistic values. See section 4.3 for more information on modifying the setpoints. The setpoint used for flow will be 90% of the

flow limit value. Make sure that the flow limit value is

set up and realistic. See section 3.3.4 for more information on setting up a flow limit.

If a flowmeter is not used, the Auto-Tuning process

should be stopped manually. Wait for the message

for "FL" to be "Tune". Then enter a zero in the AutoTune Select field to stop the process. The gains for

zone supply and zone return will still be optimized

and used.

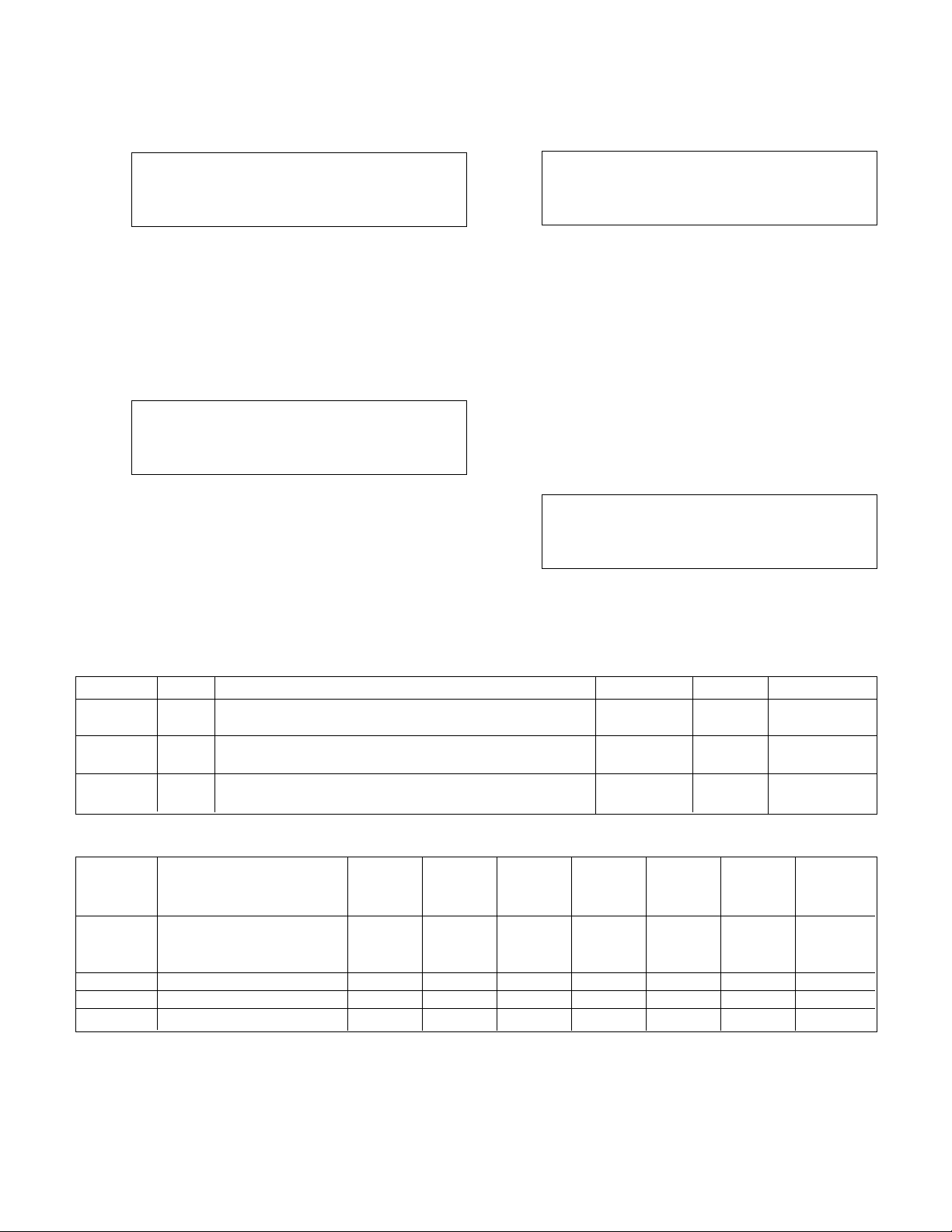

Variable Unit Description Default Value Range Field Value

Sup Idx °F Zone supply index: the difference between the system 0 0-20

supply temperature and the zone supply setpoint that will

be maintained. 0 will disable this mode of operation.

