Page 1

INSTRUCTION MANUAL

!

HS-601

REVISION G

Hoffman Specialty

®

Pilot Operated Pressure and/or

Temperature Steam Regulators

Series 2000

WARNING

CAUTION

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of steam systems in accordance with all applicable codes

and ordinances.

• To prevent serious burns, wear heat resistant gloves when opening and closing steam

valves, or handling hot e

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30m) from

the front of the pipe opening.

• To prevent property damage, personal injury, or death, cap off the gate valves if they

are not connected to a drain and when they are not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury or death.

quipment.

WARNING

Page 2

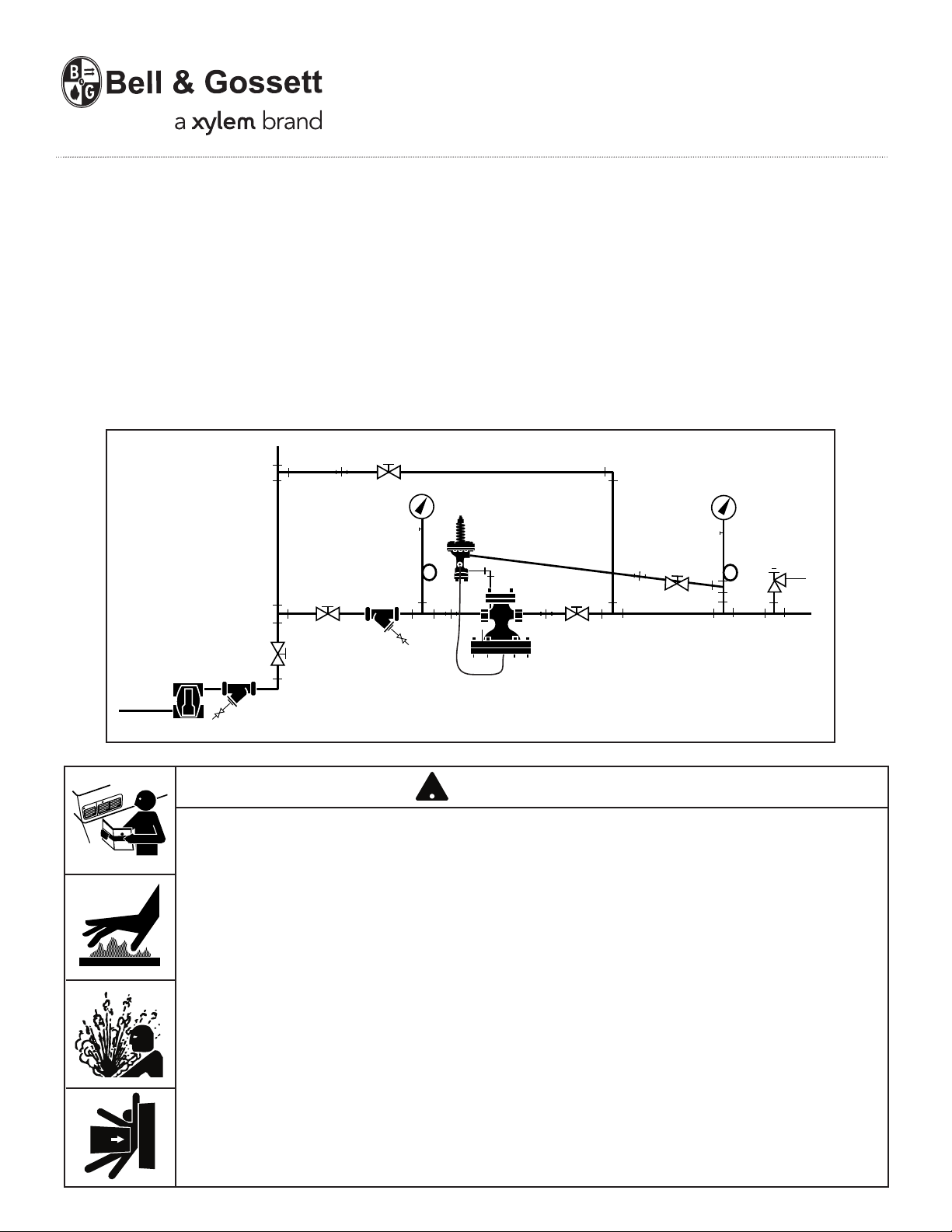

PLANNING THE INSTALLATION

Planning for the Main Valve Installation

1. The regulator main valve must be located in an

accessible straight run of horizontal piping.

OTE: Main valve must be installed with diaphragm

N

located on bottom, as shown in Main Valve Installation

illustration, page 3.

2. Allow clearance on top of the main valve to remove

the cover plate to inspect and service the valve.

3. Allow clearance under the main valve diaphragm

cover to replace diaphragms and drop out the stem

for service.

4. Piping should be sized per good engineering practice.

HVAC applications generally use 6,000 FPM velocity.

Industrial applications generally use 8,000 to 10,000

FPM.

5. Blow out all piping with steam or compressed air before

installing the main valve to remove mill scale and dirt.

6. Use long radius elbows in the low pressure piping.

Avoid the use of bull-headed tees.

7. Provide a bypass line with a globe valve to allow

inspection without interrupting service.

8. Install pressure gauges on inlet and outlet sides of

regulator to indicate system performance.

9. Install drip traps to prevent:

• Accumulation of condensate that can cause water

hammer and destroy the main valve and pilot

diaphragms.

• Slow response times that cause temperature or

pressure fluctuations.

10. Install "Y" Strainers in steam lines with the dirt pocket

turned to the side to prevent collection of condensate

that can be carried into the regulator and cause water

hammer.

11. Install pressure relief valves in accordance with local

nd national codes. The relief valve must be capable

a

of passing the full capacity of the regulator with its

largest seat trim.

Select the relief valve opening set point pressure

ased on the downstream pressure from the regulator.

b

The actual relief valve set point pressure depends on

the relationship of the flow (load) to the main valve

rated capacity.

For systems with spring or air pilots:

Determine the relief pressure set point pressure for

systems as follows:

Downstream Flow Relief valve

System (Load) opening set

Pressure (DSP) Condition point pressure

< 35 psig < 50% of capacity DSP + 5 psig

< 35 psig ≥ 51% of capacity (1.1 x DSP) + 5 psig

≥36 psig < 50% of capacity DSP + 10 psig

≥36 psig ≥ 51% of capacity (1.1 x DSP) + 10 psig

For systems with temperature pilots only:

The steam system relief valve opening set point

pressure is based on the supply steam inlet pressure

to the regulator and must be set as follows:

Supply Steam Relief valve

Inlet Pressure opening set

(SSIP) point pressure

< 35 psig SSIP + 5 psig

≥36 psig SSIP + 10 psig

12. Locate temperature regulators close to the temperature

sensing location. The temperature pilot capillary tube

must allow the sensing bulb to be fully inserted into

the system fluid.

Planning for the Pilot Installation

1. The pilot valves can be installed on either side of the

main valve. The main valve is shipped with the U-tubing

and the bleed orifice installed for left-hand side

mounting of the pilot valves. (U-tubing is mounted on

the right-hand side and the bleed orifice is installed

on the left-hand side.)

If right-hand side mounting of the pilot(s) is desired,

the U-tubing and the bleed orifice must be relocated

to the opposite sides of the main valve.

Note: Right-hand side and left-hand side positioning

is determined when the main valve inlet directly faces

the observer.

2. Determine which pilot(s) are to be used for the installation. Multiple pilots can be used in combination on

one main valve. Mount the pilot(s) as follows:

• SLD Solenoid Pilot

Always mount closest to the main valve.

2

• SPS Spring or AP Air Pressure Pilots

When used in combination with other pilots,

always mount spring or air pilots furthest from

the main valve.

• STPA Temperature Pilot

When used with pressure pilot mount closest to

main valve.

When used with pressure and solenoid pilots –

mount between pressure and solenoid pilots.

• 315 PNT or 240PNT Pneumatic Temperature

Pilots

Mounted remotely from main valve.

• GT610-IP Electronic Pilot (used with customer

supplied temperature sensor and controller)

Mounted remotely from main valve.

3. Hardware kits containing steel pipe nipples and

copper tube lines are required to mount the pilots.

Refer to "Mounting Hardware for Pilot Installation"

Page 4.

