Page 1

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

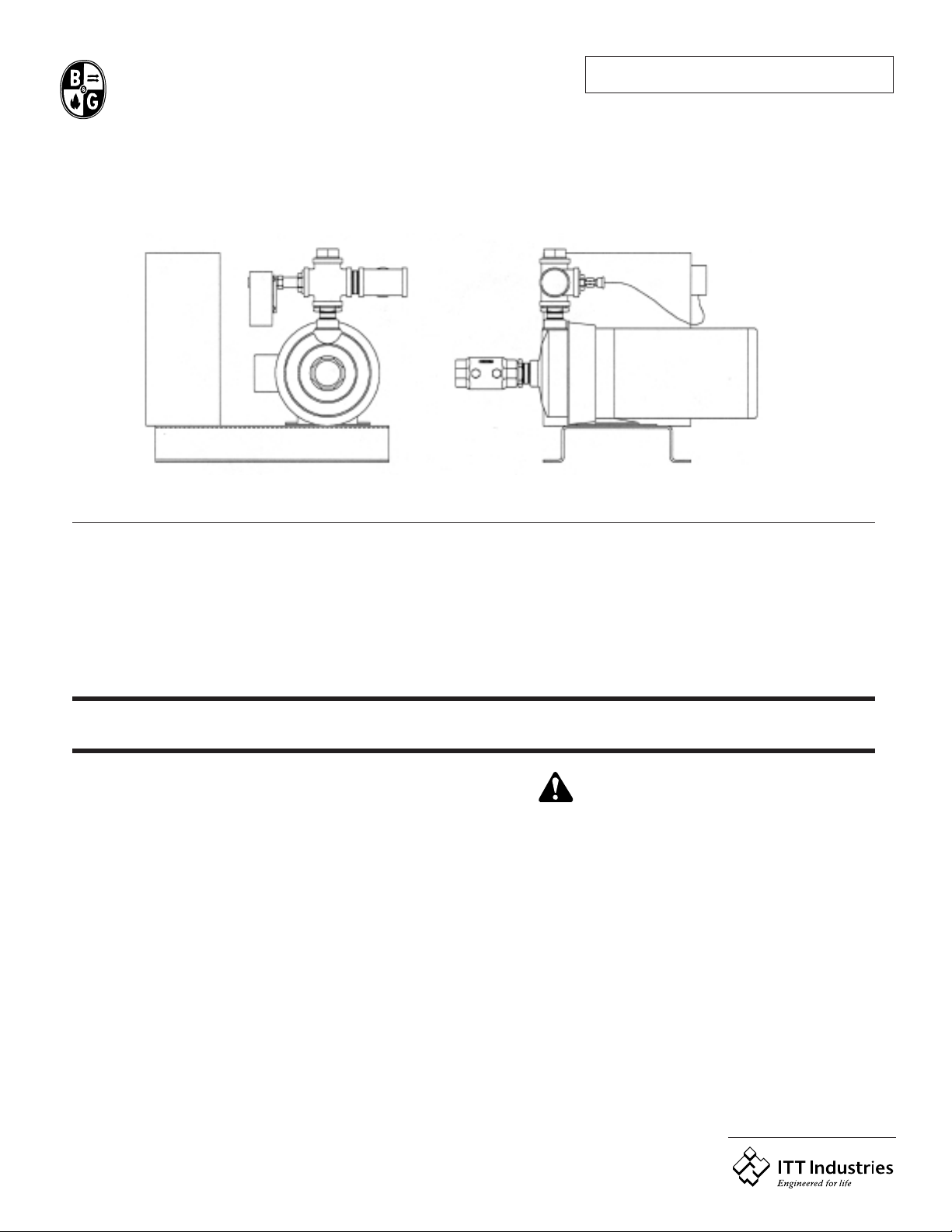

MiniBooster Pumping Package

Installation, Operation and Service Instructions

INSTRUCTION MANUAL

S13213A

Bell & Gossett

Bell & Gossett

DESCRIPTION

Single or dual pump pressure booster for boosting system

pressure by as much as 55 PSI. The pump is automatically

controlled to run on demand to save energy.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on the

MiniBooster Safety Instruction decal to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTION

MAY RESULT IN A SAFETY HAZARD!

