Page 1

70X Multiple Pump

Pressure Booster Systems

Installation, Operation and

INSTRUCTION MANUAL

S14141B

Service Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

A Bell & Gossett Packaged Pressure Booster System is factory

assembled, tested and shipped as a complete modular unit.

Each Pressure Booster System is tested to internal quality

standards.

The information contained in this manual is intended to assist

operating personnel by providing information on the characteristics of the purchased equipment. It does not relieve the

user of the responsibility to adhere to local codes and ordinances and the use of accepted practices in the installation,

operation and maintenance of this equipment. Further information pertaining to the installation, operation, and maintenance can be found in the I.O.M.s for the specific equipment

provided.

OPERATIONAL LIMITS

See unit nameplate for pump capacity, boost, full load current

draw, and operating voltage. The pump discharge pressure

must not exceed 175 PSI unless specifically designed.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on the

Safety Instruction decal to draw attention to safety related

instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY

FAILURE TO FOLLOW THE INSTRUC

A SAFETY HAZARD!

TION MAY RESULT IN

IS INVOLVED!

Page 2

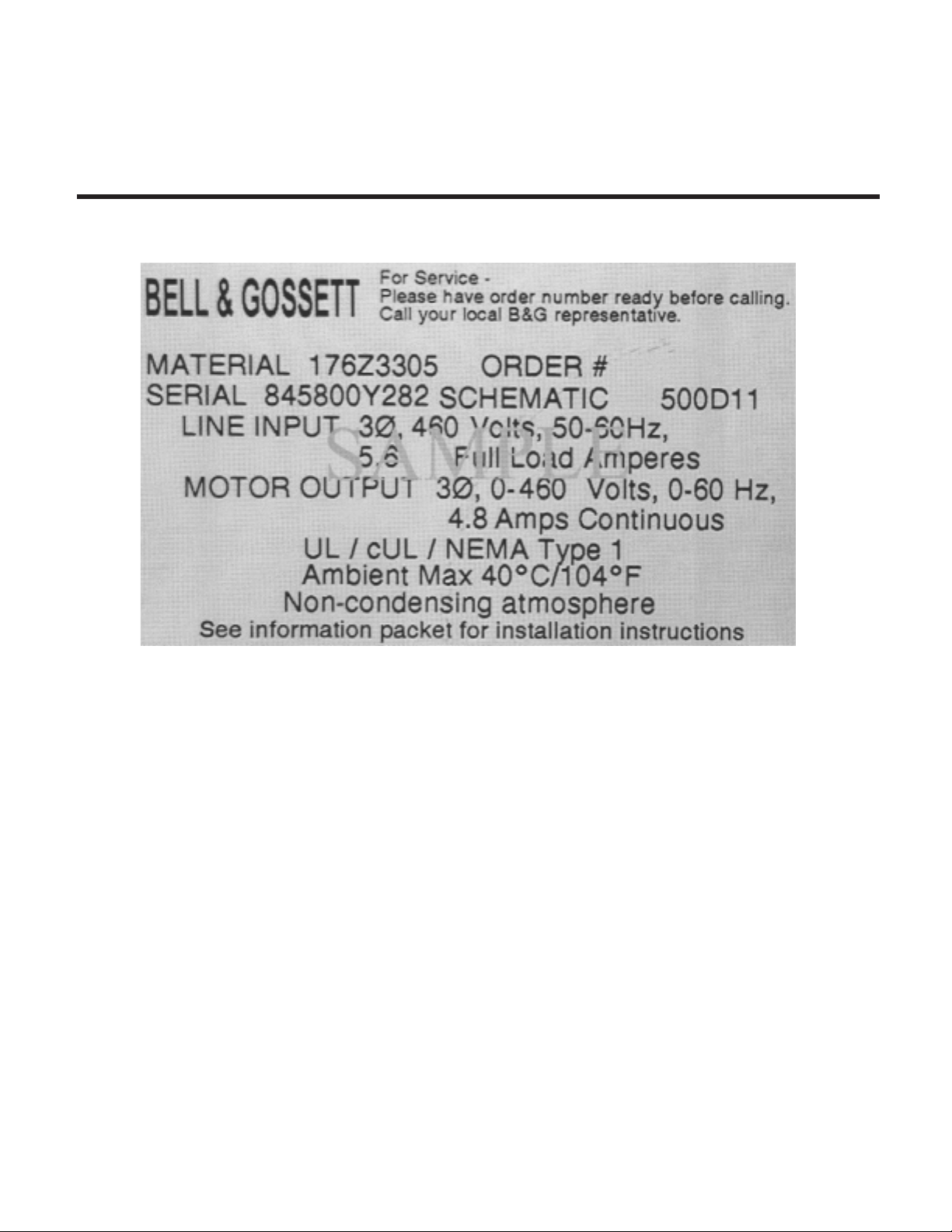

UNIT IDENTIFICATION

The unit nameplate gives identification and rating information

as identified in Figure 1.

