Page 1

INSTRUCTION MANUAL

S11574C

Heat Transfer Package

with Air Separation

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

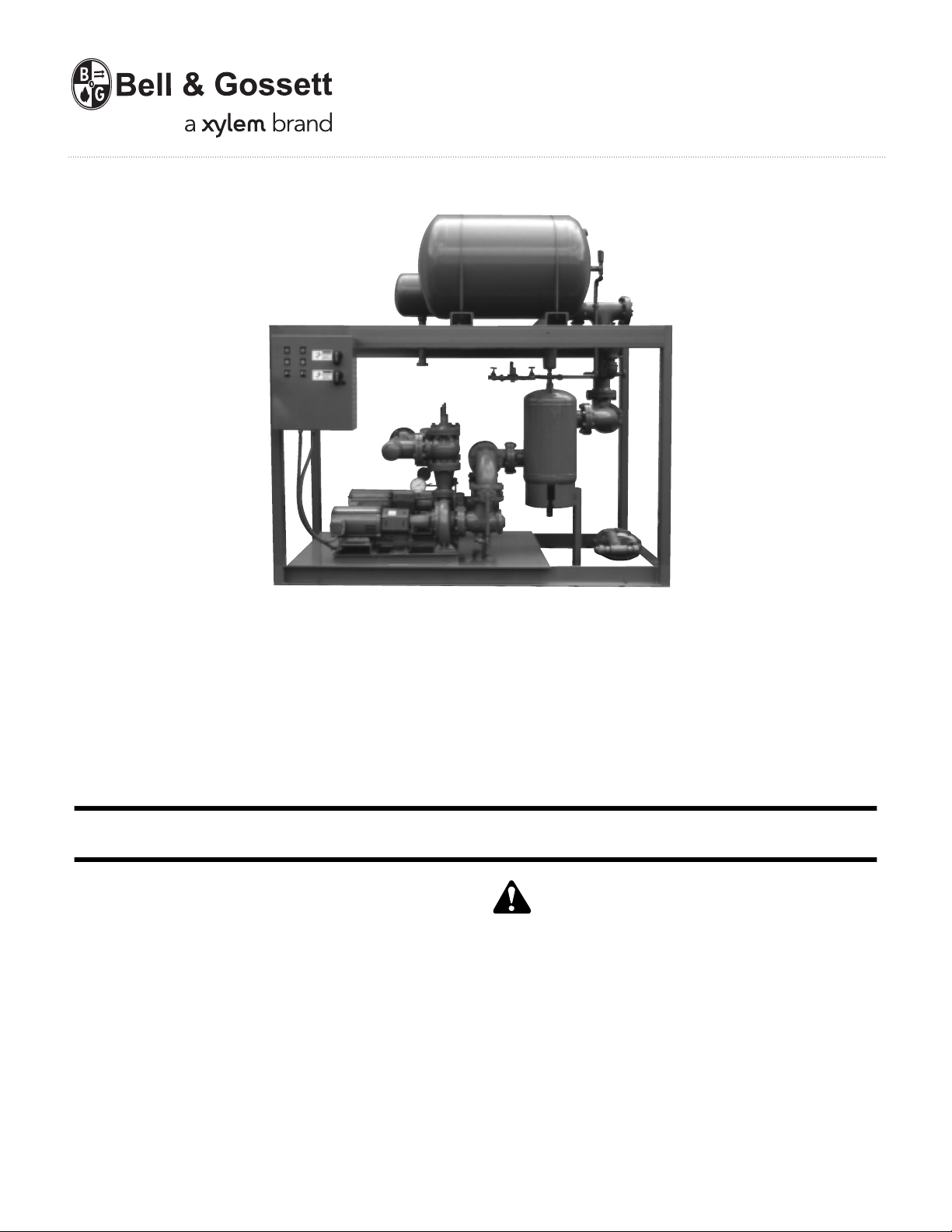

Frame mounted heat transfer package consisting of but not

limited to: heat exchanger, air separation apparatus, pump(s),

motor(s), triple duty check valve(s), relief valve(s), pressure

reducing valve, gauge(s), thermometer, and interconnecting

piping. The following options are also available: motor starter(s),

condensate trap, and steam valve.

