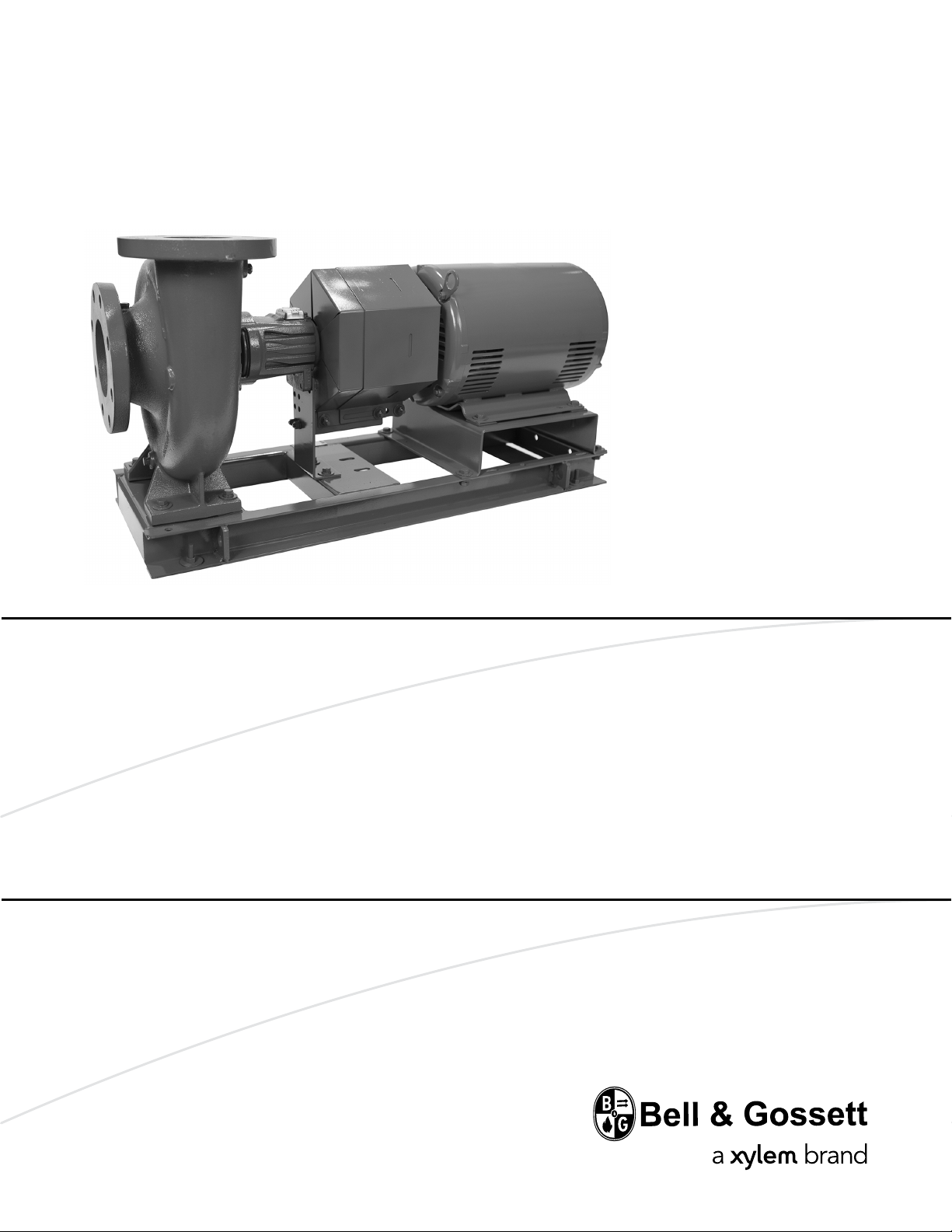

Bell & Gossett P81673 User Manual

Installation, Operation,

and Maintenance Manual

Series 1510

Table of Contents

Introduction and Safety..................................................................................................................3

Introduction..................................................................................................................................3