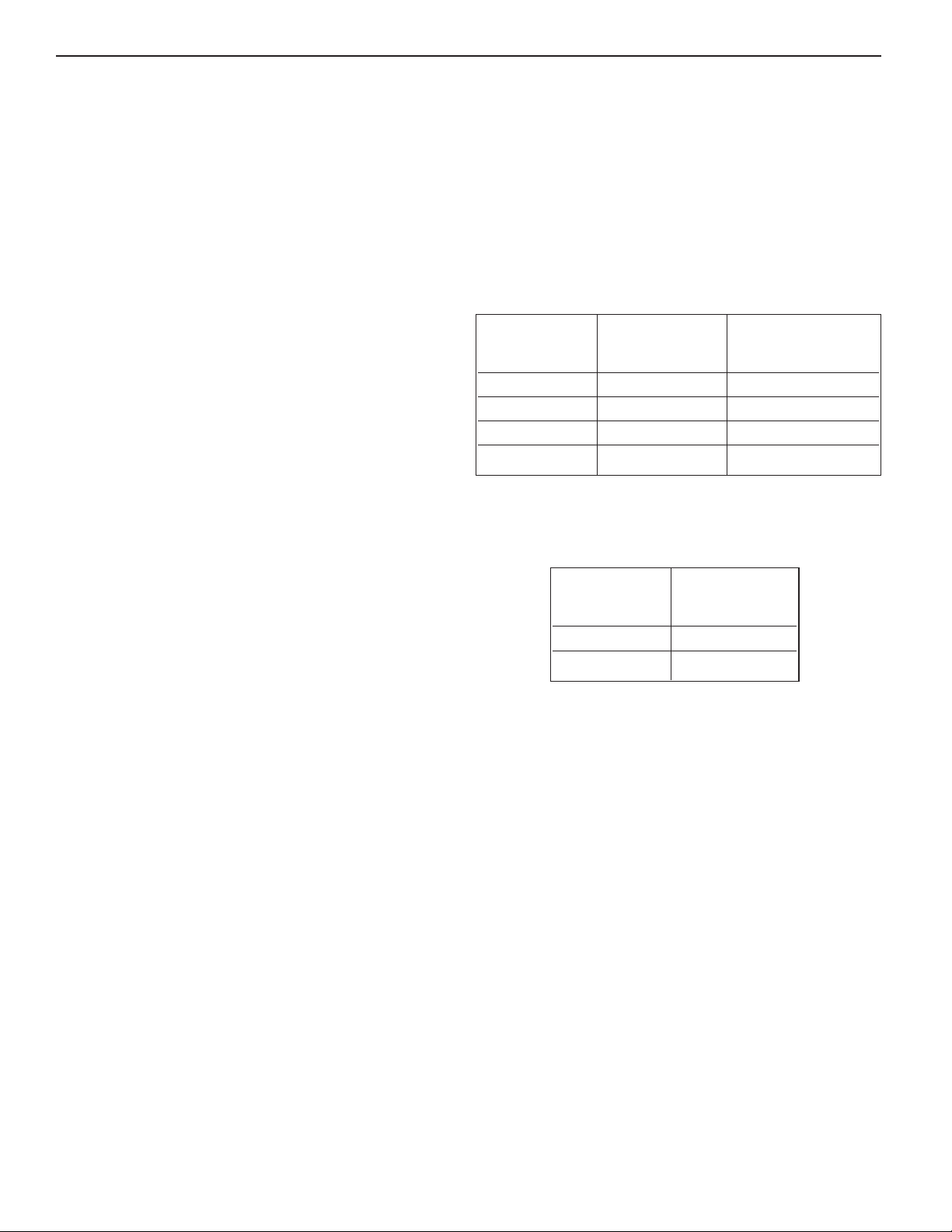

Page 3

N

10 Pipe

Diameters

O

M

H

F

G

E

J

L

P

R

S

Z

Y

X

W

U

V

T

B

A

C

K

D

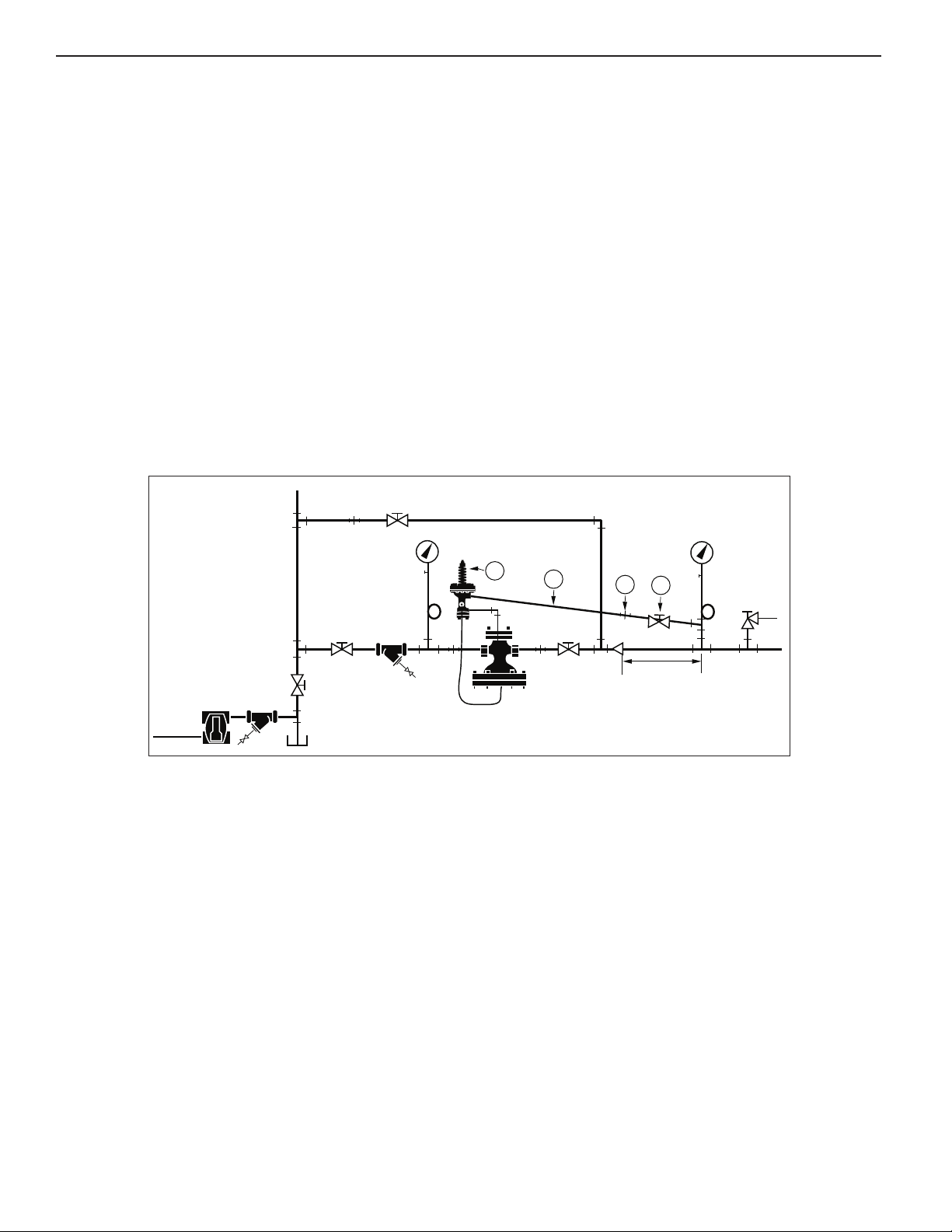

INSTALLATION DETAIL

Main Valve Installation

1. Connect a steam line (A) from the steam supply to the

area where regulator valve is to be located. Install tee

fittings (B) for a bypass line, and (C) for the regulator

line.

Note: Drip traps prevent condensate from collecting in

the piping during light loads or when the regulator is

closed. Collected condensate in the piping ahead of

the regulator can cause water hammer when the

regulator opens.

2. Install a shut off valve (E) to allow servicing the trap.

3. Provide a dirt pocket ahead of the strainer to allow

large solids to drop out.

4. Install a drip trap (H), Y-strainer (F) equipped with a

screen and blow down valve (G).

5. Cap the blow down valve outlet to prevent steam

discharge due to accidental opening of valve.

6. Connect a horizontal pipe from tee (C).

7. Connect a reducer (D), if required, to reduce the

steam line to the pipe size of the main valve.

Use additional reducers when the pipe needs to be

reduced more than two pipe sizes. When noise is a

concern, reducers should not have more than a 15

degree taper.

8. Install shut off valve (J) and Y- strainer (K). Turn the

strainer so that the screen is horizontal to prevent

condensate from collecting in the screen pocket.

Condensate pockets can carry with the steam flow,

causing water hammer that can destroy the main

valve diaphragms.

9. Install a strainer blow down valve (L).

10. Cap the blow down valve outlet to prevent steam

discharge due to accidental opening of valve.

11. Install tee, siphon loop tube, petcock, and pressure

gauge.

On NPT sized regulator valves, install a pipe union (M)

12.

to allow regulator removal for service or replacement.

13. Use compressed air or steam to clean piping before

installing the regulator.

• Cap off the end of the steam line.

• Remove caps from the strainer blow down

valves (G) and (L).

• Turn on the steam or air to full pressure and allow

it to blow down for five minutes.

• Close off compressed air or steam.

• Allow piping to cool below 100˚F.

• Reinstall end of line caps on blow down valves.

• Remove cap from end of the steam line.

14. Install main valve (N) with the direction arrow pointing

to the low-pressure side outlet piping.

NPT sized regulator valves:

• Use pipe sealant on male threads only, keeping the

sealant out of the system.

• Use a wrench on the flats of the body to tighten

the joint.

• Use the wrench on the side of the body that is being

tightened to prevent stress and distortion on the body.

Flanged regulator valves:

• Inspect flange surfaces and gaskets.

• Tighten flange bolts using a star pattern. Uneven

bolting may cause steam leakage.

15. Install silencer orifice plate (when used) immediately

after the main valve:

NPT sized regulator valves: Install orifice plate

between two ASME flanges.

Flanged regulator valves: Install the orifice plate

between the valve flange and the outlet pipe flange.

16.

On NPT sized regulator valves, install a pipe union (O)

to allow regulator removal for service or replacement.

17. Install gate valve (P).

18. Install pipe tee (R) for bypass connection.

3

Page 4

19. Install the bypass piping and globe valve (T).

1

2

4

3

5

1076

1

9

4

8

5

10

76

• Use the same size pipe for the bypass piping and

globe valve in the bypass line as the main valve (N)

to allow manual regulation during service of regulator.

Support piping to remove any stress from the

•

regulator valve body before connecting to the system.

• Make sure pipes and flanges are properly aligned to

revent stress on the regulator valve body.

p

20. Install pipe reducer (S) to increase the pipe size, if

necessary, to meet the velocity requirements.

Use additional reducers when the pipe needs to be

increased more than two pipe sizes.

21. Install a 1/4 NPT pipe tapping (U) at least 10 pipe

diameters downstream in a straight run of the

enlarged pipe for the pressure gauge and feedback

line (for spring and/or air pilots) connection.

PILOT INSTALLATION

Mounting Hardware for Pilot Installation

Note: For heat exchanger shell applications, it is

recommended that the feedback line and pressure

gauge be installed directly into the heat exchanger

shell.

22. Install pressure relief valve (V) in the downstream

iping as required by codes.

p

23. Install a tee fitting (W) for pressure feedback line.

4. Install a siphon loop tube (X), petcock (Y) and

2

pressure gauge (Z) in vertical port of tee fitting (W).

25. Connect system piping to complete the installation.

26. Refer to "Pilot Installation" for pilot mounting and

piping instructions.

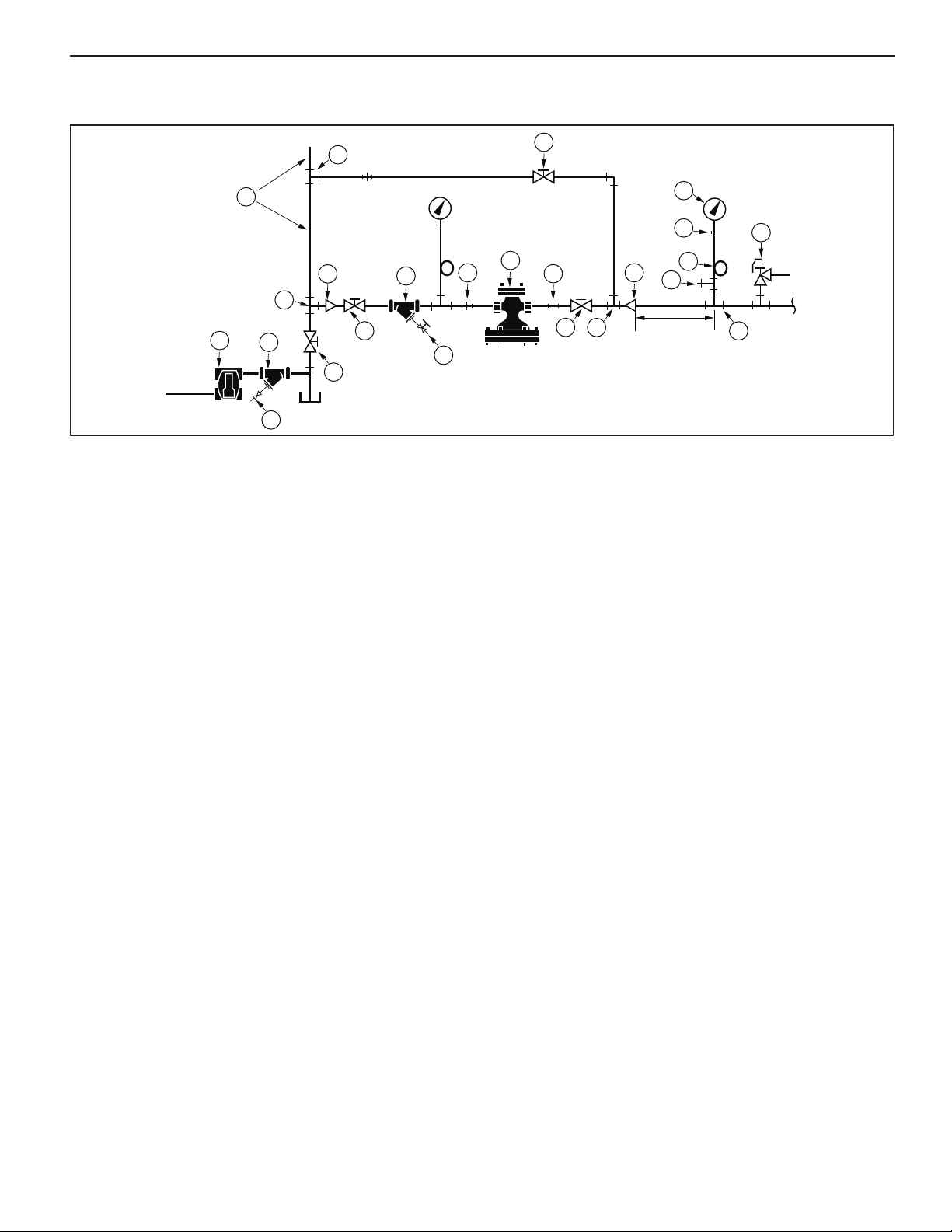

Kit A – For spring or air pilots only or in combination with

temperature or solenoid pilots.

