Page 1

VARIABLE SPEED PUMPING SYSTEMS

INSTRUCTION MANUAL

Technologic®5500 Series

Pump Controller

INSTRUCTION MANUAL

S13654B

Serial Communication Option

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

Microprocessor based dedicated pump controller for pump-

ing systems. The communication card is an optional RS-485

module that is plugged into the analog input module.

This safety alert symbol will be used in this manual and on the

Technologic 5500 Safety Instruction decal to draw attention to

safety related instructions. When used, the safety alert symbol

means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTION

MAY RESULT IN A SAFETY HAZARD!

SAFETY

INSTRUCTIONS

Page 2

2

SECTION 1 - GENERAL Page

Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Safety Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Communication Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Communication Setup Table & Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

SECTION 2 -

BACnet MSTP PIC statement for Powersav Pump controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

BACnet MSTP troubleshooting flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 3 -

Johnson Controls N2 Points list for Powersav Pump controllers . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

Johnson Controls N2 troubleshooting flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SECTION 4 -

Modbus Points list for Powersav Pump controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

Modbus troubleshooting flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

SECTION 5 -

BACnet IP Points list for Powersav Pump controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-28

BACnet IP troubleshooting flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Drawing, Operator Interface and CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

NOTE:

The information contained in this manual is intended to assist operating personnel by providing

information on the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the

use of accepted practices in the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your Technologic

5500 series pump controller can be found in the I.O.M.s for the associated equipment provided

see Manual part number S13641, Section 5, Maintenance, for a list of relevant manuals.

Bell & Gossett’s Technologic 5500 is capable of communicating via other protocols. Consult your

local Bell & Gossett Representative for further information.

Table of Contents

Page 3

3

PURPOSE OF MANUAL

This manual is furnished to acquaint you with some of the

practical ways to install, operate, and maintain this unit. Read

it carefully before doing any work on your unit and keep it

handy for future reference.

Equipment cannot operate well without proper care. To keep

this unit at top efficiency, follow the recommended installation

and servicing procedures outlined in this manual.

SAFETY INSTRUCTION

This safely alert symbol will be used in this manual and on the

unit safety instruction to draw attention to safety related instructions. When used the safety alert symbol means

ATTEN-

TION BECOME ALERT! YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN A

SAFETY HAZARD.

Your Technologic Pump Controller should have a safety

instruction decal (part #S11550). If the decal is missing or illegible contact your local B&G representative for a replacement.

ADDITIONAL SAFETY REQUIREMENTS

GROUND CONNECTIONS

A grounding terminal is provided for a dedicated ground wire

connection. All provisions of the National Electrical Code and

local codes must be followed.

COMMUNICATION SIGNALS

Shielded cable (#22 AWG, Belden type 8762, Alpha #2411, or

equal) should be installed for all D.C. control wiring. The shield

must be terminated in the Technologic Pump Controller panel.

Do not connect the shield at the other end of the cable!

Insulate the shield so that no electrical connection is made at

the other end of the cable. A twisted pair of #22 AWG conductors (Belden 8442, or equal) can be used in place of shielded

cable. The cable length must be limited to 5,000 feet for #22

AWG wire.

Section 1 - General

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the ground

lug provided in the enclosure to avoid potential safety hazards.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS PERSONAL INJURY,

DEATH, AND/OR PROPERTY DAMAGE.

DANGER: Troubleshooting live control panels exposes

personnel to hazardous voltages. Electrical trouble-

shooting must only be done by a qualified electrician.

FAIL-

URE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

FAIL-

URE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 4

4

COMMUNICATION SETUP TABLE & TESTING

See the following table for all communication menu items.

COMMUNICATION MENU ITEMS

Field

Menu Item Variable Default Range Value

COM COMM. Setting, Select: # 1 1-3

Select the software protocol to drive the communications on the

optional RS-485 port.

1 = BACnet, 2 = JC N2, 3 = MODBUS, 4 = BACnet IP

0 = EXIT

BACNET

BACnet MS/TP N/A N/A

9600, 8, 1, 1, N Slave

MAC Address: 0

SP Ovrd: (Y/N)

The first line confirms setup for the BACnet protocol. The second

line defines the 9600 bps baud rate, 8 bit data packets, 1 stop bit,

1 start bit and no parity. The third line requires user input. Obtain

the node number from the manufacturer that supplied the device

that will communicate with the Technologic Controller. Select "Y"

for SP Ovrd to allow the external device to override the local

setpoint data.

JCN2

Metasys N2 N/A N/A

9600, 8, 1, 1, N, VND

Node: # SP Ovrd: (Y/N)

The first line confirms setup for the Johnson Controls N2 protocol.

The second line defines the 9600 bps baud rate, 8 bit data packets,

1 stop bit, 1 start bit and no parity. The third line requires user input.

Obtain the node number from the manufacturer that supplied the

device that will communicate with the Technologic Controller.

Select "Y" for SP Ovrd to allow the external device to override the

local setpoint data.

MODBUS

Modbus N/A N/A

9600, 8, 1, 1, N RTU

Node: # SP Ovrd: (Y/N)

The first line confirms setup for Modbus protocol. The second line

defines the 9600 bps baud rate, 1 stop bit, 0 start bits, and no parity.

The third line requires user input. Obtain the node number from the

manufacturer that supplied the device that will communicate with the

Technologic Controller. Note: you must cycle power after changing

the node number to establish communication. Select "Y" for SP Ovrd

to allow the external device to override the local setpoint data.

BACnet IP

IP address: N/A N/A

(First Screen)

###.###.###.###

Subnet:

###.###.###.###

The second line allows the user to change or confirm the settings for

the IP address. The fourth allows the user to change or confirm the

settings for the Subnet address. Obtain the IP and Subnet addresses

from the manufacturer that supplied the device that will communicate

with the Technologic Controller. Use the numeric keypad to change

the numbers and press ENTER key to advance through the series of

three digit sets. Press the NEXT SCREEN key to advance to the

second screen.

Page 5

5

There may have been additional protocols added to the

communication setup menu, contact your Bell & Gossett

representative concerning additional protocols and setups.

See manual part number S13641 for detailed setup information concerning the other controller functions that are not

related to serial communication.

TESTING INPUTS AND OUTPUTS

At the Setup Selection menu, press the ALTERNATION/4 and

ENTER keys.

The display will show:

TEST SELECTION: #

1 = DI 4 = AO 7 = DISP

2 = DO 5 = LED 8 = COMM

3 = AI 6 = KEY 0 = EXIT

When the controller is setup to communicate with the building

automation, press the INFO/8 key while at the test selection

screen, to test the RS communication. The display will show:

Test Communication

B&G Read #

B&G Write #

If the controller is communicating properly, the numbers will

continue increasing in value. For Modbus protocol the read

and write numbers will be equal, BACnet and Johnson N2 protocol the numbers will not be equal. If the numbers are not

increasing in value then the controller is not communicating

properly. If it is not communicating, see the troubleshooting

flow charts in the following sections.

See manual part number S13641 for detailed setup information concerning the other controller functions that are not

related to serial communication.

BACnet IP

Start Delay 10 seconds 10 999

(Second Screen)

Setpoint Override N (Y/N)

Save IP Address N (Y/N)

Exit N (Y/N)

The first line allows the user to setup a time delay prior to establishing

communication after powering the unit. The second line allows the user

to select setpoint override option. Select “Y” for setpoint override to

allow the external device to override the local setpoint data. If the

addresses were changed in the previous screen the changes must be

saved by pressing the YES/7 key. Saving the changes then exiting the

menu forces the controller to cold start. ATTENTION: The cold start

will erase all user values and rest to the default variables! It is recommended that the user setup the addresses first prior to setting the rest

of the screens on the Technologic. If this is not possible then all user

data must be recorded prior to completing this step.

Page 6

6

BACNET MSTP PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT

Vendor Name: Bell & Gossett

Vendor ID: 84

Product Name: Technologic 5500 Pump Controller

Product Description:

Technologic 5500 Pump Controller is a variable speed pumping system designed for HVAC, industrial process and domestic

water booster systems. It operates either as a stand-alone controller or as part of a building-wide integrated system. The

BACnet communication interface will provide communication between Technologic 5500 pump controller and BACnet system

operating at Class 2, residing on EIA-485 media.

