Page 1

INSTRUCTION MANUAL

P86109

REVISION B

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Close Coupled

Centrifugal Pumps

Page 2

2

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on the

pump safety instruction decals to draw attention to safety related instructions. When used the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN A

SAFETY HAZARD.

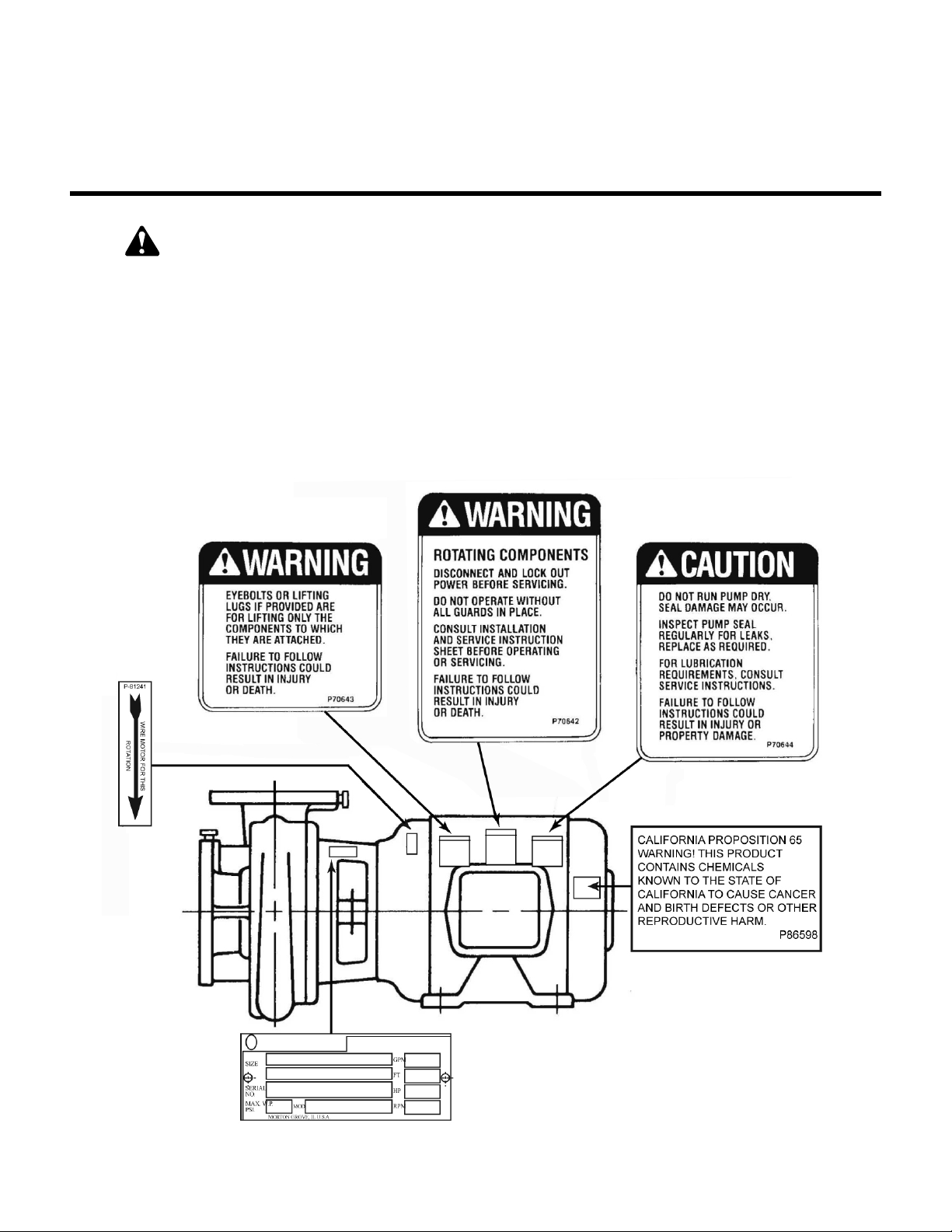

Your pump should have the following safety instruction decals

located approximately as shown. If the decals are missing or are

illegible contact your local representative for a replacement.

Additional Safety Requirements:

1. Electrical connections to be made by qualified Electrician in

accordance with all National, State and Local codes.