Safety.............................................................................................................................................3

Safety message levels............................................................................................................. 3

Safety instruction decals......................................................................................................... 4

User safety................................................................................................................................ 5

Environmental safety...............................................................................................................7

Transportation and Storage.......................................................................................................... 8

Inspect the delivery.....................................................................................................................8

Inspect the package................................................................................................................8

Inspect the unit........................................................................................................................ 8

Lifting methods............................................................................................................................8

Storage requirements.................................................................................................................9

Product Description......................................................................................................................10

General description.................................................................................................................. 10

Operational specifications....................................................................................................... 10

Table of Contents

Installation......................................................................................................................................12

Preinstallation............................................................................................................................ 12

Pump location guidelines.....................................................................................................12

Foundation requirements.................................................................................................... 13

Piping checklist......................................................................................................................13

Pump insulation checklist.....................................................................................................14

Typical installation.................................................................................................................15

Special installation.................................................................................................................15

Install the pump, driver, and coupling................................................................................... 15

Level the base on a concrete foundation ..............................................................................16

Grout the baseplate..................................................................................................................16

Coupling alignment..................................................................................................................16

Prepare for alignment...........................................................................................................17

Align the pump using a straight edge and calipers..........................................................17

Align the pump using a dial indicator................................................................................ 18

Align the Rexnord®Omega® coupling................................................................................ 19

Maximum allowable misalignment for Rexnord Omega couplings............................... 20

Fastener torque values and maximum RPM for Rexnord Omega couplings................ 21

Final alignment...................................................................................................................... 21

Commissioning, Startup, Operation, and Shutdown...............................................................23

Preparation for startup............................................................................................................. 23

Check the rotation.................................................................................................................23

Start the pump...........................................................................................................................24

Pump operation precautions...................................................................................................24

Shut down the pump................................................................................................................ 25

Make the final alignment of the pump and driver................................................................ 25

Note on the packed pump operation.....................................................................................25

Maintenance..................................................................................................................................27

Bearing maintenance................................................................................................................27

Series 1510 Installation, Operation, and Maintenance Manual 1

Table of Contents

Regrease the grease-lubricated bearings..........................................................................27

Lubricating grease requirements........................................................................................27

Disassembly............................................................................................................................... 28

Disassembly precautions......................................................................................................28

Drain the pump......................................................................................................................28

Remove the hex coupling guard.........................................................................................28

Remove the coupling............................................................................................................29

Remove the bearing frame and impeller assembly .........................................................29

Remove the impeller.............................................................................................................30

Remove the mechanical seal (1510 and 1510-F).............................................................. 30

Remove the seal or packing rings (1510-S, 1510-D, 1510-PF, and 1510-8G)...............30

Pre-assembly inspections.........................................................................................................30

Replacement guidelines.......................................................................................................31

Shaft and sleeve inspection................................................................................................. 31

Bearing frame inspection..................................................................................................... 31

Reassembly................................................................................................................................ 31

Seal assembly........................................................................................................................ 31

Impeller installation...............................................................................................................35

Assemble the packed stuffing box (1510-PF) ...................................................................35

Reinstall the bearing frame and impeller assembly (all except 1510-8G) .................... 36

Reinstall the bearing frame and impeller assembly (1510-8G).......................................36

Install the hex coupling guard............................................................................................. 36

Capscrew torque values.......................................................................................................37

Dealer servicing ....................................................................................................................37

Product warranty...........................................................................................................................38

2 Series 1510 Installation, Operation, and Maintenance Manual

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the

product can cause personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the

unit.

Introduction and Safety

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Operating, installing, or maintaining the unit in any way that is not covered in this

manual could cause death, serious personal injury, or damage to the equipment. This

includes any modification to the equipment or use of parts not provided by Xylem. If

there is a question regarding the intended use of the equipment, please contact a

Xylem representative before proceeding.

• Do not change the service application without the approval of an authorized Xylem

representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result

in physical injury, damage, or delays.

