Page 1

INSTRUCTION MANUAL

!

HS-600

REVISION D

Hoffman Specialty

®

Pilot Mounting Hardware Kits

Series 2000

Pressure and/or Temperature

Steam Regulators

• The mounting hardware kits contain all of the hardware

required to install the pilot valve(s) on the main valve.

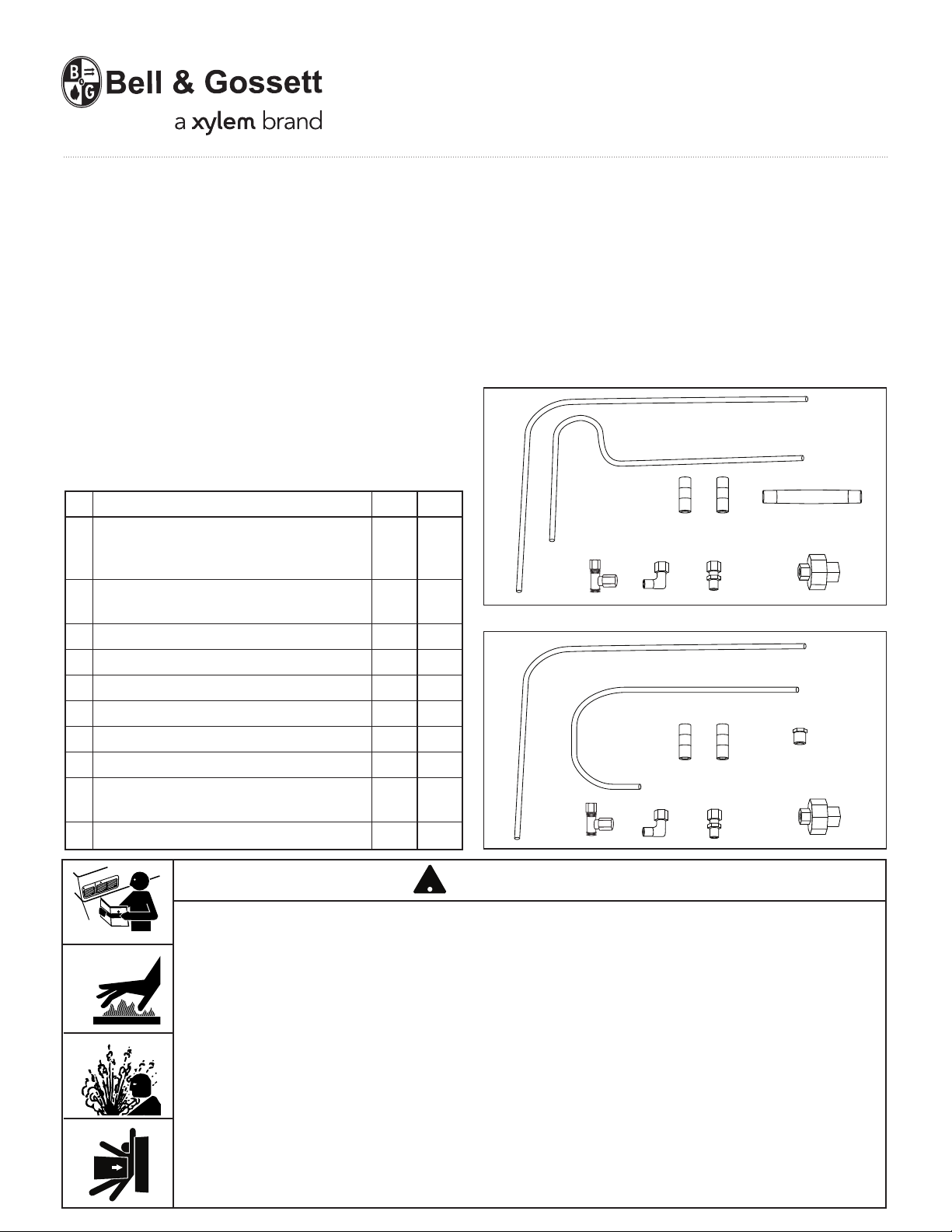

No. Part Description Kit A Kit B

1 L-Tubing; from main valve bottom

elbow connection to T-fitting XX

branch connection.