2. Motor must have properly sized starter with properly sized

heaters to provide overload and undervoltage protection.

3. If pump, motor or piping are operating at extremely high or

low temperatures, guarding or insulation is required.

4. The maximum working pressure of the pump is listed on the

pump nameplate, do not exceed this pressure.

DESCRIPTION

This centrifugal pump is a close coupled pump which

features – high efficiency, rugged construction, foot mounted

motor. These features make installation, operation and service

easy to perform.

PUMP APPLICATION

This centrifugal pump’s bronze fitted construction make it ideal

with service with the following liquids: fresh water, general

pumping and benign liquids.

Page 3

3

ADDITIONAL SAFETY REQUIREMENTS:

ELECTRICAL SAFETY:

THERMAL SAFETY:

MECHANICAL SAFETY:

WARNING: Electrical Shock Hazard

Electrical connections to be made by a qualified

electrician in accordance with all applicable codes, ordinances, and good practices.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

WARNING: Electrical Overload Hazard

Three phase motors must have properly sized heaters

to provide overload and undervoltage protection. Single

phase motors have built-in overload protectors.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

WARNING: Extreme Temperature Hazard

If pump, motor, or piping are operating at extremely

high or low temperatures, guarding or insulation is

required.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

WARNING: Excessive System Pressure Hazard

The maximum working pressure of the pump is listed

on the nameplate, do not exceed this pressure.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

WARNING: Excessive Pressure Hazard

Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of

system components and release of high temperature fluids.

This will be prevented by installing properly sized and

located compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

PUMP LOCATION

Locate the pump so there is sufficient room for inspection,

maintenance and service. If the use of a hoist or tackle is

needed, allow ample head room.

If lifting of the entire pump is required, do so with slings placed

under the pump as shown in Figure 4.

The best pump location for sound and vibration absorption is

on a concrete floor with sub soil underneath. If the pump

location is overhead, special precautions should be undertaken to reduce possible sound transmission, consult a sound

specialist.

If the pump is not on a closed system, it should be placed as

near as possible to the source of the liquid supply, and located

to permit installation with the fewest number of bends or

elbows in the suction pipe.

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) exceeds the Net

Positive Suction Head Required (NPSHR), as stated by the

pump performance curve.

WARNING: Falling Objects Hazard

Eyebolts or lifting lugs, if provided, are for lifting only

the components to which they are attached.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

FIG. 4

IMPORTANT

Do not install and operate your pump in closed

systems unless the system is constructed with properly

sized safety devices and control devices. Such devices

include the use of properly sized and located pressure relief

valves, compression tanks, pressure controls, temperature

controls, and flow controls as appropriate. If the system

does not include these devices, consult the responsible

engineer or architect before making pumps active.

Page 4

4

INSTALLATION

This pump is built to provide years of service if installed properly and attached to a suitable foundation. A base of concrete

weighing 2

1

/2 times the weight of the pump is recommended.

(Check the shipping ticket for pump weight.)

If possible, tie the concrete pad in with the finished floor.

To facilitate easy servicing, some type of expansion fitting

should be utilized. The female portion should be inserted into a

suitable hole in the floor so that its top surface is flush with the

floor surface. Thus, when the hold-down bolts are removed, the

motor can be removed by sliding it back from the pump. (See

Figure 5)

ROTATION

Pump rotation is clockwise when viewed from back of the motor.

An arrow is provided to show direction of rotation.

PIPING

Always install a section of straight pipe between the suction

side of the pump and first elbow. This reduces turbulence of the

suction by straightening out the flow of liquid before it enters the

pump. The length should be equal to five times the diameter of

the pipe.

Be sure to eliminate any pipe-strain on the pump. Support the

suction and discharge pipes independently by use of the pipe

hangers near the pump. Line up the vertical and horizontal

piping so that the bolt-holes in the pump flanges match the boltholes in the pipe flanges. DO NOT ATTEMPT TO SPRING THE

SUCTION OF DISCHARGE LINES INTO POSITION. Bearing

wear will result if suction or discharge lines are forced into position. The code for Pressure Piping (A.S.A.B.31.1) lists many

types of supports available for various applications.

As a rule, ordinary wire or band hangers are not adequate to

maintain alignment. It is very important to provide a strong, rigid

support for the suction and discharge lines.

