Page 1

INSTRUCTION MANUAL

!

HS-504

REVISION F

Hoffman Specialty

®

Series 1140 and 1141

Temperature Regulators

CAUTION

• FOLLOW ALL INSTALLATION AND

OPERATING INSTRUCTIONS.

• TURN OFF WATER OR STEAM

BEFORE SERVICING.

• WEAR HEAT-RESISTANT GLOVES

BEFORE MAKING ADJUSTMENTS.

• OPEN SUPPLY VALVES SLOWLY TO

PREVENT WATER HAMMER OR

SUDDEN SHOCK.

• HANDLE REGULATOR WITH

EXTREME CAUTION. DO NOT LIFT

REGULATOR BY ANY EXTERNAL

TUBING. DO NOT KINK OR TWIST

TUBING AND AVOID BENDING IT ON

A RADIUS LESS THAN 4" (100 mm).

• THE SENSING BULB MUST NOT BE

EXPOSED TO TEMPERATURES THAT

EXCEED THE RANGE LISTED ON THE

NAME PLATE.

• ALARMS OR CUT-OFFS SHOULD BE

INSTALLED ON CRITICAL

APPLICATIONS TO INDICATE

REGULATOR FAILURE. A LEAK

COULD CAUSE THE ACTUATOR TO

LOSE ITS CHARGE AND CAUSE THE

SYSTEM TO OVERHEAT.

• FAILURE TO FOLLOW THIS CAUTION

MAY RESULT IN PROPERTY DAMAGE

OR PERSONAL INJURY.

IMPORTANT: If you are uncertain as to the product’s

daptability for your application, please call the factory or

a

an authorized representative before installing or using the

product.

IMPORTANT: Do not install Series 1141 Temperature

Regulators in applications where ambient temperature

exceeds the regulator's set control temperature.

Page 2

OPERATING PRINCIPLE

C

B

A

Outlet

HOT

IN

COLD

IN

C

A

Inlet

OVER 10' (3 m)

PITCH TOWARD

STEAM REGULATOR

MAIN 1/2" PER FOOT

(

15 MM PER 0.3 m)

STEAM

MAIN

TRAP

10' (3 m) OR LESS

PITCH TOWARD STEAM REGULATOR

MAIN 1/2" PER FOOT

(15 mm per 0.3 m)

STEAM

MAIN

This Series 1140 regulator automatically controls the

flow of steam, water or other medium passing through

its valve by responding to temperature changes at the

ulb. The bulb contains a liquid which vaporizes when

b

heated. Vapor pressure generated in bulb is transmitted

through the capillary tubing to the flexible bellows which

moves the valve disc or plunger controlling the flow of

the medium through the valve. Movement of the bellows

is opposed by a spring, providing a means of adjustment. The regulator only controls within the temperature

range stamped on the name plate and can be adjusted

to control at any point within its range.