Kit B – For temperature pilot or solenoid pilot only.

Hardware Kit Components

No Part Description Kit A Kit B

1 L-Tubing; from main valve bottom XX

Elbow connection to tee fitting

Branch connection.

2 S-Tubing; from bleed orifice fitting X

to tee fitting on pilot.

3 Nipple, 1/4 NPT x 4" (101mm) X

4 Nipple, 1/4 NPT x 1-1/2" (38mm) (2) XX

5 Union Connection, 1/4 NPT Female XX

6 Tee fitting XX

7 L-fitting XX

8 Bushing X

9 J-Tubing; From bleed orifice fitting X

to tee fitting on pilot.

10 1/8" Tubing connector XX

4

Page 5

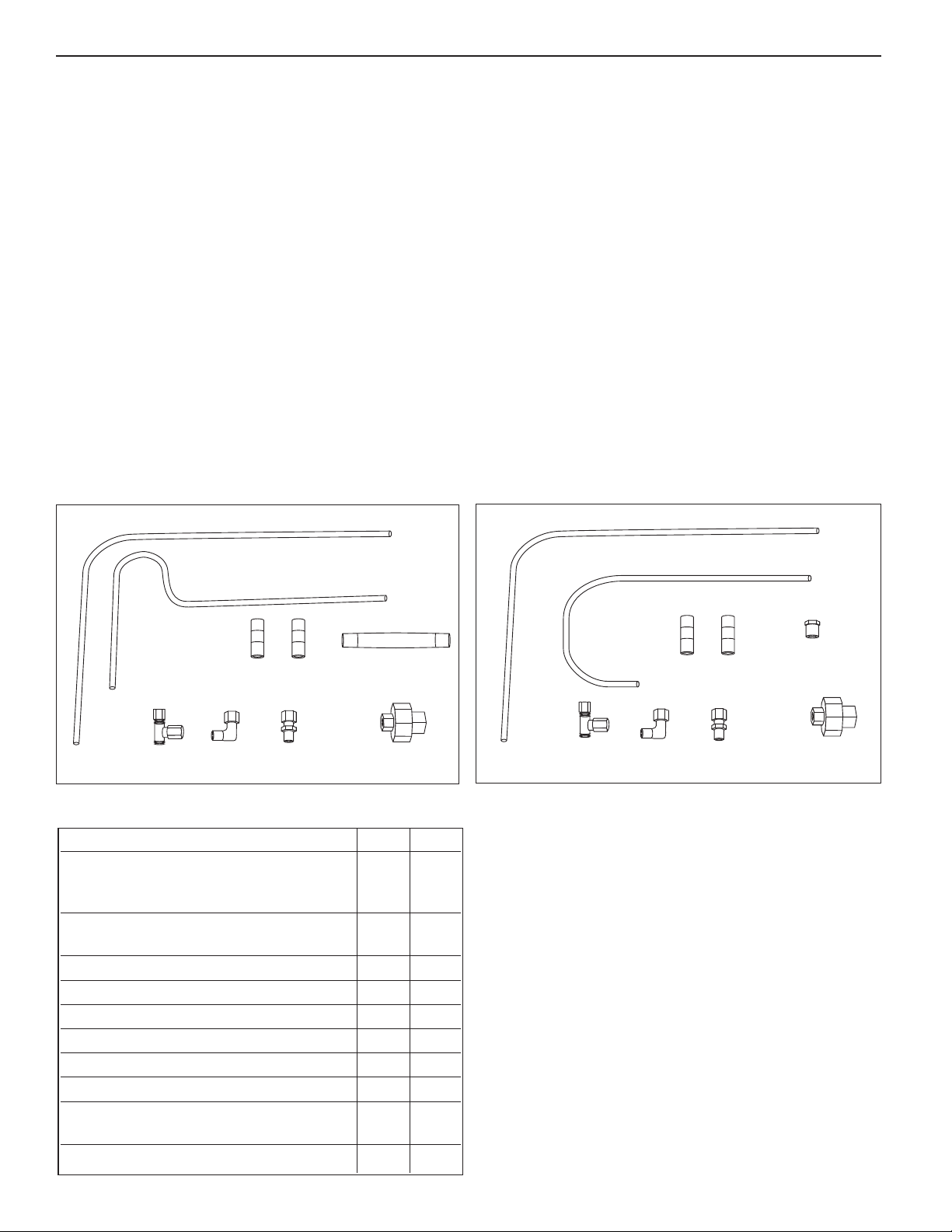

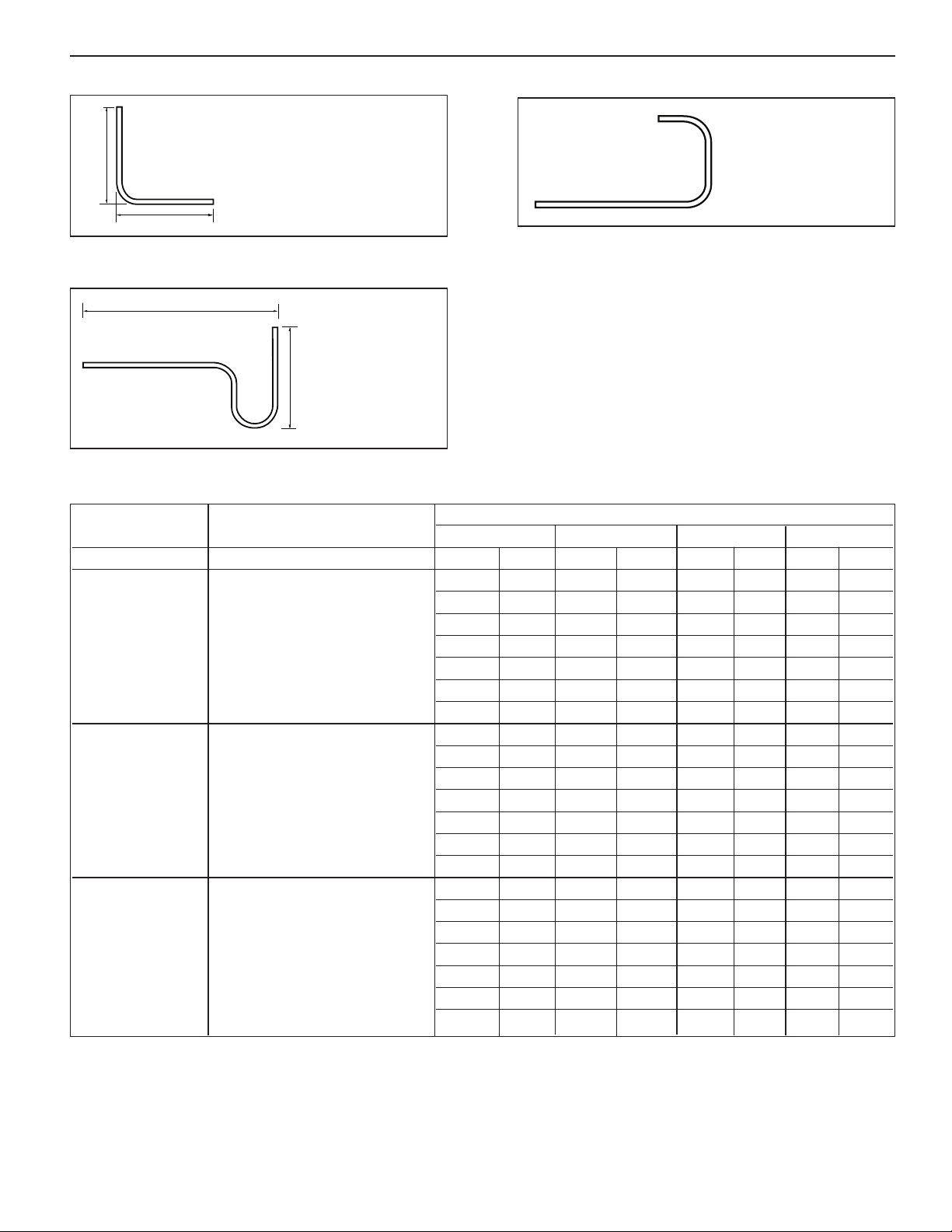

1. L-Tube

C

D

A

B

Cut L- tube to appropriate A & B

dimensions listed on Tubing Length

chart.

No cutting is required if dimension is

marked with an *.

9. J-Tube

No cutting of J-tubes

s required

i

2. S-Tube

Cut S- tube to appropriate C & D dimensions listed on

Tubing Length chart.

No cutting is

required if dimension

is marked with an *.

Tubing Length

DIMENSIONS

ABCD

PILOT MAIN VALVE SIZE In mm In mm In mm In mm

1/2 NPT, 3/4 NPT, 1 NPT 6.0 152 7.6 178 6.4 163 3.5 89

1-1/4 NPT, 1-1/2 NPT 6.8 173 8.1 206 6.4 163 4.8 122

2 NPT, 2 (50) * 8.6 218 8.2 208 6.4 163 * 5.7 145

Spring or Air 2-1/2 (65) 10.6 269 9.1 231 6.4 163 5.9 150

3 (80) 11.2 284 9.4 239 6.4 163 6.4 162

4 (100) 13.0 330 10.3 262 6.4 163 7.9 200

6 (150) *16.6 422 12.3 312 6.4 163 * 9.5 241

1/2 NPT, 3/4 NPT, 1 NPT 6.0 152 11.3 287 *10.0 254 3.5 89

1-1/4 NPT, 1-1/2 NPT 6.8 173 11.7 297 *10.0 254 4.8 122

2 NPT, 2 (50) * 8.6 218 * 11.9 302 *10.0 254 * 5.7 145

Combination 2-1/2 (65) 10.6 269 12.8 325 *10.0 254 5.9 150

Pilots 3 (80) 11.2 284 13.1 333 *10.0 254 6.4 162

4 (100) 13.0 330 13.9 353 *10.0 254 7.9 200

6 (150) *16.6 422 * 14.9 378 *10.0 254 * 9.5 241

1/2 NPT, 3/4 NPT, 1 NPT 5.2 132 7.9 200

1-1/4 NPT, 1-1/2 NPT 6.0 152 8.6 218

2 NPT, 2 (50) 7.8 198 8.8 223

Temperature 2-1/2 (65) 9.8 249 9.7 246

3 (80) 10.4 264 10.0 254

4 (100) 12.2 310 10.9 277

6 (150) 15.8 401 12.0 305

* No cutting of tube length is required.