OPERATIONAL LIMITS

The standard design pressure is 125 PSI unless otherwise indicated. The ASME nameplates will indicate the ratings of the

pressure vessels and relief valves. If a control panel is supplied

refer to the nameplate for operating voltage and full load AMP

current draw.

This safety alert symbol will be used in this manual and on

the Heat Transfer Package Safety Instruction decal to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

SAFETY

INSTRUCTIONS

Page 2

2

Heat Transfer Package

INSTRUCTIONS

UNIT IDENTIFICATION

The unit nameplate give identification and rating information as identified in Figure 1.

Units with electrical panels also are identified with a nameplate as shown in Figure 2.

Permanent records for this unit are kept by the factory number and it must therefore be

used with all correspondence and spare parts orders.

Model No.

Factory No.

Wired for Volts Hz Ph

System FL Amps

Largest Motor HP

System Flow GPM

Suction Pressure PSIG

Discharge Pressure PSIG

Pump TDH Feet

Date Code

FIGURE 2

FIGURE 1

BELL & GOSSETT

PACKAGED

PRODUCTS

MODEL NUMBER

FACTORY NUMBER

SHIPPING ORDER DATE

PUMP

HEAT EXCHANGER

Page 3

3

TABLE OF CONTENTS

HEAT TRANSFER PACKAGE

Page

SECTION 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Storage & Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Piping Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 3

Putting the Unit into Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting – Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Factory Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

APPENDIX

Start Up Check List – Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start Up Check List – Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

NOTE:

The information contained in this manual is intended to assist operating personnel by providing information on the characteristics of the purchased equipment.

It does not relieve the user of the responsibility to adhere to local codes and ordinances

and the use of accepted practices in the installation, operation and maintenance of this

equipment.

Further information pertaining to the installation, operation, and maintenance of your Heat

Transfer Package can be found in the I.O.M.s for the associated equipment provided. See

section 1.26 for a list of manual part numbers.

Page 4

4

1.1 DESCRIPTION

1.2 The Bell & Gossett Heat Transfer Package is a complete heating system providing pumping, air separation, flow control and (as an option) temperature

regulation. In addition, it is furnished with a suction/

discharge pressure gauge, ASME safety relief valve,

pressure regulating system fill valve and pump servicing shut-off valves to minimize installation time and

errors.

1.3

PURPOSE OF MANUAL

1.4 This manual is furnished to acquaint you with some of

the practical ways to install, operate, and maintain this

unit. Read it completely before doing any work on

your unit and keep it handy for future reference.

1.5 Equipment cannot operate well without proper care.

To keep this unit at top efficiency, follow the recommended installation and servicing procedures outlined

in this manual.

1.6 SAFETY INSTRUCTION

1.7 This safety alert symbol will be used in this manual to

draw attention to safety related instructions. When

used the safety alert symbol means ATTENTION

BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THIS INSTRUCTION MAY

RESULT IN A SAFETY HAZARD.

1.8

ADDITIONAL SAFETY REQUIREMENTS

1.9 Even when the motor is stopped, it should be considered “alive” as long as its controller is energized.

Keep hands away from the output shaft until the

motor has completely stopped, and the input power is

removed from the motor control panel.

1.10 Always use accurate test meters when checking electrical components. Always work with another person

in case of an emergency.

1.11

STORAGE & HANDLING

1.12 When the Heat Transfer Package is received, make a

visual inspection of the unit, checking for any damages that may have occurred in shipment. The unit

should also be checked against the shipping list to

account for the un-mounted components which are

boxed and bound to the unit.

1.13 If any damages are found or parts missing, note this

on the delivery receipt and inform your B&G Factory

Representative at once. Care should be taken to prevent damage due to dropping or jolting when moving

the unit. Transportation damage should be brought to

the carrier’s attention immediately upon receipt.

1.14 For long periods of storage, the unit should be

covered to prevent corrosion and contamination from

dirt. It should be STORED in a clean, dry location

between 0 – 170°F. The relative humidity should not

exceed 85%. The unit should be checked periodically

to ensure that no condensation has formed. After

storage, again check that it is dry before applying

power.

1.15 The unit is mounted on wooden skids which provide

for safe and easy movement to the installation site.

1.16 The final location should allow ample space for servicing all components of the unit. Be sure to allow

room for removal of the heat exchanger tube bundle,

should it be necessary.

