Page 1

INSTRUCTION MANUAL

P86272B

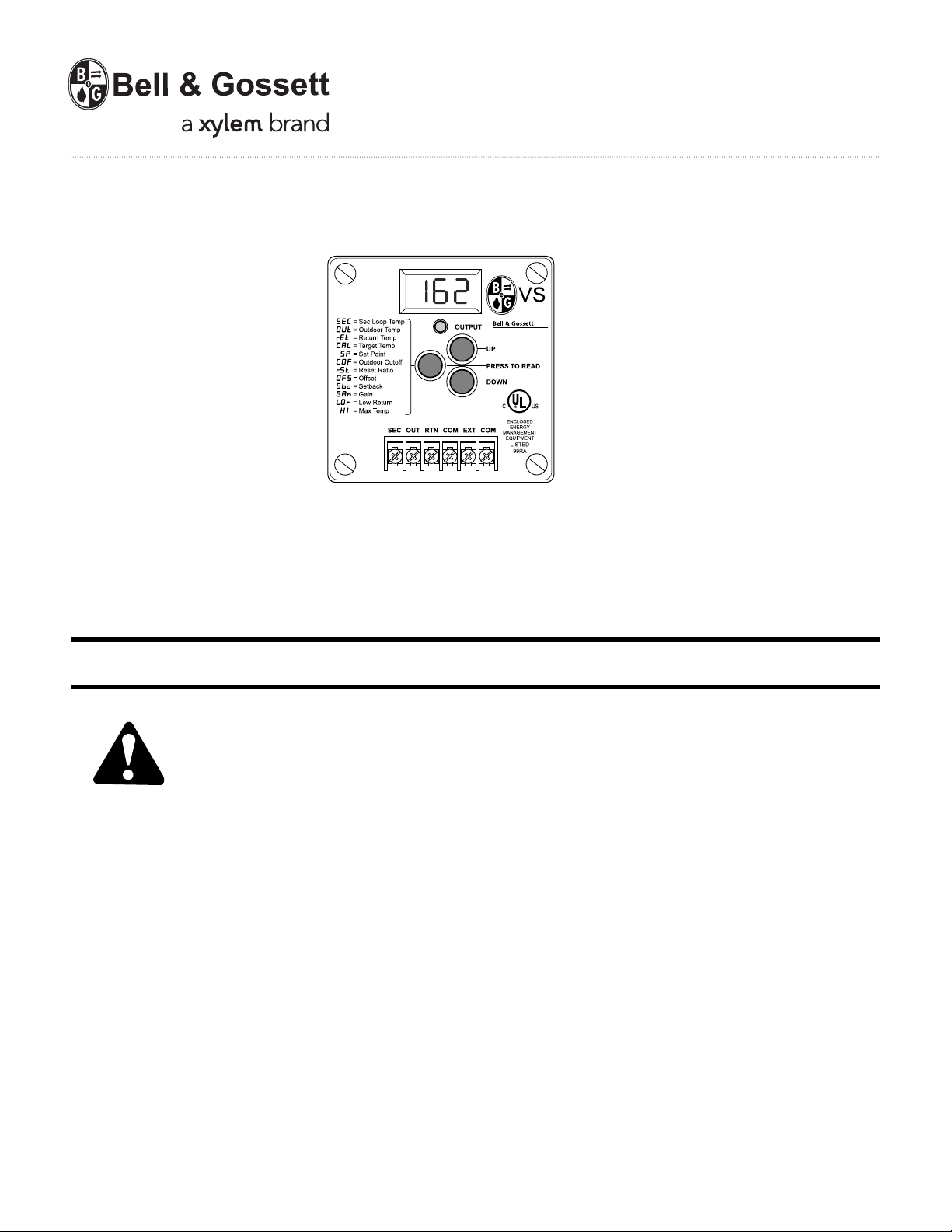

Model VS Variable Speed Pump Control

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

DESCRIPTION

The VS is a hydronic heating control. The temperature of the

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

heating water is controlled by regulating the speed of a pump

which injects water from a hot boiler loop (Primary loop) into a

cooler heating loop (Secondary loop). As the speed of the

pump increases, more hot water is sent into the Secondary

loop, and the temperature of the heating water increases.

The VS can be used as an outdoor reset control. When the

outdoor temperature falls below an adjustable start point, the

heating system is activated. The temperature of the Secondary loop water is then automatically regulated based on

outdoor temperature. The outdoor reset function maintains

constant and comfortable ambient building temperature in all

weather conditions.

The VS can also be used as a set point control. In this mode of

operation, the VS will control the pump speed to hold a constant temperature (determined by the user) in the Secondary

loop. The outdoor start temperature can be set to ON so the

set point will be held regardless of outside temperature.

The VS is equipped with a Primary loop sensor. This sensor

monitors the temperature of the boiler return water. If the

boiler return water falls below an adjustable temperature, the

VS can be configured to slow down the speed of the injection

pump to help the boiler return water temperatures recover.

The VS can be enabled or disabled from a standard thermostat

or switch, or the VS can reduce the temperature of the heating

loop water when the building is not occupied or when

occupants are sleeping.

Page 2

REQUIREMENTS

ELECTRICAL SAFETY

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections are to be made by a qualified

electrician in accordance with all applicable codes, ordinances and good practices. Failure to follow these instructions could result in serious personal injury, death and/or

property damage.

VS

Outdoor

Sensor

Secondary Loop

Sensor

Boiler Return

Sensor

VS Pump

PRIMARY

LOOP

SECONDARY

LOOP

Boiler

Primary-Secondary Variable Speed Injection Mixing

Lower Temperature System

VS

Outdoor

Sensor

Secondary Loop

Sensor

Boiler Return

Sensor

VS Pump

PRIMARY

LOOP

SECONDARY

LOOP

Boiler

Primary-Secondary Variable Speed Injection Mixing

Multiple Temperature System

VS

Outdoor

Sensor

Secondary Loop

Sensor

Boiler Return

Sensor

PRIMARY

LOOP

SECONDARY

LOOP

Boiler

Primary-Secondary

Variable Load System

VS Pump

2

OPERATIONAL LIMITS

These controls are to be used with wet rotor pumps designed

to pump liquids compatible with their cast iron, bronze or

stainless steel body constructions.