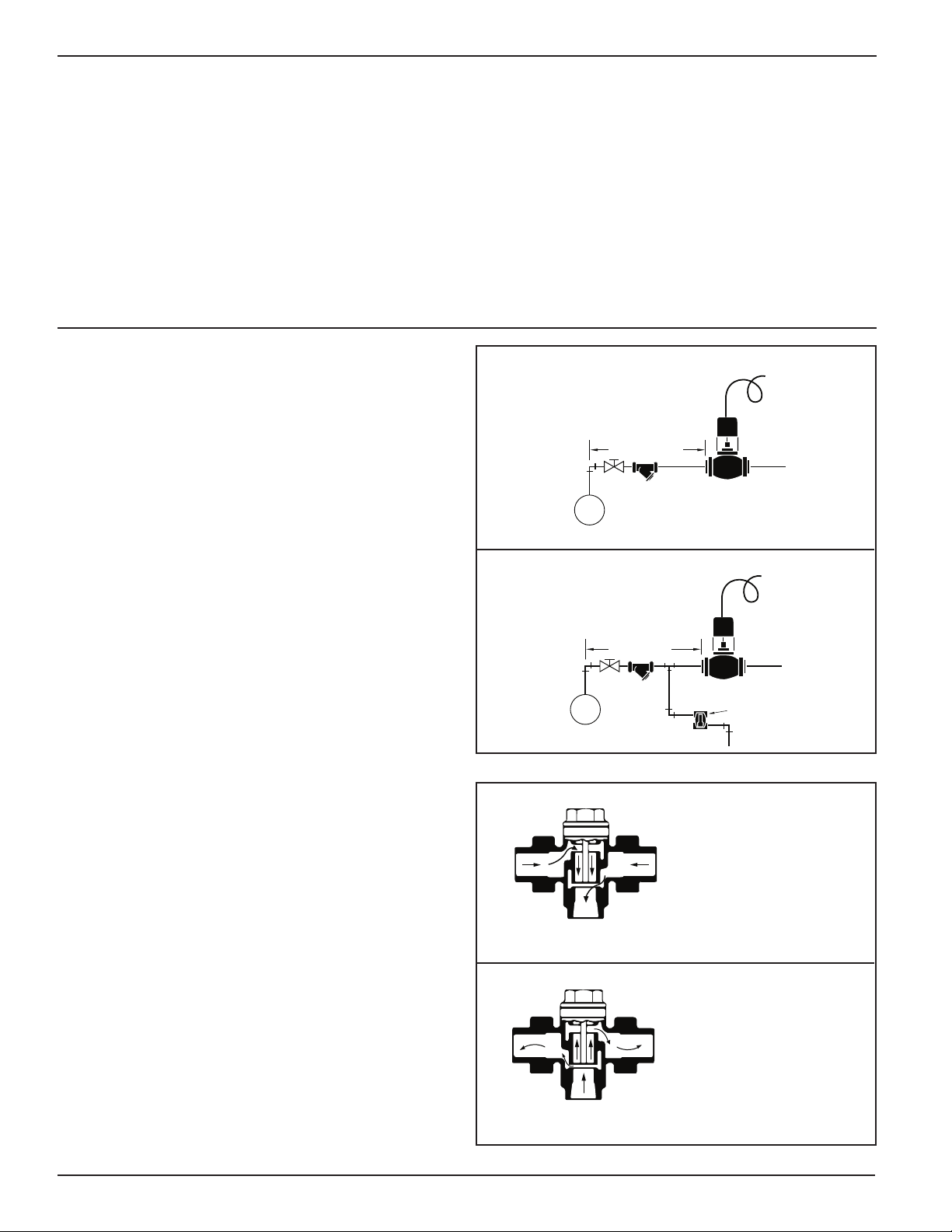

Valves used to control heating cycles are direct acting,

i.e., they shut off on increase of temperature.

Valves used to control cooling cycles are reverse acting,

i.e., they open on increase of temperature.

hree-way valves are used to mix hot and cold water,

T

or as diverting valves (see Figure 3 and 4 below).

It is necessary that the sensing bulb be completely

immersed in the fluid being controlled.

VALVE INSTALLATION

Before installing confirm proper sizing.

Oversized valves will not provide good

temperature control.

The location and installation of the regulating valve is

very important. A pipe line strainer must be installed

ahead of all double seated and balanced single seated

regulators. Single seated valves have built-in removable

strainers. However, it is still good practice to install a

strainer before all regulators and to blow all lines of

foreign matter on installation. See Figure No. 1.

The regulating valve should be installed as close as

possible to the unit being controlled. The regulator must

be installed in a vertical position, the bracket assembly

above the valve body. Install valve so that arrow cast on

valve body points in direction of steam or liquid flow.

When controlling steam, the heater or coil should be

properly vented and drained. A plain bucket trap should

not be used without some provision to eliminate air from

the coil. A drip trap should be installed ahead of all

steam regulators. See Figure No. 2.

When controlling flow of water used for cooling, the

valve can be installed on the supply end and may also

be installed on the discharge end of the unit. The

position depends largely on the particular case, as some

units, such as cylinder liners, cannot stand the full line

pressure.

When mixing hot and cold water, check valves should

be used on the supplies to the three-way valve, unless

the three way valve is used directly at heat exchanger

(see Figure No. 3) then check valve need only be on the

cold water side. To avoid temperature fluctuation of

tempered water line, the thermostatic bulb should be

located as close to three-way valve as possible.

These size valves are furnished with standard capillary

tubing, 10' (3m) length: 1/2" to 2" NPT and 2-1/2" to 4"

(65 to 100 mm).

Three-way valves are sometimes used as diverting

valves. See Figure No. 4.

2

Figure No. 1 - Trapping ahead of steam regulators

Figure No. 2 - Trapping ahead of steam regulators

Figure No. 3

Series 1140,

3-way valve

mixing service

When temperature

increases piston moves

down closing port ‘B’

opening port ‘C’.

Figure No. 4

Series 1140,

3-way valve

diverting service

When temperature

increases piston moves

down closing port ‘B’

opening port ‘C’.