1.17 The wooden skids should be removed and the base of

the frame leveled, grouted and bolted to the floor or

pad.

1.18

ELECTRICAL CONNECTIONS

1,19 The input voltage tolerance is +10/-10%.

1.20 All electronic equipment is susceptible to failure if

operated in ambient temperatures outside of its rating. The OPERATING temperature range for this unit

is 32 – 105°F. The relative humidity should not exceed

95% noncondensing. The unit should not be operated

outside these extremes.

1.21

GROUND CONNECTION

1.22 A grounding terminal is provided for a dedicated

ground wire connection. All provisions of the National

Electrical Code and local codes must be followed.

1.23

POWER WIRING

1.24 Power wire types and sizes must be selected based

upon conformance with the National Electrical Code

and all local codes and restrictions. In addition, only

copper (Cu) wire related for at least 75°C may be used

for the power connections. Refer to the input current

as listed on the motor nameplate when sizing wire.

WARNING: Prevent electrical shocks. Disconnect

the power supply before beginning installation.

Failure to follow these instructions could result in serious personal injury, death, and/or property damage.

WARNING: Electrical shock hazard. Inspect all

electrical connections prior to powering the unit.

Wiring connections must be made by a qualified electrician in accordance with all applicable codes, ordinances,

and good practices.

Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the

ground lug provided in the enclosure to avoid potential

safety hazards.

Failure to follow these instructions could

result in serious personal injury, death, and/or property

damage.

CAUTION: Burn hazard. Surfaces are hot when the

unit is in operation. Do not touch the piping, pumps,

heat exchanger, and tanks until the equipment has been

given enough time to cool down.

Failure to follow these

instructions could result in property damage and/or

moderate personal injury.

Page 5

1.25 FIELD CONNECTION DIAGRAMS

1.26 Refer to the specific Installation, Operation, and

Maintenance Manuals for specific details unique to

each component. See the list below.

Component IOM Part

(1) 1510 Pump P81673

(2) Triple Duty Valve 2"–10" V50960

(3) Triple Duty Valve 1"–1-1/2" V50899

(4) ASME Safety Relief Valve V55692

(5) Pressure Reducing Valve V55999

(6) Air Separator, Airtrol Fitting,

ASME Compression Tank S10300

(7) Enhanced Air Separator Model EAS A03852

(8) Vacuum Breaker None

(9) High Capacity Air Valve #107A A82003

(10) ASME Diaphragm

Pressurized Expansion Tanks A01500

(11) Drain-O-Tank Air Charger V56916

(12) Air Valve #87 None

(13) Heat Exchanger HT-50A-SM

(14) Suction Diffuser A91310

1.27 The following field connection diagrams should be

reviewed prior to unit installation and operation.

Drawing # Description

Job Specific Print Wiring

Job Specific Print Dimensional Drawings

1.28

PIPING CONNECTIONS

1.29 A 3/4" NPT system fill connection is located in the

piping to the expansion tank. It is provided with a gate

valve and a pressure reducing valve with built-in

anti-syphon check valve. The reducing valve is set for

12 PSI system pressure. The PRV may be adjusted to

a higher setting when installed in taller buildings.

1.30 Local codes may govern this connection when made

to a domestic cold water line.

1.31 IMPORTANT: Do not install and operate Bell &

Gossett Pumps, 3D Valves, Suction Diffusers, etc., in

closed systems unless the system is constructed with

properly sized safety devices and control devices.

Such devices include the use of properly sized and

located pressure relief valves, compression tanks,

pressure controls, temperature controls and flow controls as appropriate. If the system does not include

these devices, consult the responsible engineer or

architect before making pumps operational.

2.0

INSTALLATION INSTRUCTIONS

2.1 Location

2.2 Locate the pumping unit for ease of inspection, maintenance and service.

2.3

Leveling

2.4 Place the unit on its concrete foundation, supporting

it with steel wedges or shims.

2.5

Grouting

2.6 After the frame has been leveled and securely bolted

to the floor, a good grade of grout should be installed

beneath the base. A suggested mixture for grout is

one part Portland Cement and two or three parts

plain, sharp sand mixed with water until it will pour

easily. Commercial grout mixtures with suspended

iron particles are available. Wet the concrete base

before pouring grout. To hold wedges or shims in

place, allow the grout to flow around them and

beneath the entire length of the base flange.

