Page 1

INSTRUCTION MANUAL

Bell & Gossett

TECHNOLOGIC™1100 SERIES

PUMP CONTROLLER

The attached pages are a revision of sections 2.3.3, 2.3.4, and 2.3.5 of the Technologic 1100 Series Pump

Controller Instruction Manual (B&G Part #S11865). Replace these sections (of the manual) in entirety with

the attached.

S11865

Addendum

Revision A

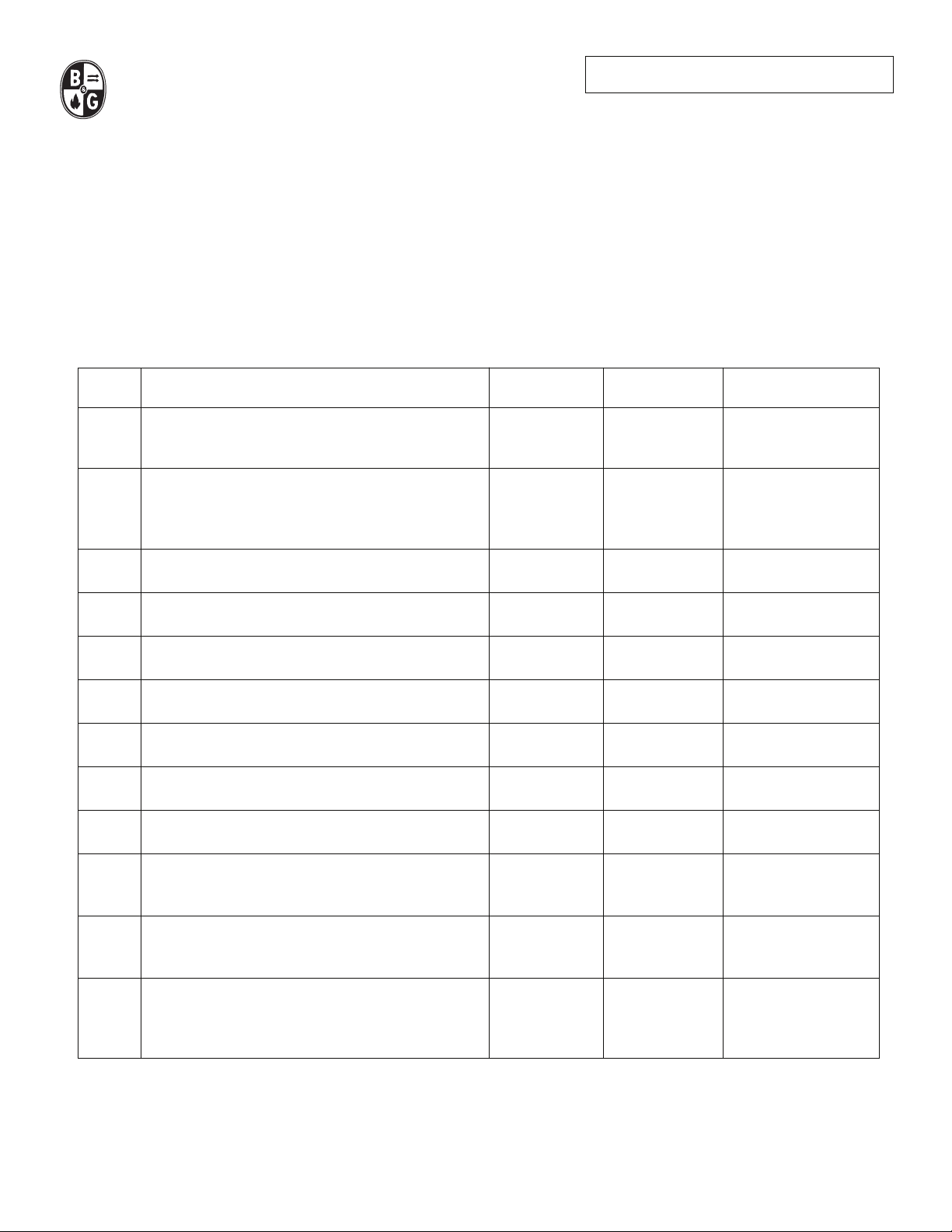

2.3.3 Confirm the system setup values per the following

table. Use the UP or DOWN ARROW keys to move

through the menu. To change values press ENTER,

Menu Default Allowable

Item # System Setup Display Value Range Field Value

01) User Password 0 0-65529

Password for entering User Setup and

password protected Service Test menu.