ZSTmr min Zone supply index timer: controlle will remain in zone 0 0-99

supply index mode for the duration of this timer

Ret Idx °F Zone return index: the difference between the system 0 0-20

supply temperature and the zone return setpoint that will

be maintained. 0 will disable this mode of operation.

ZRTmr min Zone return timer: controller will remain in zone supply 0 0-99

index mode for the duration of this timer

Table 11: Setpoint Indexing Variables

Variable Description Default Value Range Field Value

Application Select 1 if system is for heating, or select 2 if system 2 1-2

Type is for cooling

Table 12: Heat/Cool Variable

Variable Description Default Value Range

Auto-Tune Select 1 = Start Auto Tune Process 0 0-1

0 = End Auto Tune Process

Message Stop = Stopped, Tune = Tuning, Err = complete with error, N/A N/A

Comp = complete

Table 13: Auto Tune Variables

Table 14: Optimize Variables

13

If a "Tune" message does not change to "Comp" or

"Err" within 10 minutes, enter 0 to manually stop the

Auto-Tuning process. If the "Err" message is displayed in any of the fields, repeat the Auto-Tune

process. If the error persists, check the Auto-Tune

Log shown in section 4.7.9, record the information,

and contact B&G for assistance.

3.3.2.5

Optimize

From the PID Setup Menu, shown in section 3.3.2,

press 5 and ENTER to get to the Optimize screen

shown below.

PID Opti.: ? (Y/N)

Floating Range: ###%

Holding Time: ###s

Ok ? (Y/N)

Press YES and ENTER to accept the values and

return to the PID Setup Menu shown in section 3.3.2,

or press NO and ENTER to edit the fields. See Table

14 for a description of the Optimize Variables.

PID optimization is used to close the valve as much

as possible while still meeting the zone supply and

zone return setpoints.

3.3.3

Alarms Setup

From the System Setup Menu, shown in section 3.3,

press 3 and ENTER to get to the Alarms Setup

screen shown below.

AI Fail Pr. Tm = ##s

Ok ? (Y/N)

Press YES and ENTER to accept the value and return

to the System Setup Menu, shown in section 3.3, or

press NO and ENTER to edit the field. See Table 15

for a description of the Alarms Variables.

3.3.4 Flow Limit

From the System Setup screen, shown in section 3.3,

press 4 and ENTER to get to the Flow Limit screen

shown below.

Flow Limit

Pr. Tmr = ### sec

LimTm = #

AvgTmr = # Ok ? YN

To return to the System Setup Menu, shown in section 3.3, press YES and ENTER. To edit the fields,

press NO and ENTER. See Table 16 for a description of the Flow Limit variables. See Table 31 for

more information on flow limit operation.

3.3.5

System Purge

From the System Setup Menu, shown in section 3.3,

press 5 and ENTER to get to the System Purge

screen shown below.

Purge Timer = ###m

Valve Position = ###%

Ok ? (Y/N)

To return to the System Setup screen, shown in section 3.3, press YES and ENTER.

To edit the fields, press NO and ENTER. See Table

17 for a description of the Bypass Setup variables.