UNIT IDENTIFICATION

Records for this unit are kept by the order number (Q______)

and it must therefore be used with all correspondence and

spare parts orders.

PRESSURE BOOSTER SYSTEM

PREFACE

The 70X modular variable speed pressure booster system is

designed to maintain a constant discharge pressure while

minimizing power consumption by combining a variable

speed lead pump with one or two constant speed lag pumps.

This system creates an efficient and practical solution to a

building’s low demand water usage profile. A typical building’s

water demand varies throughout the course of a day and

often a single pump is capable of meeting the demand for

more than half of the day. The 70X controller manages pump

operation to match the wide range of pressure boosting system conditions. The pump controller uses a combination of

kW, pressure and speed to calculate the most efficient points

to stage on and off pumps for operation.

PREFACE

Power consumption is minimized by varying the speed of the

lead pump to satisfy a varying system demand. As the system

demand exceeds the capacity of the lead pump, a constant

speed lag pump is staged on. The constant speed lag pump

operates at full capacity while the lead variable speed pump

adjusts its speed to supplement the system requirement.

When speed demand decreases the lead pump slows down.

While monitoring system pressure, pump speed and power

consumption, the constant speed lag pump is staged off at an

optimal point and the variable speed pump takes over.

FIGURE 1 - Technologic 500X Control Panel Nameplate

2

Page 3

TABLE OF CONTENTS

70X Multiple Pump Pressure Booster Systems

Page

SECTION 1 GENERAL

Purpose of Manual ..............................................................................................................................4

Safety Requirements...........................................................................................................................4

Handling .............................................................................................................................................4

Storage................................................................................................................................................4

Ground Connections ...........................................................................................................................5

Power Wiring .......................................................................................................................................5

Field Connection Diagrams.................................................................................................................5

SECTION 2 INSTALLATION

Location...............................................................................................................................................5

Foundation .........................................................................................................................................5

Leveling ...............................................................................................................................................5

Grouting ..............................................................................................................................................5

Piping Connections .............................................................................................................................5

Misc Connections................................................................................................................................6

Lubrication ..........................................................................................................................................6

Wiring ....................................................................................................................................................

Power Wiring..................................................................................................................................6

Analog Signal Wiring .....................................................................................................................6

Pressure Transmitter Wiring ..........................................................................................................6

Differential Pressure Switch Piping and Wiring .............................................................................7

Low Suction Pressure Switch .......................................................................................................7

..........................................................................................................................................................

SECTION 3 START UP

Putting Unit into Service......................................................................................................................7

Adjustments ........................................................................................................................................7

Thermal Relief Valve .......................................................................................................................7

Pressure Reducing Valve (PRV) .....................................................................................................7

High Pressure PRV ........................................................................................................................7

Differential Pressure Switch ..........................................................................................................7

Low Suction Pressure Switch ........................................................................................................7

SECTION 4 MAINTENANCE

Maintenance (Physical)........................................................................................................................8

..........................................................................................................................................................

APPENDIX A System Piping and Unit Installation – Final Check List .......................................................................9

APPENDIX B Electrical Wiring and Control Settings – Final Check List ...................................................................9

APPENDIX C Procedure for Field Balancing Pressure Reducing Valve ..................................................................10

APPENDIX D Troubleshooting Combination Pressure Reducing and Check Valves ........................................11-12

APPENDIX E Hydropneumatic Tank Field Installation ............................................................................................12

3

Page 4

SECTION 1 - GENERAL

1.1 PURPOSE OF MANUAL

1.1.1 This manual is furnished to acquaint the user

with some of the practical ways to install,

operate, and maintain this unit. Read it carefully before doing any work on your unit and

keep it handy for future reference. This manual

provides general instructions for installation, commissioning and operation to ensure

optimal performance and reliability.

1.1.2 Equipment cannot operate well without proper

care. To keep this unit at top efficiency, follow the recommended installation and servicing procedures outlined in this manual.

1.1.3 The control panel installed on the pressure

booster system shall have a safety instruction decal (part #S11550 shown below). If the

decal is missing or illegible contact your local

B&G representative for a replacement.