Electrical Rating

VS Control: 115v, 60hz, 1Ø

Injection Pump: 115v, 60hz, 1Ø

Max. Rating 1/8 HP

Permanent Split Capacitor

Secondary Loop Pump: 115v, 60hz, 1Ø or 230v, 60hz, 1Ø

Max. Rating of 8 amps

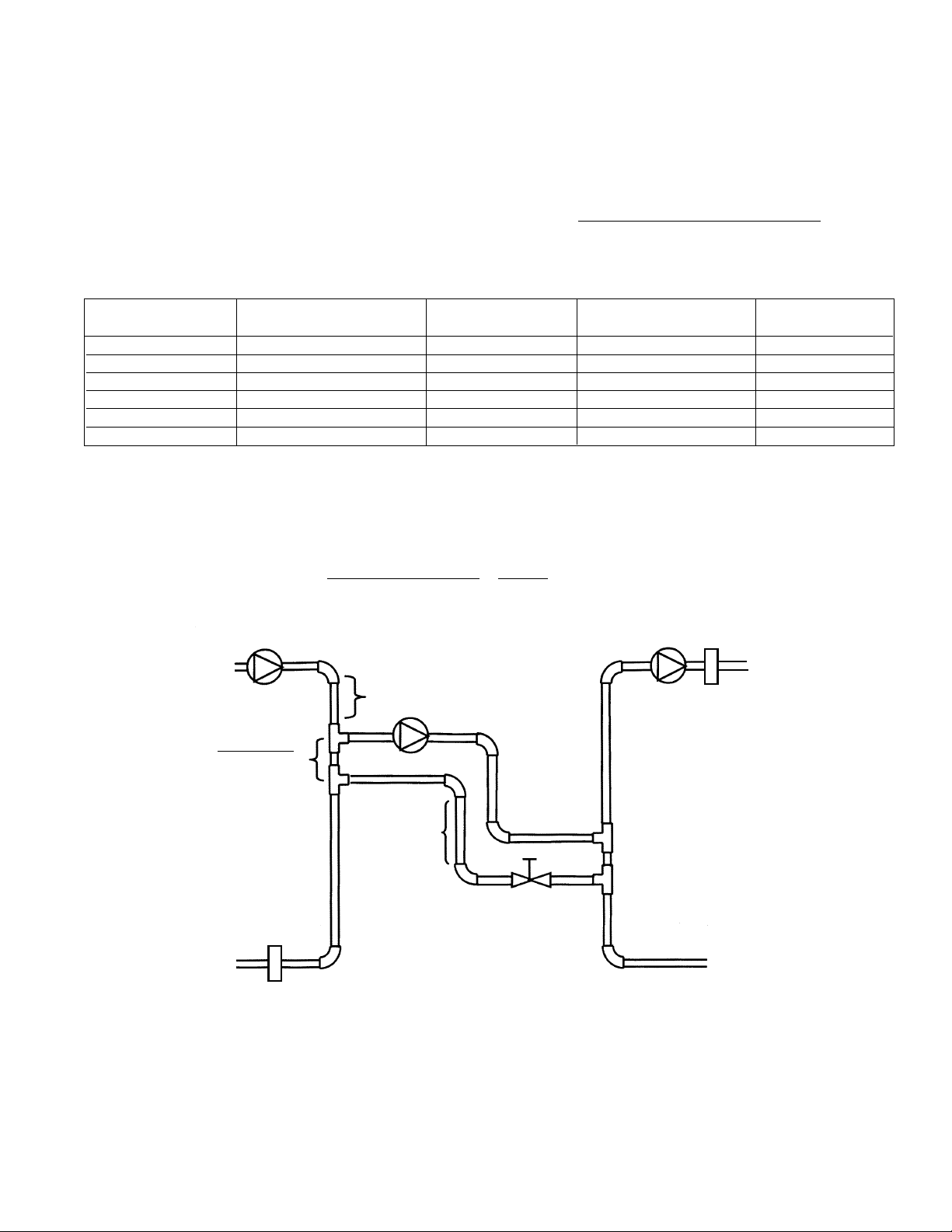

TYPICAL APPLICATIONS (Fig. 1)

Page 3

DESIGN SELECTION

To select the correct pump, pipe size and balance valve:

1.Determine the Primary Loop Temperature. This is the

temperature the primary loop will maintain.

2. Determine the Secondary Loop Temperature. This is the

design temperature of the secondary loop. If an outdoor

reset function is being employed, this is the required

temperature of the secondary loop under maximum load.

3. Determine the design temperature drop (

T or delta T) of

the secondary loop. This is the design drop in temperature through the secondary loop. In most radiant

heat applications,

T is 10. Other types of radiation such

as baseboard have a higher design

T.

4. Determine the Maximum Injection Heat Load. This is the

maximum heat requirement of the secondary loop. The

maximum injection heat load is based on the injection

pump running at the highest speed. As the pump speed

is reduced, less heat will be delivered to the secondary

loop.

5. Use the equation below to determine the design injection

flow rate.

Design Injection Flow Rate (GPM) =

Maximum Injection Heat Load (BTU/hr)

500 (T

primary - Tsecondary + Tsecondary) (ºF)

6. Use the table below to select the appropriate pump, pipe

size and balance valve.

Design Injection Injection B&G Circuit Setter

®

B&G Circuit Setter

®

B&G

Flow Rate (GPM) Pipe Size Balance Valve Valve Setting Pump

1.5

1

/2" CB-1/2 / CB-1/2S 18 / 25 NRF-22

3.5

1

/2" CB-1/2 / CB-1/2S full open / 6 NRF-22

6

3

/4" CB-3/4 / CB-3/4S full open / 12 NRF-22

10 1" CB-1 / CB-1S full open / full open NRF-22

15 11/4" CB-11/4 / CB-11/4S 5 / 5 NRF-22

24 1

1

/2" CB-11/2 full open NRF-33

Example:

1. Primary Loop Temp: 140ºF

2. Secondary Loop Temp: 100ºF

3. Design temperature drop: 10ºF

4. Maximum injection heat load: 150,000 BTU/hr

5. Calculate Injection flow rate

Design Injection Flow Rate (GPM) =

150,000 (BTU/hr)

=

150,000

= 6 GPM

500 (140 - 100 + 10) (ºF) 25,000

6. Injection Pipe size is

3

/4", full open CB-3/4 balancing valve and NRF-22

Minimum of 1' of

pipe drop required

to create a thermal

trap

Rule of Thumb

3 pipe diameters

between tees

Minimum of 8 pipe diameters upstream

and 4 pipe diameter downstream of straight

pipe on either side of tees to prevent any

possibility of “jet flow” through the

common piping.

