Page 1

Little Red Booster Pumps

Installation, Operation, & Service Instructions

INSTRUCTION MANUAL

P15776

REVISION H

INSTALLER:

PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Bell & Gossett

Bell & Gossett

NOTE:

Bell & Gossett recommends Bronze Booster Pumps be used

for pumping potable water.

DESCRIPTION

The Little Red Booster Pump features oil lubricated bearings,

carbon/ceramic seal, non-overloading permanent split-capacitor

motor with thermal protection and quiet-operating construction.

PUMP APPLICATION

The Little Red Booster Pump may be used for water circulating applications in hydronic and solar systems. It may also be

used for domestic water, but should be equipped with a

bronze pump body.

®

U

L

®

®

Page 2

2

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual and on the

pump safety instruction decal to draw attention to safety related

instructions. When used, the safety alert symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTION MAY RESULT IN

A SAFETY HAZARD.

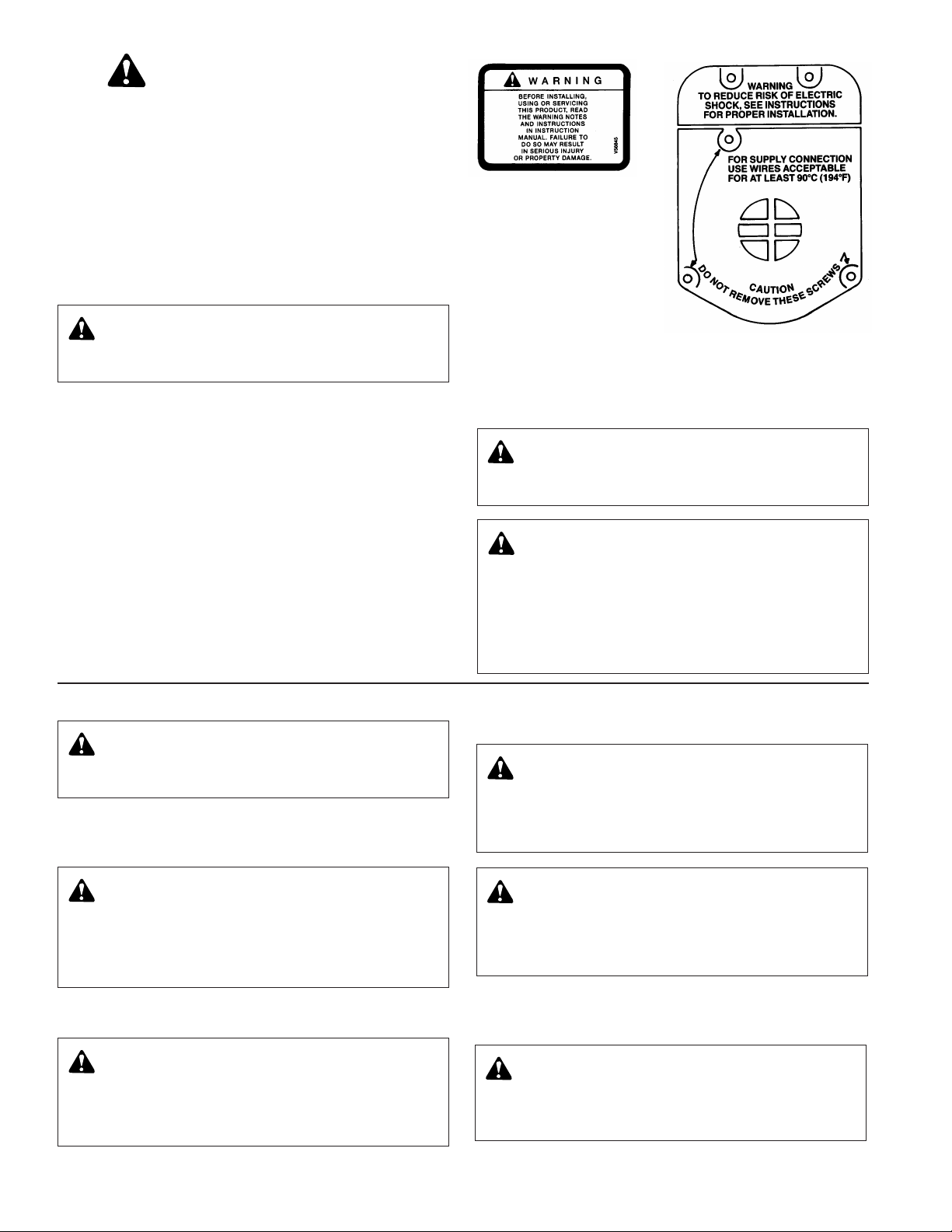

Your Little Red Booster Pump should have the warning label

displayed to the right (Fig. 2) affixed to the motor housing and

the warnings and cautions displayed at right (Fig. 3) clearly

marked in raised letters on the motor end covers. If any of

these warnings and cautions are missing or illegible, contact

your local Bell & Gossett Representative for a replacement.

ADDITIONAL SAFETY REQUIREMENTS

1. Electrical connections to be made by qualified electrician in

accordance with all national, state and local codes.

2. Adequate electrical grounding is required for the safe operation of the Little Red Booster Pump, and the use of grounded

metal conduit assures this requirement. If the means of connection to the supply-connection box (wiring compartment)

is other than grounded metal conduit, ground the pump

back to the service by connecting a copper conductor, at

least the size of the circuit conductors supplying the pump,

to the green grounding screw provided within the wiring

compartment.

Replace conduit box cover and secure with screws.

3. The maximum working pressure of the pump is listed on

the pump nameplate, do not exceed this pressure.

4. This pump is for indoor use only.

The motor housing cover is a functional component designed

to prevent accidental contact with the motor fan. Do not remove this cover unless power to the pump is disconnected

and locked out.

1. Close the valves on the suction and discharge sides of the

pump. (If no valves have been installed, it may be necessary to drain the system.)

2. Remove the conduit box cover by removing the two screws

at the top of the cover.

3. Disconnect the electrical supply lines to the pump.