1.2 SAFETY REQUIREMENTS

1.2.1 Motor must have a properly sized starter with

properly sized overload block to provide over

load and undervoltage protection. Ground

fault protection should be sized properly.

1.2.2 Refer to the motor manufacturer’s I.O.M.

(Installation, Operation & Maintenance manual) for

specific installation information.

1.2.3 Even when the motor is stopped, it should be

considered "alive" as long as its controller is

energized. Keep hands away from the output

shaft until the motor has completely stopped

and power is disconnected from the pump

controller.

1.2.4 Motor control equipment and electronic controls are connected to hazardous line volt

ages. When servicing electronic controls,

there will be exposed components at or

above line potential. Extreme care should be

taken to protect against shock. Stand on an

insulating pad and make it a habit to use only

one hand when checking components.

Always use accurate test meters when check

ing electrical components. Always work with

another person in case of an emergency.

Disconnect power when performing maintenance. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electronic control or rotating equipment.

1.3 HANDLING

1.3.1 Care should be taken to prevent damage due

to dropping or jolting when moving the unit.

Inspect the unit thoroughly for damage upon

receipt. Transportation damage should be brought

to the carrier’s attention immediately. Ensure that

sensing lines are free of crimps and kinks.

1.3.2 The unit should be unloaded and handled by qualified personnel. The unit is top heavy due to the

position of the motors. Use the motor eyebolts to

stabilize the unit while lifting to prevent overturning. Do not use the motor eyebolts to lift.

1.4 STORAGE

1.4.1 For periods of storage, the unit should be

covered to prevent corrosion and contamination from dirt. It should be stored in a clean,

dry location to prevent condensation as well

as protected from freezing. After storage,

again check that it is dry before applying

power. Specific component storage instructions must be followed in accordance with

the respective equipment manufacturer’s

recommendations.

WARNING: Make sure the area surrounding the unit

is safe. Be aware of any hazardous conditions that

can exist. Always wear protective glasses and protective

shoes when working with the unit. Do not wear loose fitting

or torn clothing. Remove all jewelry when working.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING:

Motor can start automatically. Keep

hands away from output shaft until motor is completely stopped and input power is removed from the

motor control panel. Lockout main power switch while

working near the motor shaft.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

DANGER: Troubleshooting live control panels exposes

personnel to hazardous voltages. Electrical trouble-

shooting must only be done by a qualified electrician.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: Falling Objects Hazard. Eyebolts or lifting

lugs, if provided, are for lifting only the components

to which they are attached.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

CAUTION: Extreme temperatures are to be avoided.

(Below 32ºF and above 110ºF).

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

4

Page 5

1.5 GROUND CONNECTIONS

1.5.1 A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the

National Electrical Code and local codes must be

followed.

1.6 POWER WIRING

1.6.1 Power wire types and sizes must be selected

based upon conformance with the National

Electrical Code and all local codes and restrictions. In addition, only copper (Cu) wire rated for

75°C (minimum) may be used for the power connections. Refer to the input current as listed on

the nameplate on the enclosure door when sizing

wire.

1.7 FIELD CONNECTION DIAGRAMS

1.7.1 Actual equipment manufacturers/models installed

are system specific. Refer to specific manufacturers

Installation, Operation & Maintenance Manuals for

details unique to each component. The following

instruction manual categories are supplied with

the system (if applicable):

Pump

Technologic 500X Pump Controller

(IOM part #176U7761)

Thermal Relief Valve

PRV

Check Valve

1.7.2 The following field connection diagrams

should be reviewed prior to unit installation

and operation.

SECTION 2 - INSTALLATION

2.1 LOCATION

2.1.1 Locate the pumping system in a clean, well

ventilated and properly drained location. It is recommended that the location selected facilitates

ease of inspection, maintenance and service.

Outside installations require protection from freezing.

2.2 FOUNDATION

2.2.1 This unit is built to give you years of service;

install it properly and provide a suitable foundation.

A base of concrete weighing 2-1/2 times the

weight of the unit is recommended. (Check the

shipping ticket for unit weight.) Tie the concrete

pad in with the finished floor. Foundation bolts of

proper size and pipe sleeve should be set in concrete. The pipe sleeve will allow some flexibility in

bolt alignment to match the holes in the base plate.

Allow sufficient bolt length for grout, shims, base

plate, nuts and washers.