Secondary

Loop

Secondary

Loop Pump

Primary

Loop Pump

Secondary

Loop Sensor

Boiler Return

Sensor

Primary

Loop

Injection Pump

Balance

Valve

3

FIG. 2

Based on (5) feet of pipe, (4) 90° elbows, (4) tees. Correct pipe and pump size calculation for any application should be performed by a qualified engineer or contractor.

Page 4

PIPING

PIPING OVERVIEW

• The Primary loop may have multiple injection loops or other

takeoffs. However, the piping for each injection system

must meet the requirements described below.

• The Injection piping can be installed in either a horizontal or

a vertical configuration.

• The pipe diameters of the Primary and Secondary loops

may differ.

• The Injection Piping diameter must be at least one pipe size

smaller than the smaller of the Primary and Secondary loop

piping. For example, if the Primary loop diameter is 1

1

/4"

and the Secondary loop diameter is 1", then the diameter of

the Injection piping must be

3

/4" or smaller.

• The Injection pump motor must be a fractional B&G NRF,

NBF or SSF permanent split capacitor type pump. (Refer to

operational limits on Page 2 for pump information.) The

Injection pump will control the amount of water pumped

from the Primary loop into the Secondary loop.

• A balancing valve should be installed on the injection return

piping. This helps to balance the system.

• The distance between the injection tees should be as short

as possible. The rule of thumb distance between the tees is

3 times the pipe diameter. For instance, if the pipe diameter

is 1" then the length of straight pipe between the two

injection tees should be 3".

HORIZONTAL PIPING CONFIGURATION

• The Injection piping can be installed horizontally as shown

in Fig. 2.

• The Injection supply piping should run horizontally from the

Primary to the Secondary loop.

• On the Injection piping it is necessary to install a heat trap

to prevent heat from the Primary loop entering the Secondary loop when the Injection pump is not running.

• The injection piping must drop down vertically at least 18"

and then rise back up vertically at least 18".

VERTICAL PIPING CONFIGURATION

• The Injection piping can be installed vertically.

• The Primary loop must be at least 18" vertically above the

Secondary loop.

4

CAUTION: The Injection pump and pipe sizing

should be performed by a qualified engineer or

contractor.

Secondary

Loop Sensor

Secondary

Loop Pump

Outdoor

Sensor

BLUE

RED

BLACK

120 VAC

LINE NEU

Setback or

Remote Enable

L

O

A

D

Pump

Starter /

Motor

••

Pump

Motor

•

Injection

Pump

Boiler Return

Sensor

Boiler

••

Injection pump must be connected directly to 120VAC motor N.O. pump starter.

••

Secondary pump starter/motor can be 115V or 230V.

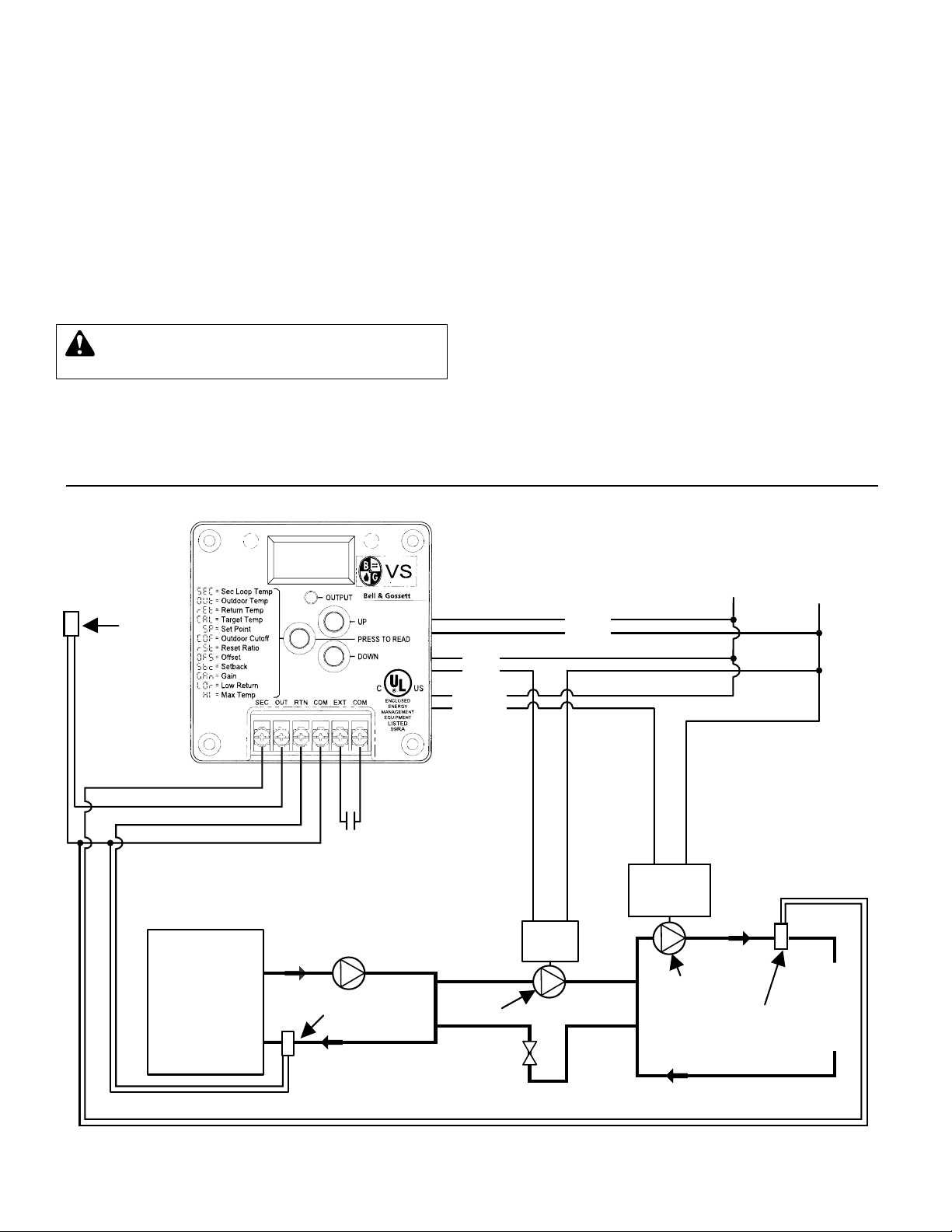

VS WIRING DIAGRAM (Fig. 3)

NOTE: Injection Pump and the VS Control MUST be

wired to the same power circuit. The secondary loop

pump can be wired to a different circuit if required.

