Page 1

INSTRUCTION MANUAL

Bell & Gossett

P81845

REVISION B

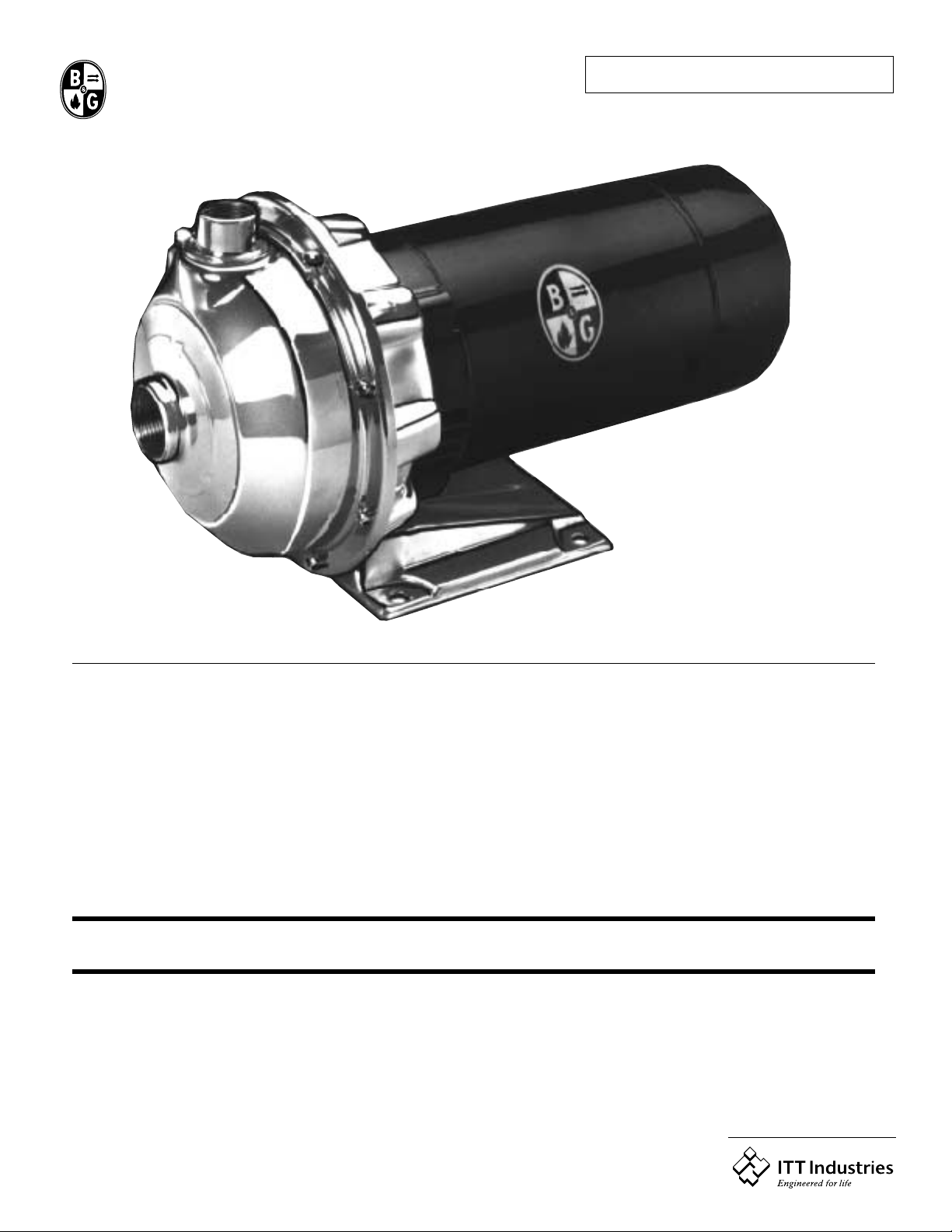

Series 3530

Centrifugal Pump

Installation, Operation and Service Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Bell & Gossett