2 S-Tubing; from bleed orifice fitting

to T-fitting on pilot.

X

3 Nipple; 1⁄4" x 4" (8 x 101mm) X

4 Nipple; 1⁄4" x 11⁄2" (8 x 38mm) (2) XX

5 Union Connection XX

6 T-fitting XX

7 L-fitting XX

8 Bushing X

9 J-Tubing; from bleed orifice fitting

to T-fitting on pilot.

X

101⁄8" Tubing Connector XX

Kit A - For spring, air or in combination with temperature

or solenoid pilots.

Kit B - For temperature pilot or solenoid pilot only.

1

2

4

1076

1

9

4

10

76

3

5

8

5

CAUTION

WARNING

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of steam systems in accordance with all applicable codes

and ordinances.

• To prevent serious burns, wear heat resistant gloves when opening and closing steam

valves, or handling hot equipment.

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30m) from

the front of the pipe opening.

• To prevent property damage, personal injury, or death, cap off the gate valves if they

are not connected to a drain and when they are not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury or death.

WARNING

Page 2

A

B

4

3

10

7

6

8

C

D

INSTALLATION PROCEDURE

STEP 1 - Prepare Hardware and Size Tubing

TOOLS NEEDED:

Tubing cutter, adjustable or pipe wrench.

Pipe sealant should be applied to all pipe threads.

•

Do not use PTFE tape.

Note: Follow manufacturers instructions for applying

pipe sealant. Keep sealant off of the first thread.