Variable Unit Description Default Value Range Field Value

PID Opti N/A Select Y to enable PID optimization or N to disable N Y/N

Floating % The percentage by which the valve position will be 3 0-20

Range decreased

Holding s Proof timer prior to decreasing valve position by the 20 0-999

Time floating range

Variable Unit Description Default Value Range Field Value

AI Fail Seconds Proof timer prior to setting an analog input failure alarm 10 0-999

Pr. Tm

Table 15: Alarm Variables

Variable Unit Description Default Value Range Field Value

Pr. Tmr Seconds Proof timer prior to starting flow limit operation 30 0-999

Lim Tmr Minutes The controller will remain in flow limit operation for the 0 0-999

duration of the timer, 0 will disable flow limit

Limit GPM Maximum flow before entering flow limit operation 40 0-65535

Table 16: Flow Limit Variables

Variable Description Default Value Range Field Value

Purge Timer The valve will remain at the Valve Position for the duration 0 0-30

of the Purge Timer. 0 min will disable purging.

Valve Position Valve will go to this position during purging. 100 0-100

Table 17: System Purge Variables

14

Purging is used to give the system time to react to

changing water temperatures on startup. If purging is

enabled, purging will occur every time the system is

started in automatic mode. Stopping and then starting the system while in automatic operation mode will

start the purging process. A command to purge the

system can also be initiated through a communications port. See Appendices F through I for the relevant communications point. When the system is

purging, "Purge" will be displayed in the Valve Status

screen shown in section 4.1.4.

3.3.6

Reset Totals

From the System Setup Menu, shown in section 3.3,

press 6 and ENTER to get to the Reset Totals screen

shown below.

Reset Total Values

Op Hours: Y/N

Gallons: Y/N

BTU: Y/N Ok ? (Y/N)

To return to the System Setup Menu, shown in section 3.3, press YES and ENTER. To edit the field,

press NO and ENTER. Table 18 gives a description

of the Reset Totals variables.

3.3.7 Date/Time Setup

From the System Setup Menu, shown in section 3.3,

press 7 and ENTER to get to the Date/Time Setup

screen shown below.

MM/DD/YYYY HH:MM:SS

Display 24 Hr Fmt: ? (Y/N)

Daylite Saving Tm: ? (Y/N)

Ok ? (Y/N)

To return to the System Setup Menu, shown in section 3.3, press YES/7 and ENTER. To edit the fields,

press NO and ENTER. See Table 19 for a description

of the Date/Time Setup variables.

3.3.8 Password Setup

From the System Setup Menu, shown in section 3.3,

press 8 and ENTER to get to the Password Setup

screen shown below.

Enable Password To:

Setup Menu ? (Y/N)

Set Point ? (Y/N)

Ok ? (Y/N)

To return to the System Setup Menu, shown in section 3.3, press YES and ENTER. To edit the fields,

press NO and ENTER. See Table 20 for a description

of the Password Setup variables.

Variable Description Default Value Range Field Value

Op Hours Set this to Y to reset the operating hours and N Y/N

commissioning date and time (see section 4.7.8.2)

GAL Set GAL to Y to reset the total gallons and Avg GPM N Y/N

(see sections 4.7.1 and 4.7.2)

BTU Set BTU to Y to reset the Avg TON, Avg MBH, and N Y/N

Tot KBTU (see sections 4.7.1 and 4.7.2)

Table 18: Reset Totals Variables

Variable Description Default Value Range Field Value

Setup Menu Enter YES for password protection of the entire setup N Y / N

menu

Set Point Enter YES for password protection of set point N Y / N

modification

Table 20: Password Variables

Variable Description Default Value Range Field Value

MM Current month (two digits), example: Jan. should be

created as 01

DD Current date (two digits), example: the 6th should be

entered as 06

YYYY Current year using all 4 digits

HH Hours (24 hour format), example: 9:00 p.m. should be

entered as 21

MM Minutes (two digits)

Display Enter YES to display the time in the 24 hour format. N Y/N

24 Hr Fmt Enter NO to display the time in AM/PM format.

Daylite Enter YES for automatic setback during daylight N Y/N

Saving TM saving time. Enter NO to disable the automatic setback

during daylight saving time.

Table 19: Date/Time Variables

15

If either of the above are set to YES the screen,

shown below, prompts the user to define the password.

ENTER NEW PASSWORD

>_______________<

Enter a password from 0-999999. Record it here or

somewhere else!

