Page 1

INSTRUCTION MANUAL

P71397

REVISION B

Series 80-SC Spacer-Coupled

Vertical In-Line Centrifugal Pump

Motor Collar Ring Setting Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

WARNING: EXTREME TEMPERATURE HAZARD

If pump, motor, or piping are operating at extremely

high or low temperature, guarding or insulation is required.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

WARNING: ELECTRICAL SHOCK HAZARD

Electrical connections to be made by a qualified electrician in accordance with all applicable codes, ordinances

and good practices. Failure to follow these instructions

could result in serious personal injury or death, and property

damage.

WARNING: UNEXPECTED STARTUP HAZARD

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious personal injury or death, and property damage.

CAUTION: The Motor Collar Ring must be set on the

motor shaft at the correct positon and set screws

torqued to the proper value. Failure to follow instructions

could result in injury or property damage.

The motor collar ring must be set on the motor shaft at a

specified distance for both TC motors and IEC motors to

insure the pump impeller is in the proper position during

pump operation. The distance to set the collar (DC) is measured from the motor mounting surface to the surface of the

collar ring closest to the motor. This distance is shown in Fig.

1 for TC motors and Fig. 2 for IEC motors (see back).

The collar ring is held in position on the motor shaft with three

set screws. These set screws must be tightened to the proper

torque to ensure that the collar does not slip as a result of

pump rotor weight and pump hydraulic thrust.

The Table at the right specifies the collar setting distance, set

screw size and set screw torque for TC motors and IEC

motors.

The set screw must be held in place after being torqued to the

correct value with a small amount of Loctite 222MS threadlocker liquid or equivalent.

COUPLER ASSEMBLY

See Series 80-SC Installation, Operation & Service Instruction

Manual.

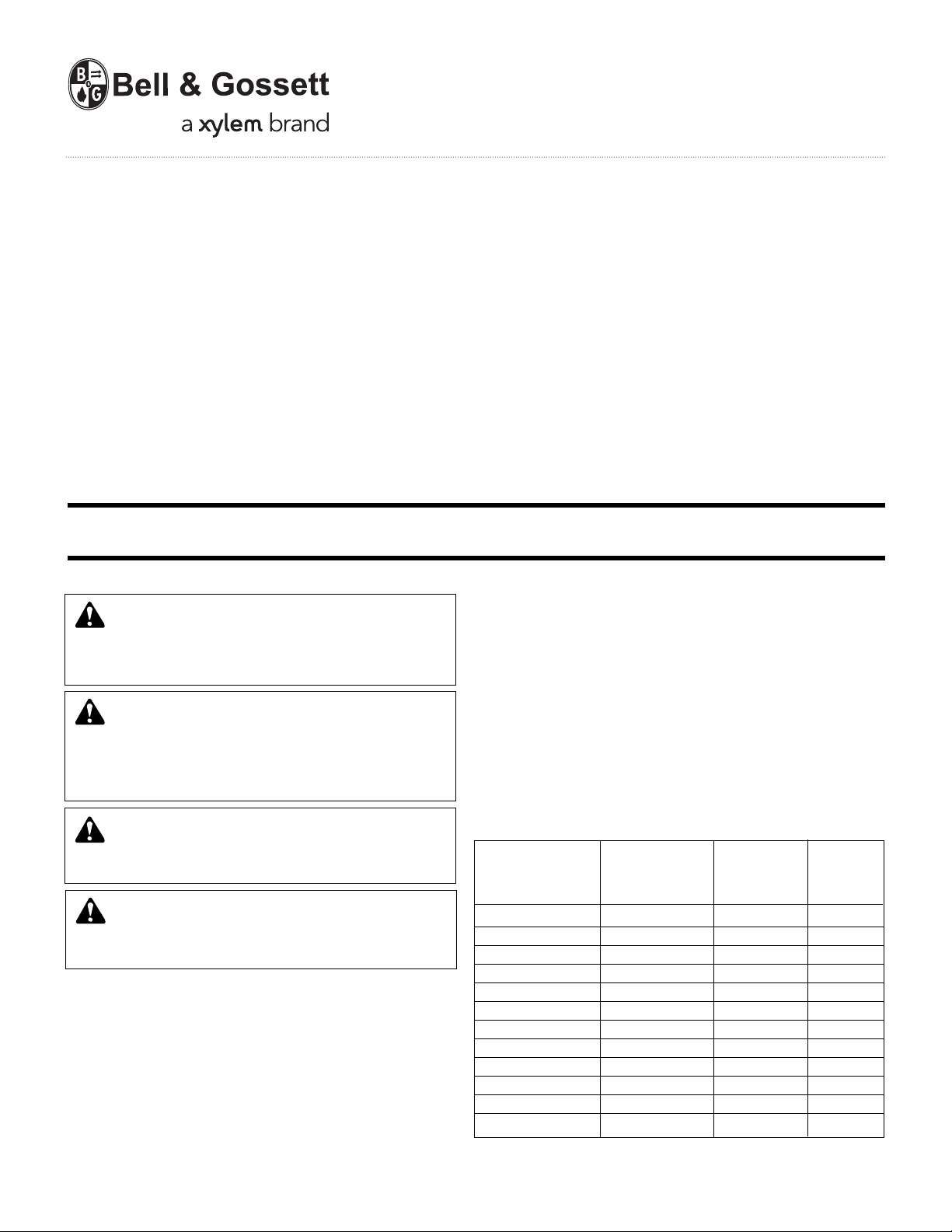

COLLAR SETTING DISTANCE

Distance Set Screw

Motor Frame Collar (DC) Set Screw Torque

Size in (mm) Size in – lbs

182TC – 184TC 2.123 (53.92) #8-36UNF 20

213TC – 215TC 2.598 (65.99) #10-32UNF 36

254TC – 256TC 3.228 (81.99) #10-32UNF 36

284TC – 286TC 3.738 (94.95) .25-28UNF 87

324TSC – 365TSC 2.858 (72.59) .25-28UNF 87

D80 IEC 1.078 (27.38) #8-36UNF 20

D90 IEC 1.472 (37.39) #8-36UNF 20

D100 – D112 IEC 1.865 (47.37) #8-36UNF 20

D132 IEC 2.628 (66.75) #10-32UNF 36

D160 IEC 3.689 (93.70) .25-28UNF 87

D180 IEC 3.689 (93.70) .25-28UNF 87

D200 IEC 3.689 (93.70) .25-28UNF 87

Page 2

FIG. 1

TC MOTOR

FIG. 2

IEC MOTOR

MOTOR

MOUNTING

SURFACE

MOTOR

MOUNTING

SURFACE

DC

COLLAR

RING

DC

COLLAR

RING

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. P71397B February 2013

Loading...

Loading...