Page 1

INSTRUCTION MANUAL

P86271B

Variable Speed NRF-VS Control with

setpoint or external signal follower

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

WARNING

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual and on the

pump Safety Instruction decal to draw attention to safety

related instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A SAFETY HAZARD.

Your NRF-VS Control should have the warning/caution label

displayed to the right (Fig. 1) on the pump conduit box. If this

warning and caution label is missing or illegible, contact your

local B&G Representative for a replacement.

FIG. 1

BEFORE INSTALLING,

USING OR SERVICING

THIS PRODUCT, READ

THE INSTRUCTIONS

TO REDUCE RISK OF

ELECTRICAL SHOCK, SEE

INSTRUCTIONS FOR

PROPER INSTALLATION.

CAUTION

FOR SUPPLY CONNEC-

TIONS USE WIRE SUITABLE FOR AT LEAST

90ºC. USE COPPER

CONDUCTORS ONLY.

EMPLOYER DES FILS

D’ALIMENTATION

ADEQUATS POUR 90°C.

FOR INDOOR USE ONLY.

EMPLOYER UNIQUEMENT

AL’INTERIEUR.

Page 2

REQUIREMENTS

ELECTRICAL SAFETY

TYPICAL APPLICATIONS

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections are to be made by a qualified

electrician in accordance with all applicable codes, ordinances and good practices. Failure to follow these instructions could result in serious personal injury, death and/or

property damage.

WARNING: ELECTRICAL GROUNDING HAZARD

Adequate electrical grounding is required for the safe

operation of B&G Pumps. The use of grounded metal conduit assures this requirement. If means of connection to the

supply – connection box (wiring compartment) is other than

grounded metal conduit, ground the pump back to the

service. Use a copper conductor at least the size of the

circuit connectors supplying the pump. Connect the ground

wire to the green grounding screw in the wiring compartment. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

