Bell & Gossett P81630F User Manual

INSTRUCTION MANUAL

P81630

REVISION F

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Series VSC® and VSCS®

Base Mounted

Centrifugal Pumps

(TO BE USED IN CONJUNCTION WITH VSC PARTS LIST CONTAINING LINE DRAWINGS)

2

ADDITIONAL SAFETY REQUIREMENTS:

ELECTRICAL SAFETY:

MECHANICAL SAFETY:

WARNING: Electrical Shock Hazard

Electrical connections to be made by a qualified

electrician in accordance with all applicable codes, ordinances, and good practices. Failure to follow these instructions could result in serious personal injury or death,

or property damage.

WARNING: Electrical Overload Hazard

Three phase motors must have properly sized

heaters to provide overload and undervoltage protection.

Single phase motors have built-in overload protectors.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

THERMAL SAFETY:

WARNING: Extreme Temperature Hazard

If pump, motor, or piping are operating at extremely

high or low temperatures, guarding or insulation is required. Failure to follow these instructions could result in

serious personal injury or death, or pr

operty damage.

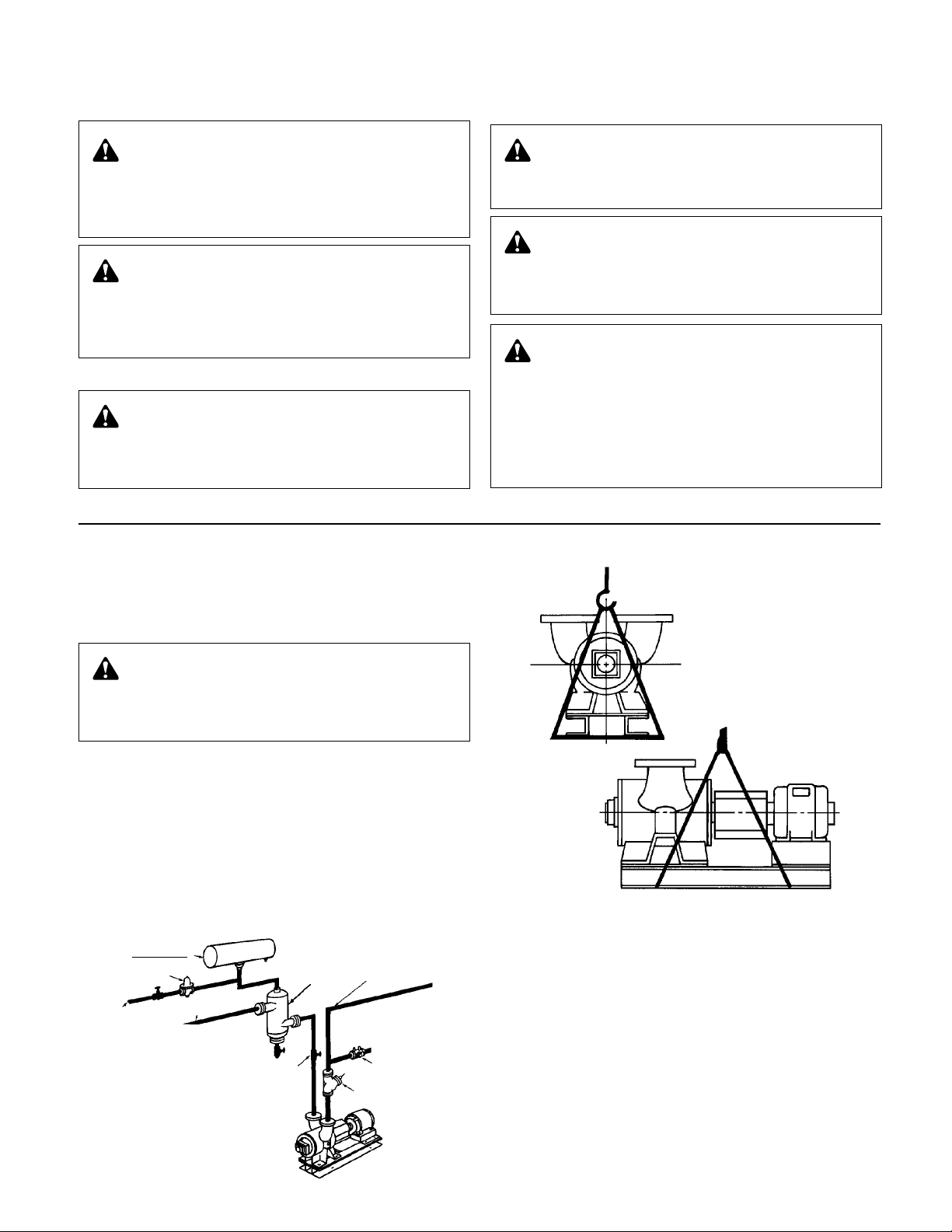

PUMP LOCATION

Locate the pump so there is sufficient room for inspection, maintenance and service. If the use of a hoist or tackle is needed,