Page 3

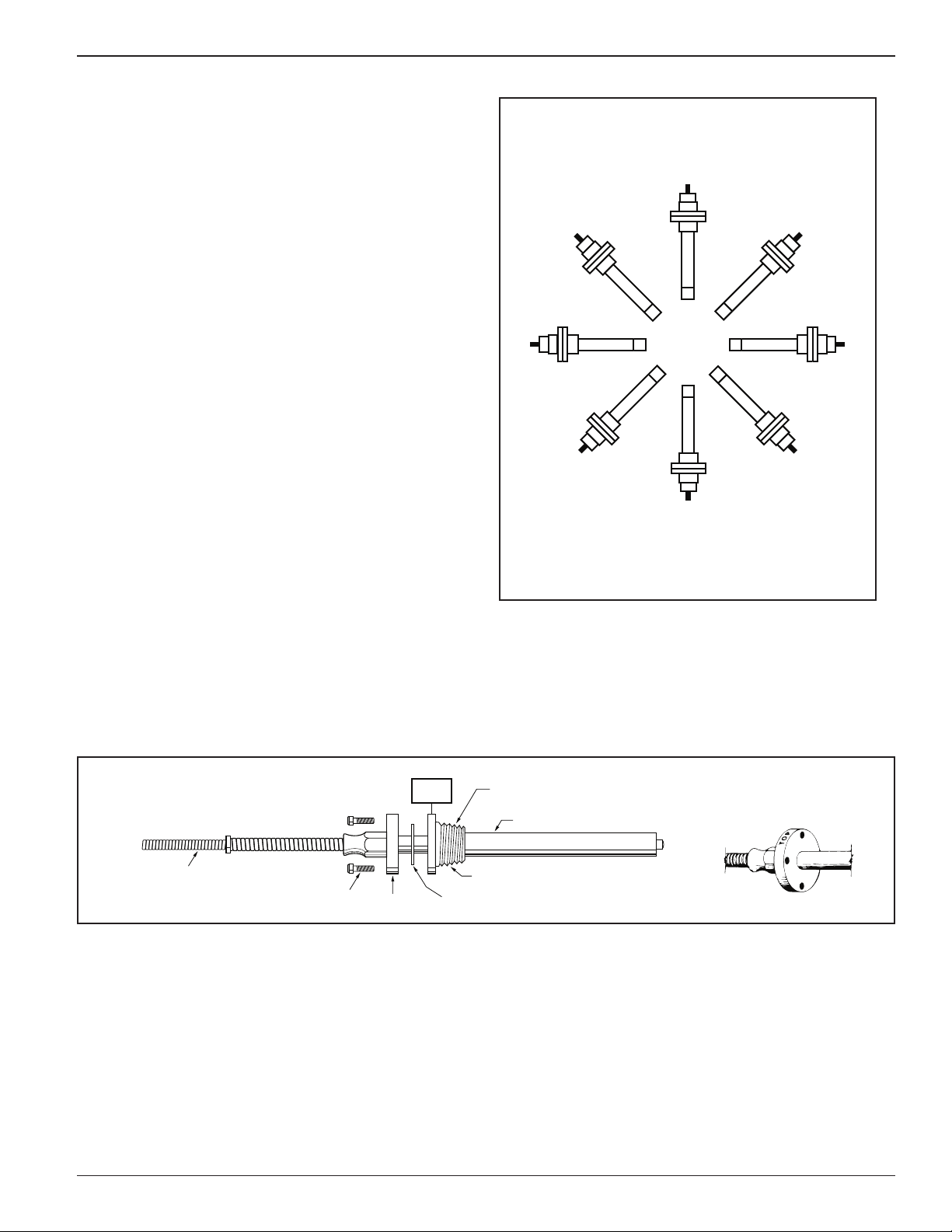

THERMOSTATIC BULB

BUSHING

GASKET

FLANGE

BUSHING SCREW

ARMORED CAPILLARY TUBING

1" NPT ON 1/2" TO 2" NPT VALVES

1-1/4" NPT ON 2-1/2" TO 4" (65 to 100 mm) VALVES

TOP

BULB INSTALLATION

IMPORTANT: Installing the bulb in the correct location

and position is extremely important.

The bulb should be installed at a point of actual system

temperature and it must be fully inserted in the fluid

being controlled.

Tanks - the bulb should be located approximately 2/3

the way up and off to a side of the tube nest. Bulbs

should be above the heating surface and no closer than

4" (100 mm) at any point.

Instantaneous heaters - the bulb should be installed in

the water outlet and as far into the heater as possible.

When a thermometer is used, it should be located PAST

the bulb at least 6 ft. (1.8 m) in the pipeline or on the

same level in the tank.

The bulb can be installed horizontally, vertically or in any

position in between the two, if the flange is uppermost

(see Figure No. 5). When installed horizontally, the word

"TOP" on the flange must be uppermost. See Figure

No. 6.

Figure No. 5 - Bulb Installation Positions

FOR CONTROLLING LIQUIDS

1. Remove the four (4) bushing screws.

2. Remove the bushing from the thermostatic bulb.

3. Determine the correct pipe size opening (see

Figure No. 6) and insert bushing in tank or

pipeline and tighten securely.

4. Insert bulb and gasket into bushing. Fasten with

the four (4) screws.

FOR CONTROLLING AIR

1. Install bulb on right angles to the air movement

and where an average temperature prevails.

Figure No. 6 - Bulb Mounting

(Incorrect)

(Incorrect)

(Incorrect)

3

Page 4

THERMOSTATIC BULB

HOT

COLD

AS CLOSE

A

S PRACTICAL

REGULATOR

T

HERMOSTATIC BULB

TOP

MIX

B

C

A

THERMOSTATIC BULB

SEPARABLE WELL

GASKET

FLANGE

BUSHING SCREW

ARMORED CAPILLARY TUBING

DISCARD BULB BUSHING WHEN

SEPARABLE WELL IS USED.

INSTALLATION

FOR THREE-WAY VALVES

1. Install the bulb as close as possible to the outlet

of the mixed water line. See Figure No. 7.

2. Immerse bulb as far as possible into the pipeline.

ALL INSTALLATIONS

The capillary tubing is the flexible tubing that connects

the bulb and the valve.

IMPORTANT: Capillary tubing may only be bent on a

4" (100 mm), or larger radius. It must never be cut,

kinked, smashed or twisted.

1. Permanently fasten the capillary tubing to a

permanent location other than steam pipes, cold

water lines, or any other place where extreme

temperatures are incurred.

2. Form a loop with a few turns of tubing and place

next to the regulator. This helps to absorb vibrations in the pipeline.

Figure No. 7 - Three-Way Valve

SEPARABLE WELL INSTALLATION

Separable wells protect the bulb and allow the bulb to be

removed without draining the pipeline or tank.