4. Remove the four flange nuts and bolts and remove the

pump from the piping.

WARNING: Before installing, using or servicing this

product. Read the warning notes and instructions in

instruction manual. Failure to do so may result in injury or

property damage.

WARNING: Rotating Component Hazard

Do not operate pump without all guards in place.

Failure to follow these instructions could result in serious

personal injury or death, and property damage.

WARNING: Excessive Pressure Hazard

WARNING: Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failure of the

system components and release of high temperature fluids.

This will be prevented by installing properly sized and located compression tanks and pressure relief valves. Failure

to follow these instructions could result in serious personal

injury or death, and property damage.

FIG. 2

FIG. 3

REMOVAL OF PUMP FROM EXISTING SYSTEM FOR REPLACEMENT

WARNING: Electrical Shock Hazard

Disconnect and lockout the power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

WARNING: Hot Water Hazard

Before draining the system, allow water to cool at

least 100°F (38°C), open the drain valve (take precautions

against water damage) and leave the drain valve open until

servicing is complete. Failure to follow these instructions

could result in serious personal injury, death and/or

property damage.

WARNING: Hot Water Hazard

Whenever disassembling a gasket joint, always use

a new gasket upon reassembly. NEVER RE-USE OLD

GASKETS. Failure to follow these instructions could result

in serious personal injury, death and/or property damage.

WARNING: Unexpected Start-Up Hazard

Single phase motors are equipped with automatic

reset overload protectors. The pump can restart without

warning. Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury, death and/or property damage.

CAUTION: Temperature Hazard

Check surfaces for high temperatures, allow the

pump temperature to reach approximately 100°F (38°C),

before proceeding. Failure to follow these instructions

could result in moderate personal injury and/or property

damage.

WARNING: High Pressure Hazard

Pressure may be present in the pump body. This

pressure can be relieved by loosening the flange bolts and

shifting the pump assembly slightly to allow the pressurized water to escape. Failure to follow these instructions

could result in serious personal injury or death.

Page 3

3

PUMP INSTALLATION

Locate the pump so there is sufficient room for inspection, maintenance and service. Bell & Gossett recommends the installation of service valves on the suction and discharge of all circulators to facilitate servicing or replacement of the circulator

without draining the system.