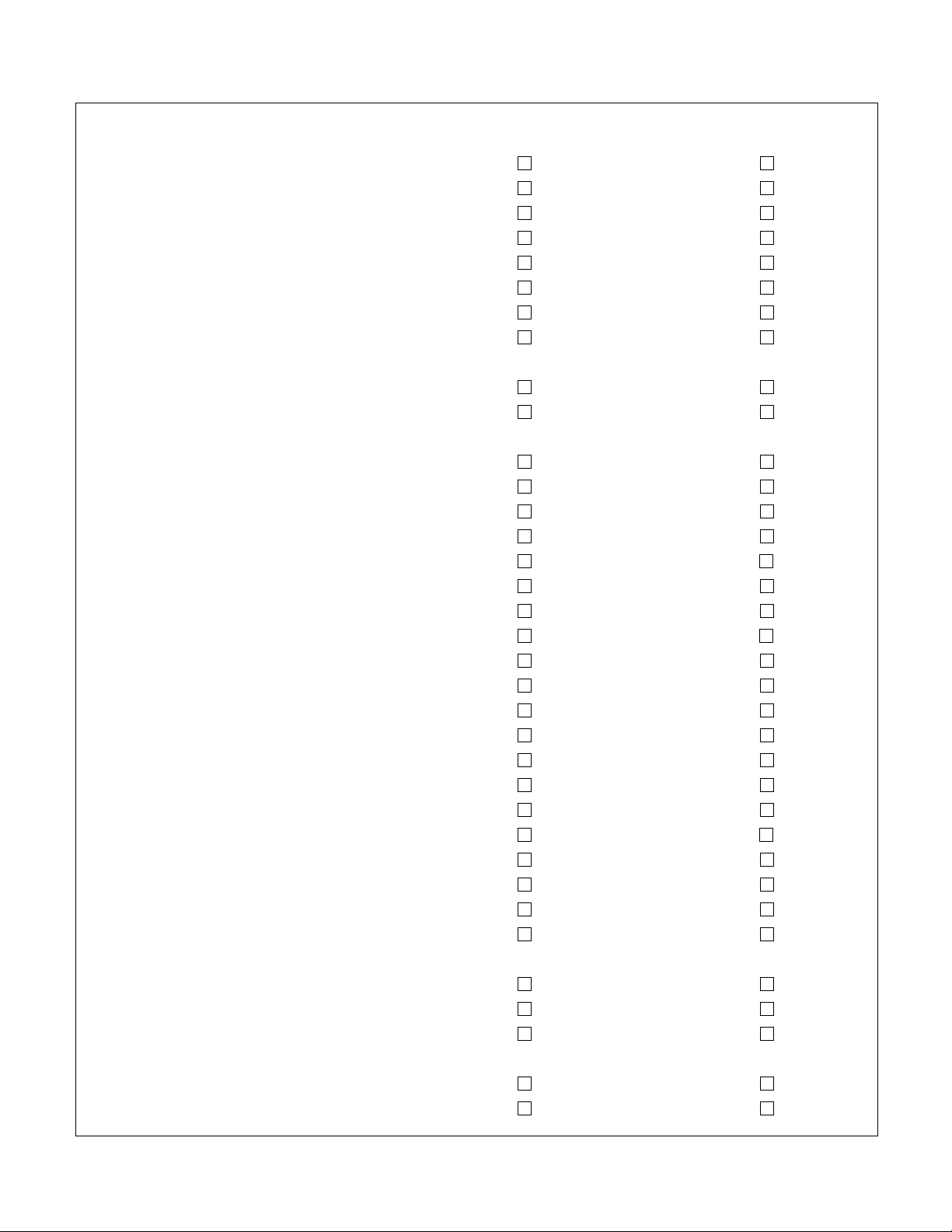

BACnet Conformance Class Supported

Class 1 Class 4

Class 2 Class 5

Class 3 Class 6

BACnet Functional Groups Supported

Clock Files

HHWS Reinitialize

PCWS Virtual Operator Interface

Event Initiation Virtual Terminal

Event Response Device Communications

COV Event Initiation Time Master

COV Event Response

X

Section 2

Page 7

7

BACnet Standard Application Services Supported

Application Initiate Executes

Service Requests Requests

AcknowledgeAlaram

ConfirmedCOVNotification

Confirmed EventNotification

GetAlarmSummary

GetEnrollmentSummary

SubscribeCOV

UnconfirmedCOVNotification

UnconfirmedEventNotification

AtomicReadFile

AtomicWriteFile

AddListElement

RemoveListElement

CreateObject

DeleteObject

ReadProperty

ReadPropertyConditional

ReadPropertyMultiple

WriteProperty

WritePropertyMultiple

DeviceCommunicationControl

ConfirmedPrivateTransfer

UnconfirmedPrivateTransfer

ReinitializeDevice

ConfirmedTextMessage

UnconfirmedTextMessage

TimeSynchronization

Who-Has

I-Have

Who-Is

I-Am

VT-Open

VT-Close

VT-Data

Authenticate

Request Key

X

X

X

Page 8

8

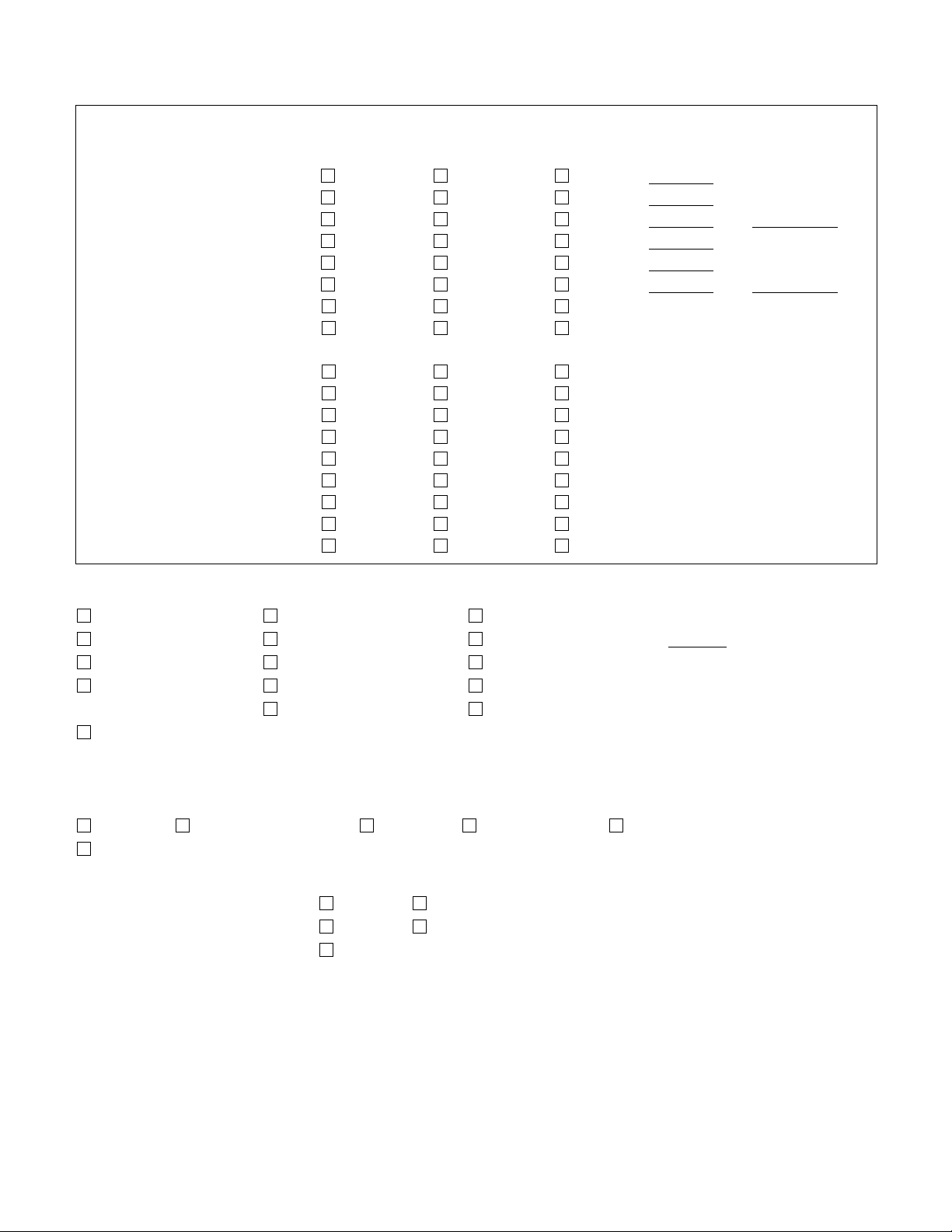

Standard Object Types Supported

Optional

Dynamically Dynamically Properties Writable

Object Type Supported Creatable Deletable Supported Properties

Analog Input None

____________

Analog Output None

____________

Analog Value None

Present Value

Binary Input None

____________

Binary Output None

____________

Binary Value None

Present Value

Calendar _________ ____________

Command _________ ____________

Device Yes N/A N/A _________ ____________

Event Enrollment _________ ____________

File _________ ____________

Group _________ ____________

Loop _________ ____________

Multi-state Input _________ ____________

Multi-state Output _________ ____________