2.3 LEVELING

2.3.1 Place the unit on its concrete foundation, support-

ing it with steel wedges or shims totaling 1" in

thickness. These wedges or shims should be put

on both sides of each anchor bolt to provide a

means of leveling the base. After leveling is complete, evenly and firmly tighten the foundation nuts.

Do not fully tighten the bolts until after grouting.

2.4 GROUTING

2.4.1 After the frame has been leveled and securely

bolted to the pad, a good grade of grout should be

installed beneath the base. A suggested mixture

for grout is: one part Portland Cement and two or

three parts plain, sharp sand mixed with water

until it will pour easily. Commercial grout mixtures

with suspended iron particles are available. Wet the

concrete base before pouring grout. Build a strong

form around the foundation to contain grout. Allow

the grout to flow around wedges & shims and

beneath the entire length of the base flange. Allow

the grout to set, usually 48 hours after pouring,

before fully tightening the foundation bolts.

2.5 PIPING CONNECTIONS

2.5.1 Important. Do not install and operate a Bell &

Gossett Pressure Booster in a closed system

unless the system is equipped with properly sized

control devices. Such devices include the use of

properly sized and located pressure relief valves,

compression tanks, pressure control, temperature

controls and flow controls as appropriate. If the

system does not include these devices, consult

the responsible engineer or architect before making pumps operational.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the

ground lug provided in the enclosure to avoid potential

safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Drawing #

Job Specific Print(s)

Job Specific Print(s)

Description

Wiring Diagram

Dimensional Drawing

DANGER: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by component eyebolts.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

DANGER: The heating of water and other fluids

causes volumetric expansion. The associated forces

may cause failure of system components and releases of

high temperature fluids. This will be prevented by installing

properly sized and located pressure relief valves and compression tanks.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN SERIOUS PROPERTY DAMAGE AND SERIOUS PERSONAL INJURY OR DEATH.

CAUTION: Extreme temperatures are to be avoided

(below 32°F and above 110°F).

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

5

Page 6

2.5.2 After hydrotesting, drain plugs are removed, to

facilitate system drainage, placed in a cloth bag

and secured to the unit. Drain plugs shall be reinstalled prior to filling the system with fluid. Inspect

all unit piping connections. Joints may also

become loose during transit due to vibration and

shock. All joints are to be checked for tightness.

Flanged joints should be checked for proper torque

of all flange bolts prior to filling the system with fluid.

2.5.3 Make all necessary system piping connections. Be

aware that connecting dissimilar metals to the

headers can lead to corrosion damage due to galvanic corrosion. The rate of corrosion is dependant

on various factors some of which are; the potential

between the dissimilar metals, electrolyte conductivity, geometry and area of the metals. Dielectric

connections are recommended between dissimilar

metals at the header connection. Be sure to eliminate any pipe strain on the unit. Support all pipes

independently by use of pipe hangers near the unit.

DO NOT ATTEMPT TO FORCE THE SUCTION OR

DISCHARGE LINES INTO POSITION. Refer to

assembly drawing for customer piping connections.

2.5.4 The maximum suction pressure shall not exceed

150 psi. Dead head pressure plus suction pressure

shall not exceed 175 psi.

2.5.5 As a rule, ordinary wire or band hangers are not

adequate to maintain alignment. It is very important to provide a strong, rigid support for the suction line. A saddle hanger is recommended.

2.5.6 For critical installations, equipment for absorbing

expansion and vibration should be installed at the

inlet and outlet connections of the unit.

2.5.7 Eccentric increasers can be used in the suction pipe

line when increasing the pipe size, with straight

sides of increaser on top to eliminate air pockets.

2.5.8 On an open system with a suction lift, a foot valve

of equal or greater area than the pump suction is

recommended. Prevent clogging by using a strainer

at the suction inlet next to the foot valve. The

strainer should have an area three times that of the

suction pipe. Provisions must be made to prime

the pump suction piping on start up. Do not start

the pump unless all suction piping is full of water.

2.6 MISCELLANOUS CONNECTIONS

2.6.1 Hydro-Pneumatic Tank (optional): The tank is supplied mounted on a separate base for ease of handling, unit installation and space considerations.

Mount the tank adjacent to the unit. A union connection is provided to allow quick connection to

the unit. The tank is intended to maintain system

pressure due to minor system leaks and periods of

low demand.

2.6.2 Pre-charge the Hydro Pneumatic tank prior to filling the system. The tank should be air charged to

the pump restart pressure minus 1 psi. If the tank

is located above the booster, the precharge pressure is calculated by pump restart pressure minus

tank elevation above pressure booster (psi) minus

1 psi.