Page 2

2

TABLE OF CONTENTS

MiniBooster

Page

SECTION 1 - General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

- Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

- Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

- Storage & Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

- Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION 2 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 3 - Putting the Unit into Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

- Adjustments & Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 4 Final Check Lists

- Start Up Check List - Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

- Start Up CheckList - Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

APPENDIX 1 Programmable Pump Sequence Control Module for Duplex Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FIELD PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

NOTE: The information contained in this manual is intended to assist operating personnel by providing information

on the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances and the use of

accepted practices in the installation, operation and maintenance of this equipment.

Further information pertaining to the installation, operation, and maintenance of your MiniBooster Pumping

System can be found in the Installation Operation and Maintanence manuals for the associated equipment

provided:

A. Bell & Gossett 3530 Pump (IOM Part #P81845)

B. Tank (Model Specific)

Page 3

3

1.0 GENERAL DESCRIPTION

1.1 The MiniBooster pumping packages will increase the

domestic water pressure at the fixtures from 20 to 55

PSI above that of the city water pressure.

1.2 Depending upon the pumping capacity required, a

Simplex (one pump) type or a Duplex (two pump)

type is used. In both types, a pressure switch starts

and stops the pump(s).

1.3 PURPOSE OF MANUAL

1.4 This manual is furnished to acquaint you with some

of the practical ways to install, operate, and maintain

this unit. Read it completely before doing any work

on your unit and keep it handy for future reference.

1.5 Equipment cannot operate well without proper care.

To keep this unit at top efficiency, follow the recommended installation and servicing procedure outlined

in this manual.

1.6 SAFETY INSTRUCTION

1.7 This safety alert symbol will be used in this manual to

draw attention to safety related instructions. When

used the safety alert symbol means ATTENTION

BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THIS INSTRUCTION MAY

RESULT IN A SAFETY HAZARD.

1.8 ADDITIONAL SAFETY REQUIREMENTS

1.9 Always use accurate test meters when checking electrical components. Always work with another person

in case of emergency.

1.10 STORAGE

1.11 For long periods of storage, the unit should be covered to prevent corrosion and contamination from

dirt. It should be STORED in a clean, dry location

between 0 and 170°F. The relative humidity should

not exceed 85%. The unit should be checked periodically to ensure that no condensation has formed.

After storage, again check that it is dry before applying power.

1.12 HANDLING

1.13 Care should be taken to prevent damage due to

dropping or jolting when moving the MiniBooster.

Transportation damage should be brought to the

carrier's attention immediately upon receipt.

1.14 TEMPERATURE AND VENTILATION

1.15 All electrical equipment is susceptible to failure if

operated in ambient temperatures outside of its rating. The OPERATING temperature range for this unit

is 32 to 105°F. The relative humidity should not

exceed 95% non-condensing. The unit should not be

operated outside these extremes.

1.16 ELECTRICAL CONNECTIONS - A.C. POWER &

SIGNALS INPUT VOLTAGE

1.17 The input voltage tolerance is +10/-10% of nameplate voltage.

1.18 GROUND CONNECTIONS

1.19 A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the National

Electrical Code and local codes must be followed.

1.20 POWER WIRING

1.21 Power wire types and sizes must be selected based

upon conformance with the National Electrical Code

and all local codes and restrictions. In addition, only

copper (Cu) wire rated for at least 75°C may be used

for the power connections. Refer to the input current

as listed on the motor nameplate when sizing wire.

1.22 FIELD CONNECTION DIAGRAMS

1.23 Refer to the 3530 pump Installation, Operation, and

Maintenance manual for specific details unique to the

pump.

1.24 The following field connection diagrams should be

reviewed prior to unit installation and operation.