Notification Class _________ ____________

Program _________ ____________

Schedule _________ ____________

Data Link Layer Option

ISO 8802-3, 10BASE5 ARCNET, coax star MS/TP master, baud rate(s): ________________

ISO 8802-3, 10BASE2 ARCNET, coax bus MS/TP slave, baud rate(s): 9600 bps

ISO 8802-3, 10BASET ARCNET, twisted pair star Point-To-Point, EIA 232, baud rate(s): ________

ISO 802-3, Fiber ARCNET, twisted pair bus Point-To-Point, modem, baud rate(s): ________

ARCNET, fiber star LonTalk, medium: _________________________

Other

Character Sets Supported

Indicating support for multiple character sets does not imply that they can all be supported simultaneously.

ANSI X3.4 IBM

™

/Microsoft™DBCS JIS C 6226 ISO 10646 (ICS-4) ISO 10646 (UCS2)

ISO 8859-1

Special Functionality

Segmented Requests Supported yes no Window Size _____________

Segmented Responses Supported yes no Window Size _____________

Router

Describe the supported routing capabilities.

N/A

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

Property Range Restrictions:

X

X

X

X

X

X

X

X

X

X

Page 9

9

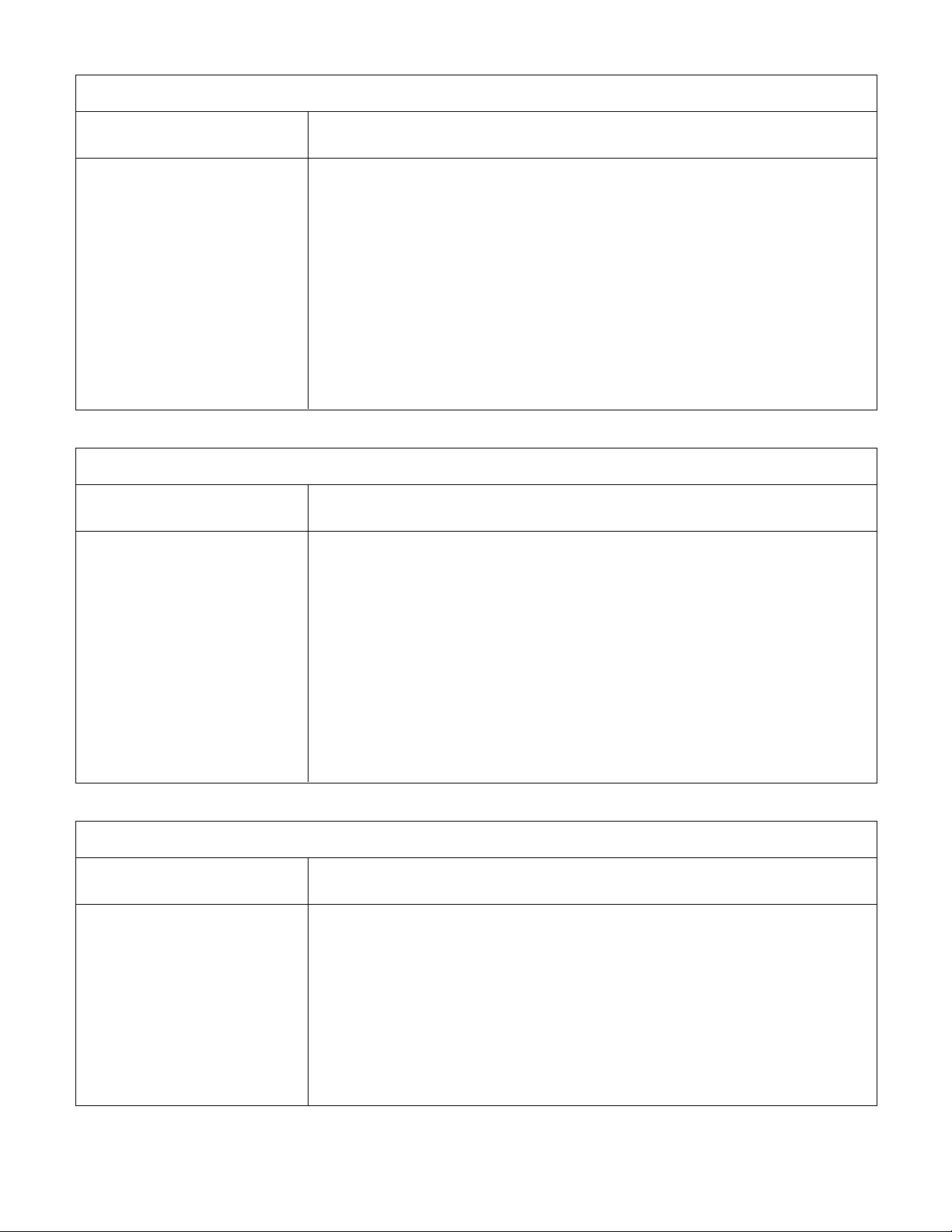

ANALOG INPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 0 Yes No

Present_Value Real Yes No

Status_Flags Bit String Yes No

Event_State Enumberated Yes No

Out_Of_Service Boolean 0,1 Yes No

Units Enumerated 0 - 65535 Yes No

High_Limit Real No No

Low_Limit Real No No

ANALOG OUTPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 1 Yes No

Present_Value Real Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Units Enumerated 0 - 141 Yes No

Priority_Array Array of Reals 16 No No

Relinquish_Defaualt Real No No

ANALOG VALUE

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 2 Yes No

Present_Value Real Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Units Enumerated 0 - 141 Yes No