2.6.3 For tanks supplied by others, refer to appendix E

for tank installation.

2.7 LUBRICATION

2.7.1 Before starting, all pumps and motors should be

checked for proper lubrication.

2.8 WIRING

2.8.1 Refer to the controller instruction manual for electrical connection, set-up and troubleshooting.

2.9 POWER WIRING

2.9.1 The Control Panel is designed to operate at a specific voltage as indicated on the control panel

nameplate. Verify proper transformer primary

wiring per the job-specific wiring diagram. Check

power leads in accordance with wiring diagram

enclosed in control cabinet. The voltage tolerance

is +10%/-10%.

2.10 ANALOG SIGNAL WIRING

2.10.1 If installing the panel on an existing system, twisted

pair shielded cable (#22 AWG, Belden type 8762,

Alpha #2411 or equal) should be installed for the

DC control wiring. The shield must be terminated

in the control panel. Do not connect the shield at

the other end of the cable! Insulate the shield so

that no electrical connection is made at the other

end of the cable. A twisted pair of #22 AWG conductors (Belden 8442 or equal) can be used in

place of shielded cable. The cable length must be

limited to 3000 feet for #22 AWG wire.

2.11 PRESSURE TRANSMITTER WIRING

(4-20 mA Analog Signals)

2.11.1 (Optional) A pressure transmitter, if supplied with

the booster unit, is installed at the discharge

header. Otherwise, a pressure transmitter is supplied loose. It is recommended that the sensor be

installed in the zone furthest away or at the most

critical zone. Refer to wiring diagram for exact terminal locations.

DANGER: Electrical shock hazard. Inspect all

electrical connections prior to powering the unit.

Wiring connections must be made by a qualified electrician

in accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

6

CAUTION: Failure to reinstall drain plugs, check all

joints for tightness and flange bolts for proper torque

could result in leaks and/or flooding.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

Page 7

2.12 DIFFERENTIAL PRESSURE SWITCH

PIPING AND WIRING

2.12.1 (Optional) Differential pressure switches are available to sense the increase in pressure between

the pump suction and discharge gauge taps that

is used to determine whether a pump is running.

The switch is wired normally closed to the control

panel. Refer to wiring diagram for exact terminal

locations. (Differential pressure switch may

require field calibration.) Ref-3.6.1.

2.13 LOW SUCTION PRESSURE

2.13.1 (Optional) Low suction pressure switch is available and intended to stop pump operation when

an insufficient pump suction condition exists. The

switch is wired normally closed to the control

panel. Refer to wiring diagram for exact terminal

locations.

SECTION 3 - START UP

3.1 PUTTING THE UNIT INTO SERVICE

3.1.1 After package is installed and foundation bolts

are tightened, check pump alignment. Refer to

specific pump Installation, Operation &

Maintenance manual for alignment procedures.

3.1.2 Fill system with fluid after reading the cautions in

the piping connection section of this manual.

3.1.3 Vent all high points in the piping system to

removed trapped air.

3.1.4 Before starting all pumps and drivers should be

checked for proper lubrication.

3.1.5 Piping should be clean and flushed prior to

operation.

3.1.6 PUMP ROTATION, 3 PHASE MOTORS ONLY

3.1.7 With the disconnect switch engaged to the "ON"

position, momentarily start and stop each motor.

Observe the pump shaft rotation.

3.1.8 If incorrect, turn the main disconnect off and inter-

change any two wire leads leaving the starter overload block and going to the motor.

3.1.9 Unit is now ready for operation.

3.2 ADJUSTMENTS

3.2.1 Final adjustments on the following adjustable

devices shall be made to match exact system

requirements.

3.3 THERMAL RELIEF VALVE

3.3.1 A thermal relief valve is installed on the discharge

header to prevent potentially dangerous thermal

pressure buildup. The valve automatically opens

on temperature increase and closes on temperature decrease. This valve acts as a safety device

and should never be removed or plugged. It is factory set to open and discharge when the water

temperature in the discharge header reaches

125°F. The 3/8" NPT opening of this valve shall be

piped to a floor drain in accordance with local codes.

3.3.2 To raise the valve opening point, turn the adjustment screw counter-clockwise; to lower the valve

opening point, turn the screw clockwise. The closing point is non adjustable, approximately 3 to 5º F

below opening point.

3.3.3 To flush valve manually, insert a screwdriver under

each side of the lower spring guide. Pry both guide

and spring away from body to open valve.

3.3.4 After long periods of operation, valve seat and disc

may become worn or pitted, allowing leakage

through valve in closed position. Internal parts can

be replace if desired.