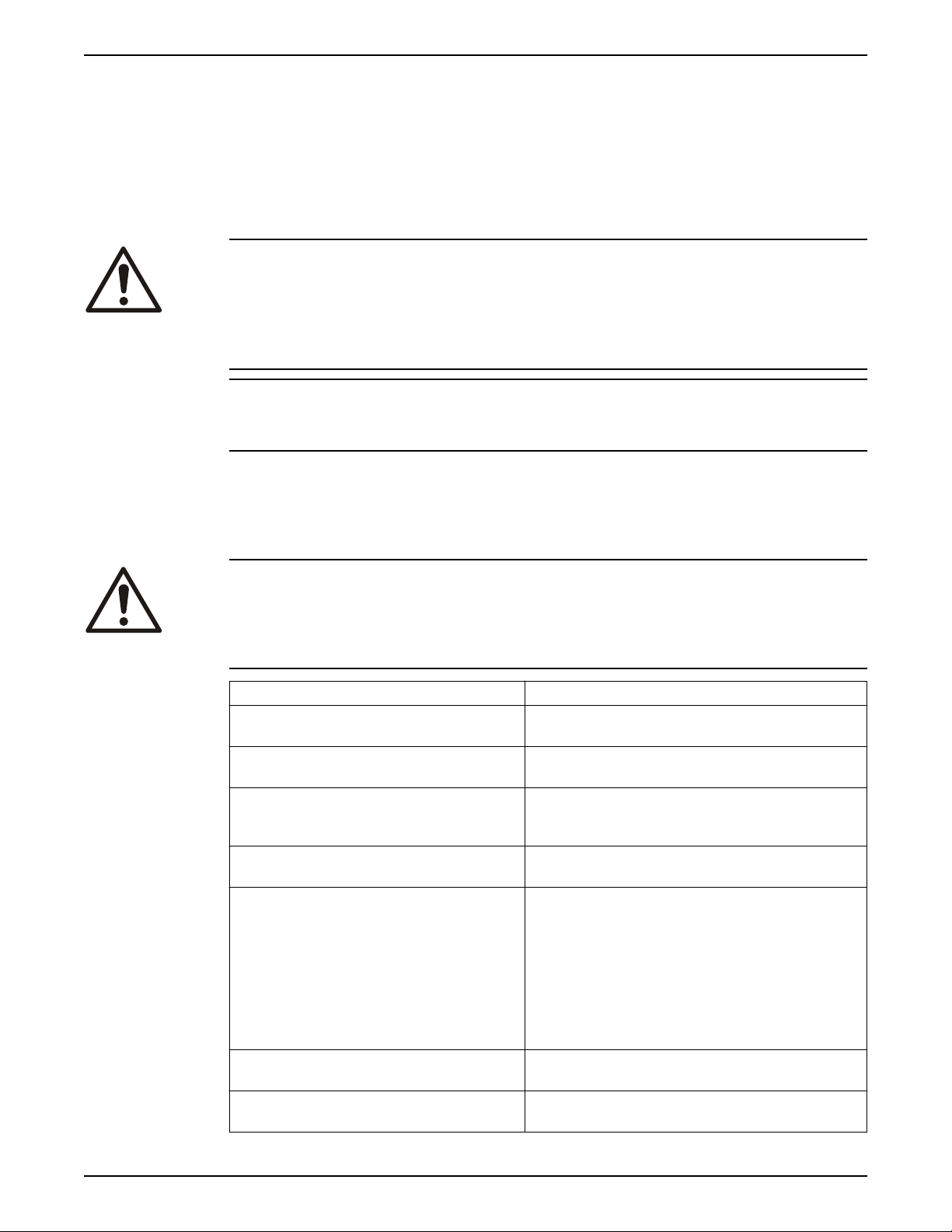

Safety message levels

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

Series 1510 Installation, Operation, and Maintenance Manual 3

Introduction and Safety

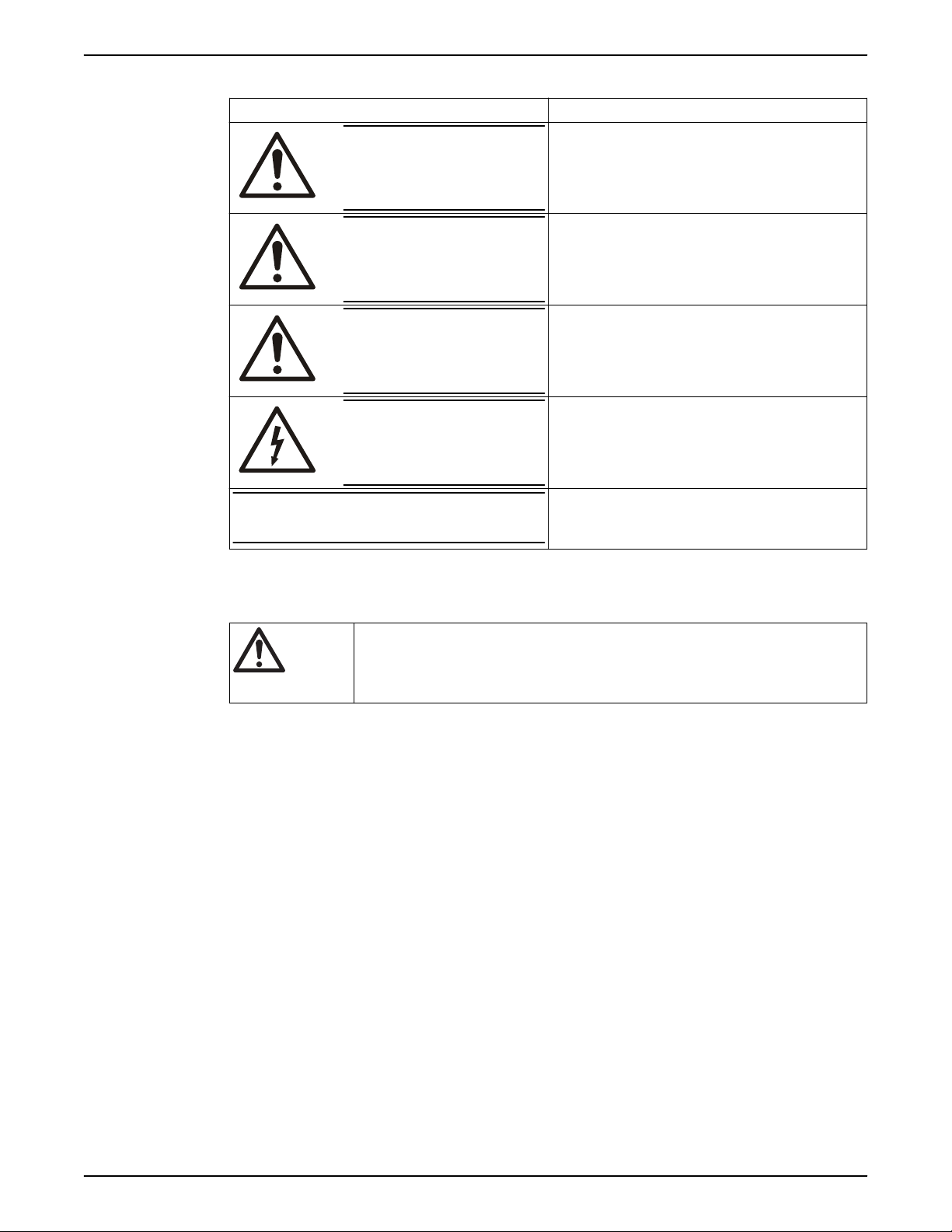

Definitions

Safety message level Indication

DANGER:

A hazardous situation which, if not avoided, will result in

death or serious injury

NOTICE:

Safety instruction decals

Alert symbol

WARNING:

CAUTION:

Electrical Hazard:

This safety alert symbol is used in manuals and on the safety instruction decals on the pump

to draw attention to safety-related instructions.