02) Factory Setup Counter 1 1-10

# of times factory setup menu was performed.

The factory menu can not be accessed

without authorization from the factory.

03) Horizontal Scroll Rate 3 1-10

Horizontal scroll rate in 100 milli-second units.

04) Stage Stable 60 6-600

Staging stabilization time in seconds.

05) Destage Proof 30 3-180

Destage proof time in seconds.

06) AFD Minimum % 30 0-30

AFD minimum % speed.

07) AFD Maximum % 100 0-100

AFD maximum % speed.

08) AFD 1 Fail Time 20 5-999

Proof time for AFD 1 failure time in seconds.

09) AFD 2 Fail Time 20 5-999

Proof time for AFD 2 failure in seconds.

10) Destage % 85 0-99

Enter the percent of the stabilize pump

speed to be used as a destage point.

11) Min. Destage % 0 0-100

Enter minimum % speed for staged

pumps to operate.

12) Forced Dstg Tmr 0 0-999

Proof time prior to forced destaging of the

lag pump when min. speed (Min. Destage %)

of staged pumps is satisfied.

modify the value using the numeric key pad or UP and

DOWN ARROW keys , press ENTER to accept the

modification.

Packaged Systems Group

Bell & Gossett

Page 2

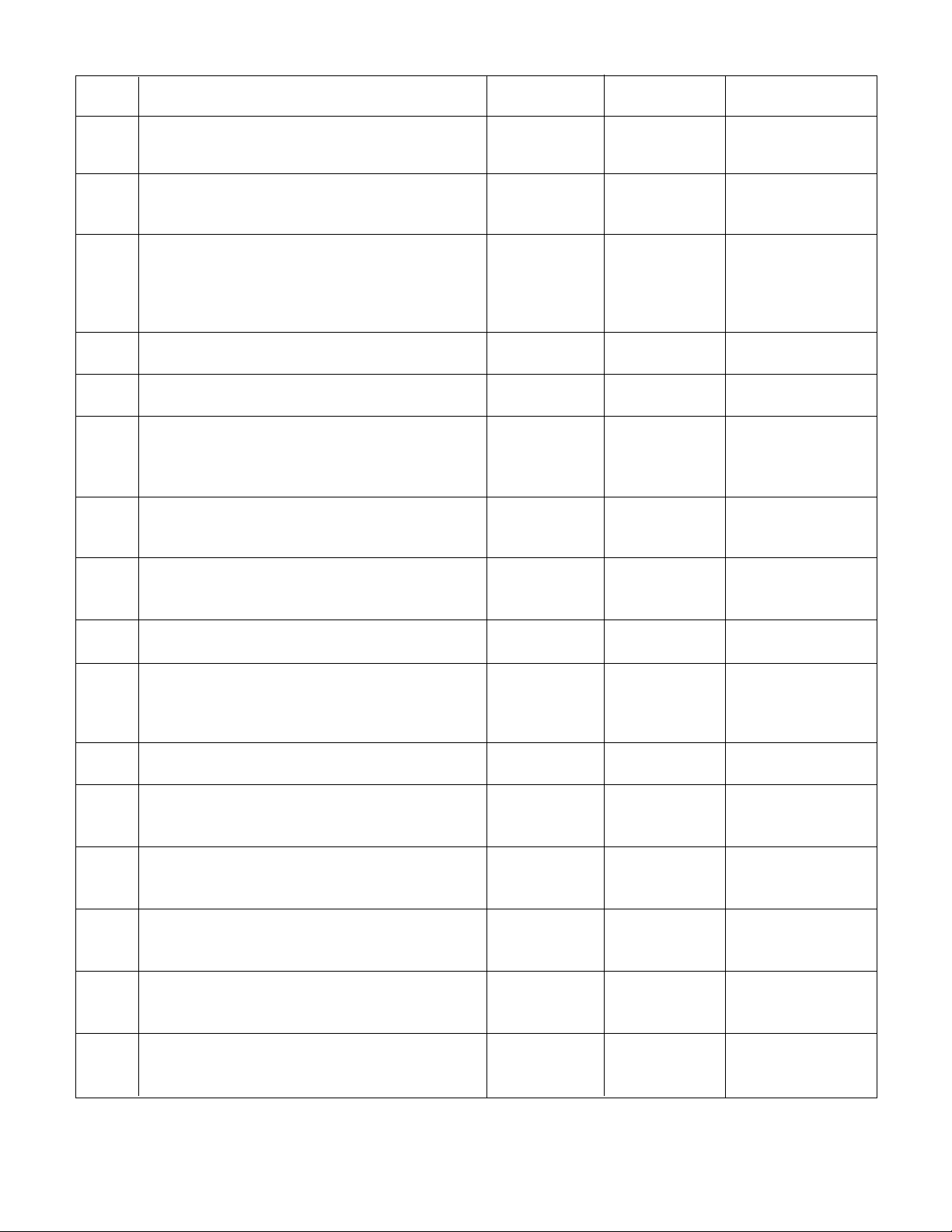

Menu Default Allowable

Item # System Setup Display Value Range Field Value

13) GPM Destg. Val = 0 0 0-9999

Enter GPM at which destage will be forced;

“0” disables this function.

14) GPM Destg. Pr. Tmr. = 0 0 0-999

Enter in seconds (0-999) value of GPM

forced destage proof timer.

15) Time Forced DeStg = 0 0 0-99

Enter in hours (0-99) time after which the lag

pump will be destaged regardless of staging

method (EOC or speed.)

“0” disables this function.

16) DP1 Proof Time 3 0-30

Pump #1 failure proof time in seconds.

17) DP2 Proof Time 3 0-30

Pump #2 failure proof time in seconds.

18) Software DP Failure 0 0-999

Process variable value used to determine

software pump failure. Enter 0 (zero) for

units with differential pressure switches.

19) DP1 Start Time 30 15-60

Time period in seconds to allow Pump 1

to start prior to detecting a pump failure.

20) DP2 Start Time 30 15-60

Time period in seconds to allow Pump 2

to start prior to detecting a pump failure.

21) Speed Default 50 0-100

Operating speed (%) when all zones fail.

22) D4 Fail Mode Pumps 2 0-2

Number of pumps to run when all drives fail

