Page 1

INSTRUCTION MANUAL

HT-50B-SM

B&G Series U Heat Exchangers

Removable Bundle Design

Single Wall, DaimonbackTM Double Wall and Hi-Temperature Units

Series SU/DSU, WU/DWU

and HTWU/DHTWU

Series TCS/DTCS and TCW/DTCW

Page 2

STORAGE

Bell

&

Gossett will not be

NOTE: If the heat exchanger cannot be installed and put into

operation immediately upon receipt at the jobsite, certain precautions are necessary to prevent deterioration during storage. Responsibility for integrity of the heat exchangers must

be assumed by the user.

responsible for damage, corrosion or other deterioration of

heat exchanger equipment during transit and storage.

Good storage practices are important, considering the high

costs of repair or replacement, and the possible delays for

items which require long lead times for manufacture. The following suggested practices are provided solely as a convenience to the user, who shall make his own decision on

whether to use all or any of them.

11. On receipt of the heat exchanger, inspect for shipping

damage to all protective covers. If damage is evident,

inspect for possible contamination and replace protective

covers as required. If damage is extensive, notify the carrier immediately.

12. If the heat exchanger is not to be placed in immediate ser-

vice, take precautions to prevent rusting or contamination.

13. Heat exchangers for oil service, made of ferrous materials,

may be pressure tested with oil at the factory. However,

the residual oil coating on the inside surfaces of the

exchanger does not preclude the possibility of rust formation. Upon receipt, fill these exchangers with appropriate

oil or coat them with a corrosion prevention compound for

storage.

14. The choice of preservation of interior surfaces during stor-

age for other service applications depends upon your system requirements and economics. Only when included in

the original purchase order specifications will specific

preservation be incorporated prior to shipment from the

factory.

15. Remove any accumulations of dirt, water, ice or snow and

wipe dry before moving exchangers into indoor storage. If

unit was not filled with oil or other preservative, open drain

plugs to remove any accumulated moisture, then reseal.

Accumulation of moisture usually indicates rusting has

already started and remedial action should be taken.

16. Store under cover in a heated area, if possible. The ideal

storage environment for heat exchangers and accessories

is indoors, above grade, in a dry, low humidity atmosphere which is sealed to prevent entry of blowing dust,

rain or snow. Maintain temperatures between 70°F and

105°F (wide temperature swings may cause condensation

and “sweating” of steel parts). Cover windows to prevent

temperature variations caused by sunlight. Provide thermometers and humidity indicators at several points, and

maintain atmosphere at 40% relative humidity or lower.

17. In tropical climates, it may be necessary to use trays of

renewable dessicant (such as silica gel), or portable dehumidifiers, to remove moisture from the air in the storage

enclosure. Thermostatically controlled portable heaters

(vented to outdoors) may be required to maintain even air

temperatures inside the enclosure.

18. Inspect heat exchangers and accessories frequently while

they are in storage.

19. If paint deterioration begins, as evidenced by discol-

oration or light rusting, consider touch-up or repainting. If

the unit is painted with our standard shop enamel, areas

of light rust may be wire brushed and touched-up with any

good quality air-drying synthetic enamel. Units painted

with special paints (when specified on customers’ orders)

may require special techniques for touch-up or repair.

Obtain specific information from the paint manufacturer.

Painted steel units should never be permitted to rust or

deteriorate to a point where their strength will be impaired.

A light surface rust, on steel units which can be repainted

after installation, will not generally cause any harm. (See

Items 3 and 4 for internal surface preservation.)

10. If the internal preservation (Items 3 and 4) appears inadequate during storage, consider additional corrosion prevention measures and more frequent inspections. Interiors

coated with rust preventive should be restored to good

condition and recoated promptly if signs of rust occur.

INSTALLATION

11. Provide sufficient clearance at the head of the unit to per-

mit removal of tube bundle from shell.

12. Provide valves and by-passes in the piping so that both

the shell and tube bundle may be by-passed to permit isolation of the unit for inspection or repairs.

13. Provide thermometer wells and pressure gauge connec-

tions in all piping to and from the unit and located as near

the unit as possible.

14. Provide convenient means for frequently cleaning the unit

as suggested under “MAINTENANCE.”

15. Provide necessary air cocks for units so they can be

purged to prevent or relieve vapor binding of either the

tube bundle or the shell.

16. Foundations must be adequate so that exchangers will not

settle and cause piping strains. Foundation bolts should

be set to allow for setting inaccuracies. In concrete footings, pipe sleeves at least one size larger than bolt diameter slipped over the bolt and cast in place are best for this

purpose, as they allow the bolt center to be adjusted after

the foundation has set.