Page 5

5

CONTROL INSTALLATION

MOUNTING THE CONTROL

• The VS is designed to mount on a standard 4"x4" electrical

box.

• Locate the VS in a convenient location near the variable

speed pump. The VS can not be mounted more than 500'

from any sensor location.

• Mount the VS away from excessive heat or cold. Ambient

operating temperature is from 20° to 120°F.

• After completing all the wiring connections (see Figure 3)

use the two corner screws provided to mount the VS to the

electrical box.

INSTALLING THE SENSORS

• The sensor wires can be extended up to 500' from the

controller. If the sensor wires are located near strong

sources of electro-magnetic interference (EMI), shielded

cable or twisted pair should be used, or the wires can be

run in a grounded metal conduit. If using shielded cable, the

shield wire should be connected to the

COM terminal on the

control and not to earth ground. Do not run wires in conduit

with line voltage.

• The Outdoor sensor should be mounted in the shade on the

north side of the building (never in direct sunlight). Keep the

sensor approximately 10' above ground level and away

from doors, windows, exhaust fans, or other heat sources.

Do not insulate.

• In a primary/secondary application, the secondary loop

sensor should be mounted downstream of the inlet loop

and before any major heating units. That will provide the

control a more accurate reading (refer to Figures 1 and 2).

• If used, the boiler return water sensor should be mounted

downstream of all the return loop piping and before the

boiler on the primary loop. (Refer to Figures 1 and 2.)

• Strap the boiler return and secondary loop sensors to the

pipe as shown in Figure 4.

• Wrap the pipe and sensor assembly with insulating tape to

insure adequate heat transfer to the sensor.

WIRING THE SENSORS

• The sensor wires have no polarity. Either wire from a sensor

can be connected to the appropriately marked VS screw

terminal (see Figure 5) or the sensor common marked

COM.

• Either or both screw terminals marked

COM can be used as

the sensor common. They are interchangeable.

• If the sensor wires have been extended, connect the shield to

a

COM terminal. Do not connect the shield at the sensor end.

• The two wires from the Secondary loop sensor must be

connected to the VS front screws marked

SEC and COM.

• The two wires from the Outdoor sensor must be connected

to the VS front screws marked

OUT and COM.

• The two wires from the Boiler return water sensor, if used,

must be connected to the VS front screws marked

RTN and

COM. (If not using this sensor, see the NOTE in Low Return

pg. 11.)

WIRING THE VS POWER

• Attach 120VAC line voltage to the two Blue wires extending

from the back of the VS.

• Use wire nuts, or wrap the connections with electrical tape.

• Class 1 voltage must enter the 4" conduit box through a

different opening from any Class 2 wiring.

WIRING THE INJECTION PUMP

• The injection pump MUST be wired to the same power

circuit as the VS control.

• The Red wires provide a solid state switching output to the

Injection pump.

• The Injection pump motor must be a fractional horsepower

permanent split capacitor type motor.

• The Red wires must be directly in series with the pump

power (see Figure 3). The signal can not be wired through

any pilot duty relays or pump starters.

• If used, safety limit switches or HOA switches must be

wired in series with the pump power.

• Use wire nuts, or wrap the connections with electrical tape.

• Class 1 voltages must enter the electrical box through a

different opening from any Class 2 wiring.

WIRING THE SECONDARY LOOP PUMP

• The Black wires provide a Normally Open (N.O.) relay

output for the Secondary loop pump.

• The Black wires are a dry contact output only, They do not

source any power.

• Use wire nuts, or wrap the connections with electrical tape.

• Class 1 voltages must enter the electrical box through a

different opening from any Class 2 wiring.

• Wire the N.O. dry contacts to the pump starter.

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lock out power before making electrical connections. Failure to follow these instructions could

result in serious personal injury, death and/or property

damage.

FIG. 4

WARNING: This Bell & Gossett control is strictly an

operating control; it should never be used as a primary limit or safety control. All equipment must have its

own certified limit and safety controls required by local

codes. The installer must verify proper operation and

correct any safety problems prior to the installation of this

Bell & Gossett control. Failure to follow these instructions

could result in serious personal injury, death and/or

property damage.

Page 6

6

WIRING THE EXT INPUT

• The EXT and COM terminals can only accept a dry contact

input.

• The control is factory supplied with a metal jumper between

the

EXT and COM terminals. If the control is not using a

Setback or Thermostat, the jumper must be left in place

and the control should be left in the default Thermostat

mode. If no wiring is connected to the

EXT and COM

terminals, the jumper must be in place for the control to

operate.

• The

EXT Input can be configured to provide one of the

following two functions:

Setback Mode

• The EXT Input can be used to accept an input from an

external clock with a normally open switching action to

lower the temperature of the Secondary loop when the

building is not occupied, or when the occupants are

sleeping. Remove the jumper between the

EXT to COM

terminals. Connect external clock to the EXT and COM

terminals.

• When the

EXT to COM terminals are open, the VS will run

normally.

• When the

EXT to COM terminals are shorted/closed the

temperature of the Secondary loop will be reduced by the

number of degrees of

Setback (see pg. 11).

Thermostat Mode

• The EXT Input can be used to accept an input from a

thermostat to activate the heating system. Remove the

jumper between the

EXT to COM terminals. Connect the

thermostat to the

EXT and COM terminals.

• When the

EXT to COM terminals are open, the VS will not

be active. Both pump outputs will be disabled.

• When the

EXT to COM terminals are shorted/closed the VS

will activate the heating system if there is a call for heat.

SETTING THE OPERATING MODES

• Whenever the VS is powered up, it will display the software

version number and then the current operating modes.

Each display will remain on the screen approximately 5

seconds. If the modes are correct, there is no need to make

any adjustments.

• Once the modes have been set for a particular application,

they will be retained in memory and will not need to be reset.

• Note that if you do change an operating mode, you will

need to reset all other settings.

• An operating mode can only be changed when it is being

displayed in the start-up sequence. To restart the sequence

it is necessary to remove power to the VS and then power it

again.

• To change a mode, hold down the center button while

pushing either the UP or DOWN button to toggle between

the settings. (Refer to Figure 5.)

• When the correct mode is selected, release the buttons and

wait approximately 5 seconds to go the next mode.

• Set the operating modes as described in sequence below:

°F or °C – Fahrenheit or Celsius Temperature Operation

• If the display shows °F then the VS will operate in

Fahrenheit degrees.

