Page 1

INSTRUCTION MANUAL

P85626C

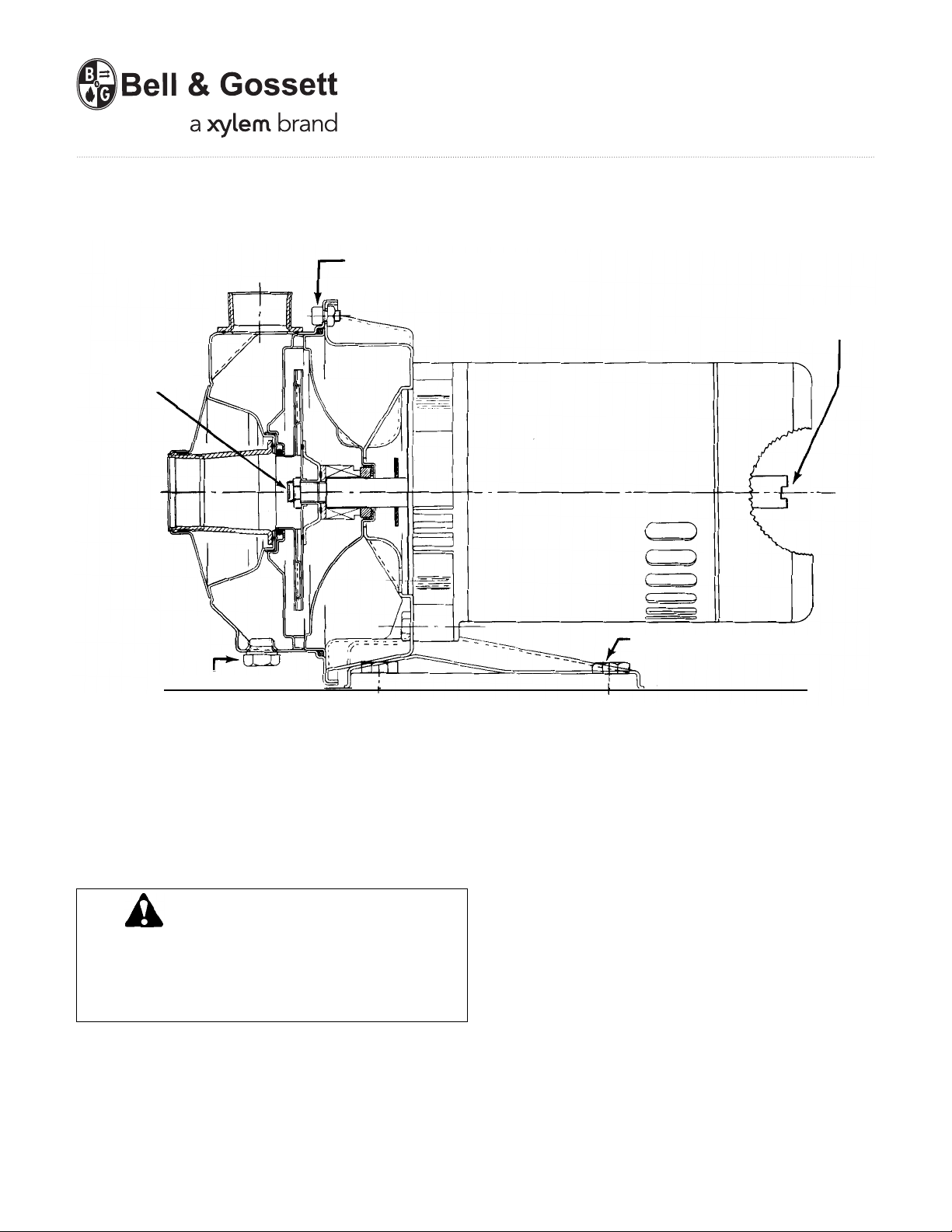

FIGURE 1

IMPELLER

LOCKNUT

PUMP DRAIN PLUG

PUMP CASING CAPSCREWS

MOTOR

SHAFT SLOT

MOUNTING CAPSCREWS

Replacement Seal Instructions for

Series 3530 Centrifugal Pumps

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

NOTE: For additional information and instructions refer to the

Installation Operation & Service Instructions Manual supplied

with your pump, or obtain a copy from your local Bell & Gossett

representative.