1. Install separable well in tank or piping.

2. Coat sensing bulb with high temperature grease.

3. Insert sensing bulb and gasket into the separable well.

4. Securely tighten with four (4) mounting screws.

Figure No. 8 - Separable Well Installation

4

Page 5

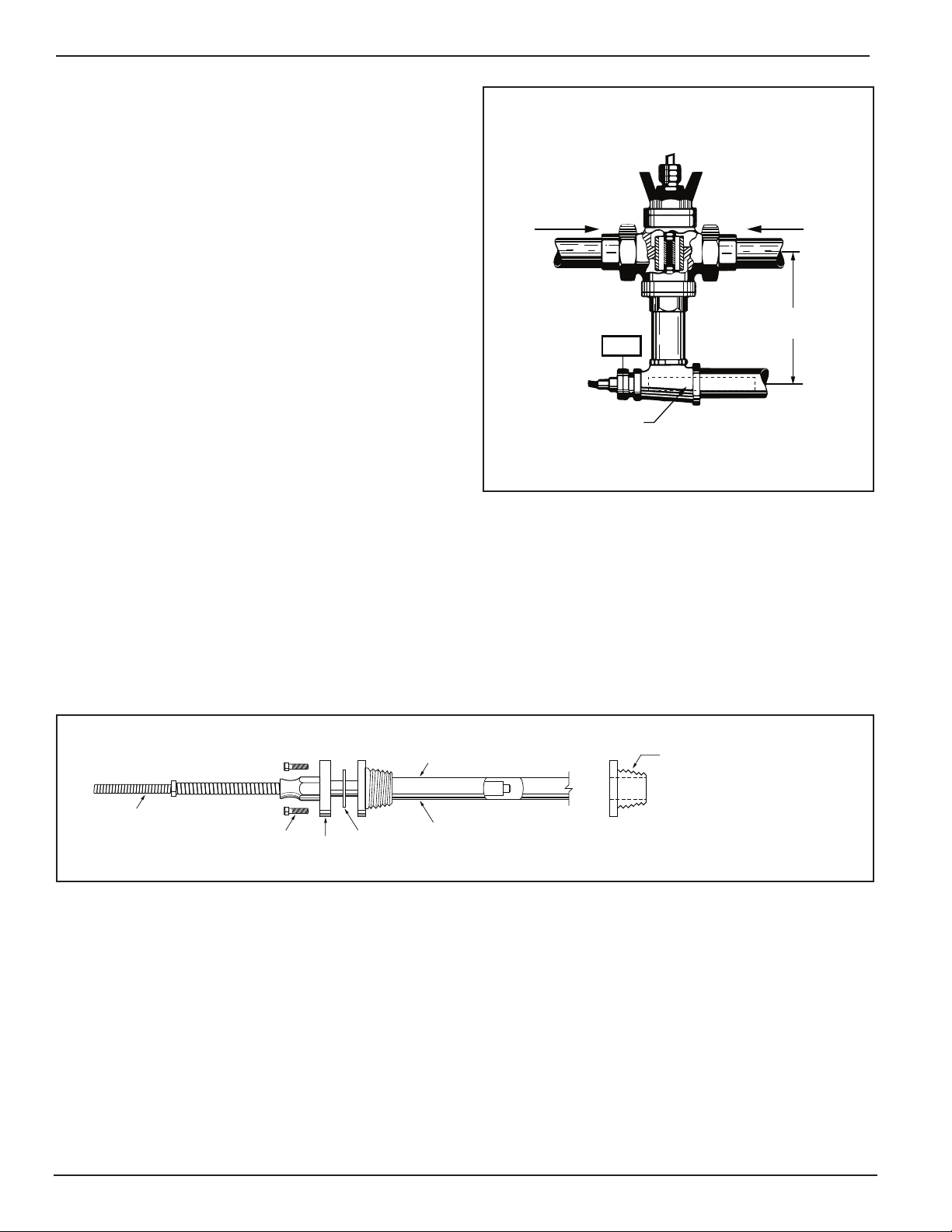

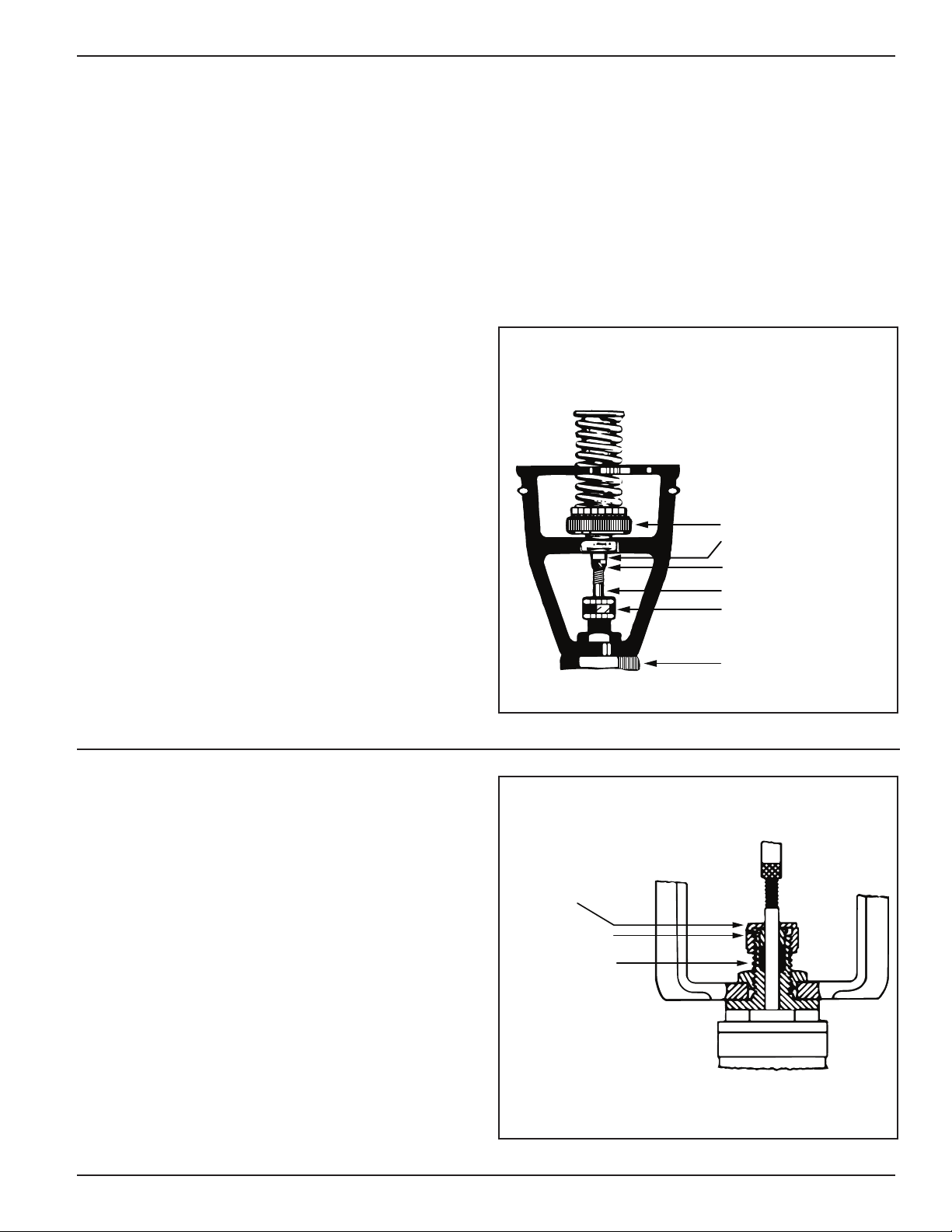

TEMPERATURE ADJUSTMENT

REGULATOR BODY

STUFFING BOX NUT

LOWER VALVE STEM

UPPER VALVE STEM

TEMPERATURE

ADJUSTMENT WHEEL

STEM ADJUSTMENT

LOCK NUT

PACKING NUT

PACKING GLAND

PACKING

This regulator can be set to control at any temperature

ithin the limits of the temperature range stamped on

w

the name plate. After placing the regulator in service,

allow about 15–30 minutes to reach stable operation,

then watch temperature, if not correct change

temperature setting as outlined hereafter. Make new

ettings as necessary until desired temperature is

s

obtained. Allow about 15–30 minutes between

changes. Oversized valves will cause extreme

temperature fluctuations.

SETTING TEMPERATURE

Turn the hand wheel in the direction indicated by arrow

(see Figure No. 9). This will compress regulating spring

and cause valve to control at a higher temperature; turning hand wheel in opposite direction causes valve to

control at a lower temperature. The wheel is mounted

on ball bearings to eliminate friction and insure easy

operation.

CHECKING VALVE STEM TRAVEL

ON TWO-WAY VALVES

The 1/2" to 2" (15 to 50 mm) bronze body regulators

have a 1/4" (6 mm) valve movement.

The 2-1/2" (65 mm) up to and including the 4" (100 mm)

flanged body valves have a 7/16" (11 mm) valve stem travel.

To check stem travel, proceed as follows:

1. See Figure No. 9.

2. Raise temperature at bulb until valve shuts off.

3. Mark lower stem using Stuffing Box Nut as

reference point.

4. Cool entire unit until bellows contracts

completely into housing.