Page 10

10

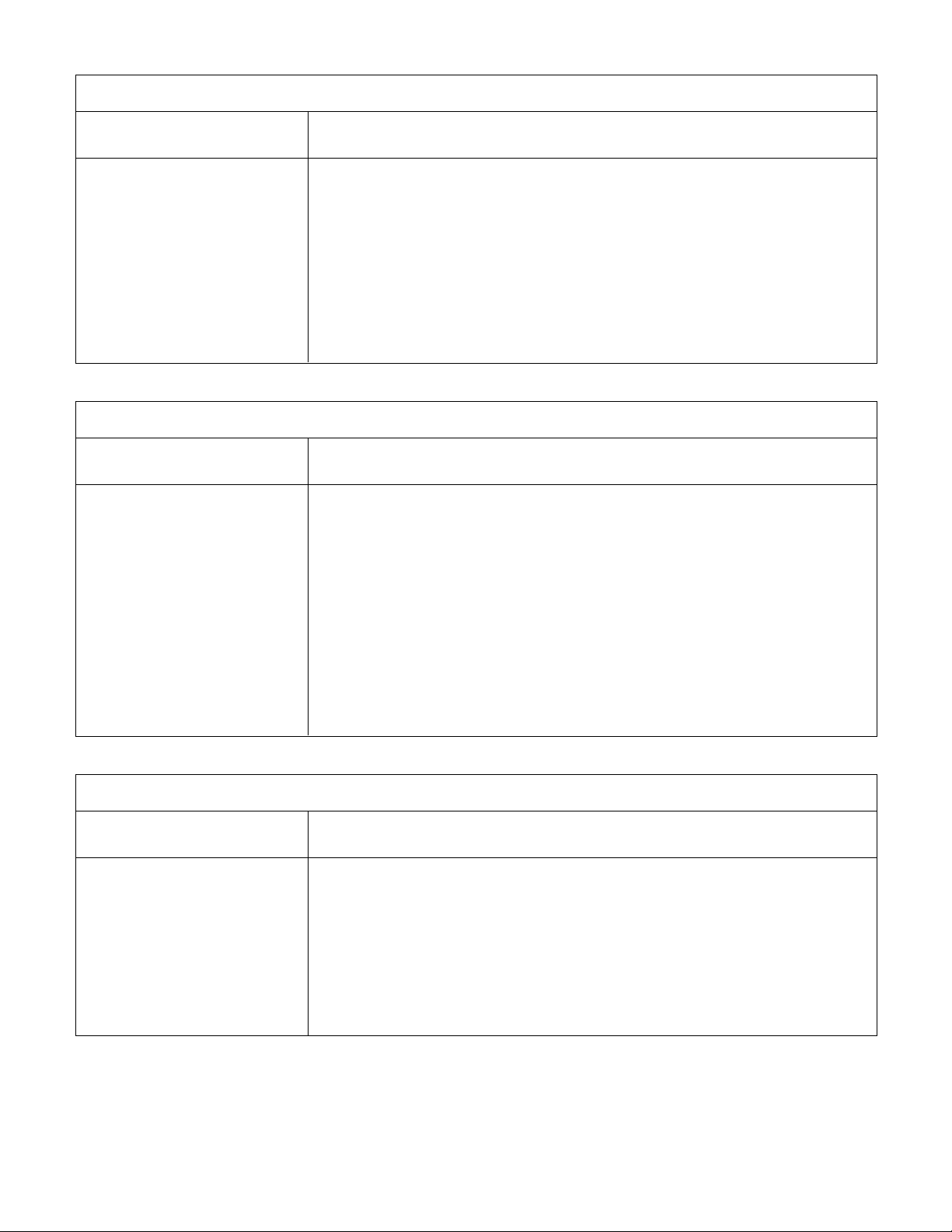

BINARY INPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 3 Yes No

Present_Value Real 0,1 Yes No

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Polarity Enumerated 0 Yes No

BINARY OUTPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 4 Yes No

Present_Value Real 0,1 Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Polarity Enumerated 0,1 Yes No

Priority_Array Array of Enumerated 16 Yes No

Relinquish_Default Enumerated Yes No

BINARY VALUE

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 5 Yes No

Present_Value Real 0,1 Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Page 11

11

BACnet Communication Objects List

Object Identifier Object Name Object Type Present Value/Range UNITS Used

Binary Input, 1 P1 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 2 P1 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 3 P1 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 4 P1 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 5 P2 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 6 P2 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 7 P2 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 8 P2 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 9 P3 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 10 P3 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 11 P3 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 12 P3 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 13 P4 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 14 P4 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 15 P4 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 16 P4 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 17 P5 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 18 P5 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 19 P5 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 20 P5 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 21 P6 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 22 P6 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 23 P6 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 24 P6 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 25 System Reset Req BINARY_INPUT 1 = Yes 0 = No

Binary Input, 26 P1 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 27 P1 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 28 P1 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 29 P2 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 30 P2 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 31 P2 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 32 P3 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 33 P3 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 34 P3 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 35 P4 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 36 P4 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 37 P4 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 38 P5 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 39 P5 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 40 P5 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 41 P6 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 42 P6 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 43 P6 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 44 Pump #1 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 45 Pump #2 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 46 Pump #3 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 47 Pump #4 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 48 Pump #5 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 49 Pump #6 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 50 System Start/Stop BINARY_INPUT 1 = Start 0 = Stop

Binary Input, 51 AI #1 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 52 AI #2 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 53 AI #3 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Page 12

12

BACnet Communication Objects List (continued)

Object Identifier Object Name Object Type Present Value/Range UNITS Used

Binary Input, 54 AI #4 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 55 AI #5 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 56 AI #6 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 57 AI #7 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 58 AI #8 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 59 AI #9 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 60 AI #10 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 61 AI #11 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 62 AI #12 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 63 AI #13 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 64 AI #14 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 65 AI #15 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 66 AI #16 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Output, 1 Pump Sequence Alternation BINARY_OUTPUT 1 = Yes 0 = No

Binary Output, 2 System Reset Request BINARY_OUTPUT 1 = Yes 0 = No

Binary Output, 3 System Start / Stop BINARY_OUTPUT 1 = Start 0 = Stop

Analog Value, 1 Process Variable #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 2 Process Variable #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 3 Process Variable #3 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 4 Process Variable #4 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 5 Process Variable #5 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 6 Process Variable #6 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 7 Process Variable #7 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 8 Process Variable #8 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 9 Process Variable #9 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 10 Process Variable #10 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 11 Process Variable #11 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 12 Process Variable #12 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 13 Process Variable #13 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 14 Process Variable #14 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 15 Process Variable #15 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 16 Process Variable #16 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 17 Flow Rate #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 18 Flow Rate #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 19 System KW ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 20 KW #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 21 KW #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 22 KW #3 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 23 KW #4 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 24 KW #5 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 25 KW #6 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 26 Sys Diff Pressure ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 27 Temp Sensor #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 28 Temp Sensor #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 29 Setpoint #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 30 Setpoint #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 31 Setpoint #3 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 32 Setpoint #4 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 33 Setpoint #5 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Page 13

13

BACnet Communication Objects List (continued)

Object Identifier Object Name Object Type Present Value/Range UNITS Used

Analog Value, 34 Setpoint #6 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 35 Setpoint #7 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 36 Setpoint #8 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 37 Setpoint #9 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 38 Setpoint #10 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 39 Setpoint #11 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 40 Setpoint #12 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 41 Setpoint #13 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 42 Setpoint #14 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 43 Setpoint #15 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 44 Setpoint #16 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 45 Speed % ANALOG_VALUE 0 to 100

Analog Value, 46 Lead Pump Number ANALOG_VALUE 1 to Pump # (in Technologic User Setup Menu)

Analog Value, 47 Active Zone Number ANALOG_VALUE 1 to Zone # (in Technologic User Setup Menu)

Analog Value, 48 Operation Mode ANALOG_VALUE 0=Manual, 1=Auto, 2=Auto Bypass,

3=Manual Bypass

Page 14

14

No

No

No

Correct the Wire

Connections.

Correct the MAC address.

The polling device must set the

device instance number = 100 on

the slave unit.

Check MAC address setting.

Ensure the polling device

knows that device instance

number is set to 100 for the

Technologic 5500 control

panel.

Yes

Yes

Yes

Yes

Yes

BACnet drivers are working

Is B&G Write Counts Active?

(Are write values non-zero and

constanly changing?)

Is B&G Read Counts Active?

(Are read values non-zero and

constanly changing?)

View the “COMMUNICATION” test screen

Is Devise Instance Number set to 100?

(B&G selceted identifiying number)

Is MAC address setting correct?

Range 1-255

Is RS485 Connection Correct?

Data <-> +; N_data <-> -

Start Troubleshooting

BACnet MSTP TROUBLESHOOTING FLOW CHART

Contact Building Control

Manufacturer for the correct

BACnet MS/TP slave unit

requirements

No

Is

B&G Read Count

Active?

Cycle the control

Panel's Power

No

No

Yes

Page 15

15

Section 3

JOHNSON CONTROLS N2 COMMUNICATION POINTS LIST

NPT NPA Point Description Range/Value Units

BI 1 Pump #1 Overload Failure 1 = Failure 0 = O.K.

BI 2 Pump #1 Failure 1 = Failure 0 = O.K.

BI 3 Pump #1 AFD Failure 1 = Failure 0 = O.K.

BI 4 Pump #1 Off Alarm 1 = Alarm 0 = O.K.