Drawing # Description Page

1MBD02 Piping: Simplex 8

1MBD03 Piping: Duplex 9

1SWD01 or

1SWD02 Wiring, Simplex (shipped w/ unit)

1SWD03 Wiring, Duplex (shipped w/ unit)

1380 _ _ Unit specific Drawing (shipped w/ unit)

WARNING: ELECTRICAL SHOCK HAZARD. IN-

SPECT ALL ELECTRICAL CONNECTIONS PRIOR TO

POWERING THE UNIT. WIRING CONNECTIONS MUST

BE MADE BY A QUALIFIED ELECTRICIAN IN ACCORDANCE WITH ALL APPLICABLE CODES, ORDINANCES,

AND GOOD PRACTICES.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: CONDUIT GROUNDS ARE NOT ADE-

QUATE. A SEPARATE GROUND WIRE MUST BE

ATTACHED TO THE GROUND LUG PROVIDED IN THE

ENCLOSURE TO AVOID POTENTIAL SAFETY HAZARDS.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: PREVENT ELECTRICAL SHOCKS. DIS-

CONNECT THE POWER SUPPLY BEFORE BEGIN-

NING INSTALLATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 4

4

2.0 INSTALLATION INSTRUCTIONS

2.1 Locate the pumping unit for ease of inspection, maintenance, and service.

2.2 Place the unit preferably on a concrete floor or

base. Level the steel base, on which the pumps are

mounted, in both directions by placing steel shims

between the base and the anchor bolts.

2.3 A well-leveled and secured unit will result in quiet

operation as well as longevity of service.

2.4 See drawing 1MBD02 (Simplex) or 1MBD03 (Duplex)

in Section 6 for general piping requirements.

2.5 Eccentric increasers can be used in the suction line

when increasing the pipe size. The straight side of

eccentric reducers should be installed with the flat

side on top to eliminate air pockets. Support the suction and discharge lines independently by the use of

pipe hangers or anchors. Do not attempt to spring

the suction and discharge lines into position. It is recommended that a three (3) valve by-pass between

the suction and discharge be installed at this time.

See drawing 1MBD02 or 1MBD03 for location of

valves.

2.5.1 IMPORTANT: Do not install and operate Bell &

Gossett Pumps in closed systems unless the system

is constructed with properly sized safety devices and

control devices. Such devices include the use of

properly sized and located pressure relief valves,

compression tanks, pressure controls, temperature

controls and flow controls as appropriate. The

MiniBooster includes a high temperatures cut out. If

the system does not include the other devices, consult the responsible engineer or architect before making pumps operational.

2.6 IMPORTANT: Unless the piping to which the vibra-

tion eliminators are connected to are properly

anchored to the floor, the benefits may not be fully

realized. See drawing 1MBD02 (Simplex) or 1MBD03

(Duplex).

2.7 The power supply required for the unit is either

230/1/60, or 208, 230, 460/3/60 with a dedicated

ground wire. Single phase motors have internal overload protection and three phase motors have external

overload protection in the control panel.

On single phase units the disconnecting means and

short circuit protection are to be supplied and mounted

by others. Three phase units have disconnecting

means and fuses for short circuit protection in the

control panel.

2.8 For units installed with an optional tank, the tank

must be installed to the top connection of the discharge cross for simplex units and the discharge

manifold for duplex units (see 1MBD02 or 1MBD03).

Precharge the tank per the tank specific IOM.

For units installed with an optional low suction pressure switch, the switch, which typically ships loose,

must be piped to the inlet 1/4" tap on the check valve

for simplex units or on of the 1/4" tap on the suction

manifold for duplex units (see 1MBD02 or 1MBD03).

See section 3.10 for instructions on setting the

switch.