5

Page 6

A

D

10 Pipe

Diameters

C

B

Bleed Orifice

The function of the bleed orifice is to bleed steam off the

ain valve diaphragm when the pilot(s) close(s). A 1/16"

m

(1.6mm) diameter orifice is standard, and is installed in

he outlet side of the main valve when shipped. This

t

diameter orifice is used in most applications.

In special situations, the bleed orifice may be drilled out

to 3/32" (2.4mm) diameter to produce faster closing time

of the main valve and thus improve response time.

• A 3/32 in. (2.4mm) diameter orifice should NOT be

used in conjunction with a temperature pilot, as

accuracy of temperature control will be reduced.

Pilot Installation Detail

• Typical applications for 3/32 in (2.4mm) diameter

leed orifice may include:

b

– Pressure differential across the reducing valve is

0 psig (3.5 bar) or greater.

5

– High pressure PRV on a 2-stage pressure

reducing station.

– Pressure reducing valve with a fast acting

pneumatic temperature regulator downstream

of the main valve.

Applies to All Pilots

1. The pilot valve(s) can be installed on either side of the

main valve. The main valve is shipped with the U-

tubing and the bleed orifice installed for left-hand side

mounting of the pilot valve(s). If right-hand side

mounting of the pilot(s) is desired, the U-tubing and

the bleed orifice must be relocated to the opposite

sides of the main valve.

Note: Right-hand side and left-hand side positioning is

determined when the main valve inlet directly faces

the observer.

2. Make sure the bleed orifice is installed in the 1/8 NPT

tapping on the outlet end of the main valve on the

opposite side from the U-tubing. Remove the 1/8 NPT

pipe plug from the bleed orifice and replace it with a

1/8 NPT x 1/4" (6mm) OD tubing, straight compression

fitting (from the hardware kit).

3. Install the 1/4 NPT x 1-1/2" (38mm) nipple and half of

the union connection (from the hardware kit) on the

inlet end of the main valve.

6

Use the 1/4 NPT x 4" (101mm) nipple and the remaining

4.

half of the union connection (from the hardware kit) to

mount the first pilot. Mount additional pilots as

required using 1/4" steel pipe nipples.

5. Install the copper tee fitting (from the hardware kit) in

the 1/8 NPT signal tapping on the side of the last pilot

with the tee pointing down.

6.

Install the L-fitting (from the hardware kit) in the tapping

at the center of the main valve diaphragm cover.

Note: For steps 7 and 8, trim the length of the copper

tubing as required (see "Tubing Length Chart", page

5) to make a neat installation. Be sure to ream the

tube to the full tube diameter after cutting.

7. Install the S- or J-copper tubing (from the hardware

kit) from the tee fitting to the bleed orifice.

8. Install the L- copper tubing (from the hardware kit)

from the bottom of the tee fitting to the L-fitting in the

main valve diaphragm cover.

Page 7

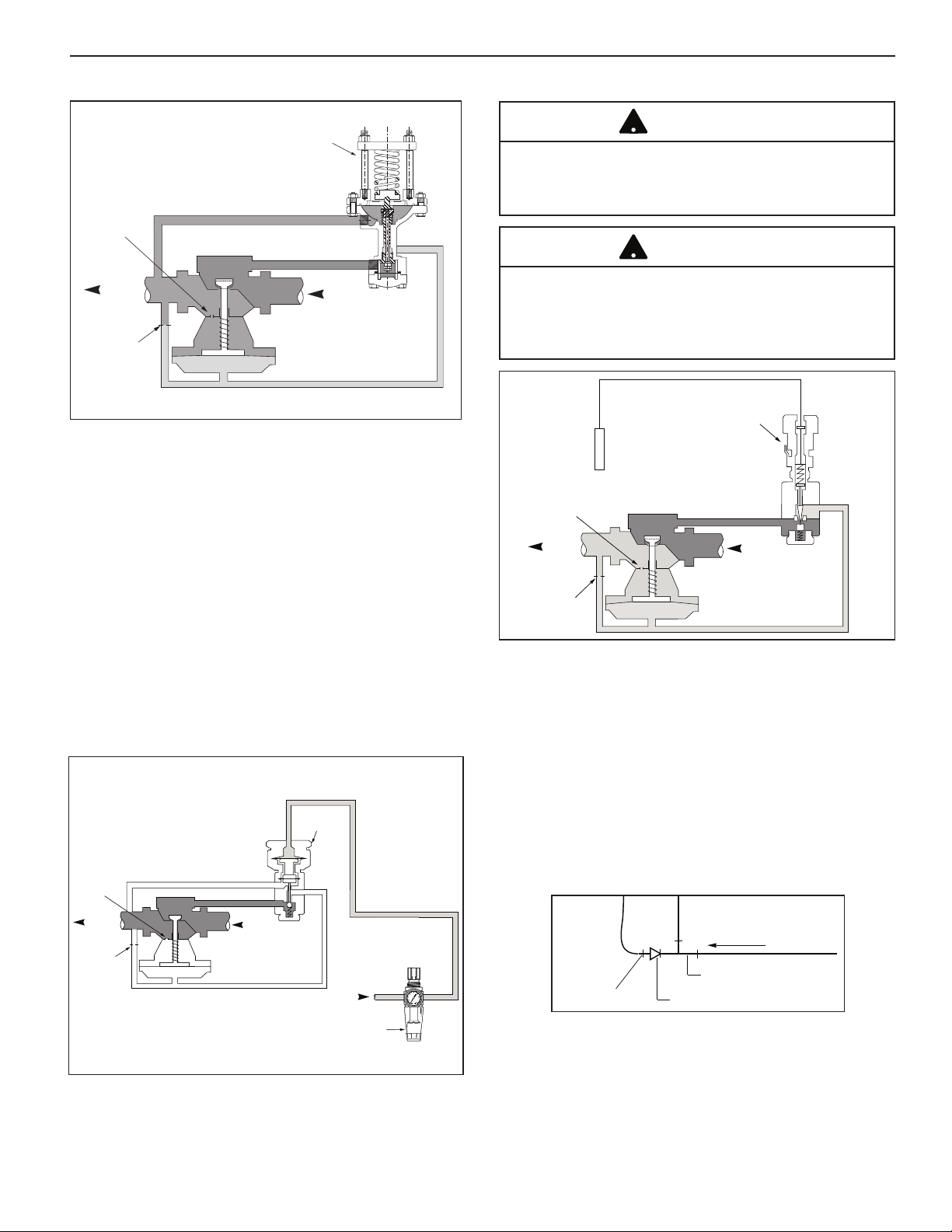

Outlet

Balance

Tube

Bleed

O

rifice

Signal

Feedback Line

Main Valve

Inlet

Pilot Inlet

S

pring

Pilot

Air Supply

Feedback Line

Balance

Tube

Outlet

Bleed

Orifice

Main Valve

Inlet

Pilot Inlet

Signal

AP Air

Pilot

Air PRV

Regulator

High Pressure

Supply Air

T

emperature

S

ensor

Balance

Tube

S

ignal

Temperature

Pilot

Outlet

Bleed

Orifice

Main Valve

I

nlet

Pilot Inlet

Spring/Air Pilots

!

!

Flow from System

Pipe Tee

Pipe Bushing

Sensing Bulb

1. The 1/4" feedback tapping must be connected to the

downstream piping for either a spring or air pressure

pilot:

• Use 1/4 black steel pipe for the feedback line (B).

• Install a 1/4 NPT shut off valve (D) and union (C)

in this line to allow service of the pilot while

operating the system on the by-pass line.

• The feedback line must pitch away from the pilot

to avoid erratic operation, excessive fouling and

eliminate water pockets.

2. When the regulator is used with a heat exchanger,

connect the feedback line (B) to the heat exchanger

shell. A tee fitting can be installed in the heat

exchanger for a vacuum breaker connection.

Temperature Pilots

CAUTION

Temperature pilot bulb will be immersed in the heated

fluid. Before immersing, check compatibility of copper

bulb with heated fluid. Failure to insure compatibility

may cause property damage.

CAUTION

System should be supplied with overheat protection

(such as temperature relief valve or aquastat solenoid

combination) at 10˚F over set temperature. Failure to follow this warning may result in property damage, personal

injury, or death.

1. When only a temperature pilot is used, the outlet

tapping port must be reduced. Use the 1/8 x 1/4

NPT bushing (from the hardware kit) in the 1/4 NPT

outlet.

2. Insert the sensing bulb so the full length of the bulb

is exposed to the fluid whose temperature is being

controlled.

a) Use a 1/2 NPT compression fitting to install the

bulb at the outlet of instantaneous heaters and

in the middle of storage tanks.

b) The preferred bulb mounting when installed in

the system piping is illustrated below:

3. For air pilot installations, connect the regulated air

pressure supply to the top of the pilot bonnet.

c) Optional dry well (separable socket) allows the

sensing bulb to be removed from the tank or

piping without draining the system.

• When using a dry well, coat the bulb with high

temperature grease or heat transfer compound,

to aid heat transfer.

• Make sure that bulb and dry well are fully

inserted into the fluid being controlled.