BI 5 Pump #2 Overload Failure 1 = Failure 0 = O.K.

BI 6 Pump #2 Failure 1 = Failure 0 = O.K.

BI 7 Pump #2 AFD Failure 1 = Failure 0 = O.K.

BI 8 Pump #2 Off Alarm 1 = Alarm 0 = O.K.

BI 9 Pump #3 Overload Failure 1 = Failure 0 = O.K.

BI 10 Pump #3 Failure 1 = Failure 0 = O.K.

BI 11 Pump #3 AFD Failure 1 = Failure 0 = O.K.

BI 12 Pump #3 Off Alarm 1 = Alarm 0 = O.K.

BI 13 Pump #4 Overload Failure 1 = Failure 0 = O.K.

BI 14 Pump #4 Failure 1 = Failure 0 = O.K.

BI 15 Pump #4 AFD Failure 1 = Failure 0 = O.K.

BI 16 Pump #4 Off Alarm 1 = Alarm 0 = O.K.

BI 17 Pump #5 Overload Failure 1 = Failure 0 = O.K.

BI 18 Pump #5 Failure 1 = Failure 0 = O.K.

BI 19 Pump #5 AFD Failure 1 = Failure 0 = O.K.

BI 20 Pump #5 Off Alarm 1 = Alarm 0 = O.K.

BI 21 Pump #6 Overload Failure 1 = Failure 0 = O.K.

BI 22 Pump #6 Failure 1 = Failure 0 = O.K.

BI 23 Pump #6 AFD Failure 1 = Failure 0 = O.K.

BI 24 Pump #6 Off Alarm 1 = Alarm 0 = O.K.

BI 25 System Reset Required 1 = Yes 0 = No

BI 26 Pump #1 Enabled 1 = Enabled 0 = Disabled

BI 27 Pump #1 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM

BI 28 Pump #1 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass

BI 29 Pump #2 Enabled 1 = Enabled 0 = Disabled

BI 30 Pump #2 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM

BI 31 Pump #2 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass

BI 32 Pump #3 Enabled 1 = Enabled 0 = Disabled

BI 33 Pump #3 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM

BI 34 Pump #3 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass

BI 35 Pump #4 Enabled 1 = Enabled 0 = Disabled

BI 36 Pump #4 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM

BI 37 Pump #4 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass

BI 38 Pump #5 Enabled 1 = Enabled 0 = Disabled

BI 39 Pump #5 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM

BI 40 Pump #5 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass

BI 41 Pump #6 Enabled 1 = Enabled 0 = Disabled

BI 42 Pump #6 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM

BI 43 Pump #6 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass

BI 44 Pump #1 On/Off 1 = On 0 = Off

BI 45 Pump #2 On/Off 1 = On 0 = Off

BI 46 Pump #3 On/Off 1 = On 0 = Off

BI 47 Pump #4 On/Off 1 = On 0 = Off

BI 48 Pump #5 On/Off 1 = On 0 = Off

BI 49 Pump #6 On/Off 1 = On 0 = Off

BI 50 System Start/Stop 1 = Start 0 = Stop

BI 51 Analog Input #1 Failure 1 = Failure 0 = O.K.

BI 52 Analog Input #2 Failure 1 = Failure 0 = O.K.

BI 53 Analog Input #3 Failure 1 = Failure 0 = O.K.

BI 54 Analog Input #4 Failure 1 = Failure 0 = O.K.

BI 55 Analog Input #5 Failure 1 = Failure 0 = O.K.

BI 56 Analog Input #6 Failure 1 = Failure 0 = O.K.

BI 57 Analog Input #7 Failure 1 = Failure 0 = O.K.

BI 58 Analog Input #8 Failure 1 = Failure 0 = O.K.

BI 59 Analog Input #9 Failure 1 = Failure 0 = O.K.

Page 16

16

JOHNSON CONTROLS N2 COMMUNICATION POINTS LIST

NPT NPA Point Description Range/Value Units

BI 60 Analog Input #10 Failure 1 = Failure 0 = O.K.

BI 61 Analog Input #11 Failure 1 = Failure 0 = O.K.

BI 62 Analog Input #12 Failure 1 = Failure 0 = O.K.

BI 63 Analog Input #13 Failure 1 = Failure 0 = O.K.

BI 64 Analog Input #14 Failure 1 = Failure 0 = O.K.

BI 65 Analog Input #15 Failure 1 = Failure 0 = O.K.

BI 66 Analog Input #16 Failure 1 = Failure 0 = O.K.

BO 1 Pump Sequence Alternation 1 = Yes 0 = No

BO 2 System Reset Request 1 = Yes 0 = No

BO 3 System Start / Stop 1 = Start 0 = Stop

ADI 1 Process Variable #1 0 to Span (in Technologic User Setup Menu)

ADI 2 Process Variable #2 0 to Span (in Technologic User Setup Menu)

ADI 3 Process Variable #3 0 to Span (in Technologic User Setup Menu)

ADI 4 Process Variable #4 0 to Span (in Technologic User Setup Menu)

ADI 5 Process Variable #5 0 to Span (in Technologic User Setup Menu)

ADI 6 Process Variable #6 0 to Span (in Technologic User Setup Menu)

ADI 7 Process Variable #7 0 to Span (in Technologic User Setup Menu)

ADI 8 Process Variable #8 0 to Span (in Technologic User Setup Menu)

ADI 9 Process Variable #9 0 to Span (in Technologic User Setup Menu)

ADI 10 Process Variable #10 0 to Span (in Technologic User Setup Menu)

ADI 11 Process Variable #11 0 to Span (in Technologic User Setup Menu)

ADI 12 Process Variable #12 0 to Span (in Technologic User Setup Menu)

ADI 13 Process Variable #13 0 to Span (in Technologic User Setup Menu)

ADI 14 Process Variable #14 0 to Span (in Technologic User Setup Menu)

ADI 15 Process Variable #15 0 to Span (in Technologic User Setup Menu)

ADI 16 Process Variable #16 0 to Span (in Technologic User Setup Menu)

ADI 17 GPM #1 0 to Span (in Technologic User Setup Menu) GPM

ADI 18 GPM #2 0 to Span (in Technologic User Setup Menu) GPM

ADI 19 System KW 0 to Span (in Technologic User Setup Menu) KW

ADI 20 KW #1 0 to Span (in Technologic User Setup Menu) KW

ADI 21 KW #2 0 to Span (in Technologic User Setup Menu) KW

ADI 22 KW #3 0 to Span (in Technologic User Setup Menu) KW

ADI 23 KW #4 0 to Span (in Technologic User Setup Menu) KW

ADI 24 KW #5 0 to Span (in Technologic User Setup Menu) KW

ADI 25 KW #6 0 to Span (in Technologic User Setup Menu) KW

ADI 26 System Differential Pressure 0 to Span (in Technologic User Setup Menu) PSI

ADI 27 Temperature Sensor #1 0 to Span (in Technologic User Setup Menu) F°

ADI 28 Temperature Sensor #2 0 to Span (in Technologic User Setup Menu) F°

ADI 29 Setpoint #1 0 to Span (in Technologic User Setup Menu)

ADI 30 Setpoint #2 0 to Span (in Technologic User Setup Menu)

ADI 31 Setpoint #3 0 to Span (in Technologic User Setup Menu)

ADI 32 Setpoint #4 0 to Span (in Technologic User Setup Menu)

ADI 33 Setpoint #5 0 to Span (in Technologic User Setup Menu)

ADI 34 Setpoint #6 0 to Span (in Technologic User Setup Menu)

ADI 35 Setpoint #7 0 to Span (in Technologic User Setup Menu)

ADI 36 Setpoint #8 0 to Span (in Technologic User Setup Menu)

ADI 37 Setpoint #9 0 to Span (in Technologic User Setup Menu)

ADI 38 Setpoint #10 0 to Span (in Technologic User Setup Menu)

ADI 39 Setpoint #11 0 to Span (in Technologic User Setup Menu)

ADI 40 Setpoint #12 0 to Span (in Technologic User Setup Menu)

ADI 41 Setpoint #13 0 to Span (in Technologic User Setup Menu)

ADI 42 Setpoint #14 0 to Span (in Technologic User Setup Menu)

ADI 43 Setpoint #15 0 to Span (in Technologic User Setup Menu)

ADI 44 Setpoint #16 0 to Span (in Technologic User Setup Menu)

ADI 45 Speed % 0 to 100 %

ADI 46 Lead Pump Number 1 to Pump # (in Technologic User Setup Menu)

ADI 47 Active Zone Number 1 to Zone # (in Technologic User Setup Menu)

ADI 48 System Operation Mode 0=Manual,1=Auto, 2=Auto Bypass, 3=Manual Bypass

Page 17

17

No

No

No

Correct the wire

connections

Change the node number

as defined by the JC

technician

The JC device requires the

JC DLL file for the Technologic

controller to allow the JC

device to see the Technologic

data points.

