Page 1

INSTRUCTION MANUAL

HS-801

REVISION D

Hoffman Specialty

®

Replacement Cover

Assembly for Series

600, 601, 602, 603 and

604 and Internal Parts &

Kits for 616/B6 Inverted

Bucket Steam Traps

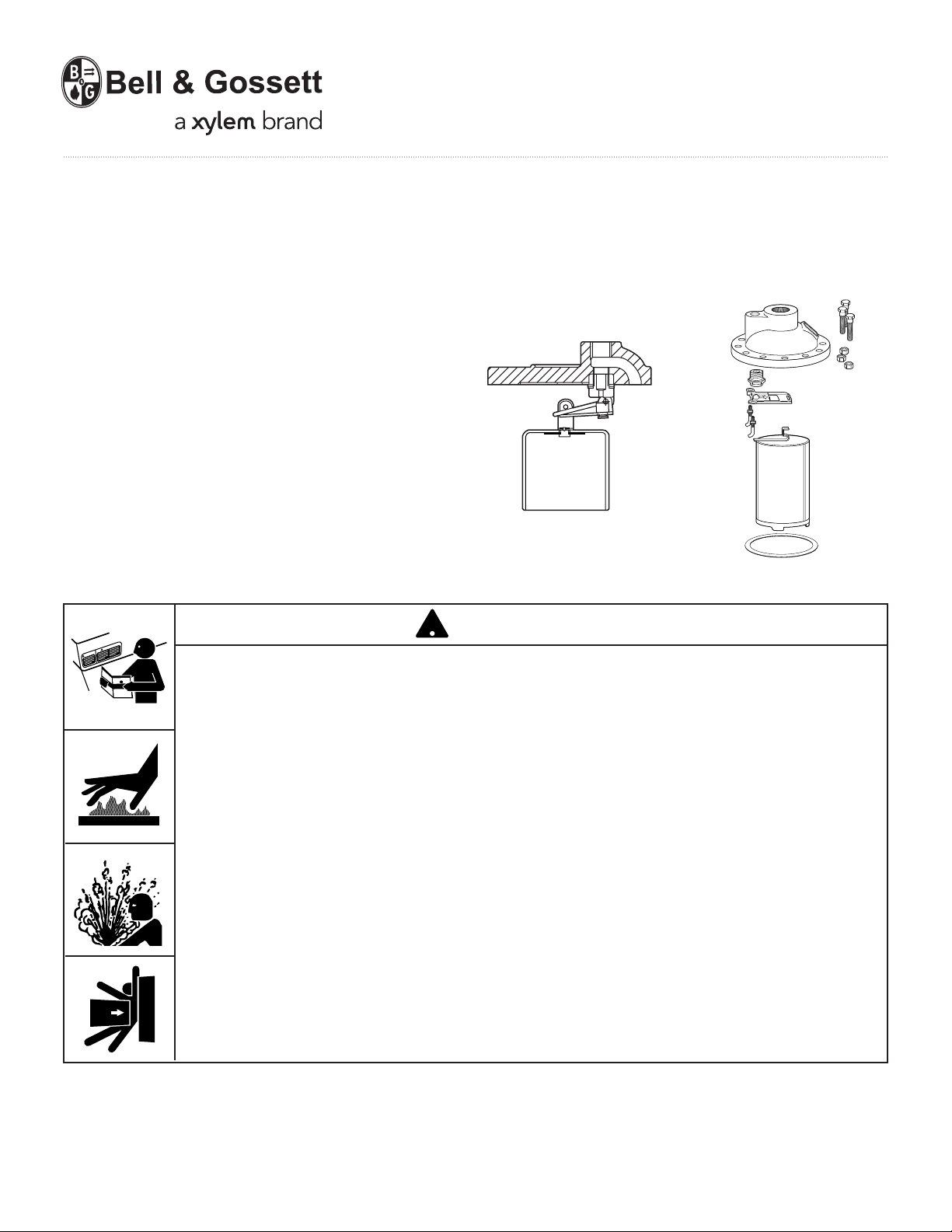

Series 600 Inverted Bucket Trap

Replacement Cover Assembly

WARNING

CAUTION

WARNING

• Before using product, read and understand instructions.