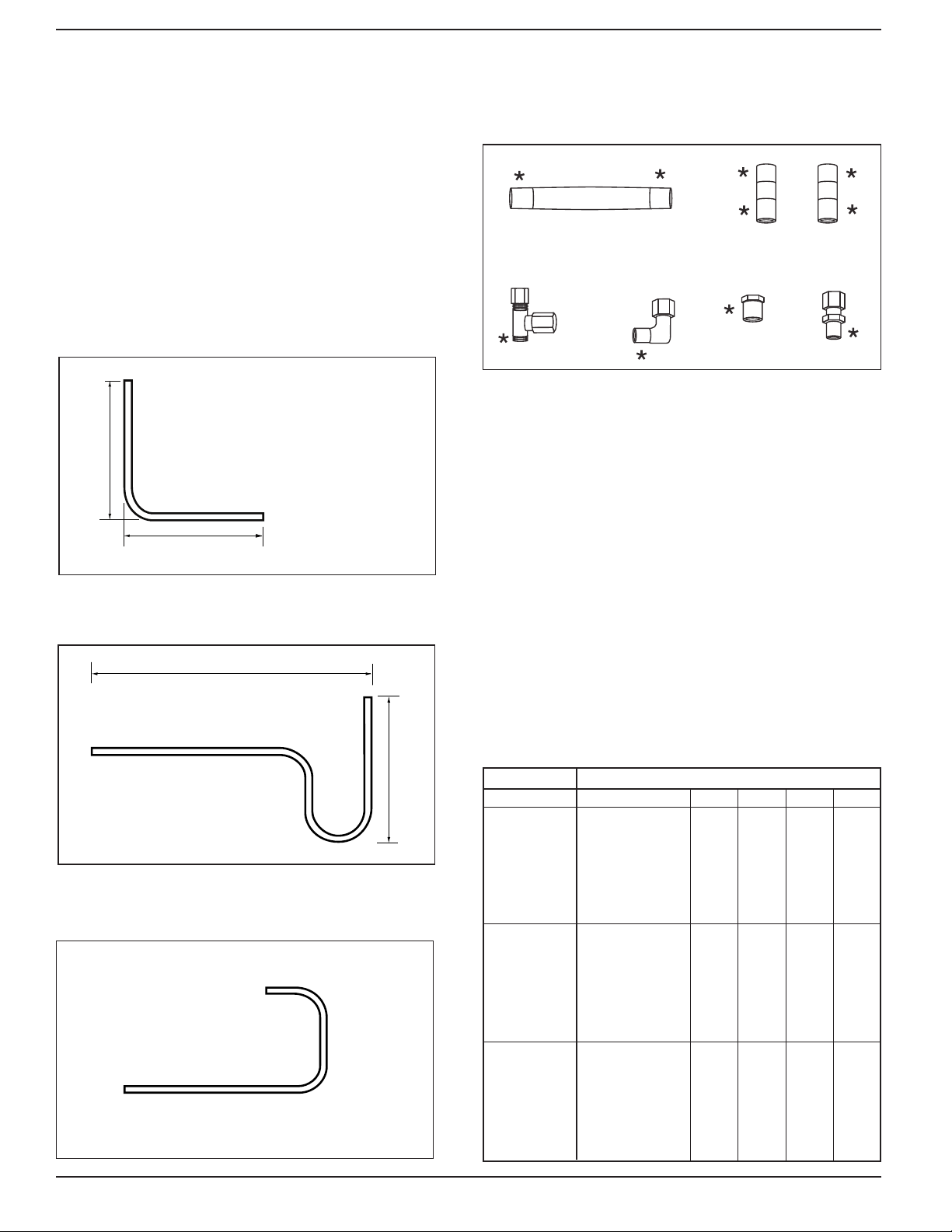

Tubing Lengths

1. L-Tube

Cut L- tube to appropriate A & B

dimensions listed on Tubing Length

chart.

pply Sealant Here

A

*

• The preformed copper tubing (included in the hardware

kits) may have to be shortened with a tubing cutter.

After cutting, ream the end to restore original tubing

diameter.

2. S-Tube

Cut S- tube to appropriate C & D

dimensions listed on Tubing

Length chart.

9. J-Tube

No cutting of J-tubes is required

Tubing Length Chart

No cutting is required if dimension is marked with an *

DIMENSIONS ( INCHES )

PILOT

Spring or air 2

Combinations 2

Temperature 2

MAIN VALVE SIZE

1

⁄2, 3⁄4, 1

1

1

⁄4 , 11⁄2

2

1

⁄2

3

4

6

1

⁄2, 3⁄4, 1

1

⁄4 , 11⁄2

1

2

1

⁄2

3

4

6

1

⁄2, 3⁄4, 1

1

⁄4 , 11⁄2

1

2

1

⁄2

3

4

6

ABCD

6

6

*811⁄16

1011⁄16

113⁄16

13

*16

6

6

*811⁄16

1011⁄16

113⁄16

13

*16

53⁄16

6

7

97⁄8

103⁄8

123⁄16

157⁄8

79⁄16

3

⁄4

81⁄16

81⁄4

91⁄8

97⁄16

105⁄16

11

⁄16

121⁄4

111⁄4

3

⁄4

113⁄4

*1115⁄16

1213⁄16

131⁄16

1315⁄16

11

⁄16

*147⁄8

715⁄16

89⁄16

7

⁄8

813⁄16

911⁄16

10

15

10

12

3

31⁄2

⁄8

6

6 3⁄8

6 3⁄8

6 3⁄8

6 3⁄8

6 3⁄8

6 3⁄8

*10

*10

*10

*10

*10

*10

*10

413⁄16

*511⁄16

515⁄16

67⁄16

715⁄16

*99⁄16

31⁄2

413⁄16

*511⁄16

515⁄16

67⁄16

715⁄16

*99⁄16

⁄16

2

Page 3

STEP 2 - Mounting Pilot Hardware

A

D

10 Pipe

Diameters

C

B

1/4 NPT

Feedback

Port

1/4 NPT Inlet

on opposite side

1/8 NPT

Signal Por t

(#6 Te e Goes

Here)

Pilot Installation Detail - For Reference Only

Applies to All Pilots

Numbers in parentheses refer to items in Kits A or B, pg. 1.

