Page 1

BELL & GOSSETT

SERVICE MANUAL

HT-320B-SM

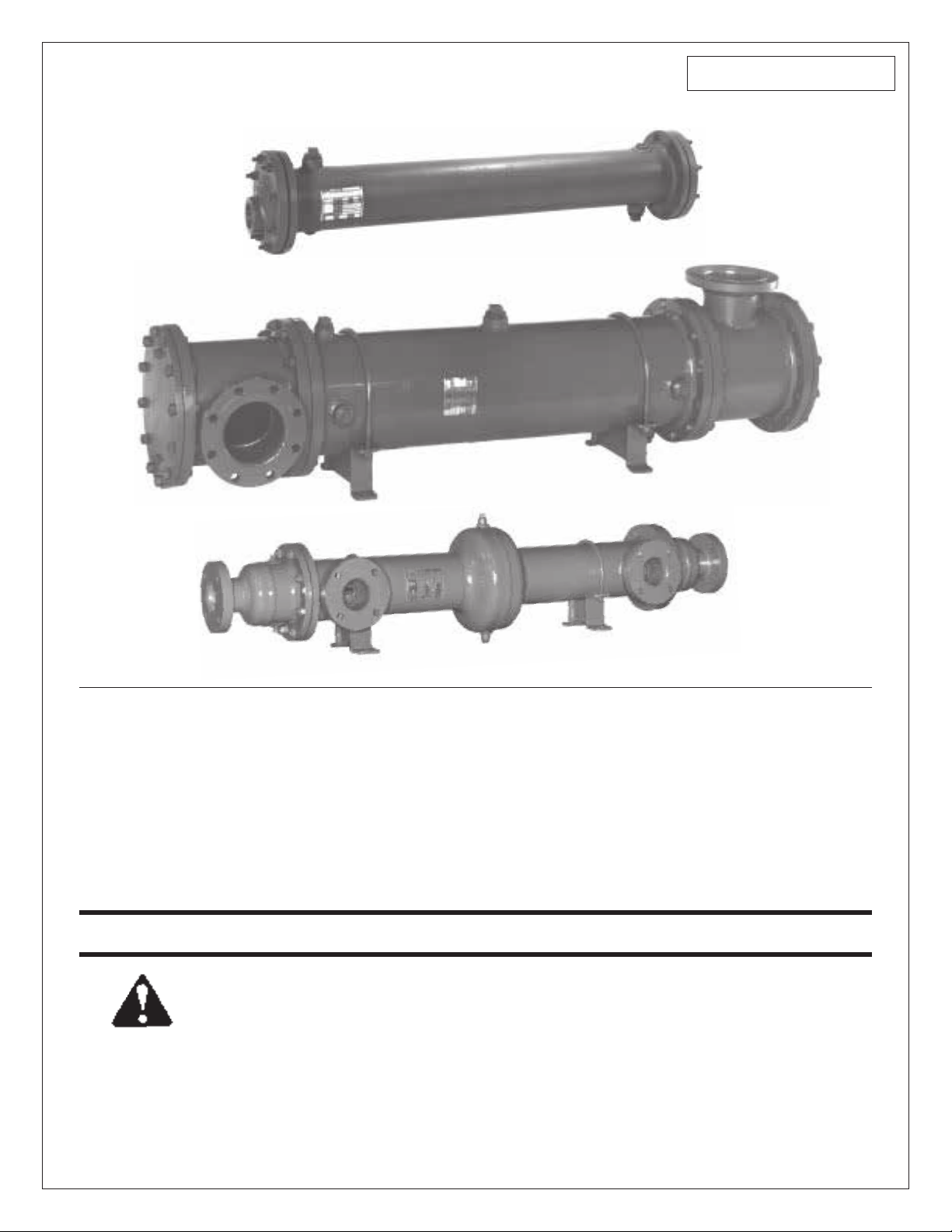

TYPE “OF” WITH CAST IRON BONNET HEADS

TYPE “OF” WITH STEEL CHANNEL HEADS

TYPE “OE” WITH STEEL BONNET HEADS

Installation, Operation and

Maintenance Manual for

Models “OF” & “OE” Straight Tube,

Fixed Tubesheet Heat Exchangers

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

SAFETY

INSTRUCTION

This safety alert symbol will be used in this manual to draw

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

© COPYRIGHT 1984, 1995

Bell & Gossett

Morton Grove, IL, U.S.A.