Where considerable temperature changes are anticipated,

fittings for absorption expansion should be installed in the

system in such a way as to avoid strain on the pump.

On an open system with a suction lift, use a foot-valve of equal

or greater area than the pump suction piping. Prevent clogging

by using a strainer at the suction inlet next to the foot-valve. The

strainer should have an area three times that of the suction pipe

with a mesh hole diameter of no less than

1

/4".

When using an isolation base, flexible piping should be used on

both the suction and discharge sides of the pump.

NOTES

1. The pipeline should have isolation valves around the pump

and have a drain valve in the suction pipe.

2. When installing the suction and discharge connection to a

threaded pump housing the use of PTFE tape sealer or a

high quality thread sealant is recommended.

PUMP INSULATION

When insulating your pump, ensure that the coverplate vent slots

and the motor remain uncovered.

FIG. 5

Page 5

5

LUBRICATION

Your pump has been lubricated at the factory, future lubrication should be in accordance with the motor manufacturers

instruction.

GENERAL INFORMATION

1. Keep the motor properly lubricated.

2. When there is a danger of freezing, drain the pump.

3. Inspect pump regularly for leaky seals or gaskets and loose

or damaged components. Replace or repair as required.

PUMP WITH STANDARD MECHANICAL SEAL

FIG. 6

Page 6

SERVICE INSTRUCTIONS

WARNING: Unexpected Startup Hazard

Disconnect and lock out power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

1. Close valves on suction and discharge sides of pump. (If no

valves have been installed, it will be necessary to drain the

system.)

CAUTION: Extreme Temperature Hazard

Check surfaces for extreme temperatures, allow

pump temperatures to reach acceptable level before proceeding. Open drain valve, do not proceed until liquid stops

coming out of drain valve. If liquid does not stop flowing

from drain valve, isolation valves are not sealing and should

be repaired before proceeding. After liquid stops flowing

from drain valve leave drain valve open and continue.

Remove the drain plug located on the bottom of the pump

volute. Do not reinstall plug or close drain valve until

reassembly is completed.

Failure to follow these instructions could result in injury or

property damage.

2. Remove motor foot capscrews. Loosen volute capscrews,

do not remove them. Use capscrews in the jack screw

holes. Start to remove the pump assembly from the volute.

CAUTION: Make certain the internal pressure is

relieved before continuing.

Failure to follow these instructions could result in injury or

property damage.

3. Remove seal flushing tube, if used.

Remove the volute capscrews and remove the pump

assembly from the volute.

4. Remove the impeller capscrew, lock washer and washer.

Remove the impeller.

5. Remove the rotating portion of the seal, use a screwdriver

to loosen the rubber ring.

6. Remove the seal insert along with the insert gasket.

7. Thoroughly clean the shaft sleeve and the coverplate seal

cavity. Inspect for surface damage like pitting, corrosion,

nicks or scratches. Replace if necessary.

8. Lubricate the shaft sleeve and coverplate seal cavity with

soapy water. (Do not use petroleum lubricant.) Install a new

cup gasket and a new seal insert with indentation side

down into the cup.

9. Slide a new rotating seal assembly onto the shaft sleeve.

With a screwdriver push on the top of the compression ring

until the seal is tight against the seal insert. Install seal

spring.

10. Install impeller, impeller washer, lock washer and capscrew,

then tighten capscrew (per torque chart).

11. Install new volute gasket then install pump assembly into

volute. Tighten volute capscrews (per torque chart). Install

seal flushing tube, if used. Install motor foot capscrews and

tighten. Install drain plug, close drain valve.

12. Open isolation valves, inspect pump for leaks, if not leaking

return pump to service.

CAPSCREW TORQUE (FOOT-POUND)

Capscrew Head

Type Marking

SAE Grade 2 6 13 25 38 60 20 190 210 300

Brass

Stainless Steel or

SAE Grade 5 10 20 35 60 90 180 325 525 800

1

/4

4 10 17 27 42 83 130 200 300

5

/16

3

/8

Capscrew Diameter

7

/16

1

/2

5

/8

3

/4

7

/8 1

DEALER SERVICING

If trouble occurs that cannot be rectified contact your local

representative. He will need the following information in order to

give you assistance.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. P86109C February 2013

1. Complete nameplate data of pump and motor.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

Loading...

Loading...