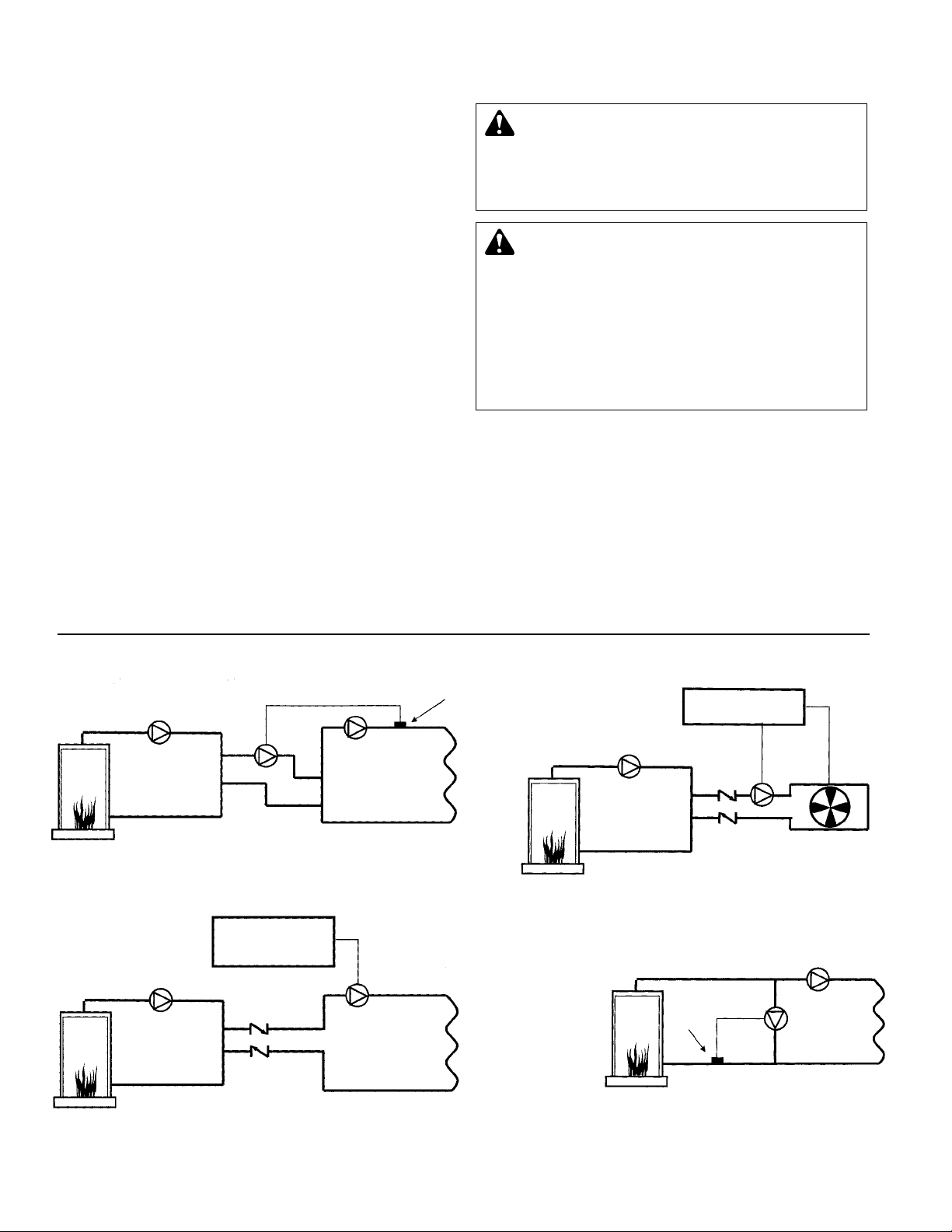

PRIMARY-SECONDARY WITH FAN COIL

PRIMARY

LOOP

Boiler

NRF-VS

Building

Management System

Boiler

Boiler

Sensor

NRF-VS

BYPASS BOILER INJECTION

Secondary Loop

Sensor

SECONDARY

LOOP

NRF-VS

PRIMARY

LOOP

Boiler

PRIMARY-SECONDARY INJECTION

SECONDARY

LOOP

PRIMARY

LOOP

Boiler

PRIMARY-SECONDARY

NRF-VS

Variable Speed

Control or Building

Management System

2

DESCRIPTION

The NRF-VS is a variable speed control for use in hydronic

heating and cooling applications. The temperature of the

water is controlled by regulating the speed of the pump which

injects water from a different temperature water loop (Primary

loop) into a controlled loop (Secondary loop). As the speed of

the pump increases, more water is sent into the Secondary

loop, resulting in a secondary loop water temperature change.

The NRF-VS can be used either to receive an external 4-20mA

or 2-10V signal to control the pump speed. This allows the

control to regulate the pump speed to match the input signal

supplied.

The NRF-VS can also be used as a set point control. In this

mode of operation, the NRF-VS will control the pump speed to

hold a constant temperature (determined by the user) in the

Secondary loop. The NRF-VS is capable of reading the loop

temperature sensor. When used in a heating application, if

the loop temperature falls below an adjustable setting, the

NRF-VS will increase the speed of the injection pump.

In addition, the NRF-VS can be used in cooling applications. In

this senario, the NRF-VS wil increase pump speed whenever

the loop temperature increases above the setpoint.

OPERATIONAL LIMITS

These controls are to be used on pumps designed to pump

liquids compatible with their cast iron, bronze or stainless

steel body constructions.

Maximum Operating Pressure: 150 PSI (10 bars).

Maximum Operating Temperature: 240ºF cast iron body,

230ºF brass and stainless steel body.

Electrical Rating: 115V, 60HZ, 1Ø.

Suitable for NRF, NBF, and SSF pumps with less than 1.1

amps pump nameplate rating.