7

Page 8

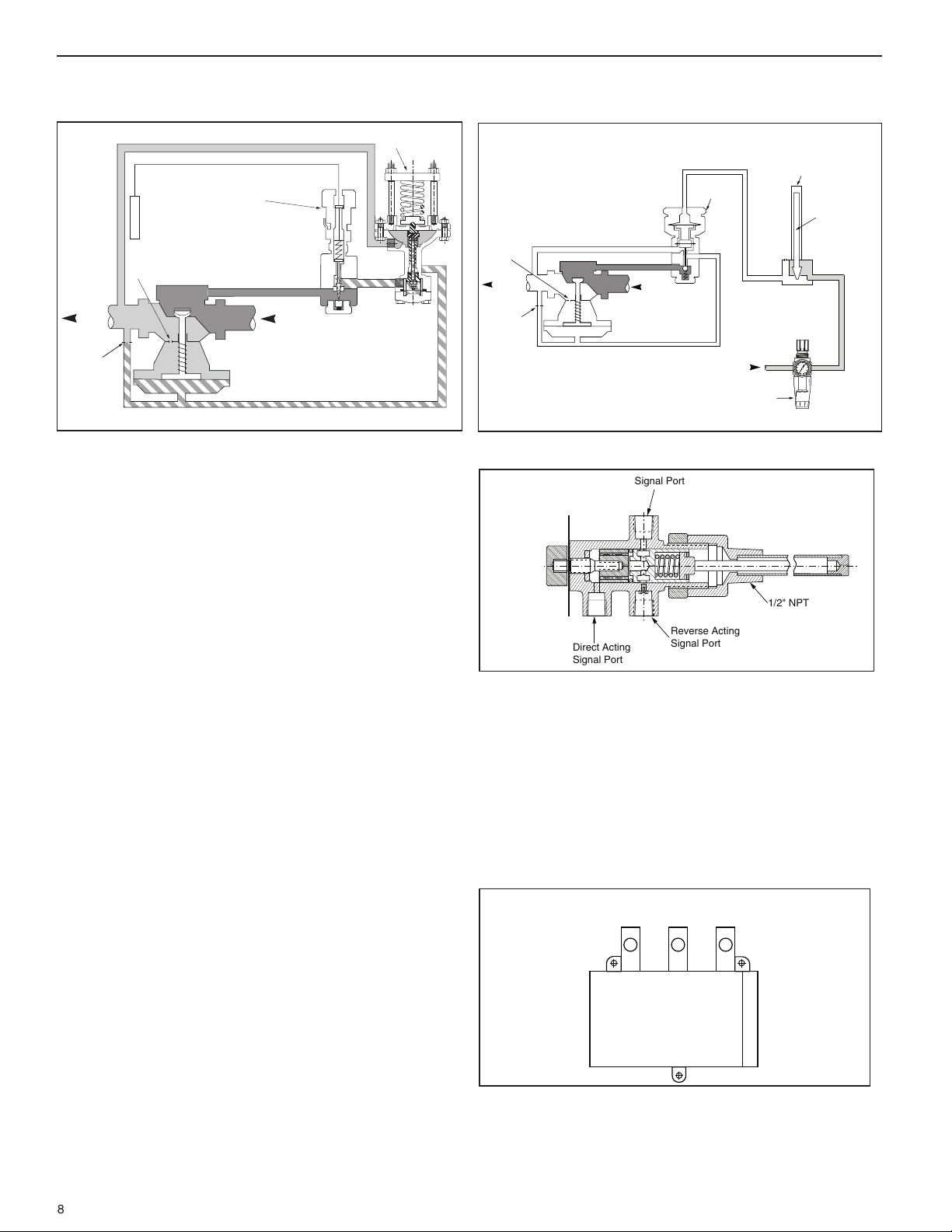

Temperature and Spring Pilot Combination

Spring Pilot

O

utlet

B

alance Tube

S

elf-Contained

Temperature

Pilot

Bleed

O

rifice

Main Valve

I

nlet

P

ilot Inlet

Air Supply

Feedback Line

Balance

Tube

Outlet

Bleed

Orifice

Main Valve

Inlet

Pilot Inlet

S

ignal

A

P Air

Pilot

Temperature

Sensor

315 PNT

T

emperature

Pilot

Air PRV

Regulator

High Pressure

Supply Air

Main

Branch

Supply

Air Port

Branch

Air Port

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

yy

yy

yyy

y

Signal Port

Reverse Acting

Signal Port

1/2" NPT

Direct Acting

Signal Port

Pneumatic Temperature and Air Pilot

Combination

1. Install the temperature pilot next to the main valve.

2. Install a 1/4" NPT nipple between the outlet tapping

port of the temperature pilot and the inlet port of the

spring pilot.

3. The 1/4" feedback tapping port of the spring pilot

must be connected to the downstream piping:

• Use 1/4 black steel pipe for the feedback line.

• Install a 1/4 NPT shut off valve and union in the

feedback line to allow service of the pilot while

operating the system on the by-pass line.

• The feedback line must pitch away from the pilot to

avoid erratic operation and excessive fouling and to

eliminate water pockets.

4. When the regulator is used with a heat exchanger,

connect the feedback line (B) (see illustration on

page 6 to the heat exchanger shell. A tee fitting can

be installed in the heat exchanger for a vacuum

breaker connection.

5. Insert the sensing bulb of the temperature pilot so the

full length of the bulb is exposed to the fluid whose

temperature is being controlled.

a) Use a 1/2 NPT compression fitting to install the

bulb at the outlet of instantaneous heaters and in

the middle of storage tanks.

b) The preferred bulb mounting when installed in the

8

system piping is illustrated on page 7.

c) Optional dry well (separable socket) allows the

sensing bulb to be removed from the tank or piping

without draining the system.

• When using a dry well, coat the bulb with high

• Make sure that bulb and dry well are fully inserted

temperature grease or heat transfer compound,

to aid heat transfer.

into the fluid being controlled.

Series 315 PNT Pilot

1. Connect a regulated air supply to the "Reverse

Acting" inlet port of the 315 PNT pneumatic

temperature pilot.

2. Do not plug the "Direct Acting" inlet port of the

pneumatic temperature pilot. This port serves as

an air bleed.

3. Connect the output "Signal" port of the pneumatic

temperature pilot to the top of the AP-1A or AP-4A

pneumatic air pilot.

Series 240 PNT Pilot

1. Connect a regulated air supply to the "Supply Air"

port of the 240 PNT pneumatic temperature pilot.

2. Connect the output "Branch Air" port of the pneumatic

temperature pilot to the top of the AP-1A or AP-4A

pneumatic air pilot.

Page 9

he following chart shows the maximum outlet steam

T

pressure that can be obtained from the main valve. The

outlet steam pressure is based on the air pressure from

PNT Air Signal Maximum Steam Pressure from Main Valve

Outlet Pressure AP-1A Pressure Pilot AP-4A Pressure Pilot

sig Bar psig Bar psig Bar

p

9 (0.62) 0 (0.00) 0 (0.00)

10 (0.69) 1 (0.07) 4 (0.28)

11 (0.76) 2 (0.14) 8 (0.55)

12 (0.83) 3 (0.21) 12 (0.82)

13 (0.90) 4 (0.28) 16 (1.10)

14 (0.97) 5 (0.35) 20 (1.38)

15 (1.04) 6 (0.41) 14 (1.66)

18 (1.24) 9 (0.62) 36 (2.50)

20 (1.38) 11 (1.76) 44 (3.00)

25 (1.73) 16 (1.10) 64 (4.40)

30 (2.07) 21 (1.45) 84 (5.80)

he pneumatic temperature pilot to an AP-1A or AP-4A

t

Pneumatic Pressure Pilot. Intermediate pressures can be

interpolated from the chart.

9

Page 10

SYSTEM START-UP

!

!

. Make sure all strainer blow down valves are closed

1

and capped to prevent accidental burns.

2. Open 1/4 NPT feedback control line shut-off valve.

3. Close inlet valve to main valve. Open outlet gate

valve and all equipment drain valves. Allow system

o drain completely.

t

CAUTION

Never open a reducing valve without positive indication

that the high pressure side is clear of condensate. Be

sure no one is in area of any open end of pipes when

steam is turned on. Failure to follow this caution may

result in serious burns.

4. Make sure bypass globe valve is tightly closed.

5. Release any actuating force on pilot(s).

Spring Close pilot valve by equally unscrewing

adjusting nuts to release compression

on the adjusting spring.

Air Adjust Air PRV Regulator to 0 psig

(0.00 bar)

Temperature Set temperature adjusting knob to the

lowest setting.

NOTE: On STPA-300 and STPA-400 pilots, loosen

the calibration set screw and move the pointer out

the way. Gently turn the adjustment knob clockwise

until the seat is completely closed. This requires that

the pilot be recalibrated, see "Adjusting Temperature

Pilots", page 11.

Solenoid Make sure normally open solenoid is

open or normally closed solenoid is

closed.

6. Slightly open steam supply inlet valve. Open only

enough to allow steam into the system.

7. Apply a small amount of force to the pilots.

Spring Gradually compress adjusting spring

y tightening adjusting nuts equally

b

until the pilot valve opens.

Air Adjust Air PRV to allow pressure to

build slightly until the air pilot valve

opens.

Temperature Increase temperature setting a couple

of degrees at a time.

Pneumatic Dial in temperature and adjust air

Temperature supply pressure to 9 psi (0.62 bar).

8. Allow system to stabilize.

9. Open steam supply inlet valve slightly more. A little

pressure will build on the inlet to the regulator, which

allows it to open and steam to flow.

10. Close all equipment drain valves.

11. Open supply inlet valve more.

12. Allow system to stabilize.

13.

Check for any leaks. Allow time for the piping to heat

up and the drip trap to drain condensate.

14. Slowly allow pressure to build until the inlet gate

valve is about half open. If there are no problems

open inlet gate valve completely.

15. Refer to "Adjusting Pilot(s)", page 11, for final pilot

adjustments.

CAUTION

Hearing protection is required if drain valves are open to

atmosphere. Failure to do so may result in hearing loss.

10

Page 11

ADJUSTING PILOTS

pring/Air Pilots

S

Adjust spring/air pilot to control the system at desired

pressure. The system pressure can be set for full steam

or partial steam flow.

ull Steam Flow – If the spring pilot is adjusted to the

F

required reduced pressure while the system is running at

full steam flow, then the reduced pressure will rise

approximately 10% when the system is running at low

steam flow.

Partial Steam Flow – If the spring pilot is adjusted to the

required reduced pressure while the system is running at

5 – 10% of full steam flow, the reduced pressure will fall

(droop) approximately 10% when the system is running at

full steam flow.

Spring Pilot

1. To increase downstream pressure, increase compression on the adjusting spring by tightening the adjusting

nuts an equal amount.

2. To decrease downstream pressure, release compression on the adjusting spring by loosening the adjusting

nuts an equal amount.

Air Pilot

1. To increase downstream pressure, increase the outlet

pressure from the air regulator. The pilot should open

at approximately 9 psig (0.62 bar).

2. To decrease downstream pressure, decrease the outlet pressure from the air regulator.

Temperature Pilot

1. To increase temperature, loosen Allen lock screw and

turn adjusting knob counterclockwise. Then securely

tighten lock screw.

2. To decrease temperature, loosen Allen lock screw and

turn adjusting knob clockwise. Then securely tighten

lock screw.

3. Once system is running, temperature can be set

immediately.

• Insert a thermometer in heated fluid.

• When thermometer (in heated fluid) indicates

temperature is 5˚F (3˚C) below the required

temperature, turn adjusting knob to lower temperature setting until steam flow stops.

The calibrated temperature dial provides an approx-

•

imate setting. If the temperature dial reading is

slightly off from the thermometer reading, the dial

should be recalibrated, as follows:

Loosen the set screw and turn the indicator and

–

the mounting collar.

Retighten the set screw after making the adjustment.

–

4. Observe the temperature while the system is running.

5. Adjust the sleeve until the desired temperature is

reached.

6. Tighten the dial set screw without turning the adjusting

sleeve.

7. When the temperature setting is complete, use the

Allen head set screw to lock the knob.

Temperature and Spring Pilot Combination

1. With the temperature pilot set to the highest temperature setting, adjust the spring pilot as noted above.

2. Adjust the temperature pilot according to instructions

above.

Pneumatic Temperature and Pneumatic Air Pilot

Combination

With this combination, steam pressure is limited rather

than controlled. The air regulator upstream of the air pilot

and pneumatic temperature pilots controls the air pilot

pressure setting. Through this combination, the air pilot

limits the steam pressure delivered by the main valve.