WARNING: All system piping to the heat ex-

changer must be adequately supported. Failure to

do so will result in excessive loads on the heat exchanger

connections causing damage and/or leakage and potential injury to adjacent personnel.

WARNING: When installing a Diamondback™

heat exchanger above a ceiling or workststion where

personnel are present, it may be necessary to install a

drip pan to collect any tell-tale drip due to internal tube

failure. Failure to do so may result in damage to the

ceiling and potential injury to personnel.

17. Loosen foundation bolts at one end of unit to allow free

expansion of shells. Oval holes in foundation brackets are

provided for this purpose.

CAUTION: Provision must be made to isolate the

heat exchanger from any external vibrations that

cause tube failures within the heat exchanger. Result is

internal leakage and mixing of the hot and cold media.

2

Page 3

18. Set exchangers level and square so that pipe connections

may be made without forcing.

CAUTION: It is up to the installer to provide

adequate support for tank heater units (2) two feet or

longer when installing them in a tank. Failure to provide

adequate support may result in premature tube failure

and/or failure of the tube/tubesheet mechanical roll joint.

12. Start operation gradually. Do not admit hot fluid to the unit

suddenly when empty or cold. Do not shock unit with cold

fluid when unit is hot.

CAUTION: Fluids must be gradually introduced to

the unit. Failure to do so can cause damage to the

heat exchanger.

13. Do not operate equipment under conditions in excess of

those specified on nameplate.

WARNING: Failure to operate the heat exchanger

within the design pressure and temperature on the

nameplate may result in damage to the heat exchanger

and potential injury to adjacent personnel.

19. Inspect all openings in exchanger for foreign material.

Remove all wooden plugs and shipping pads just before

installing. Do not expose units to the elements with pads

or other covers removed from nozzles or other openings

since rain water may enter the unit and cause severe damage due to freezing.

10.

Be sure the entire system is clean before starting operation

to prevent plugging of tubes with sand or refuse. The use

of strainers in settling tanks in pipe lines leading to the unit

is recommended.

11.

Drain connections should not be piped to a common

closed manifold.

12.

Steam hammer can cause serious damage to the tubes

of any heat exchanger. A

lowing points before an installation is made can prevent

costly repairs which may be caused by steam hammer.

a. A vacuum breaker and/or vent, should be used in

accordance with the type of steam system installed.

b. The proper trap for the steam system installed should

be used.

c. The trap and condensate return line to the trap should

be properly sized for the total capacity of the convertor.

d. The trap should be sized for the pressure at the trap,

not the inlet pressure to the steam controller.

e. Condensate should be piped and pitched to a conden-

sate receiver, condensate return pump or drain at an

elevation below the heat exchanger.

CAUTION: During times of shutdown, volumetric

expansion can occur. We recommend the installation of a properly sized relief valve on both sides of the

the heat exchanger. Failure to do so can cause damage

to the heat exchanger.

careful consideration of the fol-

OPERATION

11. When placing a unit in operation, open the vent connec-

tions and start to circulate the cold medium only. Be sure

that the passages in the exchanger are entirely filled with

cold fluids before closing the vents. The hot medium

should then be introduced gradually until all passages are

filled with liquid, close vents and slowly bring the unit up to

temperature.

CAUTION: Fluid and/or steam velocities in excess

of design operating conditions on either the shell or

tube side of the heat exchanger can cause damaging

tube erosion and/or vibrations. Result is internal leakage

and mixing of the hot and cold media. Proper setting of

system controls is required.

1

4. In all installations, there should be no pulsation of fluids

since this causes vibration and strain with resulting leaks.

1

5. Retighten bolting on all gasketed joints after the heat

exchanger has reached operation temperatures to prevent

leaks and gasket failures. Retightening should be done

uniformally and in a diametrically staggered pattern as

illustrated in “MAINTENANCE”.

16. On high pressure and high temperature applications where

an “HTWU/DHTWU” heat exchanger is used or any application where spiral wound gaskets are required, it is recommended that the gasketed joints of the heat exchanger

be retightened to the required torque (see “MAINTENANCE”) after 24 hours at operating pressures and temperatures to compensate for any relaxation or creep that

may have occurred.

17. In shutting down, flow of hot medium should be shut off

first. If it is necessary to stop circulation of cooling medium

the circulation of hot medium should also be stopped by

by-passing or otherwise.

18. Drain all fluids when shutting down to eliminate the possi-

bility of freezing and corrosion. To guard against water

hammer, condensate should be drained from steam

heaters and similar apparatus both when starting up and

when shutting down.