3.4 PRESSURE REDUCING VALVE (PRV)

3.4.1 The PRV is used to maintain a desirable pressure

at the discharge header. The PRV is preset at the

factory to the exact system requirements. If further adjustments are necessary refer to the PRV

instruction manual.

3.5 High PRESSURE PRV (If Required)

3.5.1 On systems where the system pressure reaches

above 135 psi a high pressure PRV is required to

protect the thermal relief valve from exceeding its

pressure rating. The high pressure PRV has an

adjustable range from 30 to 300 psi and is manufacturer set at 60 psi. No further adjustments are

recommended.

3.6 DIFFERENTIAL PRESSURE SWITCH (Optional)

3.6.1 The differential pressure switch has a range from

1/2-36 psid and is manufacturer set at 18 psid. It is

recommended that the setting be adjusted to 2 psi

less than the minimum pump differential pressure

to avoid nuisance alarms. The minimum pump differential pressure is equal to the pump discharge

pressure at minimum speed minus suction pressure. To adjust the setting, remove the cover. To

decrease the operating point, face the switch,

place a flat bladed screwdriver in the slots of the

main range adjustment nut and rotate from left to

right. For further information refer to switch

instruction manual supplied with the unit.

3.7 LOW SUCTION PRESSURE SWITCH (Optional)

3.7.1 Manufacturer set at 40 psi. It is recommended that

the setting be adjusted to 10 psi below rated suction pressure. To adjust the setting, remove the

cover. Turn the reference dial to the desired set

point by aligning setting on dial with the dowel pin.

WARNING: Rotating shafts can catch loose clothing.

Do not operate the pump without all guards in place.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

DANGER: High Voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing unit.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

CAUTION: Seal Damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

7

Page 8

SECTION 4 - MAINTENANCE

4.1 MAINTENANCE (PHYSICAL)

4.1.1 Refer to specific component IOM for maintenance

information.

4.1.2 Mechanical - A Series 1531 pump was lubricated

at the factory. Future lubrication should be according to the motor manufacturer’s instructions.

4.1.3 A Series 1510 pump requires regreasing after

every 2500 hours of operation or every six months

whichever occurs first. Lubricate motor per motor

manufacturer’s instruction.

4.1.4 If there is a danger of freezing, drain the pump.

Inspect pump and system piping regularly.

4.1.5 For leaky seals or gaskets and loose or damaged

components, replace or repair as required.

For more instruction on the B&G pumps see the following

manuals: 1510 (IOM Part #P81673) or 1531 (IOM Part

#P81567).

8

Page 9

9

APPENDIX A

____ 1. Is the unit base properly leveled, grouted and

secured?

____ 2. Are all lubrication points properly lubricated?

____ 3. Is the outlet side of the high temperature regulat-

ing valve connected to the drain with tubing or

pipe size 3/8" or greater?

____ 4. Is the shut-off valve to the pressure transmitter(s)

open?

____ 5. Is the shut-off valve to the pump suction open?

____ 6. Is the shut-off valve on the discharge line open?

____ 7. Is the bypass valve, if used, closed? This valve

may be left open if a check valve is installed in

series with it.

____ 8. Are the stop cocks for the check feature on the

PRV open? They must never be completely closed

during normal operation. Throttle cock if check

slamming is noted.

____ 9. Is the piping properly supported so as to prevent

strains on unit?

____ 10. Is the system, including the pumps and PRV’s,

purged of debris and air?

____ 11. Is the Hydro Pneumatic tank charged properly?

The tank must be empty of water when checking

the air charge.

____ 12. Are the bleed valves at the high temperature valve

header open?

APPENDIX B

APPENDIX B

____ 1. Does the feeder line voltage correspond to the unit

voltage? Check the unit nameplate or motor terminal connection.

____ 2. Are the feeder wires correctly sized for the load?

____ 3. Are the fuses correctly sized? They must not

exceed 1.75 times the full load current of the

motor. Usual sizing is 1.15 to 1.5 times the full

load current.

____ 4. Is the unit properly grounded?

____ 5. Have all the power terminals in the control panel

been checked for tightness? This is imperative

since stranded wires tend to "flow" and become

loose after initial installation.

____ 6. Are motor overloads set properly? Set the over-

loads to FLA as a minimum and SF x FLA as a

maximum.

____ 7. Is the pump rotation correct?

CAUTION: Seal Damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

WARNING: Electrical shock hazard. Inspect all

electrical connections prior to powering the unit.