Therefore, only the temperature is adjusted.

1. The air supply to the PNT pilot should be set between

18 and 36 psig (1.24 – 2.5 bar).

2. Turn the adjusting knob on the pneumatic temperature

pilot to the approximate desired operating temperature.

3. Insert a thermometer in heated fluid.

4. When the thermometer reaches the desired temperature, turn the PNT adjusting knob to indicate 9 psig

(0.62 bar) on the PNT pressure gauge.

5. After conditions have stabilized, make adjustments as

necessary.

For steam pressure limits, refer to "Maximum Steam

Pressure from Main Valve" chart, page 9.

MAINTENANCE

Schedule

1. Initially every 2-3 days after start-up until system is

clean.

2. Every 6 months thereafter.

Procedure:

1. Inspect joints for leaks. Tighten bolts to stop leaks.

2. Open blow down valves on strainers.

3. Allow full pressure steam to pass for two minutes.

4. Close the blow down valves.

5. Observe system pressure and readjust if required.

Control of Pressure and/or Temperature

1. Check to see that operating condition initial adjustments are still set.

2. Consider slightly altering the adjustment to see if the

system responds appropriately.

Solenoid Pilot Actuation

• Make sure solenoid is functioning properly.

Strainers

If screens in Y- strainers or pilot strainers are excessively

•

dirty, system blowdown should be done once a week.

11

Page 12

TROUBLESHOOTING

Replace the regulator or pilot(s) when parts no longer

operate properly. A new regulator is more economical

than replacing individual parts, and will provide greater

reliability.

General Series 2000 Regulator System

Troubleshooting Guidelines

Cause: Main valve undersized.

Solution: Check valve capacity against system load.

Replace with correct size valve.

Cause: Strainer plugged.

Solution: Blow down strainer screen or remove and

clean screen.

Dead End Service

The seat leakage rate for metal single seated valves is

.01% of rated flow, which is the industry standard. In

applications where .01% flow will cause pressure or temperature override, seat lapping may be required. (See

"Seat Lapping Procedure", page 14.)

Lifts in the Return Line on Heat Exchanger

Applications

An elevated return line on a heat exchanger requires

steam pressure to lift condensate. Condensate cannot

drain from the heat exchanger shell until the internal pressure is sufficient to lift the condensate. The steam pressure required to lift the condensate remains in the heat

exchanger shell. This can then cause a temperature

overshoot and wide swings in temperature.

Steam Traps Undersized

Undersized steam traps can cause condensate to back up

in a heat exchanger shell. Backed up condensate covers

some of the tubes, reducing the heat transfer surface. If

condensate backs up it may appear that the regulator is

undersized. When a temperature regulator is installed in

the steam supply, size the steam trap based on 1/2 psig

pressure differential.

Failure to Install System Recirculation Pumps

A system without a recirculation pump will have wide temperature fluctuations during start-up. The regulator will

also overshoot the temperature when system steam flow

stops, trapping steam in the heat exchanger shell due to

the response time required to close the regulator.

Low or Improper Outlet Pressure

Cause: Low inlet pressure

Solution: Correct supply pressure from the boiler.

Fully open supply valve.

Check for upstream blockage.

Cause: The regulator is not properly adjusted.

Solution:

Readjust the pilot to desired operating pressure.

Delivery Pressure High or Overrides

Cause: Bypass valve is open.

Solution: Close bypass valve.

Cause: The regulator is not properly adjusted.

Solution: Readjust the pilot to desired operating

pressure.

Cause: Bleed orifice plugged.

Solution: Clean or replace with new bleed orifice.

Cause: Dirt under the seat of main valve.

Solution: Remove top cover plate and clean the seat

surfaces.

Cause: Pilot valve malfunction.

Solution: Refer to pilot valve test and repair procedures.

Cause: Main valve oversized.

Solution: Check valve capacity against system load.

Replace with correct size valve.

Delivery Pressure or Temperature Erratic

Cause: Pressure momentarily overshoots and then

recedes to set pressure.

Solution: Valve is not responding fast enough to react to

the system. Drilling the bleed orifice out to

3/32" can increase the valve closing response

time. (Do not drill bleed orifice if a temperature

pilot is used, as temperature accuracy will be

decreased. Do not drill bleed orifice if differential pressure across the main valve is less than

40 psi as the valve may not fully open).

Cause: Sensing line improperly located in the system.

Solution: Relocate the sensing line to stable pressure

area.

Cause: Temperature bulb improperly located.

Solution: Relocate sensing bulb to make sure it is fully

inserted into the system flow path.

Cause: Feedback control line plugged.

Solution: Remove and clean.

Cause: Bleed orifice missing or worn.

Solution: Replace with new bleed orifice.

12

Page 13

MAIN VALVE TESTING

All tests can be performed on main valve while it remains

installed in the steam system, if there are gate valves

ocated upstream and downstream of the main valve.

l

1. Isolate the main valve from steam pressure by closing

the gate valves that are located upstream and downstream of the main valve.

2. If the main valve has a spring pilot or air pilot installed

on it, close the shut off valve in the feedback line to

the spring or air pilot.

3. Disconnect the pilot valves from the main valve.

4. Remove the orifice fitting from the 1/8" NPT port

located on the side of the main valve.

Test for Leakage between Plug and Seat:

1. Attach an air line to the 1/4" NPT port located on the

side of the main valve inlet.

2. Apply air to the main valve inlet.

3. Check for air leakage from the 1/8" NPT port on the

side of the main valve outlet.

• Only a small amount of leakage is allowable.

• Excessive leakage indicates either worn seat or

plug, or the seat is held open by dirt.

• Clean seat and plug and retest.

• Replace parts if necessary.

Test for Restricted Movement:

1. Attach an air line containing a pressure regulating

alve (PRV) and pressure gauge to the 1/8 NPT port

v

located in the center of the lower diaphragm case of

the main valve.

2. Disassemble the top cover from the main valve.

3. While adjusting the PRV in the air line:

• Look in the top of the main valve

• Slowly increase and decrease the air pressure to

the lower diaphragm case.

4. Increase and decrease the air pressure several times.

5. Watch the movement of the main valve stem and plug.

6. Check for jerky movement or no movement.

• The valve should stroke smoothly between the fully

closed and fully open positions within the following

pressure limits:

Pressure at Pressure at Full

Main Valve Start of Stroke Stroke

Model psig (bar) psig (bar)

2100 2.0 to 6.5 18.0 to 29.0

2200 (0.14 to 4.5) (1.2 to 2.0)

2300

2150 0.5 to 2.0 3.5 to 7.0

2250 (0.03 to 0.14) (0.24 to 5)

Test for Damaged Diaphragm:

1. Plug the 1/4 NPT port on the side of the main valve

inlet.

2. Attach an air line containing a pressure regulating

valve (PRV) and pressure gauge to the 1/8 NPT port

located in the center of the lower diaphragm case of

the main valve.

3. While adjusting the PRV in the air line, slowly

increase the air pressure on the main valve

diaphragms from 0 psig to 30 psig (0 to 2.1 bar).

Slowly decrease the pressure back to 0 psig (0 bar).

Repeat this step several times.

4. Check for air leakage from the open 1/8" NPT port on

the side on the main valve outlet while the air pressure is being cycled.

• No air leakage is permitted.

• Large air leakage indicates the diaphragms are

cracked or broken.

• Replace new diaphragms as needed.

• Jerky movement indicates the valve stem and

bushing are worn or diaphragms are damaged.

• Test for damaged diaphragms as described above.

• If diaphragms are not damaged, install a new stem

and bushing.

13

Page 14

MAIN VALVE REPAIR

Main Valve Repair

Main valves can be repaired without removing them from

the piping.

Note: If a specific problem has been located during testing,

only complete the steps required to complete repair of the

damaged parts.

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Remove the main valve top cover plate (and stem top

guide bushing on larger units).

3. Connect a source of regulated air pressure to the 1/8"

NPT port located in the center of the lower diaphragm

case of the main valve.

4. Load the main valve diaphragm chamber with 60-80

psig (4.2 to 5.6 bar) air to fully open the main valve

seat.

5. Remove the stem nut, lock washer and plug from the

stem by using an open end wrench on the stem nut

and a hex Allen key in the end of the stem to keep the

stem from rotating.

pressure from the main valve diaphragm with these

parts off because the spring tension will damage the

diaphragms.

Note: If the stem unscrews from the diaphragm button,

remove the entire stem assembly from the main valve.

• Carefully clamp on the stem with a pair of channel

locks well above the guide bushing area and remove

the nut, washer and plug.

• Reinstall the valve stem using a hex wrench in the

end of the stem to tighten the stem into the diaphragm

button. See "Tightening Torque for Series 2000 Main

Valve" chart, page 15.

6. Inspect the valve seat and plug for deep scratches or

deposits.

Replace if necessary. A special seat tool is available

•

to remove the seat from the body.

14

Important: do not release the air

• Heating the seat with a torch may be required for

eat removal.

s

7. Coat the threads and lower edge of seat flange with a

high temperature non-hardening sealant before

installing a new seat.

8. Install a new seat. A new plug and seat will require

lapping. See "Main Valve Seat Lapping Procedures,"

below.

9. To continue disassembly:

• Replace plug and stem nut onto stem to prevent

damage to diaphragm when air pressure is released.

Do not fully tighten nut.

• Relieve air pressure from the diaphragm cover.

• Unbolt the diaphragm cover and remove the

diaphragms.

• Compress the spring to lift the plug off the seat.

• Remove the plug and allow the spring to relax.

• Remove the button, stem and spring.

10. Clean the stem and guide bushing. Replace if worn.

11. Reassemble the valve in the reverse order of the

disassembly procedure described above. See

"Tightening Torque for Series 2000 Main Valve" chart,

page 15.

12. Return valve to service.

13. Check for proper operation.

Main Valve Seat Lapping Procedures

Main valve seat lapping may be required on new

installations where dead end service is required.

Lapping is also required when a new plug and seat

are installed in a main valve.

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Remove the main valve top cover plate. On larger

units, remove the stem top guide bushing.

3. Connect a source of regulated air pressure to the 1/8"

NPT port located in the center of the lower diaphragm

case of the main valve.

4. Load the main valve diaphragm chamber with 60-80

psig air to fully open the main valve seat.

5. Remove the stem nut, lock washer and plug from the

stem by using an open end wrench on the stem nut

and a hex Allen key in the end of the stem to keep the

stem from rotating.

pressure from the main valve diaphragm with these

parts off because the spring tension will damage the

diaphragms.

Note: If the stem unscrews from the diaphragm button,

remove the entire stem assembly from the main

valve.

• Carefully clamp on the stem with a pair of channel

locks well above the guide bushing area and

remove

the nut, washer and plug.

• Reinstall the valve stem using a hex wrench in the

end of the stem to tighten the stem into the

diaphragm button. See "Tightening Torque for

Important: do not release the air

Page 15

6. Inspect the valve seat and plug for deep scratches or

deposits. Clean or replace if necessary.

7. Place a light film of valve lapping compound on the

plug seating surface. Using 400 grit or finer lapping

compound is recommended. (Generally available from

automotive supply stores.)