2.7

Piping

2.8 Be sure to eliminate any pipe strain on the unit.

Support the pipes independently by use of pipe

hangers near the unit. Line up the vertical and horizontal piping so that the bolt holes of the flanges

match. DO NOT ATTEMPT TO SPRING THE PIPE

LINES INTO POSITION. The code for Pressure Piping

(A.S.A.B. 31.1) lists many types of supports available

for various applications.

2.9 As a rule, ordinary wire or band hangers are not adequate to maintain alignment. It is very important to

provide a strong, rigid support for the suction line. A

saddle hanger is recommended.

2.9.1 For critical installations, equipment for absorbing

expansion and vibration should be installed in the inlet

and outlet connections of the unit.

2.9.2 Inspect all piping connections. Joints may become

loose during transit due to vibration and shock. All

joints are to be checked for tightness. Flanged joints

should be checked for proper torque of all flange bolts

prior to filling the system with fluid.

2.9.3

Hot Water Supply Connection

2.10 The supply main may be connected directly to the

B&G Triple Duty Valve mounted on the pump discharge nozzle. In some installations, a flexible connector near the Triple Duty valve may be desirable.

2.11 Hot Water Return Connection

2.12 The return connection is made to the top opening of

the 2 pass heat exchanger head. The return piping

should approach the head such that a union or

flanged joint can be placed in the section of the piping which is at a right angle to the length of the heat

exchanger. This will allow easy removal of the head

the tube bundle without pipe interference.

2.13 Install a thermometer in the return line near the heat

exchanger.

2.14 Both supply and return mains should be piped so as

to prevent air trapping. All high points in the piping

system should be provided with manual vents to

remove excess air during initial fill. Automatic air vents

must not be used in locations where the system pressure may fall below atmospheric while pumping.

5

WARNING: The heating of water and other fluids

causes volumetric expansion. The associated

forces may cause failure of system components and

release of high temperature fluids. This will be prevented

by installing properly sized and located pressure relief

valves and compression tanks.

Failure to follow these

instruction could result in serious personal injury, death,

and/or property damage.

WARNING: Heavy load may drop if not lifted

properly. Do not lift the entire unit by the motor eye-

bolts. Lift the unit with slings placed under unit base rails.

Failure to follow these instructions could result in serious personal injury, death, and/or property damage.

CAUTION: Failure to check all joints for tightness

and flange bots for proper torque could result in

leaks and/or flooding.

Failure to follow these instructions

could result in property damage and/or moderate personal injury.

Page 6

6

2.15 Steam Supply and Piping

2.16 Care must be taken when installing the steam supply

piping to insure no condensate will flow to the pressure reducing (control) valve. Condensate impingement on the heat exchanger tubes will lead to permanent failure.

2.17

Condensate Piping

2.18 Review the condensate trap Installation, Operation, &

Maintenance manual prior to connecting the trap to

the heat exchanger. Install all recommended valves

and fittings to allow servicing the trap while the unit is

in operation. Install a strainer upstream of the trap to

protect the unit from material that may prevent it from

operating properly. Install a blowdown valve on the

strainer and periodically purge the strainer of debris.

2.19 Do not connect condensate line from trap to condensate main that is above the heat exchanger without

making special provisions to keep the heat exchanger

totally free of condensate.

2.20 If traps are installed in parallel, the following should be

done. Service valves should be installed before and

after each trap so that each trap can be serviced while

the other trap remains in service. Unions should be

installed before and after each trap, between the trap

and service valves. These allow the trap to be

replaced without shutting down the system.

2.21

Drains

2.22 There is a drain plug in the pump volute.

2.23 There is a drain on the bottom of the air separator.

This port could be used as the primary drain for the

return piping since it is the low point of the system.

2.24 The supply main cannot be drained through the air

separator above because the Triple Duty valve acts as

a check valve. The lower port on the back of the Triple

Duty valve may be used as a drain for this section of

the piping. If this is undesirable, a separate drain point

must be provided in the supply piping.