allow ample head room.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

W

ARNING: Excessive System Pressure Hazard

The maximum working pressure of the pump is listed

on the nameplate, do not exceed this pressure. Failure to

follow these instructions could r

esult in serious personal

injury or death, or property damage.

WARNING: Excessive Pr

essure Hazard

Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failur

e of system components and release of high temperature fluids.

This will be prevented by installing properly sized and

located compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

WARNING: Fall Objects Hazard

Eyebolts or lifting lugs, if provided, are for lifting only

the components to which they are attached. Failure to follow these instructions could result in serious personal

injury or death, or property damage.

If lifting of the entire pump is required, do so with slings placed

under the base rails as shown.

The best pump location for sound and vibration absorption is

on a concrete floor with subsoil underneath. If the pump location is overhead, special precautions should be undertaken to

reduce possible sound transmission, consult a sound specialist.

If the pump is not on a closed system, it should be placed as

near as possible to the source of the liquid supply, and located

to permit installation with the fewest number of bends or

elbows in the suction pipe.

COMPRESSION TANK

SHOULD BE LOCATED

ON THE SUCTION SIDE

OF THE PUMP

B&G REDUCING

VALVE

COLD

WATER

SUPPLY

FROM BOILER

CHILLER OR CONVER

TER

B&G ROLAIRTROL

AIR SEPARATOR

ISOLATION

VALVE

SUPPLY

TO SYSTEM

B&G CIRCUIT

SETTER

B&G TRIPLE DUTY

VALVE

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) meets or exceeds the

Net Positive Suction Head Required (NPSHR), as stated by the

pump performance curve.

IMPORTANT

Do not install and operate Bell & Gossett Pumps, 3D Valves,

Suction Diffusers, etc., in closed systems unless the system is

constructed with properly sized safety devices and control

devices. Such devices include the use of properly sized and

located pressure relief valves, compression tanks, pressure controls, temperature controls, and flow controls as appropriate. If

the system does not include these devices, consult the responsible engineer or architect before making pumps operational.