8. Slide the plug on the valve stem. Do not install the

ock washer or nut for lapping.

l

9. Slowly reduce the air loading on the main valve

diaphragm until the plug touches on the valve seat.

• Approximately 5 psig on Series 2100, 2200 and

2300 main valves.

• 1 to 2 psig on Series 2150 and 2250 main valves.

10. Use the following procedure:

• Rotate the plug back and forth about 90 degrees.

• Use light hand pressure.

• Lap for about 30 seconds.

• Rotate the plug 120 degrees and repeat.

• Rotate the plug another 120 degrees and repeat.

• Remove the plug and use a clean cloth to wipe

the plug.

• The plug and seat should show a dull area where

the lapping occurred.

• Inspect to make sure the plug and seat made

contact completely around the diameter.

• If the contact area is not completely around the

diameter repeat the process.

11. Increase the air loading to approximately 60-80 psig.

Make sure the plug and seat are clean. Reinstall the

plug, lock washer and nut. See "Tightening Torque for

Series 2000 Main Valve" chart, below, for torque

specification.

12. Reduce the air loading pressure on the main valve

diaphragm area to 0 psig (0 bar). Observe the stem

movement for smooth stroking.

13. Replace top cover and stem guide (if used) using a

new gasket. Tighten the cover bolts to torque shown

in the "Tightening Torque for Series 2000 Main Valve"

chart, below.

14. Reconnect the steam tubing line to the main valve

diaphragm. Slowly apply steam pressure and inspect

for external leaks. Tighten as necessary or replace

components to stop any leaks.

15. Return the main valve to service.

Main Valve Diaphragm Replacement

A leak in the diaphragm will not allow full steam pressure

to build up under the diaphragm and the valve will not

fully open.

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Remove the copper tubing line that connects to the

diaphragm cover.

3. Loosen all nuts on diaphragm cover bolts.

4. Remove the bolts completely from only one side of

the valve.

5. Use a pair of needlenose pliers to remove the

diaphragms from the side of the valve without the bolts.

6. Insert new diaphragms and replace the bolts. Using a

star pattern, tighten the diaphragm cover bolts, a

minimum of three times, to the torque value shown in

the "Tightening Torque for Series 2000 Main Valve"

chart below.

NOTE: On 2150 and 2250 main valves, connect a

source of regulated air pressure to the 1/4" NPT port

located on the opposite side of the valve from the pilot

inlet line. Load the inlet side of the valve with 30-50

psig (2.1 to 3.5 bar) pressure before tightening

diaphragm cover bolts.

7. Reinstall the copper tubing line and return valve to

service. Inspect for leaks.

Tightening Torque for Series 2000 Main Valve

* Tighten cover bolts a minimum of three times using an even star pattern.

Main Stem Nut Top Diaphragm

Valve to to Cover Cover

Size Button Stem Seat Bolts * Bolts *

in. mm lbf-ft N-m lbf-ft N-m lbf-ft N-m lbf-ft N-m lbf-ft N-m

1/2 NPT 68 11 15 10 14 31 42 31 42

3/4 NPT 68 11 15 10 14 31 42 31 42

1 NPT 68 11 15 10 14 31 42 31 42

1-1/4 NPT 20 27 20 27 20 27 75 102 31 42

1-1/2 NPT 20 27 20 27 20 27 75 102 31 42

2 NPT 20 27 20 27 20 27 75 102 75 102

2 50 20 27 20 27 20 27 75 102 75 102

2-1/2 65 31 42 43 58 30 41 150 204 75 102

3 80 31 42 43 58 30 41 150 204 75 102

4 100 31 42 43 58 40 54 150 204 150 204

6 150 31 42 43 58 50 68 150 204 250 340

15

Page 16

!

!

PILOT VALVE TESTING AND REPAIR

CAUTION

Close all steam lines that could pressurize any of the valve chambers before disassembling the system. Use caution

when opening any section or valve chamber as there may be hot condensate trapped inside. Failure to do so may

result in burns.

SPRING PRESSURE PILOT

Spring Pilot Quick Test

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Disconnect the copper tubing line from the main valve

diaphragm. Point tubing in a direction to prevent

damage or burns.

CAUTION

Quick test is done using live steam. Point tubing in a

direction to prevent property damage or burns. To prevent

serious burns, wear heat resistant gloves. Failure to follow this warning may result in property damage, personal

injury or death.

3. Release compression on adjusting spring by loosening

adjusting nuts an equal amount

4. If used in conjunction with a temperature pilot, set

temperature setting higher than the bulb temperature.

5. Slightly open the shut off valve in the steam supply to

the main valve and allow pressure to build.

6. Gradually compress the adjusting spring by tightening

adjusting nuts equally until steam passes from the

open end of the copper tubing line.

• When used in conjunction with a temperature pilot,

adjust pilot temperature setting to be higher than

the bulb temperature.

• The steam flow should discharge from the tubing

line. Release some compression on the adjusting

spring to reduce the pressure and the steam flow

should stop.

• A slight leakage is OK.

• Repeat several times.

• If the pilot does not start and stop the steam supply,

the pilot should be repaired or replaced.

7. If the pilot responds properly, the problem is elsewhere

in the system

Spring Pilot Bench Tests

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Disconnect the copper tubing lines and feedback line.

Disconnect the pipe union and remove the pilots. If

more than one pilot is used, unscrewing the 1/4" NPT

pipe nipples should separate them.

3. Mount the spring pilot in a vice to test.

4. Release compression on adjusting spring by loosening

adjusting nuts an equal amount.

5. Plug the 1/4" NPT FEEDBACK LINE port.

6. Install a 1/8" NPT pipe with a pressure gauge and

shut off valve in the SIGNAL LINE port.

7. Connect a 30 psig air supply to the 1/4" NPT pilot

INLET port.

8. Test for seat and disc leakage:

• Open shut off valve from SIGNAL LINE port.

• Apply air pressure at the INLET port.

• Check for leakage from the SIGNAL LINE port.

• If excessive leakage is indicated, replace the disc

and seat. See "Spring Pressure Pilot Repair", page 17.

9. Test for Valve movement.

•

With 30 psig air pressure at the pilot INLET connection, close the shut off valve in the SIGNAL LINE

pipe, and keep the FEEDBACK LINE port plugged.

• Adjust the spring compression loading force until

the outlet pressure is equal to 1/2 of air inlet supply.

• Slowly open and close the shut off valve in the

SIGNAL LINE pipe several times, the pressure

should be the same each time the shut off valve is

closed.

• The pressure should respond smoothly.

• If the pressure changes each time or if the reaction

of the pressure gauge is jerky, the pilot valve

movement is restricted.

• Inspect the internal components for dirt or wear.

Replace parts necessary. See "Spring Pressure

Pilot Repair."

10. Diaphragm test.

•

With 30 psig air pressure at the pilot INLET connection, close the shut off valve in the SIGNAL LINE

pipe, and keep the FEEDBACK LINE port plugged.

• Adjust the spring compression loading force until

the outlet pressure is equal to 1/2 of air inlet supply.

• Check for air leakage around the diaphragm under

the adjusting spring and pressure plate.

• If air is leaking, replace the diaphragms. See

"Spring Pressure Pilot Repair", page 17.

16

Page 17

SPRING PILOT REPAIR

yyy

yyy

yyyyy

yyyyy

yyyyy

yyyyy

yyy

yyy

yyy

yyy

yyy

yyy

yyy

y

y

yy

yy

yy

yyy

yyy

yyy

yyy

yyy

yyy

yyyyy

yyyyy

yyyyy

yyyyy

yyyy

1

2

3

4

5

7

10

12

17

16

15

6

8

9

11

13

14

1/8 NPT

1/4 NPT

Disassembly

1. Isolate the main valve from the steam line. Make

ure the internal pressure is 0 psig (0 bar) and allow

s

the valve to cool to prevent injury.

. Disconnect the copper tubing lines and feedback line.

2

Disconnect the pipe union and remove the pilots from

the main valve. If more than one pilot is used,

unscrewing the 1/4" NPT pipe nipples should separate

them.

3. Mount spring pilot in vise with adjusting spring up.

4. Release compression on adjusting spring (2) by

loosening adjusting nuts (1) an equal amount.

5. Remove diaphragm nuts (3) and lift off cowl (4). Lift

out diaphragm assembly (5, 6 & 7).

6. Disassemble diaphragm assembly by removing

diaphragm screw (7) from pressure plate (5).

7. Remove blind flange bolts (16) and take off blind

flange (15). Remove screen (12) and gasket (17).

8. Hold the pusher plate (8) and remove stem nuts (14).

Lift out stem assembly (8 & 11) and valve spring (9).

The disc (13) will drop off.

9. If the seat ring (10) requires replacement, remove it

from pilot body with a socket wrench.

Spring Pilot Inspection

1. Examine the seat and disc sealing surfaces for nicks

2. Examine the stem for build-up of pipeline contami-

Spring Pilot Seat Lapping Operations

Lap sparingly using 500 grit lapping compound and

light pressure. Heavy grinding may cause galling,

wide sealing surfaces and a grooved disc, all of

which tend to produce leakage.

Refer to lapping procedures in "Seat, Disc and Stem

Replacement" below. After the sealing surfaces are

lapped in, disassemble and clean all parts.

Seat, Disc and Stem Replacement

1. Clean the body threads of old sealing compound

2. Lap in stem to disc joint with lapping compound.

3. Secure disc (13) to stem (11) with a stem nut (14).

4. Apply lapping compound to the disc and lap in the

or other signs of damage by pipeline debris. Slight

imperfections may be removed by lapping the

surfaces together. Otherwise the seat and disc must

be replaced.

nants or erosion. Remove any build-up with a wire

brush and polish with very fine crocus cloth. Work

carefully to avoid bending the stem.

using a wire brush. Apply new sealing compound

(Copalite or equal) to the shoulder of seat ring. Let

stand until tacky before installing in pilot body.

Insert this assembly into pilot body (omit valve spring).

seat to disc joint. The stem is slotted for rotation with

a screwdriver.

5. When lapping is complete, use a clean cloth to wipe

the disc (13), seat ring (10) and stem (11).

6. Screw pusher plate (8) on stem (11). Holding disc

against its seat, adjust the pusher plate (8) so that

dimension C = 11/64" (4.4mm). A pilot travel setting

gage is supplied with each repair kit.

7. Remove stem nut, being careful not to disturb the

pusher plate adjustment. Lift stem out the top of the

pilot. Grind off stem projection B flush with upper

surface of the pusher plate.

17

Page 18

8. Reinsert stem into pilot body. Install disc and stem

!

yyy

yyy

yyy

yyy

yyy

yyyy

yyyy

yyyy

yyyy

yyyy

yyyy

yyyy

yyy

yyy

yyy

8

9

11

13

14

C

Gage

A

Prick Punch

Stem Projection "B" to be

Removed as per Instructions

nut. Check dimension C and, if correct, lock the

adjustment by prick punching the stem threads at

several points. Work carefully to avoid bending the stem.

9. Scrape away burrs raised by the prick punching.

Upper surface of pusher plate must be smooth and

flat.