When used, the safety alert symbol means that failure to follow the instructions may result in

a safety hazard.

A hazardous situation which, if not avoided, could result

in death or serious injury

A hazardous situation which, if not avoided, could result

in minor or moderate injury

The possibility of electrical risks if instructions are not

followed in a proper manner

• A potential situation which, if not avoided, could

result in undesirable conditions

• A practice not related to personal injury

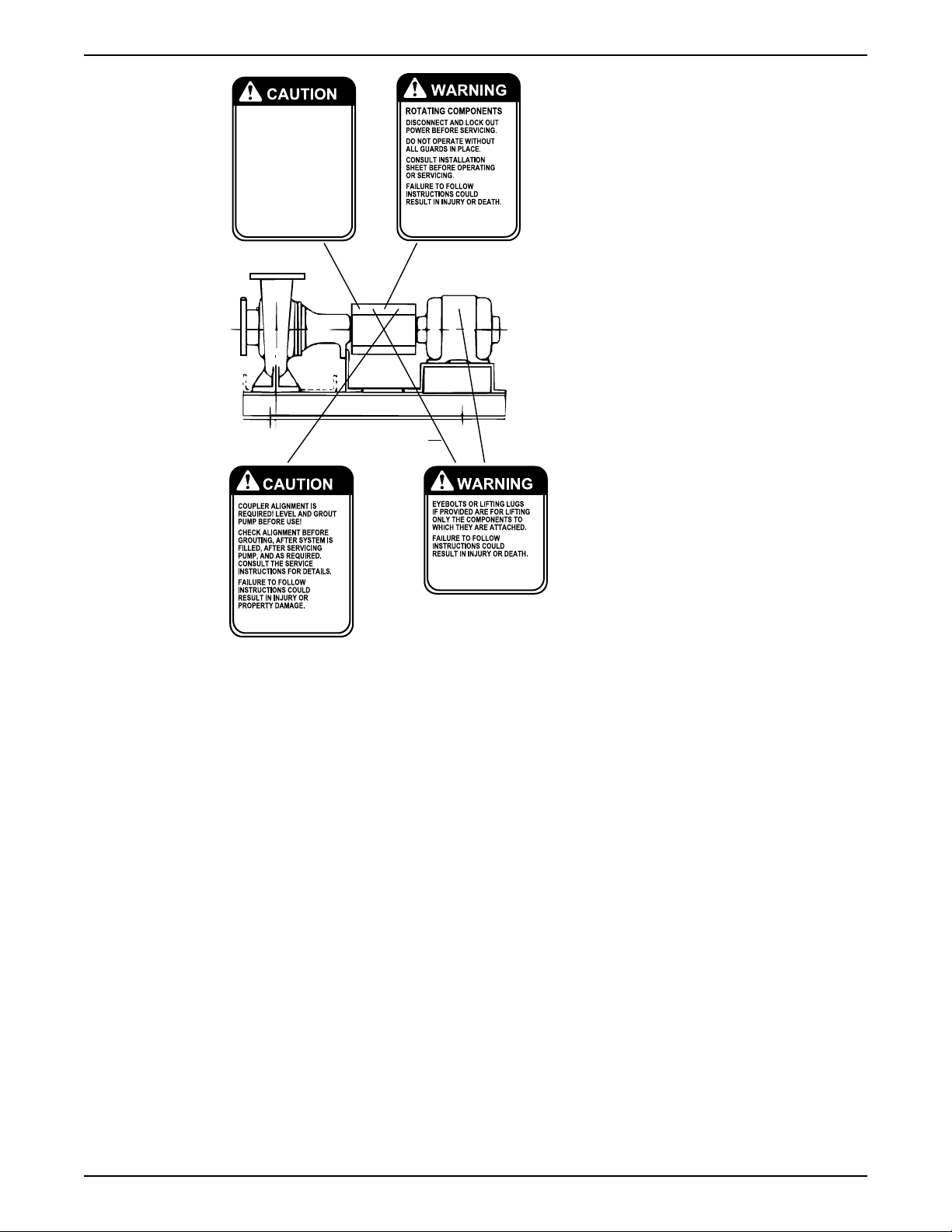

Decals

Make sure your pump has these safety instruction decals and that they are located as this

figure shows. If the decals are missing or illegible, contact your local sales and service

representative for a replacement.