2.25 Since the relief valve is located relatively high above

the floor, it is recommended that the outlet side of the

valve be piped to an open drain per local codes. The

pipe size must not be less than the outlet size and the

drain piping must run so as to avoid water trapping.

The end of the drain pipe must not be threaded to

avoid installation of a valve or plug.

2.26 The expansion tank drain is provided with a hose bibb

valve, therefore a garden hose can be used conveniently for draining.

2.27 Wiring

2.28 Check power leads in accordance with wiring diagram enclosed in control cabinet, if this option was

supplied. If a control panel was not supplied, make

wiring connection per the motor manufacturer’s

recommendations.

2.29

Lubrication

2.30 Before starting, all pumps and motors should be

checked for proper lubrication.

3.0

PUTTING THE UNIT INTO SERVICE

3.1 The following procedure is suggested for the initial

start-up.

3.2 Fill the system with water.

3.3 With the fill valve left open, vent all of the high points

in the piping system to remove the trapped air.

3.4 On units with ASME compression tanks, open the

vent valve located on the Airtrol Tank Fitting. Bleed

the air from the tank until water emits from the valve.

Close the valve.

3.5 Align pump coupling (see pump instruction sheet).

Check Bearing Lubrication.

3.6 Check pump rotation, 3 Phase motors only.

WARNING: Electrical shock hazard. Inspect all

electrical connections prior to powering the unit.

Wiring connections must be made by a qualified electrician in accordance with all applicable codes, ordinances,

and good practices.

Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.

DANGER: Explosible. Do not operate the heat

exchanger outside the limits defined on the heat

exchanger nameplate.

Failure to follow these instructions will result in serious personal injury, death,

and/or property damage.

CAUTION: Burn hazard. The system may contain

steam or hot water under pressure. Close the valves

to isolate the system. Drain and vent the system and allow

surfaces to reach acceptable temperatures prior to servicing.

Failure to follow these instructions could result in property damage and/or moderate personal

injury.

WARNING: Conduit grounds are not adequate.

A separate ground wire must be attached to ground

lug provided in the enclosure to avoid potential safety

hazards.

Failure to follow these instructions could result in serious personal injury, death, and/or property

damage.

CAUTION: Seal damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation.

Failure to follow these instructions could result in property damage and/or moderate personal

injury.

WARNING: Rotating shaft can catch loose clothing.

Do not operate the pump without all guards in place.

Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

Page 7

7

3.7 With the disconnect switch engaged to the “ON” position, turn selector switch to the “HAND” position

momentarily, then “OFF.” Observe the pump shaft

rotation.

3.8 If incorrect, turn the main disconnect off and interchange any two wire leads leaving the starter overload

block and going to the motor.

3.9 Run the pump. Take an ampere reading on the pump

motor. If it is greater than the rated nameplate full load

current,

close the Triple Duty valve (turn stem clock-

wise) until the motor current decreases to the nameplate value.

3.10 Note the value indicated by the pointer on the calibrated scale of the Triple Duty valve stem. Tag the

valve with this reading for future reference. The stem

is to be returned to the position at all times when the

pump is in operation, otherwise, motor overloading

may result.

3.11

TROUBLESHOOTING – ELECTRICAL

3.12 Starter overload relays must be manually reset when

tripped. To reset the overload relay press the external

reset button.

3.13 Pinpointing failures in the control circuitry largely

depends on the understanding of the circuit line diagram furnished with each unit and the proper use of

test instruments. Some of the recommended test

instruments are:

a) Combination Volt-Ohm-Ammeter (VOM multi-

tester) with a 600 volt AC scale (or greater).

b) Clamp-on Ammeter (Amprobe or equal) with

ampere capacity up to 100 amps.

c) Fuse puller.

3.14 Use of “Test Light” for continuity tests is not recommended since these devices do not indicate the

actual voltage present at the test point. Locating

trouble spots with the use of “Jumper Wire” is strongly

discouraged.

3.15

Failure and Probable Causes

3.16 Motor overload relay trips.

3.17 Probable causes:

(1) High ambient temperature around panel box.

(2) Actual line voltage above or below motor name-

plate voltage limits.

(3) Overload heaters improperly selected or installed

(loose hold screw).

(4) Unbalanced voltage between phases.

(5) Faulty motor.

(6) Pump loading beyond design conditions.