Page 3

OPERATION

The NRF-VS is designed to control the pump speed on an

injection system allowing the pump to inject a different water

temperature into a secondary loop to regulate its temperature.

It can be used either in heating or cooling applications using a

secondary loop temperature sensor. The sensor reads the

secondary loop temperature allowing the NRF-VS to regulate

the loop temperature by modulating the injection pump speed

accordingly to reach a set point.

A temperature knob mounted on the NRF-VS is used to adjust

the temperature set point either in heating or cooling (see Dip

Switch 2). Dip Switch 1 must be set to ON to activate the Set

Point feature. The sensor must be wired to terminals 2 and 3

when using the setpoint mode.

The NRF-VS can be controlled remotely using an external

signal to replace the set point. This allows for the external

control or system providing the input to change the pump

speed directly. No sensor is required in this setting. The

external input providing either 4-20mA signal or 2-10V signal

must be wired to terminals 1 and 2. The speed of the pump

will vary from full stop below 4mA or 2V to 100% at 20mA or

10V. Dip switch 1 must be set OFF to activate the external

signal feature.

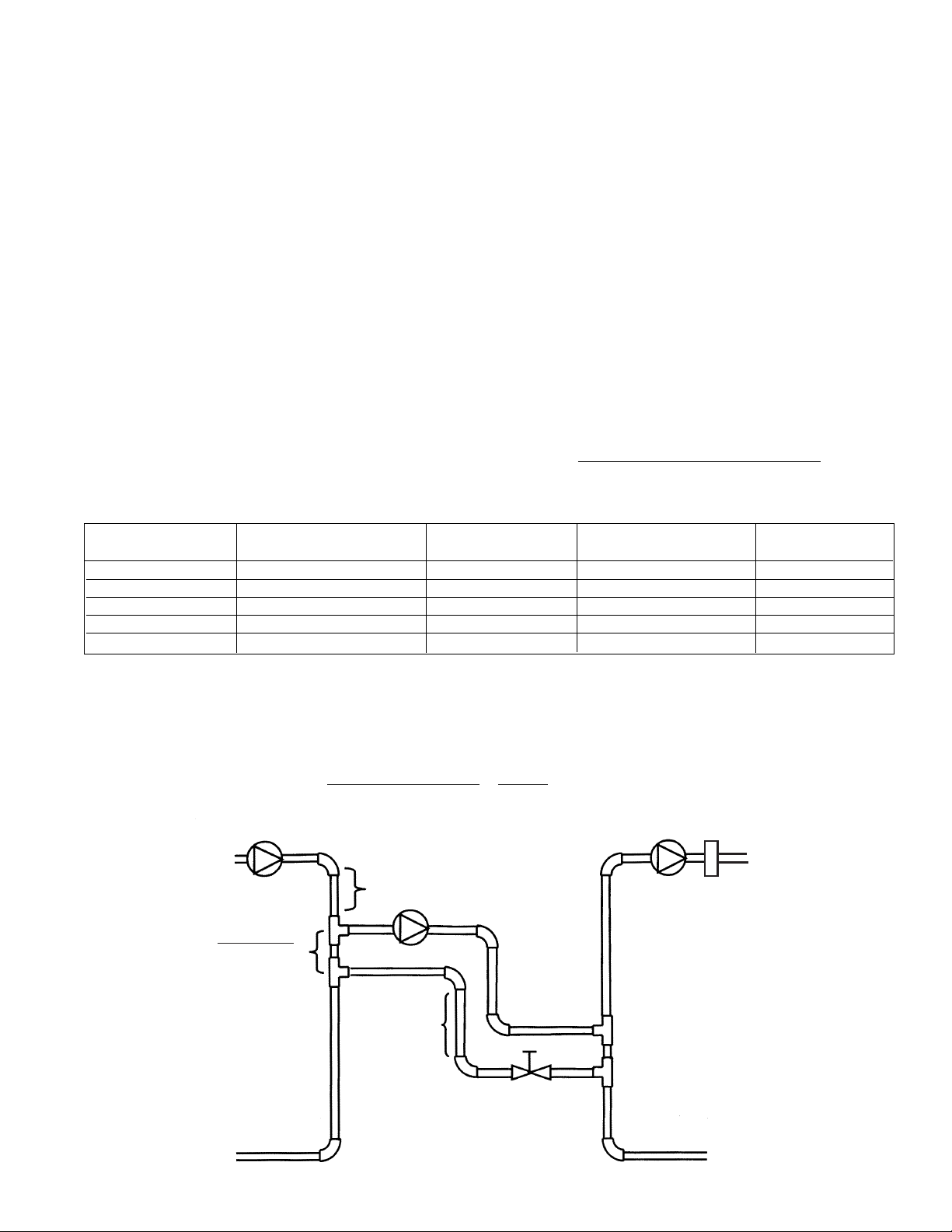

DESIGN SELECTION

To select the correct pump, pipe size and balance valve:

1.Determine the Primary Loop Temperature. This is the

temperature the primary loop will maintain.

2. Determine the Secondary Loop Temperature. This is the

design temperature of the secondary loop. If an outdoor

reset function is being employed, this is the required

temperature of the secondary loop under maximum load.

3. Determine the design temperature drop (

T or delta T) of

the secondary loop. This is the design drop in temperature through the secondary loop. In most radiant

heat applications,

T is 10. Other types of radiation such

as baseboard have a higher design

T.

4. Determine the Maximum Injection Heat Load. This is the