3

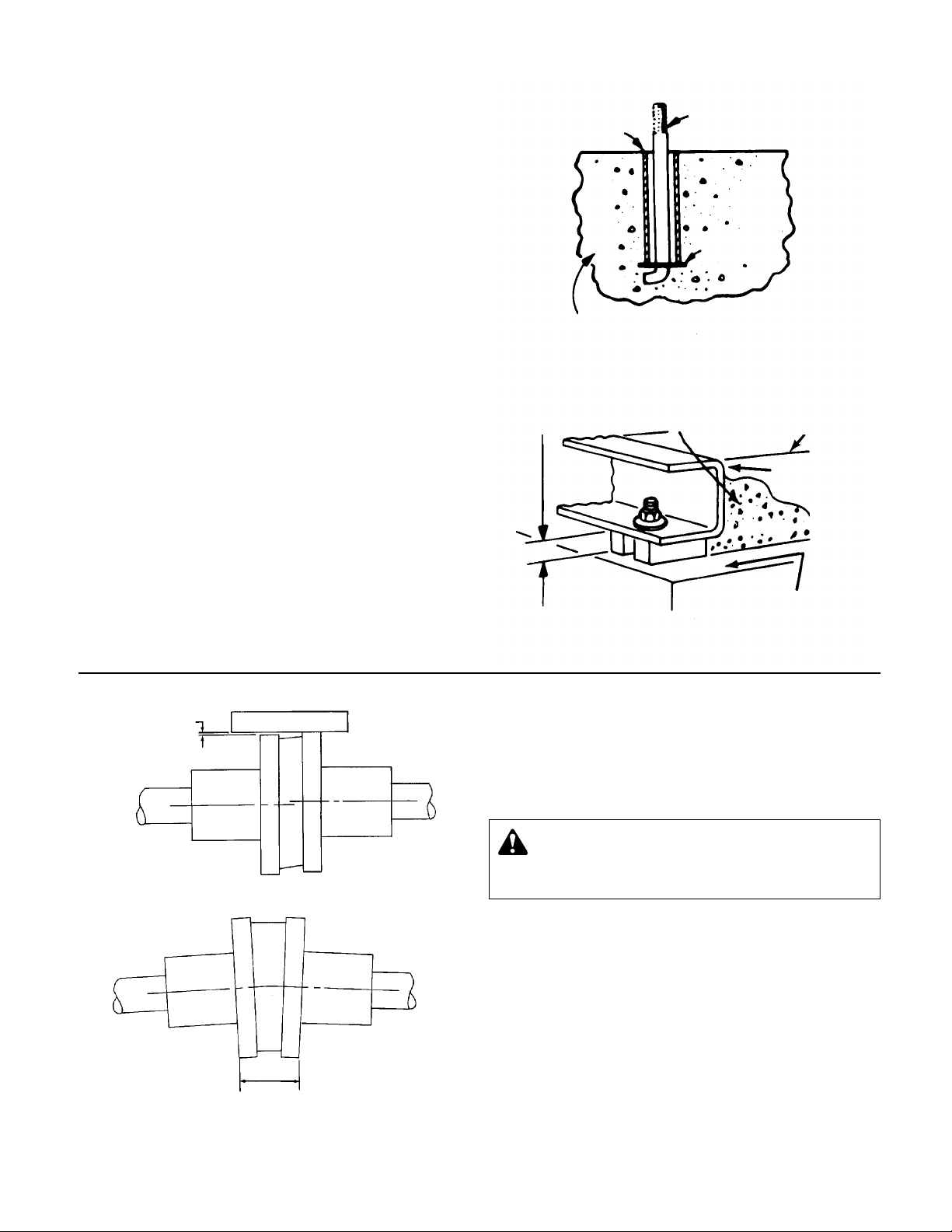

INSTALLATION

This pump is built to provide years of service if installed properly

and attached to a suitable foundation. A base of concrete weighing 21/2 times the weight of the pump is r

the shipping ticket for pump weight.)

If possible, tie the concrete pad in with the finished floor. Use

foundation bolts and larger pipe-sleeves to give room for final

bolt location. (See Figure 6A.)

ecommended. (Check

PIPE

SLEEVE

FOUNDATION

BOLT

LEVELING

Place the pump on its concrete foundation supporting it with

steel wedges or shims totaling 1" in thickness. These wedges

or shims should be put on both sides of each anchor-bolt to

provide a means of leveling the base. (See Figure 6B.)

It is very important that the pump-base be set level to avoid any

mechanical difficulties with the motor or pump. This pump was

properly aligned (if furnished with a motor) at the factory

. However, since all pump bases are flexible they may spring and twist

during shipment. Don’t pipe the pump until it is realigned. After

piping is completed and after the pump is grouted-in and bolteddown, align it again. It may be necessary to re-adjust the alignment from time to time while the unit and foundation are new.

GROUTING

After the pump has been leveled, securely bolted to the floor,

and properly aligned, a good grade of non-shrinking grout

should be poured inside the pump base. To hold wedges or

shims in place, allow the grout to flow around them.

ROTATION

The VSC & VSCS pump is available in both right- and left-hand

rotation. An arrow cast into the pump body shows the direction

of rotation.

BUILT-UP

CONCRETE FOUNDATION

ALLOW 1" FOR SHIMS.

PLACE ON BOTH SIDES

OF ANCHOR BOLTS.

APPROX.

GAP

1"

LEVELING OF PUMP BASE

ON CONCRETE FOUNDATION.

WASHER

NOTE:

TO KEEP SHIMS IN

PLACE ALLOW GROUT

TO FLOW AROUND

HOLD DOWN LUGS.

GROUT

CONCRETE

FOUNDATION

FIGURE 6A

GROUT ONLY TO

TOP OF BASE RAIL.

PUMP

BASE RAIL

FIGURE 6B

AMOUNT OF

PARALLEL

MISALIGNMENT

STRAIGHT EDGE

PARALLEL ALIGNMENT CHECK

DISTANCES ACROSS

COUPLER FLANGES

SHOULD BE EQUAL

(CHECK 4 PLACES)

ANGULAR ALIGNMENT CHECK

COUPLER ALIGNMENT

All alignment should be done by moving or shimming the motor

only. Adjustments in one direction may alter alignment in another.