Change the node number

as defined by the JC

technician

Yes

Yes

Yes

Yes

Yes

Johnson Controls N2 drivers are working

Is B&G Write count active?

(Are write values non-zero and

constantly changing?)

Is B&G Read count active?

(Are read values non-zero and

constantly changing?)

View the “COMMUNICATION” test screen

Is the device

type setting correct in the JC

master setup?

Is the node

number setting correct?

Range 1 - 255

Is RS485 Connection Correct?

Data <-> +; N_data <-> -

Start Troubleshooting

JOHNSON CONTROLS N2 TROUBLESHOOTING FLOW CHART

Contact Building Control

Manufacturer for the correct

JC N2 communication

requirements

No

Is

B&G Read Count

active?

Cycle the Control

Panel’s Power

No

No

Yes

Page 18

18

Section 4

MODBUS Communication Points List

Function Modbus

Code Points # Point Description Range/Value Address Units

02 1 Pump #1 Overload Failure 1 = Failure 0 = O.K. 10001

02 2 Pump #1 Failure 1 = Failure 0 = O.K. 10001

02 3 Pump #1 AFD Failure 1 = Failure 0 = O.K. 10003

02 4 Pump #1 Off Alarm 1 = Alarm 0 = O.K. 10004

02 5 Pump #2 Overload Failure 1 = Failure 0 = O.K. 10005

02 6 Pump #2 Failure 1 = Failure 0 = O.K. 10006

02 7 Pump #2 AFD Failure 1 = Failure 0 = O.K. 10007

02 8 Pump #2 Off Alarm 1 = Alarm 0 = O.K. 10008

02 9 Pump #3 Overload Failure 1 = Failure 0 = O.K. 10009

02 10 Pump #3 Failure 1 = Failure 0 = O.K. 10010

02 11 Pump #3 AFD Failure 1 = Failure 0 = O.K. 10011

02 12 Pump #3 Off Alarm 1 = Alarm 0 = O.K. 10012

02 13 Pump #4 Overload Failure 1 = Failure 0 = O.K. 10013

02 14 Pump #4 Failure 1 = Failure 0 = O.K. 10014

02 15 Pump #4 AFD Failure 1 = Failure 0 = O.K. 10015

02 16 Pump #4 Off Alarm 1 = Alarm 0 = O.K. 10016

02 17 Pump #5 Overload Failure 1 = Failure 0 = O.K. 10017

02 18 Pump #5 Failure 1 = Failure 0 = O.K. 10018

02 19 Pump #5 AFD Failure 1 = Failure 0 = O.K. 10019

02 20 Pump #5 Off Alarm 1 = Alarm 0 = O.K. 10020

02 21 Pump #6 Overload Failure 1 = Failure 0 = O.K. 10021

02 22 Pump #6 Failure 1 = Failure 0 = O.K. 10022

02 23 Pump #6 AFD Failure 1 = Failure 0 = O.K. 10023

02 24 Pump #6 Off Alarm 1 = Alarm 0 = O.K. 10024

02 25 System Reset Required 1 = Yes 0 = No 10025

02 26 Pump #1 Enabled 1 = Enabled 0 = Disabled 10026

02 27 Pump #1 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM 10027

02 28 Pump #1 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass 10028

02 29 Pump #2 Enabled 1 = Enabled 0 = Disabled 10029

02 30 Pump #2 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM 10030

02 31 Pump #2 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass 10031

02 32 Pump #3 Enabled 1 = Enabled 0 = Disabled 10032

02 33 Pump #3 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM 10033

02 34 Pump #3 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass 10034

02 35 Pump #4 Enabled 1 = Enabled 0 = Disabled 10035

02 36 Pump #4 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM 10036

02 37 Pump #4 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass 10037

02 38 Pump #5 Enabled 1 = Enabled 0 = Disabled 10038

02 39 Pump #5 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM 10039

02 40 Pump #5 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass 10040

02 41 Pump #6 Enabled 1 = Enabled 0 = Disabled 10041

02 42 Pump #6 Running In Variable Speed Mode 1 = In VSM 0 = Not In VSM 10042

02 43 Pump #6 Running In Bypass Mode 1 = In Bypass 0 = Not In Bypass 10043

02 44 Pump #1 On/Off 1 = On 0 = Off 10044

02 45 Pump #2 On/Off 1 = On 0 = Off 10045

02 46 Pump #3 On/Off 1 = On 0 = Off 10046

02 47 Pump #4 On/Off 1 = On 0 = Off 10047

02 48 Pump #5 On/Off 1 = On 0 = Off 10048

02 49 Pump #6 On/Off 1 = On 0 = Off 10049

02 50 System Start/Stop 1 = Start 0 = Stop 10050

02 51 Analog Input #1 Failure 1 = Failure 0 = O.K. 10051

02 52 Analog Input #2 Failure 1 = Failure 0 = O.K. 10052

02 53 Analog Input #3 Failure 1 = Failure 0 = O.K. 10053

02 54 Analog Input #4 Failure 1 = Failure 0 = O.K. 10054

02 55 Analog Input #5 Failure 1 = Failure 0 = O.K. 10055

02 56 Analog Input #6 Failure 1 = Failure 0 = O.K. 10056

02 57 Analog Input #7 Failure 1 = Failure 0 = O.K. 10057

02 58 Analog Input #8 Failure 1 = Failure 0 = O.K. 10058

02 59 Analog Input #9 Failure 1 = Failure 0 = O.K. 10059

Page 19

19

MODBUS Communication Points List (continued)

Function Modbus

Code Points # Point Description Range/Value Address Units

02 60 Analog Input #10 Failure 1 = Failure 0 = O.K. 10060

02 61 Analog Input #11 Failure 1 = Failure 0 = O.K. 10061

02 62 Analog Input #12 Failure 1 = Failure 0 = O.K. 10062

02 63 Analog Input #13 Failure 1 = Failure 0 = O.K. 10063

02 64 Analog Input #14 Failure 1 = Failure 0 = O.K. 10064

02 65 Analog Input #15 Failure 1 = Failure 0 = O.K. 10065

02 66 Analog Input #16 Failure 1 = Failure 0 = O.K. 10066

05 1 Pump Sequence Alternation 1 = Yes 0 = No 00001

05 2 System Reset Request 1 = Yes 0 = No 00002

05 3 System Start / Stop 1 = Start 0 = Stop 00003

04, 06 1 Process Variable #1 0 to Span (in Technologic User Setup Menu) 30001, 40001

04, 06 2 Process Variable #2 0 to Span (in Technologic User Setup Menu) 30002, 40002

04, 06 3 Process Variable #3 0 to Span (in Technologic User Setup Menu) 30003, 40003

04, 06 4 Process Variable #4 0 to Span (in Technologic User Setup Menu) 30004, 40004

04, 06 5 Process Variable #5 0 to Span (in Technologic User Setup Menu) 30005, 40005

04, 06 6 Process Variable #6 0 to Span (in Technologic User Setup Menu) 30006, 40006

04, 06 7 Process Variable #7 0 to Span (in Technologic User Setup Menu) 30007, 40007

04, 06 8 Process Variable #8 0 to Span (in Technologic User Setup Menu) 30008, 40008

04, 06 9 Process Variable #9 0 to Span (in Technologic User Setup Menu) 30009, 40009

04, 06 10 Process Variable #10 0 to Span (in Technologic User Setup Menu) 30010, 40010