19. Heat exchangers that are out of service for extended

periods of time should be protected against corrosion as

described in the storage requirements for new heat

exchangers.

Heat exchangers that are out of service for short periods

and use water as the flowing medium should be thoroughly

drained and blown dry with warm air, if possible. If this is

not practical, the water should be circulated through the

heat exchanger on a daily basis to prevent stagnant water

conditions that can ultimately cause corrosion.

3

Page 4

MAINTENANCE

11. Do not open heads until all pressure is off equipment, the

unit drained of all fluids, and the equipment surfaces

cooled to ambient temperature.

12. Do not blow out heat exchangers with air when operating

fluids are of a flammable or otherwise hazardous nature.

WARNING: Proper precautions must be taken

(special clothing, equipment, etc.) to protect personnel from injury due to escaping fluids or hot heat

exchanger surfaces.1

13. Provide convenient means for frequently cleaning heat

exchangers as suggested below:

a. Circulating hot wash oil or light distillate through tubes

or shell at good velocity will effectually remove sludge

or other similar soft deposits.

b. Soft salt deposits may be washed out by circulating

hot fresh water.

c. Some cleaning compounds on the market, such as

“Oakite” may be used to advantage for removing

sludge or coke, provided hot wash oil or water, as

described above, does not give satisfactory results.

d. If the above methods are ineffective for removal of hard

scale, a mechanical means may be used.

a. Following the procedures previously mentioned for

front head removal, remove the head and replace it with

a companion flange that mates with the shell body

flange. Replace the nuts and bolts/studs.

b. Pressurize the shellside of the heat exchanger with a

cold fluid, preferably water.

c. Observe all tube joints and tube ends for indication of

test fluid leakage.

d. To tighten a leaking tube joint, use a suitable parallel

roller tube expander.

CAUTION: When tightening leaking tube joints:

1. Do not roll tubes beyond the back face of the tubesheet.

Maximum rolling depth should be the tubesheet thickness

minus 1/8".

2. Do not re-roll tubes that are not leaking since this will

thin the tube wall.

The result of either of the above conditions can lead to

failure of the tube and a leaking bundle.

e. If an emergency repair of a tube is required, use suit-

able tube plugs to seal off both ends of the U-bend

tube. Some loss of performance will result until a new

replacement tube bundle is obtained. Consult your local

ITT Bell & Gossett Representative for proper replacement of the bundle.

WARNING: Care must be exercised when handling

certain fluids. Follow manufacturers instructions.

Use eye and skin protection. Wear a respirator when

required.

14.

Do not attempt to clean tubes by blowing steam through

individual tubes. This overheats the tube and results in

tube expansion strains and sometimes leaking tubes.

15. Frequently and at regular intervals, observe interior and

exterior condition of all tubes and keep them clean. Frequency of cleaning should be according to scale build-up.

CAUTION: Neglect in keeping all tubes clean may

result in complete stoppage of flow through some

tubes with consequent overheating of these tubes, resulting in severe expansion strains, leaking tube joints, and

damage to the heat exchanger.

16. Exchangers subject to fouling or scaling should be

cleaned periodically. A light sludge or scale coating on the

tube greatly reduces it effectiveness. A marked increase in

pressure drop and/or reduction in performance usually

indicates cleaning is necessary, if the unit has been

checked for air or vapor binding and this has been found

not to be the cause. Since the difficulty of cleaning

increases rapidly as the scale thickens or deposits

increase, the interval between cleanings should not be

excessive.

17. At times, it may be necessary to locate a ruptured tube or

a leaking joint between the tubes and the tubesheet of a

single wall heat exchanger. The following procedure is

recommended.

CAUTION: Field repair of Diamondback™ double

wall heat exchangers is not recommended. Rerolling of the tube joints may result in the closing of the

leak detector flow paths between the two tube walls preventing the heat exchanger from providing a positive

indication of potential cross contamination.

8. Tube bundle removal:

a. During bundle removal, the dead weight of bundle

should never be supported on individual tubes. Rest the

bundle on the tube sheet, support plates, or wood

blocks cut to fit periphery of the bundle.

b. Tube bundles may be raised using slings formed by

bending light plates into a “U” form and attaching lifting

lugs to the ends of the sheets. Baffles can be easily

bent and damaged if dragged over rough surfaces.

CAUTION: When cleaning a tube bundle, tubes

should not be hammered on with any metallic tool

and, in case it is necessary to use scrapers, care should

be exercised that the scraper is not sharp enough to cut

the metal of the tubes.