5. Reference mark should be either 1/4" or 7/16" (6

or 11 mm) above stuffing box nut, as indicated.

If valve stem has more travel than indicated, valve will

not shut off.

CHANGING VALVE DISC MOVEMENT

Under some conditions, it may be necessary to adjust the

amount of valve movement. This may occur on oil heater

installations, where only a very small quantity of steam is

equired. Too much valve opening is usually indicated by

r

a decided fluctuation of the oil temperature.

The adjustment is made by holding the upper valve stem

nd loosening the stem adjustment lock nut and then turn-

a

ing the lower valve stem to the left (clockwise) as looking

at the arrow marks on the bracket. This will decrease the

amount of valve movement. See Figure No 8.

Always securely tighten the stem adjustment lock nut

after adjustment has been made.

Figure No. 9

MAINTENANCE

VALVE STEM PACKING:

Apply one drop of oil to the packing every three months.

Replace the packing once a year, or every 6 months

in severe environments.

STRAINERS:

Clean once a month, or more frequently if dirt or

debris is present.

Y-Strainers:

Built-in Strainers on Body code 01 or 02 (single-seated type)

TRAPS:

Follow trap manufacturer's maintenance instructions.

1. Remove packing nut.

2. Lift the packing gland.

3. Install new packing.

4. Replace and hand tighten packing nut.

1. Open the blowdown valve.

2. Allow the steam or water to flow out for 2 minutes.

3. Close the valve.

1. Remove the bottom plug.

2. Remove and wash screen

3. Reinstall screen and plug.

Figure No. 10

5

Page 6

CHANGING A THERMOSTATIC

REGULATOR BODY

STUFFING BOX NUT

LOWER VALVE STEM

UPPER VALVE STEM

TEMPERATURE ADJUSTMENT WHEEL

BELLOWS HOUSING NUT

BRACKET

UPPER VALVE STEM PLATE

BELLOWS HOUSING

BELLOWS HOUSING SCREW

ARMORED CAPILLARY TUBING

BULB BUSHING SCREWS

GASKET

BULB BUSHING

THERMOSTATIC BULB

STEM ADJUSTMENT LOCK NUT

!