DANGER: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by the motor eyebolts. Lift

the unit with slings placed under the unit base rails.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: THE HEATING OF WATER AND OTHER

FLUIDS CAUSES VOLUMETRIC EXPANSION. THE

ASSOCIATED FORCES MAY CAUSE FAILURE OF SYSTEM COMPONENTS AND RELEASE OF HIGH TEMPERATURE FLUIDS. THIS WILL BE PREVENTED BY INSTALLING

PROPERLY SIZED AND LOCATED PRESSURE RELIEF

VALVES AND COMPRESSION TANKS.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: ELECTRICAL SHOCK HAZARD. IN-

SPECT ALL ELECTRICAL CONNECTIONS PRIOR TO

POWERING THE UNIT. WIRING CONNECTIONS MUST

BE MADE BY A QUALIFIED ELECTRICIAN IN ACCORDANCE WITH ALL APPLICABLE CODES, ORDINANCES,

AND GOOD PRACTICES.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: CONDUIT GROUNDS ARE NOT ADE-

QUATE. A SEPARATE GROUND WIRE MUST BE

ATTACHED TO THE GROUND LUG PROVIDED IN THE

ENCLOSURE TO AVOID POTENTIAL SAFETY HAZARDS.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

CAUTION: SEAL DAMAGE MAY OCCUR. DO NOT

RUN PUMPS DRY. FILL AND VENT THE PUMP

VOLUTE PRIOR TO OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

Page 5

5

3.0 PUTTING THE UNIT INTO SERVICE

3.1 Simplex package - for capacities up to 110 GPM.

3.2 Whenever the city water pressure falls below the system pressure switch setting the pump will start

through a power relay.

3.3 When the system pressure rises above the setting of

the system pressure switch the pump will stop (provided the minimum run timer has expired.)

3.4 Duplex package - for capacities up to 220 GPM.

3.5 The lead pump operates identically to the Simplex

package. However, if the draw rate continues to

increase beyond the capacity of the lead pump, the

system pressure will fall and cause Pump 2 On/Off

pressure switch to trip which in turn starts the lag

pump.

3.6 Both pumps will continue to run until the system

pressure rises above the setting of Pump 1 & Pump 2

pressure switches (provided the minimum run timers

have expired.)

3.7 For the duplex unit Pump 2 also acts as a Standby

for Pump 1. In the event there is a call for Pump 1

and it has failed for whatever reason, Pump 2 will

start and act as the lead pump. Once Pump 1 is

fixed, place the Pump 1 HOA into the Off/Reset position and then back to Auto to reset the unit.

3.8 Simplex and Duplex units will run when there is

demand unless one of the following conditions

occurs:

1) The optional low suction pressure switch trips due

to low city pressure

2) The high temperature cut out switch trips due to

the pump deadheading.

The low suction condition will reset automatically

when city pressure returns to an acceptable level.

If the unit cuts out on high temperature the unit can

reset automatically when there is demand by drawing

cooler water throughout the unit and across the temperature sensor. This will cool the sensor and cause

it to change state and restart the pump. A manual

purge can be done by running the unit in "Hand" for

about 5 seconds. The unit can then be put back into

"Auto" for normal operation.

3.9 ADJUSTMENTS AND SETTINGS

3.10 Low Suction Pr

essure Switch (Optional)

3.11 The pressure switch is piped into the suction line.

There is an adjusting dial located inside of the control. This adjustment controls the low suction cutout.

3.12 The differential pressure setting is fixed at 1.5 psi.

Therefore cut in pressure will be the switch setting

plus 1.5 psi.

3.13 Although the scale is calibrated in PSI, it may not correspond exactly to the actual suction gage indication.

Therefore, for critical installations, the setting should

be adjusted according to the gage reading.

3.14 The approximate settings should be set prior to placing the unit in operation to suit the pressure conditions at the installation.

3.15 System Pr

essure Switch (Simplex), Pump 1 & Pump 2

Pressur

e Switch for Duplex

3.16 This switch is piped to the discharge header piping.

There are two adjusting screws located on the top of

the control. Facing the switch, the screw on the right

hand side sets the cut-out

point. This adjustment

must be made first

.

3.17 The screw to the left and towards the front sets the

cut-in

point. Turn the screw until the proper cut-in

point is obtained.