Wiring connections must be made by a qualified electrician

in accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the ground

lug provided in the enclosure to avoid potential safety

hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

DANGER: High Voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing unit.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

ELECTRICAL WIRING AND CONTROL SETTINGS - FINAL CHECK LIST

SYSTEM PIPING AND UNIT INSTALLATION - FINAL CHECK LIST

Page 10

10

APPENDIX C

PROCEDURE FOR FIELD BALANCING PRESSURE REDUCING VALVE

COMBINATION PRESSURE REDUCING AND CHECK VALVE

Item Name Primary Function

1 Strainer Prevents orifice from clogging

2 Check Valve Prevents backflow from top of diaphragm when pumping stops.

3 Orifice Provides metered water flow to top-side of diaphragm.

4 Opening Speed Flow Control Dampens pressure fluctuations (slow opening).

5 CRD Pilot PRV.

6 Gauge Optional location for system pressure gauge.

7 Cock Adjustment for rate of closure (non-slam).

8 Check Valve Prevents backflow from top of diapgragm during normal operation.

9 Vent Bleeds air from top of diaphragm.

10 Diaphragm Divides inlet and outlet pressures.

Figure 2

1.0 Pressure Reducing valve (PRV) Adjustment

1.1 The pressure reducing valves are "factory set". If

needed, the following items should be checked

first before any attempt is made to change the

setting:

a) Does the desired system pressure correspond

to the pressure indicated on the nameplate?

b) Is the suction pressure equal to or higher than

the pressure indicated on the nameplate?

c) Is the demand (GPM) within the capacity indi-

cated on the nameplate?

d) Has the PRV been properly vented?

1.2 Any deviation from the above conditions will prevent the unit from operating at the factory (nameplate) settings.

1.3 To adjust the PRV place the pump in manual operation per Technologic 500X instruction manual.

With the pump now running, slowly close the main

gate valve downstream of the discharge header

allowing a trickle of water to flow through it. Read

the system pressure on the display. It should read

3 or 4 psi higher than the desired system pres-

sure. If not, remove the protective cap on the pilot

control valve and loosen the jam nut on the

adjusting stem of the PRV. Slowly turn the stem

clockwise to increase the delivery pressure and

counter clockwise to decrease pressure. (Note

that a pilot valve furnished for a 20 to 300 psi

range will change the main valve setting approximately 28 psi for each full turn of the adjusting

screw.) Set the screw so the system display reads

3 to 4 psi higher than the desired system pressure.

1.4 Open the gate valve fully. If feasible, draw between 50 to 80% of the designed pump capacity

to recheck valve setting. The display should now

read the desired system pressure. Tighten jam

nut and replace cap.

1.5 Repeat the above procedure for all pump and

valve combinations as required.

1.6 The CV Flow Control Valve (opening speed control) may require field adjustment if pressure hunting occurs. Normal setting of the valve is from 4 to

7 turns open. Never open more than 8 turns.

Page 11

TROUBLESHOOTING COMBINATION PRESSURE REDUCING AND CHECK VALVES

11

DANGER: Troubleshooting live control panels exposes

personnel to hazardous voltages. Electrical trouble-

shooting must only be done by a qualified electrician.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

APPENDIX D

1.0 System Pressure Higher than Desired Set Point

1.1 Primary Causes

a) Insufficient pressure on top side of diaphragm.

b) Leakage through main valve seat.

c) Pressure build-up due to thermal expansion,

such as caused by volumetric expansion of the

water in a heater connected to the system side

of the PRV.

d) Inaccurate system pressure signal.

1.2 Tests and Remedies (see Figure 2 for item numbers)

a) Install gauge, install on CRD (Item 6), if

necessary.

b) Vent air from air vent (Item 9) and from other

high points of PRV trim. Valve cover bolts may

have to be loosened on some units with PRV

mounted horizontally.

c) Check CRD set point adjustment.

d) Close stop cock (Item 7) in check line. If PRV

now operates properly, clean or replace adja-

cent check valve (Item 8).

e) Inspect CRD (Item 5) disc and seat for proper

seating.

f) Inspect strainer (Item 1) that the screen is clean.

g) Inspect orifice (Item 3) that it is not clogged.

h) Plug outlet side of CRD. If main valve closed

tight, the problem most likely is in the CRD.

Replace same. If the main valve does not close

tight, disassemble it for inspection. Check for

scored seat.