Therefore, check alignment in all directions after a correction is

made. Black rubber inserts have different horsepower load

ratings than orange Hytrel sleeves. They should not be

interchanged.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

STANDARD SLEEVE TYPE COUPLER

WITH BLACK RUBBER INSERT

Before aligning the coupler, make sure there is about 1/8" end

clearance between the sleeve and the two coupler halves.

1. Check angular misalignment using a micrometer or caliper.

Measure from the outside of one flange to the outside of the

opposite flange at four points 90° apart. DO NOT ROTATE

COUPLER. Misalignment up to 1/64" per inch of coupler

radius is permissible.

2. At four points 90° apart (DO NOT ROTATE COUPLER), measure the parallel coupler misalignment by laying a straight

edge across one coupler half and measuring the gap

between the straight edge and opposite coupler half. Up to a

1

/64" gap is permissible.

4

5

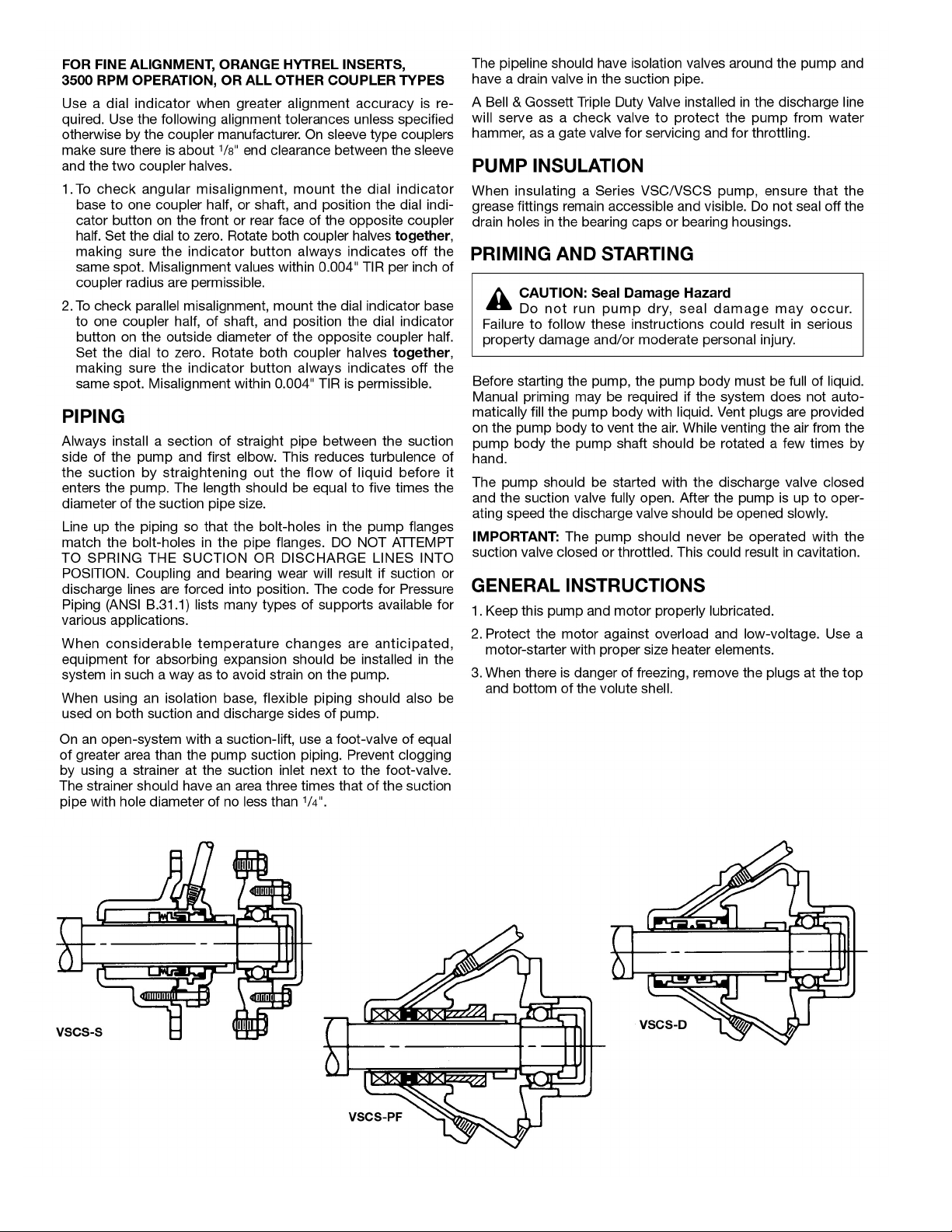

Loading...

Loading...