3.18 Although the scales are calibrated in PSI, they may

not correspond exactly to the actual discharge gage

indication. Therefore, for critical installations, the

settings should be adjusted according to the gage

reading. See wiring diagram 1SWD04 for proper settings of the system pressure switches on a duplex

unit.

3.19 Minimum run timer

3.20 For a simplex unit the minimum run timer is factory

set to 5 minutes. The setting should be verified

before unit is place into operation and adjusted if a

shorter minimum run time is desired. See Appendix 1

for instructions on using the programmable pump

sequence control module to set the minimum run

timers for a duplex unit. Appendix 1 also contains

information about setting additional parameters that

are specific to duplex units.

3.21 Aquastat

3.22 The aquastat for high temperature cut out is factory

set for 100°F and should be adjusted if a different cut

out temperature is desired. The switch should not be

set above 225°F.

3.23 Optional Tank

3.24 Since a variety of different tanks can be used with

either the simplex or duplex units refer to the specific

IOM that was shipped with the tank for installation

and operating instructions.

CAUTION: PREVENT SUBSEQUENT DAMAGE. A

UNIT SHOWING SYMPTOMS OF POSSIBLE PROBLEMS (NOISE, LEAKS, VIBRATION, AND/OR CONTINUAL

OPERATION) MUST BE CORRECTED IMMEDIATELY.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

WARNING: ELECTRICAL SHOCK HAZARD. SINGLE

PHASE OR THREE PHASE AC POWER. DISCONNECT AND LOCKOUT POWER BEFORE SERVICING THE

UNIT.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: ELECTRICAL SHOCK HAZARD. DIS-

CONNECT AND LOCKOUT POWER BEFORE SER-

VICING THE UNIT.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 6

6

4.0 FINAL CHECK LIST

A. SYSTEM PIPING AND UNIT INSTALLATION

_____ 1. Is the unit base properly leveled and

secured?

_____ 2. Are all lubrication points properly lubricated?

_____ 3. Is the shut-off valve to the pump suction

open?

_____ 4. Is the shut-off valve on the discharge line

open?

_____ 5. Is the bypass valve, if used, closed?

_____ 6. Is the piping properly supported to prevent

strains on unit?

_____ 7. Is the system, including the pumps, purged

of debris and air?

B. ELECTRICAL WIRING AND CONTROL SETTINGS

_____ 1. Does the feeder line voltage correspond to

the unit voltage? Check the unit nameplate or motor terminal connection.

_____ 2. Are the feeder wires correctly sized for the

load?

_____ 3. Have all the power terminals in the control

panel been checked for tightness? This is

imperative since stranded wires tend to "flow"

and become loose after initial installation.

_____ 4. Are the pressure controls correctly set?

The pressure switch(es) need to be set for

proper operation. Any subsequent change

in system operating conditions may require

resetting the controls. For best results,

use compressed air and a continuity meter

(across the switch) to reset the controls.

The legend plate on the control indicates

approximate readings only, therefore,

should be used with caution.

5.0 TROUBLESHOOTING

5.1 Pump will not operate:

1) Check incoming power

2) Check power fuses. Replace if blown.

3) Check transformer fuses. Replace if blown.

4) Check to see that control voltage is 120 volt.

5) Check motor overload. Reset if tripped.

6) Momentarily turn HOA switch to HAND position

and back to OFF. Does starter pull in? If starter

doesn’t pull into go to next step. If it does pull in

go to step 10.

7) Turn HOA switch to HAND position. Check volt

age across terminals for coil in starter. If voltage

is present and the starter is not pulled in, the coil

is defective and must be replaced. If voltage isn’t

present go to step 8.

8) With HOA still in HAND, check voltage between

HOT side of starter coil and the neutral (white)

wire. 120 volts should be measured. If voltage is

measured go to step 9.

9) With HOA still in HAND, check voltage between

the hot side of coil & neutral (white wire) for over

load block. 120 volts should be measured. If volt

age is measured replace the overload block. If no

voltage is present contact local B&G rep to service control circuit.