Page 2

DESCRIPTION

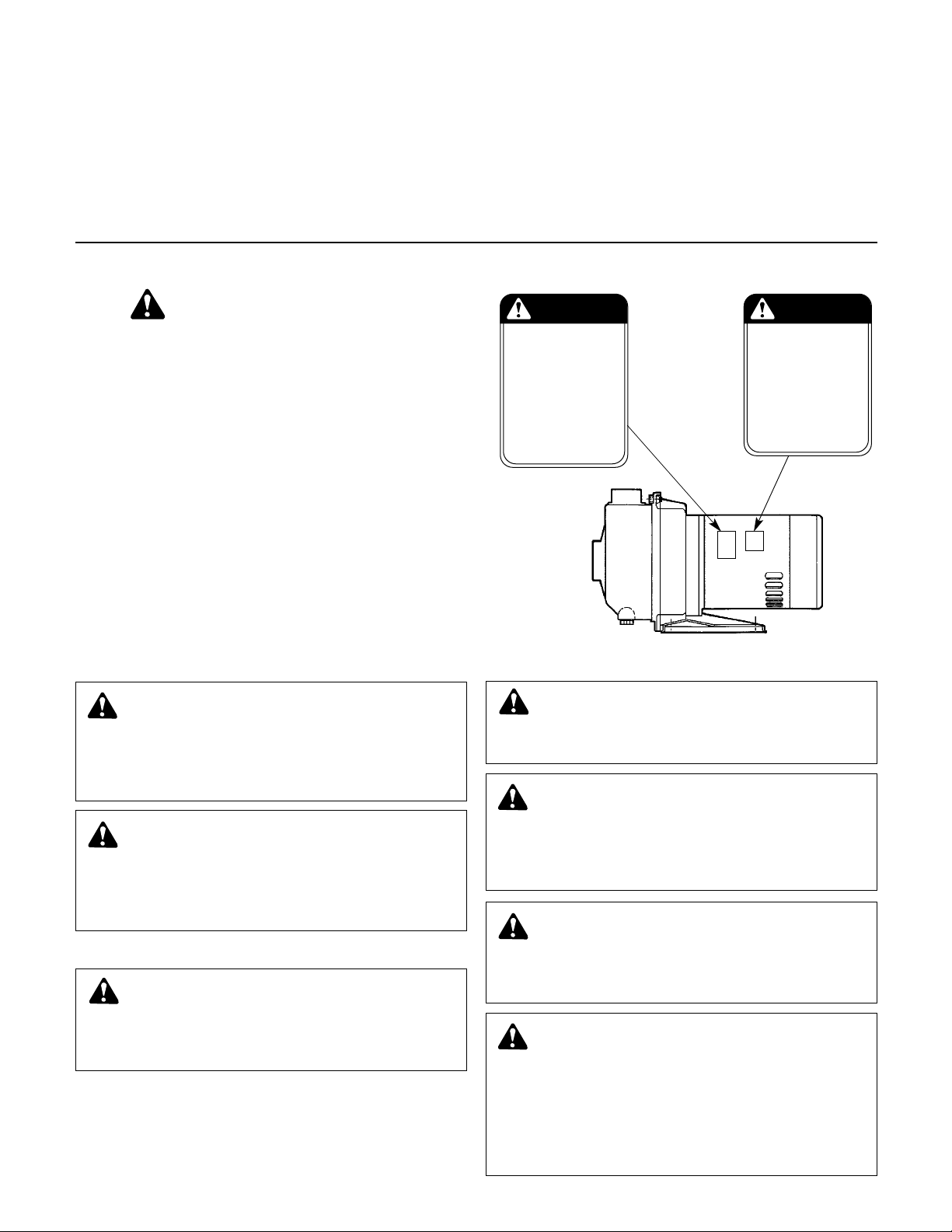

WARNING

ROTATING COMPONENTS

DISCONNECT AND LOCK OUT

POWER BEFORE SERVICING.

DO NOT OPERATE WITHOUT

ALL GUARDS IN PLACE.