• If the display shows °

C then the VS will operate in Celsius

degrees.

r or S – Reset or Set Point Operation

• If the display shows r then the VS will run with as an

outdoor reset control (see pg. 10). As it gets colder outside,

the VS will automatically increase the temperature of the

Secondary loop.

• If the display shows S then the VS will hold the selected set

point temperature in the Secondary loop. To select the

Set

Point,

see chart on pg. 8).

Sb or tt – Setback or Thermostat Mode

• If the display shows Sb then the VS will use the EXT Input

for an external clock or switch to lower temperature of the

Secondary loop. In such a case, the VS will lower

secondary loop water temperature by the amount of the

Setback (

Sbc ) on a short/closure between EXT and the

COM terminals. When switched to an open status, the VS

will go into Boost mode (increase secondary loop

temperature by the Setback (

Sbc)) for one hour.

• If the display shows

tt then the VS will use the EXT Input for

a thermostat. When the thermostat input is open, both

pump outputs will be disabled.

no or YES – Pump Exercise every 3 idle days

• If the display shows YES then the VS will activate both the

Secondary Loop pump and the Injection pump for 10

seconds every 3 idle days.

• If the display shows

no then the VS will only run the pumps

when the system requires it. This setting will prevent hot

water from being pumped into the Secondary loop when

there is no call for heat.

nrS or rS – Return Sensor

• If the display shows nrS (No Return Sensor), then the VS

will not monitor the boiler return temperature.

• If the display shows

rS (Return Sensor), then the VS will

monitor the boiler return temperature. If the Return

Temperature falls below the Low Return Temperature

LOr,

the VS will reduce the injection pump to half the current

speed until the Return Temperature rises above the

Minimum Return again.

CAUTION: If power is applied across the COM and

EXT terminals, the VS may be damaged.

Page 7

7

INITIAL SETTINGS FOR A RESET CONTROL

(see r on pg. 6)

• After setting the operating mode, the VS will display the temperature of the Secondary loop. This is the default display.

• To see and/or adjust the other parameters, press then

release the center button marked

PRESS TO READ. The VS

will display a code to indicate which parameter will be

displayed next. After two seconds, the value of the

parameter will be shown.

• For those parameters where the values can be set (shown

on chart pg. 8), press the

UP or DOWN button to change

the value while it is being displayed. Holding the

UP or

DOWN button will cause the value to change more quickly.

• The

Outdoor Cutoff (COF ), also known as warm weather

shut down, temperature setting is the outdoor temperature

above which the VS will not give heat. The factory default

setting is 60°F.

• The Reset Ratio (rSt ) determines how quickly the water

temperature in the Secondary loop will increase as the

outdoor temperature decreases (see Figure 6). Lower

numbered curves result in lower water temperatures. The

factory default curve is 7 or (1:1). This means for every

degree the outdoor temperature falls (below the

System

Start

temperature) the Secondary loop temperature will be

increased by one degree. For baseboard heat, start with 7.

For most radiant tubing applications, start with 4 and an

offset of -10 (see page 10).

• The Offset (OFS ) value is added or subtracted to the

calculated water temperature for the Secondary loop. It

effectively moves the starting point of the reset curves up

and down by the number of degrees selected (see pg. 10).

Start with the factory default setting of 0.

• The

Low Return (LOr) comes factory set to OFF. This is the

correct setting if you are not using the Boiler return water

sensor. If you do use the Boiler return sensor for boiler

protection, then the setting must be set to the boiler

manufacturer’s specification.

• The

High Supply (H I ) value must be adjusted to the

maximum temperature value specified for the Secondary

loop components.

• The

Setback (Sbc) value determines how many degrees the

Secondary loop temperature will be decreased when the

EXT Input in the Setback mode (see pg. 11) is shorted. Start

with the factory default setting of 10°F. In order to adjust

the setback value,

Sb has to be selected in the initial

operating mode sequence. If

tt is selected, the setback Sbc

will be OFF.

INITIAL SETTINGS FOR A SET POINT CONTROL

(see S on pg. 6)

• After setting the operating mode, the VS will display the

temperature of the Secondary loop. This is the default value

for the VS display.

• To see and/or adjust the other parameters, press then

release the center button marked PRESS TO READ. The VS

will display a code to indicate which parameter will be

displayed next. After two seconds, the value of the

parameter will be shown.

• For those parameters where the values can be set (shown

on chart pg. 8), press the

UP or DOWN button to change

the value while it is being displayed. Holding the

UP or

DOWN button will cause the value to change more quickly.

• The

Outdoor Cutoff (COF ), also known as warm weather

shut down, temperature setting is the outdoor temperature

above which the VS will not give heat. Set to

ON if the

system set point should be held regardless of outside

temperature. The factory default setting is 60°F.

• The

Low Return (LOr ) comes factory set to OFF. This is the

correct setting if you are not using the Boiler return water

sensor. If you do use the Boiler return sensor for boiler

protection, then the setting must be set to the boiler

manufacturer’s specification.

• The

Set Point (SP ) should be set to the desired tempera-

ture for the Secondary loop.

• The

Setback (Sbc) value determines how many degrees the

Secondary loop temperature will be decreased when the

EXT Input in the Setback mode (see pg. 11) is shorted. Start

with the factory default setting of 10°F. In order to adjust

the setback value,

Sb has to be selected in the initial

operating mode sequence. If

tt is selected, the setback Sbc

will be OFF.

SEQ. INITIAL FACTORY

NO. DISPLAY SETTING (DEFAULT) MODE DESCRIPTION

1. 1 N/A Software Version (no changes required)

2. °F or °C °F Temperature in °F or °C that the VS will operate (°F is the initial default setting)

3. r or s r Reset or Set Point Operation. r will run the VS as an outdoor reset control. As outdoor

temperature gets colder, the temperature in the secondary loop will automatically increase

(see page 10). s will run the VS so that the selected set point temperature is maintained in

the secondary loop. See chart on page 8 for instructions on setting the set point temperature.

4. Sb or tt tt Setback or Thermostat. tt setting can be used with a thermostat, when thermostat has a call for

heat (input is closed) the injection and secondary pump are allowed to operate. When thermostat

is satisfied (input is open), the pumps will not operate (turn off). ss is used with an external NO

timer or clock. When input is closed, the temperature of the secondary loop will decrease by the

amount of the setback (Sbc). When input is open, the VS will go into Boost mode for 60 minutes.

After 60 minutes, the VS will return the secondary loop to the set point temperature.