After entering a password the Verify Password screen

requires the user to confirm the password. If the confirmed number does not agree with the first number,

the Enter New Password screen is repeated to allow

the user to get both input screens to agree.

VERIFY THE PASSWORD

>_______________<

3.3.9 I/O Setup

From the System Setup Menu, shown in section 3.3,

press 9 and ENTER to get to the I/O Setup screen

shown below.

I/O Setup Select: #

1 = DI

2 = DO

3 = AO 0 = EXIT

Note:

The total available number of I/O to be config-

ured is dependent on the system setup. Complete all

previous setup screens, specifically sensors, prior to

completing the following.

3.3.9.1

DI

From the I/O Setup Menu, shown in section 3.3.9, press

1 and ENTER to get to the DI screen shown below.

Opt. DI = # Avail: = #

Code = # Delay = ##s

(Functionality)

Exit: ? (Y/N)

To return to the I/O Setup Menu, shown in section

3.3.9, press YES and ENTER. To edit the fields,

press NO and ENTER. See Table 21 for a description

of the DI variables.

3.3.9.2

DO

From the I/O Setup Menu, shown in section 3.3.9, press

2 and ENTER to get to the DO screen shown below.

Available DOs = ##

Opt. DO# = #### Code = ###

(Functionality)

Exit: ? (Y/N)

To return to the I/O Setup Menu, shown in section

3.3.9, press YES and ENTER. To edit the fields,

press NO/0 and ENTER. See Table 22 for a description of the DO variables.

Note: DO#1-8 are 24V transistor outputs. DO#9 is a

relay.

Variable Unit Description Default Value Range Field Value

Opt. DI N/A Enter the DI # that will assume the desired functionality N/A 0-10

Avail N/A This variable is not modifiable. It is here to advise the N/A 0-9

user of how many digital inputs can be customized

Code N/A Defines the desired functionality of the input, valid codes 0 0-3

are defined in Appendix C of this manual

Delay Seconds Proof timer 0 0-999

Function- N/A This message will show the functionality of the code N/A N/A

ality that was entered

Table 21: DI Variables

Variable Description Default Value Range Field Value

Available DOs This screen can not be modified. It is here to advise the 9 0-9

user of how many digital outputs can be customized

Opt. DO# Enter the DO# that will assume the desired functionality N/A 0-9

Code Enter the code to defines the desired functionality of the 0 0-6

output. Valid codes are defined in Appendix C of this

manual

Functionality This message will show the functionality of the code N/A N/A

that was entered

Table 22: DO Variables

16

3.3.9.3

AO

From the I/O Setup Menu, shown in section 3.3.9,

press 3 and ENTER to get to the AO screen shown

below.

Total Avail. AO = #

Opt. AO = # Code = #

(Functionality)

Exit: ? (Y/N)

To return to the I/O Setup Menu, shown in section

3.3.9, press YES and ENTER. To edit the fields,

press NO and ENTER. See Table 23 for a description

of the AO variables.

3.3.10 Communication Setup

From the System Setup screen, shown in section 3.3,

press 10 and ENTER to get to the Communication

Setup screen shown below.

Comm. Setting

1 = BACnet 2 = JC N2

3 = Modbus 4 = BACnet/IP

0 = Exit Select: #

Press the numeric key corresponding to the desired

Communication Setup sub-menu, and press ENTER.

3.3.10.1

BACnet

From the Communication Setup screen, shown in

section 3.3.10, press 1 and ENTER to get to the

BACnet screen shown below.

BACnet MS/TP

Baud, 8, 1, 1, N Slave

MAC = ### Inst = ####

SP Ovrd: ? Y/N Exit ? Y/N

The first line confirms setup for the BACnet protocol.

The second line defines the baud rate, 8 bit data

packets, 1 stop bit, 1 start bit and no parity. The

ZoneSav Controller is a slave device only. To return

to the Communication Setup Menu, shown in section

3.3.10, press YES and ENTER. To edit the fields,

press NO and ENTER. Table 24 gives a description

of the BACnet variables.