CONSULT INSTALLATION

AND SERVICE INSTRUCTION

SHEET BEFORE OPERATING

OR SERVICING.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70642

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70644

The Series 3530 Centrifugal Pump is a close coupled pump

which features – foot mounting, light weight design, pump

casing with top centerline discharge and self flushing mechanical seal. These features make installation, operation and service easy to perform.

SAFETY

INSTRUCTIONS

This safety alert symbol will be used in this manual and on the

pump safety instruction decals to draw attention to safety related

instructions. When used the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS

A SAFETY HAZARD.

Your Series 3530 Pump should have the following safety

instruction decals located approximately as shown. If the

decals are missing or illegible contact your local B&G representative for a replacement.

MAY RESULT IN

PUMP APPLICATION

The Series 3530 Centrifugal Pump’s stainless steel construction makes it ideal for service with the following liquids:

Domestic water, fresh water

hydronic cooling or heating, pressure boosting, general pumping and benign liquids.

For other applications contact your local B&G Representative.

, boiler feed water, condensate,

ADDITIONAL SAFETY REQUIREMENTS

ELECTRICAL SAFETY:

electrician in accordance with all applicable codes,

ordinances, and good practices.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

heaters to provide overload and under voltage protection.

Single phase motors have built-in overload protectors.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

THERMAL SAFETY:

high or low temperatures, guarding or insulation is required.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

2

WARNING: Electrical Shock Hazard

Electrical connections to be made by a qualified

WARNING: Electrical Overload Hazard

Three phase motors must have properly sized

WARNING: Extreme Temperature Hazard

If pump, motor, or piping are operating at extremely

FIGURE 1

MECHANICAL SAFETY:

WARNING: Unexpected Start-up Hazard

Disconnect and lock out power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

WARNING: Unexpected Startup Hazard

Single phase motors are equipped with automatic

reset overload protectors. Pump can restart without warning.

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

WARNING: Excessive System Pressure Hazard

The maximum working pressure of the pump is listed

on the nameplate. Do not exceed this pressure.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

WARNING: Excessive Pressure Hazard

WARNING: Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of system components and release of high temperature fluids. This

will be prevented by installing properly sized and located

compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

Page 3

PUMP LOCATION

Locate the pump so there is sufficient room for inspection,

maintenance and service. If the use of a hoist or tackle is

needed, allow ample head room.

The best pump location for sound and vibration absorption is

on a concrete floor with sub soil underneath. If the pump location is overhead, special precautions should be undertaken to reduce possible sound transmission, consult a sound specialist.

If the pump is not installed on a closed system, it should be

placed as near as possible to the source of liquid supply, and

located to permit installation with the fewest number of bends

or elbows in the suction pipe.

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) meets or exceeds

the Net Positive Suction Head Required (NPSHR), as stated by

the pump performance curve.

1. IMPORTANT

1.1 Do not install and operate ITT Bell & Gossett Pumps,

3D Valves, Suction Diffusers, etc., in closed systems

unless the system is constructed with properly sized

safety devices and control devices. Such devices

include the use of properly sized and located pressure

relief valves, compression tanks, pressure contr

temperature controls, and flow controls as appropriate.

If the system does not include these devices, consult

the responsible engineer or architect before making

pumps operational.

WARNING: Excessive Pressure Hazard

WARNING: Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of system components and release of high temperature fluids. This

will be prevented by installing properly sized and located

compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

1.2 Inspect unit for damage. Report any damage to

carrier/dealer immediately.

1.3 Electrical supply must be a separate branch circuit

with fuses or circuit breakers, wire sizes, etc., per

National and Local electrical codes. Install an all-leg

disconnect switch near pump.

ols,

1.6 Motor Protection

1.6.1 Single-phase: Thermal protection for singlephase units is sometimes built in (check nameplate). If no built-in protection is provided, use

a contactor with a proper overload. Fusing is

permissible.

1.6.2 Three-phase: Pr

properly sized magnetic starter and thermal

overloads.