4

Page 5

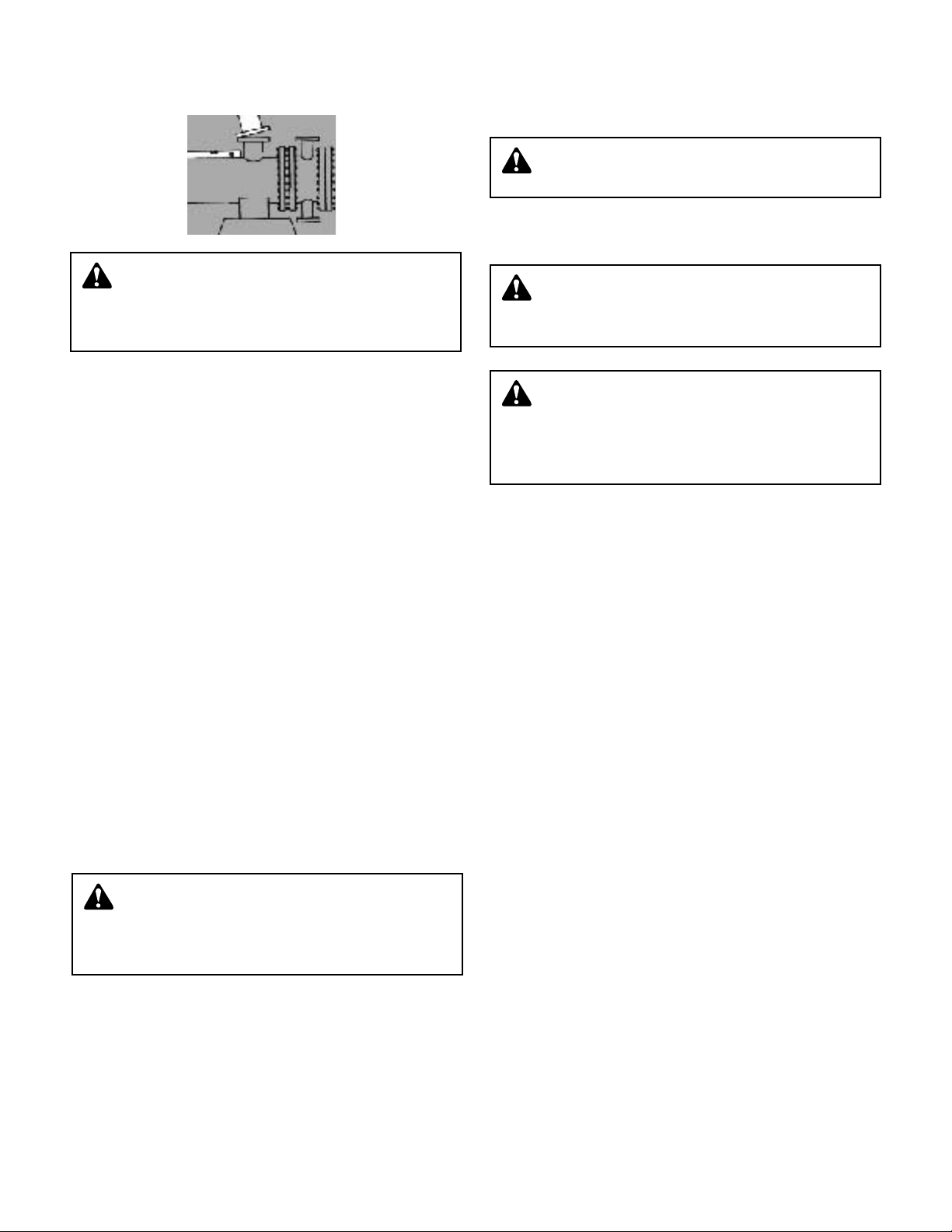

19. Before reinserting the tube bundle into the shell or collar

1

2

3

4

6

9

14

7

15

12

5

10

13

8

11

16

START

of a tank, place the ring/tank gasket over the end of the

tube bundle and bring forward to the backside of the

tubesheet.

TUBE BUNDLE

FRONT

HEAD

(PARTIALLY REMOVED)

HEAD GASKET

TANK GASKET

WARNING: It is extremely important to follow a

proper tightening sequence. If it is not followed, the

flanges can become cocked and a leak will result. When

tightening flanges with spiral wound gaskets, if cocking

occurs, the result can be deformation and non-repairable

damage to the gaskets in addition to a resultant leak.

Any gasket leak can result in potential injury to adjacent

personnel.

TIGHTENING TORQUES

COMPRESSED FIBER GASKETS

Bolt Torque Torque Max.