2.0 System Pressure Lower than Desired Set Point

2.1 Primary Causes

a) Excessive pressure on top side of diaphragm.

b) Suction pressure below design conditions

(check nameplate on panel door for design

conditions).

c) Desired system pressure is higher than design

condition (check panel nameplate).

d) Flow Rate is greater than design condition.

e) Inaccurate system pressure signal.

2.2 Tests and Remedies (see Figure 2 for item numbers)

a) Install gauge, install on CRD (Item 6), if

necessary.

b) Vent air from air vent and all high points.

c) CRD disc guide or yoke binding.

d) Check motor amps. If greater than full load

amps (motor nameplates), flow rate may be

greater than design.

e) Leak into upper diaphragm chamber. Close

stop cock (Item 7) and remove a connection

between the flow control valve (Item 4) and the

PRV valve cover. Plug the flow control side.

Open pump suction valve and start pump. If

water emits from the valve cover plate, there is

a leak passing the diaphragm into the upper

chamber.

f) Remove valve cover plate for inspection.

Remove "cancerous" buildups which may prevent diaphragm from lifting fully. Check for

binding of valve stem assembly.

g) Opening speed control valve (Item 4)

clogged in restricted flow mode (out of PRV

valve cover).

h) Orifice (Item 3) missing. The orifice fitting identi-

cal in appearance to a flare to MPT adapter,

therefore may have been inadvertently replaced

or misplaced during valve service.

i) Check pump discharge pressure. Does it corre-

spond to the TDH curve?

3.0 System Pressure Slow to Recover from Under

Pressure to Set Point

3.1 Primary Causes

a) Pressure above the diaphragm is not being

removed quickly enough.

b) Mechanical binding in main PRV or CRD pilot

valve.

c) Excessive suction supply line pressure drop.

3.2 Remedies (see Figure 2 for item numbers)

a) Any of the items of 2.2 may be a contributing

factor.

b) Readjust flow control valve (Item 4) to less

restrictive setting, turn counter clockwise.

NOTE: Forcing the stem too far CCW will shear

the stem snap ring and cause the stem to blow

out. Recommend that the stem be initially turned

CW, noting the number of turns required to seat

the stem, then backing it out CCW a few more

turns than the original setting. The maximum

CCW setting is about 9 turns.

4.0 System Pressure Overshoots Greatly and Slow to

Recover to Set Point

4.1 Primary Causes

a) Pressure above the diaphragm is not being

applied soon enough.

b) Mechanical binding in main PRV or CRD pilot

valve.

c) Leaky seat in main PRV or CRD valves.

d) Excessive suction supply line pressure drop.

e) System side surge (water hammer) due to

sudden closure of a quick opening valve.

f) Strainer (Item 1) clogged.

4.2 Remedies (see Figure 2 for item numbers)

a) Any of the items of 1.2 may be contributing

factors.

b) Install larger orifice (Item 3).

Page 12

5.0 PRV Does Not Close (Check) on

Pump Shut Down

5.1 Primary Causes

a) Insufficient pressure on top of diaphragm.

b) Leak through main valve seat or diaphragm

assembly.

5.2 Remedies (see Figure 2 for item numbers)

a) Stop cock (Item 7) closed preventing pressure

from reaching valve cover.

b) Leaking check valve (Item 2).

c) To determine whether leak is in main valve seat

or diaphragm assembly:

1. Disconnect line between flow control valve

(Item 4) and valve cover.

2. Plug flow control side.

3. Install pressure gauge in valve cover.

4. Remove vent plug in pump volute to drain

inlet side of PRV.

5. Apply pressure to top side of diaphragm by

opening shutoff valve on outlet side of PRV.

6. Read gauge pressure.

7. Close stop cock (Item 7).

If gauge pressure fails, there is a leak in the diaphragm assembly. This test, however, does not

indicate whether the seat is also leaking.

6.0 PRV Slams Shut on Pump Shut Down

6.1 Primary Causes

a) Too rapid buildup of pressure on top of

diaphragm.

b) Main valve assembly binding.

c) Check valve (Item 2) sticking open momentarily

6.2 Remedies (see Figure 2 for item numbers)

a) Throttle stop cock (Item 7).

NOTE: Closing this stop cock will completely

prevent PRV from functioning as a check valve.

b) Vent air from PRV (see 1.2b).

APPENDIX E

HYDRO-PNEUMATIC TANK FIELD INSTALLATION

Figure 3

Xylem Inc.

10661 Newkirk Street

Dallas, TX 75220

Phone: (469) 221-1200

Fax: (214) 357-5861

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. S14141B August 2012

Loading...

Loading...