1.7 Maximum Operating Limits:

Liquid Temperature: 212°F (100°C) with standard seal.

Pressure: 125 PSI.

Starts Per Hour: 20, evenly distributed.

1.8 Regular inspection and maintenance will increase ser

vice life. Base schedule on operating time. Refer to

Section 8.

ovide three-leg protection with

250°F (120

temp seal.

°C) with optional high

2. INSTALLATION

2.1 General

2.1.1 Locate pump as near liquid source as possible

(below level of liquid for automatic operation).

2.1.2 Protect from freezing or flooding.

2.1.3 Allow adequate space for servicing and ventilation.

2.1.4 All piping must be supported independently of

the pump, and must “line-up” naturally.

CAUTION: Never draw piping into place by forcing

the pump suction and discharge connections.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

2.1.5 Avoid unnecessary fittings. Select sizes to keep

friction losses to a minimum.

2.2 Units may be installed horizontally, inclined or vertically.

CAUTION: Do not install with motor below pump.

Any leakage or condensation will affect the motor.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

-

CAUTION: Always disconnect electrical power

when handling pump or controls.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

1.4 Motors must be wired for proper voltage. Motor wiring

diagram is on motor nameplate. Wire size must limit

maximum voltage drop to 10% of nameplate voltage at

motor terminals, or motor life and pump performance

will be lowered.

1.5 Always use horsepower-rated switches, contactor and

starters.

2.3 Foundation must be flat and substantial to eliminate

strain when tightening bolts. Use rubber mounts to

minimize noise and vibration.

2.4 Tighten motor hold-down bolts before connecting piping to pump.

3. SUCTION PIPING

3.1 Low static suction lift and short, direct, suction piping

is desired. For suction lift over 10 feet and liquid temperature over 120°F, consult pump performance curve

for Net Positive Suction Head Required.

3

Page 4

3.2 Suction pipe must be at least as large as the suction

connection of the pump. Smaller size will degrade

performance.

3.3 If larger pipe is r

(with straight side up) must be installed at the pump.

3.4 Installation with pump below source of supply:

3.4.1 Install full flow isolation valve in piping for inspec-

tion and maintenance.

CAUTION: Do not use suction isolation valve to

thr

ottle pump.

Failure to follow these instructions could result in serious

personal injury or death, and pr

3.5 Installation with pump above source of supply:

3.5.1 Avoid air pockets. No part of piping should be

higher than pump suction connection. Slope piping upward from liquid source.

3.5.2 All joints must be airtight.

3.5.3 Foot valve to be used only if necessary for prim-

ing, or to hold prime on intermittent service.

3.5.4 Suction strainer open area must be at least triple

the pipe area.

3.6 Size of inlet from liquid source, and minimum submergence over inlet, must be sufficient to prevent air

entering pump through vortexing. See Figs. 2-5.

3.7 User 3-4 wraps of Teflon tape to seal threaded

connections.

equired, an eccentric pipe reducer

operty damage.

4. DISCHARGE PIPING

4.1 Arrangement must include a check valve located

between a gate valve and the pump. The gate valve is

for regulation of capacity, or for inspection of the pump

or check valve.

4.2 If an increaser is required, place between check valve

and pump.

4.3 Use 3-4 wraps of Teflon tape to seal threaded

connections.

5. ROTA

5.1 Correct r

TION

otation is right-hand (clockwise when viewed

from the motor end). Switch power on and off quickly.

Observe shaft rotation. To change rotation:

5.1.1 Single-phase motor: Non-reversible.

5.1.2 Three-phase motor: Interchange any two power

supply leads.

6. OPERATION

6.1 Before starting, pump must be primed (free of air and

suction pipe full of liquid) and discharge valve partially

open.