0 = No pumps 1 = Lead pump

2 = Both pumps

23) Max Pump GPM 0 0-9999

End of curve pump protection.

24) Eoc Stg Pr. Tmr 30 0-999

Proof timer (in seconds) prior to starting

lag pump, seconds.

25) Eoc De-Stg % 50 0-100

Percentage of maximum pump GPM at a given

speed below which destaging can occur.

26) Eoc De-Stg Pr. Tmr 30 0-999

Proof timer (in seconds) prior to

stopping lag pump.

27) PID Index 1 1-5

Multiplier of P, I, & D variable for slower

PID response within PID index limit.

28) PID Index Limit 0 0-150

Deviation from setpoint

within which PID Index is active.

2

Page 3

Menu Default

Item #

29) Invert P

System Setup Display Value Range Field Value

.I.D. No Y/N

Used to change from dir

ect to reverse

Allowable

acting. P.I.D.

30) Low Suct. Pr

. Tmr 0 0-999

Low suction alarm proof time delay

in seconds. A value of 0 will disable

the option.

31) High Suct. Pr. Tmr 0 0-999

High suction alarm proof time delay

in seconds. A value of 0 will disable

the option.

32)

High Sys. Press. 0 0-30,000

V

alue when high system pressure

alarm will be activated.

33) HSP Proof Tmr 0 0-60

Proof time prior to

High System pressure shutdown.

34) NFSD Test Pr

. Tmr 0 0-999

No flow shutdown proof time delay,

seconds. A value of 0 will disable

the option.

35) Min Speed Pr. Tmr 30

0-999

Length of time (seconds) drive(s) will operate

at min. speed during no flow shutdown

sequence. If = 0 drive(s) will not stop.

36) Restart PV Drop 0 0-150

Max. difference between setpoint and

process variable prior to restart after no flow

shutdown. If = 0 no flow shutdown is disabled.

37) Min. Run Timer 10 0-999

Time period (minutes) to ignore no flow

shutdown sequence after restart from no

flow shutdown.

38) Active A-V Alarm 0 0-3

If = 0 Disabled

If = 1 Low Suction Alarm only

If = 2 High System Alarm only

If = 3 Low Suct. & High System Alarm

2.3.4 Press the CLEAR key to return to the User Setup

Menu.

2.3.5 Confirm the user setup values per the table on

page 4. Use the UP or DOWN ARROW keys to

move through the menu. To change values press

ENTER, modify the value using the numeric key

pad or UP and DOWN ARROW keys, press

ENTER to accept the modification.

3

Page 4

Loading...

Loading...