Page 2

SERVICE INSTRUCTIONS

WARNING: Unexpected Start Up Hazard

Disconnect and lockout power before servicing. Failure

to follow these instructions could result in serious personal

injury or death.

1. Close valves on suction and discharge sides of pump. (If no

valves have been installed, it will be necessary to drain the

system.)

CAUTION: Extreme Temperature Hazard

Allow pump temperature to reach acceptable level

before proceeding. Open drain valve, do not proceed until

liquid stops coming out of drain valve. If liquid does not

stop flowing from drain valve isolation valves are not sealing and should be repaired before proceeding. After liquid

stops flowing from drain valve, leave drain valve open and

continue. Remove the drain plug located on the bottom of

the pump housing. Do not reinstall plug or close drain

valve until reassembly is completed. Failure to follow these

instructions could result in moderate personal injury or

property damage.

2. Remove the capscrews holding the pump foot to the floor/

base. Loosen all 8 capscrews holding the motor bracket to the

pump casing, do not remove. Start to pull the motor assembly

out of the pump casing. Remove the 8 pump casing capscrews and remove the motor assembly.

WARNING: Excessive System Pressure Hazard

Make certain the internal pressure is relieved before

continuing. Failure to follow these instructions could result

in serious personal injury or death and property damage.

3. Remove the shaft cover from the back of the motor to expose

the slot in the motor shaft. (Depending on motor manufacturer, the shaft cover may be a button plug or a total cover.)

Impeller removal on pumps without impeller locknuts: The

impeller hub must be heated to break the adhesive bond so

the impeller can be removed from the motor shaft. Using a

propane torch, heat the impeller hub from the inside of the

impeller eye, Figure 4. With a glove on one hand, grip the

impeller O.D. and turn counterclockwise while holding the

motor shaft with a large screwdriver, Figure 5. Remove the

impeller, the seal spring, the seal head (use a screwdriver if

necessary), and the coverplate. Impeller removal for pumps

with impeller lockout: While holding the motor shaft with a

large screwdriver remove the impeller locknut and then the

impeller. The locknut adhesive may cause the impeller to

be hard to remove. If so, heat can be applied.

4. Remove the seal insert and the seal cup from the coverplate.

5. Thoroughly clean the shaft and the coverplate seat area.

Inspect for surface damage like pitting, corrosion, nicks or

scratches. Replace if necessary.

6. Lubricate the shaft and the coverplate seat with soapy

water (do not use petroleum lubricant). Install a new seal

cup and seal stationary seat into the coverplate.

NOTE: Install the indentation side of the stationary seat

into the cup.

7. Install coverplate onto motor bracket and install rotating seal

assembly.

NOTE: Place replacement seal on as far as possible by hand.

Then, using a screwdriver, press down firmly all around the

outer edge of the top compression ring until the seal is

tight against the face of the seal stationary seat.

8. Install the seal spring and then the impeller. While holding the

motor shaft, turn the impeller clockwise until the hub is tight

against the shaft shoulder. Do not exceed 10 ft-lbs. of torque.

The impeller locknut must be installed using Loctite Retaining

Compound 609 or equivalent. The shaft and locknut threads

must be clean, dry and free of oils and grease before applying the retaining compound. Apply the retaining compound

to the shaft threads and to the impeller locknut threads.

Torque locknut to 10 ft.-lbs.

IMPORTANT: The retaining compound must be allowed to

cure for at least 30 minutes before the pump is put back

into service.

Inspect coverplate O-ring, suction eye O-ring and drain and

vent plug O-rings for nicks or cuts. Replace if necessary.

®

NOTE: With a Viton

be replaced with the provided Viton

seal changeout kit, all O-rings must

®

O-rings.

9. Assemble motor to pump casing and tighten the 8 pump

casing capscrews. Tighten the pump casing capscrews in a

star pattern, do not tighten in a circular pattern. Torque casing capscrews 12 ft.-lbs. Replace the motor shaft cover.