Variable Description Default Value Range Field Value

Total Available AOs This screen can not be modified. It is here to advise the N/A 0-8

user of how many analog outputs can be customized

Opt. AO Enter the output to be configured as it appears on the N/A 0-8

wiring diagram. The analog output card can be configured

for 0-10VDC or 4-20mA signals. Remove the card from

the rack. There are two switches below the pin

connector on the back of the card. The bottom switch

#1 configures the first analog output. The top switch #2

configures the second analog output. Select position U

for 0-10VDC and position I for 4-20mA output signals.

Code Defines the desired functionality of the output. Valid 0 0-9

codes are defined in Appendix C of this manual

Functionality This message will show the functionality of the code N/A N/A

that was entered

Table 23: AO Variables

Variable Description Default Value Range Field Value

Baud The baud rate is user adjustable 9600 9600,

19200,

38400

MAC Address Obtain the node number from the manufacturer that 128 1-255

supplied the device that will communicate with the

Technologic Controller

Inst Unique instance numbers are needed only if multiple 100 0-9999

TECHNOLOGIC panels are connected to the same

network. Some BACnet devices do not require this

number to communicate with the ZonSav controller

SP Ovrd Select “Y” to allow the setpoints to be overwritten N Y/N

through the communications port

Table 24: BACnet Variables

17

3.3.10.2

Metasys N2

From the Communication Setup Menu, shown in section 3.3.10, press 2 and ENTER to get to the Metasys

N2 screen shown below.

Metasys N2

9600, 8, 1, 1, N. VND

Node = # SP Ovrd: ? Y/N

Exit ? Y/N

The first line confirms setup for the Johnson Controls

N2 protocol. The second line defines the 9600 bps

baud rate, 8 bit data packets, 1 stop bit, 1 start bit

and no parity. To return to the Communications

Setup Menu, shown in section 3.3.10, press YES and

ENTER. To edit the fields, press NO and ENTER.

Table 25 gives a description of the Metasys N2

variables.

3.3.10.3

Modbus

From the Communication Setup Menu, shown in section 3.3.10, press 3 and ENTER to get to the Modbus

screen shown below.

Modbus

9600, 8, 1, 1, N RTU

Node = # SP Ovrd: ? Y/N

Exit ? Y/N

The first line confirms setup for Modbus protocol.

The second line defines the 9600 bps baud rate, 1

stop bit, 1 start bit, and no parity. To return to the

Communications Setup Menu, shown in section

3.3.10, press YES and ENTER. To edit the fields,

press NO/0 and ENTER. Table 26 gives a description

of the Modbus variables.

3.3.10.4

BACnet/IP

From the Communication Setup Menu, shown in section 3.3.10, press 4 and ENTER to get to the

BACnet/IP screen shown below.

IP Address:

###. ###. ###. ###

Subnet:

###. ###. ###. ###

The BACnet device IP address and Subnet Mask are

provided by building management system. Press

NEXT SCREEN and the display will show:

Start Delay = ## Sec

Setpoint Ovrd: ?(Y/N)

Save IPAdd: ?(Y/N)

OK: ? (Y/N)

To return to the Communications Setup Menu, shown

in section 3.3.10, press YES and ENTER. To edit the

fields, press NO and ENTER. Table 27 gives a

description of the BACnet/IP variables.

For additional information concerning the above protocols, consult the Bell & Gossett Tech 500 Serial

Communications instruction manual (part number

S13654).

There may have been additional protocols added to

the communication setup menu, contact your Bell &

Gossett representative concerning additional protocols and setups.