!

ACTUATOR ON TWO-WAY VALVES

The Thermostatic Actuator used on the Series 1140 reg-

lators is shown in Figure No. 11. All actuator parts

u

shown form one inseparable unit, except for the bulb

bushing with its gasket and fastening screws.

he Thermostatic Actuator will only control within the

T

temperature range stamped on the name plate, which is

fastened to the bellows housing.

If it is necessary to install a new actuator, to obtain a

higher or lower range, the following procedure should be

applied. Refer to Figure No. 11.

CAUTION

ALL SUPPLY VALVES MUST BE

TURNED OFF, SYSTEM PRESSURE

MUST BE REDUCED TO 0 psi (0 bar),

AND SYSTEM TEMPERATURE MUST BE

REDUCED BELOW 100˚F (38˚C) BEFORE

REMOVING THE BULB. FAILURE TO

FOLLOW THIS CAUTION MAY RESULT

IN SERIOUS BURNS.

1. On units without a separable well, drain tank or pipe

line to a point below location of the thermostatic bulb.

2. Loosen the four (4) bulb bushing screws and slowly

break the bulb connection to make sure hot water

does not drain out, then remove four (4) screws and

take the bulb out of the bushing or well.

3. Turn temperature adjustment wheel to lowest position

(clockwise).

CAUTION

REGULATORS OPERATING LOWER THAN 120˚ - 160˚

(49˚ - 71˚C) OR IN ROOMS ABOVE 100˚F (38˚C), THE

BELLOWS MUST BE COOLED UNTIL IT CAN BE

COMPRESSED BY HAND. FAILURE TO FOLLOW

THIS CAUTION COULD DESTROY THE ACTUATOR.

4. Cool bulb and bellows at least 20˚F (-6˚C) below lowst temperature of range indicated on name plate.

e

5. Remove the bellows housing nuts and screws and lift

unit off bracket (keep bulb cool). Push down by hand

on upper valve stem plate until valve is shut. With a

pencil make a reference mark on the lower valve

stem, where stem enters stuffing box nut. This will

assist in checking total valve movement on opening

and also the thrust of the new thermostatic actuator.

6. Cool the new thermostatic actuator bulb which is to be

installed, at least 20°F (-6˚C) lower than the lowest

temperature marked on the name plate.

Actuators for valves in sizes 2-1/2" to 4" and with

ranges lower than 120° to 160°F (49 to 71°C) are

shipped with a clip, so that the bellows cannot expand

beyond limits in transit. Before removing this clip,

make sure you can compress bellows by hand. Only

then remove clip and attach housing to bracket, by

fastening the six (6) bellows housing screws. This

must be done quickly.

7. Recheck valve stem travel as outlined in paragraph

“Checking Valve Stem Travel” on page 5.

Figure No. 11

6

Page 7

CHANGING A THERMOSTATIC

REGULATOR BODY

STUFFING BOX NUT

LOWER VALVE STEM

UPPER VALVE STEM

TEMPERATURE ADJUSTMENT WHEEL

BELLOWS HOUSING NUT

BRACKET

UPPER VALVE STEM PLATE

BELLOWS HOUSING

BELLOWS HOUSING SCREW

ARMORED CAPILLARY TUBING

BULB BUSHING SCREWS

GASKET

BULB BUSHING

THERMOSTATIC BULB

STEM ADJUSTMENT LOCK NUT

!

!

ACTUATOR ON THREE-WAY VALVES

CAUTION

ALL SUPPLY VALVES MUST BE

TURNED OFF, SYSTEM PRESSURE

MUST BE REDUCED TO 0 psi (0 bar),

AND SYSTEM TEMPERATURE MUST BE

REDUCED BELOW 100˚F (38˚C) BEFORE

REMOVING THE BULB. FAILURE TO

FOLLOW THIS CAUTION MAY RESULT

IN SERIOUS BURNS.

1. Secure all water to valve and outlet from valve.

2. Drain pipe line below location of thermostatic bulb,

if no well is used.

3. When you are sure the water has been drained and all

internal pressure is relieved, remove the four bulb

bushing screws and take the thermostatic bulb out of

the bulb bushing.

4. Turn the temperature adjustment wheel to the lowest

position.

5. Cool the bulb and bellows at least 20°F (-6˚C) below the

lowest temperature range indicated on the name plate.

CAUTION

REGULATORS OPERATING LOWER THAN 120˚ - 160˚

(49˚ - 71˚C) OR IN ROOMS ABOVE 100˚F (38˚C), THE

BELLOWS MUST BE COOLED UNTIL IT CAN BE

COMPRESSED BY HAND. FAILURE TO FOLLOW

THIS CAUTION COULD DESTROY THE ACTUATOR.

6. Remove the bellows housing nuts and screws

and lift unit off bracket.

7. Turn temperature adjustment wheel up sufficiently to

ut enough tension on the spring to hold the cold port

p

shut.

8. Place a spacer 3/32" (2.4 mm) thick (2 pennies) on

upper stem plate and replace bellows housing

(completely cooled) holding it down so flange rests

on ring of bracket. If stem adjustment has not been

disturbed, stem will just move opening cold port.