5. no or YES YES Pump Exercise. YES will activate both pumps for 10 seconds every 3 idle days

no, the pumps will only run when the system requires them to operate.

6. nrS or rS nrS Boiler Return Sensor for Boiler Protection. nrS setting will not monitor the return water

temperature to the boiler. rS setting will monitor the boiler return water temperature. If the

return water drops below the Low Return Temperature (Lor) setting, the speed of the injection

pump will be reduced by half the current speed until the Return Temperature rises above

the Minimum Return Temperature.

SETTING THE OPERATING MODE (IN SEQUENCE)

Page 8

8

◆

These are sensor readings. They can not be adjusted.

◆◆

The display of each setting will remain active for approximately 20 seconds after the last adjustment. Then the display will revert to the default reading.

◆◆◆

These options are available with Reset Mode only. Select r from Startup menu.

◆◆◆◆

These options are available with Return Sensor Mode only. Select rS from Startup menu.

DISPLAY VALUES and ADJUSTMENTS

Press SELECT

DISPLAY Press and hold either the UP or DOWN button to adjust

Button

Once

OUt This is the temperature of the outdoor sensor. If it does not read correctly, check the

Outdoor Temp

◆

Troubleshooting guide.

This is the temperature of the water returning to the boiler. If this sensor is not installed

Twice

◆◆◆◆

ret it will display OPn. If the sensor is installed and does not read correctly, check the

Return Temp

◆

Troubleshooting guide. Available only when the Return Sensor (rS) is selected from the

Startup menu.

SP

This is the Set Point the Secondary Loop is to maintain. Available only when the Set

3 Times

Set Point

Point (

S) is selected from the Startup menu. It is adjustable from 100° to 180°F with

a default value of 120°F.

3 Times

◆◆◆

CAL This is the Set Point temperature calculated using the Outdoor Reset logic. Available

Calculated Temp

◆

only when Reset (r ) is selected from the Startup menu.

COF

This is the outdoor temperature below which the VS will activate the Secondary loop

Outdoor Cutoff

pump and control the variable speed pump. If the ON setting is selected, the VS will

4 Times

(warm weather)

activate or control both pumps regardless of outdoor temperature. If the OFF setting is

shut down)

selected, the VS will never activate either pump. It is adjustable from 40° to 100°F with

a default value of 60°F.

The higher the curve number selected, the faster the temperature of the Secondary loop

5 Times

◆◆◆

rSt will be increased as outdoor temperature decreases. Available only when Reset (r ) is

Reset Ratio selected from the Startup menu. (For Reset Curves see Figure 6.) It is adjustable from

1 to 12 with a default value of 7.

OFS

The Offset will adjust the calculated Secondary loop temperature (determined by the

6 Times

◆◆◆

Offset

outdoor temperature, Reset Ratio and Setback) by the amount displayed. Available only

when Reset (

r ) is selected from the Startup menu. Adjustable ±40°F.

This is the number of degrees the Secondary loop water temperature will be lowered if

7 Times

Sbc the VC is put into Setback. In addition, this amount will be added to the Secondary loop

Setback water temperature when control is in Boost (switching from Setback to normal operation)

for a full hour. It is adjustable from 0 to 30 with a default value of 10.

GAn

The Gain controls how aggressively the VS will change the pump speed when the

8 Times

Gain

Secondary loop temperature is away from the Calculated Temp or the Set Point. It is

adjustable from -10 to +10 with a default value of 0.

9 Times

◆◆◆◆

LOr With Return Water Sensor: Set to the boiler manufacturer’s specification for minimum

Low/Min Return boiler return temperature. It is adjustable from 70° to 170°F with a default value of 70°F.

This is the highest Secondary loop water temperature the VS will maintain. Available

10 Times

◆◆◆

HI only when Reset (r ) is selected from the Startup menu. It is adjustable from 100°F to

Hi Supply Temp 200°F with a default value of 160°F.

IMPORTANT: The VS is not a safety control. All appropriate safety controls must be installed.

11 Times

SEC This is the temperature reading of the Secondary loop sensor. If it does not read correctly,

Default

◆◆

2nd Loop Temp ◆check the Troubleshooting guide.

Push to

Display settings

Output Light

Indicates Status

Secondary Loop Sensor

Outdoor Sensor

Red

Push these buttons to adjust

the control settings

Digital Display defaults to read

Secondary Loop Temperature

Injection Pump

Output

Secondary Loop

Pump Output

120 VAC

Power Input

Boiler Return Sensor

Setback or remote

Enable or Disable Input

DRY CONTACT ONLY

Black

Blue

FIG. 5

Page 9

9

OPERATION

OUTPUT LIGHT

The output light has the following three indications:

Light Off

• The heating system is not active. Neither the Secondary

loop pump nor the Injection pump output are active.

Light On

• The heating source output is active. The Secondary loop

pump relay is energized, and the speed of the Injection

pump is being controlled.

Flashing

• The Secondary loop pump relay is energized to circulate

the water through the loop. The Injection pump output is

not active. This would occur when there is a call for heat,

but the temperature of the Secondary loop is satisfied so

none of the hot water from the Primary loop is needed in

the Secondary loop.

DEFAULT DISPLAY INDICATORS

The Display when not used will display the temperature of the

secondary loop. The display has the following indications:

Right Decimal Point Light

• Decimal point indicator located on the right hand side of the

right most digit of the LED display in the default display

mode will light to indicate the system is in the Setback/

Boost mode.

Left Decimal Point Light

• Decimal point indicator located on the left hand side of the

left most digit of the LED display in the default display

mode will light to indicate the Return is below the Low

Return Temperature.

OUTDOOR CUTOFF (Warm Weather Shut Down)

The Outdoor Cutoff (COF ) is the outdoor temperature below

which the Secondary loop pump will be activated to circulate

water through the loop and the Injection pump speed will be

regulated to control the temperature of the Secondary loop

water. When the outdoor temperature rises above this point,

the Secondary Pump relay (BLACK wires) and the Injection

pump output (RED wires) will be off. The Outdoor Cutoff (

COF )

is adjustable from 40°F to 100°F with a default of 60°F. The

Outdoor Cutoff (

COF ) also has two special modes:

OFF

• When the Outdoor Cutoff (COF ) is set to OFF, neither the

Secondary loop pump nor the Injection pump will run. This

can be used for testing or to disable heat to the particular

loop. Do not use this feature to turn off pumps for maintenance. For this, use the safety disconnect.