3.18

Factory Service

3.19 When requesting information from the factory, it is

imperative that the following data be available for

reference.

(a) Factory Number

(b) Model Number

(c) The

actual line voltage, current draw, suction, dis-

charge and system pressure, or other pertinent

information relative to the nature of the problem.

3.20

Maintenance

3.21 Lubricate motor and pump twice a year.

3.22 Repair any leaks in the hot water system immediately.

Prolonged entry of makeup water will seriously corrode the piping and foul the heat exchanger.

3.23 Clean out all strainers periodically.

3.24 Be aware of ‘gurgling’ sounds through the piping sys-

tem and the pump. It may indicate an air bound

expansion tank. Bleed air from tank.

3.25 When ordering replacement parts or inquiring about

the unit, always give the

complete data on the unit

nameplate as well as the component nameplate data.

DANGER: Troubleshooting live control panels

exposes personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electrician.

Failure to follow these instructions will result in

serious personal injury, death, and/or property damage.

DANGER: Troubleshooting live control panels

exposes personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electrician.

Failure to follow these instructions could result

in serious personal injury, death, and/or property

damage.

CAUTION: Prevent subsequent damage. A unit

showing symptoms of possible problems (noise,

leaks, vibration, and/or continual operation) must be corrected immediately.

Failure to follow these instructions

could result in property damage and/or moderate personal injury.

DANGER: High voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing

unit.

Failure to follow these instructions will result in

serious personal injury, death, and/or property damage.

DANGER: Troubleshooting live control panels

exposes personnel to hazardous voltages. Electrical

troubleshooting must only be done by a qualified electrician.

Failure to follow these instructions will result in

serious personal injury, death, and/or property damage.

CAUTION: Burn hazard. The system may contain

steam or hot water under pressure. Close the valves

to isolate the system. Drain and vent the system and allow

surfaces to reach acceptable temperatures prior to servicing.

Failure to follow these instructions could result in property damage and/or moderate personal

injury.

Page 8

FINAL CHECK LIST

FINAL CHECK LIST

A. SYSTEM PIPING AND UNIT INSTALLATION

_____ 1. Is the unit base properly leveled, grouted and

secured?

_____ 2. Are all lubrication points properly lubricated?

_____ 3. Are the shut-off valves to the pump gauge(s)

open?

_____ 4. Is the shut-off valve to the pump suction open?

_____ 5. Is the Triple Duty valve on the discharge line open?

_____ 6. Is the piping properly supported so as to prevent

strains on the unit?

_____ 7. Is the system, including the pump, purged of

debris and air?

CAUTION: Seal damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation. Failure to follow these instructions could re-

sult in property damage and/or moderate personal

injury.

_____ 8. Are the pump and motor shafts properly aligned?

_____ 9. Is the pump rotation correct?

_____10. Have all piping connections been made? Have all

flanged joints been checked for tightness?

B. ELECTRICAL WIRING AND CONTROL SETTINGS

_____ 1. Does the feeder line voltage correspond to the

unit voltage? Check the unit nameplate or motor

terminal connection.

WARNING: Electrical shock hazard. Inspect all

electrical connections prior to powering the unit.

Wiring connections must be made by a qualified electrician in accordance with all applicable codes, ordinances,

and good practices. Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.

_____ 2. Are the feeder wires correctly sized for the load?

_____ 3. Are the fuses in the disconnect switch correctly

sized? They must not exceed 1.75 times the full

load current of the motor. Usual sizing is 1.15 to

1.5 times the full load current.

_____ 4. Is the unit properly grounded?

WARNING: Conduit grounds are not adequate. A

separate ground wire must be attached to the

ground lug provided in the enclosure to avoid potential

safety hazards. Failure to follow these instructions could

result in serious personal injury, death, and/or property

damage.

_____ 5. Have all the power terminals in the control panel

been checked for tightness? This is imperative

since stranded wires tend to “flow” and become

loose after initial installation.

DANGER: High voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing

unit. Failure to follow these instructions will result in

serious personal injury, death, and/or property damage.

Xylem Inc.

10661 Newkirk Street

Dallas, TX 75220

Phone: (469) 221-1200

Fax: (214) 357-5861

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. S11574C August 2012

Loading...

Loading...