1. The pilot valve(s) can be installed on either side of the

main valve. The main valve is shipped with the Utubing and the bleed orifice installed for left-hand side

mounting of the pilot valve(s). If right-hand side

mounting of the pilot(s) is desired, the U-tubing and

the bleed orifice must be relocated to the opposite

sides of the main valve.

Note: Right-hand side and left-hand side positioning is

determined when the main valve inlet directly faces

the observer.

2. Make sure the bleed orifice is installed in the 1/8 NPT

tapping on the outlet end of the main valve on the

opposite side from the U-tubing. Remove the 1/8 NPT

pipe plug from the bleed orifice and replace it with a

1/8 NPT x 1/4" (6mm) OD tubing, straight compression

fitting (from the hardware kit #10).

3. Install the 1/4 NPT x 1-1/2" (38mm) nipple and half of

the union connection (from the hardware kit #4 and

#5) on the inlet end of the main valve.

Use the 1/4 NPT x 4" (101mm) nipple (#3) and the

4.

remaining

half of the union connection (from the hardware kit) to mount the first pilot. Mount additional

pilots as required using 1/4" steel pipe nipples.

5. Install the copper tee fitting (from the hardware kit #6)

in the 1/8 NPT signal tapping on the side of the

last pilot with the tee pointing down.

Identification of SPS Series Spring Pressure Pilot Ports

Install the L-fitting (from the hardware kit #7) in the tapping

6.

at the center of the main valve diaphragm cover.

Note: For steps 7 and 8, trim the length of the copper

tubing as required (see "Tubing Length Chart", page

2) to make a neat installation. Be sure to ream the

tube to the full tube diameter after cutting.

7. Install the S- or J-copper tubing (from the hardware

kit #2 or #9) from the tee fitting to the bleed orifice.

8. Install the L- copper tubing (from the hardware kit #1)

from the bottom of the tee fitting to the L-fitting in the

main valve diaphragm cover.

9. The 1/4" feedback tapping must be connected to the

downstream piping for either a spring or air pressure

pilot:

• Use 1/4 black steel pipe for the feedback line (B)

(not supplied with this kit).

• Install a 1/4 NPT shut off valve (D) and union (C)

in this line to allow service of the pilot while

operating the system on the by-pass line.

• The feedback line must pitch away from the pilot

to avoid erratic operation, excessive fouling and

eliminate water pockets.

When the regulator is used with a heat exchanger,

connect the feedback line (B) to the heat exchanger

shell. A tee fitting can be installed in the heat

exchanger for a vacuum breaker connection.

Identification of Air and Temperature Pilot Ports

Air Pilots

Signal

Inlet

Feedback

Signal

Inlet

Feedback

Temperature Pilot

Signal

Inlet

3

Page 4

Mounting Illustrations - For Reference Only

L-Fitting

L-Fitting

L-Fitting

L-Fitting

Feedback line connection not shown

*

Main Valve with Spring Pilot using Kit A

Main Valve with Solenoid and Pressure Pilots using Kit A

Main Valve

Bleed

Orifice

S-Tu bing

*

1/4" Union

Do Not Insulate

Below This Line

Main Valve with Temperature and Pressure Pilots using

Kit A

Main Valve

Bleed

Orifice

S-Tubing

Main Valve

Bleed

Orifice

1/4" Union

S-Tu bing

Do Not Insulate

Below This Line

Main Valve with Temperature Pilots Using Kit B

Main Valve

Bleed

Orifice

J-Tu b ing

*

1/4" Union

Do Not Insulate

Below This Line

TROUBLESHOOTING

Problem: Erratic Operation

Check: • Blockages/debris in orifice or lines

• Kinks in copper tubing

• Improper pitch in tubing/feedback line

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. HS-600D February 2013 Part No. 510603

*

1/4" Union

Do Not Insulate

Below This Line

SCHEDULE:

•Inspect annually or more often. In extreme

conditions refer to main valve operation

manual for testing procedure.

Loading...

Loading...