10) With starter pulled in, check voltage at bottom of

overload block. Voltage should be the same as

the incoming power. If no voltage is present,

replace the starter. If voltage is present, contact

electrician to check the leads & motor.

CAUTION: SEAL DAMAGE MAY OCCUR. DO NOT

RUN PUMPS DRY. FILL AND VENT THE PUMP

VOLUTE PRIOR TO OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN PROPERTY DAMAGE AND/OR MODERATE

PERSONAL INJURY.

DANGER: Troubleshooting live control panels ex-

poses personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electrician.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: ELECTRICAL SHOCK HAZARD. IN-

SPECT ALL ELECTRICAL CONNECTIONS PRIOR TO

POWERING THE UNIT. WIRING CONNECTIONS MUST

BE MADE BY A QUALIFIED ELECTRICIAN IN ACCORDANCE WITH ALL APPLICABLE CODES, ORDINANCES,

AND GOOD PRACTICES.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: CONDUIT GROUNDS ARE NOT ADE-

QUATE. A SEPARATE GROUND WIRE MUST BE

ATTACHED TO THE GROUND LUG PROVIDED IN THE

ENCLOSURE TO AVOID POTENTIAL SAFETY HAZARDS.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

WARNING: ELECTRICAL SHOCK HAZARD. SINGLE

PHASE OR THREE PHASE AC POWER. DISCONNECT AND LOCKOUT POWER BEFORE SERVICING THE

UNIT.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 7

7

5.2 Pump will not build pressure

1) Check rotation; rotation should be as indicated on

the pump volute. If rotation is wrong disconnect

power. For three phase motors, switch any two

leads at bottom of starter. If motor is single

phase, refer to wiring diagram on nameplate.

2) Suction valve is closed. If closed, open.

3) Motor not operating at rated RPM. Have motor

checked at local motor repair shop.

4) Internal pump damage. Take pump to authorized

pump repair facility.

5.3 Pump will not start automatically

1) No power. Restore if there is no power.

2) No control circuit. Restore control circuit power.

3) HOA switch not in the AUTO position. Turn

switch to AUTO position.

4) System pressure (Simplex) or Pump 1 & Pump 2

(Duplex) pressure switches not adjusted properly.

Refer to section 3.

WARNING: ELECTRICAL SHOCK HAZARD. IN-

SPECT ALL ELECTRICAL CONNECTIONS PRIOR TO

POWERING THE UNIT. WIRING CONNECTIONS MUST

BE MADE BY A QUALIFIED ELECTRICIAN IN ACCORDANCE WITH ALL APPLICABLE CODES, ORDINANCES,

AND GOOD PRACTICES.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

DANGER: High voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing unit.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL

RESULT IN SERIOUS PERSONAL INJURY, DEATH,

AND/OR PROPERTY DAMAGE.

Page 8

8

APPENDIX 1 - PROGRAMMABLE PUMP

SEQUENCE CONTROL MODULE

1.1 The control system allows for intelligent pump control

while improving system reliability. Timers and relays

used in a conventional controller are integrated into a

single sequence controller. Because all of the timers

and relays are software, changes can be made to the

system operation without costly re-wiring. The working program is stored on a non-volatile EEPROM chip

that is an integral part of the unit. This means there is

no danger of ever losing a program due to power

losses.

1.2 A 7-day military time clock is standard. It is maintained by a super capacitor for a minimum of 8 hours

under a power loss condition. See section 2.4 for

instructions on how to set the clock.

1.3 The following page demonstrates a typical parameter

change. The programming of the module is very similar to setting a digital watch. As each unit will contain

a program that has been specifically designed for the

application, the actual data you will see will vary from

that shown in the example.

2.0 CHANGING A PARAMETER VALUE

2.1 Adjustable Settings

2.2 If any alarms are shown on the display of the programmable pump sequence control unit press the

ESC key to proceed with the following instructions.