CAUTION: Pumped liquid provides lubrication. If

pump is run dry, r

cal seal will be damaged. Do not operate at or near zero

flow. Ener

Liquid may flash to vapor. Rotating parts r

prevent scoring or seizing.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

gy imparted to the liquid is converted into heat.

otating parts will seize and mechani-

equire liquid to

Figure 2 Figure 3

Figure 4 Figure 5

6.2 Make complete check after unit is run under operating

conditions and temperature has stabilized. Check for

expansion of piping.

7. MAINTENANCE

7.1 Close-Coupled Unit. Ball bearings are located in and

art part of the motor. They are permanently lubricated.

No greasing required.

8. DISASSEMBLY

Complete disassembly of the unit will be described.

Proceed only as far as required to perform the maintenance work needed.

8.1 Turn off power.

8.2 Drain system. Flush if necessary.

8.3 Remove motor hold-down bolts.

8.4 Disassembly of Liquid End:

8.4.1 Remove casing bolts (370).

8.4.2 Remove back pull-out assembly from casing

(100).

4

Page 5

8.4.3 Remove impeller locknut (304).

CAUTION: Do not insert screwdriver between

impeller vanes to prevent rotation of closecoupled units. Remove cap at opposite end of motor. A

screwdriver slot or a pair of flats will be exposed. Using

them will prevent impeller damage.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

8.4.4 Remove impeller (101) by turning counter-clockwise when looking at the front of the pump.

Protect hand with rag or glove.

CAUTION: Failure to remove the impeller in a

counter-clockwise direction may damage threading

on the impeller, shaft or both.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

8.4.5 With two pry bars 180 degrees apart and inserted between seal housing (184) and the motor

adapter (108), carefully separate the two parts.

The mechanical seal rotary unit (383) should

come off the shaft with the seal housing.

8.4.6 Push out the mechanical seal stationary seat

from the motor side of the seal housing.

9. REASSEMBLY

9.1 All parts should be cleaned before assembly.

9.2 Refer to parts list to identify required replacement

items. Specify pump index or catalog number when

ordering parts.

9.3 Reassembly is the reverse of disassembly.

9.4 Observe the following when reassembling the liquidend:

9.4.1 All mechanical seal components must be in good

condition or leakage may result. Replacement of

complete seal assembly, whenever seal has been

removed, is good standard practice.

It is permissible to use a light lubricant, such as

glycerin, to facilitate assembly. Do not contaminate the mechanical seal faces with lubricant.

9.4.2 Inspect casing O-ring (513) and replace if dam-

aged. This O-ring may be lubricated with petroleum jelly to ease

9.4.3 Inspect guidevane O-ring (349) and replace if

worn.

9.5 Check reassembled unit for binding. Corr

required.

9.6 Tighten casing bolts in a star pattern to prevent O-ring

binding.

10. TROUBLE SHOOTING

MOTOR NOT RUNNING

(See causes 1 thru 6)

LITTLE OR NO LIQUID DELIVERED:

(See causes 7 thru 17)

POWER CONSUMPTION TOO HIGH:

(See causes 4, 17, 18, 19, 22)

EXCESSIVE NOISE AND VIBRATION:

(See causes 4, 6, 9, 13, 15, 16, 18, 20, 21, 22)

PROBABLE CAUSE:

1. Tripped thermal pr

2. Open circuit breaker

3. Blown fuse

4. Rotating parts binding

5. Motor wired improperly

6. Defective motor

7. Not primed

8. Discharge plugged or valve closed

9. Incorrect rotation

10. Foot valve too small, suction not submerged, inlet

screen plugged.

11. Low voltage

12. Phase loss (3-phase only)

13. Air or gasses in liquid

14. System head too high

15. NPSHA too low: Suction lift too high or suction losses

excessive. Check with vacuum gauge.

16. Impeller worn or plugged

17. Incorrect impeller diameter

18. Head too low causing excessive flow rate

19. Viscosity or specific gravity too high

20. Worn bearings

21. Pump or piping loose

22. Pump and motor misaligned

otector

CHART

ect as

CAUTION: Do not lubricant guidevane O-ring

(349). Insure it is not pinched by the impeller on

reassembly.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

5

Page 6

Loading...

Loading...