Remove spacer and fasten bellows housing in place.

9. If stem does not move, unscrew upper stem from

lower stem a turn at a time until this movement is

obtained.

10. Stem should move 1/32" (0.8 mm). Screw upper

stem down on lower stem until this amount of movement is obtained.

11. Lock the two stems in this position with the stem

adjustment lock nut.

12. Attach housing to bracket.

13. Install bulb in pipe line with “top” on top.

Figure No. 12

7

Page 8

THREE WAY MIXING VALVES

CIRCULATING PUMP

CHECK

VALVE

REGULATOR

WITH 3 WAY

VALVE

COIL IN

BOILER

PORT

"A"

PORT

"C"

PORT

"B"

COLD BYPASS

HOT BYPASS

BOILER

RETURN CIRCULATION

COLD WATER

SUPPLY

TO BUILDING

IMPORTANT: When installing a three-way mixing

valve, it is necessary that return circulation be piped to

feed the cold water side of the mixing valve and heater.

See Figure No. 13.

As the temperature of the mixed liquid increases, the

piston moves toward the hot seat port B. See Figure 3

on page 2. This movement decreases the hot flow and

increases the cold flow through port C. See Figure 3 on

page 2. The thermostat maintains the piston in the

proper position for the desired mixed temperature.

Figure No. 13

TO CHECK THE OPERATION OF A THREE-WAY VALVE

USED AS A MIXING VALVE PROCEED AS FOLLOWS:

Check the packing gland to see if it is only hand tight. If

this gland is too tight, it will bind the valve stem. Then

open one or two outlets in the hot water line to establish

a flow of water through the valve. Check temperature on

thermometer. If it is not at the desired point, increase or

decrease the temperature by turning the adjustment

wheel in the proper direction for a higher or lower

temperature. The proper direction is indicated by an

arrow on valve bracket. Two turns of the adjustment

wheel should make an appreciable change in outlet

temperature.

If the temperature at the outlet drops below the desired

point, check the temperature of the hot water entering

the valve. If it is below the required temperature, the coil

or heater is not making enough hot water. This condition

must be remedied before any further adjustment can be

made on the three-way valve.

WHEN IN NEED OF INFORMATION

When contacting the factory or one of its representatives

in regard to a regulator, be sure to give all the name

plate Information, fastened to the bellows housing. This

name plate is shown in Figure No. 14.

8

Figure No. 14

Page 9

START UP PROCEDURE

!

1. Make sure inlet gate valve is closed.

2. Open outlet gate valve and all equipment drain

valves. Allow system to drain completely.

3. Make sure bypass globe valve (if provided)

is tightly closed.

4. Release any spring force on temperature

adjusting knob. Knob should be at the lowest

temperature setting for initial system startup.

5. Slightly open inlet valve (just enough to allow

steam or water into regulator). Do not allow

pressure to build up. On three-way valves open

cold water supply first, then open hot water

supply.

CAUTION: HEARING PROTECTION

IS REQUIRED IF DRAIN VALVES

ARE OPEN TO ATMOSPHERE.

Troubleshooting:

6. Allow system to stabilize.

7. Open inlet valve more.

8. Allow system to stabilize.

9. Check for leaks.

10.Close drain valves after system is hot and drain

valves are blowing steam (indication that all

condensate has been removed), or that water

valves are passing water.

11.Open inlet valve until about half open. If there are

no problems, open completely.

12.Slowly increase the spring tension by turning the

adjusting know until the desired temperature is

reached. Allow the system to stabilize (15–30

minutes). Recheck temperature setting.

Temperature Regulating

Problem:

1. System Temperature is Low.

a. Cause: Low inlet pressure.

Solution: Fully open supply valve. Clean strain-

er. Check for low boiler output or

upstream blockage and make

necessary corrections.

b. Cause: Capillary has kink. Sharp bend will

stop signal to pilot.

Solution: Replace actuator or work out kink by

hand.

c. Cause: Actuator range is incorrect. The

actuator will not operate beyond its

range.

Solution: Check indicator dial for correct

temperature range. Replace if

necessary.

d. Cause: Temperature adjustment altered.

Solution: Readjust to desired operating

condition.

e. Cause: Main valve undersized.

Solution: Check valve capacity against the

load. If insufficient, increase valve

size.

f. Cause: Piping flow restricted.

Solution: Calculate the flow velocity and

expected friction loss. If excessive,

larger inlet and outlet piping are

necessary.

Steam Valve Only

g. Cause: Condensate not draining.

Solution: Check steam trap for proper sizing

and operation. Trap should drain by

gravity into a vented return line. Avoid

lifts in the return lines.

h. Cause: Improper stem adjustment.

Solution: Check stem travel by following

instruction no. 8 on page 7.

i. Cause: Improper thermostatic bulb location.

Solution: Bulb must be fully into fluid flow being

controlled. Use reducer bushing

instead of reducers and nipples. In

storage tanks install the bulb near the

center of the tank. There must be flow

past the thermostatic bulb. As a rule

of thumb a recirculating pump should

provide a minimum of 20% design

load at all times.

j. Cause: Poor temperature response.

Solution: On units with separable well use high

temperature grate between the

thermostatic bulb and well for better

heat transfer.

k. Cause: Thermostatic bulb installed upside down.

Solution: See Figure No. 5 and follow bulb

installation instructions on page 3.