Dia. ft-lbs Increment Torque

1

/2" 40 5 60

5

/8" 80 5 120

Recommended

10. The tube bundle can be replaced using the tools and

reverse procedure given for bundle removal.

11. When installing a Diamondback™ double-wall tube bundle, make sure the leak path drain hole in the spacer ring

between the two tubesheets is in the lowest position of

the tubesheet circle.

SPACER RING

TUBESIDE

TUBESHEET

MECHANICALLY

ROLLED

TUBE

JOINT

SHELLSIDE

TUBESHEET

CLTUBE

LEAK PATH

DOUBLE-WALL TUBE JOINT

12. When replacing the heads, use a torque wrench to tighten

the bolts/studs and nuts. Use the following chart as

a guide. All torque values apply to well lubricated nut

bearing surfaces.

All bolted joints should be tightened uniformally and in a

diametrically staggered pattern as illustrated below:

SPIRAL WOUND GASKETS

Bolt/Stud Torque Torque Max.

Dia. ft-lbs Increment Torque

1

/2" 140 15 1160

5

/8" 180 15 1120

3

/4" 120 15 1200

7

/

8" 200 10 1320

1"

11/

8" 450 10 1710

11/

4" 600 10 1000

Recommended

300 10 1490

Tightening tip: It is essential that the installer follows the

gasket manufacturer’s installation guidelines when

installing gaskets. Metallic gaskets, such as the spiral

wound gaskets, usually have special installation instructions. One of these instructions includes a special procedure for tightening bolts/studs when installing new gaskets. The procedure recommends that the bolts/studs be

torqued in four stages.

a. Following the staggered tightening pattern, the bolts/

studs should be torqued to 1/3 of the recommended

tightening torque.

b. Same as a, the bolts/studs should be torqued to 2/3 of

the recommended tightening torque.

c. Same as a, the bolts/studs should be torqued to the

recommmended torque valve shown in the above chart.

d. Following the staggered tightening pattern the bolts/

studs torques should be checked for equilibrium since

the tightening of one bolt/stud can relieve the stress on

adjacent bolts/studs.

If after following the gasket manufacturer’s recommended

tightening procedure a leak still occurs, the bolts/studs

should be tightened in the torque increments shown until

the leak stops. The staggered tightening pattern is still

followed.

NOTE: When using spiral wound gaskets, both the head

and the shell/tank gaskets must be spiral wound. You cannot mix one spiral wound and one compressed fiber gasket on a heat exchanger.

13. Refer to “OPERATION” steps 5 and 6 regarding bolt retightening after start-up.

14. Where frequent disassembly of the heat exchanger is

encountered, the use of new bolting in conformance with

dimension and ASTM specifications of the original design

is recommended.

5

Page 6

TYPICAL INSTALLATIONS

FIGURE 1 — T ypical installation of a “SU/DSU” Heat Exchanger when used as a Convertor

FIGURE 2 — T ypical installation of a “SU/DSU” Heat Exchanger when used as an Instantaneous Heater

FIGURE 3 — T ypical installation of a “SU/DSU” Heat Exchanger when used with a storage tank

For proper sizing of Airtrol System consult B&G Representative

FIGURE 4 — T ypical installation of a “WU/DWU” Heat Exchanger when used as a Convertor

NOTE: All valves, pumps, tanks, vents, etc. shown as part of a “TYPICAL INSTALLATION”, are supplied by others.

Contact your Bell & Gossett Representative for these items.

6

Page 7

TYPICAL INSTALLATIONS cont.

When the “WU/DWU” is installed on a hot water boiler as shown, a B&G Flo-Control Valve

When installed on a steam boiler , note that boiler water is pumped into the “WU/DWU” Heater from the bottom of the boiler.

FIGURE 5 — T ypical installation of a “WU/DWU” Heat Exchanger when used as an Instantaneous Heater

Heating with Steam

prevents gravity circulation of boiler water when Booster is not running.

FIGURE 6 — Typical installation of a “TCS/DTCS” Tank Heater

Heating with Boiler Water

FIGURE 7 — Typical installation of a “TCS/DTCS” Tank Heater

NOTE: All valves, pumps, tanks, vents, etc. shown as part of a “TYPICAL INSTALLATION”, are supplied by others.

Contact yourÊBell & Gossett Representative for these items.

7

Page 8

Xylem Inc.

175 Standard Parkway

Cheekowaga, NY 14227

Phone: (800) 281-4111

Fax: (716) 897-1777

www.bellgossett.com

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2014 Xylem Inc. HT-50B-SM June 1997

Loading...

Loading...