Variable Description Default Value Range Field Value

Node Obtain the node number from the manufacturer that 1 0-255

supplied the device that will communicate with the

Technologic Controller

SP Ovrd Select “Y” to allow the setpoints to be overwritten N Y/N

through the communications port

Table 25: Metasys N2 Variables

Variable Description Default Value Range Field Value

Node Obtain the node number from the manufacturer that 1 255

supplied the device that will communicate with the

Technologic Controller

SP Ovrd Select “Y” to allow the setpoints to be overwritten N Y/N

through the communications port

Table 26: Modbus Variables

Variable Unit Description Default Value Range Field Value

Start Delay Seconds Time delay to start the BACnet interface 10 0-999

Set Point N/A Select YES for the external device to override the local N Y/N

Ovrd setpoint data

Save IP N/A Select YES to save IP address (restarts) N Y/N

Add

Table 27: BACnet/IP Variables

18

3.3.11

Special Functions

From the System Setup Menu, shown in section 3.3,

press 11 and ENTER to get to the Special Functions

Menu shown below.

Selection: #

1 = Summ/Wint Setting

0 = Exit

Press the numeric keys corresponding to the desired

Special Functions sub menu, and press ENTER.

3.3.11.1

Summer/Winter

From the Special Functions screen, shown in section

3.3.11, press 1 and ENTER to get to the Summer/

Winter screen shown below.

Select Sum/Wint Op: #

1 = DI 2 = Serial Com

0 = Disable

OK ? (Y/N)

Table 28, shown below, gives a description of the

Summer/Winter variables.

When Summer/Winter mode is enabled by selecting

1 or 2 above, two different sets of setpoints can be

defined. The default season is summer. When a high

signal on the digital input or serial communication

point is received, the season will change to winter.

See section 4.3 for more information.

3.3.12 Save to Flash

From the System Setup Menu, shown in section 3.3,

press 12 and ENTER to get to the Save to Flash

screen shown below.

Current Settings

Will Be Saved to

the flash ROM.

PROCEED? # (Y/N)

To return to the System Setup Menu, shown in section 3.3, press NO and ENTER. To save all of the

user setup data to the ROM in the controller, press

YES and ENTER.

3.3.13

Load from Flash

From the System Setup Menu, shown in section 3.3,

press 13 and ENTER to get to the Save to Flash

screen shown below.

**WARNING**

PRIOR SETTINGS TO BE

LOADED FROM FLASH.

PROCEED? # (Y/N)

To return to the System Setup Menu, shown in section 3.3, press NO and ENTER. To load the user

setup data, which was previously saved, press YES

and ENTER.

3.3.14 Contrast

From the System Setup Menu, shown in section 3.3,

press 14 and ENTER to get to the Brightness/

Contrast screen shown below.

Contrast is: ###

Change is: ###

Ok ? (Y/N)

To return to the System Setup Menu, shown in section 3.3, press YES and ENTER. To edit the field,

press NO and ENTER. Table 27 gives a description

of the Contrast variables.

3.4 Test Selection

From the Setup Selection menu, shown in section 3,

press 4 and ENTER to get to the Test Selection

screen shown below.

Test Selection: #

1 = DI 4 = AO 7 = Disp

2 = DO 5 = LED 8 = Comm

3 = AI 6 = Key 0 = Exit

Press the numeric key corresponding to the desired

Test Selection sub-menu, and press ENTER.

Variable Description Default Value Range Field Value

Select Select 1 to switch summer/winter setpoints based on a 0 0-2

Sum/Wint Op. digital input. Select 2 to switch summer/winter setpoints

based on a serial communications port. Select 0 to disable

Table 28: Summer/Winter Variables

Variable Description Default Value Range Field Value

Contrast is: Current contrast setting is not modifiable (40 = Light 75 40-100

Characters, 100 = Darkest Characters)

Change to: Desired Contrast Setting (Setting of 100 will reduce the 75 40-100

life of the screen)

Table 29: Brightness/Contrast Variables

19

3.4.1

DI Test

From the Test Selection Menu, shown in section 3.4,

press 1 and ENTER to get to the DI Test screen

shown below.

Digital Inputs

1234567890

0000000000

Press Clear to Exit

The zero below each corresponding input will change

to a one upon receiving a digital input. Press CLEAR

to exit the test.