Page 2

INSTALLATION

1. Provide sufficient clearance at each end of the heat exchanger

to permit rodding the tubes.

2. Provide valves and by-passes in the piping systems so that

both the shell and tube sides may be by-passed to permit

inspection or repair.

3. Provide thermometer well and pressure gauge connections in

all piping to and from the unit and locate as near the unit as

possible.

4. Provide convenient means for frequently cleaning the unit as

suggested under “Maintenance.”

5. Provide necessary air vent cocks for units so they can be

purged to prevent or relieve vapor or gas binding of either the

tube or the shell sides.

6. Foundations must be adequate so that exchangers will not

settle and cause piping strains. Foundation bolts should be

set to allow for setting inaccuracies. In concrete footings, pipe

sleeves at least one size larger than bolt diameter slipped over

the bolt and cast in place are best for this purpose, as they

allow the bolt center to be adjusted after the foundation has

set.

7. Loosen foundation bolts at one end of unit to allow free

expansion of shells. Oval holes in foundation brackets are

provided for this purpose.

8. Set exchangers level and square so that pipe connections

may be made without forcing.

9. Inspect all openings in exchanger for foreign material. Remove all thread protectors and shipping pads just before

installing. Do not expose units to the elements with pads or

other covers removed from openings since rain water may

enter the unit and cause severe damage due to freezing.

2

10. Be sure the entire system is clean before starting operation to

prevent plugging of tubes with sand or refuse. The use of

strainers in settling tanks in pipe lines leading to the unit is

recommended.

11. Drain connections should not be piped to a common closed

manifold.

12. Steam hammer can cause serious damage to the tubes of any

heat exchanger. A careful consideration of the following points

before an installation is made can prevent costly repairs which

may be caused by steam hammer.

a. A vacuum breaker and/or vent, should be used in accor-

dance with the type of steam system installed.

b. The proper trap for the steam system installed should be

used.

c. The trap and the condensate return line to the trap should

be properly sized for the total capacity of the convertor.

d. The trap should be sized for the pressure at the trap, not

the inlet pressure to the steam controller.

e. The trap must drain into an unpressurized condensate

return system. Condensate return lines must not be run at

an elevation above the bottom of the heat exchanger. To do

so may result in a buildup of the condensate level in the

heat exchanger, which could cause water hammer and

damaged tubes.

CAUTION: During times of shutdown, volumetric

expansion can occur. We recommend the installation

of a properly sized relief valve on both sides of the heat

exchanger.

Page 3

OPERATION

1. When placing a unit in operation, open the vent connections

and start to circulate the cold medium only. Be sure that the

passages in the exchanger are entirely filled with the cold fluid

before closing the vents. The hot medium should then be

introduced gradually until all passages are filled with liquid,

close vents and slowly bring the unit up to temperature.

2. Start operation gradually. Do not admit hot fluid to the unit

suddenly when empty or cold. Do not shock unit with cold fluid

when unit is hot.

CAUTION:

unit. Failure to do so can cause damage to the heat

exchanger.

3. In shutting down, flow of hot medium should be shut off first.

If it is necessary to stop circulation of cooling medium the circulation of hot medium should also be stopped by by-passing

or otherwise.

4. Do not operate equipment under conditions in excess of those

specified on nameplate.

WARNING:

within the design pressure and temperature on the

nameplate may result in damage to the heat exchanger and

potential injury to adjacent personnel.