ON

• When the Outdoor Cutoff (COF) is set to ON, the Secondary

loop pump will run regardless of outdoor temperature. The

Injection pump speed will be regulated to control the

temperature of the Secondary loop water temperature.

Follow the chart on pg. 8 to adjust the Outdoor Cutoff (

COF ).

Return is below

Low Return Temperature

••

System is in

Setback or Boost Mode

Page 10

10

RESET OPERATION

Reset Ratio (rSt )

• The Reset Ratio (rSt ) determines how the Secondary loop water

temperature will vary with outside temperature. With any ratio, the

colder it is outside, the hotter the temperature of the Secondary

loop. At a 1:1 reset ratio (Curve 7) a 1 degree drop in outdoor

temperature will increase the Secondary loop temperature by

1 degree; at the 3:1 ratio (Curve 3) an outdoor temperature drop

of 3 degrees will increase the Secondary loop temperature by

1 degree.

• The ratios are adjustable from 8:1 (Curve 1) for the least amount

of heat to a 1:4 (Curve 12) for the most amount of heat (see side

chart). With most baseboard heating applications, a 1:1 (Curve 7)

setting is a good place to start. Radiant heat applications usually

require a lower curve.

• Adjust the

Reset Ratio (rSt ) in cold weather. If the ambient space

temperatures are too cold in cold weather, increase the curve

number by one. If the space temperatures are too warm,

decrease the curve number by one. After making a change to the

ratio, wait 24 hours to evaluate the impact of the change. See

chart on pg. 8 to adjust the

Reset Ratio (rSt ).

Offset (OFS )

• The Offset (OFS ) allows you to adjust the starting points of the

Reset Ratio (rSt ) curves (see side charts). When the Offset (OFS )

is changed, that change is always directly added or subtracted to

the calculated water temperature. For instance, if the calculated

Secondary loop water temperature were 130°F and the Offset

(

OFS ) were changed from 0° to 10° (an increase of 10°), then the

calculated water temperature would immediately change to

140°F.

• Adjust the Offset (

OFS ) in mild weather. If the ambient space

temperatures are warm in mild weather, decrease the Offset

(

OFS ). If the space temperature are cold in the mild weather,

increase the Offset (

OFS ). The rule of thumb for baseboard

radiation is to change the Offset (

OFS ) by 1° or 2° for every

degree you wish to change the space temperature. See chart on

pg. 8 to adjust the Offset (

OFS).

Hi Supply Temperature (HI )

• The Hi Supply (HI ) setting is the maximum Secondary loop

temperature the VS will maintain. In some applications, it may be

necessary to limit the temperature of the water going out to the

Secondary loop. This may be done for comfort or because the

Secondary loop components or flooring may be damaged by high

temperatures.

• The Hi Supply (

HI ) should never be set higher than the maximum

value specified by either the Secondary loop component or the

flooring manufacturer. Adjust the Hi Supply (

HI ) as shown in the

chart on pg. 8.

SET POINT OPERATION

Set Point (SP )

• The Set Point (SP ) setting is the Secondary loop temperature the

VS will maintain whenever there is a call for heat.

• The Set Point (

SP ) should never be set higher than the maximum

value specified by either the Secondary loop component or the

flooring manufacturer. Adjust the Set Point (

SP ) as shown in the

chart on pg. 8.

1:4 1:3 1:2 1:1.5

220

210

200

190

180

170

160

150

140

130

Water Temperature (in °F)

120

110

100

70 60

12 11 10 9

50

40 20

10 -20

30 0 -10

Outdoor Temperature (in °F)

Reset Ratio represents Outdoor : Water

Reset Ratio Curves (Fig. 6)

1:3

11

70 405060

Outdoor Temperature

1:3

11

70 405060

Outdoor Temperature

1:3

11

With a 0° Offset, the

ratio curves begin at

100° Water Temperature.

With a -20° Offset, the

ratio curves begin at

80°Water Temperature.

130

120

110

Water Temperature

100

110

100

90

Water Temperature

80

150

1:1

4:1

1:1

7

4:1

1:1

8

7

6

5

4

3

2

1

7

2

2

7

1:1.25

1:1

1.25:1

1.5:1

2:1

3:1

4:1

8:1

With a +20°Offset, the

ratio curves begin at

120° Water Temperature.

140

130

Water Temperature

120

4:1

2

70 405060

Outdoor Temperature

Page 11

11

Setback and Boost (Sbc)

• The Setback (Sbc) setting has no effect if the VS is in

Thermostat mode (see pg. 6).

• When the VS is initialized to run in the Setback mode, the

EXT Input can be connected to an external clock or switch

(see Fig. 5). When the

EXT to COM terminals are

shorted/closed, the VS will switch to Setback mode and

reduce the temperature of the Secondary loop by the

number of degrees selected. The VS switches from Setback

mode back to Boost mode when the

EXT to COM

terminals are opened. In the Boost mode, the VS will

increase the secondary loop temperature by the number of

degrees selected in the setback for a period of one hour to

allow faster heat recovery to the zone.

Example: If the calculated Secondary water temperature is

130°F and the Setback (

Sbc) is set to 10°F, when the EXT

Input is shorted/closed, the calculated water temperature

would immediately change to 120°F. When the EXT input is

opened, the VS will go into boost mode and the calculated

water temperature would immediately change to 140°F for

a period of one hour. After the one hour of operation, the

calculated water temperature will return to the standard

operating mode of 130°F.

• The rule of thumb for adjusting the Setback (

Sbc) with

baseboard radiation is to decrease the water temperature

4° for each degree you wish to lower the ambient space

temperatures. Therefore, if you wish the space

temperatures to be 5° colder at night or when the building

is not occupied, adjust the Setback (

Sbc) to 20°. With

radiant heat, adjust the Setback (

Sbc) only 1 or 2 degrees

for each degree you wish to lower the space temperature.

OPERATION SETTINGS

Gain (GAn)

• The Gain (GAn) controls how aggressive the VS will change

the injection pump’s speed.

• A higher Gain (

GAn) setting will generate larger changes. A

lower Gain (

GAn) setting will generate smaller changes.

• If the system tends to stay below the set point, increase the

gain. If the system overshoots and undershoots the set

point rapidly, decrease the gain.

Low Return (LOr) Available with Return Sensor

Mode only (Startup menu r option)

• The Low Return (LOr) setting is designed to help speed

recovery in the event of low boiler return water temperatures. The boiler manufacturer may require a minimum

return water temperature to protect the boiler. Check with

the boiler manufacturer for the specified temperature.