3.4.2

DO Test

From the Test Selection Menu, shown in section 3.4,

press 2 and ENTER to get to the DO Test screen

shown below.

Digital Inputs

1234567890

0000000000

Enter DO # 0 (0=Exit)

Press any numeric key, numbered 1-9, corresponding to the digital output for which the state is to be

changed. Press ENTER to change the state of the

digital output. Pressing ENTER multiple times will

toggle between 0 and 1. To exit, press 0 followed by

the ENTER key.

3.4.3

AI Test

From the Test Selection Menu, shown in section 3.4,

press 3 and ENTER to get to the AI Test Screen

shown below.

Analog Inputs

1 = ###% 3 = ###%

2 = ###% 4 = ###%

Press Clear to Exit

The current % of the signal will be indicated next to

each input. 4mA = 0%, and 20mA = 100%. Press

CLEAR to exit the test, or press NEXT/PREV SCREEN

to view more inputs.

3.4.4 AO Test

From the Test Selection Menu, shown in section 3.4,

press 4 and ENTER to get to the AO Test Screen

shown below.

Analog Output Test

AO1 = ###% AO3 = ###%

AO2 = ###% AO4 = ###%

OK = ? (Y/N)

Press YES and ENTER to return to the Test Selection

Menu shown in section 3.4.

Press NO and ENTER to modify the analog outputs.

The signal is shown next to each analog output. 0%

= 0mA or 0V, and 100% = 20mA or 10V depending

on the position of the switch on the analog output

card. Enter an alternate value by using the numeric

keys and press ENTER to output the new value, or

press ENTER to move to the next channel. A03 - A06

may not be modified unless the corresponding output

cards are attached to the system.

3.4.5

LED Test

From the Test Selection screen, shown in section 3.4,

press 5 and ENTER to get to the LED Test Screen

shown below.

LED TEST

**** LED ON ****

**** LED OFF ****

**** LED BLINK ****

All of the LED's on the left key set turn on, then turn

off, then flash. The entire test takes 5 seconds to

complete prior to returning to the Test Selection

screen shown in section 3.4. Press the CLEAR key at

any time to terminate the test and return to the Test

Selection menu.

3.4.6

Key Test

From the Test Selection Menu, shown in section 3.4,

press 6 and ENTER to get to the Key Test Screen

shown below.

Key Test

Press a key to test

Press Clear to Exit

Press any key except for the CLEAR key, and the display will confirm that the key is working by displaying

the key name. Press the CLEAR key to return to the

Test Selection menu shown in section 3.4.

3.4.7 Display Test

From the Test Selection Menu, shown in section 3.4,

press YES/7 and ENTER to get to the Display Test

Screen shown below.

Press Clear to Exit

>>> 0 1 2 3 4 5 6 7 8 9>>>

>>> 0 1 2 3 4 5 6 7 8 9>>>

>>> 0 1 2 3 4 5 6 7 8 9>>>

>>> 0 1 2 3 4 5 6 7 8 9>>>

The display will scroll ASCII characters from right to

left. All four lines will be tested at the same time.

Press CLEAR to return to the Test Selection screen

shown in section 3.4.

3.4.8 Comm Test

From the Test Selection Menu, shown in section 3.4,

press 8 and ENTER to get to the Comm Test Screen

shown below.

Test Communication

B & G Read #

B & G Write #

Press Clear to Exit

20

If the controller is communicating properly with the

building automation system, the numbers will continue increasing in value. For Modbus protocol, the read

and write numbers will be equal. For BACnet and

Johnson N2 protocols, the numbers will not be equal.

If the numbers are not increasing in value, the controller is not communicating properly. If it is not communicating, check the wiring at the terminal blocks

and the RS communication card mounted on the

controller. Consult the Tech 5500 Serial Communication Manual for further assistance. Press CLEAR

to exit this test.

3.5

Default Setup

From the Setup Selection Menu, shown in section 3,

press 5 and ENTER to get to the Default screen

shown below.

*** WARNING ***