4 Series 1510 Installation, Operation, and Maintenance Manual

P70642

P70643

(2) Required

(1 Each Side)

Alternate

Location

P2002458

P70820

DO NOT RUN PUMP DRY, SEAL

DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

LUBRICATION REQUIREMENTS

CONSULT MANUALS.

PUMP: POLYUREA-BASED GREASE

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

Introduction and Safety

User safety

General safety rules

Safety equipment

Make sure that all safety instruction decals are always clearly visible and readable.

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc

hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

flash

Series 1510 Installation, Operation, and Maintenance Manual 5

Introduction and Safety

Electrical connections

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations. For more information about

requirements, see sections dealing specifically with electrical connections.

Precautions before work

Observe these safety precautions before you work with the product or are in connection

with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Allow all system and pump components to cool before you handle them.

• Make sure that the product has been thoroughly cleaned.

• Disconnect and lock out power before you service the pump.

• Check the explosion risk before you weld or use electric hand tools.

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

property.

Precautions during work

Observe these safety precautions when you work with the product or are in connection

with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is

• Never operate a pump without a properly installed coupling guard.

Wash the skin and eyes

control.

pressurized. Make sure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

Follow these procedures for chemicals or hazardous fluids that have come into

contact with your eyes or your skin:

Condition Action

Chemicals or hazardous fluids in

eyes

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

6 Series 1510 Installation, Operation, and Maintenance Manual

Condition Action

Chemicals or hazardous fluids on

skin

Environmental safety

The work area

Always keep the station clean.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable

environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless

Xylem has been informed and appropriate actions have been agreed upon.

Introduction and Safety

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

Electrical installation

Recycling guidelines

For electrical installation recycling requirements, consult your local electric utility.

Always follow local laws and regulations regarding recycling.

Series 1510 Installation, Operation, and Maintenance Manual 7

Transportation and Storage

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact the local sales representative if there is any issue.