04, 06 11 Process Variable #11 0 to Span (in Technologic User Setup Menu) 30011, 40011

04, 06 12 Process Variable #12 0 to Span (in Technologic User Setup Menu) 30012, 40012

04, 06 13 Process Variable #13 0 to Span (in Technologic User Setup Menu) 30013, 40013

04, 06 14 Process Variable #14 0 to Span (in Technologic User Setup Menu) 30014, 40014

04, 06 15 Process Variable #15 0 to Span (in Technologic User Setup Menu) 30015, 40015

04, 06 16 Process Variable #16 0 to Span (in Technologic User Setup Menu) 30016, 40016

04 17 GPM #1 0 to Span (in Technologic User Setup Menu) 30017 GPM

04 18 GPM #2 0 to Span (in Technologic User Setup Menu) 30018 GPM

04 19 System KW 0 to Span (in Technologic User Setup Menu) 30019 KW

04 20 KW #1 0 to Span (in Technologic User Setup Menu) 30020 KW

04 21 KW #2 0 to Span (in Technologic User Setup Menu) 30021 KW

04 22 KW #3 0 to Span (in Technologic User Setup Menu) 30022 KW

04 23 KW #4 0 to Span (in Technologic User Setup Menu) 30023 KW

04 24 KW #5 0 to Span (in Technologic User Setup Menu) 30024 KW

04 25 KW #6 0 to Span (in Technologic User Setup Menu) 30025 KW

04 26 System Differential Pressure 0 to Span (in Technologic User Setup Menu) 30026 PSI

04 27 Temperature Sensor #1 0 to Span (in Technologic User Setup Menu) 30027 F°

04 28 Temperature Sensor #2 0 to Span (in Technologic User Setup Menu) 30028 F°

04, 06 29 Setpoint #1 0 to Span (in Technologic User Setup Menu) 30029, 40029

04, 06 30 Setpoint #2 0 to Span (in Technologic User Setup Menu) 30030, 40030

04, 06 31 Setpoint #3 0 to Span (in Technologic User Setup Menu) 30031, 40031

04, 06 32 Setpoint #4 0 to Span (in Technologic User Setup Menu) 30032, 40032

04, 06 33 Setpoint #5 0 to Span (in Technologic User Setup Menu) 30033, 40033

04, 06 34 Setpoint #6 0 to Span (in Technologic User Setup Menu) 30034, 40034

04, 06 35 Setpoint #7 0 to Span (in Technologic User Setup Menu) 30035, 40035

04, 06 36 Setpoint #8 0 to Span (in Technologic User Setup Menu) 30036, 40036

04, 06 37 Setpoint #9 0 to Span (in Technologic User Setup Menu) 30037, 40037

04, 06 38 Setpoint #10 0 to Span (in Technologic User Setup Menu) 30038, 40038

04, 06 39 Setpoint #11 0 to Span (in Technologic User Setup Menu) 30039, 40039

04, 06 40 Setpoint #12 0 to Span (in Technologic User Setup Menu) 30040, 40040

04, 06 41 Setpoint #13 0 to Span (in Technologic User Setup Menu) 30041, 40041

04, 06 42 Setpoint #14 0 to Span (in Technologic User Setup Menu) 30042, 40042

04, 06 43 Setpoint #15 0 to Span (in Technologic User Setup Menu) 30043, 40043

04, 06 44 Setpoint #16 0 to Span (in Technologic User Setup Menu) 30044, 40044

04 45 Speed % 0 to 100 30045 %

04 46 Lead Pump Number 1 to Pump # (in Technologic User Setup Menu) 30046

04 47 Active Zone Number 1 to Zone # (in Technologic User Setup Menu) 30047

04 48 System Operation Mode 0=Manual, 1=Auto, 2=Auto Bypass, 3=Manual Bypass 30048

Page 20

20

No

No

Correct the wire

connections

Change to correct node

number

Yes

Yes

View “COMMUNICATION” test screen

Is Node number setting

correct?

Range 1 -253

Is RS485 Connection Correct?

Data <-> +; N_data <-> -

Start Troubleshooting

MODBUS TROUBLESHOOTING FLOW CHART

No

Contact Building Control

Manufacturer for the correct

Modbus Slave requirements

Are the B&G

Read/Write counters active

(non-zero)?

Cycle the Control

Panel’s Power

Check node

number

setting.

No

Are the B&G

Read/Write counters active

(non-zero)?

Yes

Modbus drivers are

working

Yes

Page 21

21

Section 5

BACnet IP Protocol Implementation Conformance Statement

Vendor Name: Bell & Gossett

Vendor ID: 84

Product Name: Technologic 5500 Pump Controller

Product Description:

Technologic 5500 Pump Controller is a variable speed pumping system designed for HVAC, industrial process and domestic

water booster systems. It operates either as a stand-alone controller or as part of a building-wide integrated system. The

BACnet communication interface will provide communication between Technologic 5500 pump controller and BACnet system

operating at Class 3, residing on Ethernet media.

BACnet Conformance Class Supported

Class 1 Class 4

Class 2 Class 5

Class 3 Class 6

BACnet Functional Groups Supported

Clock □ Files □

HHWS □ Reinitialize □

PCWS □ Virtual Operator Interface □

Event Initiation □ Virtual Terminal □

Event Response □ Device Communications □

COV Event Initiation □ Time Master □

COV Event Response □

BACnet Standard Application Services Supported

Application Initiate Executes

Service Requests Requests

AcknowledgeAlaram □ □

ConfirmedCOVNotification □ □

Confirmed EventNotification □ □

GetAlarmSummary □ □

GetEnrollmentSummary □ □

SubscribeCOV □ □

UnconfirmedCOVNotification □ □

UnconfirmedEventNotification □ □

X

Page 22

22

BACnet Standard Application Services Supported - cont.

Application Initiate Executes

Service Requests Requests

AtomicReadFile □ □

AtomicWriteFile □ □

AddListElement □ □

RemoveListElement □ □

CreateObject □ □

DeleteObject □ □

ReadProperty □

ReadPropertyConditional □ □

ReadPropertyMultiple □

WriteProperty □

WritePropertyMultiple □

DeviceCommunicationControl □ □

ConfirmedPrivateTransfer □ □

UnconfirmedPrivateTransfer □ □

ReinitializeDevice □ □

ConfirmedTextMessage □ □

UnconfirmedTextMessage □ □

TimeSynchronization □

Who-Has □

I-Have

Who-Is

□

I-Am

VT-Open

□ □

VT-Close □ □

VT-Data □ □

Authenticate □ □

Request Key □ □

X

X

X

X

X

X

X

X

XX

X

Page 23

Standard Object Types Supported

Object Type Supported

Dynamically Dynamically

Optional

Writable

Creatable Deleteable

Properties

Properties

Supported

Analog Input □ □ None ____________

Analog Output

□ □ None ____________

Analog Value

□ □ None Present Value

Binary Input

□ □ None ____________

Binary Output

□ □ None ____________

Binary Value

□ □ None Present Value

Calendar

□ □□ _________ ____________

Command

□ □□ _________ ____________

Device Yes N/A N/A _________ ____________

Event Enrollment

□ □□ _________ ____________

File

□ □□ _________ ____________

Group

□ □□ _________ ____________

Loop

□ □□ _________ ____________

Multi-state Input

□ □□ _________ ____________

Multi-state Output

□ □□ _________ ____________

Notification Class

□ □□ _________ ____________

Program

□ □□ _________ ____________

Schedule

□ □□ _________ ____________

Data Link Layer Option

□ ISO 8802-3, 10BASE5 □ ARCNET, coax star □ MS/TP master, baud rate(s): _____________________

□ ISO 8802-3, 10BASE2 □ ARCNET, coax bus □ MS/TP slave, baud rate(s): ______________________

ISO 8802-3, 10BASET

□ ARCNET, twisted pair star □ Point-To-Point, EIA 232, baud rate(s): ____________

□ ISO 802-3, Fiber □ ARCNET, twisted pair bus □ Point-To-Point, modem, baud rate(s): ____________

□ ARCNET, fiber star □ LonTalk, medium: ______________________________

□ Other

Character Sets Supported

Indicating support for multiple character sets does not imply that they can all be supported simultaneously.