9

Page 10

Problem:

2. System Temperature High

roblem:

P

3. System Temperature Erratic

a. Cause: Bypass gate valve is open.

Solution: Close the valve.

b. Cause: Capillary has kink. Sharp bend will

stop signal to pilot.

Solution: Replace actuator or work out by

hand.

c. Cause: Actuator range incorrect. The

actuator will not operate beyond

its range.

Solution: Check name plate for correct

temperature range. Replace if

necessary.

d. Cause: Temperature adjustment altered.

Solution: Readjust to desired operating

condition.

e. Cause: Oversized valve.

Solution: Check valve capacity against the

load. If excessive, install smaller

valve. Steam valves—install a steam

pressure reducing valve to reduce

capacity.

f. Cause: Improper stem adjustment.

Solution: Check stem travel by following

instruction no. 8 on page 7.

g. Cause: Improper thermostatic bulb location.

Solution: Bulb must be fully into the flow path.

Use reducing bushing instead of

reducing coupling and nipples. In

storage tanks install the bulb near

the center of the tank. There must be

flow past the thermostatic bulb, as a

rule of thumb a recirculating pump

should provide a minimum of 20%

design load at all times.

a. Cause: Thermostatic bulb installed upside down.

Solution: The bulb mounting flange has the

word top stamped in the O.D. This

must be in the up position. The bulb

may also be installed vertically with

bulb end down, flange on top.

b. Cause: Capillary has kink or defective

actuator. Sharp bend will stop

signal to pilot.

Solution: Replace actuator or work out by

hand.

c. Cause: Thermostatic bulb installed in

poor location.

Solution: Install as close as possible to

thermometer and heater coils in

instantaneous heaters.

d. Cause: Insufficient circulation through heater.

Solution: Check circulation system, and

insure sufficient circulation.

Steam Valve Only

e. Cause: Condensate not draining.

Solution: Check steam trap for proper sizing

and operation. Trap should drain by

gravity into a vented return line. Avoid

lifts in the return lines.

f. Cause: Improper stem adjustment.

Solution: Check stem travel per instructions in

this manual.

h. Cause: Poor temperature response.

Solution: On units with separable well use

high temperature grease between

the thermostatic bulb and well for

better heat transfer.

i. Cause: Thermostatic bulb installed upside down.

Solution: See Figure No. 5 and follow bulb

installation instructions on page 3.

10

Page 11

THERMOSTATIC

BULB

RELIEF

VALVE

HOT

WATER

OUTLET

DRAIN AND

BLOW-OFF

COLD

WATER

INLET

STORAGE

HEATER

TO

TRAP

VACUUM

BREAKER

TEMPERATURE

REGULATOR

S

TEAM

INLET

"Y" STRAINER

D

RIP

TRAP

THERMOMETER

WITH

STORAGE

TANK

WITHOUT

STORAGE

TANK

COLD

WATER

INLET

CHECK VALVE

MIN.

15 INCHES

VACUUM BREAKER

"Y"

STRAINER

TEMPERATURE

REGULATOR

STEAM

TRAP

SUPPLY

VALVE

DRIP

TRAP

CIRCULATOR PUMP USED WITH

STORAGE TANK

HOT WATER OUTLET

THERMOSTATIC BULB

LOCATION WHEN USED

WITH STORAGE TANK

TEMPERATURE

REGULATOR

STEAM INLET

TO TRAP

WATER LINE

THERMOSTATIC

BULB

TYPICAL INSTALLATIONS

Figure No. 15— Controlling steam coil in storage tank

Figure No. 16 — Controlling instantaneous water heater

with or without buffer storage tank.

Figure No. 17 — Controlling steam table

11

Page 12

Figure 18 — Controlling hot water plus tempered

water at a lower temperature

Figure 20 - Controlling storage tank temperature with

a diverting valve and heat exchanger

REGULATOR WITH

3-WAY VALVE

CHECK VALVE

THERMOMETER

TEMPERED

WATER

THERMOSTATIC

BULB

CHECK VALVE

THERMOMETER

HOT WATER

THERMOSTATIC

BULB

TEMPERATURE

REGULATOR

"Y" STRAINER

HEATER

CIRCULATING PUMP

RETURN

CHECK VALVE

COLD WATER

CIRCULATOR

Figure 19 — Controlling oil cooler

TO TRAP

STEAM

INLET

DRIP

TRAP

HEAT

EXCHANGER

“B” “C”

“A”

TEMPERATURE

REGULATOR

WITH BODY

CODE 06

STORAGE TANK

THERMOSTATIC

BULB

BOILER

Figure 21 — Controlling two zone hot water job for a

restaurant

REVERSE ACTING

TEMPERATURE

REGULATOR

TO WASTE

OIL COOLER

WATER INLET

NORMALLY

CLOSED

THERMOSTATIC

BULB

WARM OIL

FROM ENGINE

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. HS-504F October 2012 Part No. 517031

THERMOMETER

NOTE:

PIPING ONE SIZE

LARGER THAN THE

SYSTEM PIPING MUST

BE USED WHERE

THERMOSTATIC BULB

ENTERS LINE.

COOLED OIL

TO ENGINE

140˚F (60˚C) WATER

FOR GENERAL USE

180˚F (82˚C) WATER FOR

DISH STERILIZATION

BOILER

TEMPERATURE

REGULATOR

COLD WATER

SUPPLY

DRAIN

Loading...

Loading...