5. Drain all fluids when shutting down to eliminate possibility of

freezing and corrosion. To guard against water hammer, condensate should be drained from steam heaters and similar

apparatus both when starting up and when shutting down.

6. In all installations there should be no pulsation of fluids since

this causes vibration and strain with resulting leaks.

7. All gasketed joints should be checked after starting for leaks

and tightened if necessary.

Fluids must be gradually introduced to the

Failure to operate the heat exchanger

d. If none of the above described methods are effective for

the removal of hard scale or coke a mechanical means

may be used. The interior of the tubes may be rodded.

e. The exterior or shell side of the tubes of a fixed tube sheet

heat exchanger can only be cleaned chemically by using a

chemical dissolved in water solution. We suggest that the

user contact the manufacturer of the cleaning chemical for

instructions.

WARNING:

Care must be exercised when handling

certain fluids. Follow manufacturers instructions. Use

eye and skin protection. Wear a respirator when required.

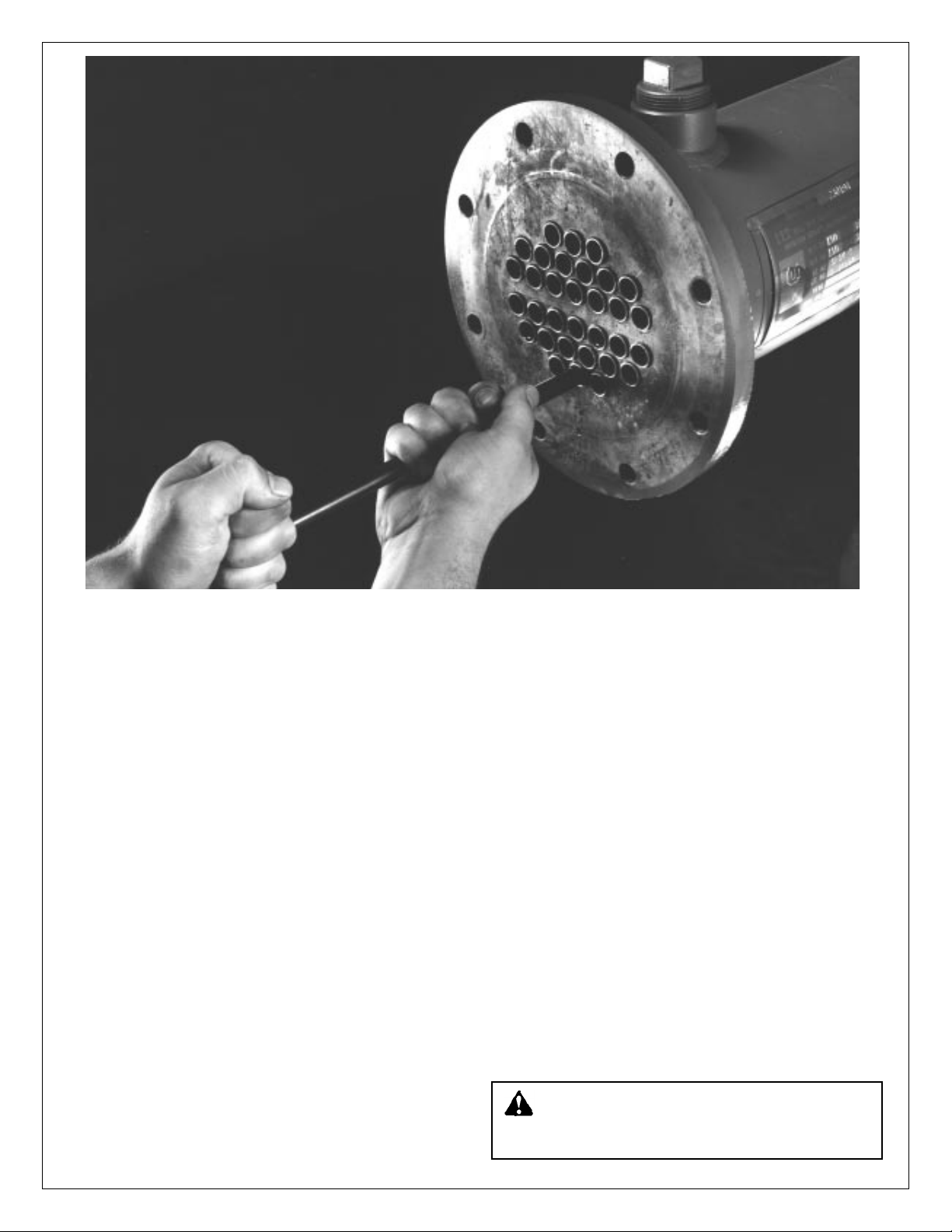

4. To clean or inspect inside of tubes, remove channel cover and

rear head. On exchangers having bonnet type heads (without

channel cover), piping must be disconnected and both heads

removed.

5. Do not attempt to clean tubes by blowing steam through individual tubes. This overheats the tube and results in tube

expansion strains and sometimes leaking tubes.

6. When replacing heads, use a torque wrench.* Tighten

diameter bolts to 40 ft. lbs. and

5

/8" diameter bolts to 80 ft. lbs.

1

/2"

If the gasket joint still leaks, tighten in 5 ft. lbs. increments until

leak stops.

* The above torque values apply to well lubricated nut bearing

surfaces.

7. All bolted joints should be tightened uniformly and in a diametrically staggered pattern as illustrated below:

START

1

6

9

14

4

16

11

8

3

13

MAINTENANCE

1. Do not open heads until all pressure is off equipment and the

unit is drained.

2. Do not blow out heat exchangers with air when operating fluids

are of a flammable or otherwise hazardous nature.

WARNING:

clothing, equipment, etc.) to protect personnel from