Install suction and discharge flanges on the pipe ends. The

use of Teflon

®

* tape sealer or a high quality thread sealant is

recommended.

Be sure to minimize any pipe-strain on the pump. Support the

suction and discharge piping by the use of pipe hangers near

the pump. Line up the vertical and horizontal piping so that the

bolt-holes in the pipe flanges match the bolt-holes in the pipe

flanges.

[DO NOT ATTEMPT TO SPRING THE SUCTION OR

DISCHARGE LINES IN POSITION. THIS MAY RESULT IN

UNWANTED STRESS IN THE PUMP BODY, FLANGE CONNECTIONS AND PIPING.]

The code for Pressure Piping

(ANSI B31.1) lists many types of support available for various

applications.

Bell & Gossett flange gaskets must be installed between the

Little Red pump body flanges and the suction and discharge

pipe flanges. Suitable fasteners for this connection are also

supplied in the Bell & Gossett fastener pack.

Apply torque in even increments to both flange bolts until a

value of 175 in-lbs (2.01 Kg-m) is reached. Both the suction

and discharge flanges must be torqued in this manner.

MODE OF DISCHARGE

The Little Red Booster Pump can be installed to discharge up

or down, horizontally left or right, but the oiling port must

always be in the twelve o’clock position (on top). Arrow on

body must point in direction of flow.

TYPICAL INSTALLATION SCHEMATIC

POWER SOURCE 115 Volt. 60 Hz.1ø

ELECTRICAL WIRING

A. Loosen screws securing the conduit box (wiring compart-

ment) cover, removing screws and cover.

B. Select one of the two holes in the side of the conduit box

and wire the motor to a 115 volt, 60 hertz, single phase

power source with number 14 AWG copper electrical wire.

Refer to your local code for wiring restrictions. Plug the

unused hole in the side of the conduit box with the plug

provided.

C. Connect the ground wire to the inside of the conduit box

with the green screw provided.

NOTE: Supply and grounding wires must be suitable for at

least 90°C (194°F).

ELECTRICAL CHARACTERISTICS

Model LR-20BF is rated at 1/20 HP, 115 volts, 1.1 F.L. amps,

60 HZ, 1ø (single phase), 2900 RPM.

Model LR-15B is rated at 1/12 HP, 115 volts, 1.75 F.L. amps,

60 HZ, 1ø (single phase), 3150 RPM.

Little Red Booster Pumps are protected with an inherent overheating device and do not require external overload protection.

SYSTEM PREPARATION

Prior to pump start up, closed heating and cooling systems

should be cleaned, drained, and refilled with clean water.

System ph must be maintained between 7 and 9.

Pressurize the pump body slowly while checking for leaks at

all gasketed joints.

PRIMING

Do not run the pump dry. These pumps must be filled with

liquid before being placed in service. Air should be vented

from the system by means of an air vent located at a high

point in the system.

LUBRICATION

All new Bell & Gossett Little Red Booster Pumps are thoroughly

tested at the factory and have been enhanced with a superior

lubrication system which requires a minimum of attention. Please

refer to the recommended lubrication instructions noted below

for the type of pump service required.

1. At installation: Pumps have been factory lubricated and do

not require additional lubrication at start-up.

2. Heating system operation: Pumps should be lubricated at

the start of every heating season. Add one tube (5cc) of

Bell & Gossett P15775 lubricating oil.

3. Continuous duty: Pump should be lubricated every six (6)

months. Add one tube (5cc) of Bell & Gossett P15775 lubricating oil.

NOTE: In lieu of genuine Bell & Gossett P15775 lubricating

oil, use one teaspoon of Mobile 1, SAE 5W-30, motor oil as

required.

IMPORTANT: Over oiling of the pump will result in the

overflow of oil from the oil reservoir.

WARNING: Electrical Shock Hazard

Disconnect and lockout the power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

WARNING: Electrical Shock Hazard

Be certain that all connections are secure and the

conduit box cover is closed before electrical power is connected. Failure to follow these instructions could result in

serious personal injury or death.