2.3 Pressing the ESC key will cause the unit display to

show the following selections:

STOP – Do not use, this will stop the program

SET PARAM – Follow instructions as follows

SET CLOCK – Follow instructions as follows

PRG NAME – The name of the program loaded in the

module, such as: 2 pump with duty

Use the up and down arrow keys to select SET PARAM

and press the OK key to accept your selection.

2.4 If you wanted to set the time you would have selected

Set Clock instead. The time would have been set the

same as any other value in the module.

2.5 After selecting SET PARAM and pressing the OK key

the display will change as shown to the right.

The parameter number

is indicated here.

The preset value is

indicated here.

A live display of the

timer in question is

shown here. This can be

helpful if you just need

to see when a timer is

about to expire.

2.6 Press the Up and down arrow keys to select the

parameter you wish to change.

2.7 Press OK to edit the displayed parameter.

2.8 Press the left and right arrow keys to select the digit

you wish to change. Selected digit will flash.

2.9 Press the up and down arrow keys to change the

value of the selected digit as required.

2.10 Press OK to accept the change. Pressing the ESC

key instead of OK will abort and the changes will not

be saved.

2.11 Use the ESC key to return to the main screen. Each

time you press the ESC key you will back up one

level from where you are until you finally return to the

normal operating screen, which is the date and time

display.

Parameter Default Variable

Number Description Setting Range

B01 Lead Pump Minimum Run Timer 10 m 0-99 m

B02 Lag Pump Miimum Run Timer 10 m 0-99 m

B04 Lead Pump Start Delay Timer 1 s 0-99 s

B05 Lag Pump Start Delay Timer 5 s 0-99 s

B07 Pump Fail to Start Delay Timer 5 s 0-99 s

B12 Low Suction/Temp Pump

Shutdown Off-Delay Timer 5 s 0-99 s

B33 Low Suction/Temp Pump

Shutdown On-Delay Timer 5 s 0-99 s

B36 Duty Cycle Alternation

Enable/Disable Switch OFF OFF/ON

When setting item B36 the OFF

selection allows the lag pump to

stage on during periods of high

demand. When B36 is set to ON

the lag pump is a standby pump

which will turn on in the event the

lead pump fails.

Page 9

MiniBooster – Simplex

Typical Field Piping

ANCHOR PIPE SECURELY

IF VIBRATION ELIMINATORS

ARE USED

CITY

SUPPLY

IF BYPASS LINE IS INSTALLED

THIS VALVE MUST BE KEPT CLOSED

DURING NORMAL OPERATION. DO NOT

INSTALL CHECK VALVE.

OPTIONAL

TANK

OPTIONAL PRESSURE

REDUCING VALVE

SUCTION & DISCHARGE

GAUGES RECOMMENDED

VIBRATION

ELIMINATOR

TO

SYSTEM

1/4" INLET TAP ON

CHECK VALVE FOR

LOW SUCTION P/S

9

Page 10

MiniBooster – Duplex

Typical Field Piping

1/4" TAP ON SUCTION

MANIFOLD FOR

LOW SUCTION P/S

OPTIONAL

TANK

ANCHOR PIPE SECURELY

IF VIBRATION ELIMINATORS

ARE USED

OPTIONAL PRESSURE

REDUCING VALVE

SUCTION & DISCHARGE

GAUGES RECOMMENDED

VIBRATION

ELIMINATOR

TO

SYSTEM

CITY

SUPPLY

IF BYPASS LINE IS INSTALLED

THIS VALVE MUST BE KEPT

CLOSED DURING NORMAL

OPERATION. DO NOT

INSTALL CHECK VALVE.

Bell & Gossett

© COPYRIGHT 2001, 2003 BY ITT INDUSTRIES, INC.

PRINTED IN U.S.A. 8-03

USA

Bell & Gossett

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-9052

www.bellgossett.com

INTL.

Bell & Gossett / Export Dept.

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-8366

www.bellgossett.com

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario,

N1H 1T1, Canada

Phone: (519) 821-1900

www.ittfpc.ca

Loading...

Loading...