10. Replace mounting capscrews. Replace drain and vent

plugs, close drain valve. Check for proper motor rotation.

11. Open isolation valves, inspect coverplate O-ring and mechanical seal for leaks. If not leaking, return pump to service.

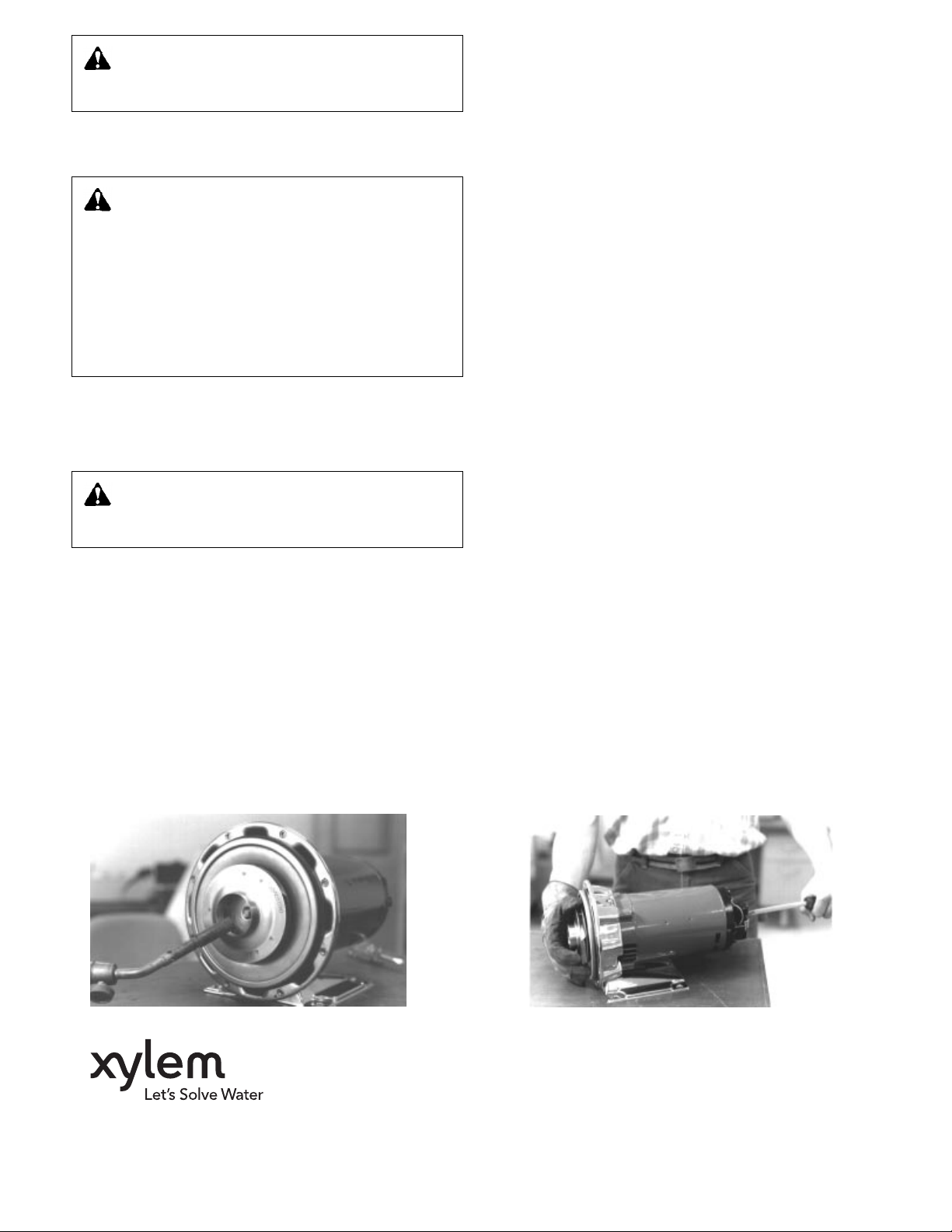

FIGURE 4 – Heat impeller hub to break adhesive bond. FIGURE 5 – Remove impeller.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. P85626C May 2012

Loading...

Loading...