• If the VS registers that the temperature of the water

returning to the boiler is below the Low Return (

LOr), the VS

will immediately reduce the Injection pump speed by half

and not allow the speed to increase again until the return

temperature rises to the Low Return (

LOr) setting. This

means that the VS will decrease the load on the Primary

loop, but will still provide some heat to the Secondary loop.

NOTE: If a minimum return water temperature is not specified

by the boiler manufacturer, or if the Secondary loop size is

such that it will have little impact on the Primary loop

temperature, the Boiler Return sensor (see Figure 2) may not

be installed. If the return sensor is not connected, the control

will ignore the

LOr setting and no error will be displayed.

TROUBLESHOOTING

No Display:

Check the 120VAC power into the Blue input wires. If power is

present, turn the power to the VS off and then back on.

Display shows or flashes OPn or SHt:

Follow the procedure for Sensors on next page.

OUTPUT light is OFF when heat is required:

Check the Outdoor Cutoff (COF ) setting (see pg. 9). If the

outdoor temperature sensor reading is above the setting, the

VS will not give heat. Also check if the VS is in the Thermostat

(

tt) mode (see pg. 6). In the Thermostat (tt) mode, the VS will

never give heat if terminals

EXT and COM are not shorted

together.

OUTPUT light is FLASHING when heat is required:

The Output light flashes when the Secondary loop pump is on

but the Injection pump is off. This will occur when the VS is

satisfied with the temperature of the Secondary loop. See

Insufficient Heat conditions below.

OUTPUT light is FLASHING or ON but Secondary loop

pump is not running:

Turn off the power to the Secondary loop pump. The VS

power must remain connected. Then disconnect all wires

attached to the VS Black wires. Test for continuity across the

Black wires. If the wires are continuous, the VS is working

properly. Check the Secondary loop pump and its power.

OUTPUT light is ON but Injection pump is not running:

If the Output light is on, the Injection pump should be running.

However, if it is running at a very low speed, it may be hard to

detect. It is possible to test the Injection pump output with a

voltmeter which can read at least 120VAC.

Place the leads of the voltmeter across the power inputs of the

Injection pump. At the highest speed, the AC Volt reading will

be approximately 120VAC. As the speed is decreased, the

reading will decrease. At the lower speeds, the reading may

fluctuate by several Volts. This is considered to be normal.

OUTPUT light is OFF or FLASHING but

Injection pump is running:

When the Output light is off or flashing, the Injection pump

should not be running. Check the wiring to see if any other

control, a HOA switch, or other switch input is causing the

pump to run. Turn the power off to the VS. If the Injection

pump continues to run, the VS is not the cause of the pump

running.

WARNING: This Bell & Gossett control is strictly an

operating control; it should never be used as a primary limit or safety control. All equipment must have its

own certified limit and safety controls required by local

codes. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

WARNING: This test can only be performed with the

Injection Pump power connected. This test should

only be performed by a qualified electrician or electrical

contractor. Failure to follow these instructions could result

in serious personal injury, death and/or property damage.

Page 12

Insufficient Heat when the OUTPUT light is ON

(Reset Operation):

Check all the settings. If the Boiler Return (rtn) sensor reading

is below the Low Return (LOr ) setting the VS will halve the

speed of the Injection pump until the boiler return

temperatures recover. The temperature of the Secondary loop

will never exceed the High Supply (HI ) setting for any

prolonged period of time. Check that the High Supply (HI ) is

not set too low. Check if the VS is in Setback and therefore

running lower water temperatures. If none of these conditions

are causing insufficient heat, then adjust the Reset Ratio (rSt )

or Offset (OFS ) (see pg. 10).

Insufficient Heat when the OUTPUT light is ON

(Set Point Operation):

Check all settings. If the Boiler Return (rtn) sensor reading is

below the Low Return (LOr ) setting (see above) the VS will

halve the speed of the Injection pump until the boiler return

temperatures recover. Check if the VS is in Setback and

therefore running lower water temperatures. If neither of these

conditions are causing insufficient heat, then increase the Gain

(GAn) (see pg. 11).

SENSORS

Each of the three VS sensors are interchangeable and can be

tested in the same way. If the Secondary loop sensor is open

or shorted, the main display will show OPn or SHt. If either the

Outdoor or the Boiler Return sensor is open or shorted, the

display will first flash the code for the sensor (either SEC or

rtn) and then flash OPn or SHt. To test the sensor, remove the

pair of sensor wires connected to the VS terminals. Take a

resistance reading across the detached wires going to the

sensor. If the reading shows:

OPEN OPn or a resistance greater than 100,000�: Check

the wires going to the sensor. They may have been broken or

become disconnected. If the wires are fine, check the

resistance at the sensor itself. If the value is still open, the

sensor has been damaged and needs to be replaced.

SHORT SHt or a resistance less than 100�: Check the wires

going to the sensor. They may have become shorted together

in the run of the wire. If not, check the resistance at the sensor

itself. If there still is no resistance, the sensor has been

damaged and needs to be replaced.

Resistances from 200� to 100,000�: Find the temperature

that corresponds to the resistance value on the chart. If the

sensor appears to be outputting correctly, check that the

wires were properly connected to the VS. If they were, the VS

may have been damaged. If the sensor is not outputting

correctly, take another reading at the sensor itself. If this is

correct, the problem is in the wiring between the sensor and

the VS. Otherwise, the sensor has been damaged, and should

be replaced.

WARNING: The VS is an operating control only. The

boiler must have all safety and limit controls required

by code. It is the responsibility of the installer to verify that

all the safety and limits are working properly before and

after the VS is installed. Failure to follow these instructions

could result in serious personal injury, death and/or

property damage.

PERIODIC INSPECTION

Bell & Gossett products are designed to provide years of

trouble free service. It is recommended that periodic inspections be made to check for potential problems with the pump

and control. If any leakage or evidence of leakage is present,

repair or replace the unit.

TEMPERATURE

SENSOR CHART

TEMPERATURE Value

(in Degrees ºF) (in 0hms)

-30 117720

-20 82823

-10 59076

0 42683

10 31215

20 23089

25 19939

30 17264

35 14985

40 13040

45 11374

50 9944

55 8714

60 7653

70 5941

80 4649

90 3667

100 2914

110 2332

120 1879

130 1524

140 1243

150 1021

160 842

170 699

180 583

190 489

200 412

210 349

220 297

230 253

240 217

250 187

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. P86272B May 2012

Loading...

Loading...