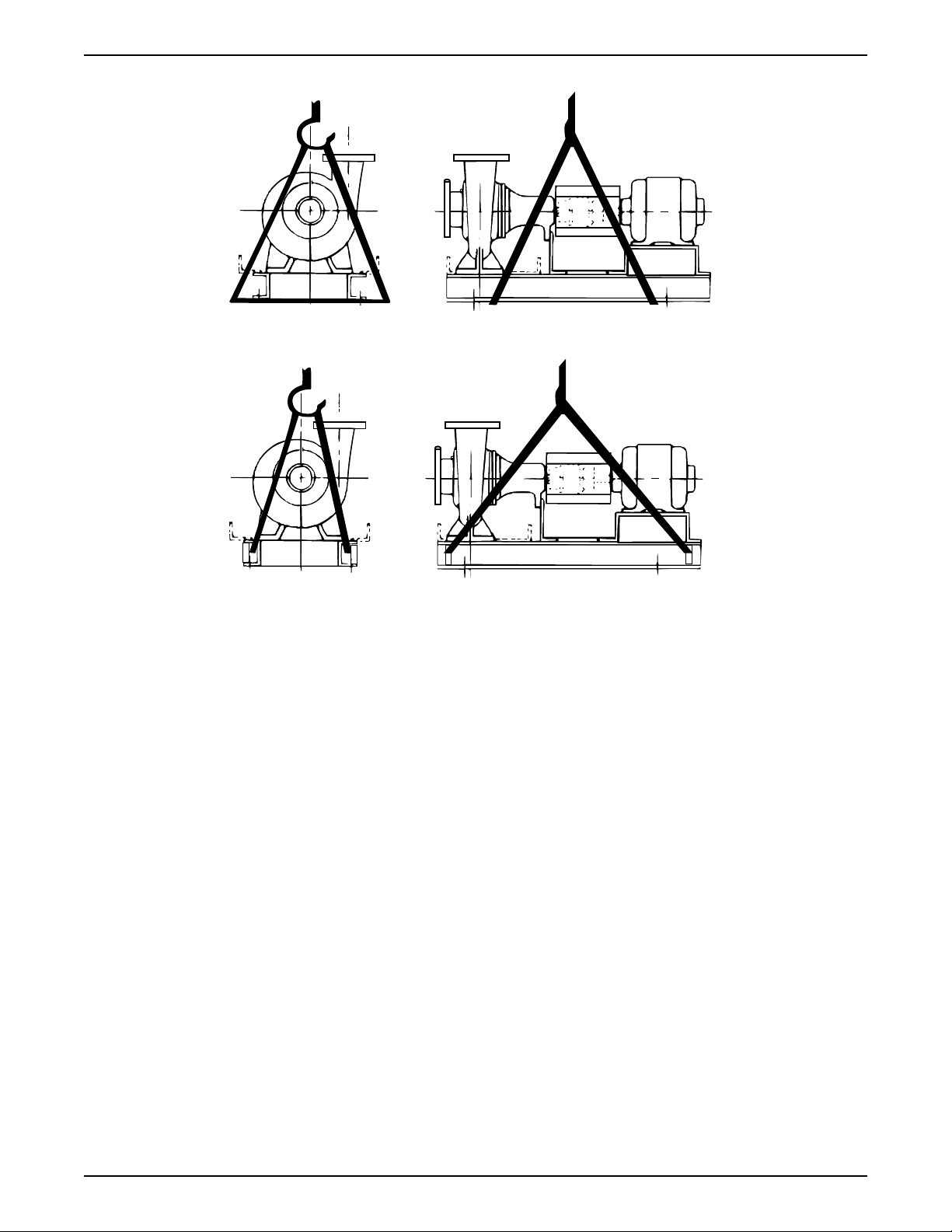

Lifting methods

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods

• Do not attach sling ropes to shaft ends.

Table 1: Methods

Pump type Lifting method

A bare pump without lifting

handles

A base-mounted pump. Use slings under the pump casing and the drive unit, under the base rails, or

this equipment can result in serious physical injury and/or equipment damage. Lift

equipment only at the specifically identified lifting points. Lifting devices such as

eyebolts, slings, and spreaders must be rated, selected, and used for the entire load

being lifted.

and wear steel-toed shoes at all times.

Use a suitable sling attached properly to solid points like the casing, the flanges, or

the frames.

through lifting lugs, when provided.

8 Series 1510 Installation, Operation, and Maintenance Manual

Examples

Transportation and Storage

Figure 1: Example of a proper lifting method

Figure 2: Example of a proper lifting method using lifting lugs

Storage requirements

If the unit will not to be installed and put into operation immediately upon arrival at the

site, or for an extended shutdown after the unit is in operation, the following requirements

for short-term storage apply:

• Store in a covered and dry location.

• Store the unit free from excessive cold or heat (below 32°F and above 110°F), dirt,

and vibration.

• Rotate the shaft by hand several times (10–15 turns) at least every 30 days.

For initial storage longer than three months, or for pump shut down after being in

operation longer than three months, contact your local sales and service representative

for long-term storage guidelines.

Series 1510 Installation, Operation, and Maintenance Manual 9

Product Description

Product Description

General description

Description

The pump is a centrifugal, frame-mounted pump. The following pump features make it

easy to install, operate, and service:

• High efficiency

• Rugged bronze-fitted construction

• Foot-mounted volute with back pullout bearing frame

• Center drop-out coupler

• Regreasable bearings

Intended applications

WARNING:

California Proposition 65 warning! This product contains chemicals known to the state of

California to cause cancer and birth defects or other reproductive harm.