maximum heat requirement of the secondary loop. The

maximum injection heat load is based on the injection

pump running at the highest speed. As the pump speed

is reduced, less heat will be delivered to the secondary

loop.

5. Use the equation below to determine the design injection

flow rate.

Design Injection Flow Rate (GPM) =

Maximum Injection Heat Load (BTU/hr)

500 (T

primary - Tsecondary + Tsecondary) (ºF)

6. Use the table below to select the appropriate pump, pipe

size and balance valve.

Design Injection Injection B&G Circuit Setter

®

B&G Circuit Setter

®

B&G

Flow Rate (GPM) Pipe Size Balance Valve Valve Setting Pump

1.5

1

/2" CB-1/2 / CB-1/2S 18 / 25 NRF-22

3.5

1

/2" CB-1/2 / CB-1/2S full open / 6 NRF-22

6

3

/4" CB-3/4 / CB-3/4S full open / 12 NRF-22

10 1" CB-1 / CB-1S full open / full open NRF-22

15 1

1

/4" CB-11/4 / CB-11/4S 5 / 5 NRF-22

Example:

1. Primary Loop Temp: 140ºF

2. Secondary Loop Temp: 100ºF

3. Design temperature drop: 10ºF

4. Maximum injection heat load: 150,000 BTU/hr

5. Calculate Injection flow rate

Design Injection Flow Rate (GPM) =

150,000 (BTU/hr)

=

150,000

= 6 GPM

500 (140 - 100 + 10) (ºF) 25,000

6. Injection Pipe size is

3

/4", full open CB-3/4 balancing valve and NRF-22

Minimum of 1' of

pipe drop required

to create a thermal

trap

Rule of Thumb

3 pipe diameters

between tees

Minimum of 8 pipe diameters upstream

and 4 pipe diameter downstream of straight

pipe on either side of tees to prevent any

possibility of “jet flow” through the

common piping.

Secondary

Loop

Secondary

Loop Pump

Primary

Loop Pump

Secondary

Loop Sensor

Primary

Loop

Injection Pump

Balance

Valve

3

FIG. 2

Based on (5) feet of pipe, (4) 90° elbows, (4) tees. Correct pipe and pump size calculation for any application should be performed by a qualified engineer or contractor.

Page 4

PIPING

PIPING OVERVIEW

• The Primary loop may have mulitple injection loops or other

takeoffs. However, the piping for each injection system

must meet the requirements described below.