10. Check that the valve travel A = 3/64" (1.2mm). This

need not be exact. Stem should move smoothly.

Binding indicates a bent stem.

11. Remove stem nut and disc; withdraw stem. Install

stem with valve spring disc and both stem nuts in

place.

Spring Pilot Assembly

1. Reassemble the pilot in the reverse order of the

disassembly procedure described above.

2. When replacing diaphragms, apply sealing compound

(Copalite or equal) sparingly to the shoulder of the

diaphragm screw (7).

IR PRESSURE PILOT

A

Air Pilot Quick Test

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

ool to prevent injury.

c

2. Disconnect the copper tubing line from the main valve

diaphragm. Point tubing in a direction to prevent

damage or burns.

CAUTION

Quick test is done using live steam. Point tubing in a

direction to prevent property damage or burns. To prevent

serious burns, wear heat resistant gloves. Failure to follow this warning may result in property damage, personal

injury or death.

3. Back off air loading pressure.

4. If used in conjunction with a temperature pilot, set

temperature setting higher than the bulb temperature.

5. Slightly open the shut off valve in the steam supply to

the main valve and allow pressure to build.

Pressure

Range Number of

Psig (bar) Spring Color Diaphragms

2 – 30 (0.1 – 2.0) BLUE 2

5 – 60 (0.3 – 4.1) RED 2

20 – 175 (1.4 – 11.9) GOLD 3

3. When replacing gaskets, be sure that any serrated

sealing surfaces are cleaned of old gasket material.

18

6. Increase the air loading pressure on the pilot until

steam passes from the open end of the copper tubing

line.

• When used in conjunction with a temperature pilot,

adjust pilot temperature setting to be higher than

the bulb temperature.

• The steam flow should discharge from the tubing

line. Lower air pressure and the flow should stop.

• A slight leakage is OK.

• Repeat several times.

• If the pilot does not start and stop the steam supply,

the pilot should be repaired or replaced.

7. If the pilot responds properly the problem is elsewhere in the system.

Page 19

Air Pilot Bench Tests

y

yy

y

y

yy

y

yy

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Disconnect the copper tubing lines and feedback line.

Disconnect the pipe union and remove the pilots. If

more than one pilot is used, unscrewing the 1/4 " NPT

pipe nipples should separate them.

3. Mount individual air pilot in a vice to test.

4. Plug the 1/4" NPT FEEDBACK tapping.

5. Install a 1/8" NPT pipe with a pressure gauge and

shut off valve in the SIGNAL port.

6. Connect a 30 psig air supply to the pilot IN connection.

7. Test for seat and ball leakage.

• Open shut off valve from SIGNAL port.

• Apply air pressure at the IN port.

• Check for leakage from the SIGNAL port. Only a

small amount of leakage is allowable.

• If excessive leakage is indicated replace the ball

and seat. See "Air Pilot Repair."

8. Test for Valve Movement.

• With 30 psig air pressure at the pilot Inlet connection,

close the shut off valve in the SIGNAL pipe.

•

Load air pressure on the top of the pilot until pressure

is equal to 1/2 of air supply.

• Slowly open and close the shut off valve several

times, the pressure should be the same each time

the shut off valve is closed.

• The pressure should respond smoothly.

• If the pressure changes each time or if the reaction

of the pressure gauge is jerky, the pilot valve

ovement is restricted.

m

• Inspect the internal components for dirt or wear.

. Diaphragm test.

9

AP-1A:

With a 30 psig air supply to the FEEDBACK tapping,

•

the SIGNAL line and IN tapings plugged, check for

air leakage from the top of the pilot.

• If air is leaking, replace the diaphragms.

AP-4A:

•

With a 30 psig air supply to the FEEDBACK tapping,

the SIGNAL line and IN tapings plugged, check for

air leakage from the vent hole of the pilot.

• If air is leaking, replace the lower diaphragms.

• With a 30 psig air supply to the top of the pilot, the

SIGNAL line taping, FEEDBACK taping and IN

taping plugged, check for air leakage from the vent

hole of the pilot.

• If air is leaking, replace the upper diaphragms.

• With a 30 psig air supply to the top of the pilot, the

SIGNAL line taping, FEEDBACK taping and IN

taping plugged, check for air leakage from the vent

hole of the pilot.

• If air is leaking, replace the upper diaphragms.

Air Pilot Disassembly

Model AP-1A Model AP-4A

HOUSING

UPPER DIAPHRAGM

BUTTON

DIAPHRAGM(S)

LOWER DIAPHRAGM

BUTTON

STEM

BODY

BALL

SEAT GASKET

SEAT

STRAINER

SPRING

PLUG GASKET

BOTTOM

PLUG

SPRING

SPACER

VENT

HOLE

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig (0 bar) and allow the

valve to cool to prevent injury.

2. Disconnect the copper tubing lines and feedback line.

3. Disconnect the pipe union and remove the pilots from

the main valve.

4. If more than one pilot is used, unscrewing the 1/4"

NPT pipe nipples should separate them.

5. Mount air pilot in vise with bottom up and unscrew

the plug.

6. Remove the bottom plug and brass washer. Remove

from vice and turn upright. The spring, ball, strainer

and stem will drop out.

Note: The bottom portion of Model AP-1A and AP-4A

is the same. Model AP-4A has a small spring spacer

below the spring.

7. Mount the pilot in the vice again with the bottom up.

8. Remove the seat using a 9/16" thinwall socket.

19

Page 20

!

!

!

Air Pilot Disassembly (cont’d)

9. Inspect and clean all parts and gasket sealing areas.

eplace any worn or damaged parts.

R

• Reassemble using non-hardening sealant on the

plug threads.

• Note: The hollowed out end of the stem goes

against the ball.

10. To service the upper end of the pilot:

• Mount it in a vice with the top up.

• Unscrew and remove the upper housing.

11. Remove upper diaphragm button, diaphragm(s) and

lower diaphragm button.

Note: Model AP-4A has 2 sets of diaphragms and a

pusher spacer mounted between them.

12. Inspect and clean all parts, replace diaphragm(s) and

worn or defective items.

13. Diaphragms should be biased down by using air

pressure in the top port before finally tightening

housing to body.

14. Install stem with the counterbore end facing the ball.

(See magnified view of the stem and ball below.) The

flat end of the stem should face the lower diaphragm

button.

TEMPERATURE PILOT

Temperature Pilot Testing

CAUTION

Before removing sensing probe, the system must be

drained and pressure relieved and cooled, unless a

separable well is provided. Failure to follow this

procedure may result in serious burns.

CAUTION

Temperature pilot bulb will be inserted in the heated fluid.

Before immersing check compatibility of copper bulb with

the heated fluid. Failure to follow this caution may result

in serious burns.

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Disconnect the copper tubing line from the main valve

diaphragm. Point tubing in a direction to prevent

damage or burns.

Tightening Torque: Models AP-1A and AP-4A Air Pilots

lbf-ft N-m

Bottom Cap 80 – 90 108 – 122

Housing to Body 100 – 120 136 – 163

Model AP-4A: Air 150 – 170 204 – 231

cover to housing

CAUTION

This test is done using live steam. Point tubing in a direction

to prevent property damage or burns. To prevent serious

burns, wear heat resistant gloves. Failure to follow this

warning may result in property damage, personal injury or

death.

3. Back off temperature setting by turning the temperature knob. A setscrew in the adjusting knob locks the

setting. Loosen the setscrew to turn the knob.

4. If used in conjunction with a spring pilot make sure

the spring adjustment has the spring pilot open.

5. Slightly open the shut off valve in the steam supply to

the main valve and allow pressure to build.

6. Increase the temperature setting on the pilot until

steam passes from the open end of the copper tubing

line.

7. Back off temperature setting and the steam flow

should stop. A slight leakage is OK.

8. Repeat several times.

9. If the pilot does not start and stop the steam supply it

should be repaired or replaced.

10. If the pilot responds properly the problem is elsewhere

in the system.

20

Page 21

Temperature Pilot Repair

yy

yy

y

y

y

150…F

70 …C 60 …C 50 …C

125…F

1. Put pilot in vise with top up. Remove the bottom plug

(4). The strainer (8), spring (5) and button (6) should

drop out when the bottom plug is removed.

2. Remove the seat (2) using a 9/16" thinwall socket.

The valve plug (9) will drop out also.

Temperature Pilot

15. ACTUATOR ASSEMBLY

3. Clean and inspect all parts, lap plug (9) and seat (2)

with 400 grit lapping compound. Replace if necessary.

4. Apply non-hardening sealant to bottom plug (4)

threads. Reassemble pilot.

5. Retest pilot.

◆ ADJUSTMENT KNOB

◆

ALLEN LOCK SCREW

◆ BELLOWS

HOUSING

◆ BULB

◆ CALIBRATION

SET SCREW

12. ADJUSTMENT

SLEEVE

✽

1. BODY

3. GASKET

6. BUTTON

5. SPRING

14 .PUSH

ROD

13. OVERHEAT

ASSEMBLY

11. GASKET

10. SEAL

BELLOWS

ASSEMBLY

9. PLUG

2. SEAT

Notes: ◆ Assembly not required

in the field.

✽

Numbers indicate

assembly sequence.

8. STRAINER

4. BOTTOM

PLUG

7. GASKET

21

Page 22

Temperature Actuator Assembly Testing

1. Loosen calibration set screw on indicator ring. Drop

away from dial.

. Loosen Allenlock set screw on knob assembly.

2

Unscrew adjustment knob assembly from actuator.

3. Insert flat ended smooth wooden dowel into the

bellows.

Note: Bellows should be firm. If it is spongy, the

actuator has lost its liquid fill. For more precise testing,

use a depth micrometer. The bellows should move

0.00057 inch (0.0144mm) per degree change of the

sensing bulb.

4. If the actuator does not operate properly, it must be

replaced.

Temperature Actuator Assembly Installation

1. Loosen the calibration ring screw and the adjustment

knob screw.

2. Under normal conditions. Slowly rotate the knob

counterclockwise to increase temperature, or clockwise to decrease temperature to achieve the desired

system temperature.

3. Allow system temperature to stabilize at the desired

set-point temperature and normal load conditions.

Securely tighten the adjustment knob set screw.

. Rotate calibration ring so that the indicator arrow is in

4

alignment with the desired set-point temperature.

Securely tighten the calibration ring set screw.

Seal Bellows Replacement Assembly

. Remove actuator assembly. Complete steps 1-2

1

under "Temperature Actuator Assembly Testing"

above.

2. Turn body assembly over with bottom plug up. The

push rod and overheat assembly will drop out.

3. Place body assembly in vise with adjustment sleeve

turned up.

4. Unthread adjustment sleeve from body.

5. Remove from vise and turn body over with bottom

plug up. The brass washer, bellows assembly and

plug will drop out.

6. Inspect parts and replace as necessary.

7. Reassemble and recalibrate actuator. Complete steps

1-5 under "Temperature Actuator Assembly

Installation" above.

Tightening Torque for Temperature Pilots

lbf-ft N-m

Bottom Cap 80 – 90 108 – 122

Brass Sleve to Body 80 – 90 108 – 122

22

Page 23

23

Page 24

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. HS-601G October 2012 Part No. 510549

Loading...

Loading...