FIG. 4

RIGHT OR

LEFT

UP OR

DOWN

FIG. 5

PUMP

MOTOR

FUSIBLE DISCONNECT

OR CIRCUIT BREAKER

BY OTHERS

PUMP MOTOR

INHERENTLY

PROTECTED

TO REMOTE

CONTROL

IF REQUIRED

WARNING: Hot Water Leakage Hazard

Pressurize the pump body slowly while checking for

leaks at all joints with gaskets. Failure to follow these

instructions could result in serious personal injury and/or

property damage.

*Teflon®is a registered trademark of E.I. DuPont de Nemours and Company.

Page 4

Bell & Gossett

© COPYRIGHT 1982, 2004 BY ITT INDUSTRIES, INC.

PRINTED IN U.S.A. 1-04

USA

Bell & Gossett

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-9052

http://www.bellgossett.com

INTL.

Bell & Gossett / Export Dept.

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone: (847) 966-3700

Facsimile: (847) 966-8366

http://www.bellgossett.com

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario,

N1H 1T1, Canada

Phone: (519) 821-1900

INSTRUCTIONS FOR PUMP REPAIR

1. Follow steps 1 through 4 of section titled “REMOVAL OF

PUMP FROM EXISTING SYSTEM FOR REPLACEMENT.”

2. Loosen the four capscrews that hold the motor housing to

the pump body. Remove these screws and remove the

housing from the pump body.

3. Place the pump on a flat work surface and insert the plastic

assembly tool (furnished with the repair kit) into the rear

motor housing coverplate middle horizontal vent holes.

Push forward until it engages the rotor cooling fins. This will

lock the rotor allowing removal of the impeller.

4. Remove the impeller nut – left hand thread! – from the pump

shaft. Remove the impeller and rotating seal assembly.

5. Clean the ceramic seat with a clean rag and inspect for

grooving or cracks. If it shows no grooving or cracks, it

may be cleaned and reused.

6. If the ceramic is to be replaced, the face plate must be removed from the motor housing. Remove it by gently prying it away from the motor housing.

7. Remove the damaged ceramic seat and boot if necessary.

Reinstall new parts in the face plate recess and reposition

the face plate on the motor housing. Gently tap the face

plate evenly around its diameter driving it into the recess

provided in the motor housing.

INSTRUCTIONS FOR PUMP REPAIR

8. Press the rotor fully forward with the plastic assembly

tool. Clean the shaft and sleeve before installing the seal.

9. Press the replacement carbon seal assembly firmly into

the recess in the back side of the impeller.

10. Assemble the seal/impeller assembly to the pump shaft

by pushing the rotor fully forward with the plastic assembly tool. Then slide the seal/impeller assembly onto the

pump shaft until the seal face contacts the ceramic seat.

11. Continue holding the rotor fully forward with the assembly

tool. Install and torque the impeller nut – left hand thread!

– to 15 in-lb (0.17 Kg-m) torque.

12. Clean the recess in the pump body and install a new body

gasket.

13. Install the pump in the body and secure with four capscrews. Apply torque evenly in a criss cross pattern to 40

in-lb (0.46 Kg-m) increments to a torque of 80 in-lb (0.92

Kg-m).

14. Reinstall into the system using new flange gaskets. For

instructions, see sections “PUMP INSTALLATIONS”

through and including “LUBRICATION.”

CONDUIT BOX

COVER

CAPACITOR

NAME PLATE

CAPACITOR RETAINER

STATOR & HSG. ASM.

OIL

HOLE

PLUG

BODY

BODY GASKET

COVERPLATE ASM

WICK COVERPLATE

IMP. CUSHION

IMP. NUT

SHAFT SLEEVE

SEAL ASM

IMPELLER

PERMAWICK

THRUST

COLLAR

OIL RETAINER

THRUST DRIVER

MOTOR HSG. COVER

FIG. 6

ROTOR & SHAFT ASM.

PERIODIC INSPECTION

Bell & Gossett Booster Pumps are designed to provide years of

trouble free service. It is recommended that periodic inspections be made to check for potential problems with the pump. If

PERIODIC INSPECTION

any leakage or evidence of leakage is present repair or replace

the unit.

Loading...

Loading...