The pump is intended for use with these pumped fluids:

• Unheated domestic and fresh water

• Boiler feed water

• Condensate

• Hydronic cooling or heating

• Benign liquids

• Pressure boosting

• General liquid transfer

Rotation

Pump rotation is clockwise when viewed from the back of the motor. An arrow is also

located on the pump to show the direction of rotation.

Operational

Mechanical seal specifications

specifications

This table describes the specifications of each mechanical seal type.

Seal type Parameter Value

Standard seals, BUNA pH range limits for BUNA pH 7–9

Standard seals, EPT pH range limits for EPT pH 7–11

Flushed single seals

Flushed double seals

1,3,4

1,3,4

Liquid temperature range that

complies with the pH range limits for

BUNA

Liquid temperature range that

complies with the pH range limits for

EPT

pH range limits pH 7–9

Liquid temperature range 0˚F to 250˚F (-18˚C to 121˚C)

pH range limits pH 7–9

Liquid temperature range 0˚F to 250˚F (-18˚C to 121˚C)

-20˚F to 225˚F (-29˚C to 107˚C)

-20˚F to 250˚F (-29˚C to 121˚C)

10 Series 1510 Installation, Operation, and Maintenance Manual

Product Description

Seal type Parameter Value

2

Packing

pH range pH 7–9

Liquid temperature range 0˚F to 200˚F (-18˚C to 93˚C)

Table notes

1. An external flush is required on low pressure systems that contain a high

concentration of abrasives.

2. Use packing on open or closed systems which require a large amount of makeup

water, as well as systems that are subjected to a wide variety of chemical conditions

and solids buildup.

3. For operating temperatures above 250°F, a cooled flush is required and is

recommended for temperatures above 225°F for optimum seal life. On closed

systems, cooling is accomplished by inserting a small heat exchanger in the flush line

to cool the seal flushing fluid.

4. Flush-line filters and sediment separators are available on request.

Series 1510 Installation, Operation, and Maintenance Manual 11

Installation

Installation

Preinstallation

Precautions

WARNING:

• When installing in a potentially explosive environment, make sure that the motor is

properly certified.

• You must ground (earth) all electrical equipment. This applies to the pump

equipment, the driver, and any monitoring equipment. Test the ground (earth) lead to

verify that it is connected correctly.

NOTICE:

Supervision by an authorized Xylem representative is recommended to ensure proper

installation. Failure to do so may result in equipment damage or decreased performance.

Evaluate the installation in order to determine that the Net Positive Suction Head Available

(NPSHA) meets or exceeds the Net Positive Suction Head Required (NPSHR), as stated by

the pump performance curve.

Pump location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this

equipment can result in serious physical injury and/or equipment damage. Lift equipment

only at the specifically identified lifting points. Lifting devices such as eyebolts, slings, and

spreaders must be rated, selected, and used for the entire load being lifted.

Guideline Explanation/comment

Keep the pump as close to the liquid source as

practically possible.

Make sure that the space around the pump is

sufficient.

If you require lifting equipment such as a hoist or

tackle, make sure that there is enough space above

the pump.

Protect the unit from weather and water damage due

to rain, flooding, and freezing temperatures.

Do not install and operate the equipment in closed

systems unless the system is constructed with

properly-sized safety devices and control devices.

Take into consideration the occurrence of unwanted

noise and vibration.

If the pump location is overhead, undertake special

precautions to reduce possible noise transmission.

This minimizes the friction loss and keeps the suction piping

as short as possible.

This facilitates ventilation, inspection, maintenance, and

service.

This makes it easier to properly use the lifting equipment and

safely remove and relocate the components to a safe location.

This is applicable if nothing else is specified.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices, consult the

engineer or architect in charge before you operate the pump.

The best pump location for noise and vibration absorption is

on a concrete floor with subsoil underneath.

Consider a consultation with a noise specialist.

12 Series 1510 Installation, Operation, and Maintenance Manual

Loading...

Loading...