injury due to escaping fluids.

3. Provide convenient means for frequently cleaning heat

exchangers as suggested below:

a. Circulating hot wash oil or light distillate through tubes or

shell at good velocity will effectually remove sludge or other

similar soft deposits.

b. Soft salt deposits may be washed out by circulating hot

fresh water.

c. Some cleaning compounds on the market, such as

“Oakite” may be used to advantage for removing sludge or

coke, provided hot wash oil or water, as described above,

does not give satisfactory results.

Proper precautions must be taken (special

7

12

2

15

10

5

8. Frequently and at regular intervals, observe interior and exterior condition of all tubes and keep them clean. Frequency of

cleaning should be according to scale build-up.

CAUTION:

Neglect in keeping all tubes clean may

result in complete stoppage of flow through some

tubes with consequent overheating of these tubes, resulting

in severe expansion strains, leaking tube joints, and damage

to the heat exchanger.

9. Exchangers subject to fouling or scaling should be cleaned

periodically. A light sludge or scale coating on the tube greatly

reduces its effectiveness. Therefore, low-fouling fluids should

be used in the shell side of all heat exchangers with nonremovable tube bundles. A marked increase in pressure drop

and/or reduction in performance usually indicates cleaning is

necessary, especially if the unit has been checked for air or

vapor binding and this has been found not to be the cause.

Since the difficulty of cleaning increases rapidly as the scale

thickens or deposits increase, the interval between cleanings

should not be excessive.

3

Page 4

CASING AND TUBE

BUNDLE ASSEMBLY

FRONT

HEAD

FRONT

HEAD

GASKET

NAMEPLATE

CROSS SECTIONAL VIEW OF

FIXED TUBE CONSTRUCTION

When ordering replacement parts give name of part,

National Board Number and factory number from nameplate.

REAR

HEAD

GASKET

REAR

HEAD

For further information, contact Bell & Gossett Heat Transfer Products, 175 Standard Parkway, Cheektowaga, NY 14227,

Phone (716) 862-4171 — Facsimile (716) 862-4176.

PRINTED IN U.S.A. 5-95

Bell & Gossett

Morton Grove, IL, U.S.A.

Loading...

Loading...