• The Injection piping can be installed in either a horizontal or

a vertical configuration.

• The pipe diameters of the Primary and Secondary loops

may differ.

• The Injection Piping diameter must be at least one pipe size

smaller than the smaller of the Primary and Secondary loop

piping. For example, if the Primary loop diameter is 1

1

/4"

and the Secondary loop diameter is 1", then the diameter of

the Injection piping must be

3

/4" or smaller.

• The Injection pump motor must be a fractional B&G NRF,

NBF or SSF permanent split capacitor type pump. (Refer to

operational limits on Page 2 for pump information.) The

Injection pump will control the amount of water pumped

from the Primary loop into the Secondary loop.

• A balancing valve should be installed on the injection return

piping. This helps to balance the system.

• The distance between the injection tees should be as short

as possible. The rule of thumb distance between the tees is

3 times the pipe diameter. For instance, if the pipe diameter

is 1" then the length of straight pipe between the two

injection tees should be 3".

HORIZONTAL PIPING CONFIGURATION

• The Injection piping can be installed horizontally as shown

in Fig. 2.

• The Injection supply piping should run horizontally from the

Primary to the Secondary loop.

• On the Injection piping it is necessary to install a heat trap

to prevent heat from the Primary loop entering the Secondary loop when the Injection pump is not running.

• The injection piping must drop down vertically at least 18"

and then rise back up vertically at least 18".

VERTICAL PIPING CONFIGURATION

• The Injection piping can be installed vertically.

• The Primary loop must be at least 18" vertically above the

Secondary loop.

INSTALLING SENSOR

• In a primary/secondary application, the secondary loop

sensor should be mounted downstream of the inlet loop and

before any major heating units. That will provide the control

a more accurate temperature reading (Refer to Fig. 2.)

• Strap the cylindrical sensor to the pipe as shown in Fig. 3.

• Wrap the pipe and sensor assembly with insulating tape to

insure adequate heat transfer to the sensor.

• The sensor wires can be extended up to 500' from the

controller. If the sensor wires are located in an area with

strong sources of electro-magnetic interference (EMI), the

wires must be run in a grounded metal conduit. Do not run

wires in conduit with line voltage.

WIRING

NOTE: If the NRF-VS control is already installed on the pump,

skip the NRF-VS control installation section and proceed to

the “wiring the sensors” section.

NRF-VS CONTROL INSTALLATION

1. Disconnect the electrical supply to the pump.

2. Remove the screw that holds the steel conduit box cover

to the pump.

3. Remove the conduit box cover. The NRF-VS control

assembly replaces the conduit box cover.

4. Disconnect the black and white motor leads from the

power supply.

5. Position the plastic base for the NRF-VS control

assembly onto the steel conduit box with the warning/

caution label to the rear of the pump.

6. Secure the plastic base to the conduit box with one 8-32

screw provided.

7. Verify that the electrical rating of the NRF-VS control

matches the values shown on the nameplate of the

circulator.

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lock out power before making elec-

trical connections. Failure to follow these instructions could

result in serious personal injury or death.

4

CAUTION: The Injection pump and pipe sizing

should be performed by a qualified engineer or

contractor. Failure to follow these instructions could

cause inadequate system performance and/or property

damage.

FIG. 3

Page 5

8. Make the electrical connections according to the wiring

diagram provided (See Fig. 4). Route the power wiring

through one of the

7

/8" diameter holes in the steel conduit

box. The control or sensor wiring must pass through the

7

/8" diameter hole in the plastic enclosure.

9. Attach 120VAC line voltage to the orange wire extending

from the back of the NRF-VS. Wire the neutral wire to

either of the orange wires extending from the back of the

NRF-VS.

WIRING THE SENSORS FOR SETPOINT CONTROL

• Sensor terminals are located on the back of the NRF-VS

control board.