!

616/B6 Cover and Internal Parts

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of steam systems in accordance with all applicable codes

and ordinances.

• To prevent serious burns, the internal pressure of the trap must be 0 psi (0 bar) before

servicing.

• To prevent serious burns, wear heat resistant gloves when opening and closing steam

valves, or handling hot equipment.

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30m) from

the front of the pipe opening.

• To prevent property damage, personal injury, or death, cap off the gate valves if they

are not connected to a drain and when they are not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury or death.

IMPORTANT: To prevent system damage from water

hammer or sudden shock, open supply valves slowly.

If you are uncertain about the product’s adaptability for

your application, please call the factory or authorized

representative before using the product.

The trap seat rating (stamped on the nameplate) must

be equal to or greater than the maximum system

pressure.

Page 2

INSTALLATION –

TOOLS NEEDED:

One (1) socket or open-end wrench and one (1) scraper.

Series 600 through 604 Replacement Cover Assemblies

• Using wrench, loosen and remove cover assembly bolts (A).

• Remove cover assembly (B) and internal parts.

• Using scraper, remove gasket (C).

• Clean body gasket surface and inspect and clean body bowl (D).

• Install cover gasket.

• Install cover assembly with internal parts attached and hand tighten

cover assembly bolts (A). Using wrench or socket, tighten cover

assembly bolts (A) in pattern illustrated below.

• Prime trap before putting in service.