ANSI X3.4

□ IBM‰/Microsoft‰ DBCS □ JIS C 6226 □ ISO 10646 (ICS-4) □ ISO 10646 (UCS2)

□ ISO 8859-1

Special Functionality

Segmented Requests Supported □ yes no Window Size _____________

Segmented Responses Supported

□ yes no Window Size _____________

Router

□

Describe the supported routing capabilities. N/A

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

Property Range Restrictions:

X

X

X

X

X

X

X

X

X

X

23

Page 24

24

ANALOG INPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 0 Yes No

Present_Value Real Yes No

Status_Flags Bit String Yes No

Event_State Enumberated Yes No

Out_Of_Service Boolean 0,1 Yes No

Units Enumerated 0 - 65535 Yes No

High_Limit Real No No

Low_Limit Real No No

ANALOG OUTPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 1 Yes No

Present_Value Real Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Units Enumerated 0 - 141 Yes No

Priority_Array Array of Reals 16 No No

Relinquish_Defaualt Real No No

ANALOG VALUE

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 2 Yes No

Present_Value Real Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Units Enumerated 0 - 141 Yes No

Page 25

25

BINARY INPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 3 Yes No

Present_Value Real 0,1 Yes No

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Polarity Enumerated 0 Yes No

BINARY OUTPUT

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 4 Yes No

Present_Value Real 0,1 Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Polarity Enumerated 0,1 Yes No

Priority_Array Array of Enumerated 16 Yes No

Relinquish_Default Enumerated Yes No

BINARY VALUE

Technologic 5500

BACnet Property Return Data Type Range Required Writable

Object_Identifier

Octet String Octet(4) Yes No

Object_Name Character String Char(16) Yes No

Object_Type Enumerated 5 Yes No

Present_Value Real 0,1 Yes Yes

Status_Flags Bit String Yes No

Event_State Enumberated 0 Yes No

Out_Of_Service Boolean 0,1 Yes No

Page 26

26

Technologic 5500

BACnet Communication Objects List

Object Identifier Object Name Object Type Present Value/Range UNITS Used

Binary Input, 1 P1 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 2 P1 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 3 P1 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 4 P1 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 5 P2 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 6 P2 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 7 P2 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 8 P2 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 9 P3 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 10 P3 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 11 P3 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 12 P3 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 13 P4 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 14 P4 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 15 P4 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 16 P4 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 17 P5 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 18 P5 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 19 P5 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 20 P5 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 21 P6 Overload Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 22 P6 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 23 P6 AFD Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 24 P6 Off BINARY_INPUT 1 = Alarm 0 = O.K.

Binary Input, 25 System Reset Req BINARY_INPUT 1 = Yes 0 = No

Binary Input, 26 P1 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 27 P1 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 28 P1 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 29 P2 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 30 P2 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 31 P2 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 32 P3 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 33 P3 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 34 P3 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 35 P4 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 36 P4 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 37 P4 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 38 P5 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 39 P5 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 40 P5 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 41 P6 Enabled BINARY_INPUT 1 = Enabled 0 = Disabled

Binary Input, 42 P6 in Variable Speed BINARY_INPUT 1 = In VSM 0 = Not In VSM

Binary Input, 43 P6 In Bypass Mode BINARY_INPUT 1 = In Bypass 0 = Not In Bypass

Binary Input, 44 Pump #1 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 45 Pump #2 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 46 Pump #3 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 47 Pump #4 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 48 Pump #5 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 49 Pump #6 On/Off BINARY_INPUT 1 = On 0 = Off

Binary Input, 50 System Start/Stop BINARY_INPUT 1 = Start 0 = Stop

Binary Input, 51 AI #1 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 52 AI #2 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 53 AI #3 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 54 AI #4 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 55 AI #5 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 56 AI #6 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Page 27

27

Technologic 5500

BACnet Communication Objects List (continued)

Object Identifier Object Name Object Type Present Value/Range UNITS Used

Binary Input, 57 AI #7 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 58 AI #8 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 59 AI #9 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 60 AI #10 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 61 AI #11 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 62 AI #12 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 63 AI #13 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 64 AI #14 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 65 AI #15 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Input, 66 AI #16 Failure BINARY_INPUT 1 = Failure 0 = O.K.

Binary Output, 1 Pump Sequence BINARY_OUTPUT 1 = Yes 0 = No

Alternation

Binary Output, 2 System Reset Request BINARY_OUTPUT 1 = Yes 0 = No

Binary Output, 3 System Start / Stop BINARY_OUTPUT 1 = Start 0 = Stop

Analog Value, 1 Process Variable #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 2 Process Variable #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 3 Process Variable #3 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 4 Process Variable #4 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 5 Process Variable #5 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 6 Process Variable #6 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 7 Process Variable #7 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 8 Process Variable #8 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 9 Process Variable #9 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 10 Process Variable #10 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 11 Process Variable #11 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 12 Process Variable #12 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 13 Process Variable #13 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 14 Process Variable #14 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 15 Process Variable #15 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 16 Process Variable #16 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 17 Flow Rate #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 18 Flow Rate #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 19 System KW ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 20 KW #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 21 KW #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 22 KW #3 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 23 KW #4 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 24 KW #5 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 25 KW #6 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 26 Sys Diff Pressure ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 27 Temp Sensor #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 28 Temp Sensor #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 29 Setpoint #1 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 30 Setpoint #2 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 31 Setpoint #3 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 32 Setpoint #4 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 33 Setpoint #5 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 34 Setpoint #6 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 35 Setpoint #7 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 36 Setpoint #8 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 37 Setpoint #9 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Page 28

28

Analog Value, 38 Setpoint #10 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 39 Setpoint #11 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Object Identifier Object Name Object Type Present Value/Range UNIT Used

Analog Value, 40 Setpoint #12 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 41 Setpoint #13 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 42 Setpoint #14 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 43 Setpoint #15 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 44 Setpoint #16 ANALOG_VALUE 0 to Span (in Technologic User Setup Menu)

Analog Value, 45 Speed % ANALOG_VALUE 0 to 100

Analog Value, 46 Lead Pump Number ANALOG_VALUE 1 to Pump # (in Technologic User Setup Menu)

Analog Value, 47 Active Zone Number ANALOG_VALUE 1 to Zone # (in Technologic User Setup Menu)

Analog Value, 48 Operation Mode ANALOG_VALUE 0=Manual, 1=Auto, 2=Auto Bypass,

3=Manual Bypass.

Technologic 5500

BACnet Communication Objects List (continued)

Page 29

29

No

No

No

Connect Ethernet cable.

Correct IP address in Tech

Controller.

Correct subnet address in

Tech Controller.

Call Factory for help.

Yes

Yes

Yes

Yes

Yes

BACnet/IP Drive is working

Are B&G Read Write Counts Active?

Are B&G Read Write Counts Active?

View the “COMMUNICATION” test screen

Is Subnet address set correctly

in the Tech Controller?

###.###.###.###

Is IP address set correctly

in the Tech Controller?

###.###.###.###

Is Ethernet cable connected to

Technologic Controller?

Start Troubleshooting

TECHNOLOGIC 5500 BACnet/IP TROUBLESHOOTING FLOW CHART

Check the Ethernet cable

connection & BACnet program

type selection.

No

Does Controller

response the "Ping"

command?

Use "Ping" command

to check the Ethernet

connection.

No

No

Yes

Page 30

RACK O

SERIAL COMMUNICATION

OPTIONAL I/O

OPTIONAL I/O

DIGITAL INPUT

ANALOG INPUT

ANALOG OUTPUT

RACK 1

RS COMMUNICATION DETAIL

DATA

n_DATA

IF321 SERIAL COM

1

2 3 4 5

6 7 8 9

SLOT 2

SLOT 1

SLOT 0

RACK 2

TB1

55

56

G

ETHERNET

RJ-45 CONNECTOR

DRAWING, OPERATOR INTERFACE AND CPU

Page 31

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

10661 Newkirk Street

Dallas, TX 75220

Phone: (469) 221-1200

Fax: (214) 357-5861

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. S13654B August 2012

Loading...

Loading...