• To set the NRF-VS for use with a temperature sensor, set

Dip Switch 1 to On.

• Pass the sensor wiring through the

7

/8" hole in the plastic

enclosure. Low voltage wiring must be separated from

power wiring.

• The sensor wires have no polarity. Connect either wire from

the sensor to terminals 2 and 3. (See Fig. 5)

• Sensors are typically installed on the secondary loop. (See

Fig. 2)

• On a sensor failure or short the pump will run at full speed

and LED Lights will blink indicating a fault status.

WIRING THE EXTERNAL SIGNAL INPUT

4-20MA OR 2-10V

• External signal terminals are located on the back of the

NRF-VS control board. (See Fig. 6).

• To wire the NRF-VS for use with an external signal either

4-20mA or 2-10V, set Dip Switch 1 to Off.

• The NRF-VS DOES NOT source current for the signal. The

current must be supplied by the control or system

supplying the signal.

• Pass the sensor wiring through the

7

/8" hole in the plastic

enclosure. Low voltage wiring must be separated from

power wiring.

• Polarity is important when using an External Signal. Always

connect the common to terminal 2 while the signal side is

connected to terminal 1.

• On a signal error the pump will fully stop and LED Lights

will blink indicating a fault status.

• When using 4-20mA input signal, make sure the input

source can supply at least 10V.

• When using 2-10V input signal, make sure the input source

can supply at least 20mA.

DIP SWITCH SETTINGS

Dip Switch 1 (Input Mode 4-20mA/2-10V or Setpoint)

1=Off (4-20mA/2-10V), 1=On (Setpoint) Default 1=Off

• This control can vary the pump speed based on either an

External Signal of 4-20mA/2-10V or a Temperature

Setpoint.

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections are to be made by a qualified

electrician in accordance with all applicable codes, ordinances and good practies. Failure to follow these instructions could result in serious personal injury, death and/or

property damage.

CAPACITOR

Black

Black

Black

Orange

Orange

Neut

Line

White

White

White

Power Switch

Surge Suppressor

5

FIG. 4

FIG. 5

FIG. 6

External Signal Wiring

123

External Signal

123

Sensor Wiring

Common

Dip Switches

Input Mode Setting

Dip Switch 1

4-20mA

2-10V

Setpoint

Temperature Sensor

Page 6

6

Setpoint (Dip Switch 1=On)

• The Dial on the NRF-VS allows for set point temperature

adjustment. Use a small screwdriver to turn the dial so that

the arrow lines up with the desired setpoint temperature.

• The pump speed will vary based on the difference between

the secondary loop sensor reading and the set point on the

NRF-VS.

External Signal (Dip Switch 1=Off)

• Below 4mA or 2V, the pump will fully stop. At 20mA or 10V

the pump will run at full speed.

• The temperature dial is deactivated when control is in the

external signal mode.

Dip Switch 2 (Control Mode Heating or

Cooling) Available with Setpoint Only

2=Off (Heating), 2=On (Cooling) Default 2=Off

• When Heating is selected, the control will increase pump

speed when the loop temperature drops further from the

Setpoint. When loop temperature is higher than the

setpoint, the control will turn off the pump. Refer to the

outer range of 70º-200ºF shown in the scale.

• In Cooling, the control will increase pump speed the higher

the loop temperature increases above the Setpoint. When

the setpoint is reached and maintained, the control will turn

off the pump. Refer to the inner range of 30º-100ºF shown

in the scale.

Dip Switch 3 (Output Mode Linear or Logarithmic)

3=Off (Linear), 3=On (Logarithmic) Default 3=Off

Linear (Dip Switch 3=Off)

Linear operation is based on a linear relationship between

percent of flow of the pump and BTU output of the terminal

unit. Typical application is when the pump injects into a

constant circulating loop, which includes the terminal unit.