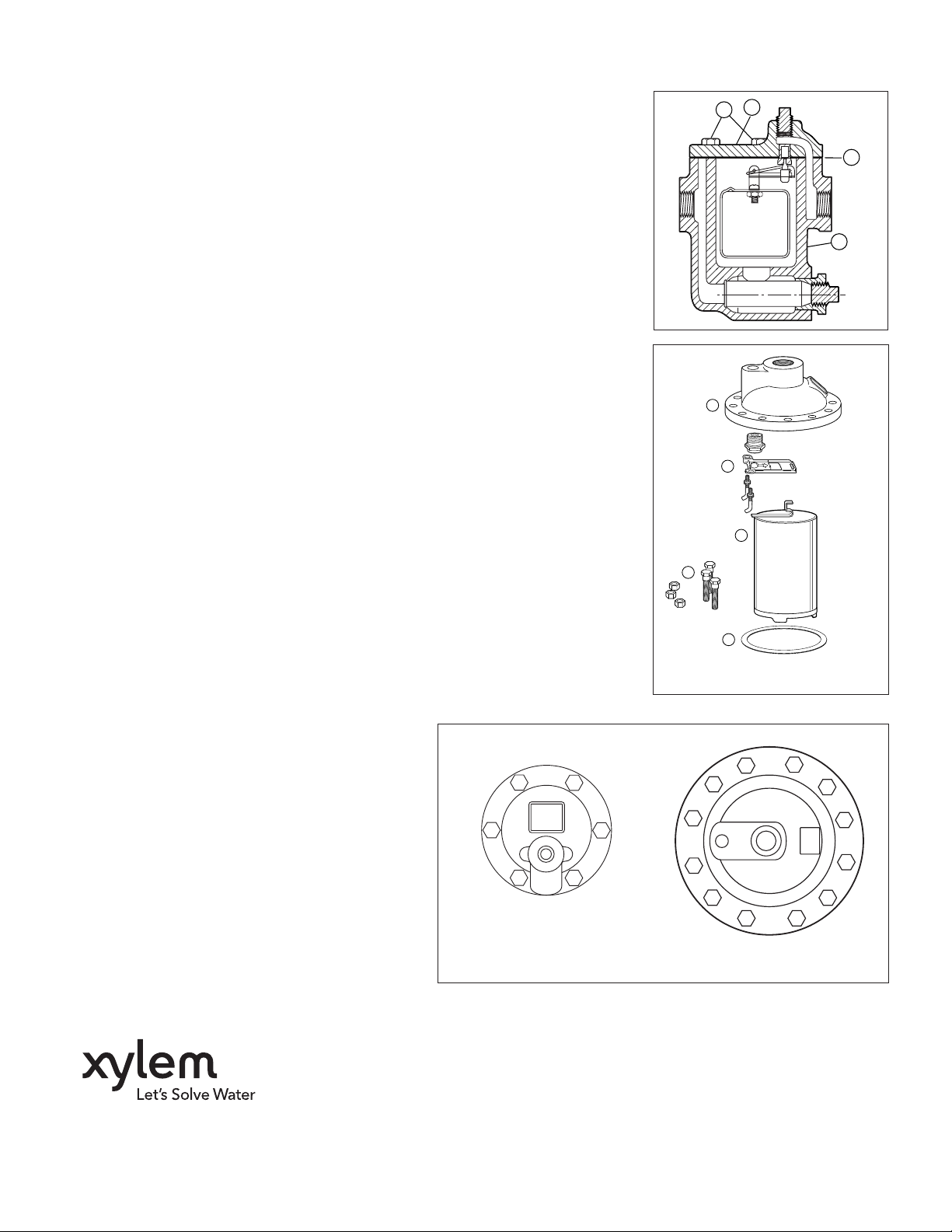

Series 616 and B6 Replacement Internal Components

• Using wrench, loosen and remove cover assembly bolts and nuts (J).

• Remove cover assembly and internal parts (E, F, H) together from the body.

• Clean the gasket surfaces of the body and cover using a scraper; in normal

maintenance, inspect and clean the interior of the body. Replace gasket (G).

• For internal parts (F) replacement, remove the bucket assembly (H) from the

lever. Loosen the nuts of the guide pins that hold the lever assembly. Turn the

guide pins (note orientation of the bend on the end of the pin) so the lever

assembly will come off the pins. Remove the pins. Remove the seat from the

cover.

• Install the new seat and tighten securely. Install the guide pins with the locking

nuts into the cover to a height of 1 9/32" (32mm). Orient the bend of the pins

toward the center and parallel to each other, lock in this position by tightening

the nuts against the cover. Position the pre-assembled lever and pin (E) onto

the guide pins. Be sure the lever swings freely and the lever pin moves into

the center of the seat when the lever assembly is approximately parallel to the

surface of the seat. Hook the bucket (H) to the lever through the slot. If old

bucket is reused, be sure bleed hole in top of bucket is clear.

• Place the cover gasket (G) on the body. Position the cover and internal parts

onto the body. Hand-assemble the 12 bolts through the cover and body and

secure the bolts with the nuts and tighten in the pattern shown below.

Retighten them to the torque values in the same pattern.

• Prime the trap prior to returning to service.

Cover assembly bolts must be tightened in numerical order as shown.

Retighten bolts in order to torque values:

Models 600, 601 and 602: 25 lbf•ft (34 N•m)

Models 603, 604, 616 and B6: 30 lbf•ft (41 N•m)

46

PRIMING – After repair or service, bucket traps

must be primed. This can easily be done by one of

two methods:

1.Remove the pipe plug from the trap cover and

fill the body by pouring water through the

tapping above the seat. Replace the pipe plug.

2.Close the downstream valve on the discharge

side of the equipment. When condensate has

filled the body of the trap, slowly open the

valve. The trap will self prime.

1

3

600-604 Series Bolt

Tightening Pattern

2

5

B

A

E

F

H

J

G

B6/616 Internal Parts

12

7

1

5

9

3

B6/616 Series Bolt

Tightening Pattern

C

D

4

10

6

2

8

11

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. HS-801D October 2012 Part No. 510909

Loading...

Loading...