Logarithmic (Dip Switch 3=On)

Logarithmic operation is based on non-linear relationship

between percent of flow of the pump and BTU output of the

terminal unit. In order to achieve the desired linear output, the

NRF-VS provides a logarithmic output to compensate for the

non-linear terminal output. Typical application is when the

pump injects directly into the terminal unit.

Dip Switch 4 (Gain) Available with Setpoint Only

4=Off (Normal), 4=On (Fast) Default 4=Off

• The Gain is how aggressive the control should behave

when loop temperature is far from Setpoint. It governs the

amount of change the control applies to pump speed.

• Normal gain is typically used in applications where the

sensor temperature changes gradually during operation.

• Fast gain is typically used in applications where the sensor

temperature changes rapidly during operation.

Dip Switch 5 (Pump Exercise)

5=On (Exercise), 5=Off (No Exercise) Default 5=On

• This Dip Switch regulates if the pump should be exercised

when stayed idle for a long period of time. When set to

Exercise, pump will run at full speed for a period of 10

seconds when left in idle status for a period of 72 hours.

Temperature Dial

Heating/Cooling Mode Setting

Dip Switch 2 (Setpoint only)

Heating Cooling

Output Mode Setting

DIP Switch 3

Linear Logarithmic

3 3

100%

BTU Output

0% 100%

100%

Terminal Unit Output

BTU Output

0% 100%

% of Flow

Linear

Desired

Output

Logarithmic

% of Flow

Logarithmic

Gain Setting

DIP Switch 4

Normal Fast

4 4

Pump Exercise Setting

DIP Switch 5

No Exercise Exercise

10 Sec every

3 idle days

Page 7

POWER UP SEQUENCE

At initial power up, the NRF-VS will run at full speed for 5

seconds. It will then run at low speed for 5 seconds, before

adjusting to the appropriate speed. Monitor the pump at initial

power up. If the pump does not operate as indicated above,

the Gain (DIP Switch 4) can be adjusted to On (Fast) to

increase the minimum power setting.

OUTPUT LIGHTS

The NRF-VS cover has 6 LED lights to indicate operation and

faulty status.

THE GREEN OUTPUT LIGHT

Represents power to the NRF-VS. When constantly On, the

control is powered.

THE RED OUTPUT LIGHTS

Represent pump speed in increments of 20%. If only one Red

light is on, the pump speed is equal to or below 20%. If 2 Red

lights are On, the pump speed is equal to or below 40%.

When 3 Red lights are On, the pump speed is equal to or

below 60%. When 4 Red lights are On, the pump speed is

equal to or below 80%. When all Red lights are On, the pump

is running from 80% to full speed.

FLASHING LIGHTS

• This indicates an error in the input signal. If NRF-VS is set

to 4-20mA/2-10V, the signal must be below 0.5mA or

0.25V. Check input signal and wiring.

• If NRF-VS is set to Set Point, the sensor has fault status,

either shorted or opened. Check sensor wires and Ohm

reading against sensor temperature chart.

PERIODIC INSPECTION

Bell & Gossett products are designed to provide years of

trouble free service. It is recommended that periodic inspections be made to check for potential problems with the pump

and control. If any leakage or evidence of leakage is present,

repair or replace the unit.

TEMPERATURE Value

(in Degrees ºF) (in 0hms)

30 17264

35 14985

40 13040

45 11374

50 9944

55 8714

60 7653

70 5941

80 4649

90 3667

100 2914

110 2332

120 1879

130 1524

140 1243

150 1021

160 842

170 699

180 583

190 489

200 412

210 349

220 297

230 253

WARNING: The NRF-VS is an operating control only.

The boiler must have all safety and limit controls

required by code. It is the responsibility of the installer to

verify that all the safety and limits are working properly

before and after the NRF-VS is installed. Failure to follow

these instructions could result inserious personal injury,

death and/or property damage.

7

TEMPERATURE

SENSOR CHART

Page 8

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. P86271B May 2012

Loading...

Loading...